Static Loads Influence on Modal Properties of the Composite Cylindrical Shells with Integrated Sensor Network

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimens and the Test Bench

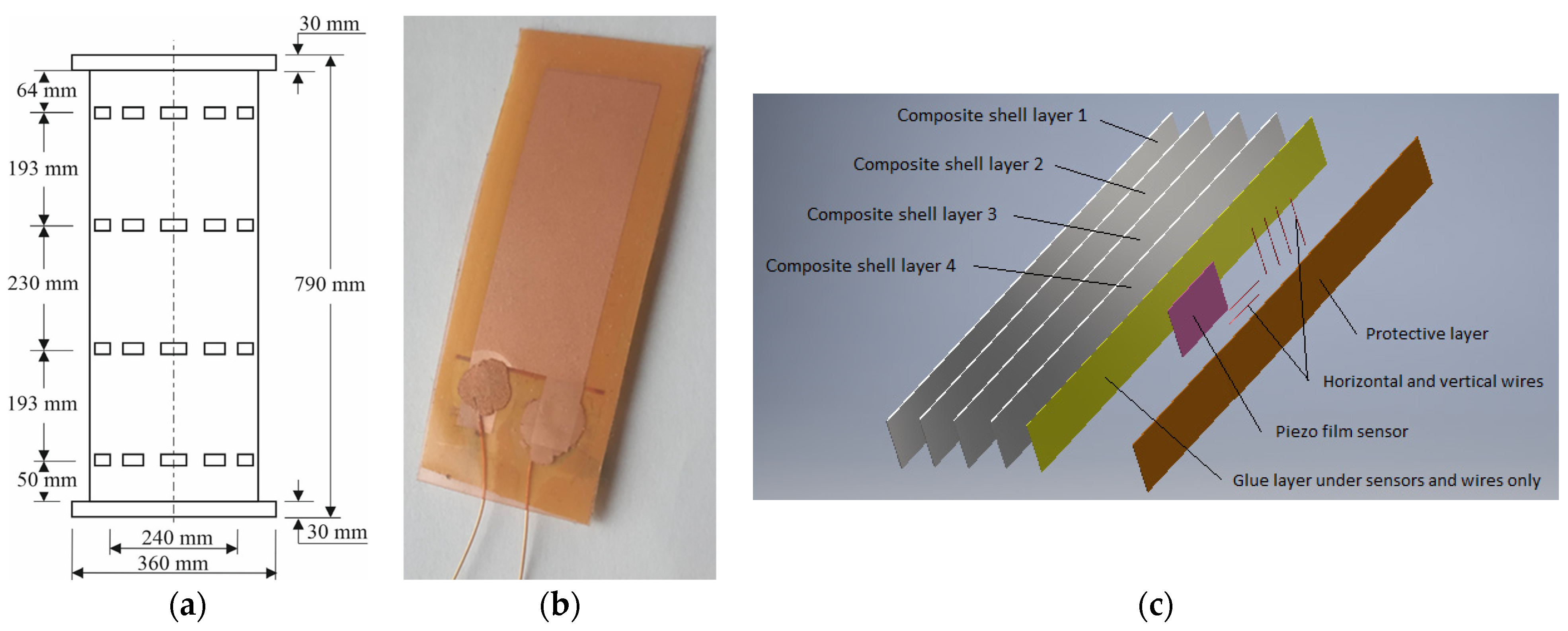

2.1.1. Specimens

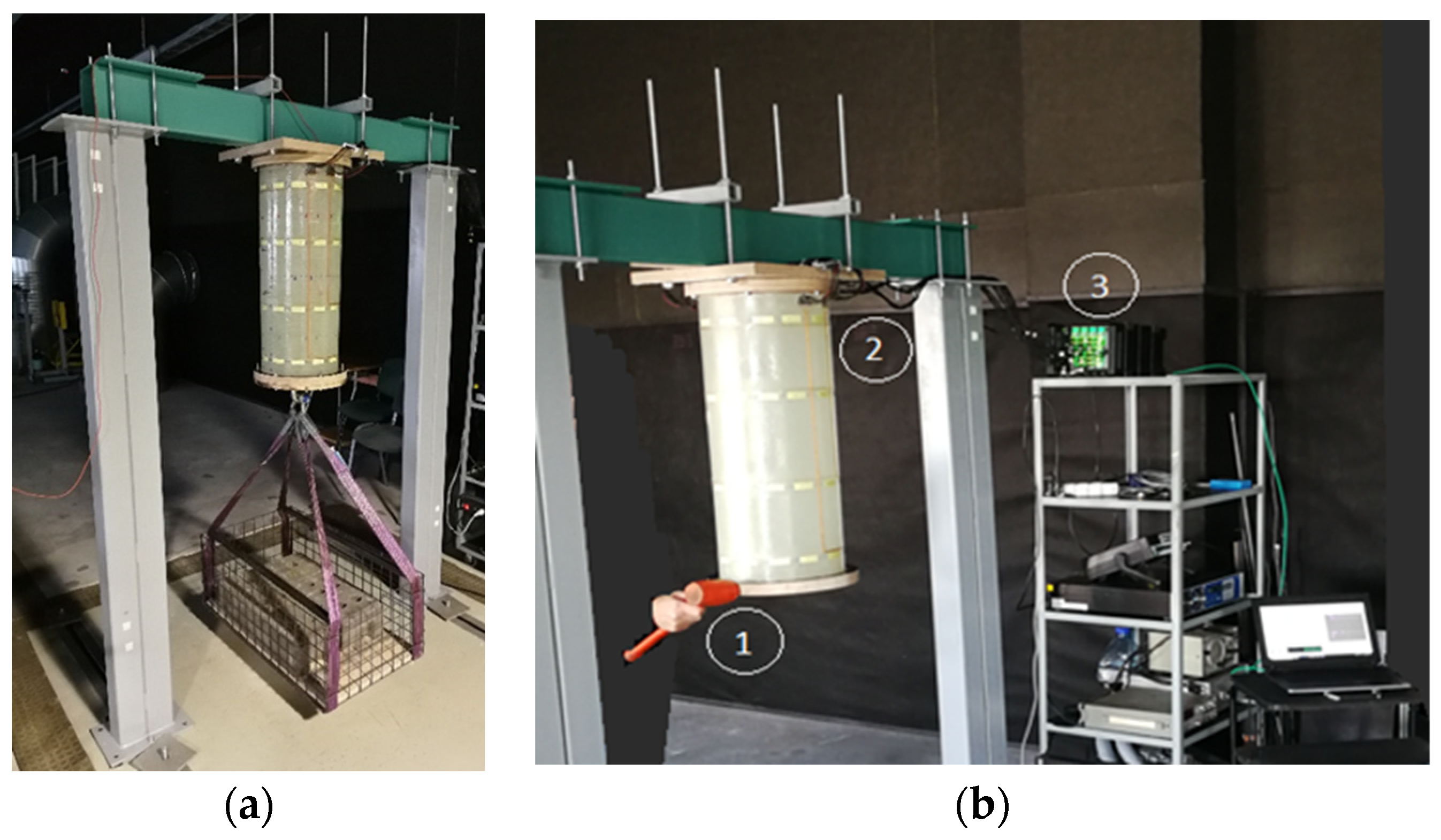

2.1.2. The Test Bench

2.1.3. Testing and Measurements

2.2. Modal Data Development

2.2.1. Typical MP

2.2.2. Individual MP

2.2.3. Primary Modal Estimates

2.2.4. Modal Enhancement

2.3. Numerical Modelling of Specimens

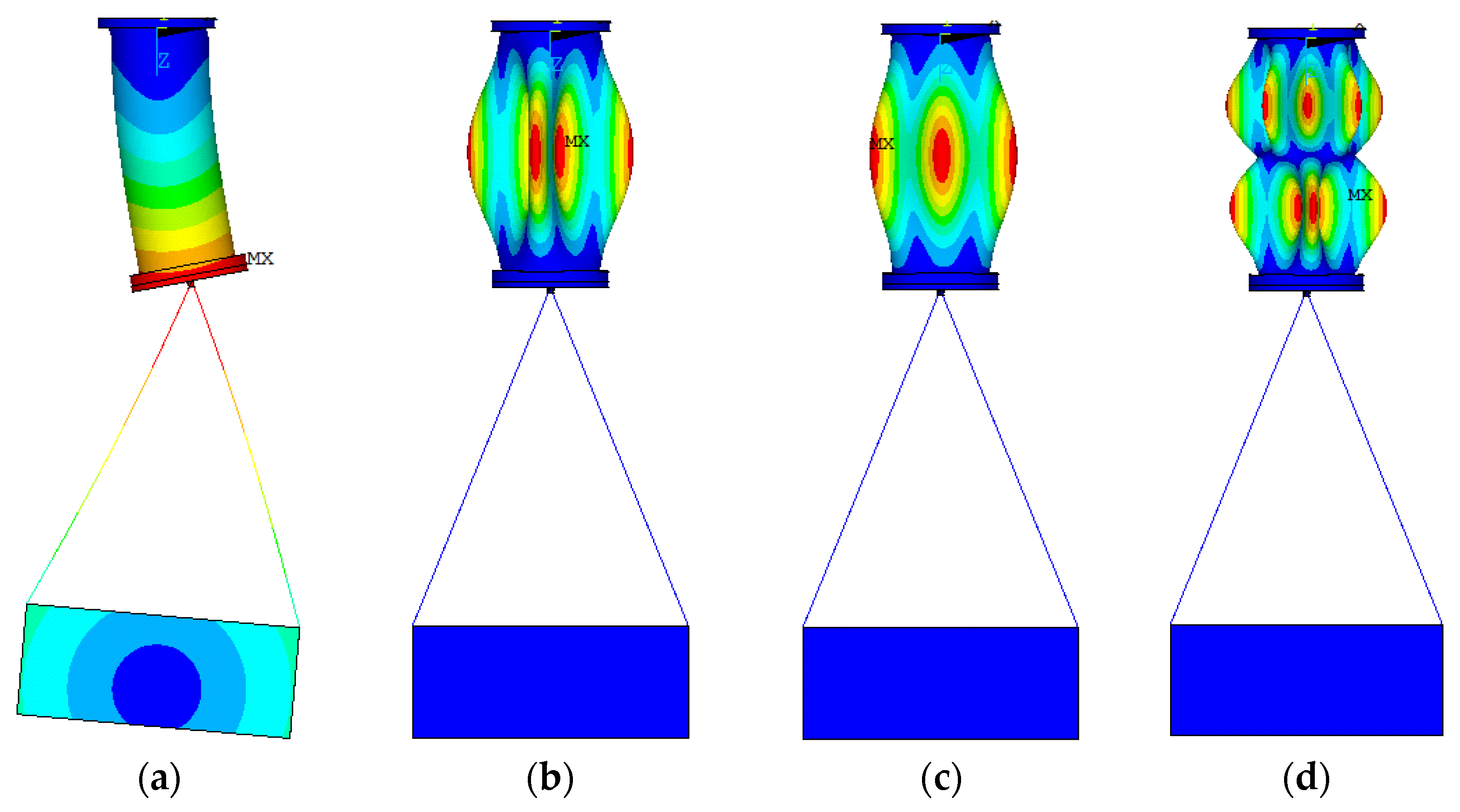

2.3.1. Prestressed Modal Analysis

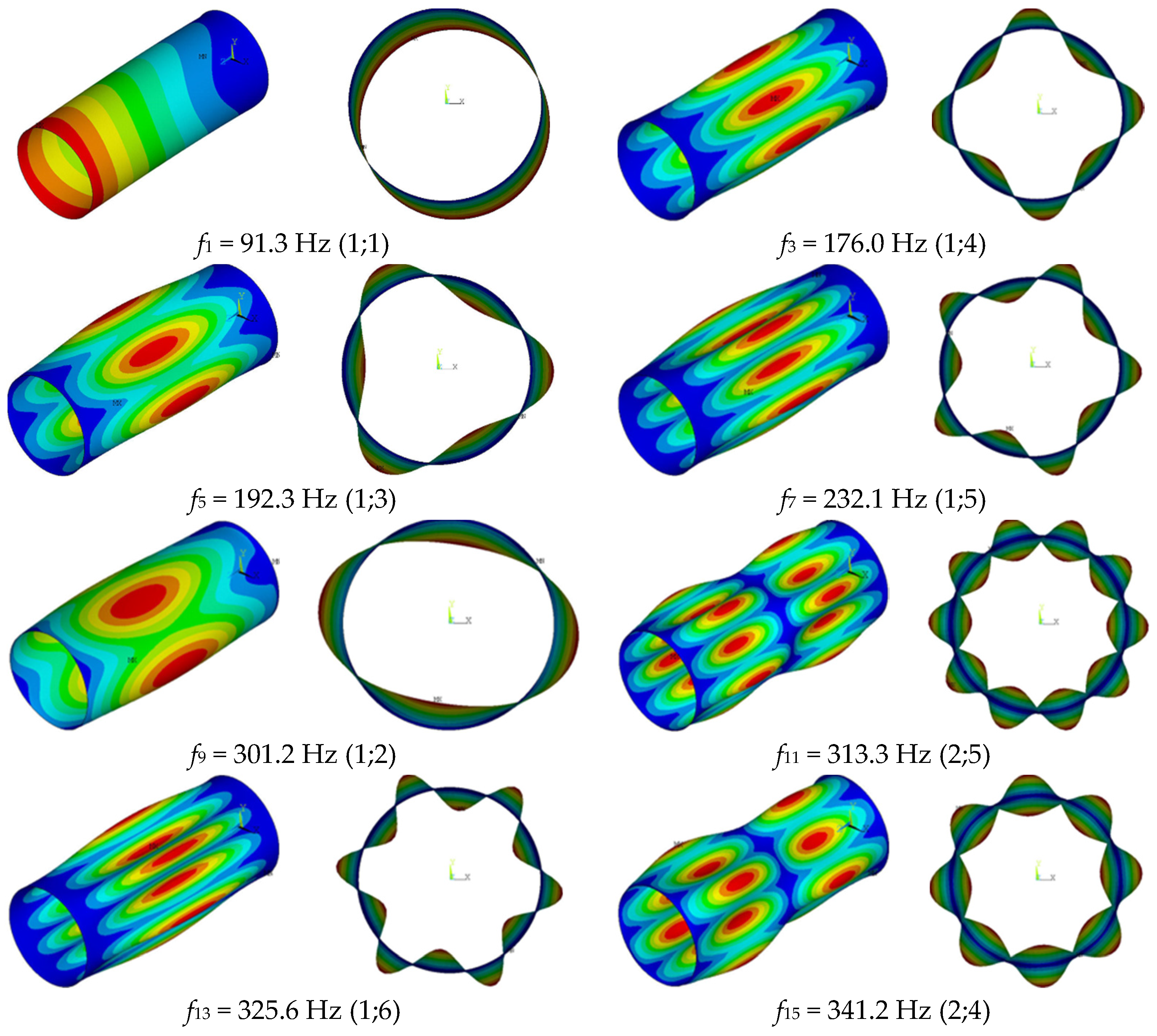

2.3.2. Finite Element Model of a Composite Cylindrical Shell

2.3.3. Calibration of Numerical Model

3. Results

3.1. Modal Data Development

3.2. Modal Testing Specimens

3.2.1. Model Verification

3.2.2. Static Load Influence on Frequencies

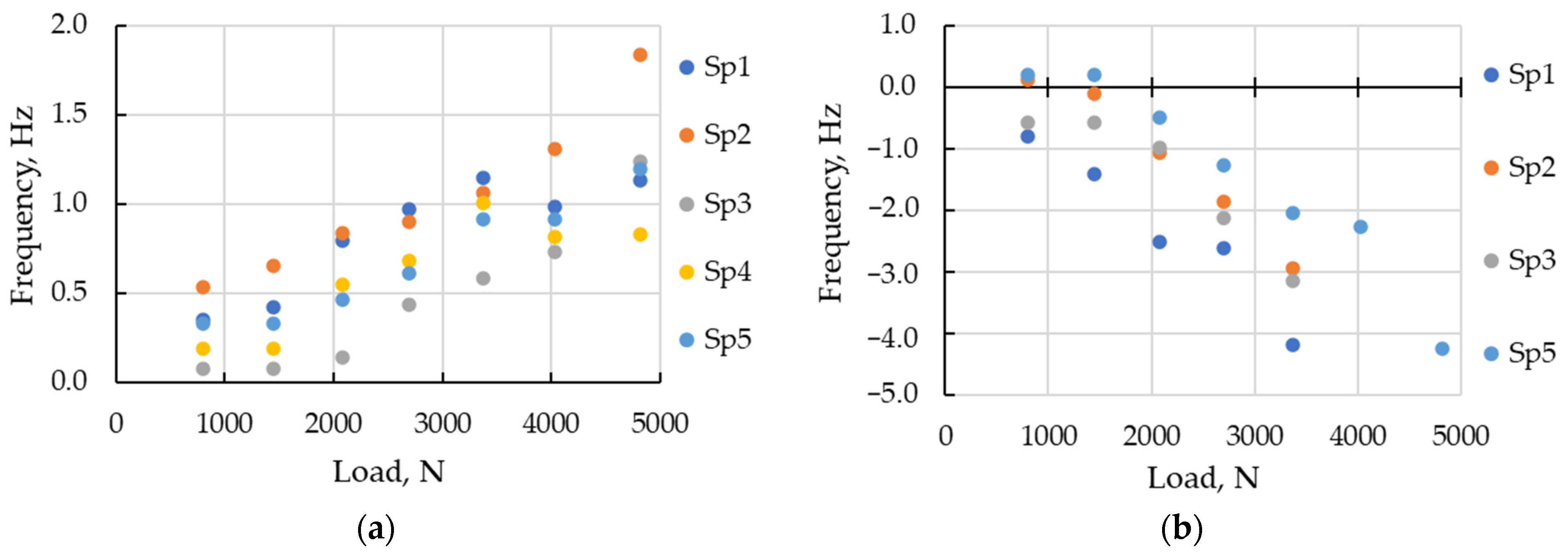

3.2.3. Static Load Influence on Modal Damping

4. Discussion

5. Conclusions

- The preliminary tensile load leads to an increase of the frequency in the numerical model, whose change follows a linear relationship. The differences between the natural frequencies of the structure in the range of applied loads does not exceed 2%.

- The tensile load influence functions for modal frequency and shape parameters, obtained from the experimental data, were not fully consistent with the numerical analysis, but showed a consistent pattern, repeating for all samples.

- Commonality of influence functions for single-type structures confirm the possibility of experimentally determining above functions of modal parameters in order to use them for monitoring tasks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leissa, A.W. Vibration of Shells; NASA SP 288: Washington, DC; U.S. Government Printing Office: Washington, DC, USA, 1973; 428p. [Google Scholar]

- Amabili, M. Nonlinear Vibrations and Stability of Shells and Plates; Cambridge University Press: New York, NY, USA, 2008; 392p. [Google Scholar]

- Flugge, W. Stresses in Shells; Springer: New York, NY, USA, 1973; 499p. [Google Scholar]

- Donnell, L.H. Beams, Plates and Shells; McGraw-Hill Book Company: New York, NY, USA, 1976; 453p. [Google Scholar]

- Armenàkas, A.E.; Gazis, D.C.; Herrmann, G. Vibrations of Circular Cylindrical Shells; Pergamon Press: Oxford, UK, 1969; 224p. [Google Scholar]

- Mushtari, K.M.; Galimov, K.Z. Non-Linear Theory of Thin Elastic Shells; National Science Foundation: Alexandria, VA, USA, 1957; 374p. [Google Scholar]

- Evensen, D.A. Nonlinear vibrations of circular cylindrical shells. In Thin-Shell Structures: Theory, Experiment and Design; Fung, Y.C., Sechler, E.E., Eds.; Prentice Hall: Hoboken, NJ, USA, 1974; pp. 133–155. [Google Scholar]

- Den Hartog, J.P. Mechanical Vibrations; Dover Publications: Mineola, NY, USA, 1985; 449p. [Google Scholar]

- Bokaian, A. Natural frequencies of beams under tensile axial loads. J. Sound Vib. 1990, 142, 481–498. [Google Scholar] [CrossRef]

- Ondra, V.; Titurus, B. Theoretical and experimental modal analysis of a beam-tendon system. Mech. Syst. Signal Process. 2019, 132, 55–71. [Google Scholar] [CrossRef]

- Nugroho, G.; Priyosulistyo, H.; Suhendro, B. Evaluation of Tension Force Using Vibration Technique Related to String and Beam Theory to Ratio of Moment of Inertia to Span. Procedia Eng. 2014, 95, 225–231. [Google Scholar] [CrossRef]

- Alazwari, M.A.; Mohamed, S.A.; Elather, M.A. Vibration analysis of laminated composite higher order beams under varying axial loads. Ocean Eng. 2022, 252, 111203. [Google Scholar] [CrossRef]

- Kashani, M.; Hashemi, S.M. Dynamic Finite Element Modelling and Vibration Analysis of Prestressed Layered Bending–Torsion Coupled Beams. Appl. Mech. 2022, 3, 103–120. [Google Scholar] [CrossRef]

- Soedel, W. Vibration of Shells and Plates, 2nd ed.; Taylor & Francis: New York, NY, USA, 2005; 586p. [Google Scholar]

- Franzoni, F.; Degenhardt, R.; Albus, J.; Arbelo, M.A. Vibration correlation technique for predicting the buckling load of imperfection-sensitive isotropic cylindrical shells: An analytical and numerical verification. Thin-Walled Struct. 2019, 140, 236–247. [Google Scholar] [CrossRef]

- Harutyunyan, D.; Rodrigues, A.M. The Buckling Load of Cylindrical Shells Under Axial Compression Depends on the Cross-Sectional Curvature. J. Nonlinear Sci. 2023, 33, 27. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; Bittrich, L.; Jansen, E.; Tita, V.; Spickenheuer, A. Buckling Optimization of Composite Cylinders for Axial Compression: A Design Methodology Considering a Variable-Axial Fiber Layout. Compos. Struct. 2019, 222, 110928. [Google Scholar] [CrossRef]

- Yadav, A.; Amabili, M.; Panda, S.K.; Dey, T.; Kumar, R. A semi-analytical approach for instability analysis of composite cylindrical shells subjected to harmonic axial loading. Compos. Struct. 2022, 296, 115882. [Google Scholar] [CrossRef]

- Tong, L. Free Vibration of Axially Loaded Laminated Conical Shells. J. Appl. Mech. 1999, 66, 758–763. [Google Scholar] [CrossRef]

- Bedri, R.; Al-Nais, M.O. Prestressed Modal Analysis Using Finite Element Package ANSYS International Conference on Numerical Analysis and Its Applications. In Proceedings of the 3rd International Conference Numerical Analysis and Its Applications, Rousse, Bulgaria, 29 June–3 July 2004; pp. 171–178. [Google Scholar]

- Maia, N.M.M.; Silva, J.M.M. Theoretical and Experimental Modal Analysis; Research Studies Press: Taunton, UK, 1997; 488p. [Google Scholar]

- Abdelghani, M.; Gourst, M.; Biolchini, T. On-Line Modal Monitoring of Aircraft Structures under Unknown Excitation. Mech. Syst. Signal Process. 1999, 13, 839–853. [Google Scholar] [CrossRef]

- Shepitko, T.; Shepitko, E.; Afanasev, V. Computer simulation models for consideration of seasonal trends influence on the structural dynamics of bridges. Commun. Sci. Lett. 2019, 2, 5–10. [Google Scholar] [CrossRef]

- Zahid, F.B.; Ong, Z.C.; Khoo, S.Y. A review of operational modal analysis techniques for in-service modal identification. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 398. [Google Scholar] [CrossRef]

- James, G.H. Modal parameter estimation from space shuttle flight data. In Proceedings of the 21st International Modal Analysis Conference, Kissimmee, FL, USA, 3–6 February 2003. [Google Scholar]

- Clarke, H.; Stainsby, J.; Carden, E.P. Operational modal analysis of resiliently mounted marine diesel generator/alternator. In Rotating Machinery, Structural Health Monitoring, and Shock and Vibration Topics, Volume 5, Proceedings of the 30th International Modal Analysis Conference Series, Jacksonville, CT, USA, 14 February 2011; Proulx, T., Ed.; Springer: New York, NY, USA, 2011; pp. 1461–1473. [Google Scholar] [CrossRef]

- Møller, N.; Gade, S. Application of Operational Modal Analysis on Cars. In Proceedings of the Noise and Vibration Conference and Exhibition, Grand Traverse, MI, USA, 5–8 May 2003; pp. 1970–1977. [Google Scholar] [CrossRef]

- Pan, C.; Ye, X.; Mei, L. Improved Automatic Operational Modal Analysis Method and Application to Large-Scale Bridges. J. Bridge Eng. 2021, 26, 04021051. [Google Scholar] [CrossRef]

- Capanna, I.; Cirella, R.; Aloisio, A.; Alaggio, R.; Di Fabio, F.; Fragiacomo, M. Operational Modal Analysis, Model Update and Fragility Curves Estimation, through Truncated Incremental Dynamic Analysis, of a Masonry Belfry. Buildings 2021, 11, 120. [Google Scholar] [CrossRef]

- Singh, H.; Grip, N.; Nicklasson, P.J. A comprehensive study of signal processing techniques of importance for operation modal analysis (OMA) and its application to a high-rise building. Nonlinear Stud. 2021, 28, 389–412. [Google Scholar]

- Zhang, P.; He, Z.; Cui, C.; Ren, L.; Yao, R. Operational Modal Analysis of Offshore Wind Turbine Tower under Ambient Excitation. J. Mar. Sci. Eng. 2022, 10, 1963. [Google Scholar] [CrossRef]

- Kim, H.C.; Kim, M.H.; Choe, D.E. Structural health monitoring of towers and blades for floating offshore wind turbines using operational modal analysis and modal properties with numerical-sensor signals. Ocean Eng. 2019, 188, 106226. [Google Scholar] [CrossRef]

- Safonovs, A.; Kovalovs, A.; Mironovs, A.; Chate, A. Finite Element Model of Closed Composite Cylinder and its Experimental Verification. In Proceedings of the 21st International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 25–27 May 2022. [Google Scholar] [CrossRef]

- Mironov, A.; Safonovs, A.; Mironovs, D.; Doronkin, P.; Kuzmickis, V. Health Monitoring of Serial Structures Applying Piezoelectric Film Sensors and Modal Passport. Sensors 2023, 23, 1114. [Google Scholar] [CrossRef]

- Mironov, A.; Doronkin, P.; Priklonskiy, A.; Yunusov, S. Adaptive Technology Application for Vibration-Based Diagnostics of Roller Bearings on Industrial Plants. Transp. Telecommun. 2014, 15, 233–242. [Google Scholar] [CrossRef]

- Allemang, R. The Modal Assurance Criterion (MAC): Twenty Years of Use and Abuse. Sound Vib. 2003, 37, 14–21. [Google Scholar]

- Liu, G.R.; Quek, S.S. The Finite Element Method: A Practical Course; Butterworth-Heinemann: London, UK, 2003; pp. 180–184. [Google Scholar]

- Rucevskis, S.; Kovalovs, A.; Chate, A. Optimal Sensor Placement in Composite Circular Cylindrical Shells for Structural Health Monitoring. IOP Conf. Ser. J. Phys. Conf. 2011, 23, 012034. [Google Scholar] [CrossRef]

- Kovalovs, A.; Rucevskis, S. Identification of elastic properties of composite plate. IOP Conf. Ser. Mater. Sci. Eng. 2011, 23, 012021. [Google Scholar] [CrossRef]

- EN 338:2009; Structural Timber. Strength Classes. European Committee for Standardization (CEN): Brussels, Belgium, 2009.

- Ručevskis, S.; Rogala, T.; Katunin, A. Optimal Sensor Placement for Modal-Based Health Monitoring of a Composite Structure. Sensors 2022, 22, 3867. [Google Scholar] [CrossRef]

| Engineering Constants | E1, GPa | E2 = E3, GPa | G12 = G13, GPa | G23, GPa | ν12 = ν13 | ν23 |

|---|---|---|---|---|---|---|

| Value | 40.90 | 11.14 | 1.70 | 3.01 | 0.416 | 0.23 |

| Order | Mode (m;n) | Frequency (Hz) | Δf (%) | |

|---|---|---|---|---|

| Experiment | Simulation | |||

| 1 | 2 | 3 | 4 | 5 |

| 1 | (1;1) | 78.4 | 91.3 | 12.9 |

| 2 | (1;1′) | 104.8 | 91.3 | 12.9 |

| 3 | (1;4) | 174.5 | 176.0 | 0.9 |

| 4 | (1;4′) | 175.9 | 176.0 | 0.1 |

| 5 | (1;3) | 185.0 | 192.3 | 3.9 |

| 6 | (1;3′) | 185.0 | 192.3 | 3.9 |

| 7 | (1;5) | 230.2 | 232.1 | 0.8 |

| 8 | (1;5′) | 232.4 | 232.1 | 0.1 |

| 9 | (1;2) | 261.9 | 301.2 | 15.0 |

| 10 | (1;2′) | 266.2 | 301.2 | 13.2 |

| 11 | (2;5) | 315.6 | 313.3 | 0.7 |

| 12 | (2;5′) | 319.2 | 313.3 | 1.8 |

| 13 | (1;6) | 321.0 | 325.6 | 1.4 |

| 14 | (1;6′) | - | 325.6 | - |

| 15 | (2;4′) | 344.5 | 341.2 | 1.0 |

| 16 | (2;4′) | - | 341.2 | - |

| Order | Mode (m;n) | Tensile Force, N | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 167 | 804 | 1442 | 2080 | 2698 | 3375 | 4032 | 4817 | ||

| Frequency, Hz | |||||||||

| 1 | (1;1) | 54.1 | 43.0 | 34.5 | 31.1 | 28.3 | 26.0 | 24.2 | 22.5 |

| 2 | (1;4) | 177.4 | 177.8 | 178.2 | 178.7 | 179.1 | 179.5 | 180.0 | 180.5 |

| 3 | (1;3) | 200.6 | 201.1 | 201.4 | 201.8 | 202.2 | 202.6 | 203.0 | 203.5 |

| 4 | (1;5) | 232.4 | 232.7 | 233.1 | 233.4 | 233.7 | 234.1 | 234.4 | 234.9 |

| 5 | (2;5) | 314.6 | 315.5 | 316.4 | 317.3 | 318.2 | 319.1 | 320.0 | 321.1 |

| 6 | (1;6) | 325.8 | 326.0 | 326.3 | 326.5 | 326.8 | 327.1 | 327.3 | 327.6 |

| 7 | (1;2) | 337.8 | 338.1 | 338.4 | 338.6 | 338.9 | 339.1 | 339.4 | 339.7 |

| 8 | (2;4) | 346.0 | 346.8 | 347.7 | 348.5 | 349.3 | 350.2 | 351.0 | 352.1 |

| Order | Experiment | Simulation | Δi (%) | ||

|---|---|---|---|---|---|

| Mode (m;n) | Frequency (Hz) | Mode (m;n) | Frequency (Hz) | ||

| 1 | 2 | 3 | 4 | 5 | 6 |

| 1 | (1;1) | - | (1;1) | 54.1 | - |

| 2 | (1;1′) | - | (1;1′) | 56.9 | - |

| 3 | (1;4) | 179.2 | (1;4) | 177.4 | 1.0 |

| 4 | (1;4′) | 182.5 | (1;4′) | 177.4 | 2.8 |

| 5 | (1;3) | 189.2 | (1;3) | 200.6 | −6.0 |

| 6 | (1;3′) | 193.3 | (1;3′) | 200.6 | −3.8 |

| 7 | (1;5) | 233.7 | (1;5) | 232.4 | 0.6 |

| 8 | (1;5′) | 239.1 | (1;5′) | 232.4 | 2.8 |

| 9 | (1;2) | 268.9 | (2;5) | 314.6 | −17.0 |

| 10 | (1;2′) | 275.5 | (2;5′) | 314.6 | −14.2 |

| 11 | (1;6) | 313.7 | (1;6) | 325.8 | −3.8 |

| 12 | (1;6′) | 327.8 | (1;6′) | 325.8 | 0.6 |

| 13 | (2;5) | 321.6 | (1;2) | 337.8 | −5.0 |

| 14 | (2;5′) | - | (1;2′) | 337.8 | |

| 15 | (2;4) | 353.6 | (2;4) | 346.0 | 2.2 |

| 16 | (2;4′) | 356.7 | (2;4′) | 346.0 | 3.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mironov, A.; Kovalovs, A.; Chate, A.; Safonovs, A. Static Loads Influence on Modal Properties of the Composite Cylindrical Shells with Integrated Sensor Network. Sensors 2023, 23, 3327. https://doi.org/10.3390/s23063327

Mironov A, Kovalovs A, Chate A, Safonovs A. Static Loads Influence on Modal Properties of the Composite Cylindrical Shells with Integrated Sensor Network. Sensors. 2023; 23(6):3327. https://doi.org/10.3390/s23063327

Chicago/Turabian StyleMironov, Aleksey, Andrejs Kovalovs, Andris Chate, and Aleksejs Safonovs. 2023. "Static Loads Influence on Modal Properties of the Composite Cylindrical Shells with Integrated Sensor Network" Sensors 23, no. 6: 3327. https://doi.org/10.3390/s23063327

APA StyleMironov, A., Kovalovs, A., Chate, A., & Safonovs, A. (2023). Static Loads Influence on Modal Properties of the Composite Cylindrical Shells with Integrated Sensor Network. Sensors, 23(6), 3327. https://doi.org/10.3390/s23063327