Digital Fringe Projection-Based Clamping Force Estimation Algorithm for Railway Fasteners

Abstract

1. Introduction

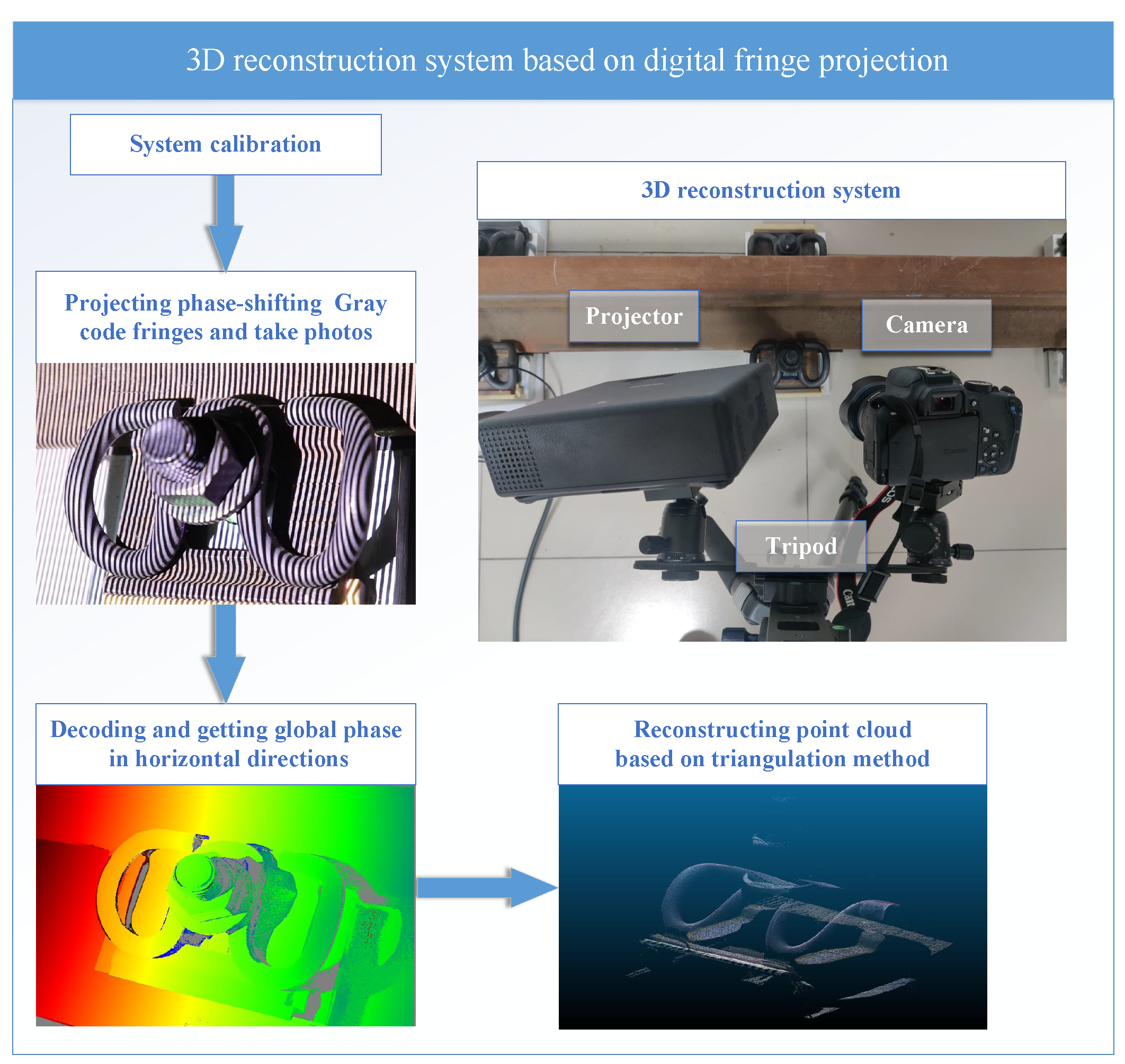

2. System Overview

3. Methodology

3.1. Structured-Light Reconstruction System

3.2. Clamping Force Estimation Algorithm

3.2.1. Point Cloud Denoising

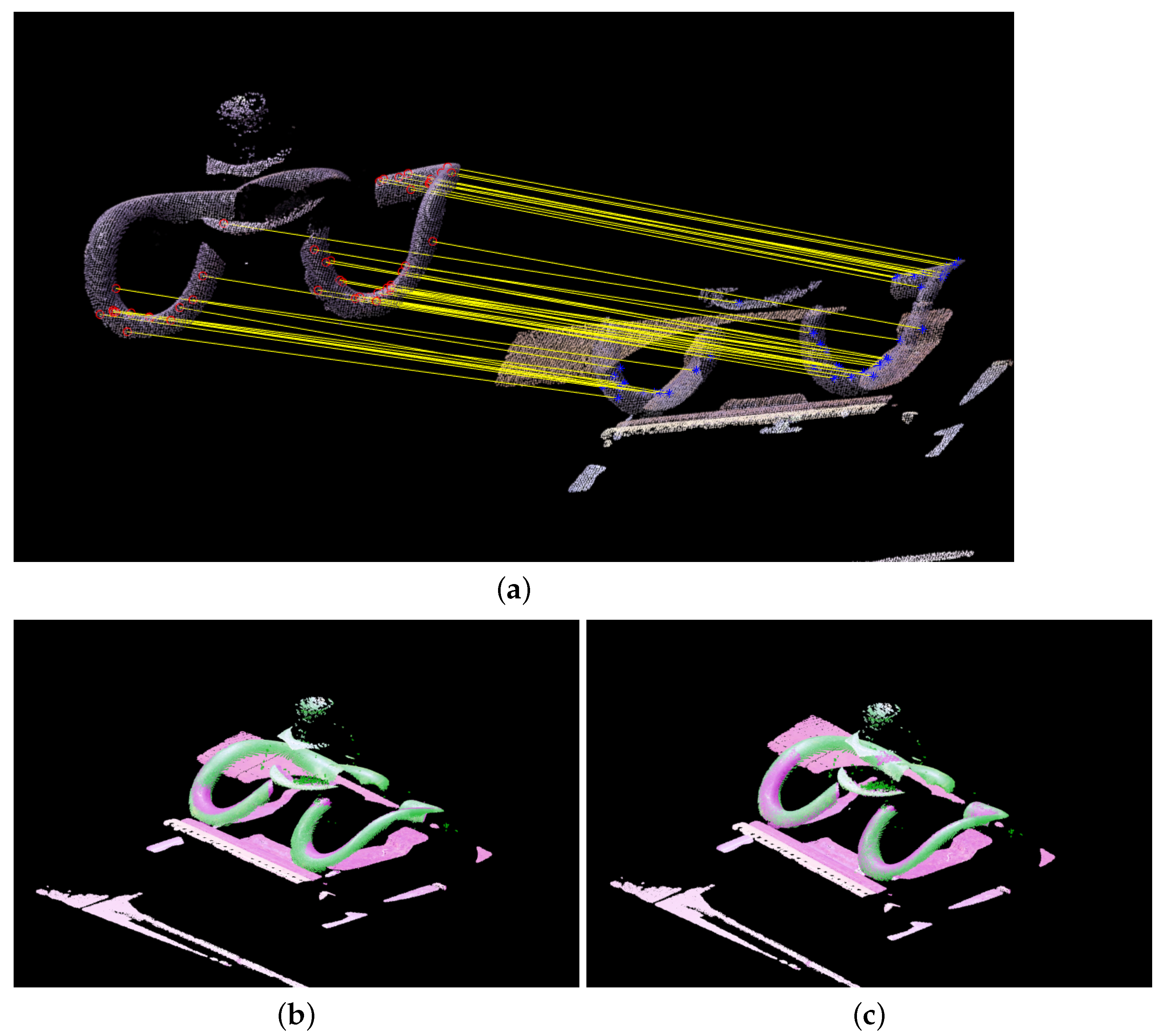

3.2.2. Point Cloud Registration and Specific Region Selection

- Coarse Registration Using FPFHIn the FPFH algorithm, the estimated normals of point clouds are used to calculate the local features of the point clouds. It is an improved version of the point feature histograms (PFH) algorithm [28]. FPFH feature descriptors are robust under different sampling densities. In the method described in this study, the FPFH features of the reference point cloud and those of the point cloud to be matched are calculated, then the method proposed by Zhou et al. [28] is used to find the matching features between the two. After this, the coarse registration of the point cloud is conducted. For the calculation of FPFH features, three feature values of a pair of points in the point cloud need to be calculated. Suppose that points and have normals and in their neighborhoods. Then, a local coordinate system can be established on one of the points , as shown in Figure 3. Based on the positions of the normals and the two points, three angles can be obtained, and then the eigenvalues used by FPFH can be obtained as:The feature descriptor is calculated as follows.Step 1: Solve the surface normal for each point in the point cloud.Step 2: Calculate the point pair feature for each point and the k adjacent points. Place the three values in a histogram by normalizing each eigenvalue and then apportioning them into b intervals of the same size, thereby obtaining a histogram with intervals formed by the combinations of the three sets of intervals. The histogram generated by these k point pair features can be used as a simplified point feature histogram (SPFH) for point .Step 3: Generate the SPFH for each of the k points adjacent to .Step 4: Generate the final FPFH descriptor of based on SPFH features with different weights:where the weight is the distance between point and the adjacent points.

- Fine Registration Using ICP Algorithm: After FPFHAfter FPFH coarse registration has been performed, the two point clouds will or should roughly coincide; then, the iterative closest point (ICP) algorithm is applied for fine registration. This algorithm solves a rigid body transformation to minimize the following objective functions:where and are the set of matching points in the point cloud to be registered and the reference point cloud. The singular value decomposition (SVD) method or the nonlinear optimization method can be used to minimize this function. Details of the algorithm are given in the paper by Besl and McKay [29].

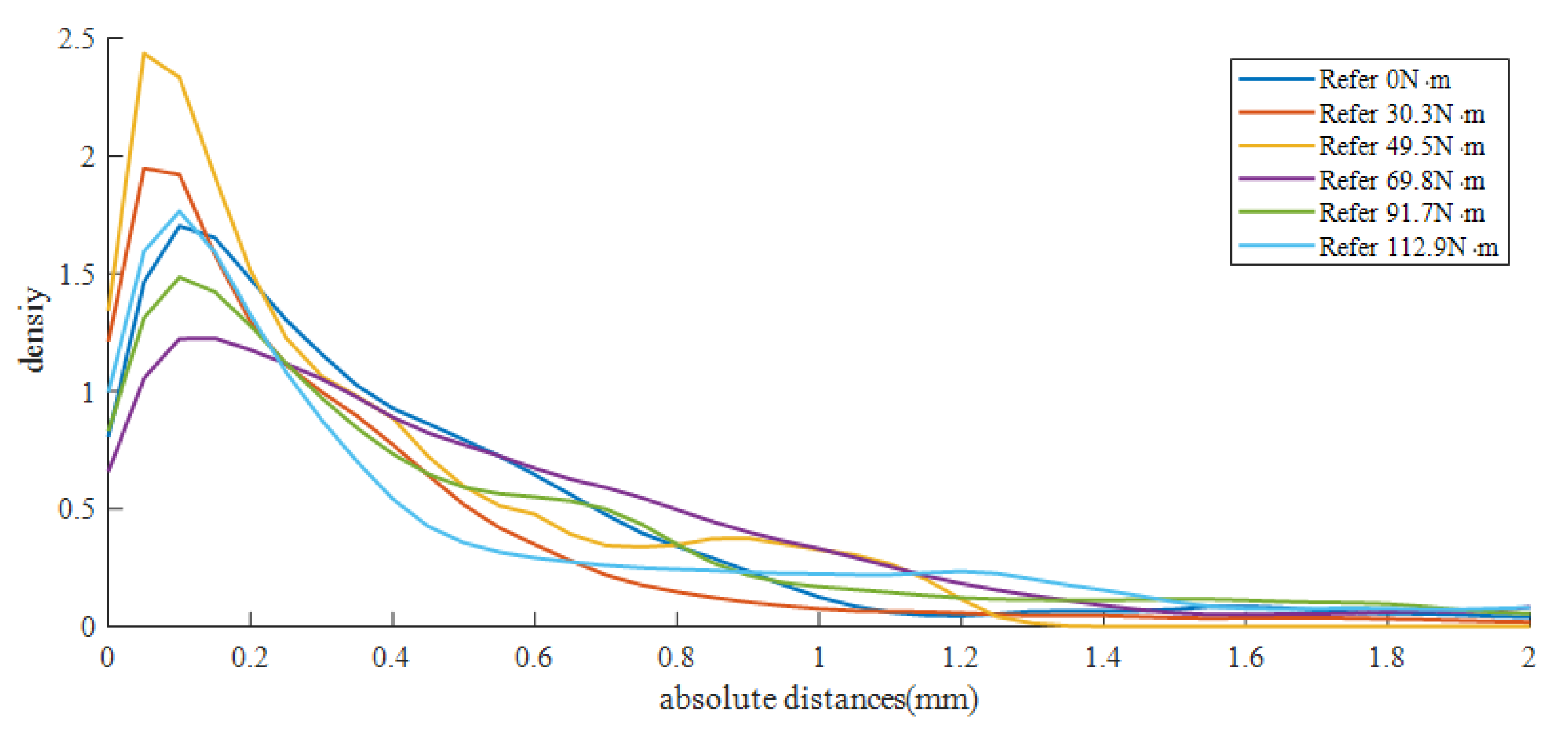

3.2.3. Comparisons with Multiple Reference Point Clouds

3.2.4. Estimation of Point Cloud Distance Distribution

3.2.5. Regression Analysis

4. Testing, Results, and Analysis

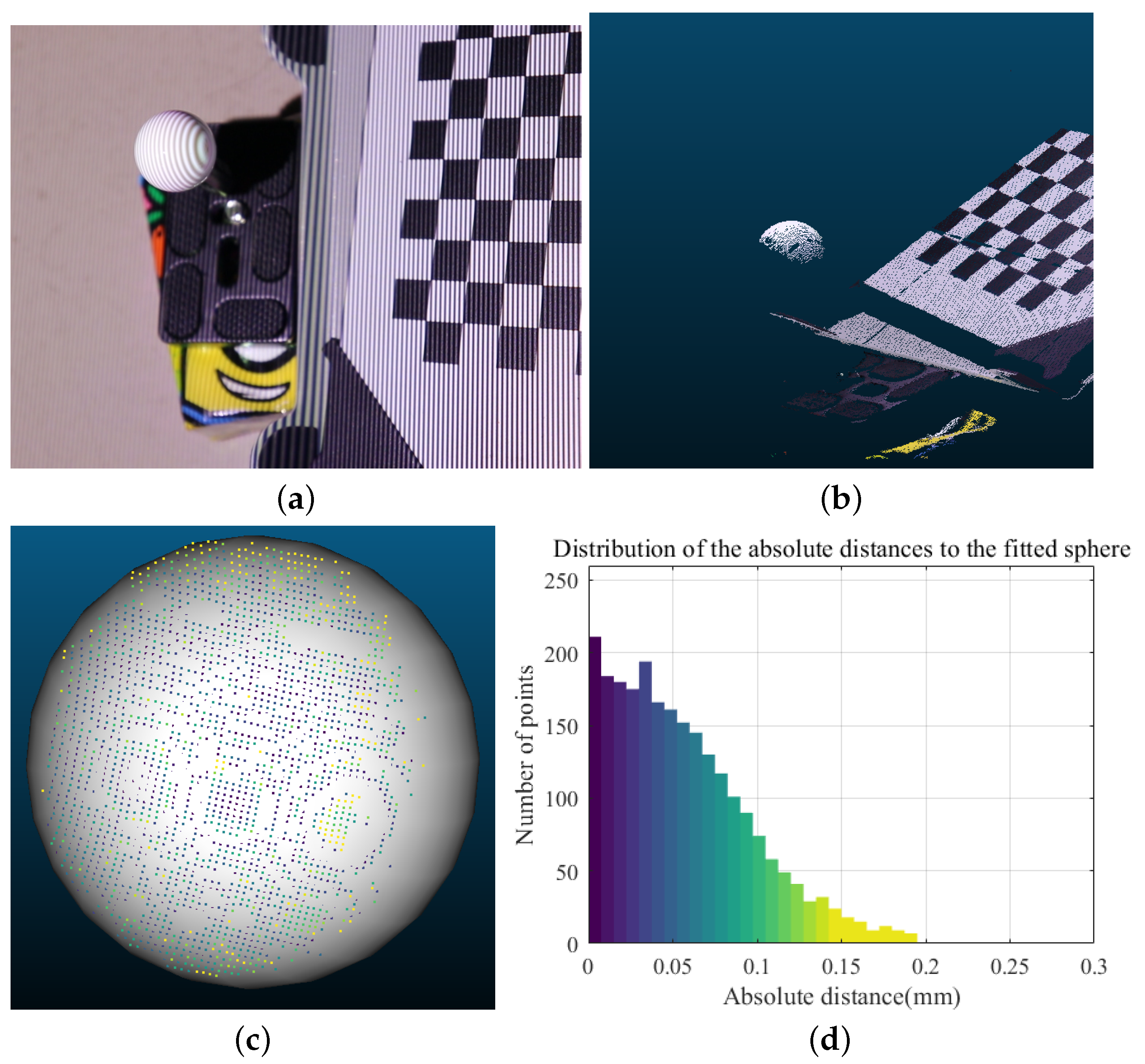

4.1. Evaluation of the 3D Reconstruction System

4.2. Point Cloud Preprocessing Experiment

4.3. Point Cloud Comparison Experiment and Analysis

4.4. Analysis of Regression Effects

4.5. Evaluation of Algorithm

- Tested by giving fasteners random stress. Because the elastic state of the rail fastener is often random, a random clamping torque can be applied and recorded, and then the algorithm can be predicted and evaluated. During the experiment, we applied a random loop pressure from 0 to 120 N·m to the fastener.

- Testing the fastener in two states: full tightening and loosening. In a batch work environment, it is necessary to monitor whether the fasteners are in a tight or loose state condition, so this method can be used to evaluate whether the algorithm has a direct binary judgement. Tensile torque requirements for Type II fasteners range between 100 and 140 N·m, in line with the TB/T 3065-2002 standard of the Chinese rail industry mentioned above. In this paper, we use more than 100 N·m fasteners and fasteners in or near a loose state (tightening torque less than 30 N·m) for the algorithm prediction.

- Test by gradually increasing the fastener stress. To compare the two methods, the fasteners are tightened in a step-by-step fashion. For each clamping torque, the torque was changed from 20 N·m to 110 N·m, increasing by approximately 10 N·m each time, with two 3D scans at different angles.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mao, Q.Z.; Cui, H.; Hu, Q.W.; Ren, X.C. A rigorous fastener inspection approach for high-speed railway from structured light sensors. Isprs J. Photogramm. Remote Sens. 2018, 143, 249–267. [Google Scholar] [CrossRef]

- Song, Y.; Liu, Z.; Rønnquist, A.; Nåvik, P.; Liu, Z. Contact wire irregularity stochastics and effect on high-speed railway pantograph–catenary interactions. IEEE Trans. Instrum. Meas. 2020, 69, 8196–8206. [Google Scholar] [CrossRef]

- He, X.; Wu, T.; Zou, Y.; Chen, Y.F.; Guo, H.; Yu, Z. Recent developments of high-speed railway bridges in China. Struct. Infrastruct. Eng. 2017, 13, 1584–1595. [Google Scholar] [CrossRef]

- Wei, J.H.; Liu, C.; Ren, T.Q.; Liu, H.X.; Zhou, W.J. Online Condition Monitoring of a Rail Fastening System on High-Speed Railways Based on Wavelet Packet Analysis. Sensors 2017, 17, 12. [Google Scholar] [CrossRef] [PubMed]

- Gibert, X.; Patel, V.M.; Chellappa, R. Robust fastener detection for autonomous visual railway track inspection. In Proceedings of the 2015 IEEE Winter Conference on Applications of Computer Vision, Waikoloa, HI, USA, 5–9 January 2015; IEEE: Piscataway, NJ, USA; pp. 694–701. [Google Scholar]

- Bai, T.B.; Yang, J.W.; Xu, G.Y.; Yao, D.C. An optimized railway fastener detection method based on modified Faster R-CNN. Measurement 2021, 182, 9. [Google Scholar] [CrossRef]

- Dong, B.; Li, Q.; Wang, J.; Huang, W.; Dai, P.; Wang, S. An end-to-end abnormal fastener detection method based on data synthesis. In Proceedings of the 2019 IEEE 31st International Conference on Tools with Artificial Intelligence (ICTAI), Portland, OR, USA, 4–6 November 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 149–156. [Google Scholar] [CrossRef]

- Wang, D.; Su, H.; Chen, G.; Xu, D.; Wang, L.; Zhao, X. Defect Detection Method of Railway Fastener Based on SPP-improved ResNet. In Proceedings of the 2021 CAA Symposium on Fault Detection, Supervision, and Safety for Technical Processes (SAFEPROCESS), Chengdu, China, 17–18 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–6. [Google Scholar]

- Pan, Y.; Ma, Y.L.; Dong, Y.Q.; Gu, Z.X.; Wang, D.L. A Vision-Based Monitoring Method for the Looseness of High-Strength Bolt. IEEE Trans. Instrum. Meas. 2021, 70, 14. [Google Scholar] [CrossRef]

- Wang, C.Y.; Wang, N.; Ho, S.C.; Chen, X.M.; Song, G.B. Design of a New Vision-Based Method for the Bolts Looseness Detection in Flange Connections. IEEE Trans. Ind. Electron. 2020, 67, 1366–1375. [Google Scholar] [CrossRef]

- Dai, X.; Peng, Y.; Wang, K.C.; Yang, E.; Li, J.Q.; Ding, S. Railway fastener detection method based on 3D images. In ICRT 2017: Railway Development, Operations, and Maintenance; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 938–946. [Google Scholar]

- Cui, H.; Hu, Q.W.; Mao, Q.Z. Real-Time Geometric Parameter Measurement of High-Speed Railway Fastener Based on Point Cloud from Structured Light Sensors. Sensors 2018, 18, 19. [Google Scholar] [CrossRef]

- Zhan, Y.; Dai, X.; Yang, E.; Wang, K.C.P. Convolutional neural network for detecting railway fastener defects using a developed 3D laser system. Int. J. Rail Transp. 2021, 9, 424–444. [Google Scholar] [CrossRef]

- Sun, J.H.; Xie, Y.X.; Cheng, X.Q. A Fast Bolt-Loosening Detection Method of Running Train’s Key Components Based on Binocular Vision. IEEE Access 2019, 7, 32227–32239. [Google Scholar] [CrossRef]

- Zhang, S. Recent progresses on real-time 3D shape measurement using digital fringe projection techniques. Opt. Lasers Eng. 2010, 48, 149–158. [Google Scholar] [CrossRef]

- Zhang, S. High-Speed 3D Imaging with Digital Fringe Projection Techniques; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Eccles, W. A new approach to the checking of the tightness of bolted connections. In Proceedings of the 2014 Lubrication, Maintenance, and Tribotechnology, Manchester, UK, 25–27 June 2014. [Google Scholar]

- Shoberg, R.S. Engineering fundamentals of threaded fastener design and analysis. I. Fastening 2000, 6, 26–29. [Google Scholar]

- Sansoni, G.; Corini, S.; Lazzari, S.; Rodella, R.; Docchio, F. Three-dimensional imaging based on Gray-code light projection: Characterization of the measuring algorithm and development of a measuring system for industrial applications. Appl. Opt. 1997, 36, 4463–4472. [Google Scholar] [CrossRef] [PubMed]

- Sansoni, G.; Carocci, M.; Rodella, R. Three-dimensional vision based on a combination of gray-code and phase-shift light projection: Analysis and compensation of the systematic errors. Appl. Opt. 1999, 38, 6565–6573. [Google Scholar] [CrossRef]

- Zeng, J.; Ma, W.; Jia, W.; Li, Y.; Li, H.; Liu, X.; Tan, M. Self-Unwrapping Phase-Shifting for Fast and Accurate 3-D Shape Measurement. IEEE Trans. Instrum. Meas. 2022, 71, 1–12. [Google Scholar] [CrossRef]

- Moreno, D.; Taubin, G. Simple, accurate, and robust projector-camera calibration. In Proceedings of the 2012 Second International Conference on 3D Imaging, Modeling, Processing, Visualization & Transmission, Zurich, Switzerland, 13–15 October 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 464–471. [Google Scholar]

- Nayar, S.K.; Krishnan, G.; Grossberg, M.D.; Raskar, R. Fast separation of direct and global components of a scene using high frequency illumination. In ACM SIGGRAPH 2006 Papers; Association for Computing Machinery: New York, NY, USA, 2006; pp. 935–944. [Google Scholar]

- Feng, S.; Zuo, C.; Zhang, L.; Tao, T.; Hu, Y.; Yin, W.; Qian, J.; Chen, Q. Calibration of fringe projection profilometry: A comparative review. Opt. Lasers Eng. 2021, 143, 106622. [Google Scholar] [CrossRef]

- Hu, W.; Hu, Q.J.; Wang, Z.H.; Gao, X. Dynamic Point Cloud Denoising via Manifold-to-Manifold Distance. IEEE Trans. Image Process. 2021, 30, 6168–6183. [Google Scholar] [CrossRef]

- Mattei, E.; Castrodad, A. Point Cloud Denoising via Moving RPCA. Comput. Graph. Forum 2017, 36, 123–137. [Google Scholar] [CrossRef]

- Rusu, R.B.; Marton, Z.C.; Blodow, N.; Dolha, M.; Beetz, M. Towards 3D Point cloud based object maps for household environments. Robot. Auton. Syst. 2008, 56, 927–941. [Google Scholar] [CrossRef]

- Zhou, Q.Y.; Park, J.; Koltun, V. Fast global registration. In Proceedings of the 2016 European Conference on Computer Vision, Amsterdam, The Netherlands, 11–14 October 2016; Springer: Cham, Switzerland, 2016; pp. 766–782. [Google Scholar]

- Besl, P.J.; McKay, N.D. Method for registration of 3-D shapes. In Sensor Fusion IV: Control Paradigms and Data Structures; SPIE: Bellingham, WA, USA, 1992; Volume 1611, pp. 586–606. [Google Scholar]

- Jafari, B.; Khaloo, A.; Lattanzi, D. Deformation tracking in 3D point clouds via statistical sampling of direct cloud-to-cloud distances. J. Nondestruct. Eval. 2017, 36, 65. [Google Scholar] [CrossRef]

- Urbach, D.; Ben-Shabat, Y.; Lindenbaum, M. DPDist: Comparing point clouds using deep point cloud distance. In Proceedings of the 16th European Conference on Computer Vision, Glasgow, UK, 23–28 August 2020; Springer: Cham, Switzerland, 2020; pp. 545–560. [Google Scholar]

- Ahmad Fuad, N.; Yusoff, A.R.; Ismail, Z.; Majid, Z. Comparing the performance of point cloud registration methods for landslide monitoring using mobile laser scanning data. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, 42, 11–21. [Google Scholar]

- Heidenreich, N.B.; Schindler, A.; Sperlich, S. Bandwidth selection for kernel density estimation: A review of fully automatic selectors. AStA Adv. Stat. Anal. 2013, 97, 403–433. [Google Scholar] [CrossRef]

- Botev, Z.I.; Grotowski, J.F.; Kroese, D.P. KERNEL DENSITY ESTIMATION VIA DIFFUSION. Ann. Stat. 2010, 38, 2916–2957. [Google Scholar] [CrossRef]

- Silverman, B.W. Density Estimation for Statistics and Data Analysis; Routledge: Oxfordshire, UK, 2018. [Google Scholar]

- Miao, R.S.; Shen, R.L.; Zhang, S.H.; Xue, S.L. A Review of Bolt Tightening Force Measurement and Loosening Detection. Sensors 2020, 20, 18. [Google Scholar] [CrossRef]

- Hong, H.; Lee, H.; Jeong, N.; Baek, K.; Suh, M. A study on an equivalent model of the threaded fasteners in complex structures through tightening and loosening analysis. J. Mech. Sci. Technol. 2020, 34, 1195–1205. [Google Scholar] [CrossRef]

- Mansson, K.; Shukur, G. A Poisson ridge regression estimator. Econ. Model. 2011, 28, 1475–1481. [Google Scholar] [CrossRef]

- Muniz, G.; Kibria, B.M.G. On Some Ridge Regression Estimators: An Empirical Comparisons. Commun. Stat.-Simul. Comput. 2009, 38, 621–630. [Google Scholar] [CrossRef]

- Zeng, Z.; Tian, C.; Tu, Q.; Shuaibu, A.A.; Wang, W. Experimental study on the longitudinal resistance of WJ-8 fasteners subjected to torque and vertical loading in continuously welded rails. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2020, 234, 1071–1080. [Google Scholar] [CrossRef]

- Zhong, Y. Intrinsic shape signatures: A shape descriptor for 3D object recognition. In Proceedings of the 2009 IEEE 12th International Conference on Computer Vision Workshops, ICCV Workshops, Kyoto, Japan, 27 September–4 October 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 689–696. [Google Scholar]

- Dormann, C.F.; Elith, J.; Bacher, S.; Buchmann, C.; Carl, G.; Carre, G.; Marquez, J.R.G.; Gruber, B.; Lafourcade, B.; Leitao, P.J.; et al. Collinearity: A review of methods to deal with it and a simulation study evaluating their performance. Ecography 2013, 36, 27–46. [Google Scholar] [CrossRef]

| Scan No. | No. of Scan Points | Radius of Fitted Sphere (mm) | Maximum Error (mm) | RMSE of Fit (mm) |

|---|---|---|---|---|

| 1 | 2501 | 10.0863 | 0.3141 | 0.0566 |

| 2 | 2920 | 10.0175 | 0.4860 | 0.0824 |

| 3 | 3019 | 10.0991 | 0.5953 | 0.0585 |

| 4 | 2975 | 10.0252 | 0.3144 | 0.0584 |

| 5 | 3055 | 10.0357 | 0.3152 | 0.0532 |

| Registration Method | No. of Tests | No. of Registration Failures | Successful Registration Rate | Average Time Spent onRegistration (s) | Average Registration RMSE (mm) |

|---|---|---|---|---|---|

| ICP | 132 | 7 | 94.70% | 2.7121 | 0.4464 |

| FGR | 132 | 125 | 5.30% | 0.5403 | 1.5622 |

| ISS | 132 | 65 | 49.24% | 0.3558 | 1.3390 |

| FPFH | 132 | 2 | 98.48% | 1.1528 | 0.5210 |

| FGR + ICP | 132 | 2 | 98.48% | 1.7718 | 0.3587 |

| ISS + ICP | 132 | 1 | 99.24% | 1.8444 | 0.3467 |

| FPFH + ICP | 132 | 0 | 100% | 2.4011 | 0.3292 |

| Regression Method | Tightening Torque (N·m) | Clamping Force (kN) | ||

|---|---|---|---|---|

| Maximum Error | RMSE | Maximum Error | RMSE | |

| LSR | 72.504 | 19.505 | 15.169 | 4.080 |

| SVR | 49.664 | 11.923 | 10.390 | 2.494 |

| PLSR | 26.225 | 9.744 | 5.486 | 2.038 |

| Ridge Regression | 25.302 | 9.274 | 5.293 | 1.940 |

| Test Method | Tightening Torque RMSE (N·m) | Clamping Force RMSE (kN) | Average Time Spent on Prediction (s) |

|---|---|---|---|

| Random Stress | 13.530 | 2.831 | 24.53 |

| Fully tightened and loosened stress | 11.887 | 2.487 | 23.16 |

| Regularly increase stress | 13.383 | 2.800 | 24.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.; Hong, Y.; Wang, Y.; Niu, Y.; Zhang, H.; Chu, C. Digital Fringe Projection-Based Clamping Force Estimation Algorithm for Railway Fasteners. Sensors 2023, 23, 3299. https://doi.org/10.3390/s23063299

Fan Z, Hong Y, Wang Y, Niu Y, Zhang H, Chu C. Digital Fringe Projection-Based Clamping Force Estimation Algorithm for Railway Fasteners. Sensors. 2023; 23(6):3299. https://doi.org/10.3390/s23063299

Chicago/Turabian StyleFan, Zhengji, Yingping Hong, Yunfeng Wang, Yanan Niu, Huixin Zhang, and Chengqun Chu. 2023. "Digital Fringe Projection-Based Clamping Force Estimation Algorithm for Railway Fasteners" Sensors 23, no. 6: 3299. https://doi.org/10.3390/s23063299

APA StyleFan, Z., Hong, Y., Wang, Y., Niu, Y., Zhang, H., & Chu, C. (2023). Digital Fringe Projection-Based Clamping Force Estimation Algorithm for Railway Fasteners. Sensors, 23(6), 3299. https://doi.org/10.3390/s23063299