Energy Harvesting and Task-Aware Multi-Robot Task Allocation in Robotic Wireless Sensor Networks

Abstract

1. Introduction

1.1. Motivation

1.2. Our Contributions

- To the best of our knowledge, this is the first work that considers the task-allocation problem with energy-harvesting nodes.

- When tackling the MRTA problem, our optimization includes all of the distance to be traveled by each node to reach its assigned task, the energy required for executing each task, the battery level at each node, and the energy-harvesting capabilities of the robot nodes.

- This work presents three MRTA algorithms: Classical MRTA Approach, Task-aware MRTA Approach, EH and Task-aware MRTA Approach.

1.3. Organization

2. Related Work

2.1. Multi-Robot Task Allocation

2.2. Task Allocation in Energy-Harvesting (EH) Wireless Sensor Networks (WSN)

3. System Model and Problem Definition

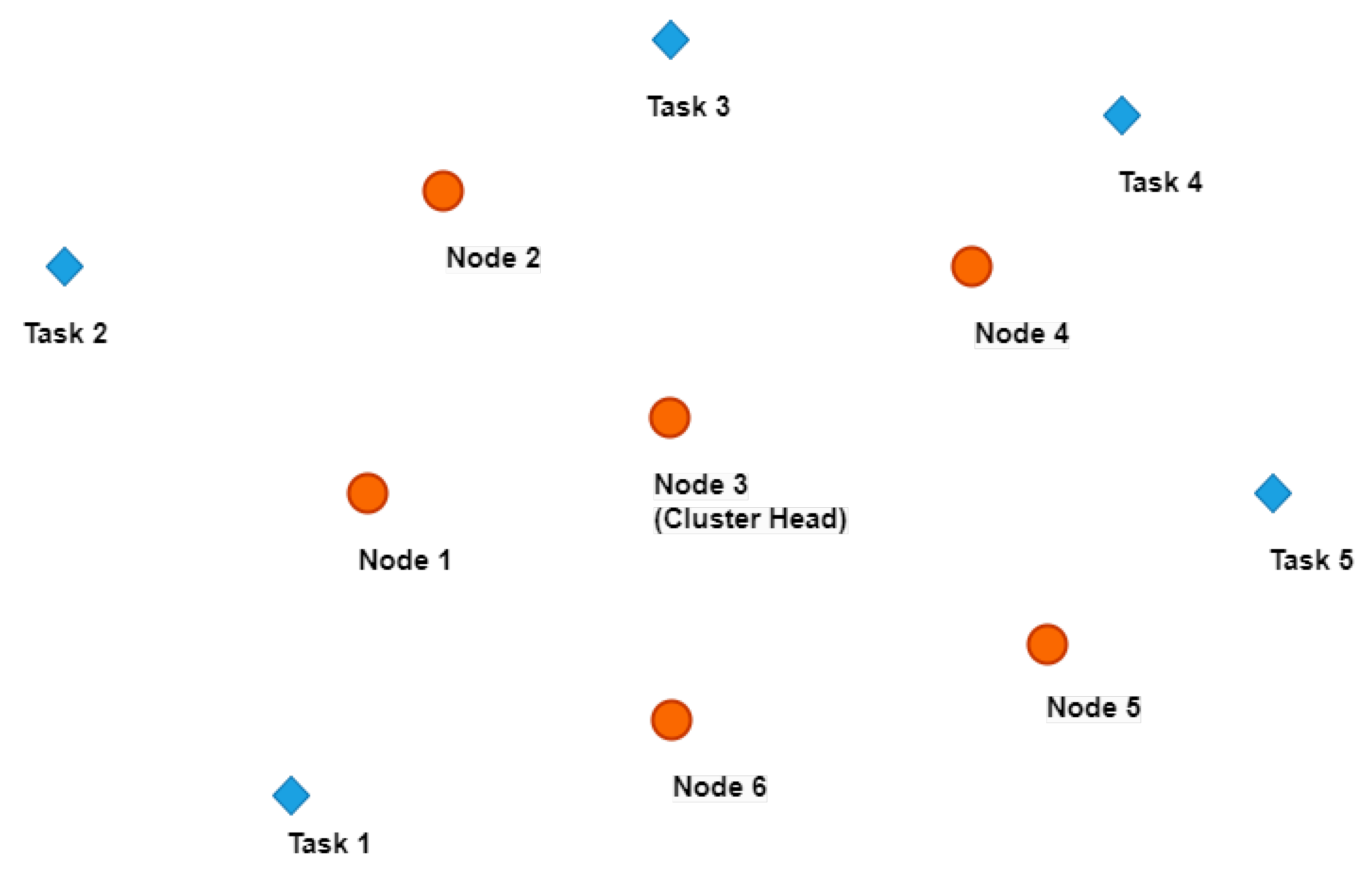

3.1. System Model

3.2. Problem Definition

4. Proposed Multi-Robot Task-Allocation (MRTA) Approaches

4.1. Classical MRTA Approach

| Algorithm 1 Classical MRTA Algorithm |

| Initialization: The index set of tasks is . Algorithm: (1) Match each robot with a task. for (2) For each robot i, calculate the costs all of the traveled distance and battery level by each node. (3) For each robot i, look at the costs of other robots. (4) If the cost decreases when the two robots change the tasks each other. (5) The robots swap their assigned tasks. (6) Otherwise, robots do not change their assigned tasks. end |

4.2. Task-Aware MRTA Approach

| Algorithm 2 Task-aware MRTA Algorithm |

| Initialization: The index set of tasks is . Algorithm: (1) Match each robot with a task. for (2) For each robot i, calculate the costs all of the traveled distance, battery level by each node and the energy required for executing each task. (3) For each robot i, look at the costs of other robots. (4) If the cost decreases when the two robots change the tasks each other. (5) The robots swap their assigned tasks. (6) Otherwise, robots do not change their assigned tasks. end |

4.3. EH and Task-Aware MRTA Approach

| Algorithm 3 EH and Task-aware MRTA Algorithm |

| Initialization: The index set of tasks is . Algorithm: (1) Match each robot with a task. for (2) For each robot i, calculate the costs all of the traveled distance and battery level by each node, the energy required for executing each task and the prediction of harvested energy at each node. (3) For each robot i, look at the costs of other robots. (4) If the cost decreases when the two robots change the tasks with each other. (5) The robots swap their assigned tasks. (6) Otherwise, robots do not change their assigned tasks. end |

5. Numerical Results

5.1. Independent and Identically Distributed (I.I.D.) EH Process

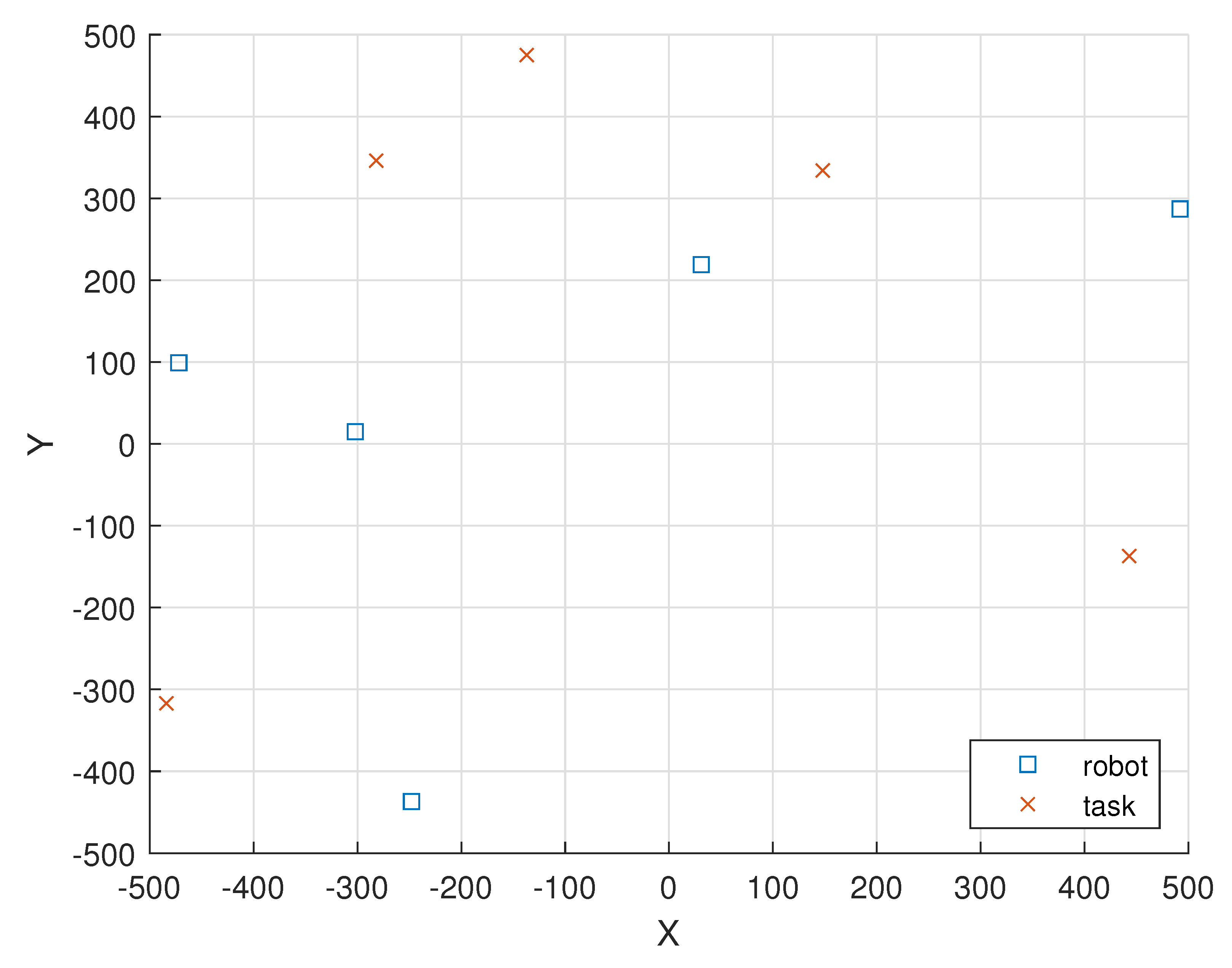

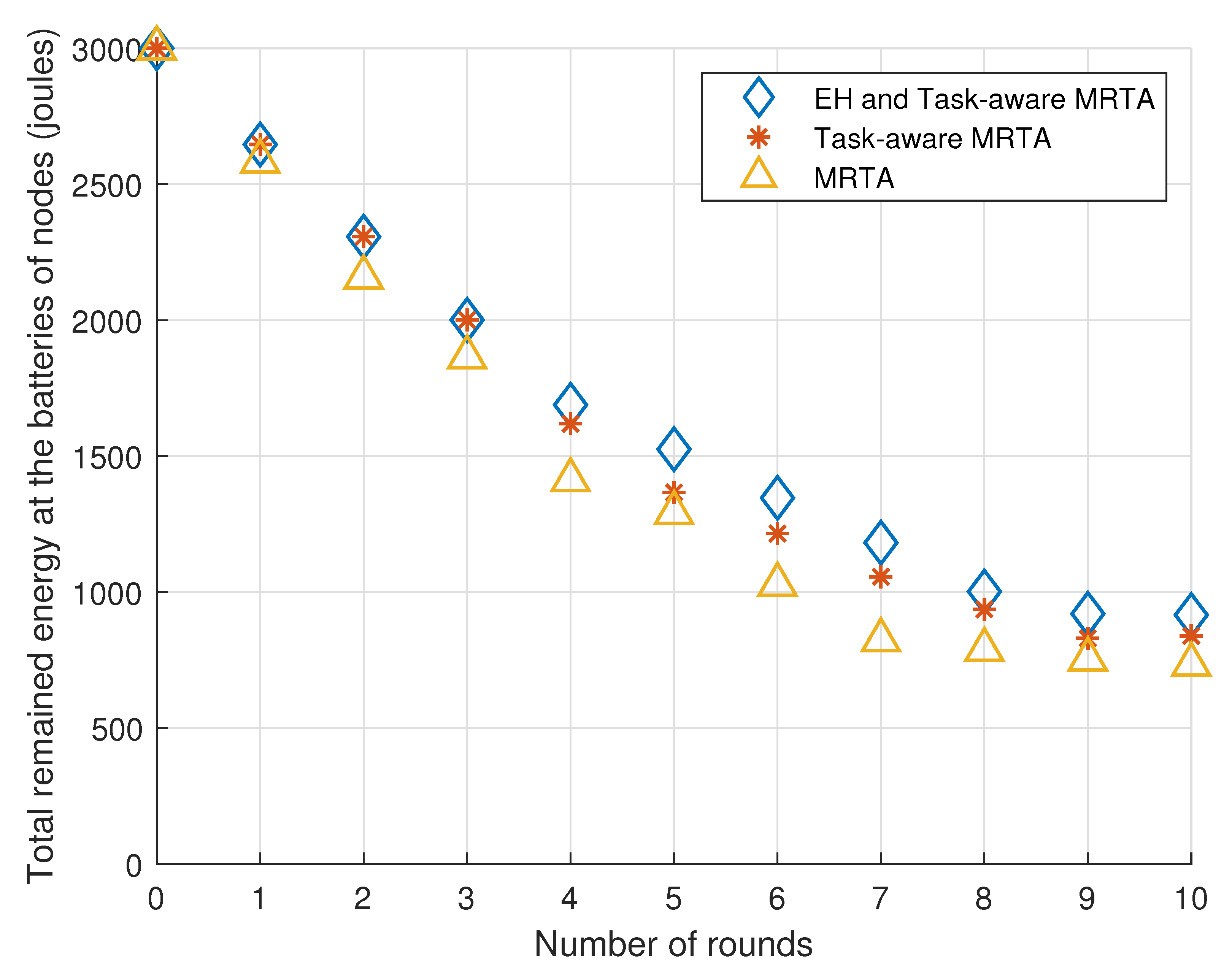

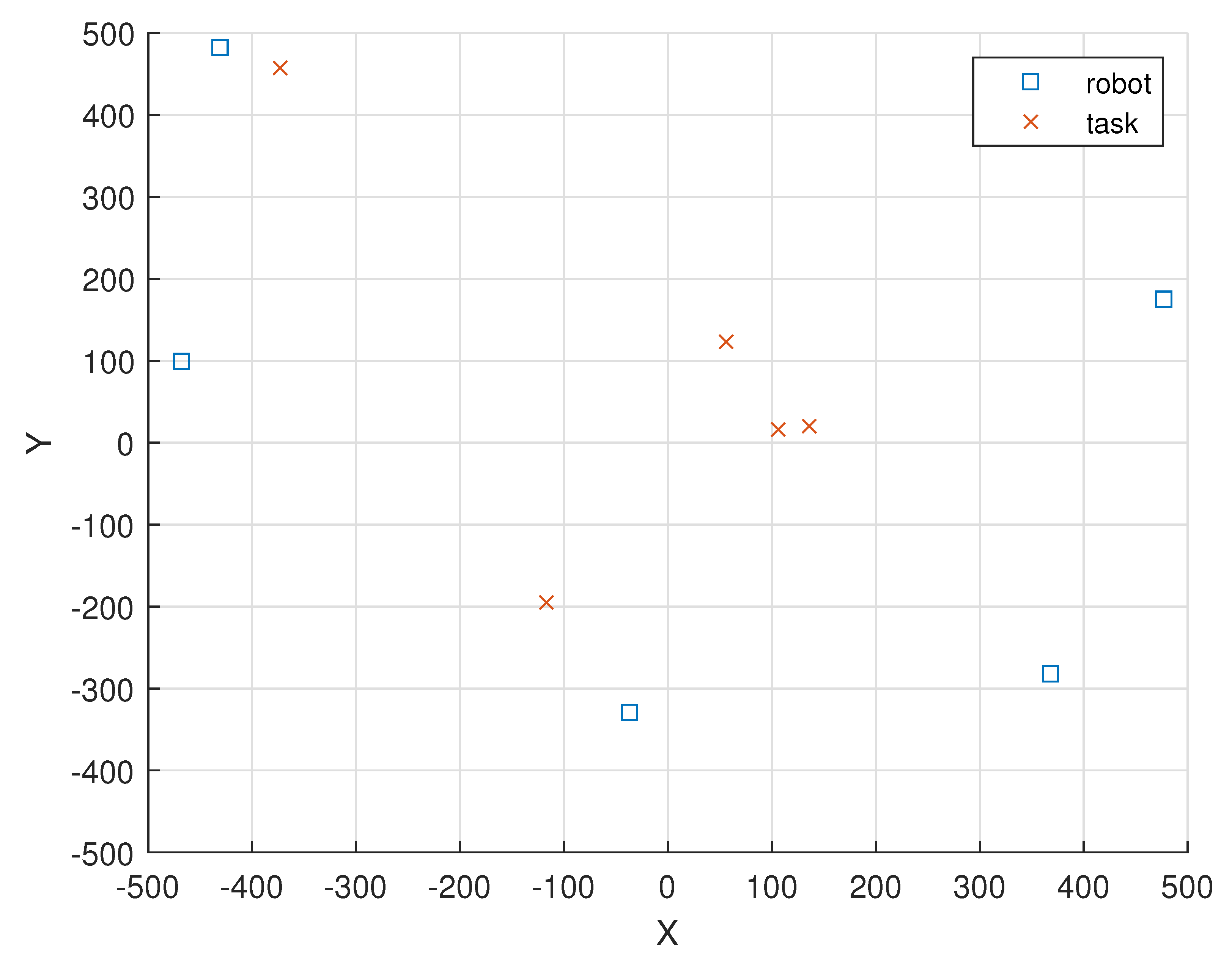

5.1.1. 5 I.I.D. EH Robot Case

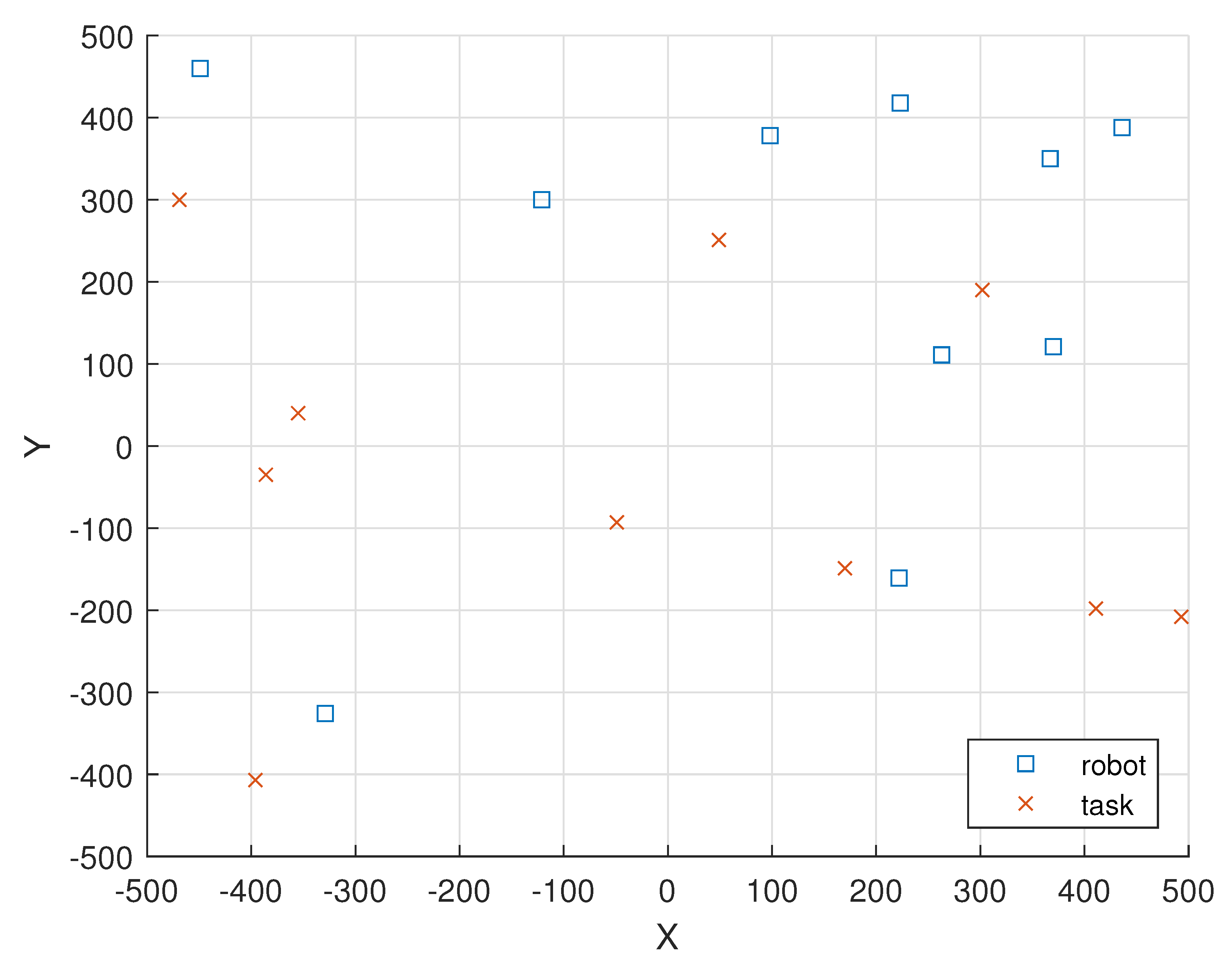

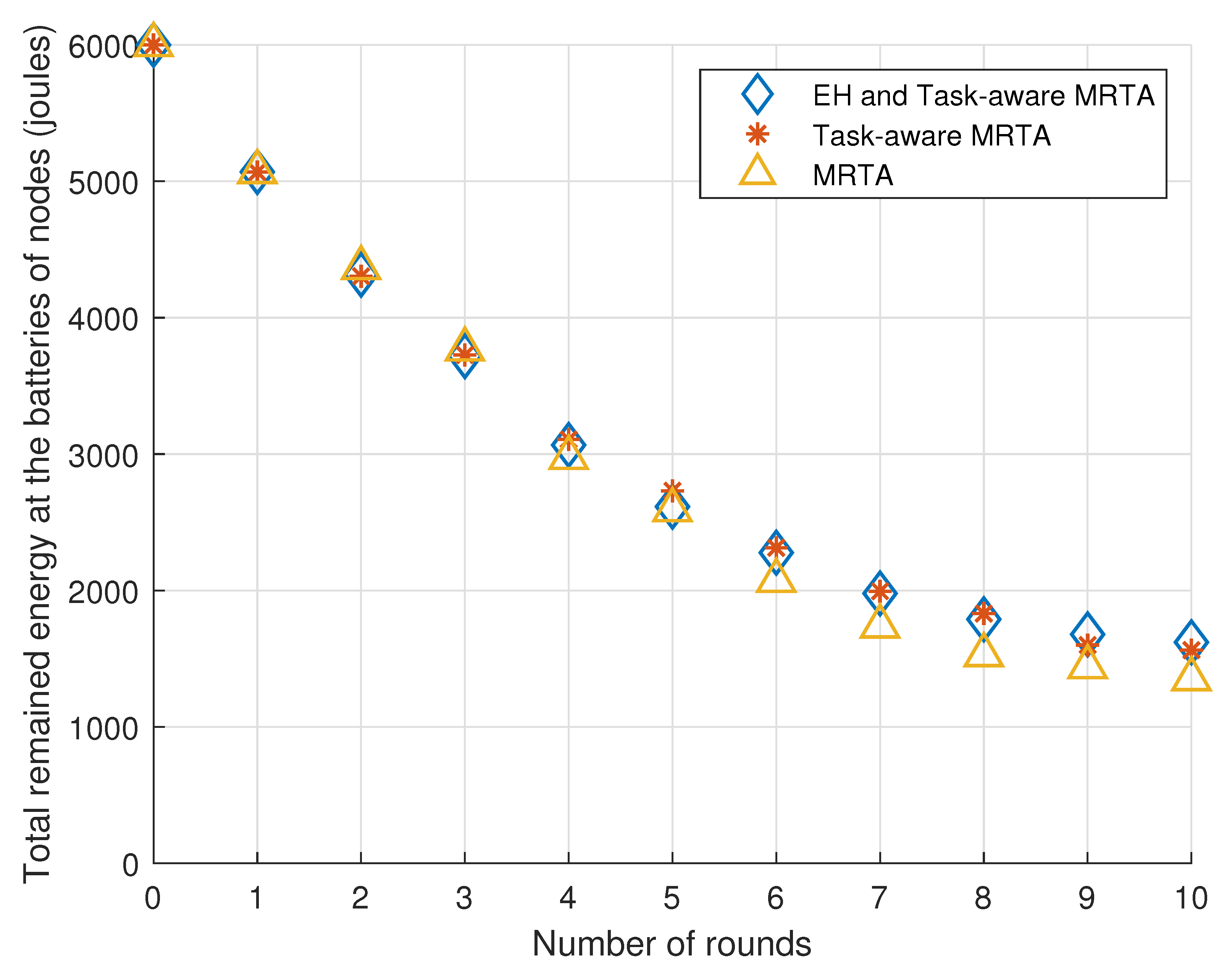

5.1.2. 10 I.I.D. EH Robot Case

5.2. Markov EH Process

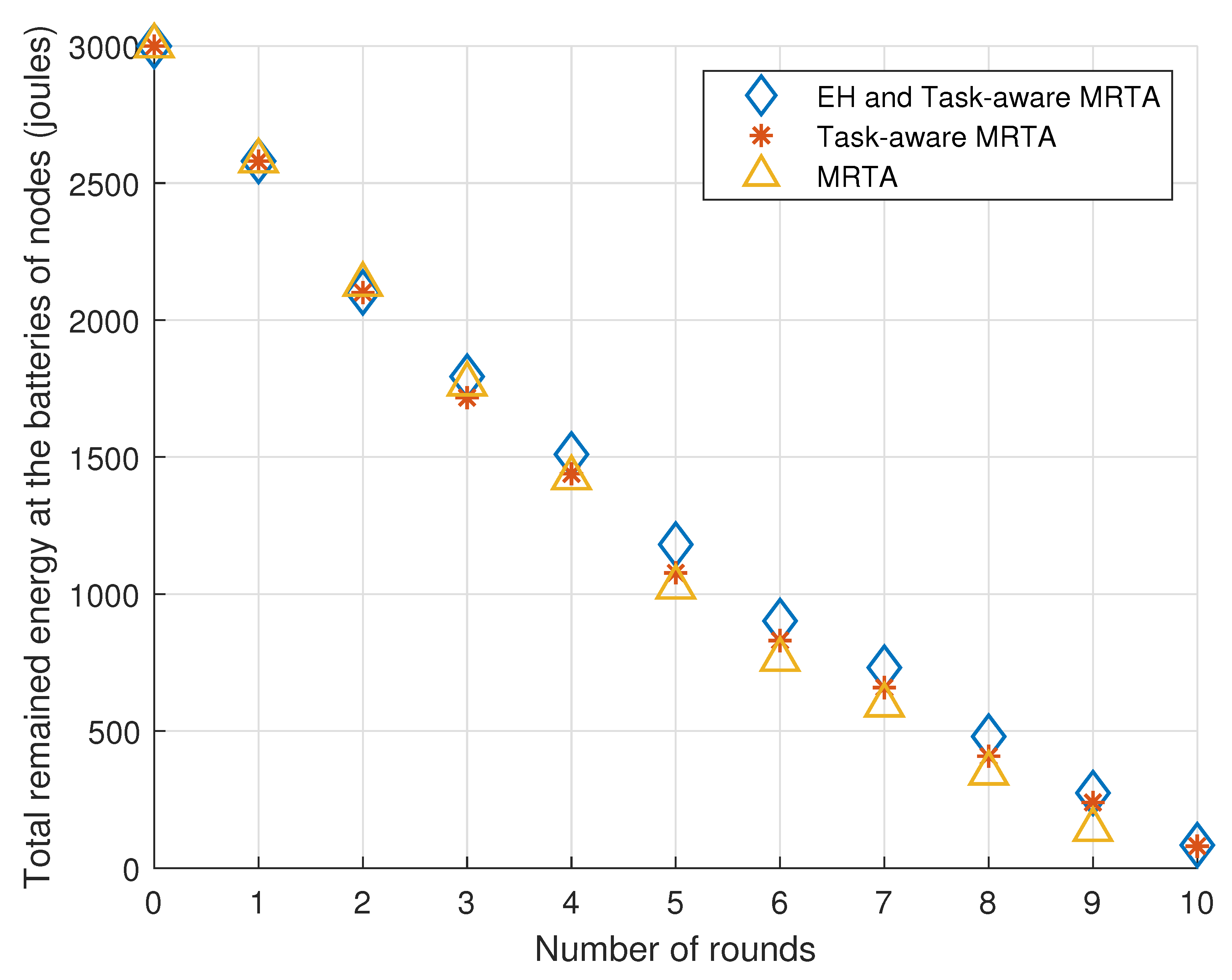

5.2.1. 5 Markov EH Robot Case

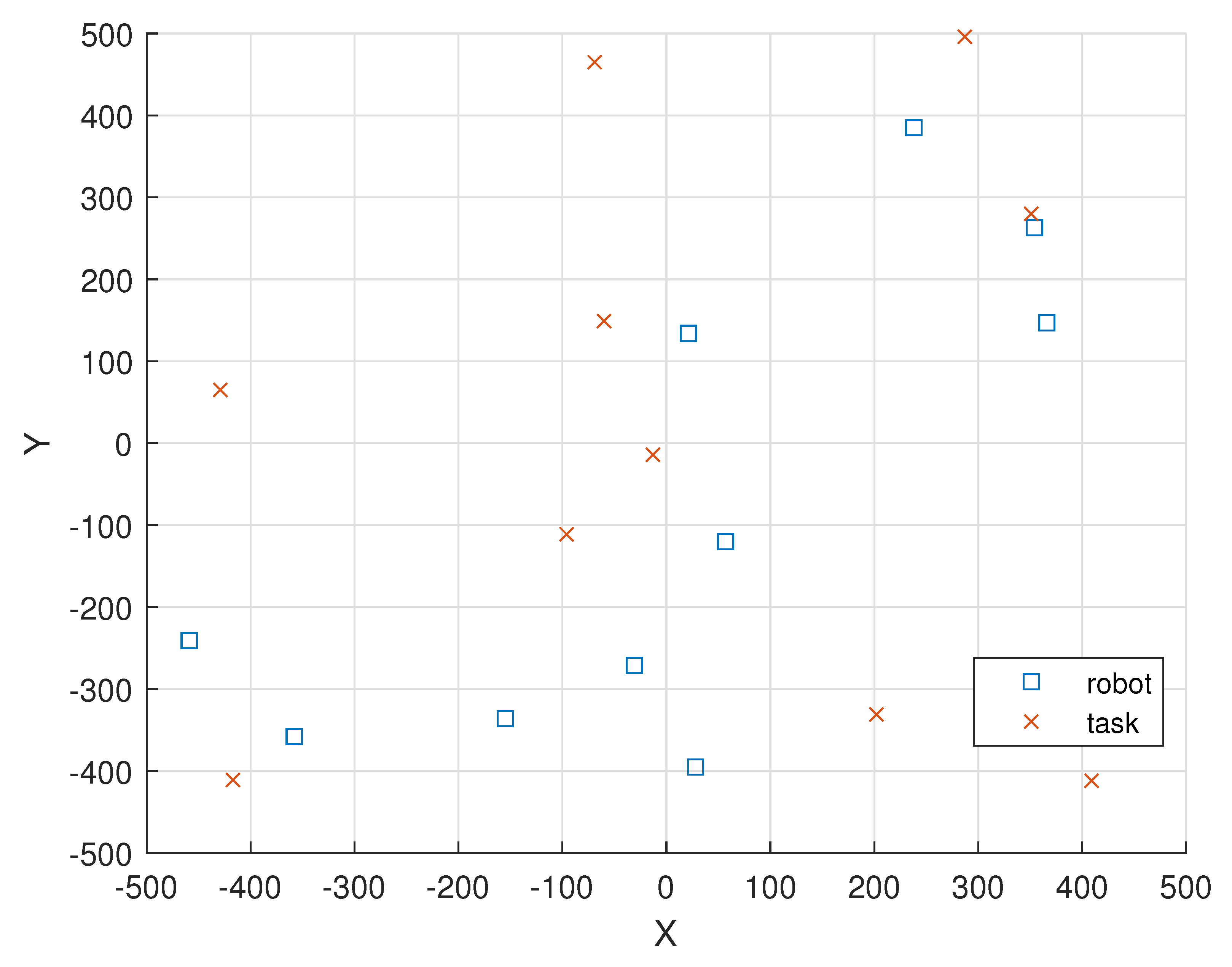

5.2.2. 10 Markov EH Robot Case

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MRTA | Multi-robot Task Allocation |

| EH | Energy Harvesting |

| WSN | Wireless Sensor Network |

| RWSN | Robotic and Wireless Sensor Network |

| EH-WSN | Energy-Harvesting Wireless Sensor Network |

| IID | Independent and identically distributed |

| GA | Genetic Algorithm |

| B&B | Branch and Bound Algorithm |

References

- 21 ideas for the 21st century. Business Week, 30 August 1999; pp. 78–167.

- Chong, C.-Y.; Kumar, S.P. Sensor networks: Evolution, opportunities, and challenges. Proc. IEEE 2003, 91, 1247–1256. [Google Scholar] [CrossRef]

- Akyildiz, I.F.; Su, W.; Sankarasubramaniam, Y.; Cayirci, E. A survey on sensor networks. IEEE Commun. Mag. 2002, 40, 102–114. [Google Scholar] [CrossRef]

- Lukic, M.; Barnawi, A.; Stojmenovic, I. Robot Coordination for Energy-Balanced Matching and Sequence Dispatch of Robots to Events. IEEE Trans. Comput. 2015, 64, 1416–1428. [Google Scholar] [CrossRef]

- Gautam, A.; Thakur, A.; Dhanania, G.; Mohan, S. A distributed algorithm for balanced multi-robot task allocation. In Proceedings of the 2016 11th International Conference on Industrial and Information Systems (ICIIS), Roorkee, India, 3–4 December 2016; pp. 622–627. [Google Scholar] [CrossRef]

- Shue, S.; Conrad, J. A Survey of Robotic Applications in Wireless Sensor Networks. In Proceedings of the IEEE Southeastcon 2013, Jacksonville, FL, USA, 4–7 April 2013; pp. 1–5. [Google Scholar]

- Ryu, J.H.; Irfan, M.; Reyaz, A. A review on sensor network issues and robotics. J. Sens. 2015, 2015, 1–14. [Google Scholar] [CrossRef]

- Ghosh, P.; Gasparri, A.; Jin, J.; Krishnamachari, B. Robotic wireless sensor networks. In Mission-Oriented Sensor Networks and Systems: Art and Science. Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2019; Volume 164. [Google Scholar]

- Luo, L.; Chakraborty, N.; Sycara, K. Provably-Good Distributed Algorithm for Constrained Multi-Robot Task Assignment for Grouped Tasks. IEEE Trans. Robot. 2015, 31, 19–30. [Google Scholar] [CrossRef]

- Dasgupta, P. Multi-robot task allocation for performing cooperative foraging tasks in an initially unknown environment. In Innovations in Defence Support Systems-2: Socio-Technical Systems; Jain, L.C., Aidman, E.V., Abeynayake, C., Eds.; Springer: Berlin, Germany, 2011; pp. 5–20. [Google Scholar]

- Lim, S.; Rus, D. Stochastic motion planning with path constraints and application to optimal agent, resource, and route planning. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; pp. 4814–4821. [Google Scholar]

- Jones, E.G.; Dias, M.B.; Stentz, A. Time-extended multi-robot coordination for domains with intra-path constraints. Auton. Robot. 2011, 30, 41–56. [Google Scholar] [CrossRef]

- Lenagh, W.; Dasgupta, P.; Munoz-Melendez, A. A spatial queuing based algorithm for multi-robot task allocation. Robotics 2015, 4, 316–340. [Google Scholar] [CrossRef]

- Gerkey, B.P.; Mataric, M.J. A formal analysis and taxonomy of task allocation in multi-robot systems. Int. J. Robot. Res. 2004, 23, 939–954. [Google Scholar] [CrossRef]

- Hojda, M. Task allocation in robot systems with multi-modal capabilities. IFAC-PapersOnLine 2015, 48, 2109–2114. [Google Scholar] [CrossRef]

- Zitouni, F.; Harous, S.; Maamri, R. A Distributed Approach to the Multi-Robot Task Allocation Problem Using the Consensus-Based Bundle Algorithm and Ant Colony System. IEEE Access 2020, 8, 27479–27494. [Google Scholar] [CrossRef]

- Comert, C.; Kulhandjian, M.; Gul, O.M.; Touazi, A.; Ellement, C.; Kantarci, B.; D’Amours, C. Analysis of Augmentation Methods for RF Fingerprinting under Impaired Channels. In Proceedings of the 2022 ACM Workshop on Wireless Security and Machine Learning (ACM WiSeML 2022), San Antonio, TX, USA, 19 May 2022; pp. 3–8. [Google Scholar]

- Gul, O.M.; Kulhandjian, M.; Kantarci, B.; Touazi, A.; Ellement, C.; D’Amours, C. On the Impact of CDL and TDL Augmentation for RF Fingerprinting under Impaired Channels. In Proceedings of the 48th Wireless World Research Forum (WWRF 2022), Abu Dhabi, United Arab Emirates, 7–9 November 2022; pp. 1–6. [Google Scholar]

- Gul, O.M.; Kulhandjian, M.; Kantarci, B.; Touazi, A.; Ellement, C.; D’Amours, C. Fine-grained Augmentation for RF Fingerprinting under Impaired Channels. In Proceedings of the IEEE 27th International Workshop on Computer Aided Modeling and Design of Communication Links and Networks (IEEE CAMAD 2022), Paris, France, 2–4 November 2022; pp. 1–6. [Google Scholar]

- Comert, C.; Gul, O.M.; Kulhandjian, M.; Touazi, A.; Ellement, C.; Kantarci, B.; D’Amours, C. Secure Design of Cyber-Physical Systems at the Radio Frequency Level: Machine and Deep Learning-Driven Approaches, Challenges and Opportunities. In Artificial Intelligence for Cyber-Physical Systems Hardening. Engineering Cyber-Physical Systems and Critical Infrastructures; Traore, I., Woungang, I., Saad, S., Eds.; Springer: Cham, Switzerland, 2022; Volume 2. [Google Scholar] [CrossRef]

- Kuhn, H.W. The hungarian method for the assignment problem. Nav. Res. Logist. Q. 1955, 2, 83–97. [Google Scholar] [CrossRef]

- Nanjanath, M.; Gini, M. Dynamic Task Allocation for Robots via Auctions. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, Orlando, FL, USA, 15–19 May 2006; pp. 2781–2788. [Google Scholar]

- Michael, N.; Zavlanos, M.M.; Kumar, V.; Pappas, G.J. Distributed multi-robot task assignment and formation control. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Pasadena, CA, USA, 19–23 May 2008; pp. 128–133. [Google Scholar]

- Viguria, A.; Howard, A.M. An integrated approach for achieving multirobot task formations. IEEE/ASME Trans. Mechatron. 2009, 14, 176–186. [Google Scholar] [CrossRef]

- Giordani, S.; Lujak, M.; Martinelli, F. A Distributed Algorithm for the Multi-Robot Task Allocation Problem. In Proceedings of the Trends in Applied Intelligent Systems 23rd International Conference on Industrial Engineering and Other Applications of Applied Intelligent Systems, IEA/AIE 2010, Cordoba, Spain, 1–4 June 2010; Proceedings, Part I. pp. 721–730. [Google Scholar]

- Trigui, S.; Koubaab, A.; Cheikhrouhoue, O.; Yousseff, H.; Bennaceurg, H.; Sritig, M.F.; Javed, Y. A Distributed Market-Based Algorithm for the Multi-Robot Assignment Problem. Procedia Comput. Sci. 2014, 32, 1108–1114. [Google Scholar] [CrossRef]

- Lukic, M.; Stojmenovic, I. Energy-balanced matching and sequence dispatch of robots to events: Pairwise exchanges and sensor assisted robot coordination. In Proceedings of the 10th IEEE 10th International Conference on Mobile Ad-Hoc and Sensor Systems, Hangzhou, China, 14–16 October 2013; pp. 249–253. [Google Scholar]

- Luo, L.; Chakraborty, N.; Sycara, K. Distributed algorithm design for multi-robot task assignment with deadlines for tasks. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 3007–3013. [Google Scholar]

- Martin, J.G.; Frejo, J.R.D.; García, R.A.; Camacho, E.F. Multi-robot task allocation problem with multiple nonlinear criteria using branch and bound and genetic algorithms. Intel. Serv. Robot. 2021, 14, 707–727. [Google Scholar] [CrossRef]

- Shin, H.S.; Li, T.; Lee, H.I.; Tsourdos, A. Sample greedy based task allocation for multiple robot systems. Swarm Intell. 2022, 16, 233–260. [Google Scholar] [CrossRef]

- Li, W.; Delicato, F.C.; Zomaya, A.Y. Adaptive energy-efficient scheduling for hierarchical wireless sensor networks. ACM Trans. Sensor Netw. (TOSN) 2013, 9, 23–30. [Google Scholar] [CrossRef]

- AbdelSalam, H.S.; Olariu, S. Toward efficient task management in wireless sensor networks. IEEE Trans. Comput. 2011, 60, 78–96. [Google Scholar] [CrossRef]

- Edalat, N.; Chen-Khong, T.; Wendong, X. An auction-based strategy for distributed task allocation in wireless sensor networks. Comput. Commun. 2012, 60, 916–928. [Google Scholar] [CrossRef]

- Liu, S.; Qiu, Q.; Wu, Q. Energy Aware Dynamic Voltage and Frequency Selection for Real-Time Systems with Energy Harvesting. In Proceedings of the Design, Automation, and Test in Europe, Munich, Germany, 10–14 March 2008. [Google Scholar]

- Liu, S.; Wu, Q.; Qiu, Q. An Adaptive Scheduling and Voltage Frequency Selection Algorithm for Real-time Energy Harvesting Systems. In Proceedings of the 2009 46th ACM/IEEE Design Automation Conference, San Francisco, CA, USA, 26–31 July 2009. [Google Scholar]

- Moser, C.; Brunelli, D.; Thiele, L.; Benini, L. Lazy Scheduling for Energy Harvesting Sensor Nodes. In Proceedings of the IFIP Working Conference on Distributed and Parallel Embedded Systems, Braga, Portugal, 11–13 October 2006. [Google Scholar]

- Moser, C.; Brunelli, D.; Thiele, L.; Benini, L. Real-time scheduling for energy harvesting sensor nodes. Real-Time Syst. J. 2007, 37, 233–260. [Google Scholar] [CrossRef]

- Zhu, T.; Mohaisen, A.; Ping, Y.; Towsley, D. DEOS: Dynamic energy-oriented scheduling for sustainable wireless sensor networks. In Proceedings of the 2012 Proceedings IEEE INFOCOM, Orlando, FL, USA, 25–30 March 2012; pp. 2363–2371. [Google Scholar]

- La Porta, T.; Petrioli, C.; Spenza, D. Sensor-mission assignment in wireless sensor networks with energy harvesting. In Proceedings of the 2011 8th Annual IEEE Communications Society Conference on Sensor, Mesh and Ad Hoc Communications and Networks, Salt Lake City, UT, USA, 27–30 June 2011; pp. 413–421. [Google Scholar]

- Edalat, N.; Motani, M. Energy-aware task allocation for energy harvesting sensor networks. J. Wirel. Com. Netw. 2016, 2016, 28. [Google Scholar] [CrossRef]

- Boyd, S.; Vandenberghe, L. Convex Optimization; Cambridge University Press: New York, NY, USA, 2004. [Google Scholar]

- Ashraf, N.; Faizan, M.; Asif, W.; Qureshi, H.K.; Iqbal, A.; Lestas, M. Energy management in harvesting enabled sensing nodes: Prediction and control. J. Netw. Comput. Appl. 2019, 132, 104–117. [Google Scholar] [CrossRef]

| Notation | Explanations |

|---|---|

| S | Index set of robots |

| M | Number of tasks |

| Number of robots | |

| t | Time slot |

| K | The number of time slots in each round |

| The cluster head in round t | |

| Remained energy in the battery of ith robot | |

| Energy harvested by robot i in TS t | |

| M-to-M task-allocation algorithm | |

| G | Set of all matching dispatch algorithms |

| T | Index set of tasks |

| ith task | |

| Position of robot i | |

| Position of the task assigned to robot i in round t under the algorithm | |

| Energy consumed by node i to execute task in round t | |

| Energy consumed by a node to travel unit distance (position change) |

| Round | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| EH & Task-aware MRTA | 3000 | 2646 | 2307 | 2001 | 1689 | 1525 | 1346 | 1182 | 1002 | 920 | 916 |

| Task-aware MRTA | 3000 | 2646 | 2307 | 2001 | 1619 | 1366 | 1215 | 1056 | 937 | 829 | 838 |

| MRTA | 3000 | 2584 | 2158 | 1864 | 1412 | 1291 | 1027 | 823 | 788 | 753 | 733 |

| EH & Task-aware MRTA/MRTA | 1.000 | 1.024 | 1.069 | 1.073 | 1.196 | 1.181 | 1.311 | 1.436 | 1.272 | 1.222 | 1.250 |

| Task-aware MRTA/MRTA | 1.000 | 1.024 | 1.069 | 1.073 | 1.147 | 1.058 | 1.183 | 1.283 | 1.189 | 1.101 | 1.143 |

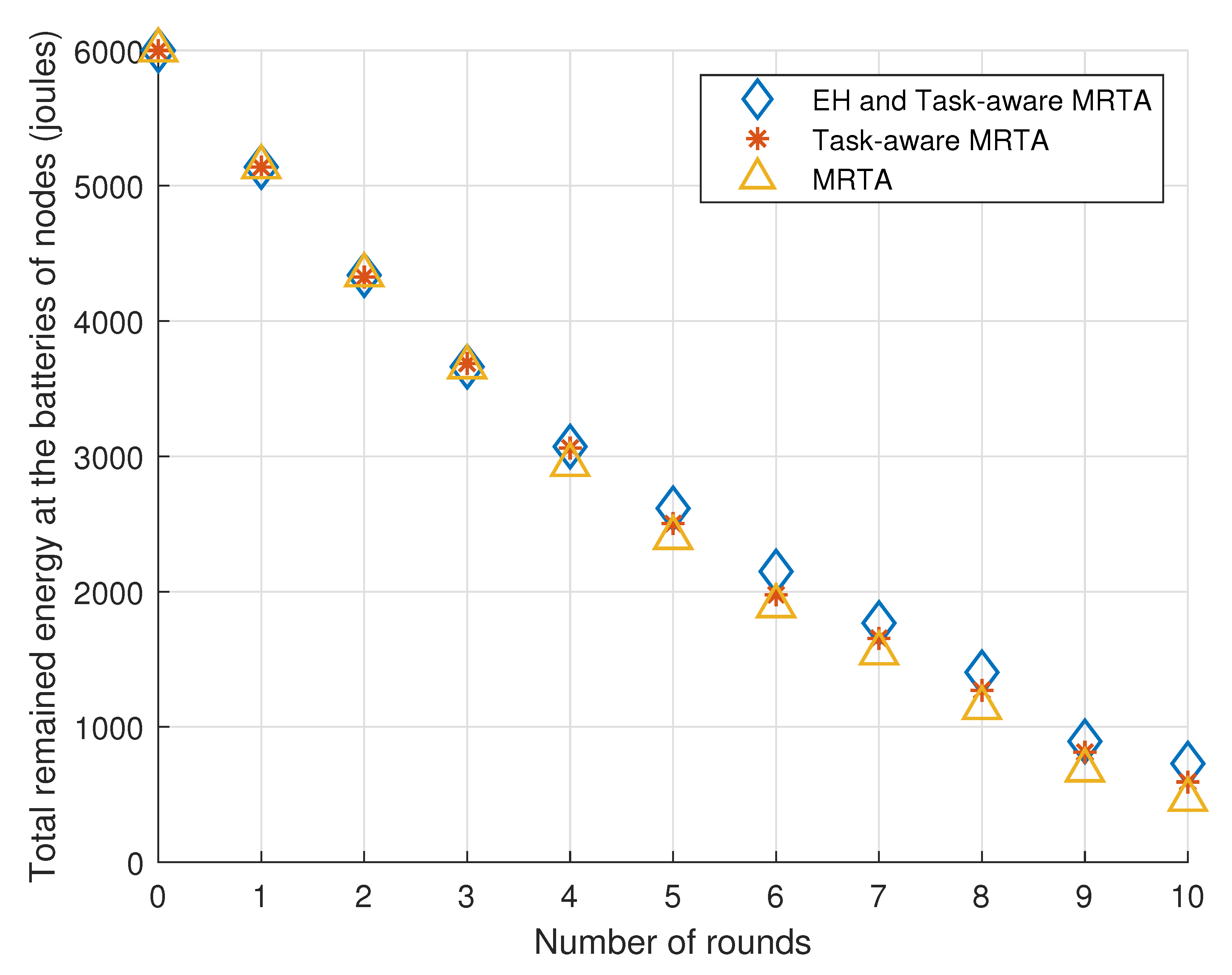

| Round | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| EH & Task-aware MRTA | 6000 | 5069 | 4365 | 3768 | 3107 | 2615 | 2313 | 1994 | 1830 | 1678 | 1620 |

| Task-aware MRTA | 6000 | 5069 | 4316 | 3727 | 3067 | 2731 | 2277 | 1978 | 1789 | 1600 | 1563 |

| MRTA | 6000 | 5069 | 4304 | 3718 | 2973 | 2589 | 2072 | 1737 | 1526 | 1439 | 1351 |

| EH & Task-aware MRTA/MRTA | 1.000 | 1.000 | 1.014 | 1.013 | 1.045 | 1.110 | 1.116 | 1.148 | 1.199 | 1.166 | 1.199 |

| Task-aware MRTA/MRTA | 1.000 | 1.000 | 1.003 | 1.002 | 1.032 | 1.055 | 1.099 | 1.139 | 1.172 | 1.112 | 1.157 |

| Round | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| EH & Task-aware MRTA | 3000 | 2580 | 2101 | 1794 | 1510 | 1181 | 902 | 732 | 480 | 274 | 84 |

| Task-aware MRTA | 3000 | 2580 | 2101 | 1766 | 1439 | 1077 | 830 | 659 | 408 | 239 | 80 |

| MRTA | 3000 | 2580 | 2129 | 1717 | 1424 | 1025 | 761 | 594 | 346 | 140 | NA |

| EH & Task-aware MRTA/MRTA | 1.000 | 1.000 | 1.013 | 1.042 | 1.060 | 1.152 | 1.185 | 1.232 | 1.179 | 1.957 | NA |

| Task-aware MRTA/MRTA | 1.000 | 1.000 | 1.013 | 1.029 | 1.011 | 1.051 | 1.091 | 1.109 | 1.179 | 1.707 | NA |

| Round | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| EH & Task-aware MRTA | 6000 | 5138 | 4339 | 3662 | 3072 | 2616 | 2149 | 1768 | 1404 | 894 | 729 |

| Task-aware MRTA | 6000 | 5138 | 4325 | 3687 | 3061 | 2503 | 1977 | 1655 | 1270 | 813 | 593 |

| MRTA | 6000 | 5138 | 4339 | 3659 | 2937 | 2398 | 1893 | 1544 | 1140 | 680 | 463 |

| EH & Task-aware MRTA/MRTA | 1.000 | 1.000 | 1.000 | 1.016 | 1.046 | 1.091 | 1.135 | 1.145 | 1.232 | 1.315 | 1.575 |

| Task-aware MRTA/MRTA | 1.000 | 1.000 | 0.997 | 1.001 | 1.042 | 1.044 | 1.044 | 1.072 | 1.114 | 1.196 | 1.281 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gul, O.M. Energy Harvesting and Task-Aware Multi-Robot Task Allocation in Robotic Wireless Sensor Networks. Sensors 2023, 23, 3284. https://doi.org/10.3390/s23063284

Gul OM. Energy Harvesting and Task-Aware Multi-Robot Task Allocation in Robotic Wireless Sensor Networks. Sensors. 2023; 23(6):3284. https://doi.org/10.3390/s23063284

Chicago/Turabian StyleGul, Omer Melih. 2023. "Energy Harvesting and Task-Aware Multi-Robot Task Allocation in Robotic Wireless Sensor Networks" Sensors 23, no. 6: 3284. https://doi.org/10.3390/s23063284

APA StyleGul, O. M. (2023). Energy Harvesting and Task-Aware Multi-Robot Task Allocation in Robotic Wireless Sensor Networks. Sensors, 23(6), 3284. https://doi.org/10.3390/s23063284