Reliability Assessment of a Vision-Based Dynamic Displacement Measurement System Using an Unmanned Aerial Vehicle

Abstract

1. Introduction

2. Materials and Methods

2.1. Camera Calibration

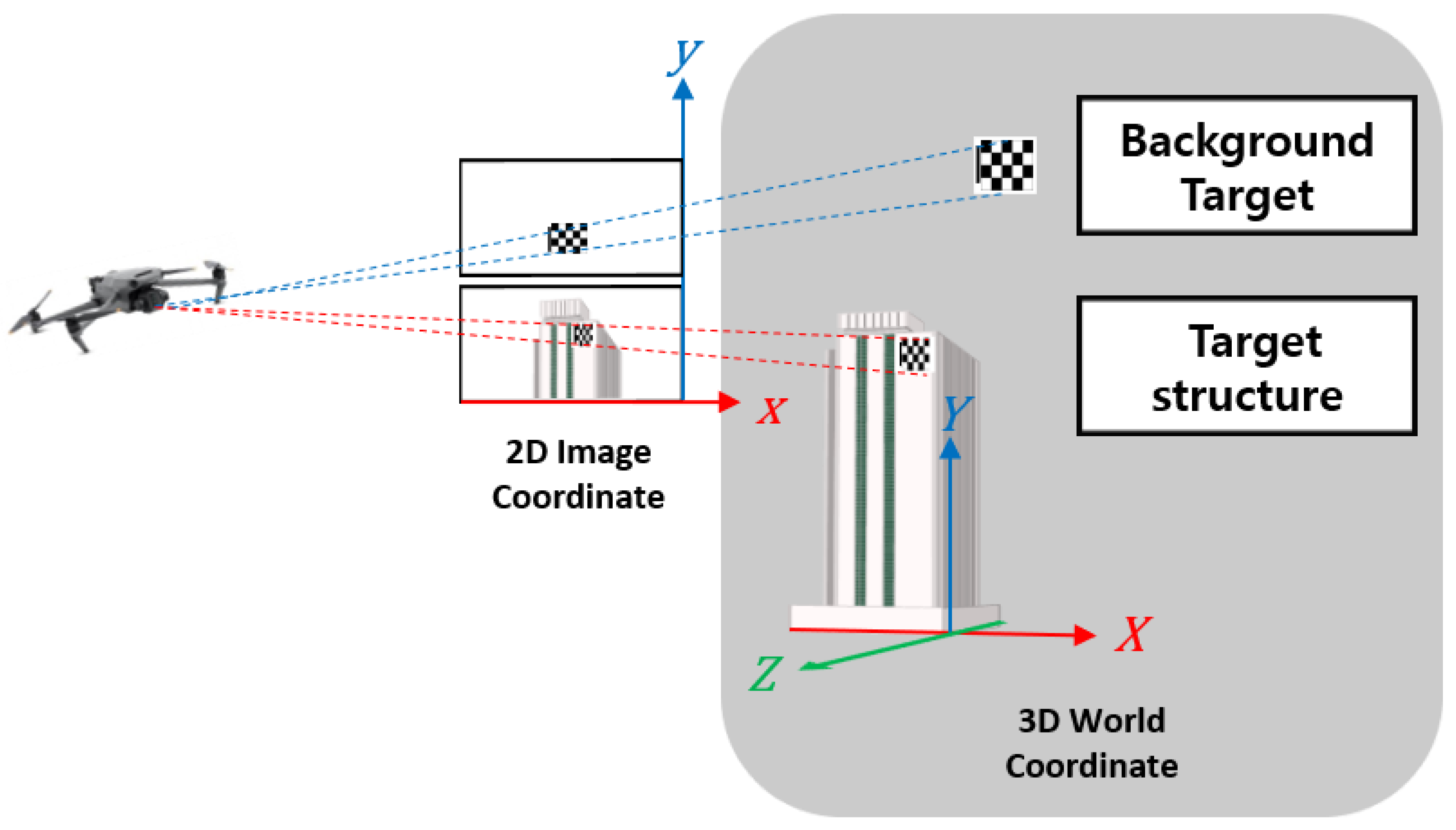

2.2. UAV Movement Correction

3. Vibration Measurement Performance Verification of VDMS Using a UAV

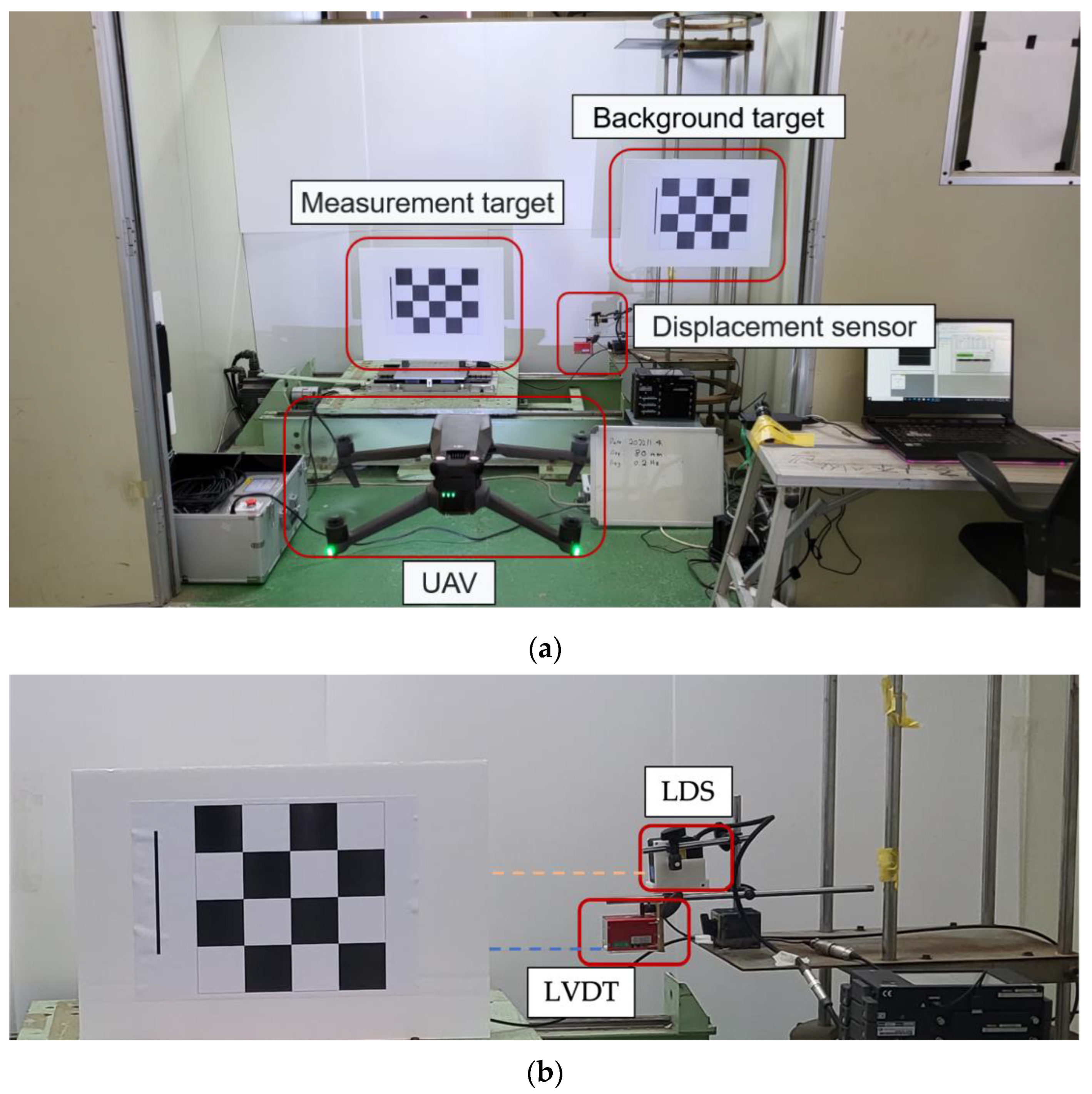

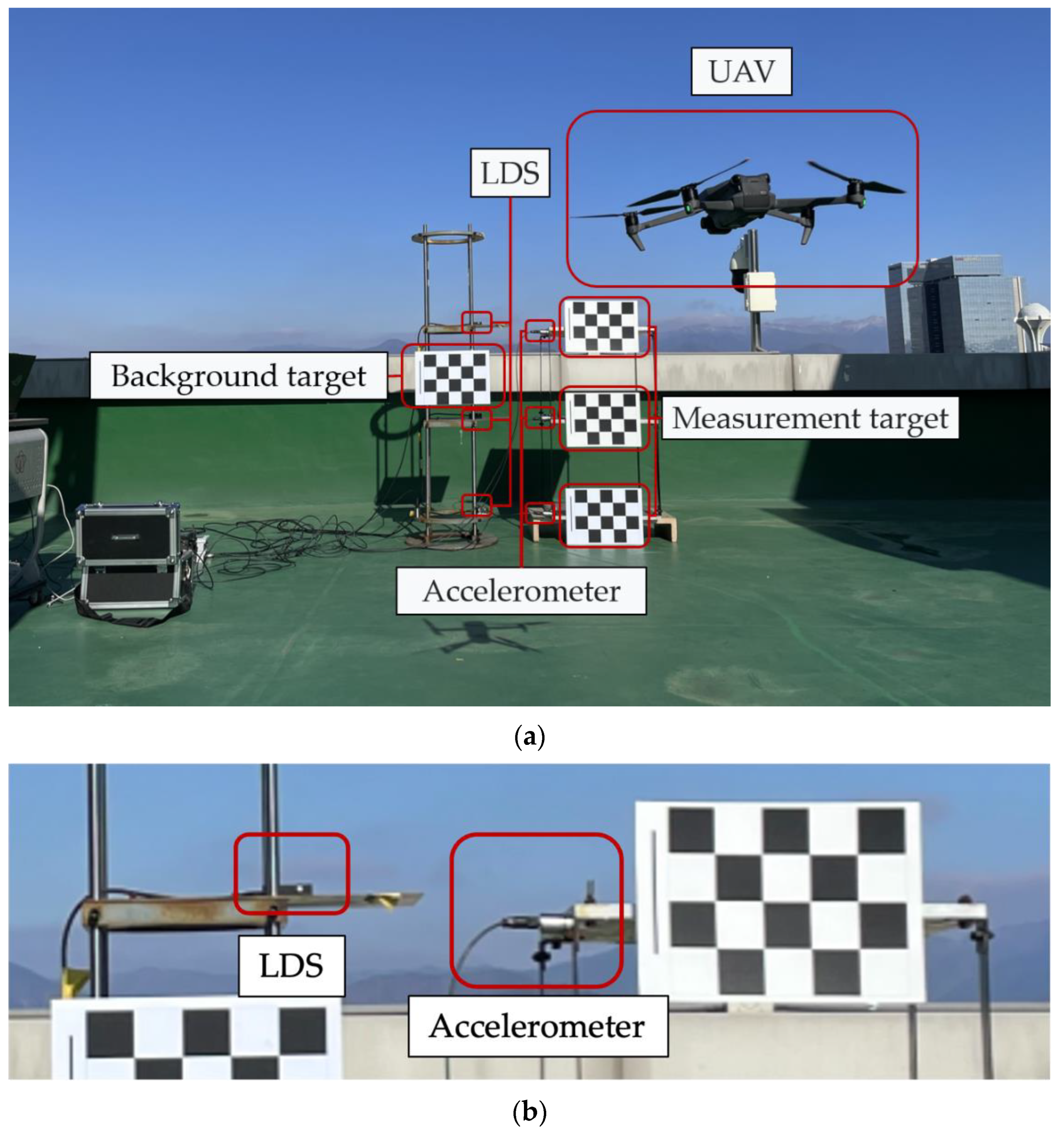

3.1. Test Overview

3.2. Measurement Equipment Configuration

3.3. Analysis of Measurement Results

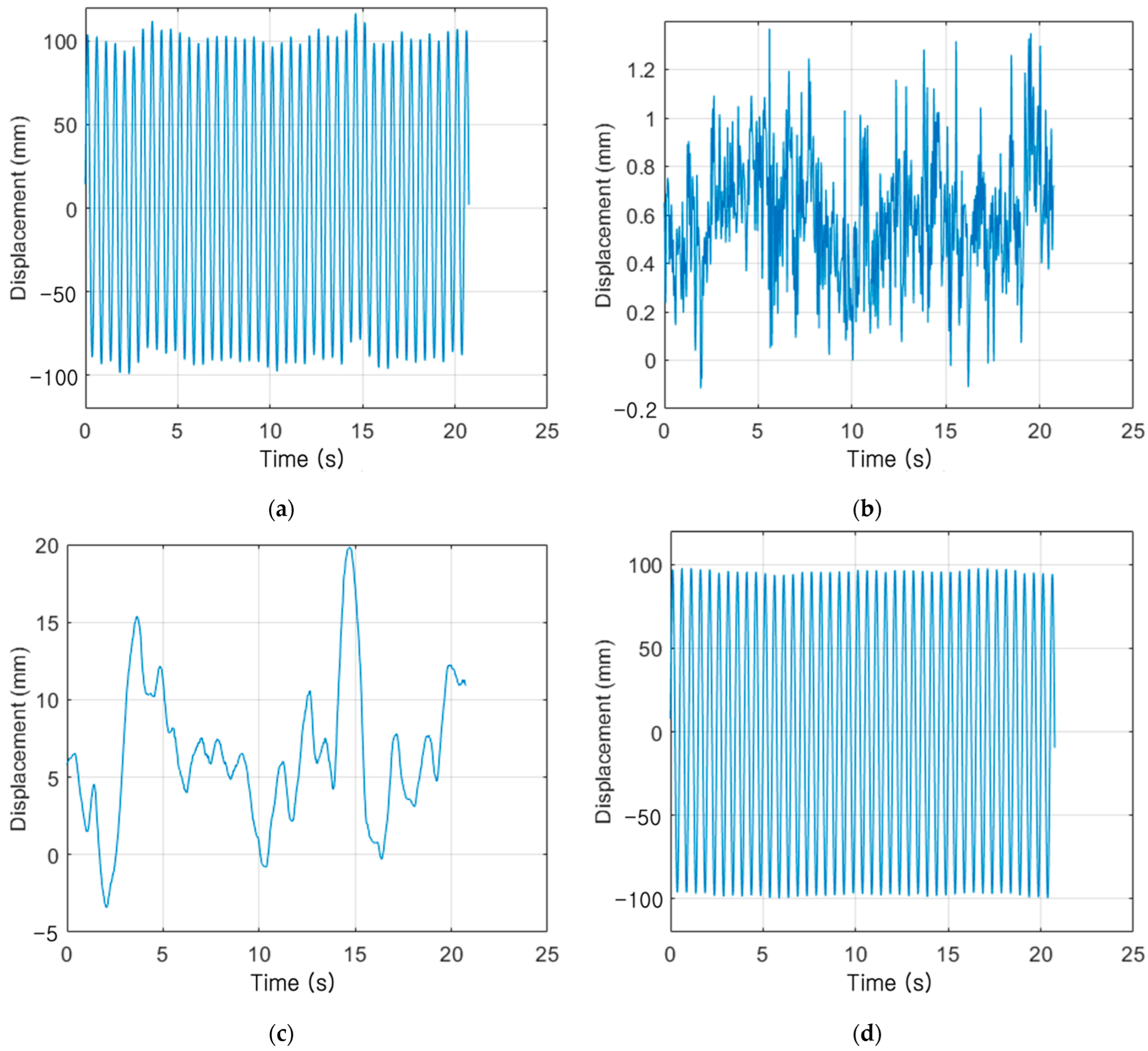

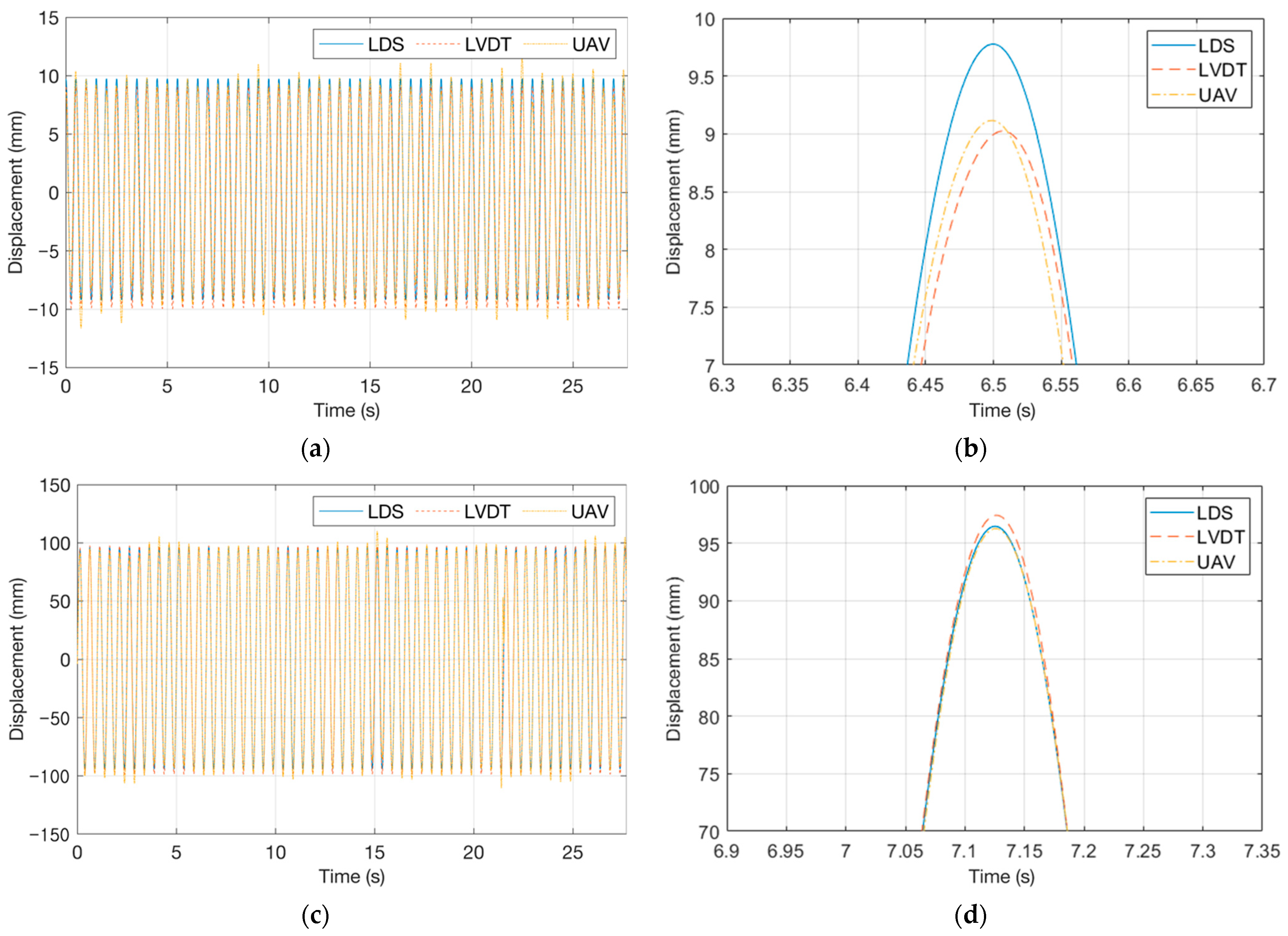

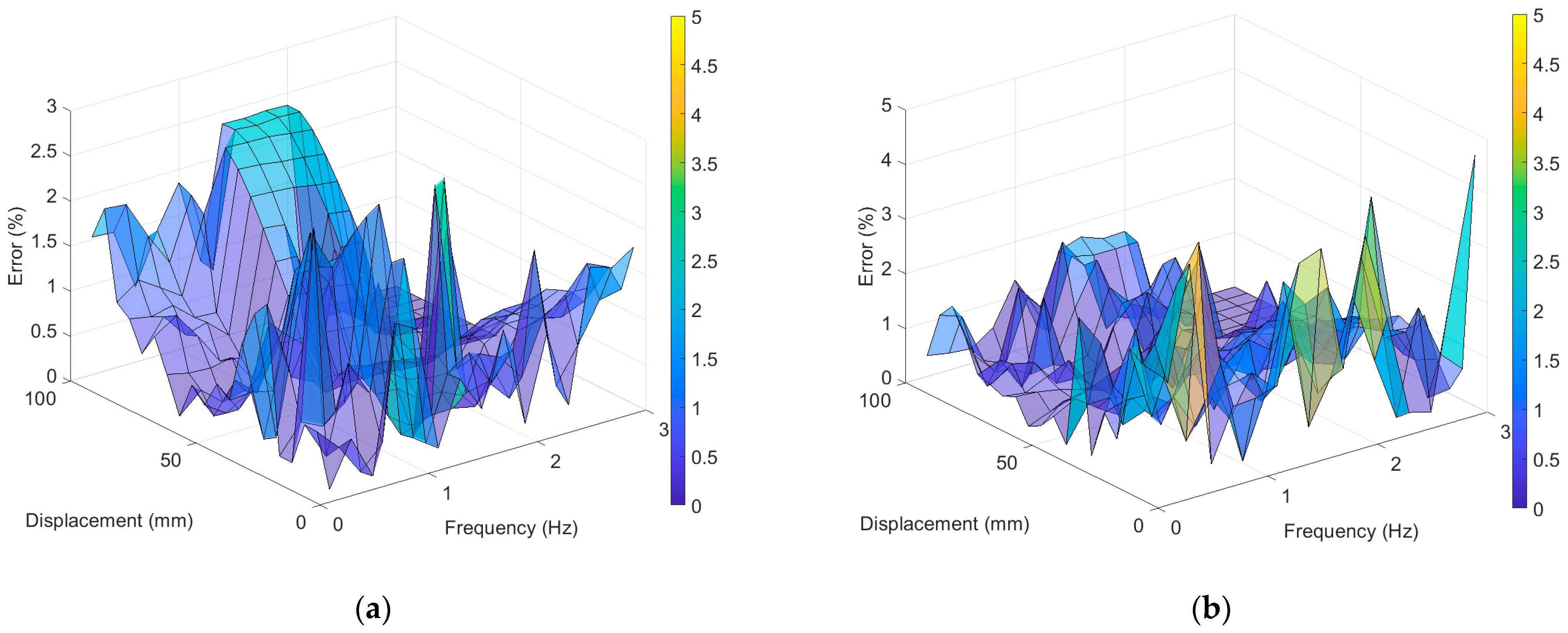

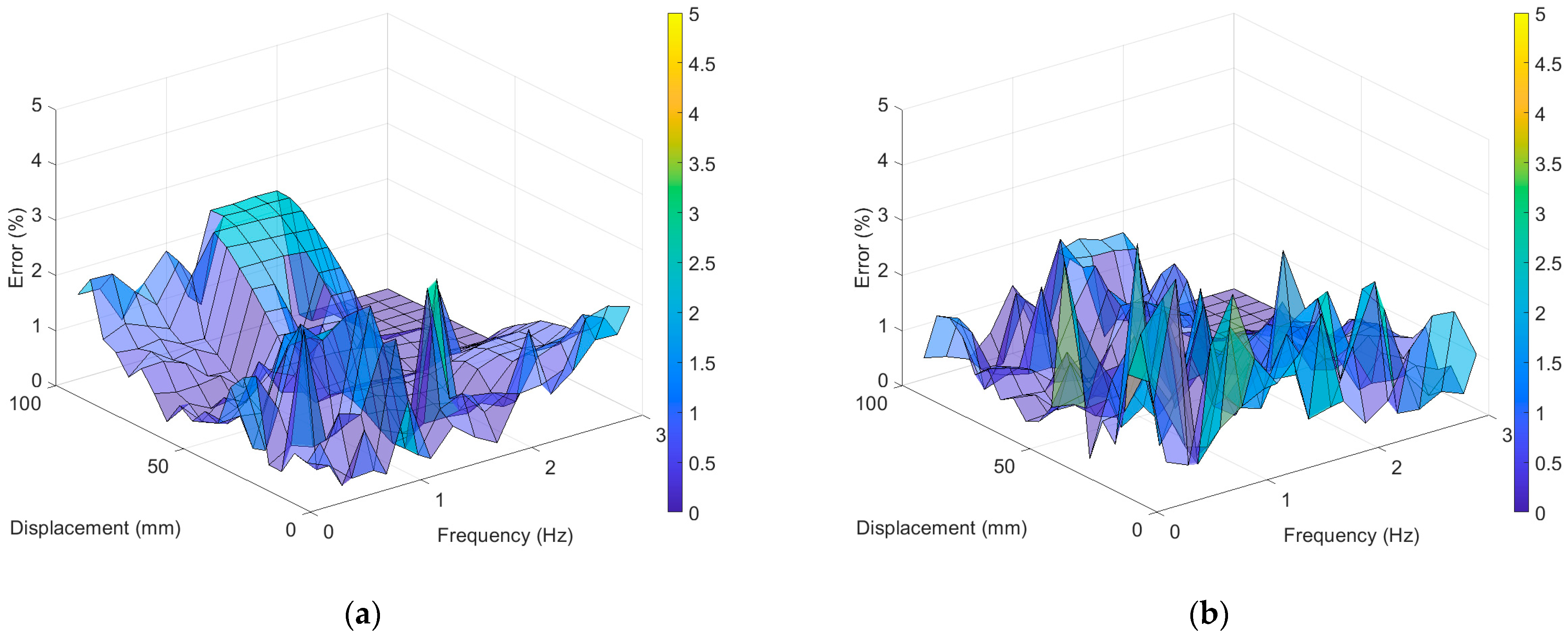

3.3.1. Analysis of Displacement Response Measurement Results

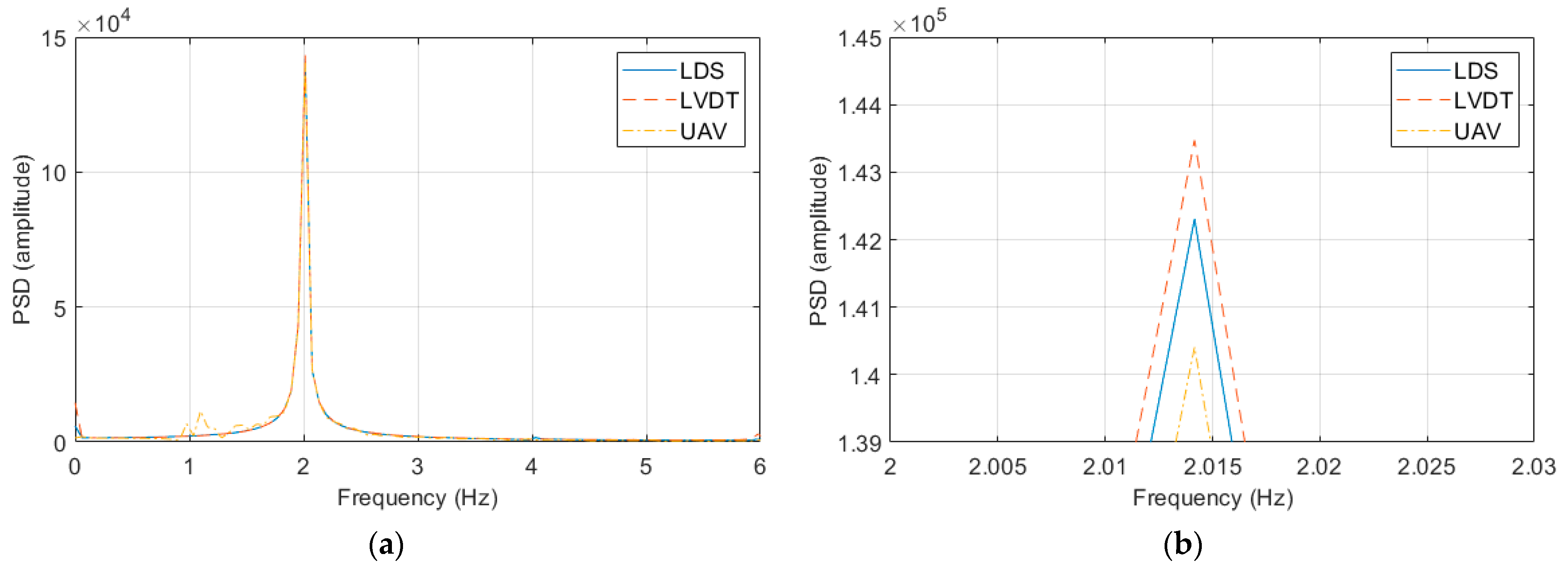

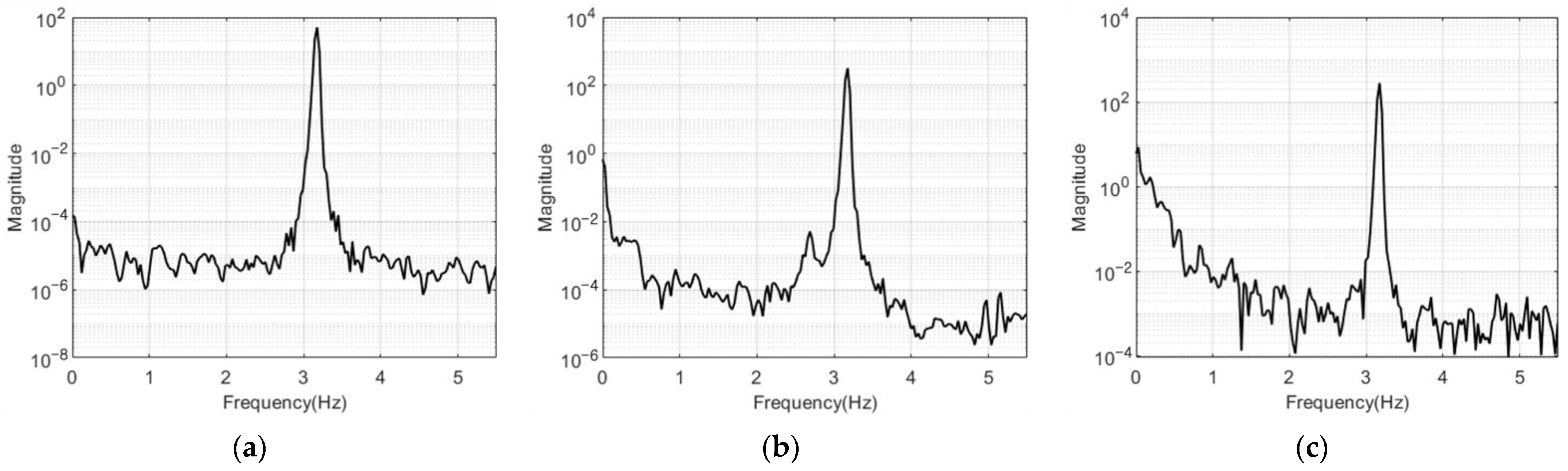

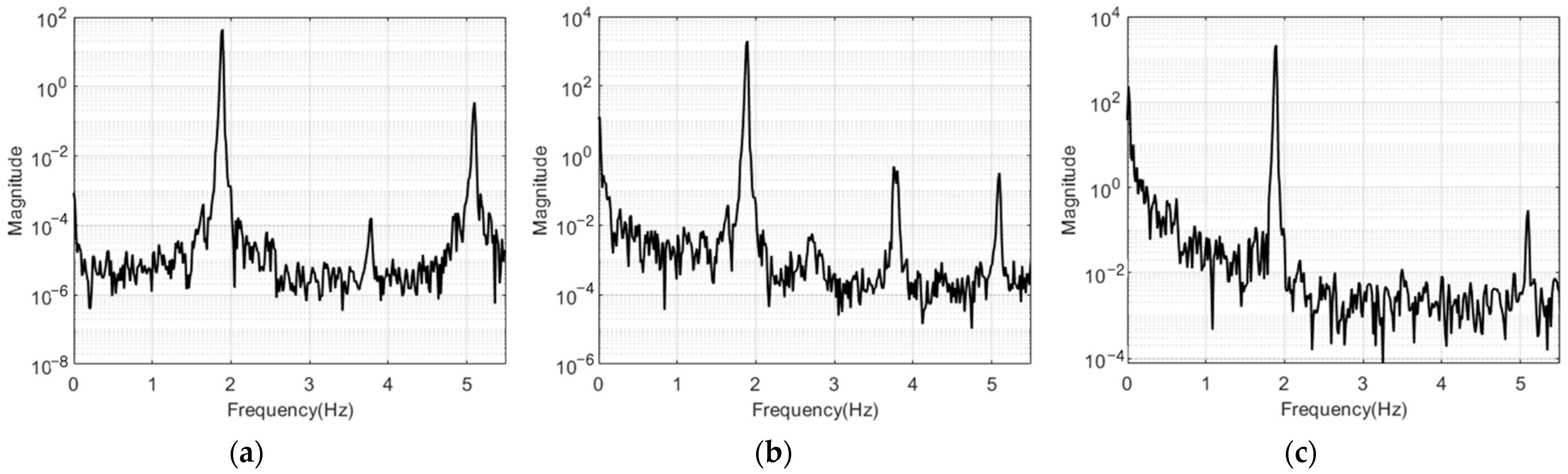

3.3.2. Analysis of Measurement Results in the Frequency Domain

4. Structure Measurement Accuracy Verification Test

4.1. Test Overview

4.2. Analysis of Measurement Results

4.2.1. Mode Frequency Estimation Results

4.2.2. Damping Ratio Estimation Results

4.2.3. Mode Shape Estimation Results

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Worden, K.; Dulieu-Barton, J.M. An overview of intelligent fault detection in systems and structures. Struct. Health Monit. 2004, 3, 85–98. [Google Scholar] [CrossRef]

- Cho, S.; Spencer, B.F., Jr. Sensor attitude correction of wireless sensor network for acceleration-based monitoring of civil structures. Comput. Aided Civ. Infrastruct. Eng. 2015, 30, 859–871. [Google Scholar] [CrossRef]

- Khuc, T.; Catbas, F.N. Computer vision-based displacement and vibration monitoring without using physical target on structures. Struct. Infrastruct. Eng. 2017, 13, 505–516. [Google Scholar] [CrossRef]

- Gentile, C. Application of microwave remote sensing to dynamic testing of stay-cables. Remote Sens. 2010, 2, 36–51. [Google Scholar] [CrossRef]

- Oberholster, A.J.; Heyns, P.S. Online condition monitoring of axial-flow turbomachinery blades using rotor-axial Eulerian laser Doppler vibrometry. Mech. Syst. Signal Process. 2009, 23, 1634–1643. [Google Scholar] [CrossRef]

- Nassif, H.H.; Gindy, M.; Davis, J. Comparison of laser Doppler vibrometer with contact sensors for monitoring bridge deflection and vibration. Struct. Faults Repair 2005, 38, 213–218. [Google Scholar] [CrossRef]

- Xu, L.; Guo, J.J.; Jiang, J.J. Time–frequency analysis of a suspension bridge based on GPS. J. Sound Vib. 2002, 254, 105–116. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Vision-based multipoint displacement measurement for structural health monitoring. Struct. Control Health Monit. 2016, 23, 876–890. [Google Scholar] [CrossRef]

- Que, Y.; Dai, Y.; Ji, X.; Leung, A.K.; Chen, Z.; Tang, Y.; Jiang, Z. Automatic classification of asphalt pavement cracks using a novel integrated generative adversarial networks and improved VGG model. Eng. Struct. 2023, 277, 115406. [Google Scholar] [CrossRef]

- Ali, L.; Alnajjar, F.; Jassmi, H.A.; Gocho, M.; Khan, W.; Serhani, M.A. Performance Evaluation of Deep CNN-Based Crack Detection and Localization Techniques for Concrete Structures. Sensors 2021, 21, 1688. [Google Scholar] [CrossRef]

- Zhao, S.; Kang, F.; Li, J.; Ma, C. Structural health monitoring and inspection of dams based on UAV photogrammetry with image 3D reconstruction. Autom. Constr. 2021, 130, 103832. [Google Scholar] [CrossRef]

- Zhao, S.; Kang, F.; Li, J. Concrete dam damage detection and localisation based on YOLOv5s-HSC and photogrammetric 3D reconstruction. Autom. Constr. 2022, 143, 104555. [Google Scholar] [CrossRef]

- Tang, Y.; Zhu, M.; Chen, Z.; Wu, C.; Chen, B.; Li, C.; Li, L. Seismic performance evaluation of recycled aggregate concrete-filled steel tubular columns with field strain detected via a novel mark-free vision method. Structures 2022, 37, 426–441. [Google Scholar] [CrossRef]

- Zona, A. Vision-based vibration monitoring of structures and infrastructures: An overview of recent applications. Infrastructures 2021, 6, 4. [Google Scholar] [CrossRef]

- Peters, W.H.; Ranson, W.F. Digital imaging techniques in experimental stress analysis. Opt. Eng. 1982, 21, 427–431. [Google Scholar] [CrossRef]

- Schumacher, T.; Shariati, A. Monitoring of structures and mechanical systems using virtual visual sensors for video analysis: Fundamental concept and proof of feasibility. Sensors 2013, 13, 16551–16564. [Google Scholar] [CrossRef]

- Spencer, B.F.; Hoskere, V.; Narazaki, Y. Advances in computer vision-based civil infrastructure inspection and monitoring. Engineering 2019, 5, 199–222. [Google Scholar] [CrossRef]

- Park, S.W.; Park, H.S.; Kim, J.H.; Adeli, H. 3D displacement measurement model for health monitoring of structures using a motion capture system. Measurement 2015, 59, 352–362. [Google Scholar] [CrossRef]

- Choi, H.S.; Cheung, J.H.; Kim, S.H.; Ahn, J.H. Structural dynamic displacement vision system using digital image processing. NDT E Int. 2011, 44, 597–608. [Google Scholar] [CrossRef]

- Kim, H.; Shin, S. Reliability verification of a vision-based dynamic displacement measurement for system identification. J. Wind Eng. Ind. Aerodyn. 2019, 191, 22–31. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q.; Ozer, E.; Fukuda, Y.A. Vision-based sensor for noncontact structural displacement measurement. Sensors 2015, 15, 16557–16575. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.J.; Shinozuka, M. Real-time displacement measurement of a flexible bridge using digital image processing techniques. Exp. Mech. 2006, 46, 105–114. [Google Scholar] [CrossRef]

- Lee, J.H.; Ho, H.N.; Lee, J.J.; Shinozuka, M. An advanced vision-based system for real-time displacement measurement of high-rise buildings. Smart Mater. Struct. 2012, 21, 10. [Google Scholar] [CrossRef]

- Lydon, D.; Lydon, M.; Taylor, S.; Del Rincon, J.M.; Hester, D.; Brownjohn, J. Development and field testing of a vision-based displacement system using a low cost wireless action camera. Mech. Syst. Signal Process. 2019, 121, 343–358. [Google Scholar] [CrossRef]

- Ngeljaratan, L.; Moustafa, M.A. Structural health monitoring and seismic response assessment of bridge structures using target-tracking digital image correlation. Eng. Struct. 2020, 213, 110551. [Google Scholar] [CrossRef]

- Scislo, L. Single-Point and Surface Quality Assessment Algorithm in Continuous Production with the Use of 3D Laser Doppler Scanning Vibrometry System. Sensors 2023, 23, 1263. [Google Scholar] [CrossRef]

- Metni, N.; Hamel, T. A UAV for bridge inspection: Visual servoing control law with orientation limits. Autom. Constr. 2007, 17, 3–10. [Google Scholar] [CrossRef]

- Shen-En, C.; Corey, R.; Chuck, B.; Edd, H. Small-format aerial photography for highway-bridge monitoring. J. Perform. Constr. Facil. 2011, 25, 105–112. [Google Scholar] [CrossRef]

- Zhang, C.; Elaksher, A. An unmanned aerial vehicle-based imaging system for 3D measurement of unpaved road surface distresses. Comput. Aided Civ. Infrastruct. Eng. 2012, 27, 118–129. [Google Scholar] [CrossRef]

- Ellenberg, A.; Branco, L.; Krick, A.; Bartoli, I.; Kontsos, A. Use of unmanned aerial vehicle for quantitative infrastructure evaluation. J. Infrastruct. Syst. 2015, 21, 04014054. [Google Scholar] [CrossRef]

- Yeum, C.M.; Dyke, S.J. Vision-based automated crack detection for bridge inspection. Comput. Aided Civ. Infrastruct. Eng. 2015, 30, 759–770. [Google Scholar] [CrossRef]

- Perry, B.J.; Guo, Y. A portable three-component displacement measurement technique using an unmanned aerial vehicle (UAV) and computer vision: A proof of concept. Measurement 2021, 176, 109222. [Google Scholar] [CrossRef]

- Ribeiro, D.; Santos, R.; Cabral, R.; Saramago, G.; Montenegro, P.; Carvalho, H.; Correia, J.; Calçada, R. Non-contact structural displacement measurement using Unmanned Aerial Vehicles and video-based systems. Mech. Syst. Signal Process. 2021, 160, 107869. [Google Scholar] [CrossRef]

- Yoon, H.; Hoskere, V.; Park, J.W.; Spencer, B.F. Cross-correlation-based structural system identification using unmanned aerial vehicles. Sensors 2017, 17, 2075. [Google Scholar] [CrossRef] [PubMed]

- Yoon, H.; Shin, J.; Spencer, B.F., Jr. Structural displacement measurement using an unmanned aerial system. Comput. Aided Civ. Infrastruct. Eng. 2018, 33, 183–192. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, G.; Moon, D.S.; Yoon, H. Vision-based displacement measurement using a camera mounted on a structure with stationary background targets outside the structure. Struct. Control Health Monit. 2022, 29, e3095. [Google Scholar] [CrossRef]

- Weng, Y.; Shan, J.; Lu, Z.; Lu, X.; Spencer, B.F., Jr. Homography-based structural displacement measurement for large structures using unmanned aerial vehicles. Comput. Aided Civ. Infrastruct. Eng. 2021, 36, 1114–1128. [Google Scholar] [CrossRef]

- Yan, Z.; Jin, Z.; Teng, S.; Chen, G.; Bassir, D. Measurement of bridge vibration by UAVs combined with CNN and KLT optical-flow method. Appl. Sci. 2022, 12, 5181. [Google Scholar] [CrossRef]

- Wang, X.; Lo, E.; De Vivo, L.; Hutchinson, T.C.; Kuester, F. Monitoring the earthquake response of full-scale structures using UAV vision-based techniques. Struct. Control Health Monit. 2022, 29, e2862. [Google Scholar] [CrossRef]

- Han, Y.; Wu, G.; Feng, D. Vision-based displacement measurement using an unmanned aerial vehicle. Struct. Control Health Monit. 2022, 29, e3025. [Google Scholar] [CrossRef]

- Zhang, Z. A flexible new technique for camera calibration. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1330–1334. [Google Scholar] [CrossRef]

- Available online: https://www.mathworks.com/help/vision/camera-calibration.html (accessed on 17 February 2023).

- Available online: https://ekais.kr/kais/item.php?it_id=1616043998 (accessed on 17 February 2023).

- Available online: https://tml.jp/e/product/transducers/dp.html (accessed on 13 February 2023).

- Available online: https://tml.jp/e/product/instrument/tmr311.html (accessed on 13 February 2023).

- Available online: https://www.dji.com/kr/mavic-3 (accessed on 13 February 2023).

- Available online: https://www.mmf.de/empfindlich.htm#kb12-ks48 (accessed on 13 February 2023).

- Brincker, R.; Zhang, L.; Andersen, P. Output-Only Modal Analysis by Frequency Domain Decomposition. In Proceedings of the ISMA25: 2000 International Conference on Noise and Vibration Engineering, Leuven, Belgium, 13–15 September 2000; Sas, P., Moens, D., Eds.; Katholieke Universiteit: Leuven, Belgium, 2000; pp. 717–723. [Google Scholar]

| Component | Model | Technical Specifications |

|---|---|---|

| Shaking table |  TE Solution’s portable 1-axis vibration device | Maximum speed: 4.8 m/s Rated thrust: 140 N Rated current: 2.2 Arms Thermal resistance: 1.48 K/W |

| LVDT |  Tokyo Sokki’s DP-500E | Capacity: 500 mm Sensibility: 20 μ strain/mm Nonlinearity: 0.3% rated output |

| LDS |  KAIS’s KL3-W400 | Measurement distance: 500 mm Measurable range: ±200 mm Optical mode: Diffuse reflection Resolution: 10 μm |

| Data logger |  Tokyo Sokki’s TMR-311 | Sampling time: 1–1000 ms (set by every 1 ms) Power supply: AC 100–240 V, 50/60 Hz, 100 VA at maximum Measurement range: ±20,000 × 10−6 strain (bridge excitation DC 2V) |

| UAV |  DJI’s MAVIC 3 | Takeoff weight: 895 g Max flight time: 46 min Max hovering time: 40 min Max wind speed resistance: 12 m/s |

| UAV Camera |  DJI’s Hasselblad Camera | Sensor: 4/3 CMOS, Effective pixels: 20 MP ISO Range: 100–6400 Shutter Speed: 8–1/8000 s FOV: 84° Format Equivalent: 24 mm Aperture: f/2.8 to f/11 Focus: 1 m to ∞ (with autofocus) Video Resolution: H.264/H.265 5.1K: 5120 × 2700@24/25/30/48/50fps DCI 4K: 4096 × 2160@24/25/30/48/50/60/120fps 4K: 3840 × 2160@24/25/30/48/50/60/120fps FHD: 1920 × 1080@24/25/30/48/50/60/120/200fps |

| Number of Stories | Mode | Accelerometer | LDS | UAV |

|---|---|---|---|---|

| 1 | 1st | 3.17383 | 3.17383 | 3.17383 |

| 2 | 1st | 1.89209 | 1.89209 | 1.89209 |

| 2nd | 5.09644 | 5.09644 | 5.09644 |

| Number of Stories | Accelerometer | LDS | UAV |

|---|---|---|---|

| 1 | 0.447102% | 0.382332% (14.48663) | 0.456488% (2.09930) |

| 2 | 0.638349% | 0.622776% (2.43957) | 0.636799% (0.24281) |

| Number of Stories | Number of Modes | LDS | UAV |

|---|---|---|---|

| 1 | 1st | 1 | 1 |

| 2 | 1st | 0.9999 | 0.9996 |

| 2nd | 0.9900 | 0.9972 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Kim, G. Reliability Assessment of a Vision-Based Dynamic Displacement Measurement System Using an Unmanned Aerial Vehicle. Sensors 2023, 23, 3232. https://doi.org/10.3390/s23063232

Kim H, Kim G. Reliability Assessment of a Vision-Based Dynamic Displacement Measurement System Using an Unmanned Aerial Vehicle. Sensors. 2023; 23(6):3232. https://doi.org/10.3390/s23063232

Chicago/Turabian StyleKim, Hongjin, and Guyeon Kim. 2023. "Reliability Assessment of a Vision-Based Dynamic Displacement Measurement System Using an Unmanned Aerial Vehicle" Sensors 23, no. 6: 3232. https://doi.org/10.3390/s23063232

APA StyleKim, H., & Kim, G. (2023). Reliability Assessment of a Vision-Based Dynamic Displacement Measurement System Using an Unmanned Aerial Vehicle. Sensors, 23(6), 3232. https://doi.org/10.3390/s23063232