In this Section, we present the results of the relevant parameter identification and control. The fundamental objective is the simultaneous estimation of the gravitational term (i.e., the associated relevant parameters) while keeping the tracking error low thanks to the online adaptation. For that reason, both performance criteria are evaluated and compared. The reliability is also evaluated by measuring the rate of variation of the control action and the rate of variation of the estimation of the relevant parameter. A raw PD+G controller is the baseline for comparing all the methods, which leads to an important consideration: great tracking accuracy can be obtained by just increasing the proportional and derivative gains of the PD. However, this can lead to severe oscillations of the control action, which tries to adapt blindly to any condition, leading to saturations of the actuators and a great sensitivity to noise, stimulating high frequency vibration nodes. This situation becomes inadmissible when it concerns human–robot interaction. This is a justification for why an adaptive control scheme with relatively low gains turns out to be interesting compared with a PD+G. The comparison will be established using the same gains for both controllers: the proportional gains are 5800 for the external limbs and 65,000 for the central limb, and the derivative gains are 400 for the external limbs and 875 for the central limb. These gains were chosen in a previous experiment with no disturbances in combination with a stationary gravity compensator. Afterwards, the gravity compensator was replaced by the estimator in the experiments with the changing environment.

4.1. Experimental Procedure

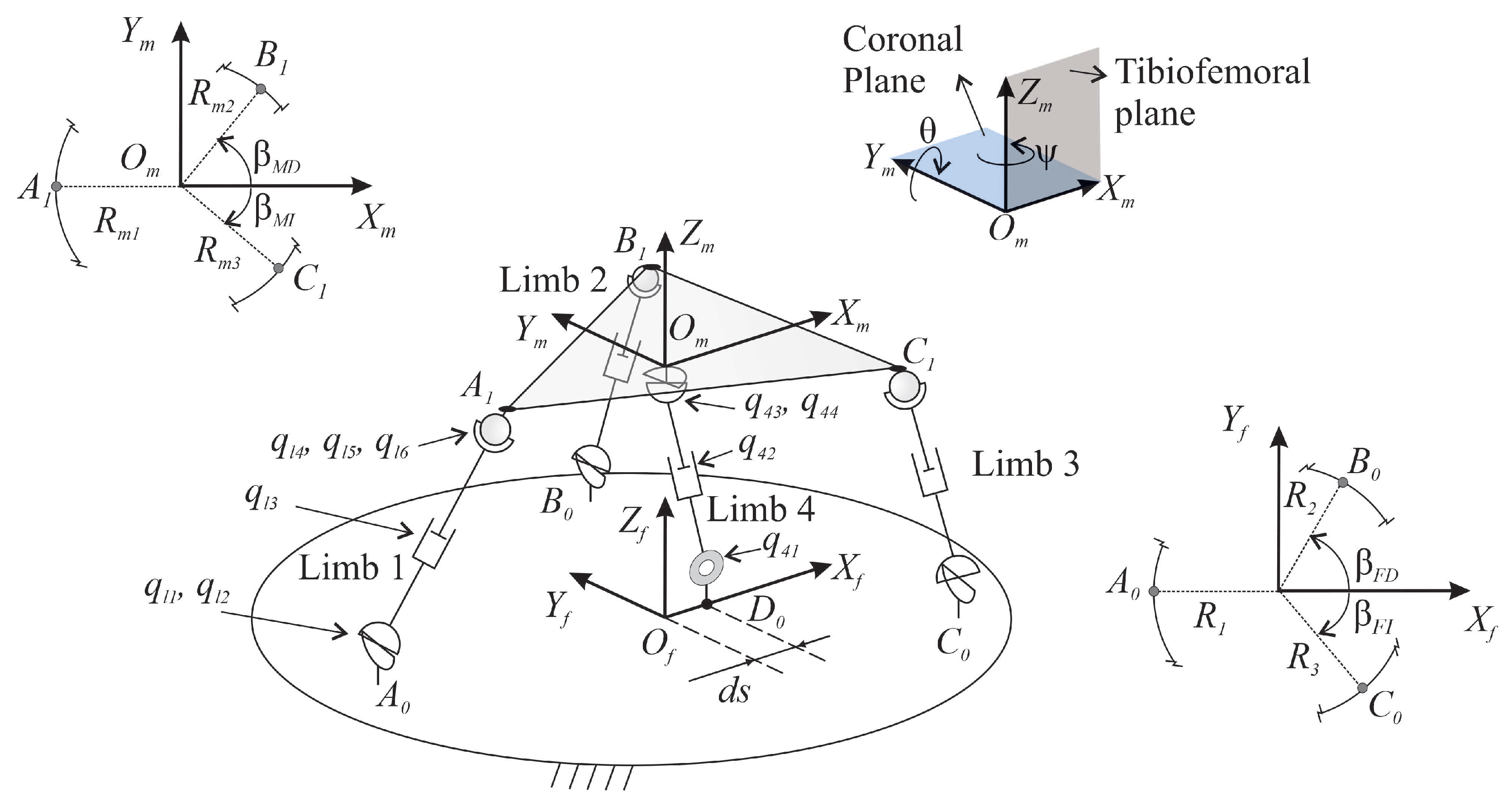

Each leg of the actual robot is driven by a prismatic actuator, Festo DNCE 32-BS10 for the external limbs (, , ) and NIASA M100-F16 for the central limb (), all attached to Maxon 148867 DC motors, which are commanded by ESCON 50/5 servocontrollers. These controllers offer an accurate current control of the motors, and the current-torque relationship is defined according to their datasheets. DC motors are equipped with incremental encoders with a resolution of 500 counts per turn.

The control unit is connected to an industrial computer through acquisition cards. The reading of the position using the encoder is accomplished through a PCI 1784 Advantech card, with four 32-bit quadruple AB phase encoder counters, while control actions are provided with a 12-bit, 4 channel PCI 1720 Advantech card. The program receives the set of references in the format of generalized active coordinates , coming from the solution of the inverse kinematics given the cartesian coordinates of the end-effector. This reference is sampled at a rate of 100 Hz and the positions, velocities, and control actions are stored for posterior analysis.

The controllers described in this paper are implemented in a modular way, using real-time middleware OROCOS (Open Robot COntrol Software) [

45] combined with Robot Operating System (ROS) [

46], and the C++ programming language.

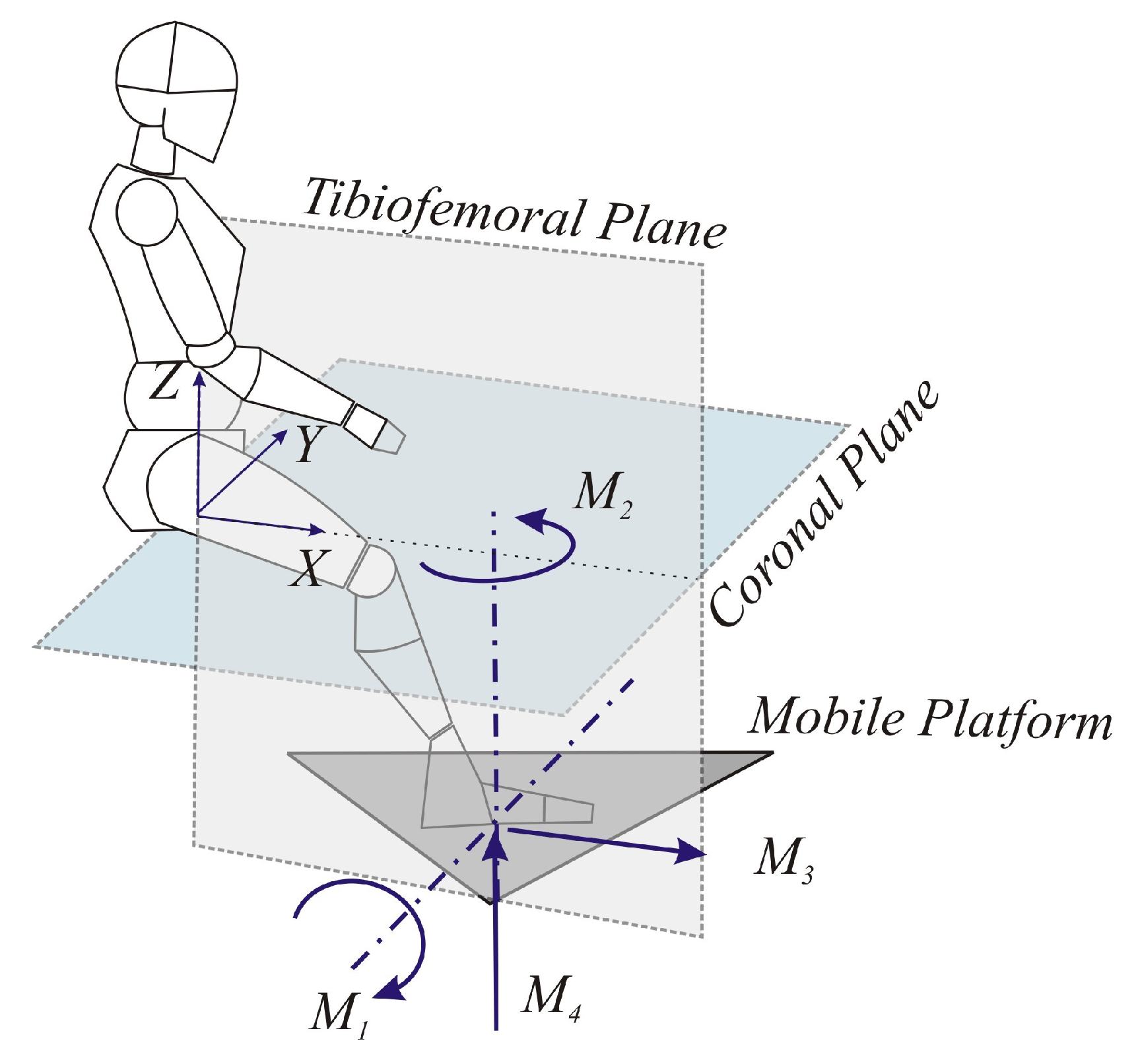

For these experiments, the trajectories employed involve sinusoidal movements around the generalized coordinates (

,

,

,

), which entail two hip flexions combined with a flexion–extension of knee [

36]. Note that different trajectories will stimulate different inertial parameters; thus, mild changes are expected when trying to generalize. Although the trajectories are defined in cartesian coordinates, the sensors and actuators are directly related to joint coordinates, so the first step is to apply Inverse Kinematics to transform the trajectory from cartesian space to joint space. Likewise, the controller works in joint space, so all the performance criteria are also evaluated in joint coordinates. Since the controllers work without a force sensor to estimate the gravitational term, the experiments are performed using payloads of known weight instead of the human limb. This is very convenient to evaluate our controllers because the sensor is not needed and also because it offers much more stable measurements that allow a clearer assessment and comparison of the controllers. However, the same test can be performed with the human limb to perform exercises as explained in

Section 2.1. In fact, the trajectory employed is suitable for rehabilitation purposes.

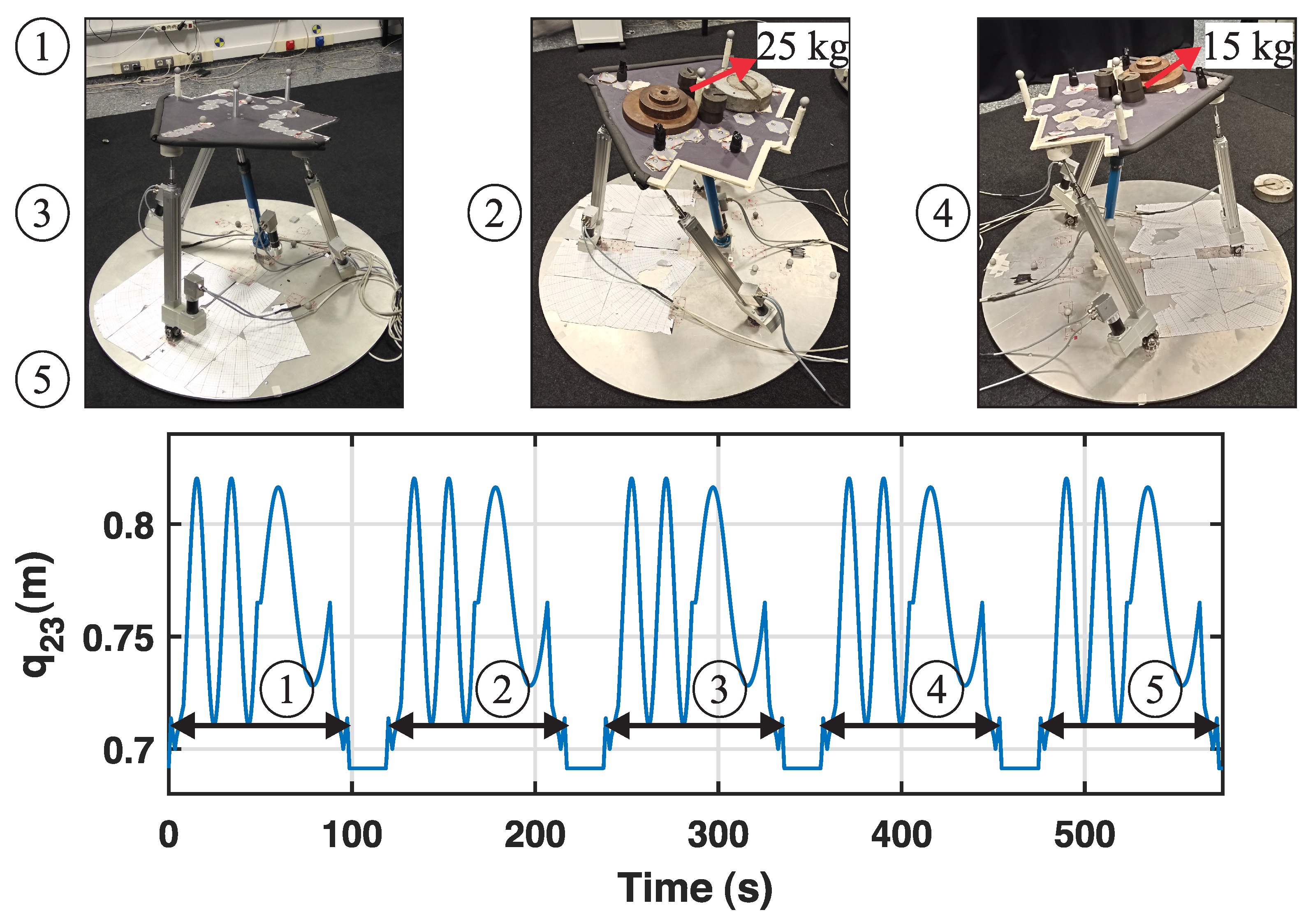

During the experiment, four pauses are introduced where the robot maintains the mobile platform in a fixed horizontal position, waiting for a payload to be placed (or removed) for 20 s before the real rehabilitation exercise is performed. Starting with no payload (stage 1), a 25 kg payload is placed at instant

s (stage 2) and removed at

s (stage 3). Afterwards, a 15 kg payload is placed at

s (stage 4) and removed at

s (stage 5).

Figure 8 shows the experiment of mass adition in the real PR.

4.2. Model-Based Controllers with Online Identification of the Gravitational Term

In this Section, we compare the results from estimators and error tracking for the two designed controllers and also the baseline, where the gravitational part is calculated by taking the entire set of relevant parameters as fixed.

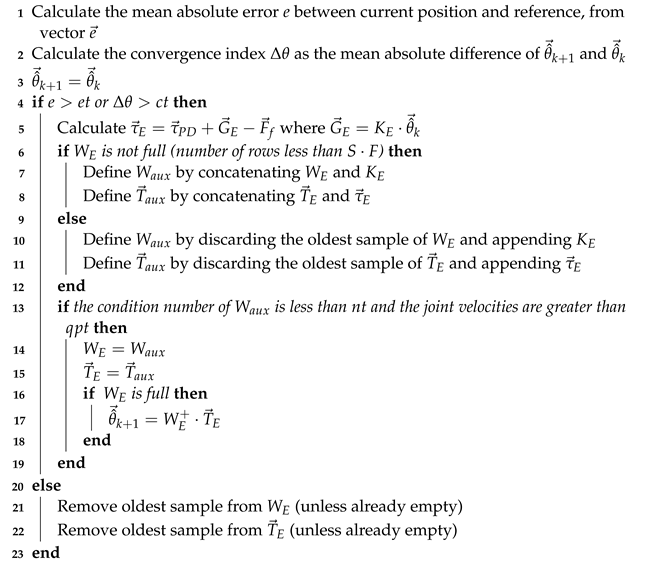

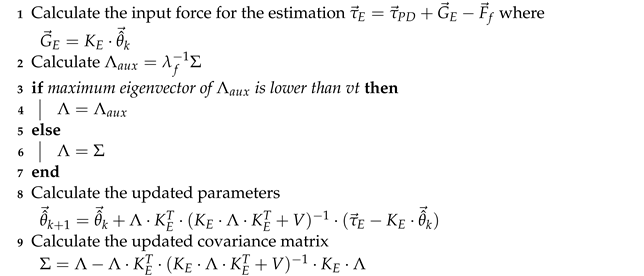

Regarding the proposed controllers, the rest of the parameters (thresholds) are set to the default values provided in the description of the algorithm. Special attention is required on tuning the window size (set to 400, i.e., the estimation lasts approximately four seconds) and the forgetting factor (0.999) of both controllers, which offer a good tradeoff between the accuracy and timing of the estimations. Most of these constants are initially tuned by a Genetic Algorithm [

47] in simulation to establish a fair comparison, and slightly modified in the actual robot.

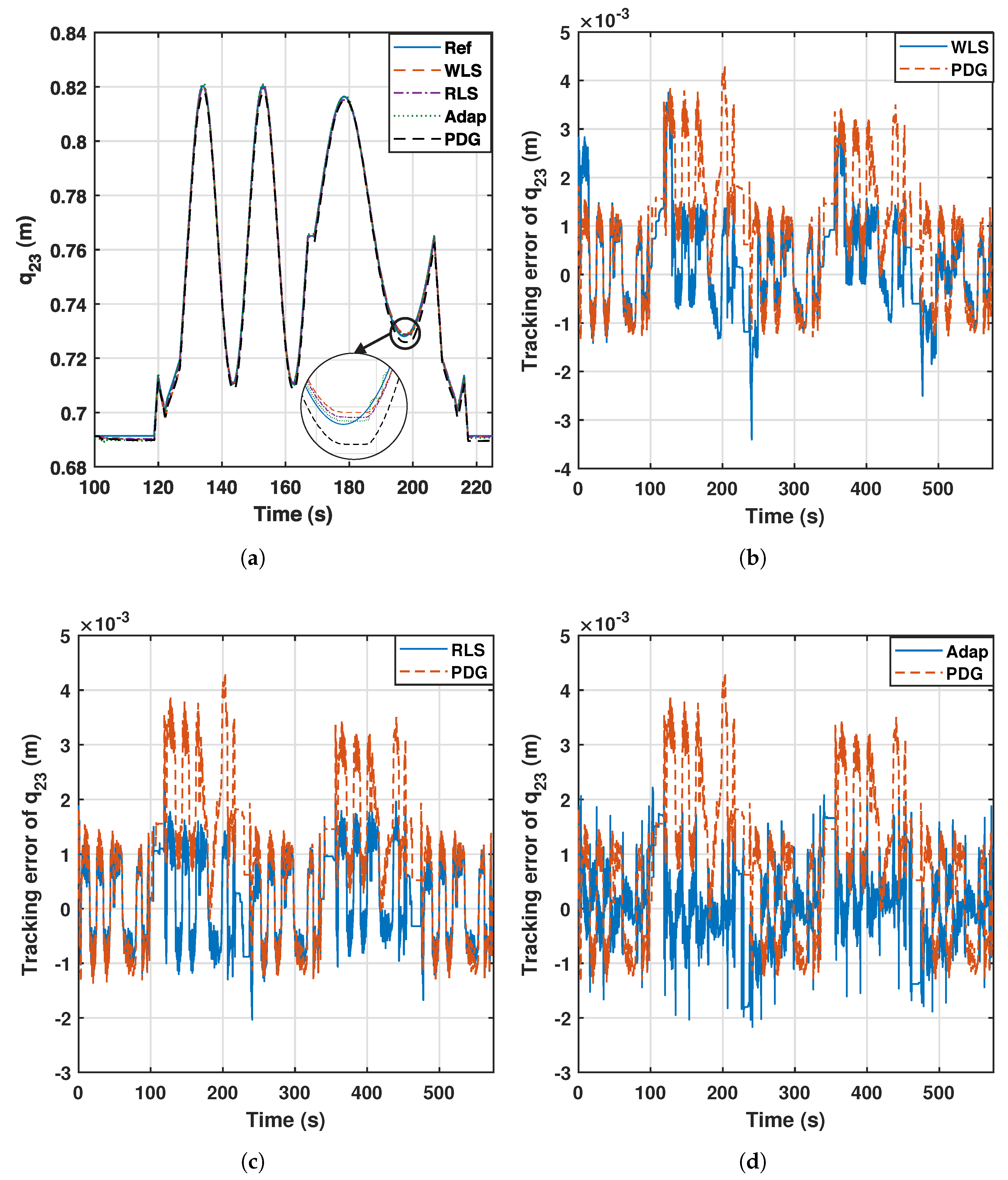

The trajectory of the performed experiment is shown in

Figure 9a for the

generalized coordinate, during the second stage, in which the 25 kg payload is on the platform. All controllers offer good accuracy, but according to

Figure 9b–d, which represent the absolute tracking error of the second generalized coordinate, the adaptive and the proposed controllers outperform the raw baseline controller when the payload is placed on the mobile platform.

From these results, the adaptive and proposed controllers maintain the error below the baseline even when the payload is on the mobile platform. The baseline is more affected because the PD+G considers a constant set of relevant parameters. The results show some peaks of 4.5 mm after a mass addition. The WLS controller also presents some error peaks at the beginning of each stage (see

Figure 9b), as it uses this error history to eventually perform a new estimation and improve the tracking a few seconds later.

Table 5 depicts the mean absolute error (MAE) at each stage of the experiment for the second generalized coordinate, and the last row represents the rate of variation of the control action, calculated as follows:

where

n is the number of samples of the trajectory, and

is the control action at instant

k, applied in this analysis by the second actuator. High values of this parameter imply sudden changes of the control action.

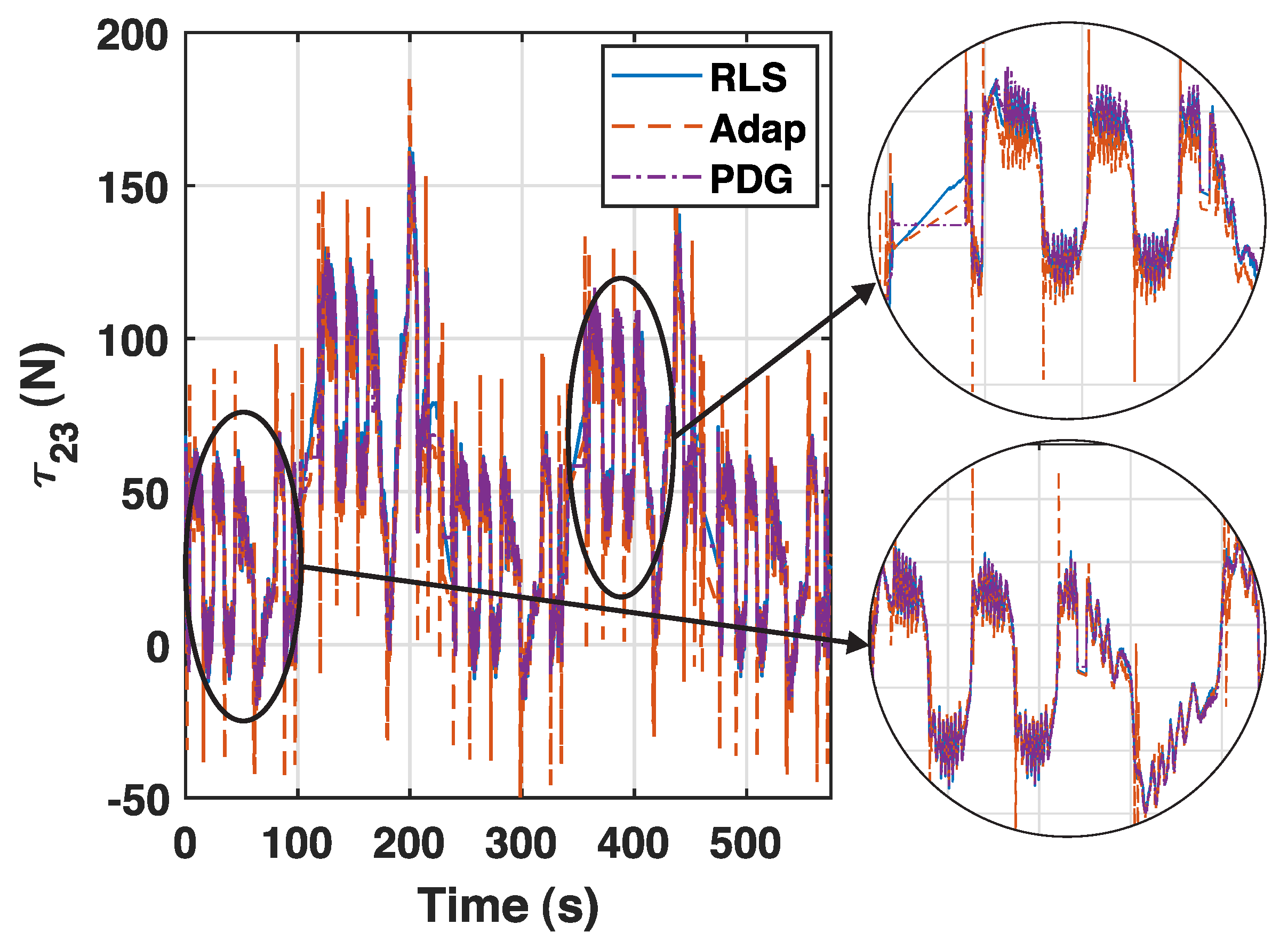

All controllers keep the error below 1 mm at stages 1, 3 and 5, in which no payload is used. However, the raw PD+G suffers the effect of the added mass at stages 2 and 4. This effect is compensated for by the rest of the controllers, which keep their errors low. Moreover, the WLS and RLS controllers maintain the nature of the raw PD+G in terms of the smoothness of the control action. The adaptive controller manages to lower the tracking error at the expense of a more fluctuating action according to the last row of

Table 5, and this effect is illustrated in

Figure 10.

The adaptive controller presents several peaks along the trajectory, while the new controllers remain approximately as smooth as the baseline. This is essentially because both proposed controllers share the fundamental structure of the raw PD+G, while the regression of the adaptive controller is performed via sliding modes. Moreover, the new controllers with online estimator are easier to tune than the adaptive controller, as only one parameter with intuitive meaning (the window size in the case of the WLS controller, or the forgetting factor in the RLS controller) is required in the controller design.

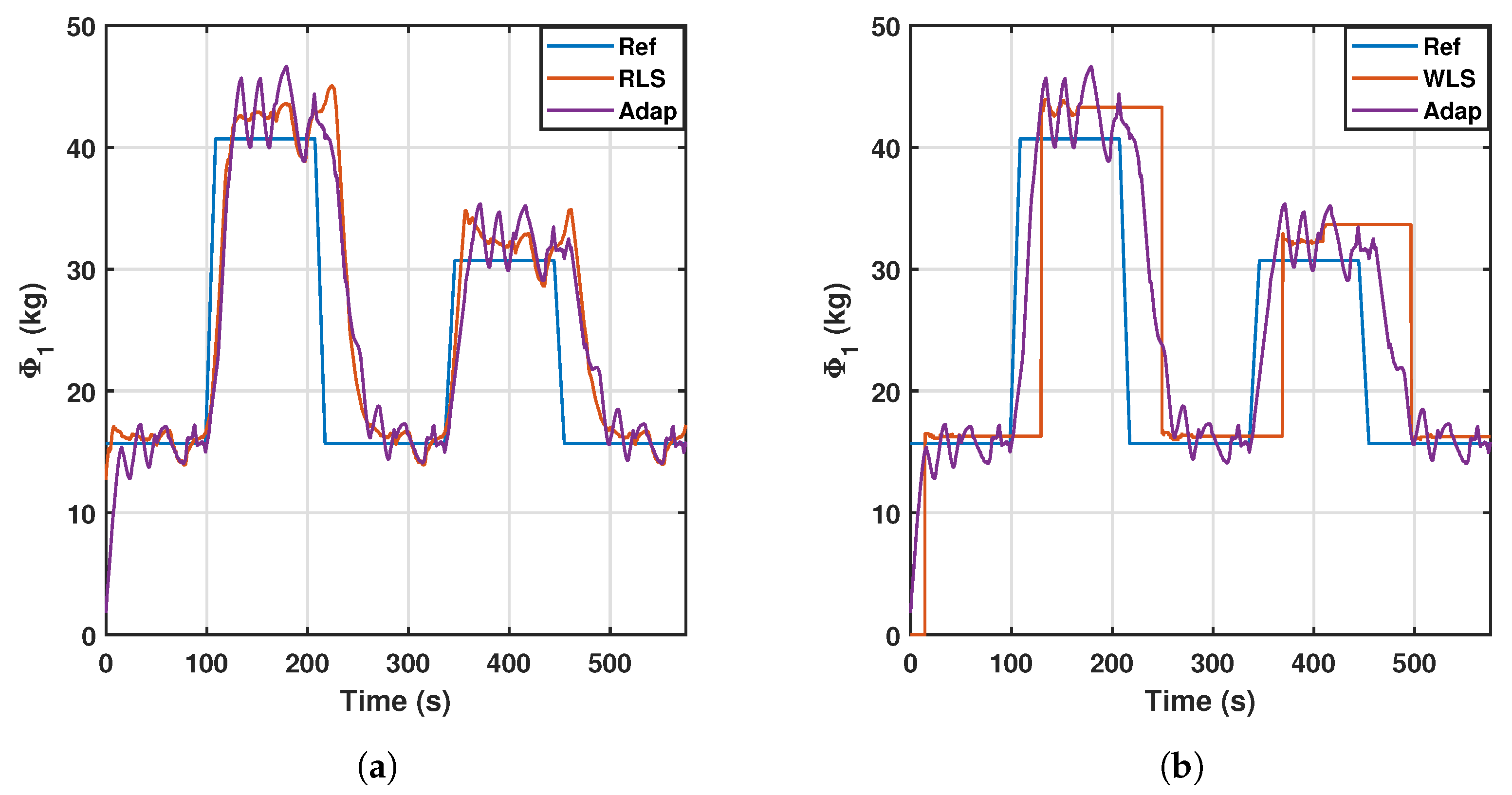

Another important variable to analyze is the estimation of the first relevant parameter, which is illustrated in

Figure 11 for the adaptive, WLS, and RLS controllers. The figure shows the effect of both controllers quite well. Starting from a zero-payload reference point of 15.6 kg (according to the first row of

Table 4), the payload is changed at 20-s intervals, and then remains constant for 100 s. The window-based controller performs very few estimations; thus, it is suitable for situations where the estimation is intended to be constant until a noticeable change occurs during operation.

However, for dynamic monitoring of the relevant parameter, it would be more interesting to use adaptive or recursive least squares identification, which are capable of updating the relevant parameter immediately, at the expense of a less stable signal.

Rehabilitation exercises can be classified in (i) passive exercises, in which the patient does not exert any effort upon the rehabilitation agent, in this case the mobile platform of the PR. Here, the gravitational term stays more stable and includes the weight of the patient’s leg since no extra force is being applied. In contrast, for (ii) active exercises, the patient must exert extra forces on the mobile platform and the gravitational term is expected to dynamically change during the exercise. The choice of algorithm could be based for instance on this classification. In this regard, a WLS controller would be more suitable for passive exercises, to make very few estimations and only if the gravitational force severely changes, while a RLS controller can perform better in active exercises to catch the dynamic behavior of the changing forces.

Table 6 shows the errors of estimation of the first relevant parameter and the rate of variation with the three controllers (WLS, RLS, and adaptive), and reflects the previous statement: WLS presents a greater error but lower rate of variation, while RLS has a lower error at the expense of an increment in the rate of variation. Overall, RLS outperforms the adaptive controller in the estimation task.

It is interesting to note that all of the controllers approximately converge at the true value when no payload is present. However, the error increases for all of them when the payload is placed on the platform. There are two reasons for this mismatch. Firstly, the standard relevant parameters of

Table 4 are estimated using data from a set of various trajectories distinct from the one tested in this experiment; thus, inertial parameters are excited in different ways. Another fact arises when the payload is placed on the platform, as not only is the total mass (represented by the first parameter) increased, but also other inertial properties (centers of mass, moments, etc.) that present a lower contribution to the dynamics are affected, altering, to a certain extent, the value of the other relevant parameters, which are forced to remain constant. The estimation of the first relevant parameter absorbs this effect, which is indeed a good way to avoid reflecting these discrepancies in the tracking error. A recording of the experiment using the RLS controller to estimate the first parameter is available in

https://imbio3r.ai2.upv.es/nuevo_video/hybrid-control-identification-one-parameter-high-speed-high-resolution-video-summary (accessed on 22 January 2023).

The last aspect to discuss is the performance of the controllers when trying to estimate a second relevant parameter. In this regard, an additional experiment is conducted using the recursive least squares controller, which is shown in

Figure 12. In this experiment, the payload positioning follows the sequence of the previous experiments. However, a second relevant parameter is estimated, which remains constant. The results show that the tracking of the first relevant parameter remains accurate, and the second relevant parameter rapidly agrees with the true value from the beginning of the experiment. The tracking error does not experience any substantial change, and its overall mean absolute value for the second generalized coordinate is 0.80, which is similar to those presented in

Table 5. This experiment shows the generalization capabilities of the proposed controllers and can be viewed in

https://imbio3r.ai2.upv.es/nuevo_video/hybrid-control-identification-two-parameters-high-speed-high-resolution-video-summary (accessed on 22 January 2023).