Development of an Active Optical Lens for Arc Flashing Detection

Abstract

1. Introduction

2. Materials and Methods

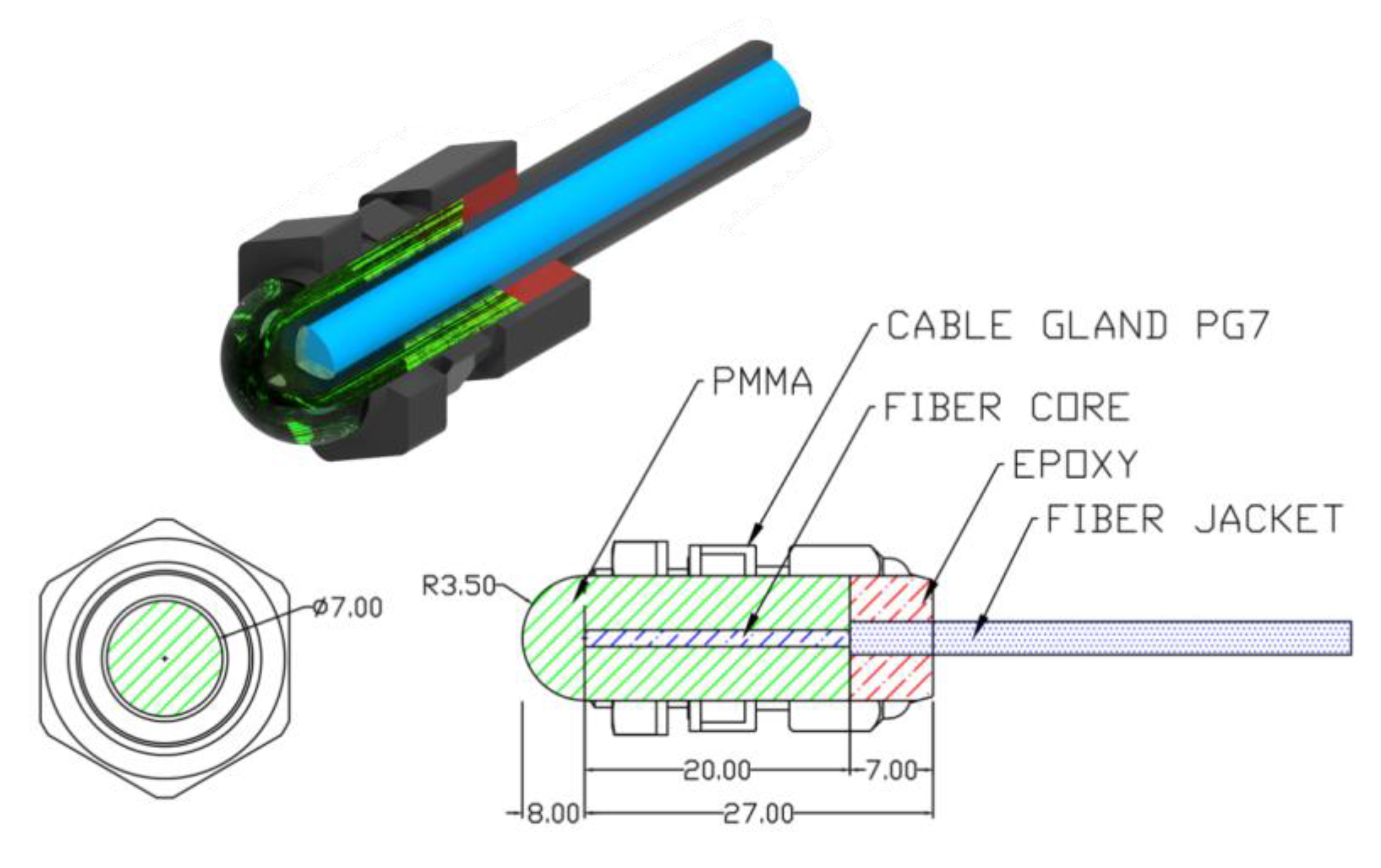

2.1. PMMA Sensor

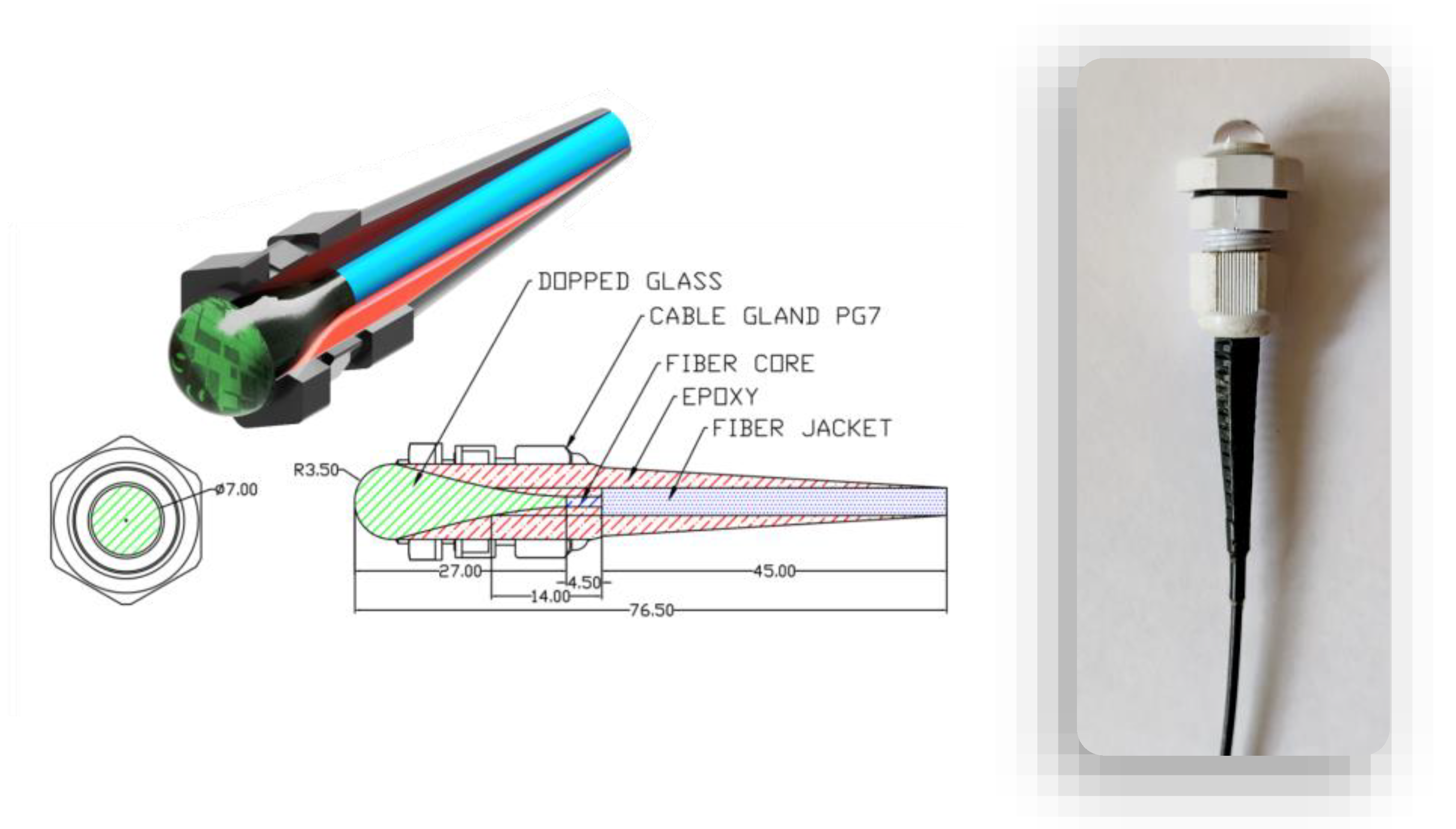

2.2. Glass-Based Sensor

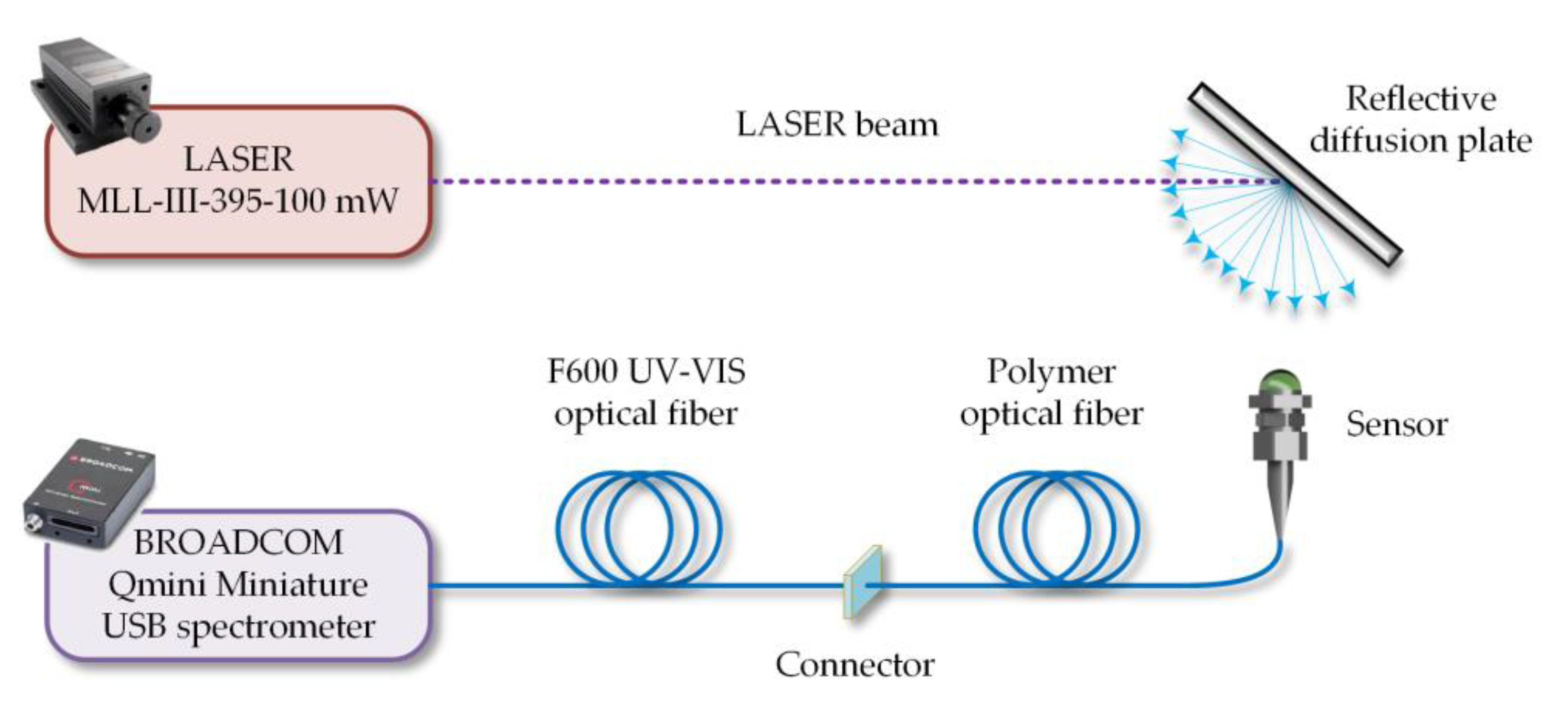

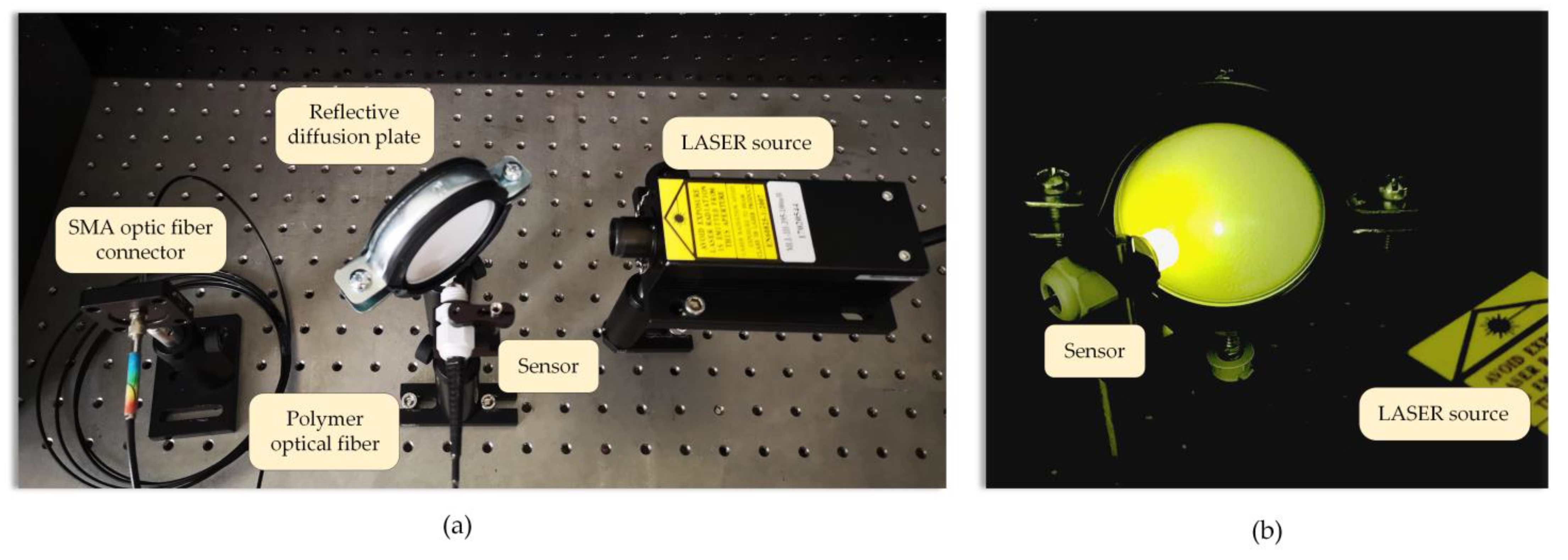

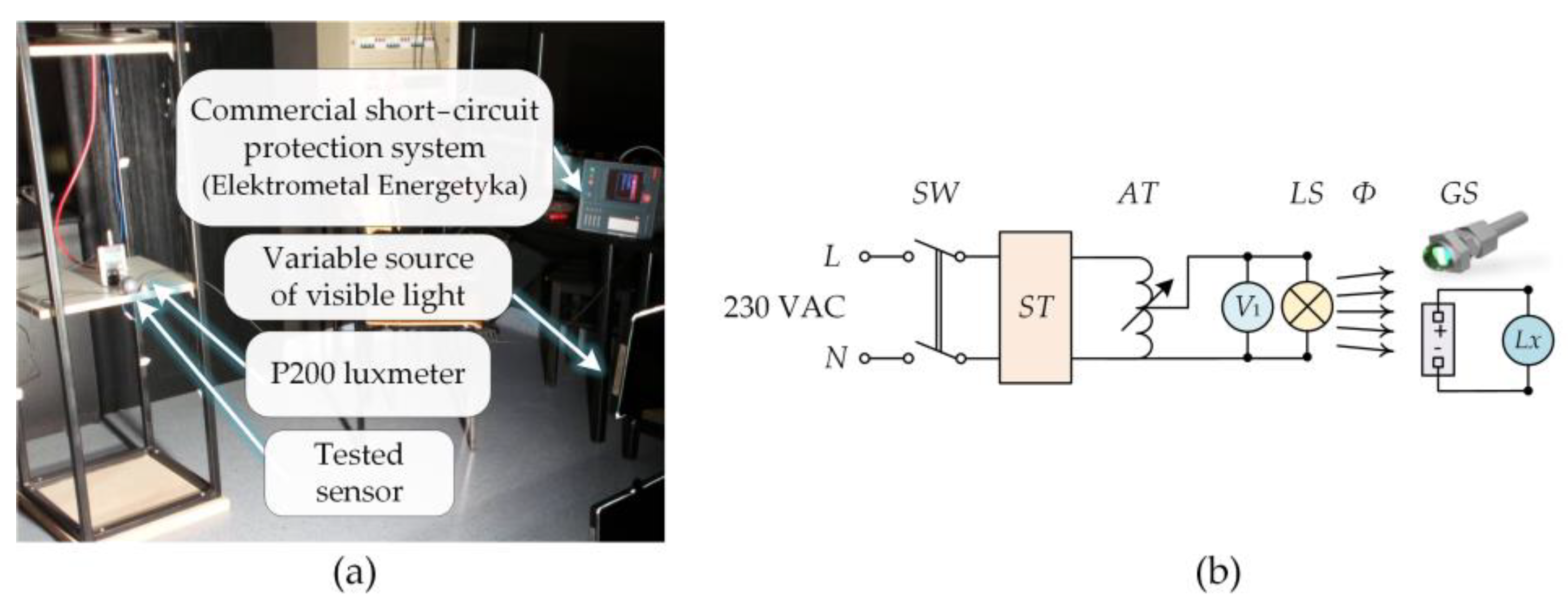

2.3. Laboratory Test Bench for the Optical Characterization of the Sensor Heafds

3. Results and Discussion

4. Conclusions

- producing phosphate glasses doped with europium and terbium ions;

- conducting measurements of the luminescence spectra of the produced glasses;

- making lenses with the use of polymers and doped glasses;

- designing and practically realizing sensors with the produced glasses;

- measuring the luminescent properties and sensitivity of the produced sensors in laboratory conditions;

- conducting an analysis of the absorption properties of the selected fluorescent materials (polymers and doped glasses) consisting in determining the ability to detect radiation within the ultraviolet spectrum;

- conducting measurements of the emission bands of the polymers doped with dyes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jeong, H.; Kim, Y.; Kim, Y.H.; Rho, B.S.; Kim, M.J. Fiber-Optic Arc Flash Sensor Based on Plastic Optical Fibers for Simultaneous Measurements of Arc Flash Event Position. Opt. Eng. 2017, 56, 027103. [Google Scholar] [CrossRef]

- Simms, J.; Johnson, G. Protective Relaying Methods for Reducing Arc Flash Energy. In Proceedings of the 2011 IEEE Industry Applications Society Annual Meeting, Orlando, FL, USA, 9–13 October 2011; pp. 1–12. [Google Scholar]

- Muhr, M.; Schwarz, R. Partial Discharge Measurement as a Diagnostic Tool for HV-Equipments. In Proceedings of the 2006 IEEE 8th International Conference on Properties and applications of Dielectric Materials, Bali, Indonesia, 26–30 June 2006; pp. 195–198. [Google Scholar]

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A Review of the Properties and Applications of Poly (Methyl Methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Pawar, E. A Review Article on Acrylic PMMA. IOSR J. Mech. Civ. Eng. 2016, 13, 1–4. [Google Scholar] [CrossRef]

- Rajeh, A.; Ragab, H.M.; Abutalib, M.M. Co Doped ZnO Reinforced PEMA/PMMA Composite: Structural, Thermal, Dielectric and Electrical Properties for Electrochemical Applications. J. Mol. Struct. 2020, 1217, 128447. [Google Scholar] [CrossRef]

- Nafee, S.S.; Hamdalla, T.A.; Darwish, A.A.A. Studies of the Morphology and Optical Properties of Nano Erbium Oxide Embedded in PMMA Matrix. Opt. Laser. Technol. 2020, 129, 106282. [Google Scholar] [CrossRef]

- Alsaad, A.M.; Ahmad, A.A.; Dairy, A.R.; Al-anbar, A.S.; Al-Bataineh, Q.M. Spectroscopic Characterization of Optical and Thermal Properties of (PMMA-PVA) Hybrid Thin Films Doped with SiO2 Nanoparticles. Results Phys. 2020, 19, 103463. [Google Scholar] [CrossRef]

- Sharma, R.; Mahto, V.; Vuthaluru, H. Synthesis of PMMA/Modified Graphene Oxide Nanocomposite Pour Point Depressant and Its Effect on the Flow Properties of Indian Waxy Crude Oil. Fuel 2019, 235, 1245–1259. [Google Scholar] [CrossRef]

- Alhazime, A.A.; El-Shamy, N.T.; Benthami, K.; Barakat, M.M.E.; Nouh, S.A. Effect of Gamma Radiation on the Structural, Thermal and Optical Properties of PMMA/Sn 0.75 Fe 0.25 S 2 Nanocomposite. J. Polym. Eng. 2021, 41, 119–126. [Google Scholar] [CrossRef]

- Kailasnath, M.; Kumar, N.; Nampoori, V.P.N.; Vallabhan, C.P.G.; Radhakrishnan, P. Excitation Wavelength Dependence of Energy Transfer in Dye Mixture Doped Polymer Optical Fibre Preforms. J. Photochem. Photobiol. A Chem. 2008, 199, 236–241. [Google Scholar] [CrossRef]

- Miluski, P. Luminescent Properties of Oxazine 170 Perchlorate Doped PMMA Fiber. Fibers 2017, 5, 15. [Google Scholar] [CrossRef]

- El-Bashir, S.; AlSalhi, M.; Al-Faifi, F.; Alenazi, W. Spectral Properties of PMMA Films Doped by Perylene Dyestuffs for Photoselective Greenhouse Cladding Applications. Polymers 2019, 11, 494. [Google Scholar] [CrossRef]

- Kaysir, M.R.; Fleming, S.; MacQueen, R.W.; Schmidt, T.W.; Argyros, A. Optical Gain Characterization of Perylene Red-Doped PMMA for Different Pump Configurations. Appl. Opt. 2016, 55, 178. [Google Scholar] [CrossRef]

- Imwiset, K.J.; Ogawa, M. Highly Luminescent Inorganic–Organic Hybrids with Molecularly Dispersed Perylene. Inorg. Chem. 2021, 60, 9563–9570. [Google Scholar] [CrossRef]

- Grandes, J.; Illarramendi, M.A.; Arrospide, E.; Bikandi, I.; Aramburu, I.; Guarrotxena, N.; García, O.; Zubia, J. Temperature Effects on the Emission of Polymer Optical Fibers Doped with Lumogen Dyes. Opt. Fiber Technol. 2022, 72, 102980. [Google Scholar] [CrossRef]

- Wilson, L.R.; Richards, B.S. Measurement Method for Photoluminescent Quantum Yields of Fluorescent Organic Dyes in Polymethyl Methacrylate for Luminescent Solar Concentrators. Appl. Opt. 2009, 48, 212. [Google Scholar] [CrossRef]

- Bentoumi, G.; Dai, X.; Pruszkowski, E.; Li, L.; Sur, B. A Novel Boron-Loaded Liquid Scintillator for Neutron Detection. AECL Nucl. Rev. 2012, 1, 57–59. [Google Scholar] [CrossRef]

- Erol, E.; Vahedigharehchopogh, N.; Kıbrıslı, O.; Ersundu, M.Ç.; Ersundu, A.E. Recent Progress in Lanthanide-Doped Luminescent Glasses for Solid-State Lighting Applications—A Review. J. Phys. Condens. Matter 2021, 33, 483001. [Google Scholar] [CrossRef]

- Chen, X.; Sun, T.; Wang, F. Lanthanide-Based Luminescent Materials for Waveguide and Lasing. Chem. Asian J. 2020, 15, 21–33. [Google Scholar] [CrossRef]

- Liang, Y.; Liu, F.; Chen, Y.; Wang, X.; Sun, K.; Pan, Z. Extending the Applications for Lanthanide Ions: Efficient Emitters in Short-Wave Infrared Persistent Luminescence. J. Mater. Chem. C Mater. 2017, 5, 6488–6492. [Google Scholar] [CrossRef]

- Rimbach, A.C.; Steudel, F.; Ahrens, B.; Schweizer, S. Tb3+, Eu3+, and Dy3+ Doped Lithium Borate and Lithium Aluminoborate Glass: Glass Properties and Photoluminescence Quantum Efficiency. J. Non. Cryst. Solids. 2018, 499, 380–386. [Google Scholar] [CrossRef]

- Hsouna, N.; Bouzidi, C. White Luminescence and Energy Transfer Studies in Tb3+-Eu3+ Co-Doped Phosphate Glasses. Solid State Sci. 2022, 134, 107053. [Google Scholar] [CrossRef]

- Caldiño, U.; Álvarez, E.; Speghini, A.; Bettinelli, M. New Greenish-Yellow and Yellowish-Green Emitting Glass Phosphors: Tb3+/Eu3+ and Ce3+/Tb3+/Eu3+ in Zinc Phosphate Glasses. J. Lumin. 2013, 135, 216–220. [Google Scholar] [CrossRef]

- Ebendorff-Heidepriem, H.; Ehrt, D. Formation and UV Absorption of Cerium, Europium and Terbium Ions in Different Valencies in Glasses. Opt. Mater. 2000, 15, 7–25. [Google Scholar] [CrossRef]

- Sołtys, M.; Pisarska, J.; Leśniak, M.; Sitarz, M.; Pisarski, W.A. Structural and Spectroscopic Properties of Lead Phosphate Glasses Doubly Doped with Tb 3+ and Eu 3+ Ions. J. Mol. Struct. 2018, 1163, 418–427. [Google Scholar] [CrossRef]

- Saad, M.; Stambouli, W.; Mohamed, S.A.; Elhouichet, H. Ag Nanoparticles Induced Luminescence Enhancement of Eu3+ Doped Phosphate Glasses. J. Alloys Compd. 2017, 705, 550–558. [Google Scholar] [CrossRef]

- Vijayakumar, R.; Marimuthu, K. Luminescence Studies on Ag Nanoparticles Embedded Eu3+doped Boro-Phosphate Glasses. J. Alloys Compd. 2016, 665, 294–303. [Google Scholar] [CrossRef]

- Soltani, I.; Hraiech, S.; Horchani-Naifer, K.; Elhouichet, H.; Gelloz, B.; Férid, M. Growth of Silver Nanoparticles Stimulate Spectroscopic Properties of Er 3+ Doped Phosphate Glasses: Heat Treatment Effect. J. Alloys Compd. 2016, 686, 556–563. [Google Scholar] [CrossRef]

- Meza-Rocha, A.N.; Lozada-Morales, R.; Speghini, A.; Bettinelli, M.; Caldiño, U. White Light Generation in Tb3+/Eu3+/Dy3+ Triply-Doped Zn(PO3)2 Glass. Opt. Mater. 2016, 51, 128–132. [Google Scholar] [CrossRef]

- Arafonova, D.S.; Sidorov, A.I. Fiber-Optic Indicator of the Appearance of a Spark and an Arc with Spectral Conversion of the Radiation to Be Detected. J. Opt. Technol. 2011, 78, 735. [Google Scholar] [CrossRef]

- Kazachkov, Y.P. Determining the Position of a Luminous Area inside a Fiber-Optic Bundle. J. Opt. Technol. 1999, 66, 260. [Google Scholar] [CrossRef]

- Kazachkov, Y.P. Side-Face Radiation Trapping by Optical Fibers. Tech. Phys. Lett. 2008, 34, 895–897. [Google Scholar] [CrossRef]

- Miluski, P.; Kochanowicz, M.; Zmojda, J.; Silva, A.P.; Reis, P.N.B.; Ragin, T.; Dorosz, D. UV Sensing Optode for Composite Materials Environment Monitoring. Sci. Eng. Compos. Mater. 2019, 26, 240–243. [Google Scholar] [CrossRef]

- Zmojda, J.; Kochanowicz, M.; Miluski, P.; Dorosz, D. Side-Detecting Optical Fiber Doped with Tb3+ for Ultraviolet Sensor Application. Fibers 2014, 2, 150–157. [Google Scholar] [CrossRef]

- Lyons, W.B.; Fitzpatrick, C.; Flanagan, C.; Lewis, E. A Novel Multipoint Luminescent Coated Ultra Violet Fibre Sensor Utilising Artificial Neural Network Pattern Recognition Techniques. Sens. Actuators A Phys. 2004, 115, 267–272. [Google Scholar] [CrossRef]

- Agafonova, D.S.; Kolobkova, E.V.; Ignatiev, A.I.; Nikonorov, N.V.; Shakhverdov, T.A.; Shirshnev, P.S.; Sidorov, A.I.; Vasiliev, V.N. Luminescent Glass Fiber Sensors for Ultraviolet Radiation Detection by the Spectral Conversion. Opt. Eng. 2015, 54, 117107. [Google Scholar] [CrossRef]

- Zmojda, J.; Dorosz, D.; Kochanowicz, M.; Miluski, P.; Czajkowski, K.; Ragin, T. Visible Emission in Sm 3+ and Tb 3+ Doped Phosphate Glass Excited by UV Radiation. In Proceedings of the Photonics Applications in Astronomy, Communications, Industry and High-Energy Physics Experiments 2013, Wilga, Poland, 27 May–2 June 2013; p. 890306. [Google Scholar] [CrossRef]

- E2TANGO Bay Controllers (600,800,1000,1200)—Elektrometal Energetyka. Available online: https://elektrometal-energetyka.pl/e%c2%b2tango-mv-protection-relays/e%c2%b2tango-bay-controllers-60080010001200/ (accessed on 25 January 2023).

- L-200P Precision Luxmeter-Sonopan. Available online: https://www.sonopan.com.pl/en/products/light/precision-illuminance-meter-l-200-with-p-200/ (accessed on 21 January 2023).

- Xia, Y.; Zou, X.; Zhang, H.; Zhao, M.; Chen, X.; Jia, W.; Su, C.; Shao, J. Luminescence and Energy Transfer Studies of Eu3+-Tb3+ Co-Doped Transparent Glass Ceramics Containing BaMoO4 Crystallites. J. Alloys Compd. 2019, 774, 540–546. [Google Scholar] [CrossRef]

- ZL-4A-Arc Fault Protection-SPIE ENERGOTEST Sp. z o.o. Available online: https://www.spie-energotest.pl/en/products/zl-4a-arc-fault-protection.html (accessed on 21 January 2023).

- Fiber Loop Sensors-Arcteq. Available online: https://www.arcteq.fi/product/fiber-loop-sensors/ (accessed on 22 January 2023).

| Ingredients | Molar Content [mol.%] | Mass [g] |

|---|---|---|

| P2O5 | 65 | 10.678 |

| Al2O3 | 9 | 1.062 |

| BaO | 7 | 1.242 |

| ZnO | 6 | 0.565 |

| Na2O | 5 | 0.358 |

| MgO | 6 | 0.280 |

| Eu2O3 | 2 | 0.815 |

| Σ | 100 | 15.000 |

| Ingredients | Molar Content [mol.%] | Mass [g] |

|---|---|---|

| P2O5 | 65 | 10.655 |

| Al2O3 | 9 | 1.060 |

| BaO | 7 | 1.240 |

| ZnO | 6 | 0.564 |

| Na2O | 5 | 0.357 |

| MgO | 6 | 0.279 |

| Tb2O3 | 2 | 0.845 |

| Σ | 100 | 15.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Awramiuk, P.; Sadowska, K.; Wiater, J.; Sajewicz, D.; Kochanowicz, M.; Walendziuk, W.; Żmojda, J.M. Development of an Active Optical Lens for Arc Flashing Detection. Sensors 2023, 23, 2629. https://doi.org/10.3390/s23052629

Awramiuk P, Sadowska K, Wiater J, Sajewicz D, Kochanowicz M, Walendziuk W, Żmojda JM. Development of an Active Optical Lens for Arc Flashing Detection. Sensors. 2023; 23(5):2629. https://doi.org/10.3390/s23052629

Chicago/Turabian StyleAwramiuk, Paweł, Karolina Sadowska, Jarosław Wiater, Dariusz Sajewicz, Marcin Kochanowicz, Wojciech Walendziuk, and Jacek M. Żmojda. 2023. "Development of an Active Optical Lens for Arc Flashing Detection" Sensors 23, no. 5: 2629. https://doi.org/10.3390/s23052629

APA StyleAwramiuk, P., Sadowska, K., Wiater, J., Sajewicz, D., Kochanowicz, M., Walendziuk, W., & Żmojda, J. M. (2023). Development of an Active Optical Lens for Arc Flashing Detection. Sensors, 23(5), 2629. https://doi.org/10.3390/s23052629