Sensitivity Enhancement of 2D Material-Based Surface Plasmon Resonance Sensor with an Al–Ni Bimetallic Structure

Abstract

1. Introduction

2. Structure and Numerical Model of SPR Sensor

2.1. Refractive Index of Various Layer Components

2.2. Theoretical Model of SPR Sensor and Evaluation Parameters

2.3. Performance Evaluation Formula

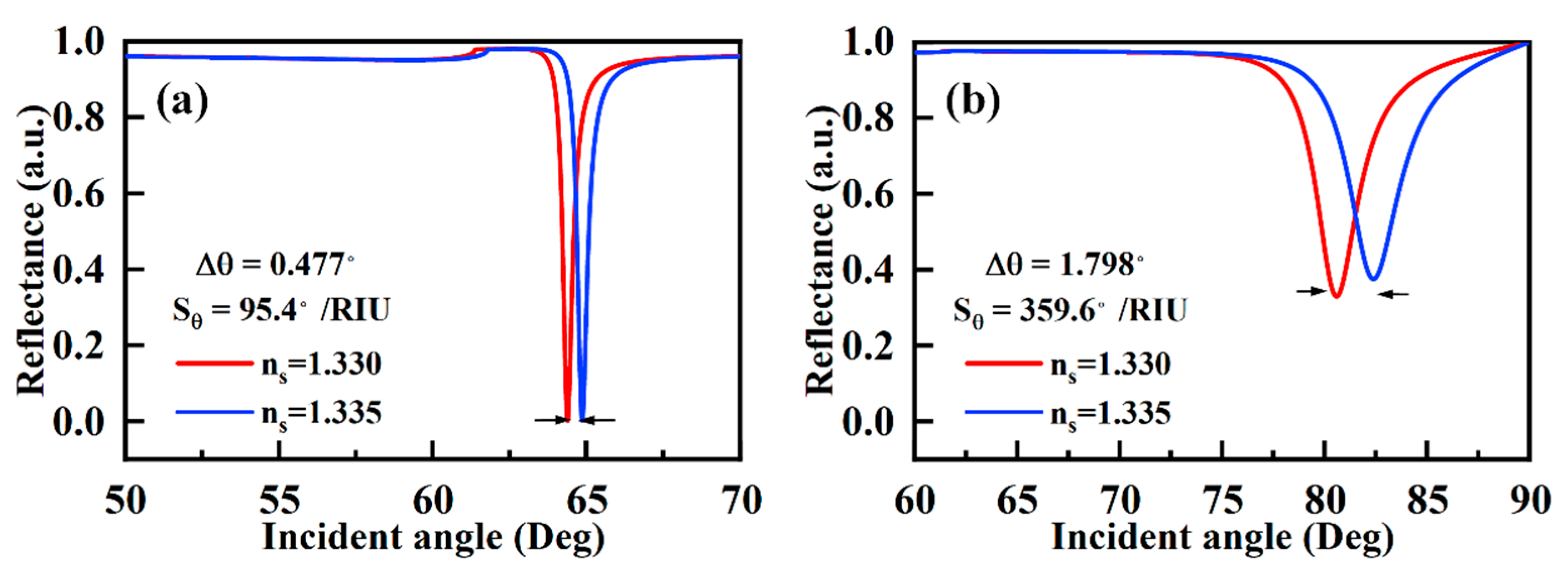

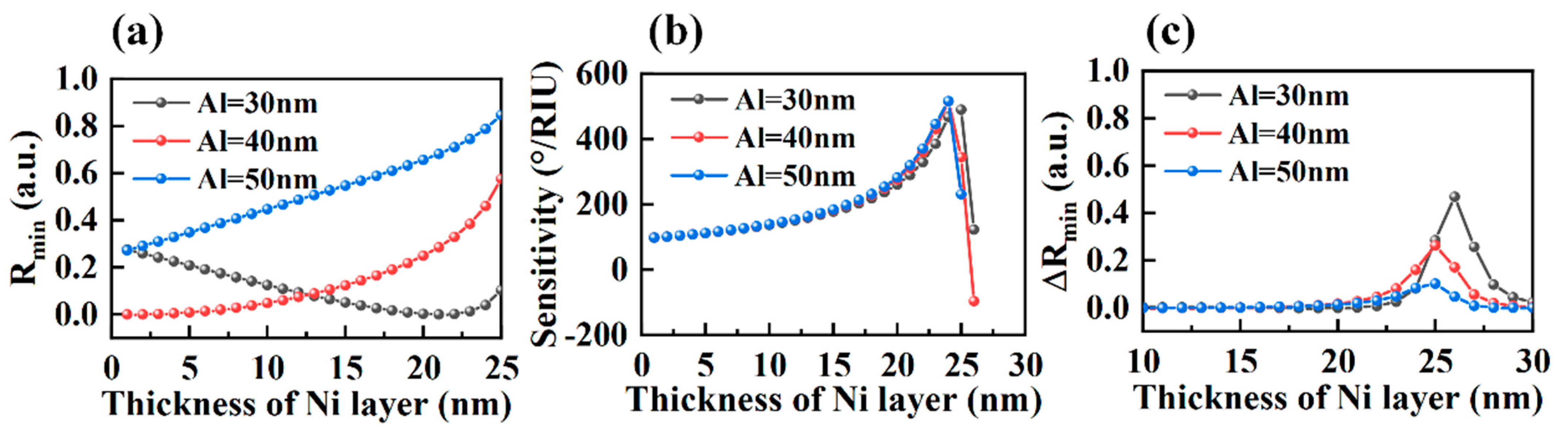

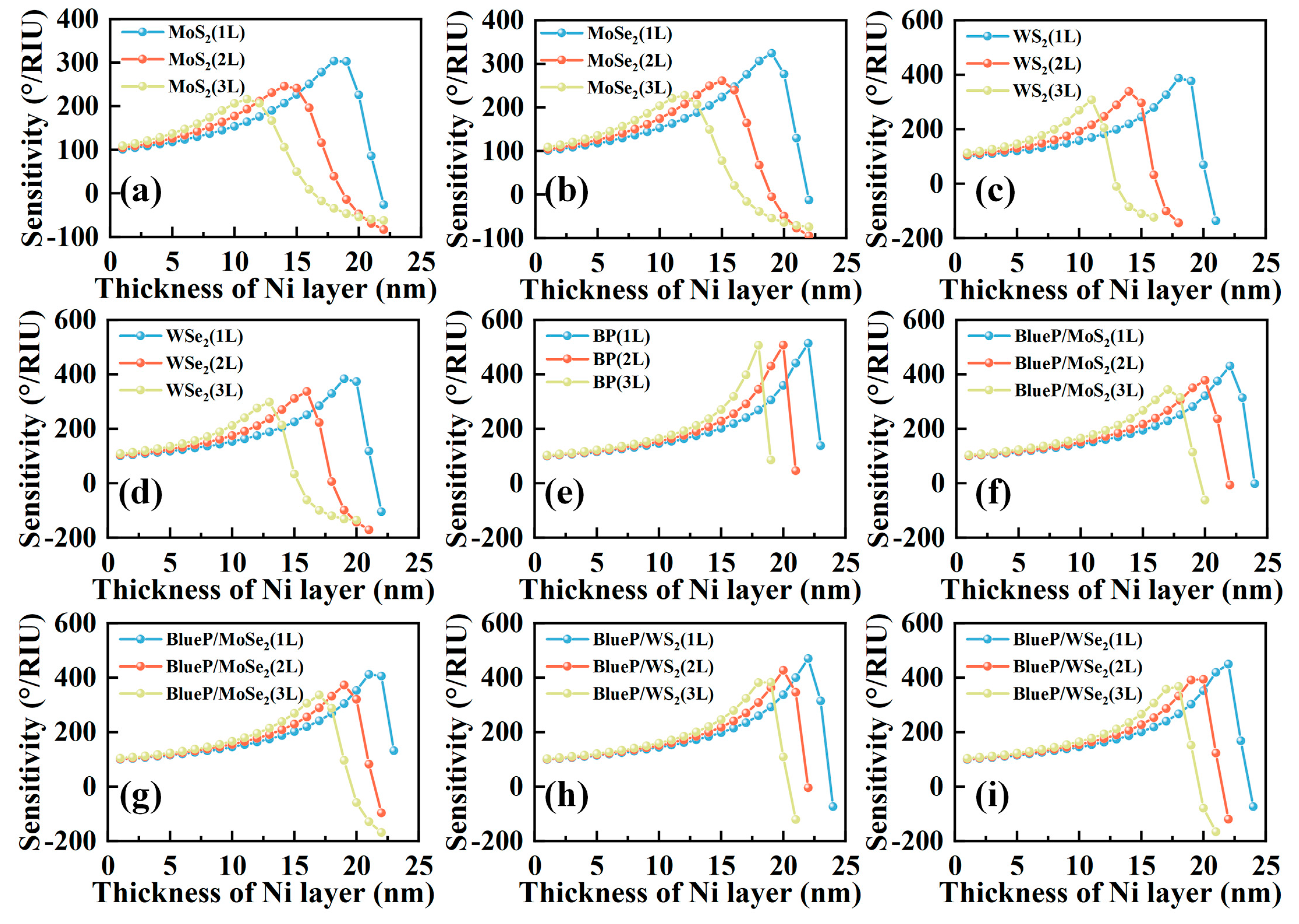

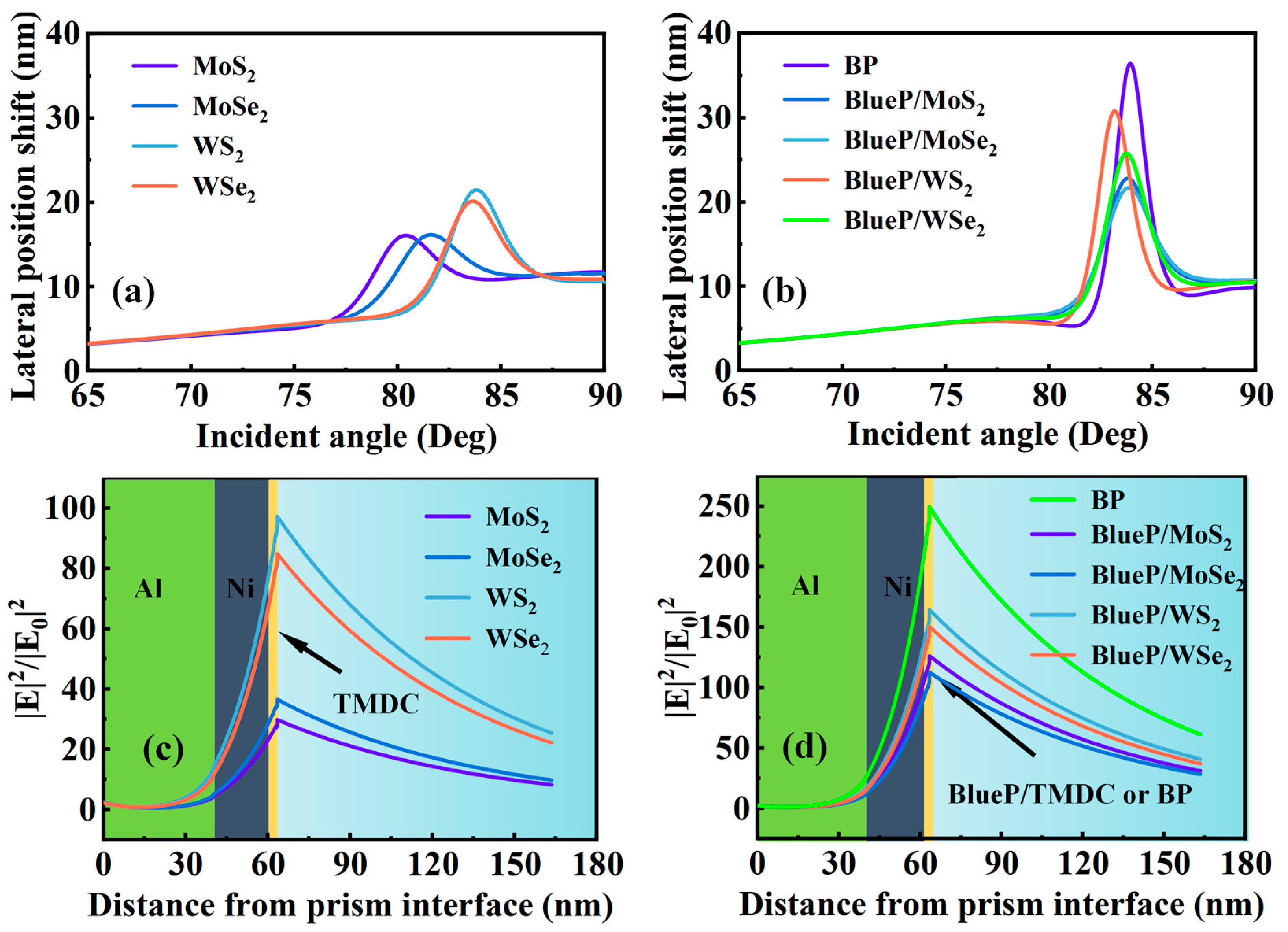

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, J.; Hong, S.; Choi, Y. Sensitive Detection of Formaldehyde Gas Using Modified Dandelion-Like SiO(2)/Au Film and Surface Plasmon Resonance System. J. Nanosci. Nanotechnol. 2019, 19, 4807–4811. [Google Scholar] [CrossRef] [PubMed]

- Kaushik, S.; Tiwari, U.K.; Deep, A.; Sinha, R.K. Two-dimensional transition metal dichalcogenides assisted biofunction-alized optical fiber SPR biosensor for efficient and rapid detection of bovine serum albumin. Sci. Rep. 2019, 9, 6987. [Google Scholar] [CrossRef] [PubMed]

- Mudgal, N.; Yupapin, P.; Ali, J.; Singh, G. BaTiO3-Graphene-Affinity Layer–Based Surface Plasmon Resonance (SPR) Biosensor for Pseudomonas Bacterial Detection. Plasmonics 2020, 15, 1221–1229. [Google Scholar] [CrossRef]

- Yakes, B.J.; Buijs, J.; Elliott, C.T.; Campbell, K. Surface plasmon resonance biosensing: Approaches for screening and characterising antibodies for food diagnostics. Talanta 2016, 156-157, 55–63. [Google Scholar] [CrossRef] [PubMed]

- Bae, Y.M.; Son, S.Y.; Lee, K.-H.; Kim, K.; Seol, S.K.; Kim, D. Enhancement of the sensitivity of surface plasmon resonance biosensor by modifying the metal surface. J. Biomed. Nanotechnol. 2013, 9, 1060–1064. [Google Scholar] [CrossRef]

- Wu, L.; You, Q.; Shan, Y.; Gan, S.; Zhao, Y.; Dai, X.; Xiang, Y. Few-layer Ti3C2Tx MXene: A promising surface plasmon resonance biosensing material to enhance the sensitivity. Sensors Actuators B Chem. 2018, 277, 210–215. [Google Scholar] [CrossRef]

- Han, L.; Chen, Z.; Huang, T.; Ding, H.; Wu, C. Sensitivity Enhancement of Ag-ITO-TMDCs-Graphene Nanostructure Based on Surface Plasmon Resonance Biosensors. Plasmonics 2019, 15, 693–701. [Google Scholar] [CrossRef]

- Kumar, R.; Pal, S.; Prajapati, Y.K.; Saini, J.P. Sensitivity Enhancement of MXene Based SPR Sensor Using Silicon: Theoretical Analysis. Silicon 2020, 13, 1887–1894. [Google Scholar] [CrossRef]

- Wang, Y.; Meng, S.; Liang, Y.; Li, L.; Peng, W. Fiber-optic surface plasmon resonance sensor with multi-alternating metal layers for biological measurement. Photonic Sens. 2013, 3, 202–207. [Google Scholar] [CrossRef]

- Wang, M.; Huo, Y.; Jiang, S.; Zhang, C.; Yang, C.; Ning, T.; Liu, X.; Li, C.; Zhang, W.; Man, B. Theoretical design of a surface plasmon resonance sensor with high sensitivity and high resolution based on graphene–WS2 hybrid nanostructures and Au–Ag bimetallic film. RSC Adv. 2017, 7, 47177–47182. [Google Scholar] [CrossRef]

- Liu, L.; Wang, M.; Jiao, L.; Wu, T.; Xia, F.; Liu, M.; Kong, W.; Dong, L.; Yun, M. Sensitivity enhancement of a graphene–barium titanate-based surface plasmon resonance biosensor with an Ag–Au bimetallic structure in the visible region. J. Opt. Soc. Am. B 2019, 36, 1108–1116. [Google Scholar] [CrossRef]

- Zhao, X.; Huang, T.; Ping, P.S.; Wu, X.; Huang, P.; Pan, J.; Wu, Y.; Cheng, Z. Sensitivity Enhancement in Surface Plasmon Resonance Biochemical Sensor Based on Transition Metal Dichalcogenides/Graphene Heterostructure. Sens. Basel 2018, 18, 2056. [Google Scholar] [CrossRef] [PubMed]

- Ordal, M.A.; Bell, R.J.; Alexander, R.W. Optical properties of fourteen metals in the infrared and far infrared: Al, Co, Cu, Au, Fe, Pb, Mo, Ni, Pd, Pt, Ag, Ti, V and W. Appl. Opt. 1985, 24, 4493–4499. [Google Scholar] [CrossRef]

- Ehrenreich, H.; Philipp, H.R.; Olechna, D.J. Optical Properties and Fermi Surface of Nickel. Phys. Rev. 1963, 131, 2469–2477. [Google Scholar] [CrossRef]

- Liu, N.; Wang, S.; Cheng, Q.; Pang, B.; Lv, J. High Sensitivity in Ni-Based SPR Sensor of Blue Phosphorene/Transition Metal Dichalcogenides Hybrid Nanostructure. Plasmonics 2021, 16, 1567–1576. [Google Scholar] [CrossRef]

- AlaguVibisha, G.; Nayak, J.K.; Maheswari, P.; Priyadharsini, N.; Nisha, A.; Jaroszewicz, Z.; Rajesh, K.; Jha, R. Sensitivity enhancement of surface plasmon resonance sensor using hybrid configuration of 2D materials over bimetallic layer of Cu–Ni. Opt. Commun. 2020, 463, 125337. [Google Scholar] [CrossRef]

- Basak, N.; Sultana, N.; Mitu, S.A.; R, V.K.; Al-Zahrani, F.A.; Patel, S.K.; Ahmed, K. Exploration of LSPR-based Refractive Index Sensor Coated with Silver-MgF2 Layer. Plasmonics 2022, 18, 271–282. [Google Scholar] [CrossRef]

- Wang, Q.; Cao, S.; Gao, X.; Chen, X.; Zhang, D. Improving the Detection Accuracy of an Ag/Au Bimetallic Surface Plasmon Resonance Biosensor Based on Graphene. Chemosensors 2022, 10, 10. [Google Scholar] [CrossRef]

- Hossain, M.M.; Talukder, M.A. Gate-controlled graphene surface plasmon resonance glucose sensor. Opt. Commun. 2021, 493, 126994. [Google Scholar] [CrossRef]

- Chen, S.; Lin, C. Sensitivity analysis of graphene multilayer based surface plasmon resonance biosensor in the ultraviolet, visible and infrared regions. Appl. Phys. A 2019, 125, 230. [Google Scholar] [CrossRef]

- Rahman, M.S.; Anower, M.S.; Hasan, M.R.; Hossain, M.B.; Haque, M.I. Design and numerical analysis of highly sensitive Au-MoS2-graphene based hybrid surface plasmon resonance biosensor. Opt. Commun. 2017, 396, 36–43. [Google Scholar] [CrossRef]

- Kushwaha, A.S.; Kumar, A.; Kumar, R.; Srivastava, S.K. A study of surface plasmon resonance (SPR) based biosensor with improved sensitivity. Photonics Nanostructures Fundam. Appl. 2018, 31, 99–106. [Google Scholar] [CrossRef]

- Lin, Z.; Jiang, L.; Wu, L.; Guo, J.; Dai, X.; Xiang, Y.; Fan, D. Tuning and Sensitivity Enhancement of Surface Plasmon Resonance Biosensor with Graphene Covered Au-MoS 2-Au Films. IEEE Photonics J. 2016, 8, 1–8. [Google Scholar] [CrossRef]

- Kaushik, S.; Tiwari, U.K.; Pal, S.S.; Sinha, R.K. Rapid detection of Escherichia coli using fiber optic surface plasmon resonance immunosensor based on biofunctionalized Molybdenum disulfide (MoS2) nanosheets. Biosens. Bioelectron. 2019, 126, 501–509. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Wang, Q.; Zhao, W.-M. A novel SPR sensor sensitivity-enhancing method for immunoassay by inserting MoS2 nanosheets between metal film and fiber. Opt. Lasers Eng. 2020, 132, 106135. [Google Scholar] [CrossRef]

- Sun, P.; Wang, M.; Liu, L.; Jiao, L.; Du, W.; Xia, F.; Liu, M.; Kong, W.; Dong, L.; Yun, M. Sensitivity enhancement of surface plasmon resonance biosensor based on graphene and barium titanate layers. Appl. Surf. Sci. 2019, 475, 342–347. [Google Scholar] [CrossRef]

- Rifat, A.A.; Mahdiraji, G.A.; Ahmed, R.; Chow, D.M.; Sua, Y.M.; Shee, Y.G.; Adikan, F.R.M. Copper-Graphene-Based Photonic Crystal Fiber Plasmonic Biosensor. IEEE Photonics J. 2016, 8, 1–8. [Google Scholar] [CrossRef]

- Ouyang, Q.; Zeng, S.; Jiang, L.; Hong, L.; Xu, G.; Dinh, X.-Q.; Qian, J.; He, S.; Qu, J.; Coquet, P.; et al. Sensitivity Enhancement of Transition Metal Dichalcogenides/Silicon Nanostructure-based Surface Plasmon Resonance Biosensor. Sci. Rep. 2016, 6, 28190. [Google Scholar] [CrossRef]

- Wu, L.; Guo, J.; Wang, Q.; Lu, S.; Dai, X.; Xiang, Y.; Fan, D. Sensitivity enhancement by using few-layer black phospho-rus-graphene/TMDCs heterostructure in surface plasmon resonance biochemical sensor. Sens. Actuators B Chem. 2017, 249, 542–548. [Google Scholar] [CrossRef]

- Peng, Q.; Wang, Z.; Sa, B.; Wu, B.; Sun, Z. Electronic structures and enhanced optical properties of blue phosphorene/transition metal dichalcogenides van der Waals heterostructures. Sci. Rep. 2016, 6, 31994. [Google Scholar] [CrossRef]

- Shivangani; Alotaibi, M.F.; Al-Hadeethi, Y.; Lohia, P.; Singh, S.; Dwivedi, D.K.; Umar, A.; Alzayed, H.M.; Algadi, H.; Baskoutas, S. Numerical Study to Enhance the Sensitivity of a Surface Plasmon Resonance Sensor with BlueP/WS(2)-Covered Al(2)O(3)-Nickel Nanofilms. Nanomater. Basel 2022, 12, 2205. [Google Scholar] [CrossRef] [PubMed]

- Alagdar, M.; Yousif, B.; Areed, N.F.; Elzalabani, M. Improved the quality factor and sensitivity of a surface plasmon resonance sensor with transition metal dichalcogenide 2D nanomaterials. J. Nanopart. Res. 2020, 22, 1–13. [Google Scholar] [CrossRef]

- Das, C.M.; Ouyang, Q.; Kang, L.; Guo, Y.; Dinh, X.-Q.; Coquet, P.; Yong, K.-T. Augmenting sensitivity of surface plasmon resonance (SPR) sensors with the aid of anti-reflective coatings (ARCs). Photonics Nanostruct. Fundam. Appl. 2020, 38, 100760. [Google Scholar] [CrossRef]

- Karki, B.; Pal, A.; Singh, Y.; Sharma, S. Sensitivity enhancement of surface plasmon resonance sensor using 2D material barium titanate and black phosphorus over the bimetallic layer of Au, Ag, and Cu. Opt. Commun. 2022, 508, 127616. [Google Scholar] [CrossRef]

- Yue, C.; Lang, Y.; Zhou, X.; Liu, Q. Sensitivity enhancement of an SPR biosensor with a graphene and blue phos-phorene/transition metal dichalcogenides hybrid nanostructure. Appl. Opt. 2019, 58, 9411–9420. [Google Scholar] [CrossRef] [PubMed]

- Luo, C.; Guo, J.; Wang, Q.; Xiang, Y.; Wen, S. Electrically controlled Goos-Hänchen shift of a light beam reflected from the metal-insulator-semiconductor structure. Opt. Express 2013, 21, 10430–10439. [Google Scholar] [CrossRef] [PubMed]

- Meshginqalam, B.; Barvestani, J. Performance Enhancement of SPR Biosensor Based on Phosphorene and Transition Metal Dichalcogenides for Sensing DNA Hybridization. IEEE Sens. J. 2018, 18, 7537–7543. [Google Scholar] [CrossRef]

- Pandey, A.K. Plasmonic sensor utilizing Ti3C2Tx MXene layer and fluoride glass substrate for bio- and gas-sensing ap-plications: Performance evaluation. Photonics Nanostructures Fundam. Appl. 2020, 42, 100863. [Google Scholar] [CrossRef]

- Prabowo, B.A.; Hermida, I.D.P.; Manurung, R.V.; Purwidyantri, A.; Liu, K.-C. Nano-film aluminum-gold for ultra-high dynamic-range surface plasmon resonance chemical sensor. Front. Optoelectron. 2019, 12, 286–295. [Google Scholar] [CrossRef]

- Pal, S.; Verma, A.; Prajapati, Y.K.; Saini, J.P. Sensitive detection using heterostructure of black phosphorus, transition metal di-chalcogenides and MXene in SPR sensor. Appl. Phys. A 2020, 126, 809. [Google Scholar] [CrossRef]

- Nisha, A.; Maheswari, P.; Anbarasan, P.M.; Rajesh, K.B.; Jaroszewicz, Z. Sensitivity enhancement of surface plasmon resonance sensor with 2D material covered noble and magnetic material (Ni). Opt. Quantum Electron. 2019, 51, 19. [Google Scholar] [CrossRef]

- Deng, Y.; Luo, Z.; Conrad, N.J.; Liu, H.; Gong, Y.; Najmaei, S.; Ajayan, P.M.; Lou, J.; Xu, X.; Ye, P.D. Black phosphorus-monolayer MoS2 van der Waals heterojunction p-n diode. ACS Nano 2014, 8, 8292–8299. [Google Scholar] [CrossRef] [PubMed]

- Mao, N.; Tang, J.; Xie, L.; Wu, J.; Han, B.; Lin, J.; Deng, S.; Ji, W.; Xu, H.; Liu, K.; et al. Optical Anisotropy of Black Phosphorus in the Visible Regime. J. Am. Chem. Soc. 2016, 138, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Weiss, N.O.; Duan, X.; Cheng, H.-C.; Huang, Y.; Duan, X. Van der Waals heterostructures and devices. Nat. Rev. Mater. 2016, 1, 1–17. [Google Scholar] [CrossRef]

| Material | Thickness of Monolayer (nm) | Refractive Index |

|---|---|---|

| MoS2 | 0.65 | 5.08 + 1.1723 i |

| MoSe2 | 0.70 | 4.62 + 1.0063 i |

| WS2 | 0.80 | 4.9 + 0.3124 i |

| WSe2 | 0.70 | 4.55 + 0.4332 i |

| BP | 0.53 | 3.5 + 0.01 i |

| BlueP/MoS2 | 0.75 | 2.81 + 0.32 i |

| BlueP/MoSe2 | 0.78 | 2.77 + 0.35 i |

| BlueP/WS2 | 0.75 | 2.48 + 0.17 i |

| BlueP/WSe2 | 0.78 | 2.69 + 0.22 i |

| Material | Optimized Layers (L) | Thickness of Ni (nm) | Sensitivity (°/RIU) | FWHM (Deg) | FOM |

|---|---|---|---|---|---|

| BP | 1 | 22 | 514.0 | 3.890 | 132.1337 |

| MoS2 | 1 | 18 | 303.8 | 6.941 | 43.7689 |

| MoSe2 | 1 | 19 | 324.4 | 7.003 | 46.3230 |

| WS2 | 1 | 18 | 387.6 | 4.819 | 80.4316 |

| WSe2 | 1 | 19 | 383.6 | 4.982 | 76.9972 |

| BlueP/MoS2 | 1 | 22 | 420.4 | 5.111 | 82.2540 |

| BlueP/MoSe2 | 1 | 21 | 412.2 | 4.440 | 92.8378 |

| BlueP/WS2 | 1 | 22 | 470.2 | 4.187 | 112.3000 |

| BlueP/WSe2 | 1 | 22 | 449.8 | 4.714 | 95.4179 |

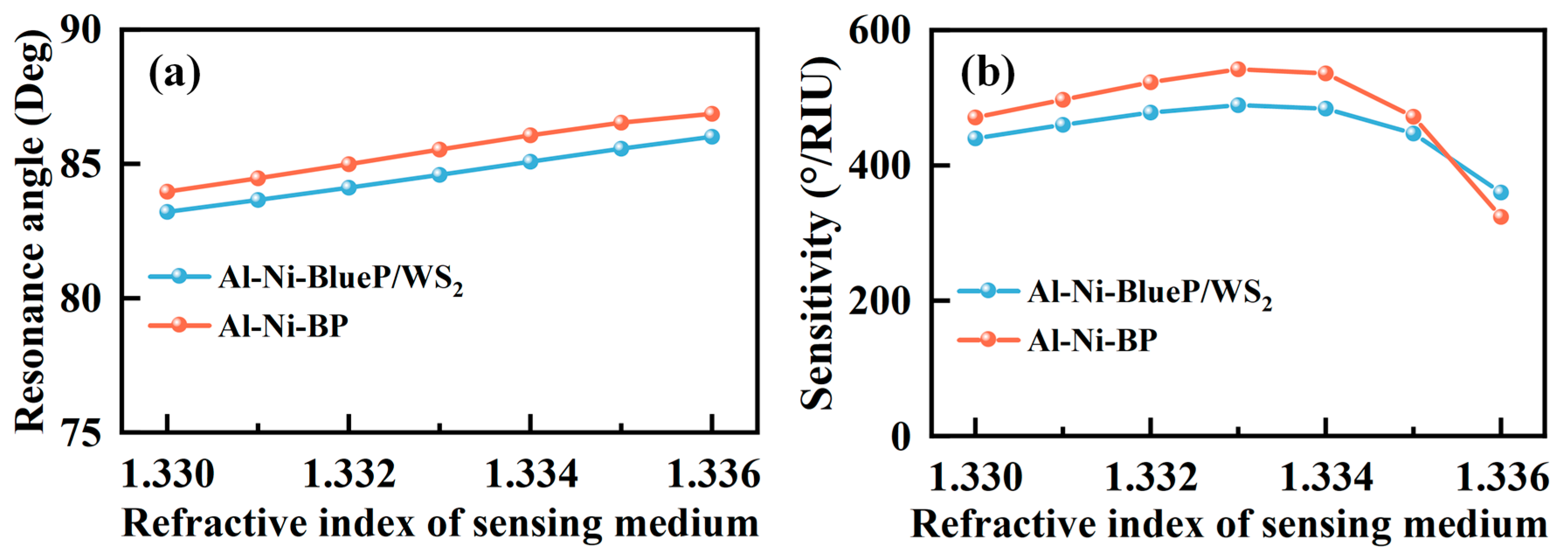

| Reference | Multi-Layer Structure | Angular Sensitivity@1.330 (°/RIU) | Maximum Angular Sensitivity (°/RIU) | Average Angular Sensitivity (°/RIU) |

|---|---|---|---|---|

| [41] | Au–MoS2–Ni–Graphene | 229 | 286 | 238@1.33~1.35 |

| [11] | Ag–Au–BaTiO3–Graphene | 294 | 294 | 283@1.332~1.346 |

| [31] | Ag–WS2–Ni–Graphene | 243.3 | - | - |

| [16] | Cu–Ni–WS2 | 480.0 | - | - |

| [12] | WS2–Al–WS2–Graphene | 315.5 | - | - |

| This Work | Al–Ni–BlueP/WS2 | 470.2 | 489 | 466@1.330~1.335 |

| This Work | Al–Ni–BP | 514.0 | 542 | 507@1.330~1.335 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, M.; Li, M.; Li, M.-Y.; Wen, X.; Deng, S.; Liu, S.; Lu, H. Sensitivity Enhancement of 2D Material-Based Surface Plasmon Resonance Sensor with an Al–Ni Bimetallic Structure. Sensors 2023, 23, 1714. https://doi.org/10.3390/s23031714

Hu M, Li M, Li M-Y, Wen X, Deng S, Liu S, Lu H. Sensitivity Enhancement of 2D Material-Based Surface Plasmon Resonance Sensor with an Al–Ni Bimetallic Structure. Sensors. 2023; 23(3):1714. https://doi.org/10.3390/s23031714

Chicago/Turabian StyleHu, Miaosen, Min Li, Ming-Yu Li, Xiaoyan Wen, Shuo Deng, Sisi Liu, and Haifei Lu. 2023. "Sensitivity Enhancement of 2D Material-Based Surface Plasmon Resonance Sensor with an Al–Ni Bimetallic Structure" Sensors 23, no. 3: 1714. https://doi.org/10.3390/s23031714

APA StyleHu, M., Li, M., Li, M.-Y., Wen, X., Deng, S., Liu, S., & Lu, H. (2023). Sensitivity Enhancement of 2D Material-Based Surface Plasmon Resonance Sensor with an Al–Ni Bimetallic Structure. Sensors, 23(3), 1714. https://doi.org/10.3390/s23031714