1. Introduction

Artificial satellites are watching the earth for global-scale wireless networking and scientific data gathering. With telecommunication and weather surveillance, satellites are indispensable to the surveillance and reconnaissance of target regions. Nowadays, LEO satellites are produced for commercial services and deployed in orbit 800 km to 1000 km above the earth’s surface, which comes with a short cycle of production and which forms a space-borne network of an overwhelming number of satellites, called a constellation [

1,

2]. Transponders are essential to satellites of any kind and any missions for ground-to-space and satellite-to-satellite wireless links.

The transponder is a wireless communication system that receives RF signals and transmits them, whether it is geostationary or on a LEO satellite. Its configuration is represented by the system block diagram comprising plenty of circuits and components, from the receiver to the transmitter. The chain of the signal flow meets the components of signal amplification, channel selection, channel splitting and combining, switching, demodulation and modulation, etc. For successful tasking, system integration (SI) is important, but the functions of the individual components are more prioritized. Active components connected to control blocks have an increased degree of freedom in meeting the requirements even after SI. As for passive components such as and input and output multiplexers (MUXes) for channel splitting and combining, and filters for channel selection, functions are not controllable after fabrication and assembly. Great care should be taken of their design and fabrication. While active components such as MMIC amplifiers do not weigh much, the passive components of waveguide (WG) filters and WG-MUXes tend to be heavy. Along with the feed horn and reflector antenna, WG passive elements are of great concern in terms of size control and weight control in the building of a satellite transponder. This becomes a critical matter to the cost required in the making and maintaining of LEO satellites and microsatellites.

In satellite communication, high-frequency signals must be so strong that they can travel hundreds to thousands of kilometers when emanated from the antenna. The filters, like other passive components in the feed assembly of the antenna, are made out of metallic waveguides to ensure high Q-factors and endure high power and the heat [

3,

4,

5,

6,

7]. This is why the structures are bulky and heavy. Reducing their size is a crucial factor to saving on costs in developing and launching satellites. Choocadee and Akatimagool showed second- and third-order rectangular WG BPFs [

3]. Typical-size cavities are combined in series through irises for channel selectivity. San-Blas and Boria took action to reduce the size of the WG filter by integrating coaxial lines with rectangular cavities [

4]. The length of their third-order filter is the same as that of the conventional third-order BPFs. Valencia and Cogollos put in SIR parts with cavity resonators coupled through a mixture of E-plane and H-plane steps [

5]. Their WG BPF is longer than four wavelengths. Teberio and Percaz meandered the straight topology of a BPF to reduce the area that the filter occupies [

6]. The added waveguide to the mitered E-plane bend sections couple with half-wavelength cavities, and the total length has almost no change. Sullca and Guglielmi changed a straight geometry to a staircase by opening the two spots on the broad wall of each cavity for coupling [

7]. The trace in the longitudinal axis is decreased, but the total length is similar to that in [

5]. overran overview of the latest rectangular waveguide bandpass filters, including the reports above, as they follow the design technique of half-wavelength cavities, shows that effective size reduction is nowhere to be found. One might suggest applying metamaterial filter designs in microstrip and CPW lines, such as those in [

8,

9], to waveguide components, but this turns out to be not possible, because of differences in geometries and modes. Another idea might be to set up a metamaterial resonator, which is much shorter than the typical cavity and geometrically appropriate for the waveguide.

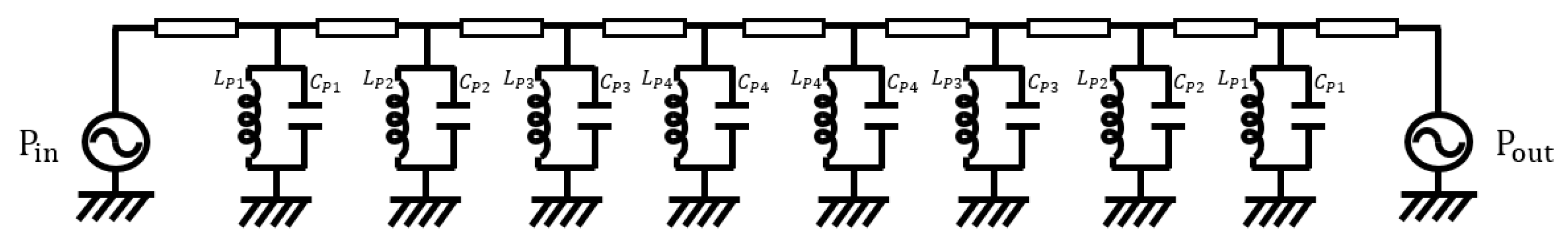

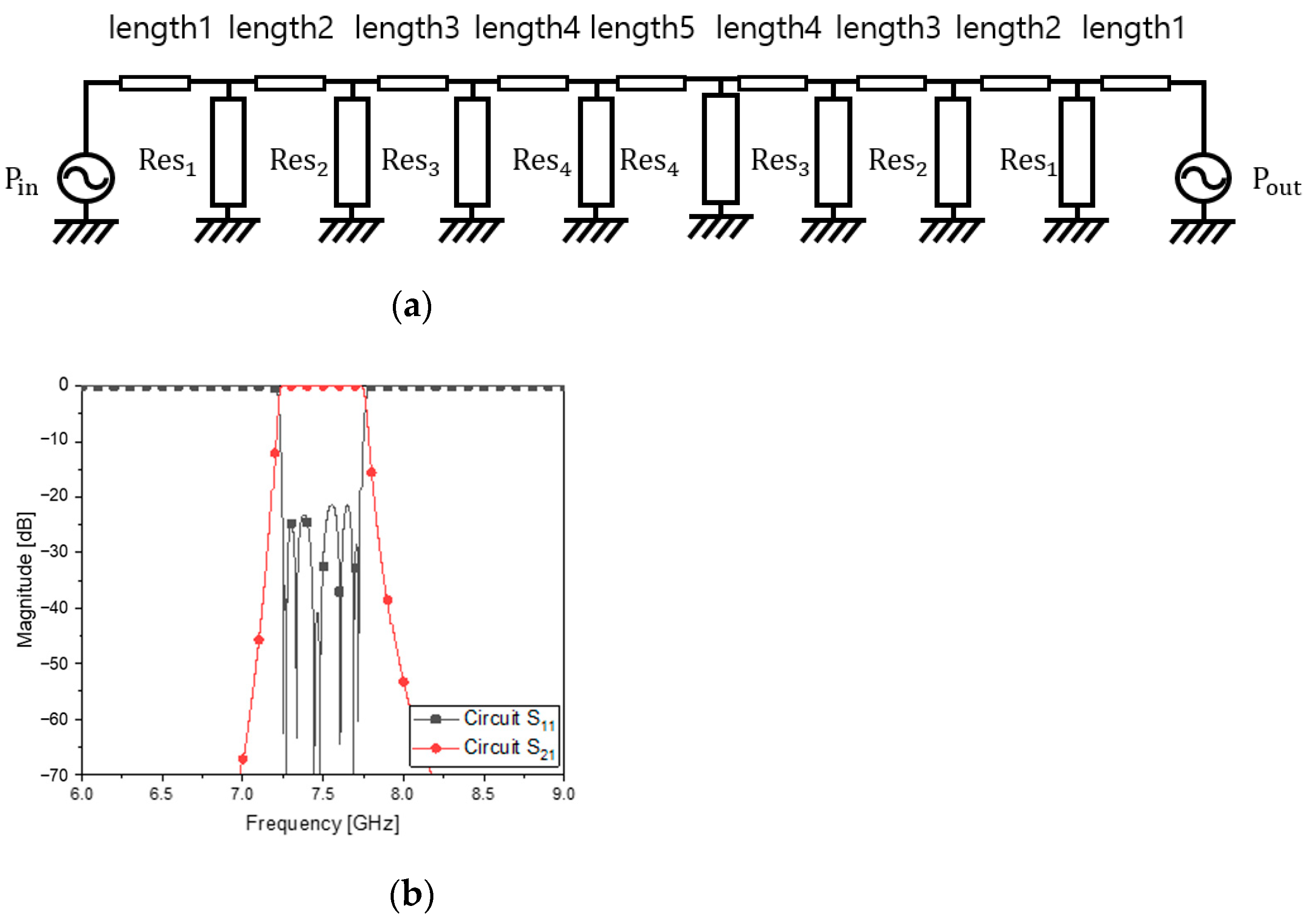

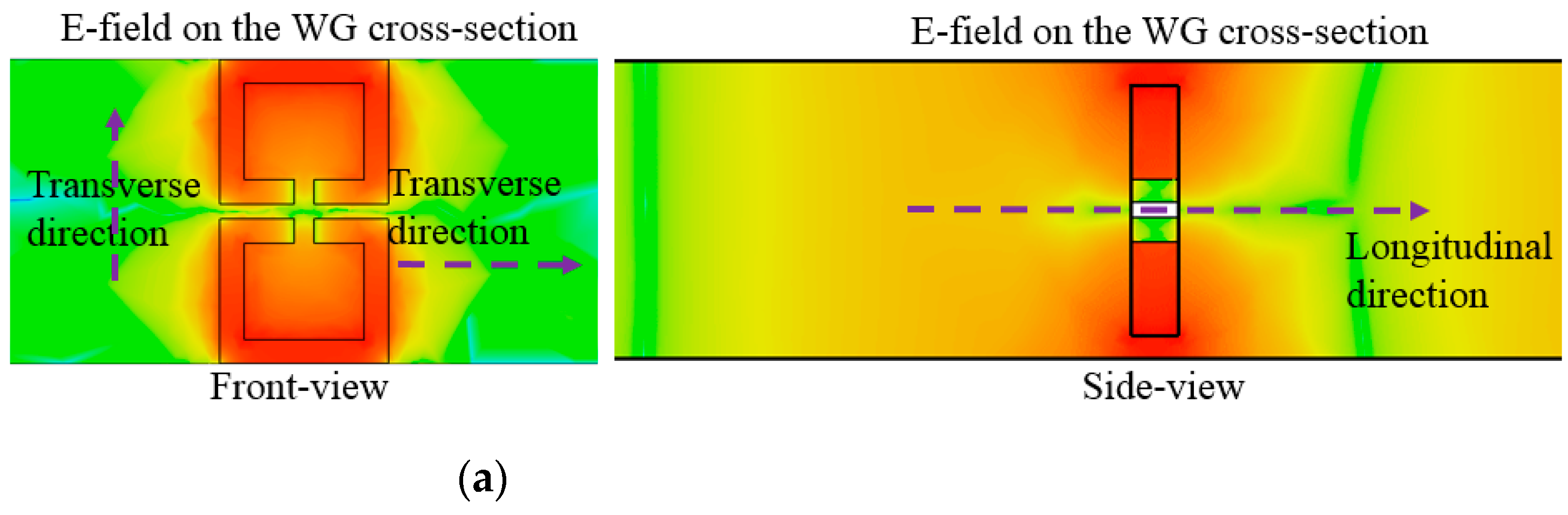

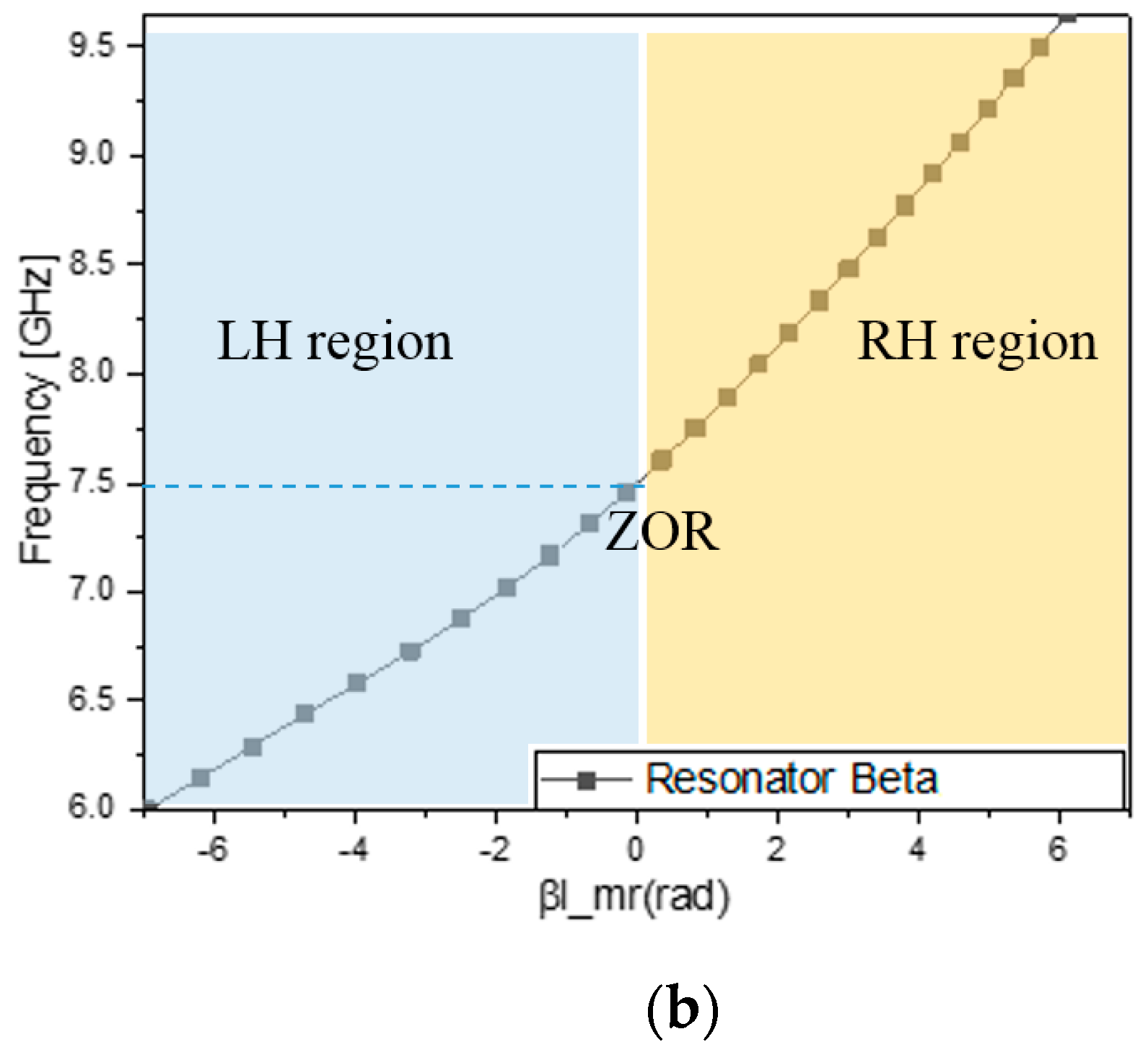

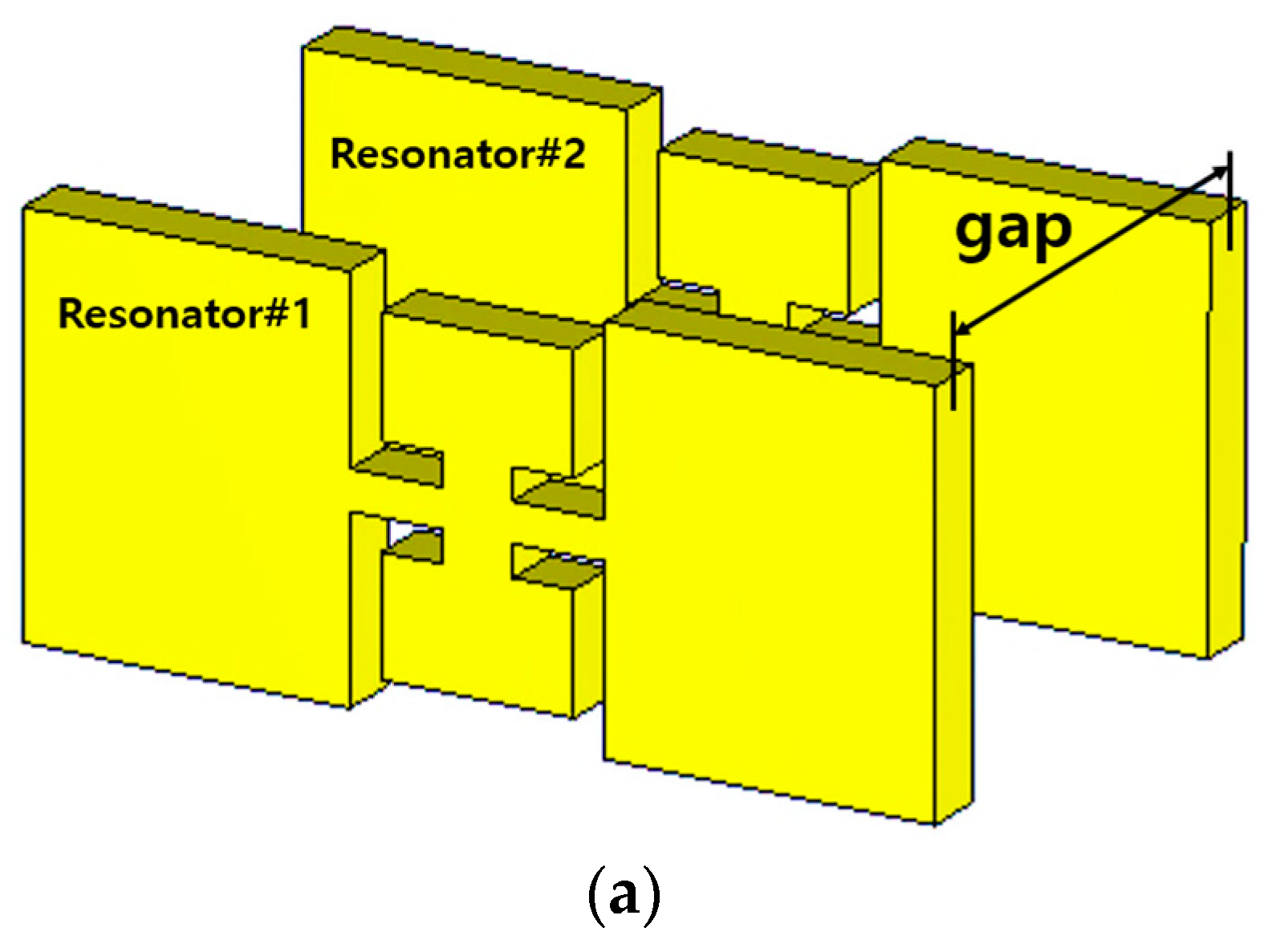

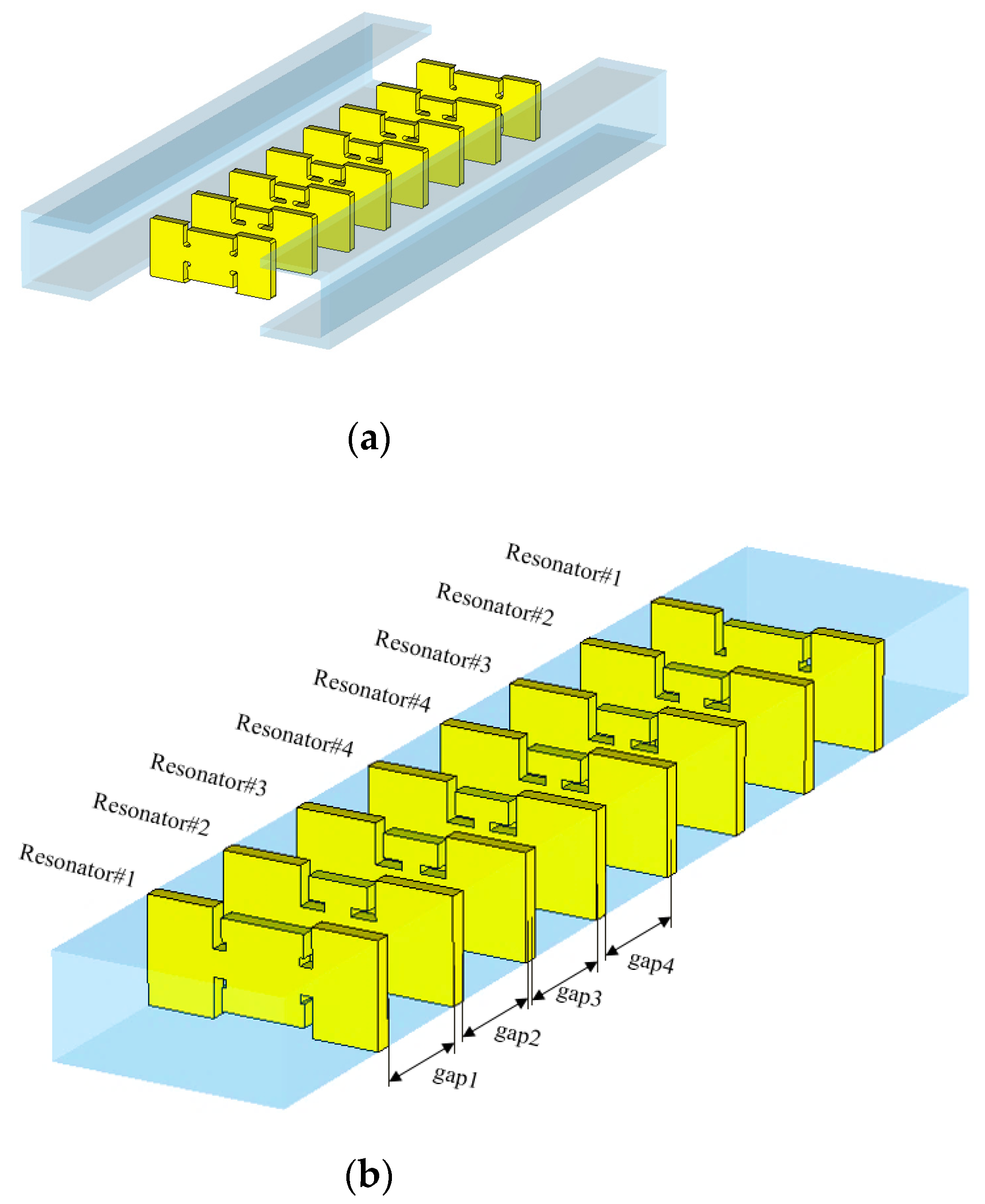

This paper proposes the novel design method of realizing the compact WG BPF of a high order for a satellite communication system by devising and using a waveguide metamaterial resonator. First, the zeroth-order resonator is formed on the cross section of the standard waveguide, compliant with the CRLH circuit model. The geometrical parameters are of 10

−1 mm to avoid the problems of fabrication tolerance, whose lower precision makes this design much tougher than others, using 10

-2 mm, with more expensive facilities. Second, the ZOR as a building block for the equivalent network of the eighth-order BPF is substituted for conventional cavities. Third, the resonators are cascaded through short waveguide sections as coupling elements to generate the passband. Additionally, the stopbands have high attenuation. Fourth, the WG BPF of ZORs and coupling elements is physically prototyped by the CNC-milling technique. Fifth, the metallic WG filter is transformed into a 3D-printed version to lower the weight of the structure, potentially proper for fast and mass production. According to [

10,

11,

12], this is the first 3D-printed metamaterial waveguide bandpass filter that has been made by the PC PEKK-based additive process. Sixth, its performance is tested. The suggested method is evaluated by circuit modeling, full-wave EM simulation and measurement. Good agreement between the theoretical results and the experimental results is unveiled from the procedural steps. As noted in the required specifications on the WG BPF, the passband has about ≤1 dB and ≤−15 dB as the insertion loss and the reflection coefficient, respectively; the stopband has 40 dB of noise suppression, whereas its 3D-printed version has a little degraded insertion loss and return loss owing to material loss and surface roughness. Regarding size reduction, the proposed PBFs of metallic and 3D-printed waveguides are 14 cm for the eighth-order filtering, while the conventional waveguide filter of the seventh order is of 20 cm in length. This effect will be obvious for much-higher-order filters and multiplexers.

3. Fabrication of the WG ZOR BPF and Testing the Prototype

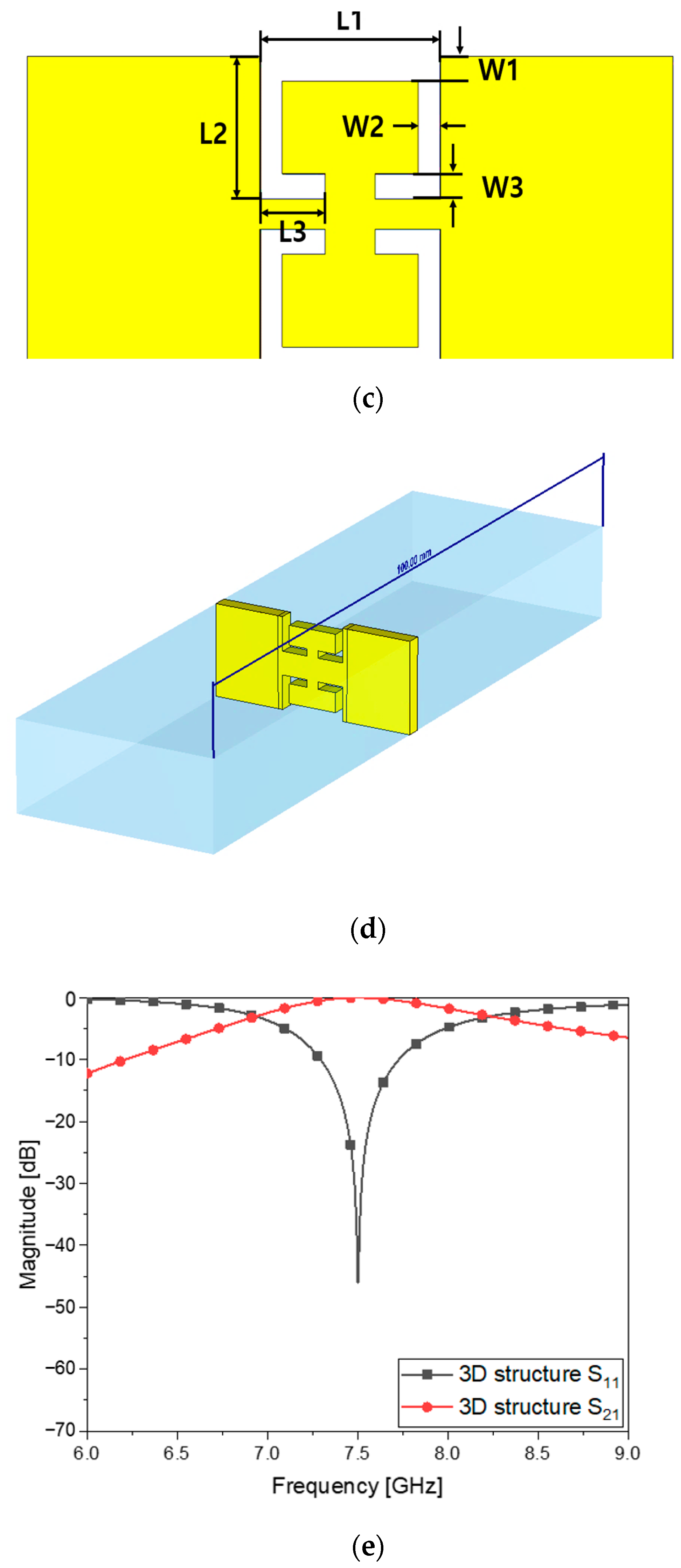

The designed waveguide filter is fabricated and measured to validate the proposed method and geometry. Because the CNC-milling technique is conducted for fabrication, taking into account that the end-mill tip cannot realize the aforementioned shapes of the cross sections of the thin resonators 100%, the round corners appear instead of the sharp right-angle ones. Though the design has been performed with the unit of 10

-1 mm as a coarse approach to ease the mechanical tolerance, the round corners are inevitable. The secondary procedure of design is performed to keep the function of the WG BPF satisfactory, as in

Figure 6. This leads to the modified values for the geometrical parameters.

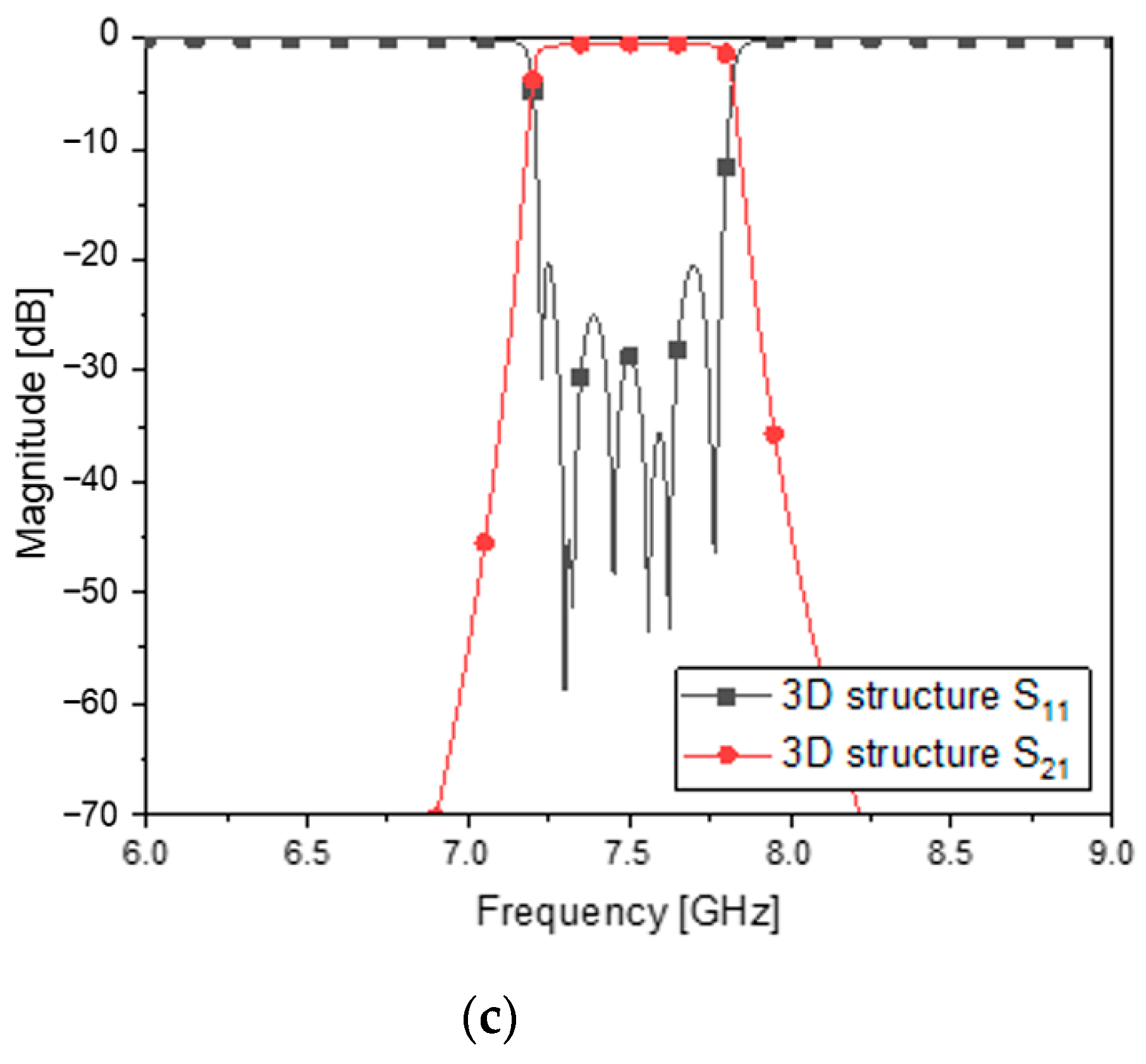

Despite the geometrical change in the front view of the flat metamaterial resonators, it is necessary to keep the frequency response compliant with the specifications. The corners become round and weaken the slot capacitance and the inductance on the edges of the metal patches and their intermediate strip. This means that at a microwave frequency band, it degrades the initial performance of the BPF. In the realistic case,

Figure 3c and

Figure 6 are rendered as in

Figure 7a–c. Some of the physical dimensions have to be fine to be in the unit of 10

−2 mm and no courser in order to achieve the required frequency response. Setting up the structure in the electromagnetic analysis software with the values for the geometrical parameters, the transmission and reflection coefficients are obtained as in

Figure 7d, which meets the design requirement. This is very different from cavity filters presented by [

15,

16,

17] in terms of shape and length, and it is physically realized as follows:

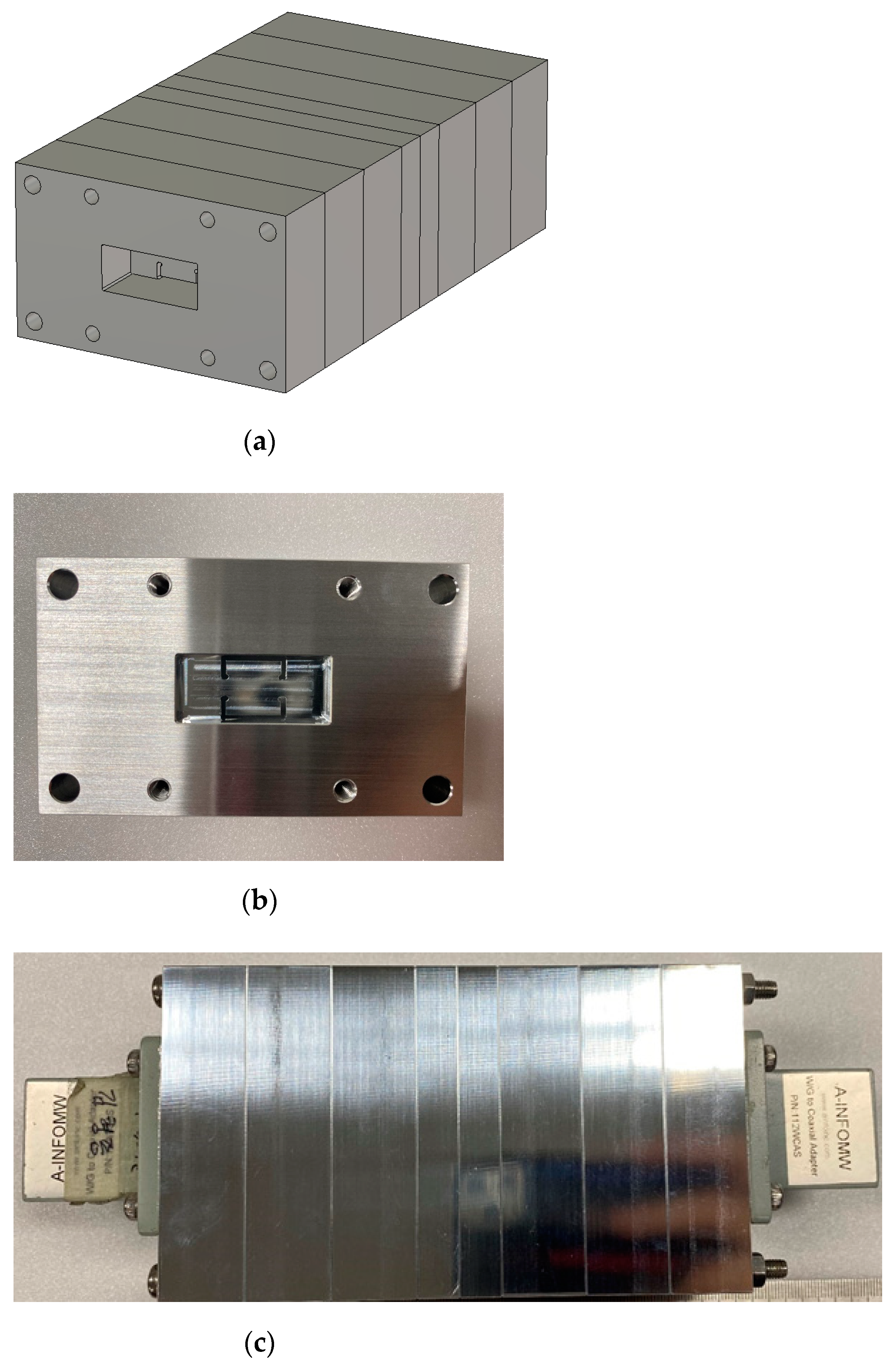

Following

Table 7, the aluminum ingot is carved to the WG metamaterial resonators and coupling sections in the milling process as in

Figure 8a, and they are pieced together to the eight-pole BPF as in

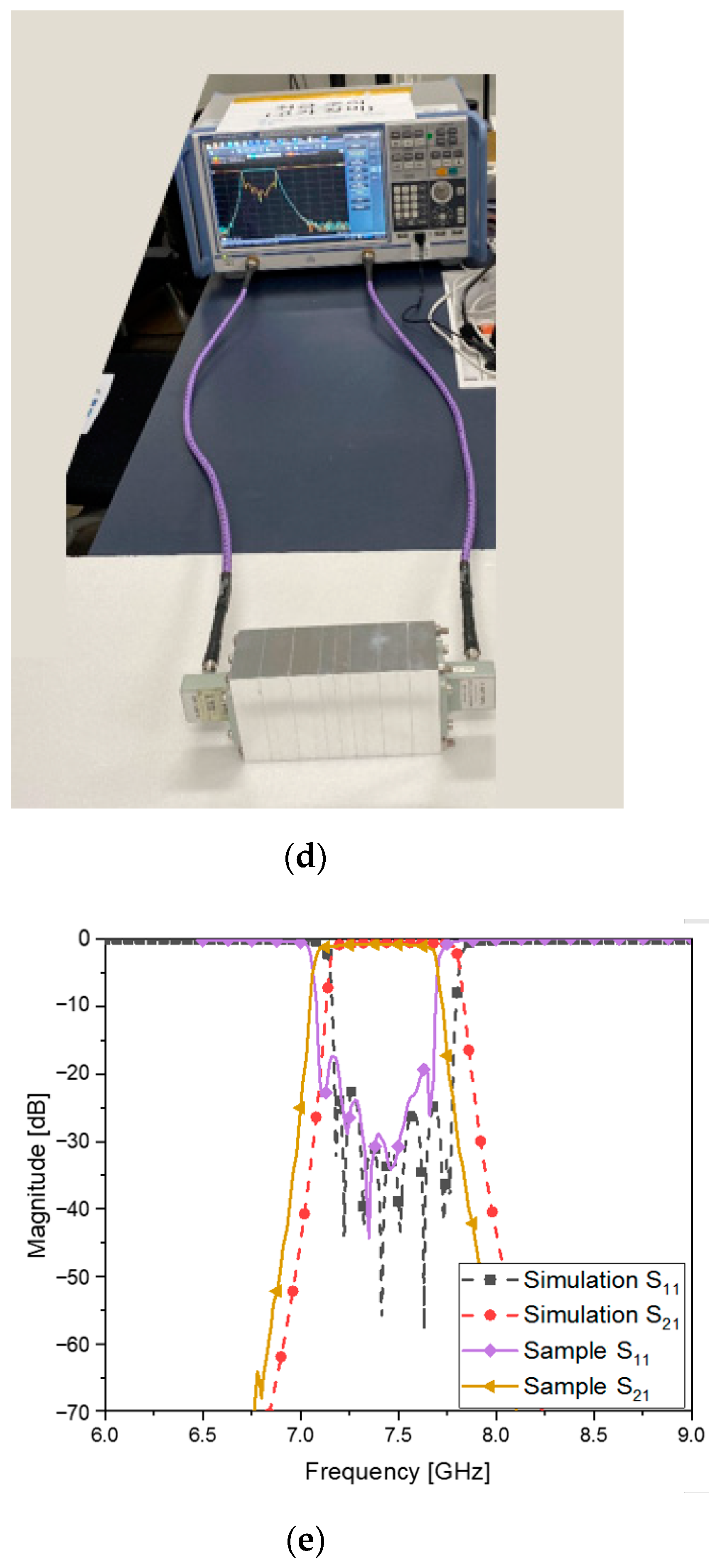

Figure 8b,c. The original structure becomes a little longer and wider because of its having parts for mechanical assembly with holes, bolts and a flange body for WG-port connecting. However, the size of the core has the length of 14 cm for the eighth-order filtering. With this harness, the WG BPF is tested to determine the frequency response. This experiment conducted as in

Figure 8d produces S

11 and S

21 as in

Figure 8e. The insertion loss and the reflection coefficients are about −0.9 dB and −19 dB in the passband, respectively. The roll-off that this manufactured metamaterial filter makes is satisfactory with an attenuation of almost −40 dB. There occurs a discrepancy between the simulated and measured results such that the frequency is shifted downward a bit. It is inferred that connected pieces in the longitudinal direction do not tightly contact each other, making a tiny gap between metal rims with rotational misalignment. This proposed geometry goes through another novel approach for technical improvement. The remarkable size reduction enabled by the introduction to the waveguide metamaterial resonators meets the 3D-printing technique on the basis of fused deposition modeling (FDM), turning into extra weight reduction.

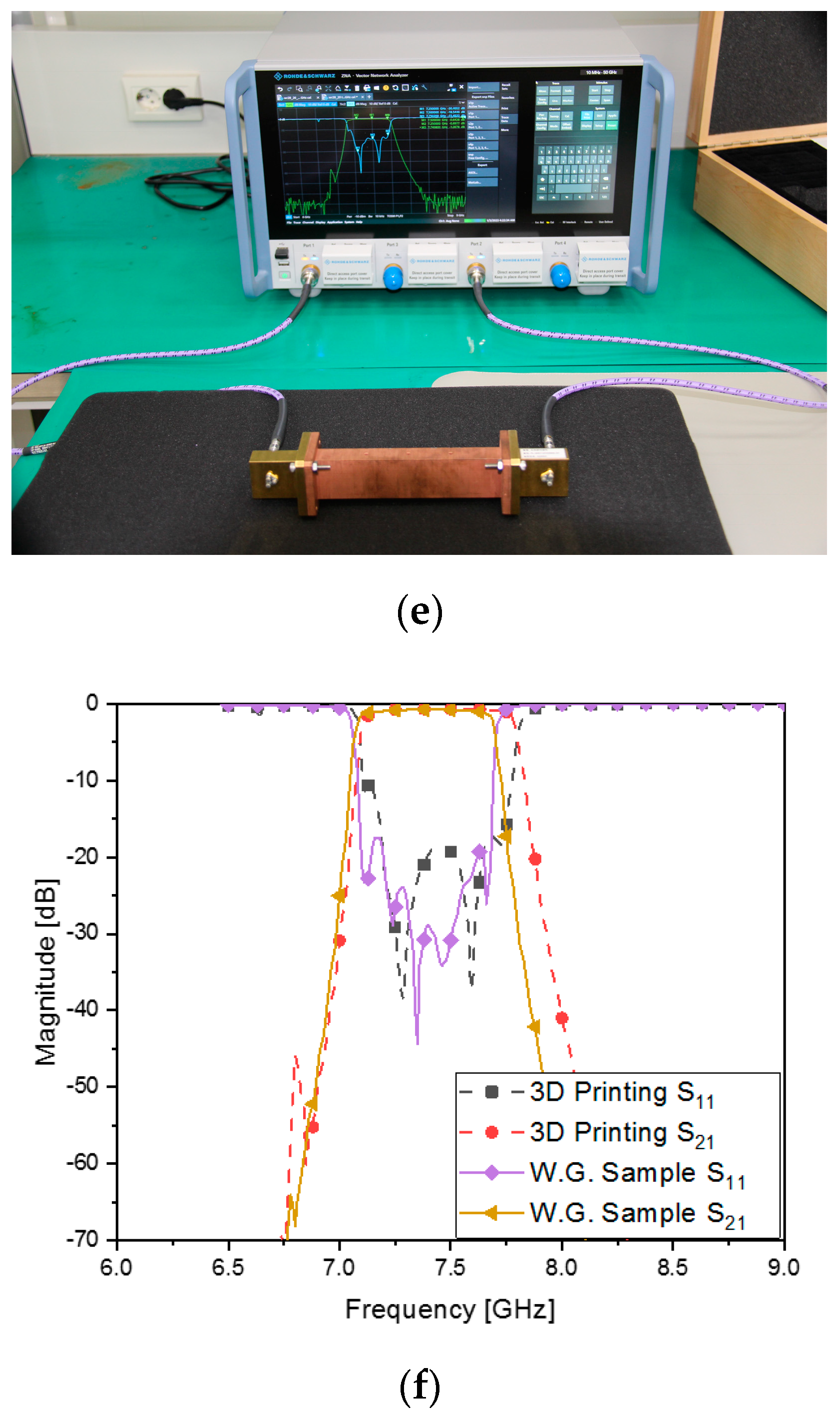

The metallic WG ZOR filter has been transformed to its 3D-printed version, manufactured as in

Figure 9a, which was introduced by [

18]. Using the 3D printer of FDM shown in

Figure 9b, a polymer named PC (Polycarbonate) is additively grown to become the geometry appearing in

Figure 9c,d owing to the filament projected by the tip of Stratasys (Fortus 450 mc) [

19]. The inner and outer surfaces of the polymer are coated with copper, combined with electroless plating. PC is a superior plastic that has high strength, excellent fracture toughness and better heat resistance compared to conventional plastics, and it uses soluble supports for forming the structure. The produced 3D-printed structure is coated with the combined dry-and-wet fused metal coating process to have electrical properties. To improve the adhesion force, a plasma dry etching is applied to the pretreatment process. Then Pd (palladium) and Sn (tin) as reaction catalysts are used to improve the plating uniformity and adhesion strength of the electroless plating. Inside the rectangular body, the space consists of the ZOR resonators and coupling elements, as in

Figure 8a,b. The novel structure is measured as in

Figure 9e, whose s-parameters match those in

Figure 9f, as the results: the electrical properties that are in good agreement with the CNC-milling-based WG BPF comply with the requirement. A small-scale error occurs, such as the upwards expansion of the upper band edge. It is assumed that the central resonators, such as numbers four and five, have the slots of the cross section disturbed by the surface roughness of the polymer and the discrepancies in width, length and thickness as blobs. Instead of one-round manufacturing, experiences in finding the right conditions for selecting the material, for positioning the tip, for the heat, for the density and for the time accumulated from repeated manufacturing will make the implementation better. Around 1362 g of the aluminum WG ZOR BPF has been lowered to approximately 54 g in the 3D-printed version. Both of the novel prototypes of the eighth-order bandpass filters are attractive to the placement in LEO satellites and microsatellites.

The characteristics of the proposed filter and reference BPF structures are compared as in

Table 8. Most of all, the proposed filter has the shortest resonator as the WG metamaterial, which results in a good insertion loss from the complete structure at the length of 140 mm for a relatively low frequency, while [

5,

7] have lengths of around 128 mm and 231 mm each for a relatively high frequency. If the proposed method is applied to 11 GHz, the total length is expected to be 95 mm, which is shorter than [

5] according to a quick estimation. This work, refs. [

5,

7] are high-order filters, giving high levels of attenuation in the stopbands, but [

15,

16,

17] take four cavities, showing poor noise-suppression effects. If [

15,

16,

17] are elongated to high-order filters, the lengths and insertion loss will be larger. Because the operation frequency of this work is much lower than others’ and has to use a WR-112 cross section as the largest, the 7.5-GHz filter might be the heaviest from

Table 1 when the same order is assumed for all the compared cases. Thus, the total length must be as small as possible, enabled by the metamaterial resonators. The proposed filter is compared with the nonmetamaterial filter in terms of size and function.

The cavity filter as a nonmetamaterial RF component is also designed to meet the requirement in

Table 1. The total length of the conventional filter is 222 mm, and its frequency response is shown in

Figure 10. S

11 conv and S

21 conv are satisfactory and are almost the same as the s-parameters of the proposed filter from the comparison. For the same cross section, the proposed filter is shorter than the conventional waveguide filter, as clearly seen in

Figure 10.

4. Conclusions

A novel design method and geometry of the waveguide bandpass filter are suggested. Substantial size reduction and excellent bandpass filtering functions are made possible by coming up with the waveguide CRLH resonator, which leads to a very thin structure, much shorter than the half wavelength for the conventional cavities. The ZOR phenomenon is generated with the transverse geometrical parameters of the waveguide cross section, unlike other metamaterials, which utilize longitudinal line segments. The ZOR as the thin waveguide part does not block the incoming RF signal but instead passes it to the next ZOR. By cascading the ZORs through transmission sections as the coupling elements, the passband becomes distinct with the steeper skirt in the stopband. An eighth-order ZOR BPF is designed and simulated, moving to the stage of fabrication. It is manufactured into the aluminum waveguide filter and the PC 3D-printed WG ZOR BPF. The prototyped BPFs are measured and compared with each other and with simulated results. As to the passband, the insertion loss and the reflection coefficient are around ≤1 dB and ≤−15 dB, respectively, from simulation to measurement. The attenuation of ≥40 dB at 7 GHz and 8 GHz is achieved as desired in the specifications. The length of the WG ZOR BPF is 14 cm for the eighth pole, but the length of the conventional one is 20 cm even in the seven-pole case. To take a further step in decreasing the weight of the filter, the CNC-milling prototype and the 3D-printing technology are developed. The frequency responses are acceptable to use in the satellite transponder. The proposed filters make the LEO and scientific satellites much lighter, with a weight of 54 g, which is a weight that has been greatly reduced compared with the conventional WG filters.