Displacement Measurement Method Based on Double-Arrowhead Auxetic Tubular Structure

Abstract

:1. Introduction

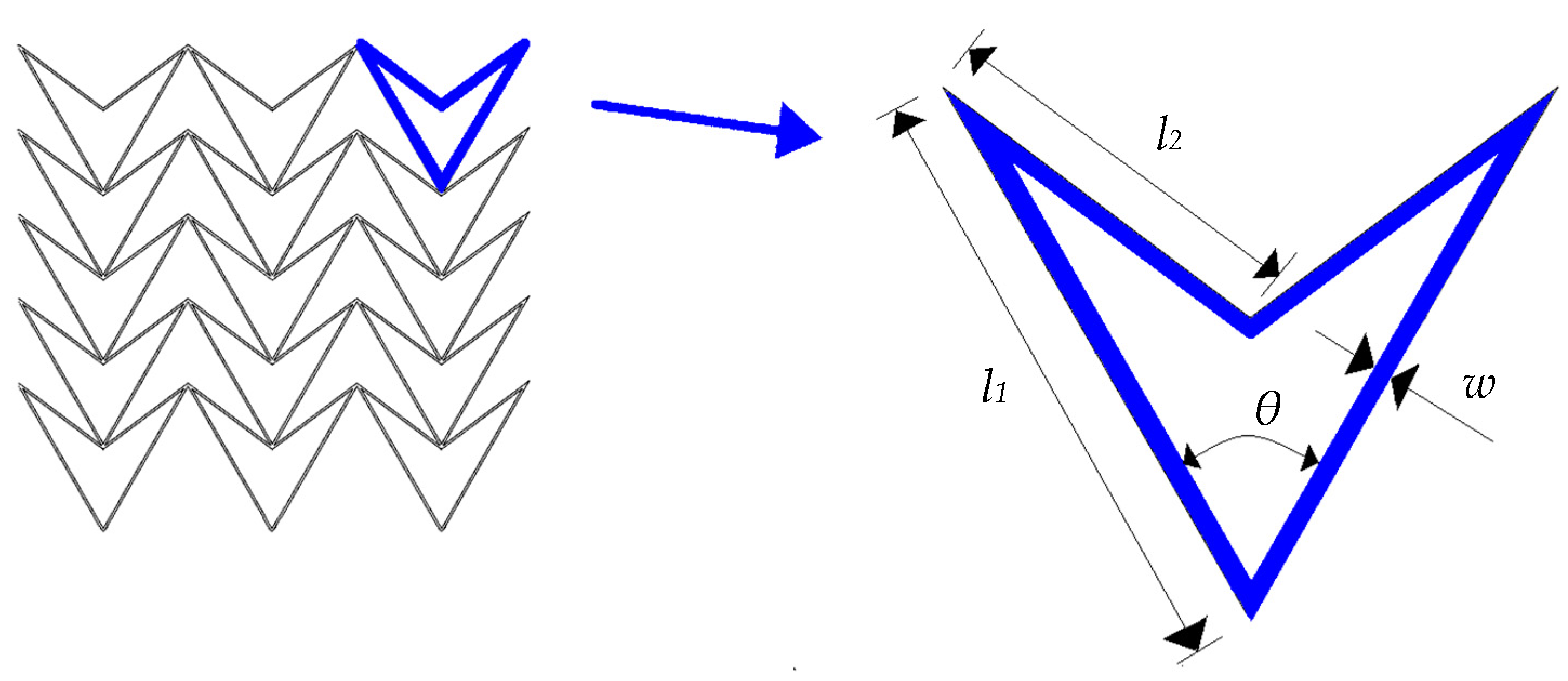

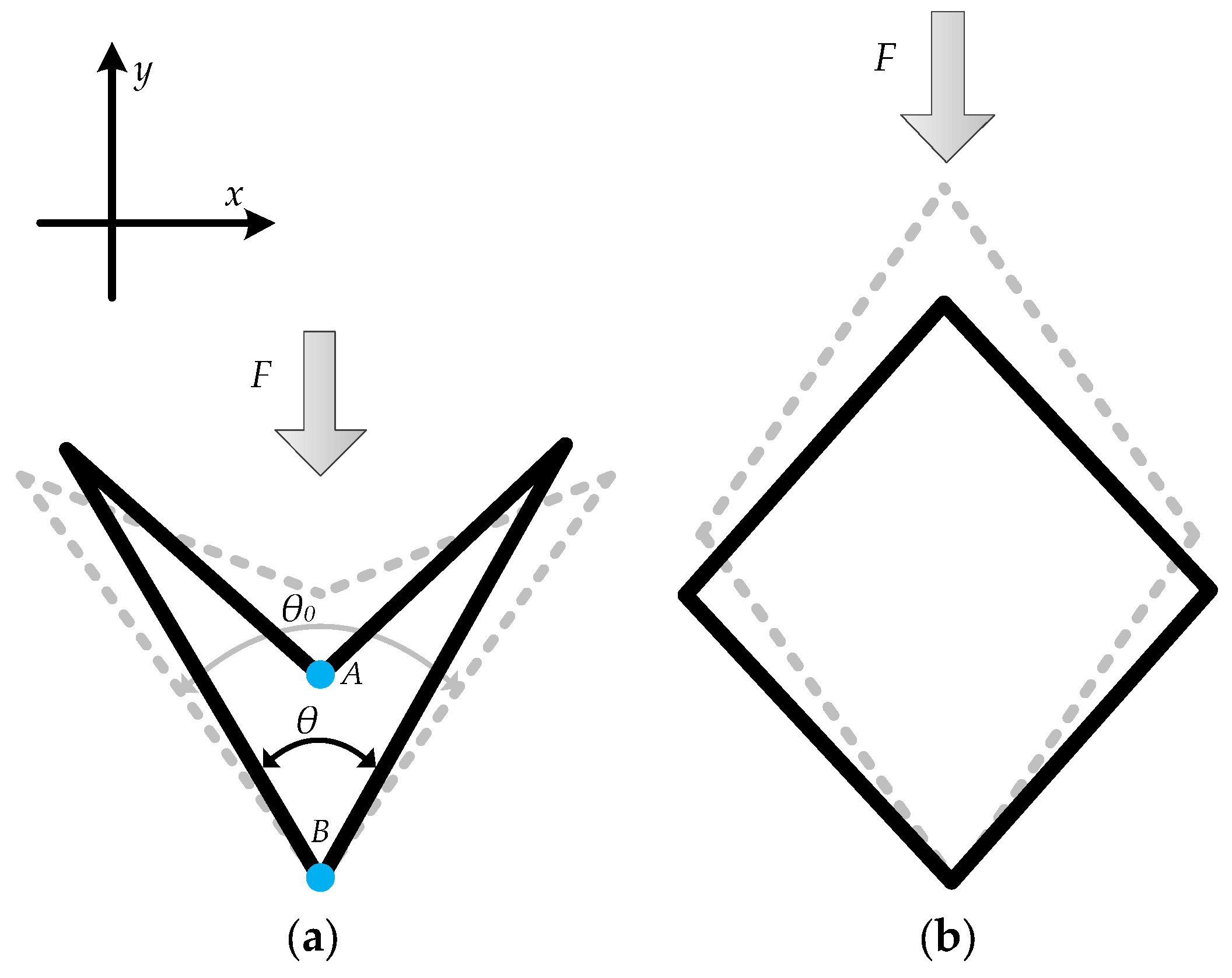

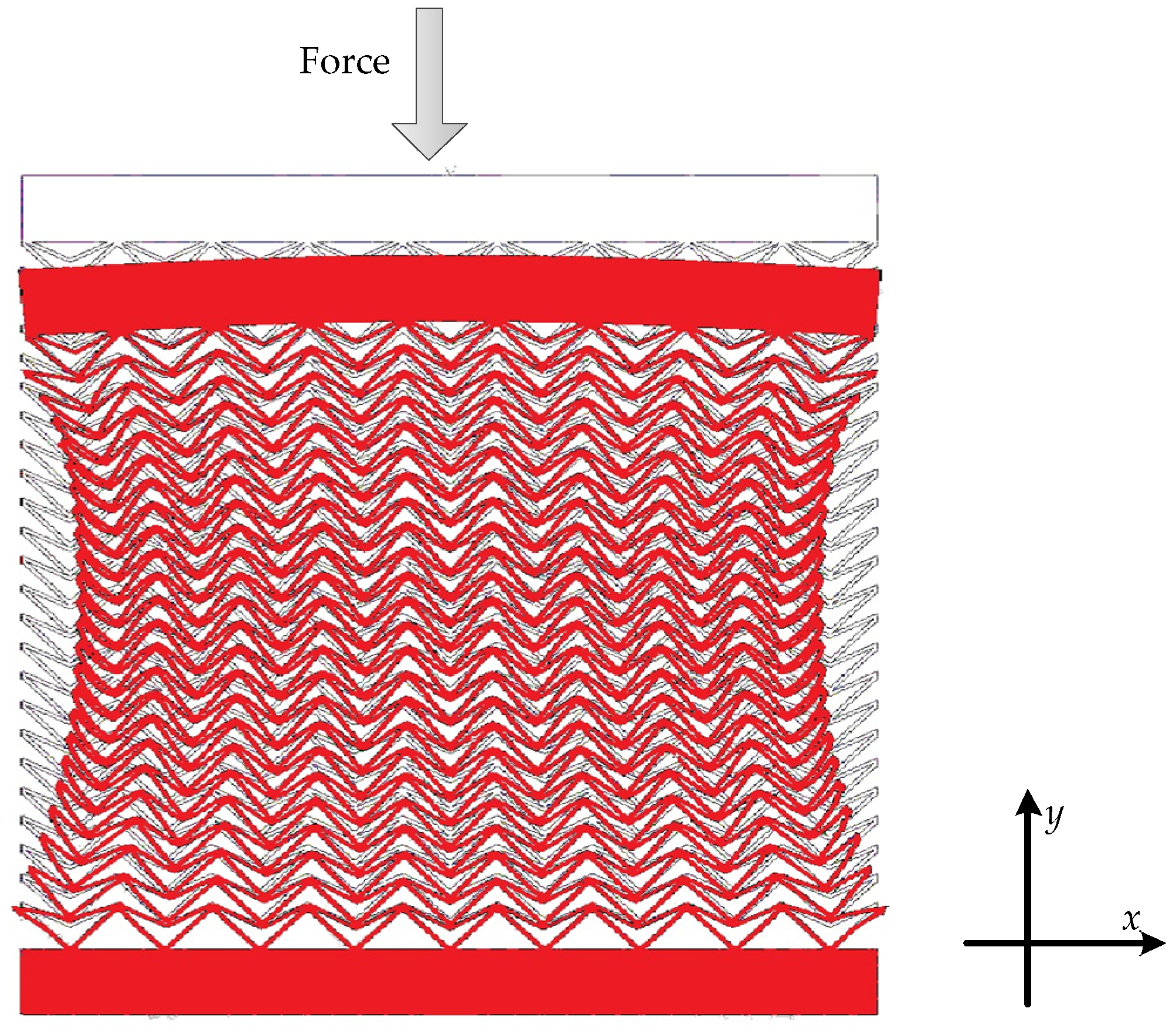

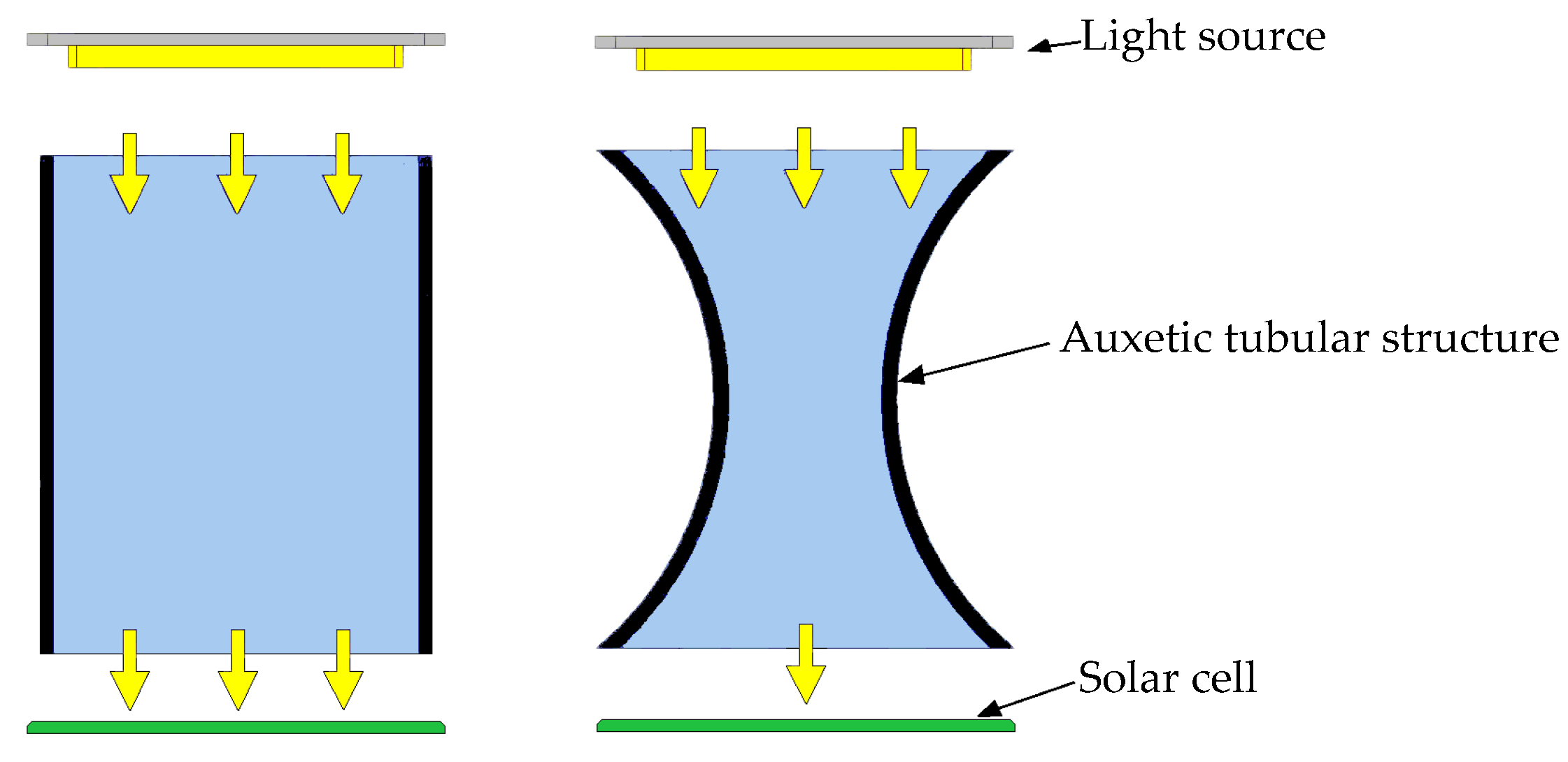

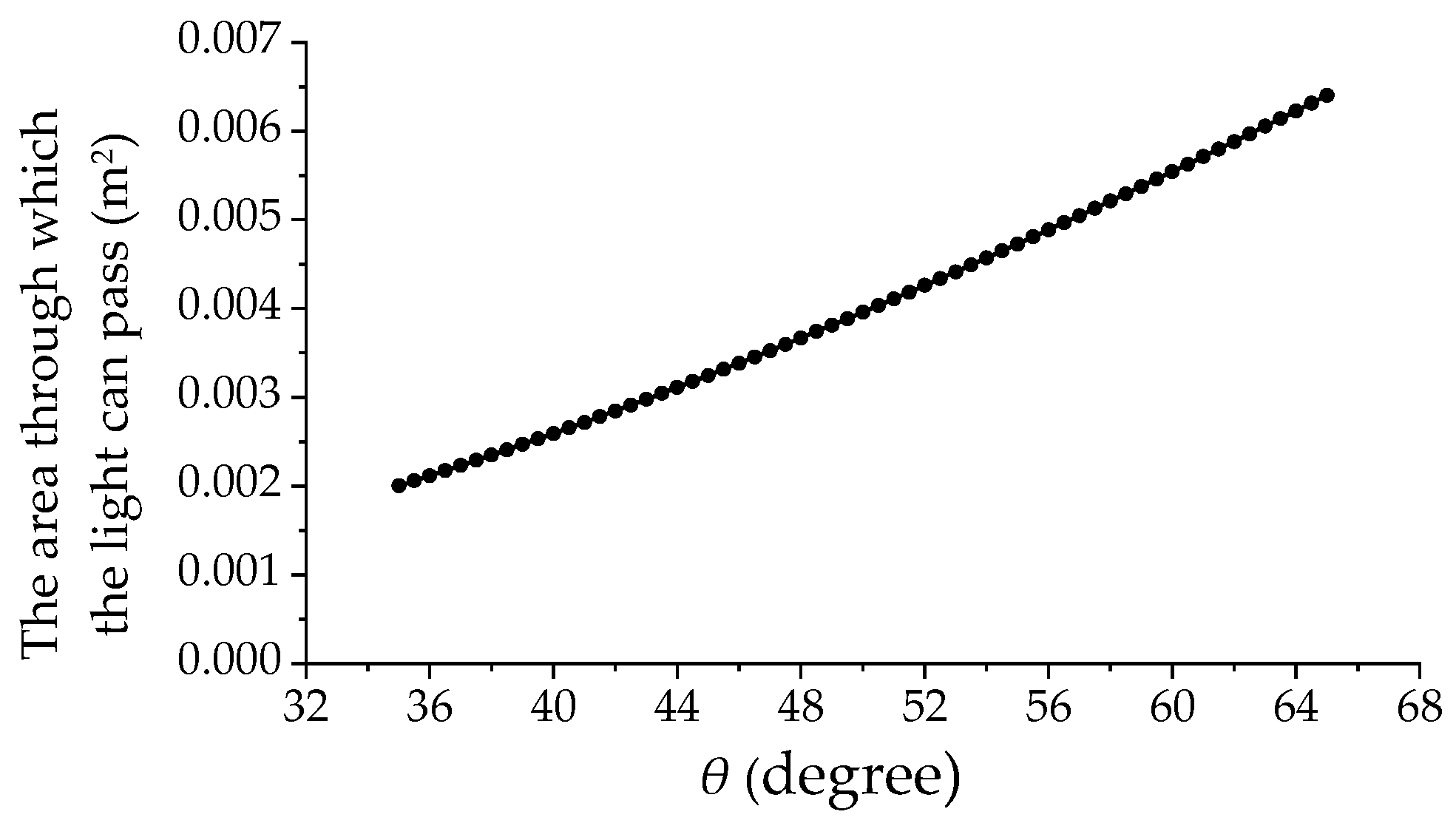

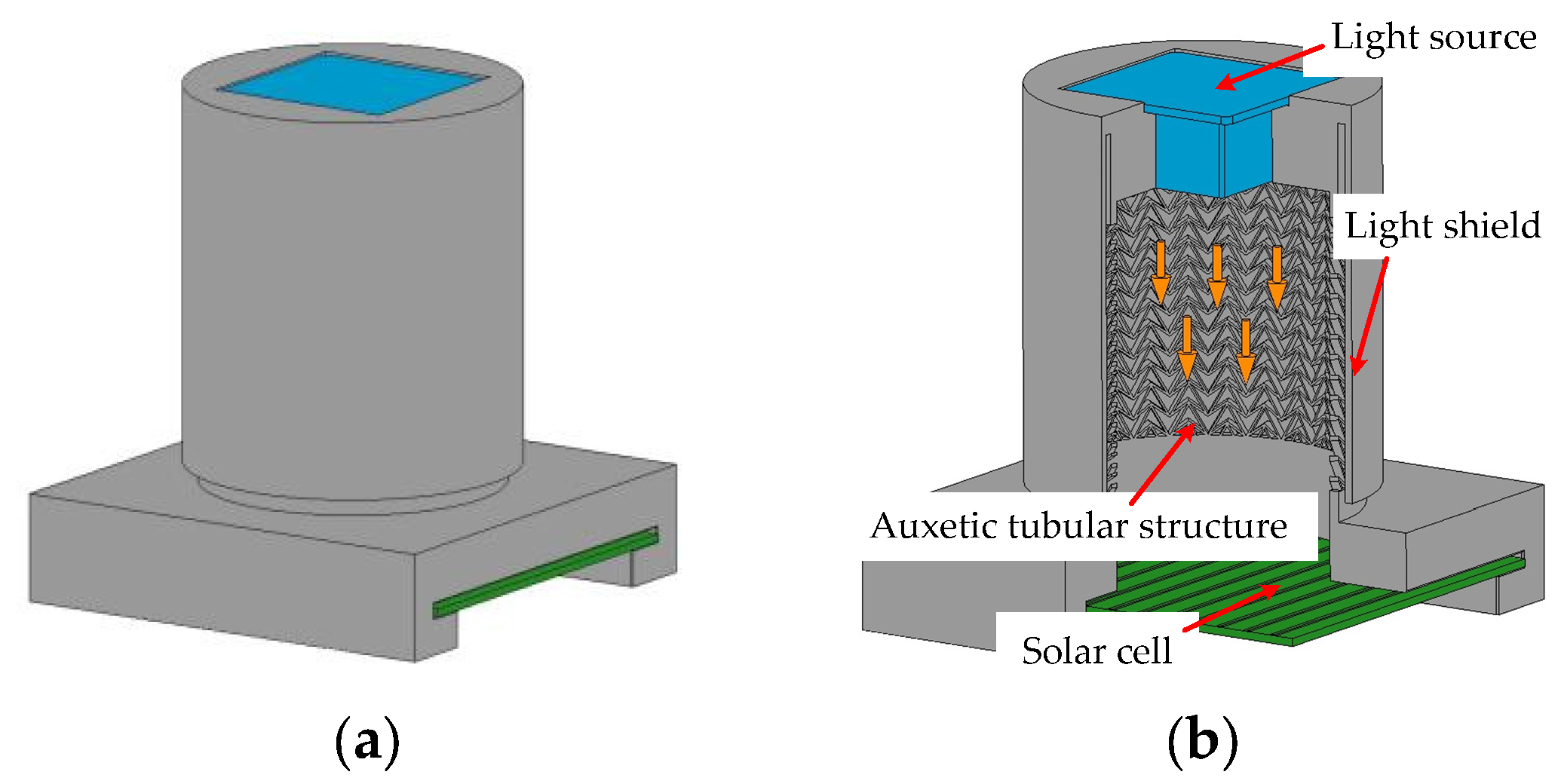

2. Structures and Methods

3. Experimental Study

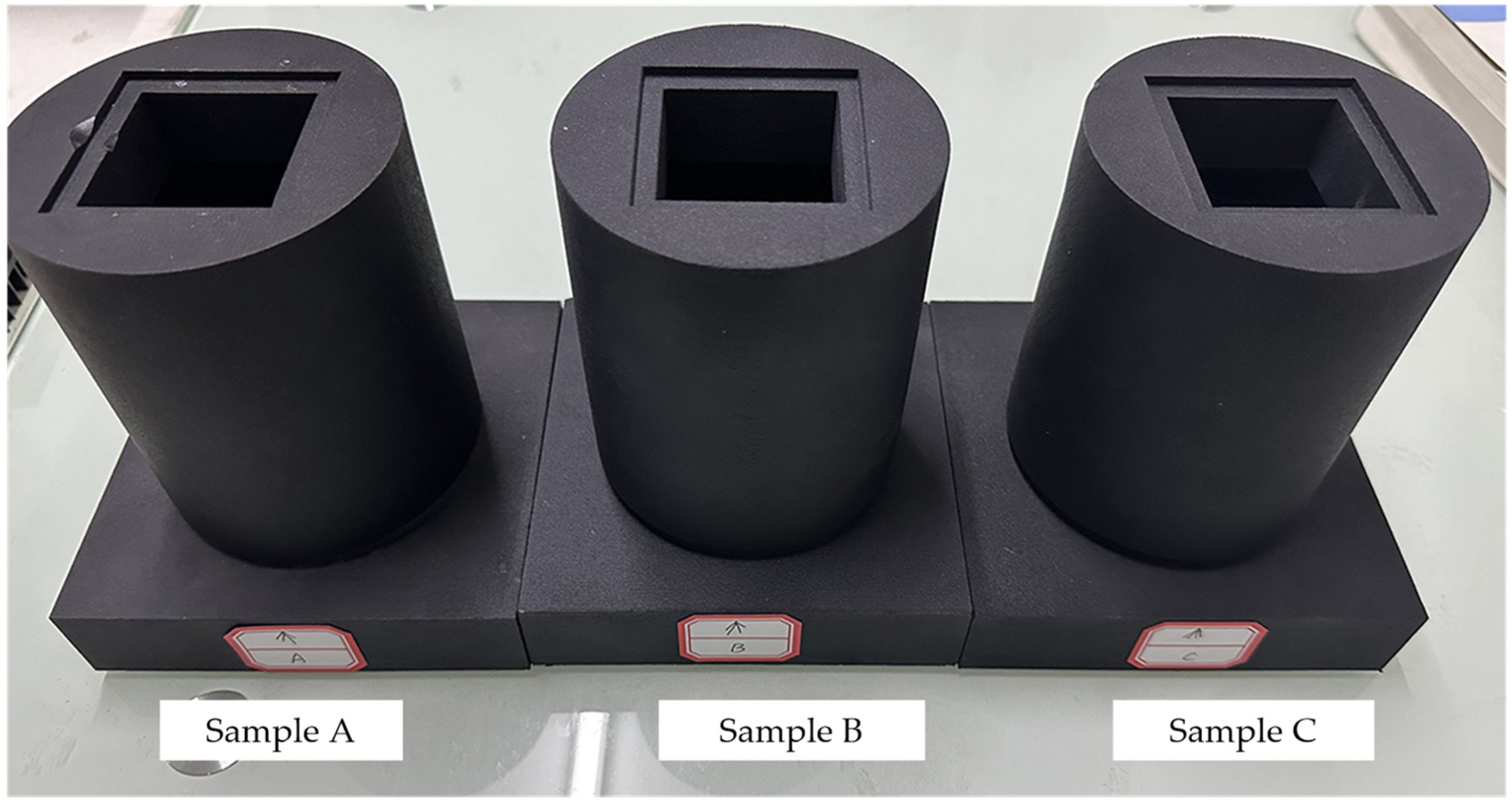

3.1. Specimen Geometry

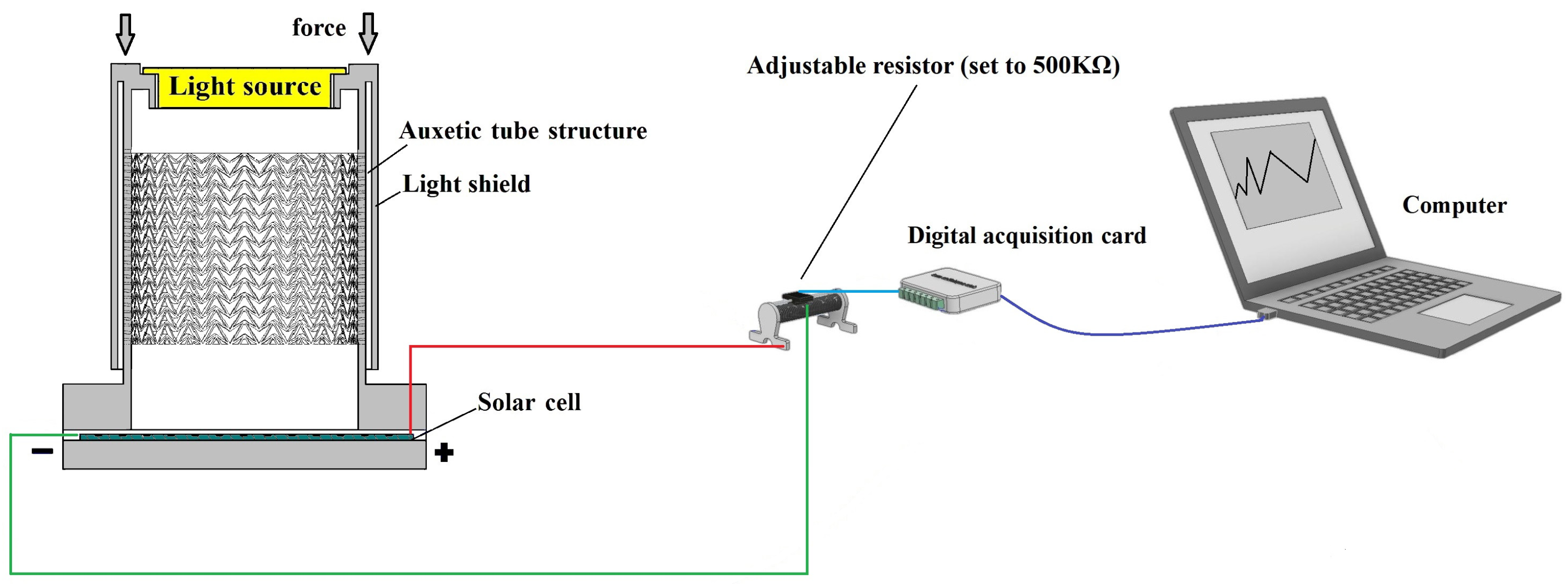

3.2. Experimental Set-Up

4. Results and Discussion

5. Conclusions

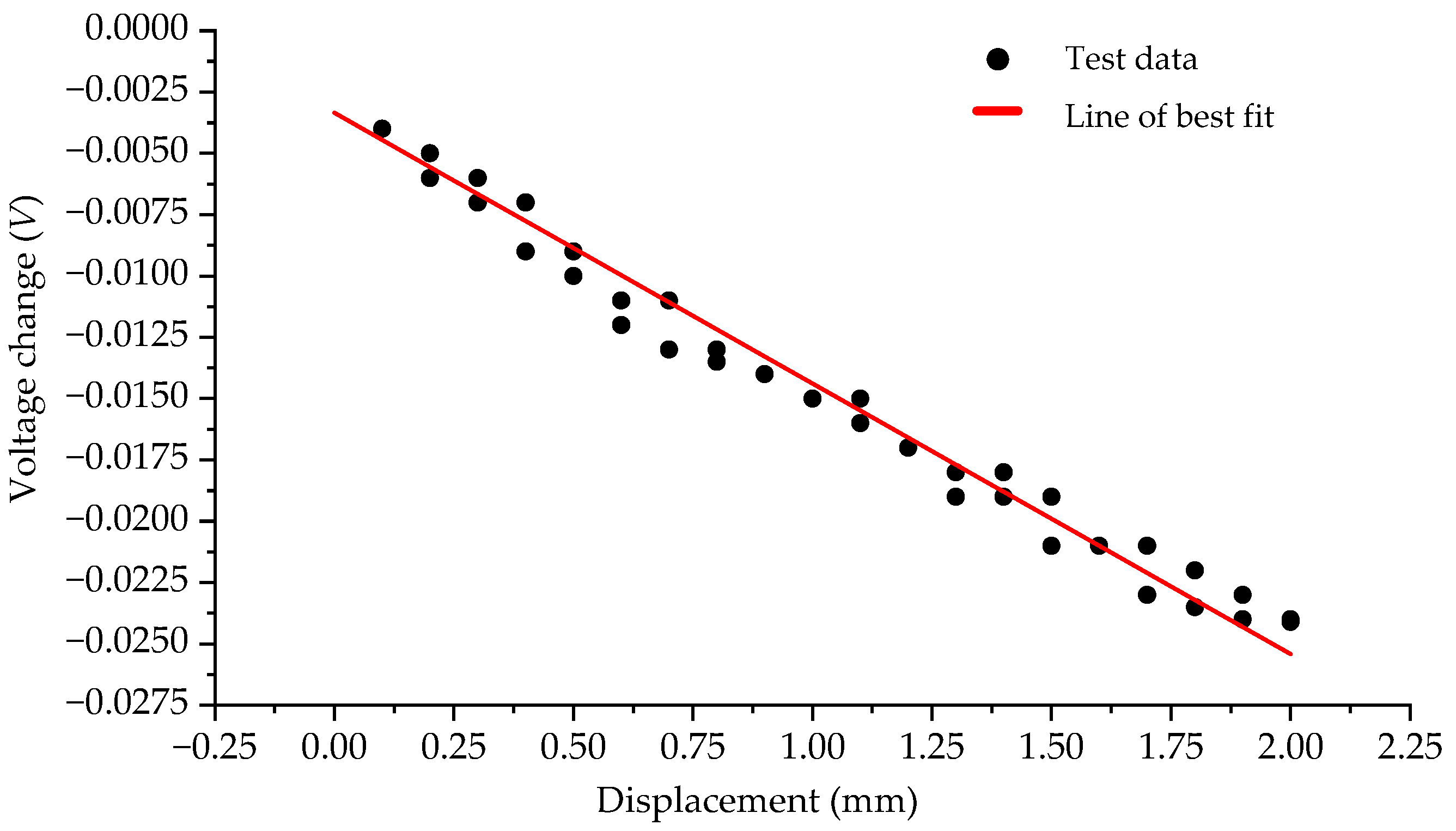

- The proposed displacement measurement method using ATSs and solar cells demonstrates good linearity overall and the linear error does not exceed 8%.

- The sensitivity of the proposed method is determined to be 0.011 V/mm. This sensitivity can be further improved by optimizing the design of the DA ATS.

- Good repeatability with minor variations in sensitivity indicates that the proposed method is robust.

- The close agreement between the experimental results obtained using different samples as measurement devices suggests that the proposed method can maintain a high level of reliability and sensitivity when replacing the measurement device, and further supports the robustness and dependability.

- The proposed measurement method offers the advantage of independence between the measurement device, light source, and solar cell. This allows for easy replacement or interchangeability, customization based on specific requirements, and simplified maintenance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Massimo, S.; Gianluca, B.; Vincenzo, S.; Leila, S.; Giuseppe, F. A survey on current-mode interfaces for bio signals and sensors. Sensors 2023, 23, 2194. [Google Scholar] [CrossRef]

- Simic, M.; Radovanovic, M.; Stavrakis, A.K.; Jeoti, V. Wireless readout of resistive sensors. IEEE Sens. J. 2022, 22, 4235–4245. [Google Scholar] [CrossRef]

- Hidalgo-López, J.A. A simple digital readout circuit for differential resistive or capacitive sensors. Meas. Sci. Technol. 2023, 34, 085117. [Google Scholar] [CrossRef]

- Yuta, K.; Hidetoshi, T. Spiral spring-supported force plate with an external eddy current displacement sensor. Actuators 2023, 12, 16. [Google Scholar] [CrossRef]

- Tong, P.; Wu, L.; Yanchen, A.; Su, R.; Wu, Y.L. A novel eddy current sensor for displacement measurement with high accuracy and long range. IEEE Sens. J. 2023, 23, 12066–12705. [Google Scholar] [CrossRef]

- Wang, S.C.; Xie, B.R.; Huang, S.M. Design and analysis of small size eddy current displacement sensor. Sensors 2022, 22, 7444. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Zhang, S.; Zhang, F.; Duan, Z.; Wang, Y. Monitoring the opening of rapid palatal expansion (RPE) in a 3D-printed skull model using fiber optic F-P sensors. Sensors 2023, 23, 7168. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, C.; Zheng, T.; Wu, H.; Wu, Q.; Wang, Y. Wearable optical fiber sensors in medical monitoring applications: A review. Sensors 2023, 23, 6671. [Google Scholar] [CrossRef]

- Pendao, C.; Silva, I. Optical fiber sensors and sensing networks: Overview of the main principles and applications. Sensors 2022, 22, 7554. [Google Scholar] [CrossRef]

- Lee, T.; Beresna, M.; Masoudi, A.; Brambilla, G. Enhanced-backscattering and enhanced-backreflection fibers for distributed optical fiber sensors. J. Light. Technol. 2023, 41, 4051–4064. [Google Scholar] [CrossRef]

- Evans, K.E.; Alderson, A. Auxetic materials: Functional materials and structures from lateral thinking! Adv. Mater. 2000, 12, 617–628. [Google Scholar] [CrossRef]

- Körner, C.; Liebold-Ribeiro, Y. A systematic approach to identify cellular auxetic materials. Smart Mater. Struct. 2015, 24, 025013. [Google Scholar] [CrossRef]

- Mardling, P.; Alderson, A.; Jordan-Mahy, N.; Le Maitre, C.L. The use of auxetic materials in tissue engineering. Biomater. Sci. 2020, 8, 2074–2083. [Google Scholar] [CrossRef]

- Tahir, D.; Zhang, M.; Hu, H. Auxetic materials for personal protection: A review. Phys. Status Solidi B 2022, 259, 2200324. [Google Scholar] [CrossRef]

- Mir, M.; Ali, M.N.; Sami, J.; Ansari, U. Review of mechanics and applications of auxetic structures. Adv. Mater. Sci. Eng. 2014, 2014, 753496. [Google Scholar] [CrossRef]

- Muslija, A.; Lantada, A.D. Deep reactive ion etching of auxetic structures: Present capabilities and challenges. Smart Mater. Struct. 2014, 23, 087001. [Google Scholar] [CrossRef]

- Balan P, M.; Mertens A, J.; Raju Bahubalendruni, M.V.A. Auxetic mechanical metamaterials and their futuristic developments: A state-of-art review. Mater. Today Commun. 2023, 34, 105285. [Google Scholar] [CrossRef]

- Sinha, P.; Mukhopadhyay, T. Programmable multi-physical mechanics of mechanical metamaterials. Mat. Sci. Eng. R 2023, 155, 100745. [Google Scholar] [CrossRef]

- Guo, M.-F.; Yang, H.; Ma, L. Design and analysis of 2D double-U auxetic honeycombs. Thin-Walled Struct. 2020, 155, 106915. [Google Scholar] [CrossRef]

- Stefan, T.; Ana, B.; Alina, S. Complex analysis of an auxetic structure under compressive loads. Sustainability 2023, 15, 6805. [Google Scholar] [CrossRef]

- Jefferson, A.J.; Johannes, S.; Andreas, S.; Farrukh, H.; Kumar, S. Dynamic crushing of tailored honeycombs realized via additive manufacturing. Int. J. Mech. Sci. 2022, 219, 107126. [Google Scholar] [CrossRef]

- Wang, X.-T.; Wang, B.; Li, X.-W.; Ma, L. Mechanical properties of 3D re-entrant auxetic cellular structures. Int. J. Mech. Sci. 2017, 131–132, 396–407. [Google Scholar] [CrossRef]

- Peyman, T.; Mahdi, S.; Sanaz, K. Flexural analysis of second-order corrugated composite cores: Experimental, numerical, and theoretical studies. J. Strain. Anal. Eng. 2023, 58, 560–571. [Google Scholar] [CrossRef]

- Sohrab, K.; Dan, Z. Corrugated all-composite sandwich structures. Part 1: Modeling. Compos. Sci. Technol. 2009, 69, 913–919. [Google Scholar] [CrossRef]

- Magnucka-Blandzi, E.; Magnucki, K.; Wittenbeck, L. Mathematical modeling of shearing effect for sandwich beams with sinusoidal corrugated cores. Appl. Math. Model. 2015, 39, 2796–2808. [Google Scholar] [CrossRef]

- Chulho, Y.; Hitesh, D.V.; Young, C. Behavior of auxetic structures under compression and impact forces. Smart Mater. Struct. 2018, 27, 025012. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H. Auxetic materials and their potential applications in textiles. Text. Res. J. 2014, 84, 1600–1611. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H. Tensile and forming properties of auxetic warp-knitted spacer fabrics. Text. Res. J. 2017, 87, 1925–1937. [Google Scholar] [CrossRef]

- Ge, Z.; Hu, H. Innovative three-dimensional fabric structure with negative Poisson’s ratio for composite reinforcement. Text. Res. J. 2013, 83, 543–550. [Google Scholar] [CrossRef]

- Shirzad, M.; Zolfagharian, A.; Bodaghi, M.; Nam, S.Y. Auxetic metamaterials for bone-implanted medical devices: Recent advances and new perspectives. Eur. J. Mech. A-Solids 2023, 98, 104905. [Google Scholar] [CrossRef]

- Chetan, J.C.; Prafull, S.T.; Santosh, K.S. 3D printing of composite sandwich structures for aerospace applications. In High-Performance Composite Structures, Composites Science and Technology; Praveen Kumar, A., Sadasivuni, K.K., AlMangour, B., Abdul bin Majid, M.S., Eds.; Springer: Singapore, 2022; pp. 45–73. [Google Scholar] [CrossRef]

- Dong, S.; Hu, H. Sensors based on auxetic materials and structures: A review. Materials 2023, 16, 3603. [Google Scholar] [CrossRef]

- Li, P.; Zhang, X.; Zhang, Z.; Wen, Q. Application of re-entrant honeycomb auxetic structure in force measurements. IEEE Sens. J. 2021, 21, 24202–24208. [Google Scholar] [CrossRef]

- Wen, Q.; Li, P.; Zhang, Z.; Hu, H. Application of negative Poisson’s ratio honeycomb structure in force measurement. Sens. Rev. 2022, 42, 1–7. [Google Scholar] [CrossRef]

- Zhang, Z.; Wen, Q.; Li, P.; Hu, H. Application of double arrowhead auxetic honeycomb structure in dis-placement measurement. Sens. Actuators A Phys. 2022, 333, 113218. [Google Scholar] [CrossRef]

- Jitkanya, W.; Alex, T.G.; Peter, A.D.; Leire, M.; Bruce, B.; Robert, M.S.; Haritz, S.; Corie, L.C.; Alshakim, N. 3D printing ionogel auxetic frameworks for stretchable sensors. Adv. Mater. Technol. 2019, 4, 1900452. [Google Scholar] [CrossRef]

- Saman, F.; Gary, G.; Jeong-Beom, I. MetaMembranes for the sensitivity enhancement of wearable piezoelectric metasensors. Sensors 2022, 22, 1909. [Google Scholar] [CrossRef]

- Li, Y.; Luo, S.; Yang, M.-C.; Liang, R.; Zeng, C. Poisson ratio and piezoresistive sensing: A new route to high-performance 3d flexible and stretchable sensors of multimodal sensing capability. Adv. Funct. Mater. 2016, 26, 2900–2908. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, Z.; Matsuhisa, N.; Qi, D.; Leow, W.R.; Yang, H.; Yu, J.; Chen, G.; Liu, Y.; Wan, C.; et al. Auxetic mechanical metamaterials to enhance sensitivity of stretchable strain sensors. Adv. Mater. 2018, 30, 1706589. [Google Scholar] [CrossRef]

- Tyler, J.C.; Brett, C.H.; Pierre, R.; Alexander, V.S.; Carlo, M. HACS: Helical auxetic yarn capacitive strain sensors with sensitivity beyond the theoretical limit. Adv. Mater. 2022, 35, 2209321. [Google Scholar] [CrossRef]

- Xu, B.; Arias, F.; Brittain, S.T.; Zhao, X.M.; Grzybowski, B.; Torquato, S.; Whitesides, G.M. Making negative Poisson’s ratio microstructures by soft lithography. Adv. Mater. 1999, 11, 1186–1189. [Google Scholar] [CrossRef]

- Lee, J.W.; Soman, P.; Park, J.H.; Chen, S.; Cho, D.-W. A tubular biomaterial construct exhibiting a negative poisson’s ratio. PLoS ONE 2016, 11, e0155681. [Google Scholar] [CrossRef] [PubMed]

- Luo, C.; Han, C.Z.; Zhang, X.Y.; Zhang, X.G.; Ren, X.; Xie, Y.M. Design, manufacturing and applications of auxetic tubular structures: A review. Thin-Walled Struct. 2021, 163, 107682. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, X.; Ren, X.; Xie, Y.; Wu, Y.; Zhou, Y.; Wang, S.; Han, C. A novel type of tubular structure with auxeticity both in radial direction and wall thickness. Thin-Walled Struct. 2021, 163, 107758. [Google Scholar] [CrossRef]

- Guo, M.-F.; Yang, H.; Ma, L. Design and characterization of 3D AuxHex lattice structures. Int. J. Mech. Sci. 2020, 181, 105700. [Google Scholar] [CrossRef]

- Gao, Q.; Liao, W.-H.; Wang, L.; Huang, C. Crashworthiness optimization of cylindrical negative Poisson’s ratio structures with inner liner tubes. Struct. Multidiscip. Optim. 2021, 64, 4271–4286. [Google Scholar] [CrossRef]

- Ali, M.N.; Busfield, J.J.C.; Rehman, I.U. Auxetic oesophageal stents: Structure and mechanical properties. Int. J. Mech. Sci. 2014, 25, 527–553. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Xu, Z.; Zhang, Z.; Lei, H.; Bai, Y.; Fang, D. Mechanical properties and energy absorption capability of AuxHex structure under in-plane compression: Theoretical and experimental studies. Int. J. Mech. Sci. 2019, 159, 43–57. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, S.-H.; Qin, Q.-H.; Wang, H. Tunable compressive properties of a novel auxetic tubular material with low stress level. Thin-Walled Struct. 2021, 164, 107882. [Google Scholar] [CrossRef]

- Wang, W.; Jin, Y.; Mu, Y.; Zhang, M.; Du, J. A novel tubular structure with negative Poisson’s ratio based on gyroid-type triply periodic minimal surfaces. Virtual Phys. Prototy. 2023, 18, e2203701. [Google Scholar] [CrossRef]

- Wang, L.; Chen, M.; Chen, G.; Luo, T.; Liu, F. Loading capacity prediction of the auxetic tubular lattice structures by multiscale shakedown analysis. Compos. Struct. 2023, 314, 116938. [Google Scholar] [CrossRef]

- Plewa, J.; Plonska, M.; Feliksik, K. An experimental study of auxetic tubular structures. Materials 2022, 15, 5245. [Google Scholar] [CrossRef] [PubMed]

- Qiao, J.X.; Chen, C.Q. Impact resistance of uniform and functionally graded auxetic double arrowhead honeycombs. Int. J. Impact. Eng. 2015, 83, 47–58. [Google Scholar] [CrossRef]

- Thinvongpituk, C.; Chomkwah, V. Experimental and numerical studies on the behavior of cylindrical and conical shells with varying thickness along the length subjected to axial compression. Glob. J. Res. Eng. 2010, 10, 92–100. [Google Scholar]

- Gu, L.; Xu, Q.; Zheng, D.; Zou, H.; Liu, Z.; Du, Z. Analysis of the mechanical properties of double arrowhead auxetic metamaterials under tension. Text. Res. J. 2020, 90, 2411–2427. [Google Scholar] [CrossRef]

- Chulho, Y.; Hitesh, D.V.; Young, C. Analyses on the in-plane impact resistance of auxetic double arrowhead honeycombs. J. Appl. Mech. 2015, 82, 051007. [Google Scholar] [CrossRef]

| Parameter Name | Value | Unit |

|---|---|---|

| θ | 35–65 | degree |

| l1 | 5.5 | mm |

| l2 | 4.5 | mm |

| w | 0.5 | mm |

| N | 48 | / |

| Parameter Name | Value | Unit |

|---|---|---|

| θ | 60 | degree |

| l1 | 5.5 | mm |

| l2 | 4.5 | mm |

| w | 0.5 | mm |

| Parameter Name | Value | Unit |

|---|---|---|

| Length | 110 | mm |

| Width | 80 | mm |

| Conversion efficiency | 20% | / |

| Experiment Order | Sensitivity | Unit |

|---|---|---|

| 1st | 0.01088 | V/mm |

| 2nd | 0.01085 | V/mm |

| 3rd | 0.01089 | V/mm |

| 4th | 0.01086 | V/mm |

| 5th | 0.01083 | V/mm |

| Sample | Sensitivity | Unit |

|---|---|---|

| A | 0.01103 | V/mm |

| B | 0.01088 | V/mm |

| C | 0.01112 | V/mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, Q.; Li, P.; Zhang, Z.; Hu, H. Displacement Measurement Method Based on Double-Arrowhead Auxetic Tubular Structure. Sensors 2023, 23, 9544. https://doi.org/10.3390/s23239544

Wen Q, Li P, Zhang Z, Hu H. Displacement Measurement Method Based on Double-Arrowhead Auxetic Tubular Structure. Sensors. 2023; 23(23):9544. https://doi.org/10.3390/s23239544

Chicago/Turabian StyleWen, Qingguo, Pengju Li, Zhengkai Zhang, and Hong Hu. 2023. "Displacement Measurement Method Based on Double-Arrowhead Auxetic Tubular Structure" Sensors 23, no. 23: 9544. https://doi.org/10.3390/s23239544

APA StyleWen, Q., Li, P., Zhang, Z., & Hu, H. (2023). Displacement Measurement Method Based on Double-Arrowhead Auxetic Tubular Structure. Sensors, 23(23), 9544. https://doi.org/10.3390/s23239544