Design and Implementation of an Embedded Data Acquisition System for Vehicle Vertical Dynamics Analysis

Abstract

:1. Introduction

2. Materials and Methods

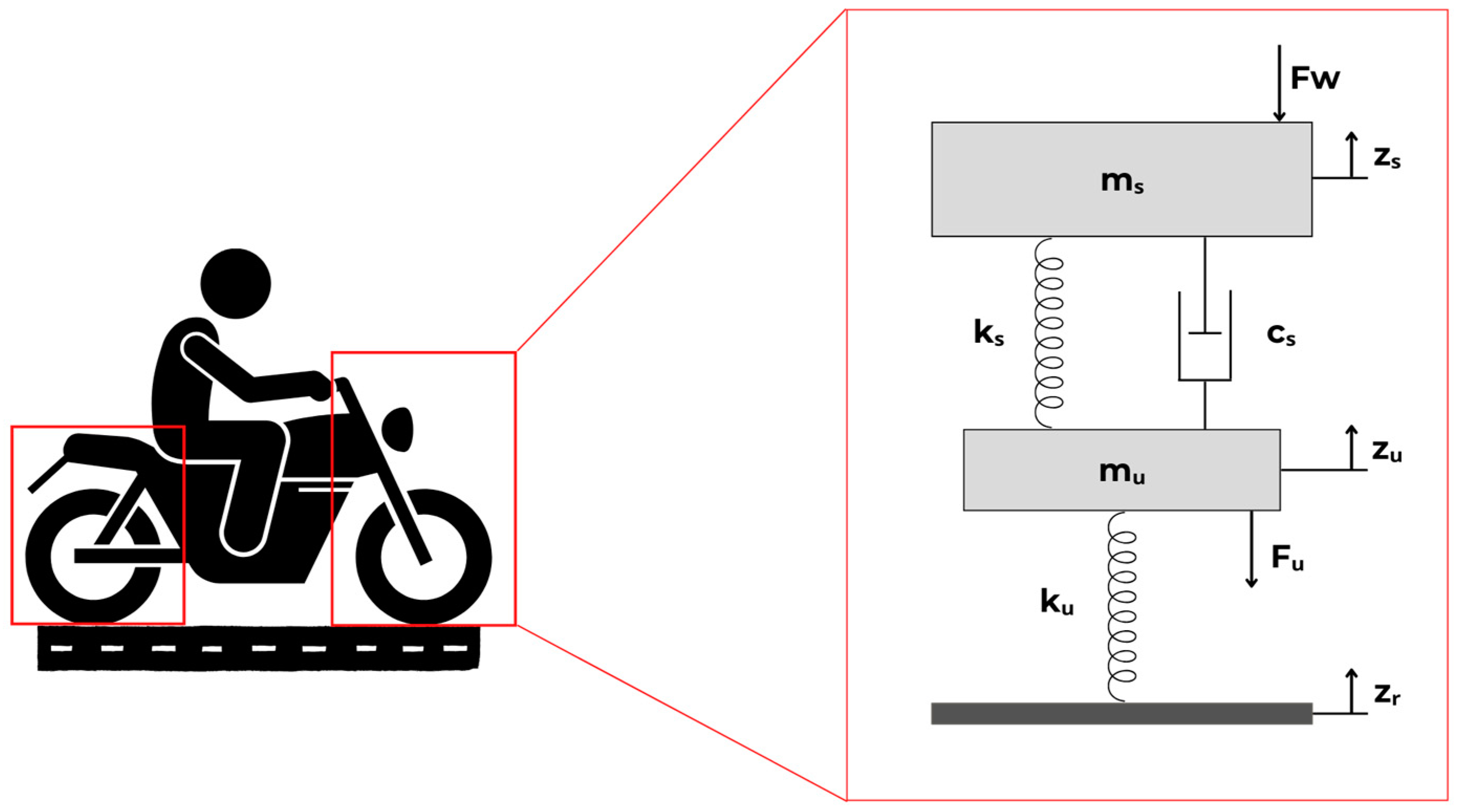

2.1. Modeling of the Mass-Spring-Damper System

2.2. Mathematical Modeling of the System

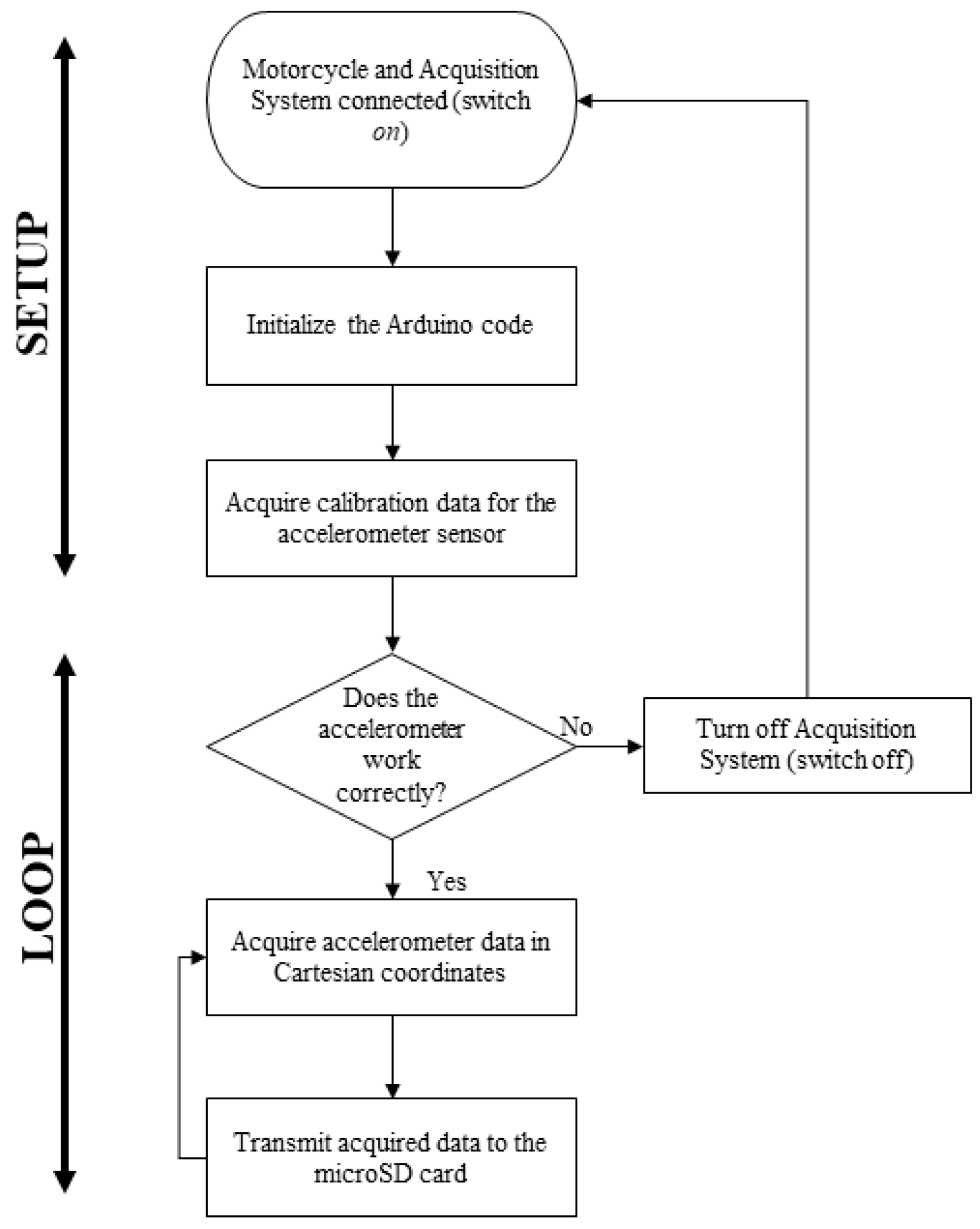

2.3. Embedded Data Acquisition System

2.4. Vehicle Implementation

3. Results and Discussions

- Condition 1 (C1): cobblestone pavement (170 m);

- Condition 2 (C2): asphalt pavement with three-speed reducers (750 m).

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fernandes, C.G.; Del Rio Duarte, M. A Semi-Analytical Approach for Vehicle Ride Simulation. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 2008. [Google Scholar] [CrossRef]

- Junior, F.G.; Silva, F.N.; Miranda, B.M.; David, D.; Diniz, S.; Silva, A.A. Dynamic Response Analysis of an Absorber Subjected to Vibration. 2013, pp. 7162–7171. Available online: https://abcm.org.br/anais/cobem/2013/PDF/1738.pdf (accessed on 29 August 2023).

- Neto, A.J.V.; Fernandes, C.G.; Pedroso, R.; Vianna, E. Trucks Ride Simulation—Tuning Optimization. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Automatyka, P.D.P.; Dąbek, P. Evaluation of Low-Cost MEMS Accelerometers for Measurements of Velocity of Unmanned Vehicles. Pomiary Autom. Robot. 2013, 17, 102–113. [Google Scholar]

- Agrawal, S.; Kumar, V.; Anand, N.; Agarwal, V.K.; Islam, A. Development of Data Acquisition System and Data Analysis Technique for Automotive Applications. In Proceedings of the 2016 World Conference on Futuristic Trends in Research and Innovation for Social Welfare (Startup Conclave), Coimbatore, India, 29 February–1 March 2016; Volume 50, p. 16358542. [Google Scholar] [CrossRef]

- Pal Singh, H.; Singh, R. Low Cost Data Acquisition System for Road-Vehicle Interaction Using Arduino Board. J. Phys. Conf. Ser. 2021, 1831, 012031. [Google Scholar] [CrossRef]

- Baruah, J.K.; Dhar, S.; Bera, R. Field Trial of a Low-Cost Data Acquisition System Developed for Advanced Driver-Assistance System. Telecommun. Radio Eng. (Engl. Transl. Elektrosvyaz Radiotekhnika) 2020, 79, 703–711. [Google Scholar] [CrossRef]

- Pandey, A.K.; Arora, S. Onboard Data Acquisition System to Monitor the Vehicle. In Ambient Communications and Computer Systems; Advances in Intelligent Systems and Computing; Hu, Y.-C., Tiwari, S., Mishra, K.K., Trivedi, M.C., Eds.; Springer Singapore: Singapore, 2019; Volume 904, pp. 265–271. ISBN 978-981-13-5933-0. [Google Scholar]

- Ulinuha, A.; Jatmiko; Riza, A.G. Design and Implementation of Data Acquisition Device and Instrumentation Based on Microcontroller for Electric Motorcycle. In 2nd Borobudur International Symposium on Science and Technology (BIS-STE 2020); Atlantis Press: Dordrecht, The Netherlands, 2021; Volume 203, pp. 17–24. [Google Scholar] [CrossRef]

- Ab Rahman, A.F.; Selamat, H.; Alimin, A.J.; Muslim, M.T.; Msduki, M.M.; Khamis, N. Automotive Real-Time Data Acquisition Using Wi-Fi Connected Embedded System. Elektr. J. Electr. Eng. 2019, 18, 7–12. [Google Scholar] [CrossRef]

- Elmehraz, N.; Katkoori, S.; Kourtellis, A.; Lin, P.S. Prototyping of a Portable Data Logging Embedded System for Naturalistic Motorcycle Study. In Proceedings of the 2013 International Conference on Connected Vehicles and Expo (ICCVE), Las Vegas, NV, USA, 2–6 December 2013; pp. 471–472. [Google Scholar] [CrossRef]

- Teli, S.; Mani, C. Smart Real Time Embedded Arduino Based Data Acquisition System. Int. J. Res. Eng. Technol. 2015, 04, 258–262. [Google Scholar] [CrossRef]

- Moreno, C.; González, A.; Olazagoitia, J.L.; Vinolas, J. The Acquisition Rate and Soundness of a Low-Cost Data Acquisition System (LC-DAQ) for High Frequency Applications. Sensors 2020, 20, 524. [Google Scholar] [CrossRef] [PubMed]

- Cossalter, V.; Doria, A.; Garbin, S.; Lot, R. Frequency-Domain Method for Evaluating the Ride Comfort of a Motorcycle. Veh. Syst. Dyn. 2006, 44, 339–355. [Google Scholar] [CrossRef]

- Andria, G.; Attivissimo, F.; Di Nisio, A.; Lanzolla, A.M.L.; Pellegrino, A. Development of an Automotive Data Acquisition Platform for Analysis of Driving Behavior. Measurement 2016, 93, 278–287. [Google Scholar] [CrossRef]

- Vehicle Load Transfer—BND TechSource. Available online: https://vdocuments.net/vehicle-load-transfer-5693b63c3499b.html (accessed on 4 May 2021).

- Konieczny, Ł. Analysis of Simplifications Applied in Vibration Damping Modelling for a Passive Car Shock Absorber. Shock Vib. 2016, 2016, 6182847. [Google Scholar] [CrossRef]

- Gillespie, T.D. Fundamentals of Vehicle Dynamics; Society of Automotive Enginners, Inc.: Warrendale, PA, USA, 1992. [Google Scholar]

- Freitas, L.M.P., Jr. A Study about the Vertical Dynamic of a MacPherson Vehicle Suspension System. Available online: https://www.teses.usp.br/teses/disponiveis/18/18149/tde-19012011-114031/en.php (accessed on 12 July 2023).

- Kulkarni, A.; Ranjha, S.A.; Kapoor, A. A Quarter-Car Suspension Model for Dynamic Evaluations of an in-Wheel Electric Vehicle. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 232, 1139–1148. [Google Scholar] [CrossRef]

- Soares, A.L.V. Elastokinematic and Ride Analisys of a Off-Road Competition Vehicle Double Rate Suspension Using a Multibody Model; Biblioteca Digital de Teses e Dissertações da Universidade de São Paulo: São Carlos, Brazil, 2007. [Google Scholar]

- González, A.; Olazagoitia, J.L.; Vinolas, J. A Low-Cost Data Acquisition System for Automobile Dynamics Applications. Sensors 2018, 18, 366. [Google Scholar] [CrossRef] [PubMed]

- Ambrož, M. Raspberry Pi as a Low-Cost Data Acquisition System for Human Powered Vehicles. Measurement 2017, 100, 7–18. [Google Scholar] [CrossRef]

- Rajeev, N. PratheekSudi Natural Frequency, Ride Frequency and Their Influence in Suspension System Design. J. Eng. Res. Appl. 2019, 9, 60–64. [Google Scholar]

- Cossalter, V. Motorcycle Dynamics, 2nd ed.; Cossalter, V., Ed.; Wiley Online Library: Hoboken, NJ, USA, 2006; ISBN 9781430308614. [Google Scholar]

- Puigrefagut, A.R. Analysis and Improvements in the Damping Mechanism of a Motocross Bike; University of Girona: Girona, Spain, 2016. [Google Scholar]

- Eligar, S.S.; Banakar, R.M. Data Acquisition Model for Road Profiling and Its Statistical Validation. In Proceedings of the 2018 International Conference on Electrical, Electronics, Communication, Computer, and Optimization Techniques (ICEECCOT), Msyuru, India, 14–15 December 2018; pp. 84–89. [Google Scholar]

- Park, J.-W.; Sim, S.-H.; Jung, H.-J.; Spencer, B.F., Jr. Development of a Wireless Displacement Measurement System Using Acceleration Responses. Sensors 2013, 13, 8377–8392. [Google Scholar] [CrossRef]

| Parameter | Front Suspension | Rear Suspension |

|---|---|---|

| mu (kg) | 30.15 | 30.15 |

| ms (kg) | 70.35 | 70.35 |

| ks (N/mm) | 4.22 | 80.00 |

| cs (N·s/mm) | 31.53 | 194.07 |

| ku (N/mm) | 115.54 | 106.19 |

| Parameter | Value/Range |

|---|---|

| Operating voltage (V) | 3 to 5 |

| ADC resolution (bits) | 16 |

| Gyro range (°/s) | ±250, 500, 1000, 2000 |

| Accelerometer range (g; 9.81 m/s2) | ±2, ±4, ±8, ±16 |

| Temperature sensor reading (°C) | 40 to 85 |

| Component | Quantity | Unitary Value ($) |

|---|---|---|

| Arduino Pro Mini | 2 | 5.04 |

| Accelerometer MPU-6050 | 2 | 3.36 |

| MicroSD card module | 2 | 2.61 |

| TP4056 lithium battery charger module | 2 | 1.29 |

| MT3608 Step-Up Boost Power Converter | 2 | 2.02 |

| Power rocker switch | 2 | 0.36 |

| RGB Led | 2 | 0.12 |

| 18650 Battery holder 3 Slots | 2 | 1.97 |

| 18650 Lithium battery | 2 | 3.17 |

| Total | 39.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venceslau de Souto, J.I.; Barbosa da Rocha, Á.; Duarte, R.N.C.; de Moura Fernandes, E. Design and Implementation of an Embedded Data Acquisition System for Vehicle Vertical Dynamics Analysis. Sensors 2023, 23, 9491. https://doi.org/10.3390/s23239491

Venceslau de Souto JI, Barbosa da Rocha Á, Duarte RNC, de Moura Fernandes E. Design and Implementation of an Embedded Data Acquisition System for Vehicle Vertical Dynamics Analysis. Sensors. 2023; 23(23):9491. https://doi.org/10.3390/s23239491

Chicago/Turabian StyleVenceslau de Souto, Joyce Ingrid, Álvaro Barbosa da Rocha, Raimundo Nonato Calazans Duarte, and Eisenhawer de Moura Fernandes. 2023. "Design and Implementation of an Embedded Data Acquisition System for Vehicle Vertical Dynamics Analysis" Sensors 23, no. 23: 9491. https://doi.org/10.3390/s23239491

APA StyleVenceslau de Souto, J. I., Barbosa da Rocha, Á., Duarte, R. N. C., & de Moura Fernandes, E. (2023). Design and Implementation of an Embedded Data Acquisition System for Vehicle Vertical Dynamics Analysis. Sensors, 23(23), 9491. https://doi.org/10.3390/s23239491