Development of an Intelligent Wind Erosion Monitoring System

Abstract

:1. Introduction

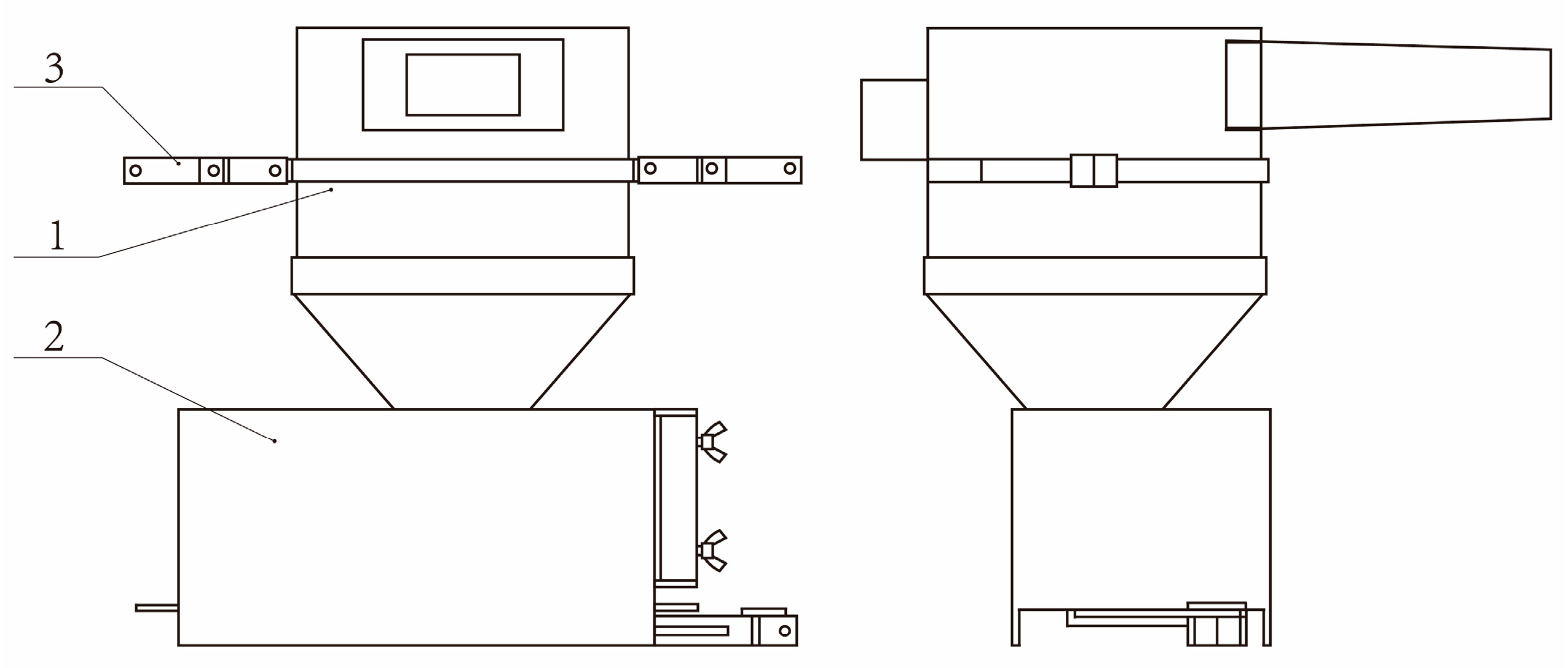

2. Composition and Function of Intelligent Wind Erosion Monitoring System

3. Experimental Section

3.1. Design of Wind Pressure Error Elimination Scheme for Load Cell

3.1.1. The Design of the Sand Collecting Unit and the Orthogonal Experimentation for the Positioning of Parts in the Collection and Deceleration Part

3.1.2. Wind Pressure Simulation Experiment Based on ANSYS Fluent

3.1.3. Wind Pressure Error Elimination Verification Experiment

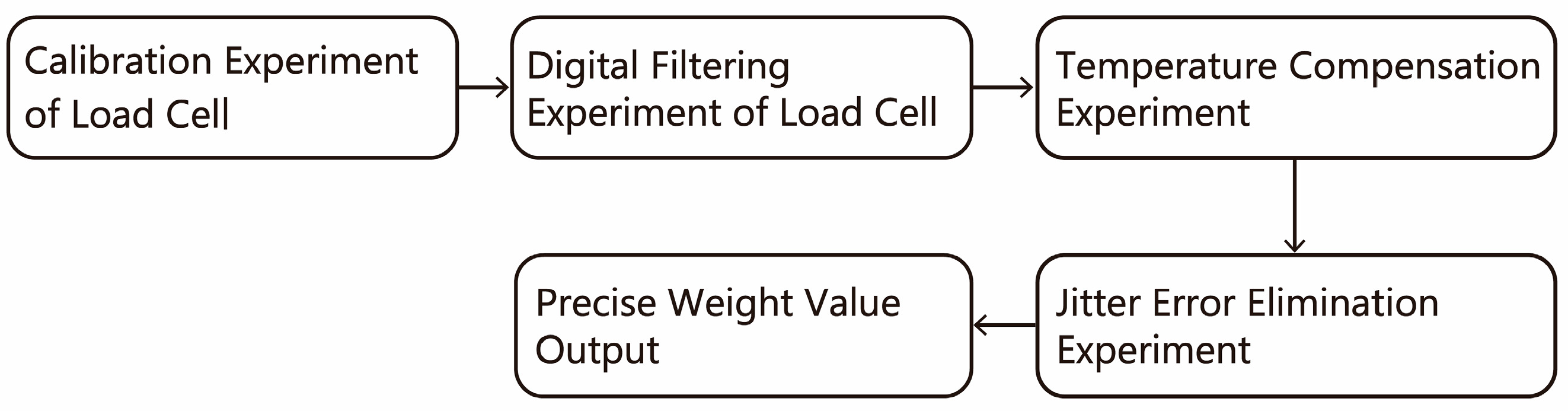

3.2. Design of High Precision Calibration Scheme for Load Cell

3.2.1. Calibration Experiment of Load Cell

3.2.2. Digital Filtering Design of Load Cell

3.2.3. Temperature Compensation Design

3.2.4. Jitter Compensation Design

3.2.5. Experiment and Verification of Calibration Compensation

4. Result

4.1. Analysis of the Experimental Results for Wind Pressure Error Elimination

4.1.1. Analysis of the Results of the Orthogonal Experiment for the Positioning of Parts in the Collection and Deceleration Part

4.1.2. Analysis of the Magnitude of the Pressure Values Acting on Load Cell at the Sand Outlet

4.1.3. Display of Wind Pressure Error Elimination Effect

4.2. Analysis of the Experimental Results for High-Precision Calibration of Load Cell

4.2.1. Linearity Characteristics of Load Cell

4.2.2. Analysis of the Digital Filtering Results for the Load Cell

4.2.3. Using Cubic Spline Interpolation Function for Temperature Compensation of the Load Cell

4.2.4. Comparison and Application of Two Neural Networks in Eliminating Jitter Error

4.2.5. Analysis of the Final Results of the Calibration Compensation Experiment

5. Discussion

6. Conclusions

- (1)

- Designed a collection speed reduction device to slow down the high-speed natural sand. Based on Ansys fluent, the collected deceleration part was simulated and the pressure generated by residual windblown sand on the load cell after deceleration was predicted. The accuracy of the estimated pressure value was analyzed in the simulation scenario, and the error caused by the wind pressure was eliminated, which improved the acquisition accuracy of the load cell.

- (2)

- Developed a specific implementation plan for precision calibration of the load cell itself, and completed the sensor calibration experiment, temperature compensation experiment, simulation of natural wind jitter error elimination experiment, and the flexible use of median filter and cubic spline interpolation function. Real-time monitoring of the system’s jitter parameters was performed using the JY61 six-axis acceleration sensor. Two neural network models were trained in MATLAB 2021a software using jitter parameters, load cell measurement results, and load cell expected results. The best solution for eliminating jitter errors was determined by comparing the final error elimination effects. The accuracy calibration of the load cell was completed [32].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, J.; Zhang, G.; Zhang, Y.; Guan, X.; Wei, Y.; Guo, R. Global desertification vulnerability to climate change and human activities. Land Degrad. Dev. 2020, 31, 1380–1391. [Google Scholar] [CrossRef]

- Koohestani, B.; Darban, A.K.; Mokhtari, P.; Darezereshki, E.; Yilmaz, E. Geopolymerization of soil by sodium silicate as an approach to control wind erosion. Int. J. Environ. Sci. Technol. 2021, 18, 1837–1848. [Google Scholar] [CrossRef]

- Xie, S.; Qu, J.; Xu, X.; Pang, Y. Interactions between freeze–thaw actions, wind erosion desertification, and permafrost in the Qinghai–Tibet Plateau. Nat. Hazards 2017, 85, 829–850. [Google Scholar] [CrossRef]

- Chepil, W.; Woodruff, N. The physics of wind erosion and its control. Adv. Agron. 1963, 15, 211–302. [Google Scholar]

- Li, J.; Shang, J.; Huang, D.; Tang, S.; Zhao, T.; Yang, X.; Zhang, Q.; Liu, K.; Shao, X. Grazing and cultivated grasslands cause different spatial redistributions of soil particles. Int. J. Environ. Res. Public Health 2019, 16, 2639. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Ding, G.-D.; Yu, M.-H.; Gao, G.-L.; Zhao, Y.-Y.; Wu, G.-H.; Wang, L. Effect of straw checkerboards on wind proofing, sand fixation, and ecological restoration in shifting sandy land. Int. J. Environ. Res. Public Health 2018, 15, 2184. [Google Scholar] [CrossRef] [PubMed]

- Peri, P.L.; Bloomberg, M. Windbreaks in southern Patagonia, Argentina: A review of research on growth models, windspeed reduction, and effects oncrops. Agrofor. Syst. 2002, 56, 129–144. [Google Scholar] [CrossRef]

- Wang, L.-Y.; Xiao, Y.; Rao, E.-M.; Jiang, L.; Xiao, Y.; Ouyang, Z.-Y. An assessment of the impact of urbanization on soil erosion in Inner Mongolia. Int. J. Environ. Res. Public Health 2018, 15, 550. [Google Scholar] [CrossRef]

- Alemu, M.M. Ecological benefits of trees as windbreaks and shelterbelts. Int. J. Ecosyst 2016, 6, 10–13. [Google Scholar]

- Skidmore, E. Wind erosion climatic erosivity. Clim. Chang. 1986, 9, 195–208. [Google Scholar] [CrossRef]

- Liu, J.; Kimura, R.; Wu, J. Vertical Profiles of Wind-Blown Sand Flux over Fine Gravel Surfaces and Their Implications for Field Observation in Arid Regions. Atmosphere 2020, 11, 1029. [Google Scholar] [CrossRef]

- Merva, G.; Peterson, G. Wind erosion sampling in the North Central Region. Microfiche Collect. 1983, 22. [Google Scholar]

- Shao, Y.; McTainsh, G.; Leys, J.; Raupach, M. Efficiencies of sediment samplers for wind erosion measurement. Soil Res. 1993, 31, 519–532. [Google Scholar] [CrossRef]

- Greeley, R.; Leach, R.N.; Williams, S.H.; White, B.R.; Pollack, J.B.; Krinsley, D.H.; Marshall, J.R. Rate of wind abrasion on Mars. J. Geophys. Res. Solid Earth 1982, 87, 10009–10024. [Google Scholar] [CrossRef]

- Fryrear, D. A field dust sampler. J. Soil Water Conserv. 1986, 41, 117–120. [Google Scholar]

- Wang, T.; Qu, J.; Tan, L.; Gao, Y.; Zhang, K.; Shi, B. Aeolian sediment transport over the Gobi with high gravel coverage under extremely strong winds in the Hundred Miles windy area along the Lanzhou-Xinjiang High-Speed Railway. J. Wind Eng. Ind. Aerodyn. 2022, 220, 104857. [Google Scholar] [CrossRef]

- Goossens, D.; Nolet, C.; Etyemezian, V.; Duarte-Campos, L.; Bakker, G.; Riksen, M. Field testing, comparison, and discussion of five aeolian sand transport measuring devices operating on different measuring principles. Aeolian Res. 2018, 32, 1–13. [Google Scholar] [CrossRef]

- Sherman, D.; Swann, C.; Barron, J. A high-efficiency, low-cost aeolian sand trap. Aeolian Res. 2014, 13, 31–34. [Google Scholar] [CrossRef]

- Kosmadakis, I.; Tsardaklis, P.; Ioannou, K.; Zaimes, G.N. A Novel Fully Automated Soil Erosion Monitoring System. In Proceedings of the HAICTA, Kavala, Greece, 17–20 September 2015; pp. 80–84. [Google Scholar]

- Giménez, A.; Lozano, F.J.; Torres, J.A.; Asensio, C. Automated system for soil wind erosion studies. Comput. Electron. Agric. 2019, 164, 104889. [Google Scholar] [CrossRef]

- Cui, Y.; Guo, Z.; Chang, C.; Wang, R.; Li, J. A Continuous-weighing Sand Trap: Design and field evaluations. J. Desert Res. 2018, 38, 1166. [Google Scholar]

- Kim, J.-R.; Lin, C.-W.; Lin, S.-Y. The use of InSAR phase coherence analyses for the monitoring of aeolian erosion. Remote Sens. 2021, 13, 2240. [Google Scholar] [CrossRef]

- Sarnecki, R.; Wiśniewski, W.; Ślusarski, W.; Wiłkojć, P. Traceable calibration of automatic weighing instruments operating in dynamic mode. In Proceedings of the MATEC Web of Conferences, Paris, France, 19–21 September 2017; p. 02005. [Google Scholar]

- Shang, H.; Duan, M.; Duan, X.; Zhang, H. The Research of Eiderdown Quantitative Conveying and Automatic Weighing Method Based on PLC Control. In Proceedings of the 2nd International Conference on Mechatronics Engineering and Information Technology (ICMEIT 2017), Dalian, China, 13–14 May 2017; pp. 653–661. [Google Scholar]

- Boschetti, G.; Caracciolo, R.; Richiedei, D.; Trevisani, A. Model-based dynamic compensation of load cell response in weighing machines affected by environmental vibrations. Mech. Syst. Signal Process. 2013, 34, 116–130. [Google Scholar] [CrossRef]

- Richiedei, D.; Trevisani, A. Shaper-Based Filters for the compensation of the load cell response in dynamic mass measurement. Mech. Syst. Signal Process. 2018, 98, 281–291. [Google Scholar] [CrossRef]

- Pietrzak, P.; Meller, M.; Niedźwiecki, M. Dynamic mass measurement in checkweighers using a discrete time-variant low-pass filter. Mech. Syst. Signal Process. 2014, 48, 67–76. [Google Scholar] [CrossRef]

- Battistelli, G.; Chisci, L. Kullback–Leibler average, consensus on probability densities, and distributed state estimation with guaranteed stability. Automatica 2014, 50, 707–718. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, X.; Hao, X.; Liu, R.; Hu, B. Filtering processing of belt scale signal based on MATLAB. In Proceedings of the International Workshop on Automation, Control, and Communication Engineering (IWACCE 2022), Wuhan, China, 19–21 August 2022; pp. 60–67. [Google Scholar]

- Tiboni, M.; Bussola, R.; Aggogeri, F.; Amici, C. Experimental and model-based study of the vibrations in the load cell response of automatic weight fillers. Electronics 2020, 9, 995. [Google Scholar] [CrossRef]

- Lianlei, Z.; Kaipeng, L. Warpage Analysis and Optimization of Pencil Case Based on Moldflow. Agric. Equip. Veh. Eng. 2018, 56, 79–82. [Google Scholar]

- Tiboni, M.; Incerti, G.; Remino, C.; Lancini, M. Comparison of signal processing techniques for condition monitoring based on artificial neural networks. In Proceedings of the Advances in Condition Monitoring of Machinery in Non-Stationary Operations, CMMNO’2018, Santander, Spain, 20–22 June 2018; pp. 179–188. [Google Scholar]

| Levels | Factors | ||||

|---|---|---|---|---|---|

| (A) The Size of the Air Intake (mm × mm) | (B) The Diameter of the Cylindrical Diverter (mm) | (C) The Distance between the Top Point of the Tail Outlet and the Highest Point of the Equipment (mm) | (D) The Diameter of the Tail Outlet (mm) | (E) The Diameter of the Sand Outlet (mm) | |

| 1 | 45 × 25 | 40 | 19 | 18 | 30 |

| 2 | 45 × 30 | 60 | 39 | 23 | 40 |

| 3 | 50 × 25 | 80 | 59 | 28 | 50 |

| 4 | 50 × 30 | 100 | 79 | 33 | 60 |

| Test Number | A | B | C | D | E | Average Wind Speed at the Sand Outlet (m·s−1) |

|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 11.48 |

| 2 | 1 | 2 | 2 | 2 | 2 | 6.69 |

| 3 | 1 | 3 | 3 | 3 | 3 | 4.66 |

| 4 | 1 | 4 | 4 | 4 | 4 | 3.45 |

| 5 | 2 | 1 | 2 | 3 | 4 | 4.01 |

| 6 | 2 | 2 | 1 | 4 | 3 | 4.65 |

| 7 | 2 | 3 | 4 | 1 | 2 | 8.89 |

| 8 | 2 | 4 | 3 | 2 | 1 | 12.36 |

| 9 | 3 | 1 | 3 | 4 | 2 | 6.33 |

| 10 | 3 | 2 | 4 | 3 | 1 | 9.89 |

| 11 | 3 | 3 | 1 | 2 | 4 | 3.82 |

| 12 | 3 | 4 | 2 | 1 | 3 | 5.78 |

| 13 | 4 | 1 | 4 | 2 | 3 | 6.61 |

| 14 | 4 | 2 | 3 | 1 | 4 | 4.96 |

| 15 | 4 | 3 | 2 | 4 | 1 | 9.75 |

| 16 | 4 | 4 | 1 | 3 | 2 | 7.93 |

| Factors | A | B | C | D | E |

|---|---|---|---|---|---|

| K1 | 26.28 | 28.43 | 27.88 | 31.11 | 43.48 |

| K2 | 29.91 | 26.19 | 26.23 | 29.48 | 29.84 |

| K3 | 25.82 | 27.12 | 28.31 | 26.49 | 21.7 |

| K4 | 29.25 | 29.52 | 28.84 | 24.18 | 16.24 |

| k1 | 6.57 | 7.11 | 6.97 | 7.78 | 10.87 |

| k2 | 7.48 | 6.55 | 6.56 | 7.37 | 7.46 |

| k3 | 6.46 | 6.78 | 7.08 | 6.62 | 5.43 |

| k4 | 7.31 | 7.38 | 7.21 | 6.05 | 4.06 |

| R | 1.16 | 0.83 | 0.65 | 1.73 | 6.81 |

| Average Wind Speed at the Air Intake (m·s−1) | Average Wind Speed at the Sand Outlet (m·s−1) | Average Wind Speed at the Tail Outlet (m·s−1) | Relative Pressure at the Sand Outlet (pa) |

|---|---|---|---|

| 20 | 7.235 | 7.764 | 32.916 |

| 19 | 6.8 | 7.587 | 30.15 |

| 18 | 6.399 | 7.522 | 27.271 |

| 17 | 6.105 | 6.867 | 23.855 |

| 16 | 5.776 | 6.093 | 19.568 |

| 15 | 5.545 | 4.924 | 17.072 |

| 14 | 5.207 | 5.104 | 14.047 |

| 13 | 4.742 | 4.915 | 12.185 |

| 12 | 4.393 | 4.466 | 10.792 |

| 11 | 4.034 | 4.048 | 8.818 |

| 10 | 3.589 | 3.702 | 7.263 |

| 9 | 3.269 | 3.349 | 5.883 |

| 8 | 3.014 | 2.867 | 4.683 |

| 7 | 2.614 | 2.284 | 3.644 |

| 6 | 2.163 | 1.983 | 2.728 |

| 5 | 1.822 | 1.829 | 1.929 |

| 4 | 1.147 | 1.385 | 1.295 |

| 3 | 1.095 | 1.01 | 0.744 |

| 2 | 0.724 | 0.679 | 0.334 |

| 1 | 0.357 | 0.351 | 0.084 |

| Test Number | Experimental Values | BP Prediction Values | GA—BP Prediction Values | BP Prediction Error | GA-BP Prediction Error |

|---|---|---|---|---|---|

| 1 | 99.561 | 95.087 | 98.716 | −4.474 | −0.845 |

| 2 | 98.042 | 97.038 | 97.866 | −1.004 | −0.176 |

| 3 | 93.967 | 92.457 | 94.050 | −1.51 | 0.083 |

| 4 | 97.675 | 94.059 | 95.514 | −3.616 | −2.161 |

| 5 | 93.644 | 97.416 | 93.752 | 3.772 | 0.108 |

| 6 | 82.761 | 91.755 | 83.744 | 8.995 | 0.983 |

| 7 | 91.026 | 89.886 | 90.897 | −1.139 | −0.129 |

| 8 | 94.143 | 96.334 | 94.322 | 2.192 | 0.179 |

| 9 | 97.487 | 99.37 | 98.831 | 1.883 | 1.344 |

| 10 | 99.421 | 98.262 | 98.92 | −1.159 | −0.501 |

| 11 | 96.596 | 97.276 | 97.043 | 0.681 | 0.448 |

| 12 | 95.58 | 96.23 | 96.58 | 0.65 | 0.999 |

| 13 | 96.994 | 98.77 | 98.04 | 1.776 | 1.046 |

| 14 | 96.44 | 98.445 | 95.896 | 2.005 | −0.544 |

| 15 | 96.189 | 96.869 | 96.706 | 0.68 | 0.517 |

| 16 | 97.845 | 96.314 | 97.624 | −1.531 | −0.221 |

| 17 | 97.292 | 97.618 | 97.006 | 0.326 | −0.287 |

| 18 | 98.006 | 98.019 | 97.962 | 0.013 | −0.044 |

| 19 | 97.407 | 99.713 | 99.031 | 2.306 | 1.624 |

| 20 | 98.054 | 97.358 | 97.535 | −0.697 | −0.519 |

| 21 | 99.689 | 98.822 | 98.832 | −0.867 | −0.857 |

| 22 | 98.014 | 98.225 | 98.627 | 0.21 | 0.612 |

| 23 | 96.994 | 98.77 | 98.04 | 1.776 | 1.046 |

| 24 | 96.44 | 98.445 | 95.896 | 2.005 | −0.544 |

| 25 | 96.189 | 96.869 | 96.706 | 0.68 | 0.517 |

| 26 | 97.845 | 96.314 | 97.624 | −1.531 | −0.221 |

| 27 | 96.392 | 97.618 | 97.006 | 1.226 | 0.613 |

| 28 | 97.006 | 98.019 | 97.962 | 1.013 | 0.956 |

| 29 | 97.407 | 99.713 | 99.031 | 2.306 | 1.624 |

| 30 | 98.054 | 97.358 | 97.535 | −0.697 | −0.519 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Li, C.; Lin, J.; Ni, S. Development of an Intelligent Wind Erosion Monitoring System. Sensors 2023, 23, 9389. https://doi.org/10.3390/s23239389

Wang L, Li C, Lin J, Ni S. Development of an Intelligent Wind Erosion Monitoring System. Sensors. 2023; 23(23):9389. https://doi.org/10.3390/s23239389

Chicago/Turabian StyleWang, Linhu, Chengyu Li, Jianhui Lin, and Siwen Ni. 2023. "Development of an Intelligent Wind Erosion Monitoring System" Sensors 23, no. 23: 9389. https://doi.org/10.3390/s23239389

APA StyleWang, L., Li, C., Lin, J., & Ni, S. (2023). Development of an Intelligent Wind Erosion Monitoring System. Sensors, 23(23), 9389. https://doi.org/10.3390/s23239389