Trajectory Tracking Control of Transformer Inspection Robot Using Distributed Model Predictive Control

Abstract

:1. Introduction

- (1)

- A DMPC algorithm is proposed to solve the transformer inspection robot trajectory tracking control problem. With the proposed DMPC, the performance and robustness of the tracking control can be improved.

- (2)

- Through the DMPC method, by decoupling the transformer inspection robot’s motion into five subsystems, the computational complexity of the trajectory tracking control can be reduced while the tracking performance can be maintained.

- (3)

- We validate the proposed method in a variety of simulations. The simulations aim to demonstrate the advantages of the DMPC tracking method compared with some other baseline methods.

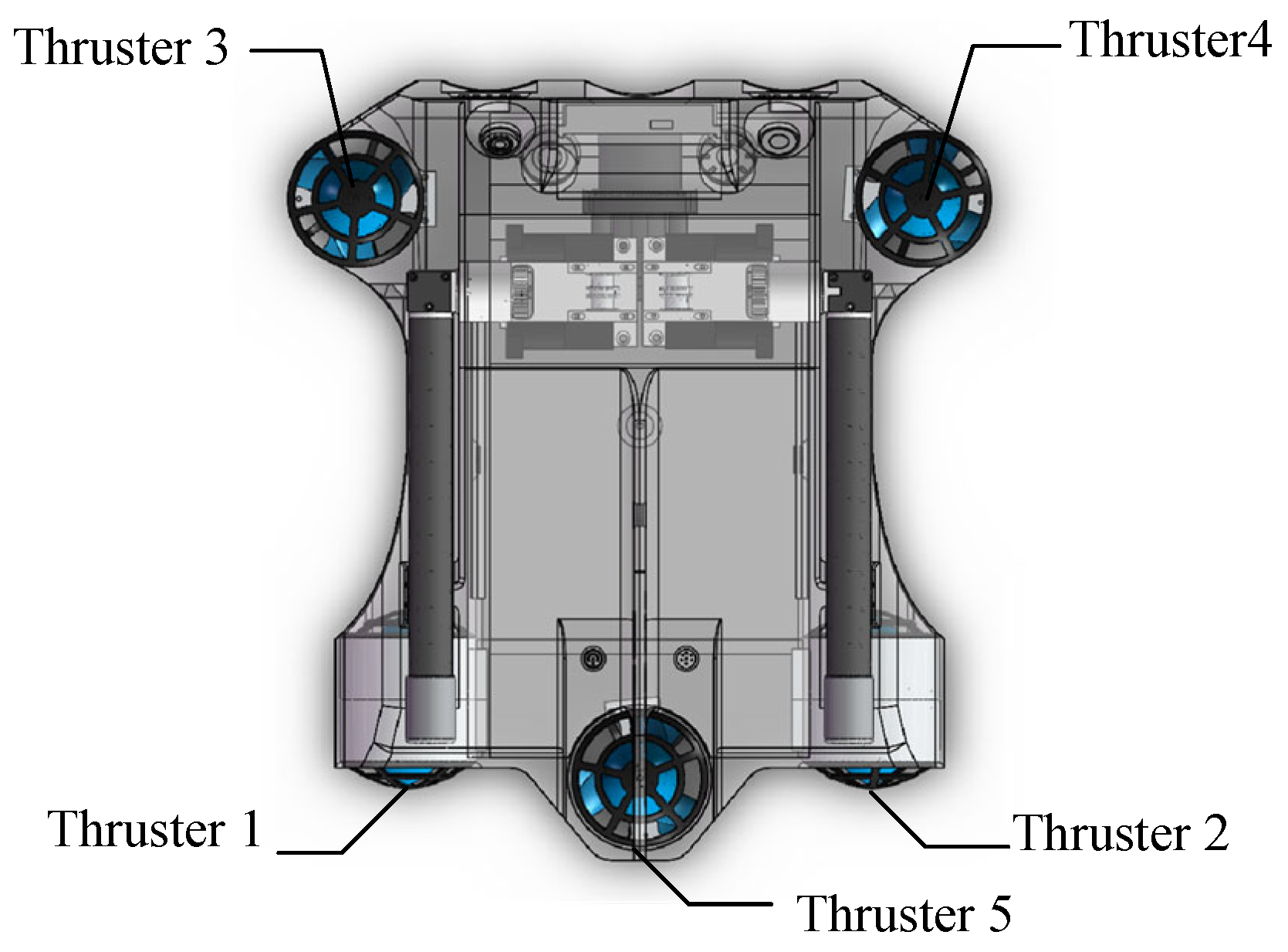

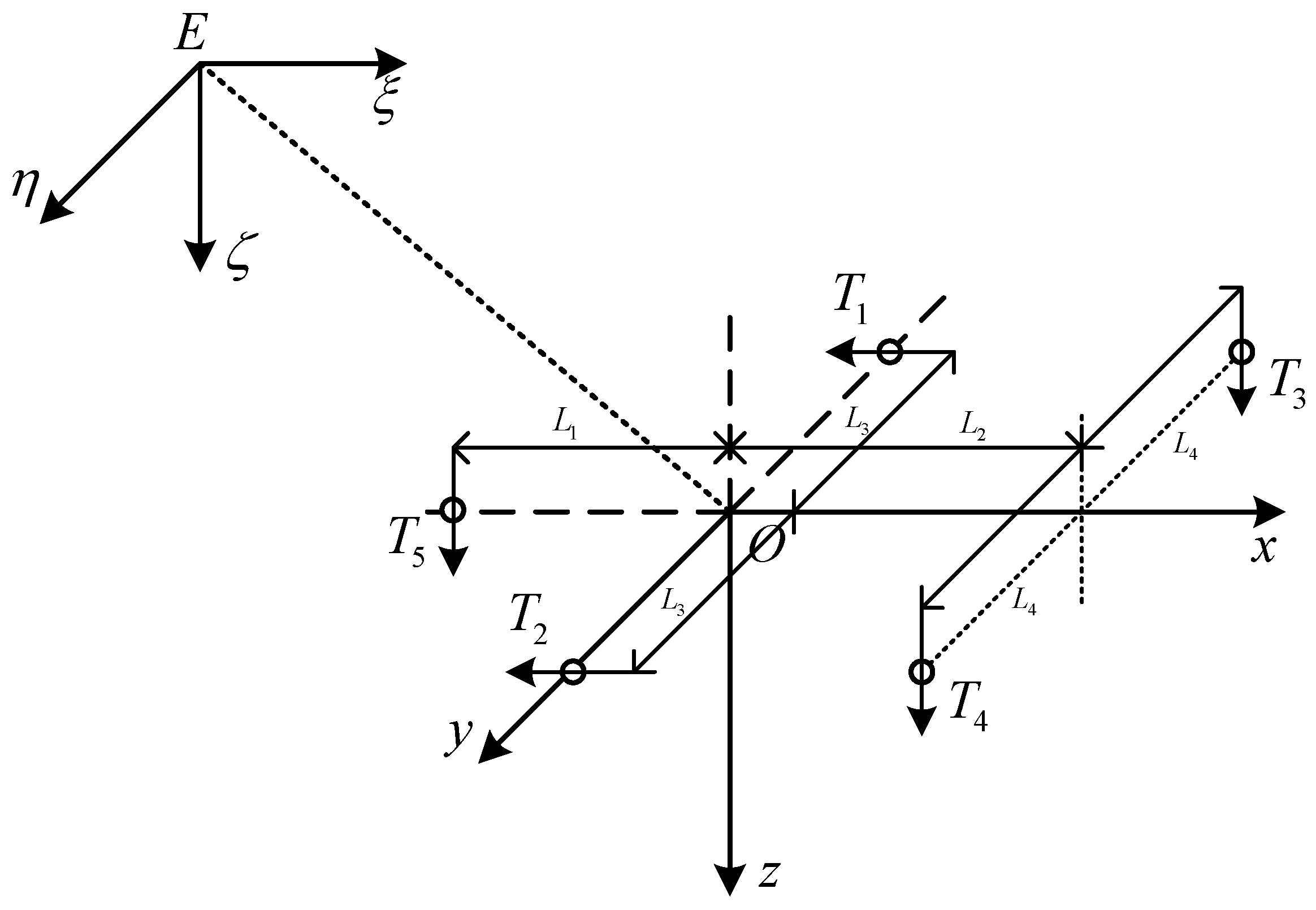

2. System Modeling

2.1. Kinematic Model

2.2. Dynamic Model

3. Problem Formulation

4. Distributed Model Predictive Control Algorithm Design

| Algorithm 1 Distributed model predictive control (DMPC). |

|

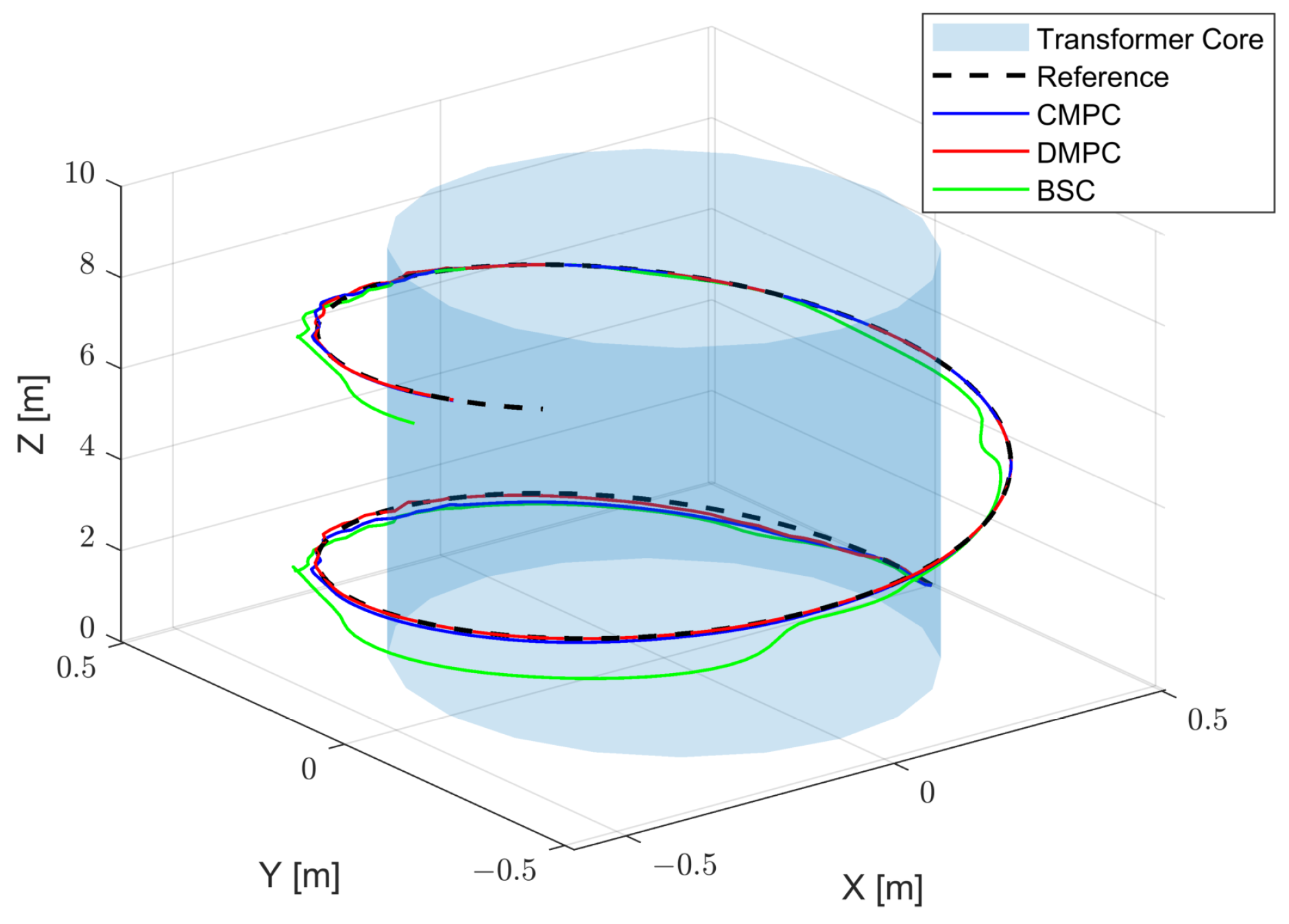

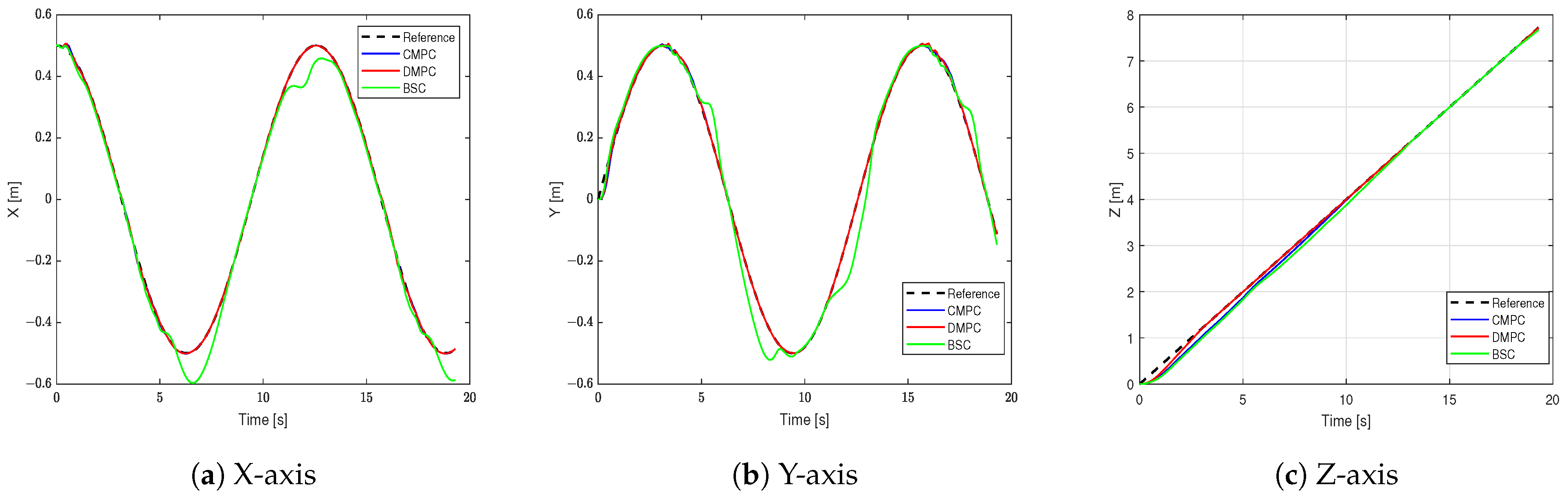

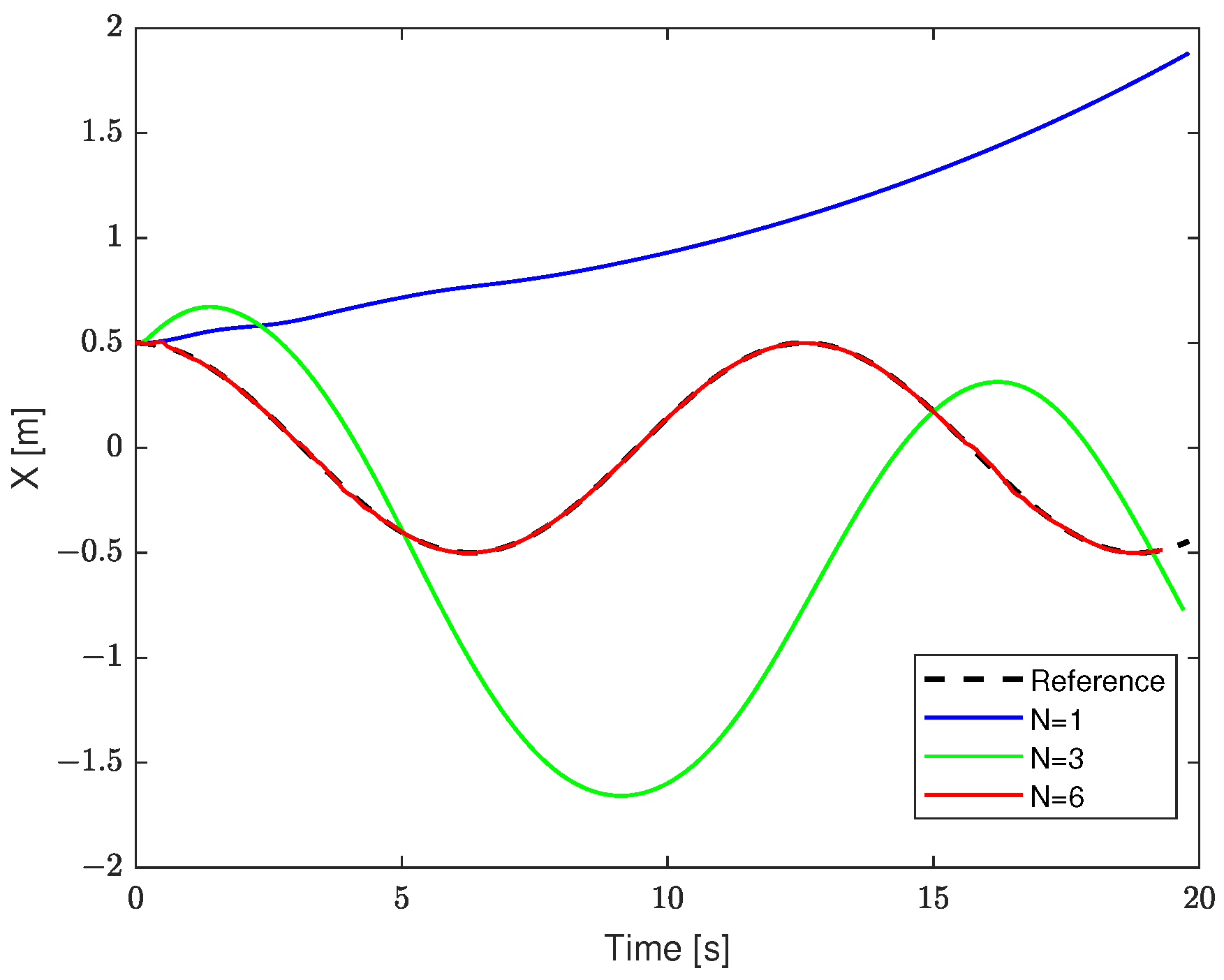

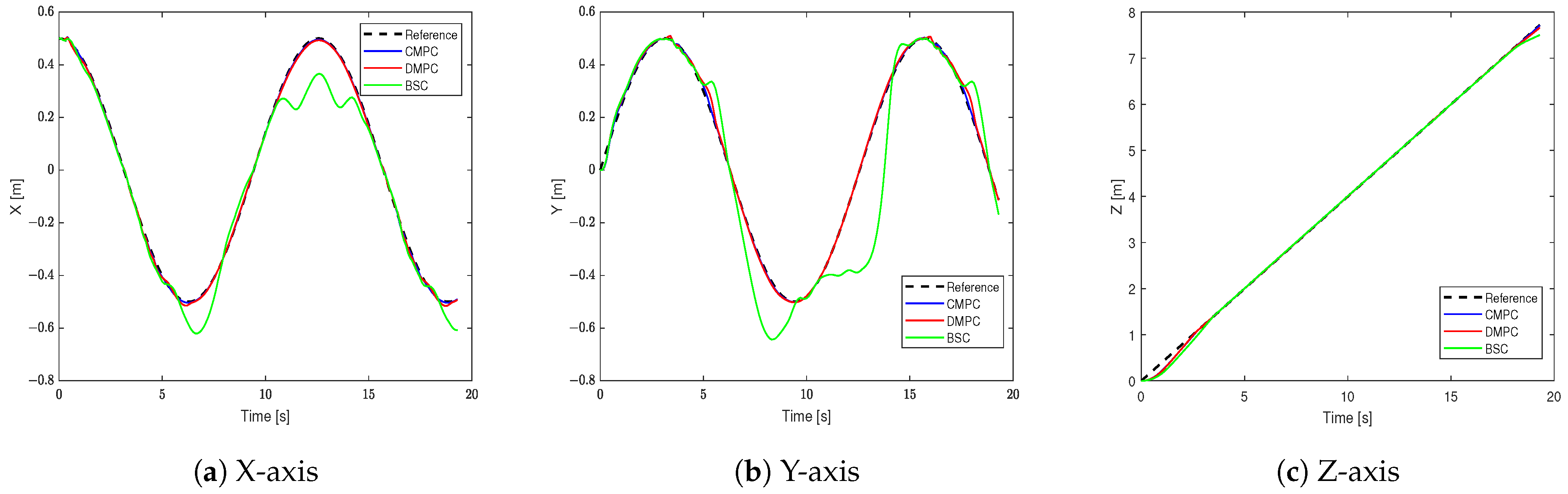

5. Simulation of Trajectory Tracking Based on the DMPC

5.1. Simulation Setup

5.2. Tracking Performance and Results Analysis

5.3. Robustness Test

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, B.; An, F.; Song, Q.; Yu, Z.; Zeng, R. Development and application of dc transformer based on dual-active-bridge. Proc. Csee 2021, 41, 288–298. [Google Scholar]

- Xu, J.; Wang, M.; Qiao, L. Backstepping-based controller for three-dimensional trajectory tracking of underactuated unmanned underwater vehicles. Control. Theory Appl. 2014, 31, 1589–1596. [Google Scholar]

- Qu, Y.; Xiao, B.; Fu, Z.; Yuan, D. Trajectory exponential tracking control of unmanned surface ships with external disturbance and system uncertainties. ISA Trans. 2018, 78, 47–55. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.; Zhu, D.; Yang, S.X. A bioinspired filtered backstepping tracking control of 7000-m manned submarine vehicle. IEEE Trans. Ind. Electron. 2013, 61, 3682–3693. [Google Scholar] [CrossRef]

- Xia, G.; Shao, X.; Zhao, A. Robust nonlinear observer and observer-backstepping control design for surface ships. Asian J. Control 2015, 17, 1377–1393. [Google Scholar] [CrossRef]

- Soylu, S.; Proctor, A.A.; Podhorodeski, R.P.; Bradley, C.; Buckham, B.J. Precise trajectory control for an inspection class ROV. Ocean Eng. 2016, 111, 508–523. [Google Scholar] [CrossRef]

- Tabataba’i-Nasab, F.S.; Moosavian, S.A.A.; Khalaji, A.K. Tracking Control of an Autonomous Underwater Vehicle: Higher-Order Sliding Mode Control Approach. In Proceedings of the 2019 7th International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 20–21 November 2019; pp. 114–119. [Google Scholar]

- Wu, Z.; Peng, H.; Hu, B.; Feng, X. Trajectory tracking of a novel underactuated AUV via nonsingular integral terminal sliding mode control. IEEE Access 2021, 9, 103407–103418. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, X.; Chen, T.; Yan, Z.; Yang, Z. Trajectory tracking control of an underactuated AUV based on backstepping sliding mode with state prediction. IEEE Access 2019, 7, 181983–181993. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Kong, H.; Ke, F. Model Predictive Tracking Control of Nonholonomic Mobile Robots with Coupled Input Constraints and Unknown Dynamics. IEEE Trans. Ind. Inform. 2019, 15, 3196–3205. [Google Scholar] [CrossRef]

- Zhang, J.; Fang, Z.; Zhang, Z.; Gao, R.; Zhang, S. Trajectory Tracking Control of Nonholonomic Wheeled Mobile Robots Using Model Predictive Control Subjected to Lyapunov-based Input Constraints. Int. J. Control Autom. Syst. 2022, 20, 1640–1651. [Google Scholar] [CrossRef]

- Liu, S.S.; Ding, T.F.; Ge, M.F.; Dong, X.G.; Liu, Z.W. Multiquadrotor Formation Tracking with Mixed Constraints: A Hierarchical Rolling Optimization Approach. IEEE Trans. Aerosp. Electron. Syst. 2023, 59, 7269–7280. [Google Scholar]

- Gao, Y.; Wang, D.; Wei, W.; Yu, Q.; Liu, X.; Wei, Y. Constrained Predictive Tracking Control for Unmanned Hexapod Robot with Tripod Gait. Drones 2022, 6, 246. [Google Scholar] [CrossRef]

- Yu, J.; Zhu, Z.; Lu, J.; Yin, S.; Zhang, Y. Modeling and MPC-Based Pose Tracking for Wheeled Bipedal Robot. IEEE Robot. Autom. Lett. 2023, 8, 7881–7888. [Google Scholar] [CrossRef]

- Xie, H.; Dai, L.; Lu, Y.; Xia, Y. Disturbance Rejection MPC Framework for Input-Affine Nonlinear Systems. IEEE Trans. Autom. Control 2022, 67, 6595–6610. [Google Scholar] [CrossRef]

- Sun, S.; Romero, A.; Foehn, P.; Kaufmann, E.; Scaramuzza, D. A Comparative Study of Nonlinear MPC and Differential-Flatness-Based Control for Quadrotor Agile Flight. IEEE Trans. Robot. 2022, 38, 3357–3373. [Google Scholar] [CrossRef]

- Ding, T.; Zhang, Y.; Ma, G.; Cao, Z.; Zhao, X.; Tao, B. Trajectory tracking of redundantly actuated mobile robot by MPC velocity control under steering strategy constraint. Mechatronics 2022, 84, 102779. [Google Scholar] [CrossRef]

- Dai, L.; Yu, Y.; Zhai, D.H.; Huang, T.; Xia, Y. Robust Model Predictive Tracking Control for Robot Manipulators with Disturbances. IEEE Trans. Ind. Electron. 2021, 68, 4288–4297. [Google Scholar] [CrossRef]

- Dai, L.; Lu, Y.; Xie, H.; Sun, Z.; Xia, Y. Robust Tracking Model Predictive Control with Quadratic Robustness Constraint for Mobile Robots with Incremental Input Constraints. IEEE Trans. Ind. Electron. 2021, 68, 9789–9799. [Google Scholar] [CrossRef]

- Huang, J.; An, H.; Yang, Y.; Wu, C.; Wei, Q.; Ma, H. Model Predictive Trajectory Tracking Control of Electro-Hydraulic Actuator in Legged Robot with Multi-Scale Online Estimator. IEEE Access 2020, 8, 95918–95933. [Google Scholar] [CrossRef]

- Gan, W.; Zhu, D.; Hu, Z.; Shi, X.; Yang, L.; Chen, Y. Model Predictive Adaptive Constraint Tracking Control for Underwater Vehicles. IEEE Trans. Ind. Electron. 2020, 67, 7829–7840. [Google Scholar] [CrossRef]

- Yan, Z.; Gong, P.; Zhang, W.; Wu, W. Model predictive control of autonomous underwater vehicles for trajectory tracking with external disturbances. Ocean Eng. 2020, 217, 107884. [Google Scholar] [CrossRef]

- Gong, P.; Yan, Z.; Zhang, W.; Tang, J. Lyapunov-based model predictive control trajectory tracking for an autonomous underwater vehicle with external disturbances. Ocean Eng. 2021, 232, 109010. [Google Scholar] [CrossRef]

- Gong, P.; Yan, Z.; Zhang, W.; Tang, J. Trajectory tracking control for autonomous underwater vehicles based on dual closed-loop of MPC with uncertain dynamics. Ocean Eng. 2022, 265, 112697. [Google Scholar] [CrossRef]

- Yan, Z.; Yan, J.; Cai, S.; Yu, Y.; Wu, Y. Robust MPC-based trajectory tracking of autonomous underwater vehicles with model uncertainty. Ocean Eng. 2023, 286, 115617. [Google Scholar] [CrossRef]

- Li, J.; Du, J.; Chen, C.P. Command-filtered robust adaptive NN control with the prescribed performance for the 3-D trajectory tracking of underactuated AUVs. IEEE Trans. Neural Netw. Learn. Syst. 2021, 33, 6545–6557. [Google Scholar] [CrossRef]

- Guerreiro, B.J.; Silvestre, C.; Cunha, R.; Pascoal, A. Trajectory tracking nonlinear model predictive control for autonomous surface craft. IEEE Trans. Control. Syst. Technol. 2014, 22, 2160–2175. [Google Scholar] [CrossRef]

- Heshmati-Alamdari, S.; Karras, G.C.; Marantos, P.; Kyriakopoulos, K.J. A robust predictive control approach for underwater robotic vehicles. IEEE Trans. Control. Syst. Technol. 2019, 28, 2352–2363. [Google Scholar] [CrossRef]

- Shen, C.; Shi, Y.; Buckham, B. Integrated path planning and tracking control of an AUV: A unified receding horizon optimization approach. IEEE/ASME Transactions on Mechatronics 2016, 22, 1163–1173. [Google Scholar] [CrossRef]

- Shen, C.; Shi, Y.; Buckham, B. Trajectory tracking control of an autonomous underwater vehicle using Lyapunov-based model predictive control. IEEE Trans. Ind. Electron. 2017, 65, 5796–5805. [Google Scholar] [CrossRef]

- Negenborn, R.R.; Maestre, J.M. Distributed model predictive control: An overview and roadmap of future research opportunities. IEEE Control. Syst. Mag. 2014, 34, 87–97. [Google Scholar]

- Dunbar, W.B.; Caveney, D.S. Distributed receding horizon control of vehicle platoons: Stability and string stability. IEEE Trans. Autom. Control 2011, 57, 620–633. [Google Scholar] [CrossRef]

- Hao, S.; Du Yu, B.D.; Haodong, L. Accelerated Solution Method for Vehicle Trajectory Tracking Based on Model Predictive Control. J. Hunan Univ. (Nat. Sci.) 2020, 47, 19–25. [Google Scholar]

- Bian, Y.; Zhang, J.; Li, C.; Xu, B.; Qin, Z.; Hu, M. Distributed Model Predictive Depth and Surge Velocity Control of Multiple Autonomous Underwater Vehicles. J. Hunan Univ. (Nat. Sci.) 2022, 49, 45–54. [Google Scholar]

- Shen, C.; Shi, Y. Distributed implementation of nonlinear model predictive control for AUV trajectory tracking. Automatica 2020, 115, 108863–108872. [Google Scholar] [CrossRef]

| Moving | T1 | T2 | T3 | T4 | T5 |

|---|---|---|---|---|---|

| Surge | 1 | 1 | 0 | 0 | 0 |

| Sway | 0 | 0 | 0 | 0 | 0 |

| Heave | 0 | 0 | |||

| Roll | 0 | 0 | 0 | ||

| Pitch | 0 | 0 | |||

| Yaw | 0 | 0 | 0 |

| Control Method | Computation Time/s |

|---|---|

| Centralized MPC | 0.3729 |

| Distributed MPC | 0.0348 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, L.; Xiang, G.; Ma, C.; Jiang, X.; Dian, S. Trajectory Tracking Control of Transformer Inspection Robot Using Distributed Model Predictive Control. Sensors 2023, 23, 9238. https://doi.org/10.3390/s23229238

Wei L, Xiang G, Ma C, Jiang X, Dian S. Trajectory Tracking Control of Transformer Inspection Robot Using Distributed Model Predictive Control. Sensors. 2023; 23(22):9238. https://doi.org/10.3390/s23229238

Chicago/Turabian StyleWei, Lai, Guofei Xiang, Congjun Ma, Xuejian Jiang, and Songyi Dian. 2023. "Trajectory Tracking Control of Transformer Inspection Robot Using Distributed Model Predictive Control" Sensors 23, no. 22: 9238. https://doi.org/10.3390/s23229238

APA StyleWei, L., Xiang, G., Ma, C., Jiang, X., & Dian, S. (2023). Trajectory Tracking Control of Transformer Inspection Robot Using Distributed Model Predictive Control. Sensors, 23(22), 9238. https://doi.org/10.3390/s23229238