Machine Vision System for Automatic Adjustment of Optical Components in LED Modules for Automotive Lighting

Abstract

:1. Introduction

- Reliability and robustness: The hardware devices and the software algorithms used to obtain the optimal fixing position and adjust the module should guarantee that it complies with the regulation.

- Capability for real-time adjustment: Since the automatic adjustment system is one element of the production chain, the process must be performed in the pre-established amount of time. These cycle time requirements will significantly affect the positioning algorithms.

- Adaptability: The automated adjustment system should be easily adapted to different models of LED modules. For this reason, it is absolutely necessary that the system’s components may be included, eliminated, or even modified with ease.

2. Definition of the Problem and Related Work

2.1. LED Modules for Automotive Lighting

Manual Positioning and Quality Control

- Remove the parts that prevent access to the active optical components.

- Loosen the screws securing the optical component.

- Switch on the module and project the light beam onto a front screen.

- Manually adjust the relative position of the optical components according to the aspect of the projected image. This step was subjected to the limitations of visual perception and the fatigue caused by the observation of light distributions with strong light–dark contrast.

- Once the correct position of the components has been found (limited by the poor visual precision of the human eye), lock this position by screwing on the optical part.

- Mount and screw the rest of the non-functional components of the module.

- Check the photometry of the module on the photometric bench again.

2.2. Related Works on Automatic Assembling of Parts with Dimensional Variations

3. Description of the Machine Vision System

3.1. Hardware Architecture

- Camera and photometric tunnel.

- A Host PC to synchronise all the processes, execute the computer vision, and position the control algorithms.

- Tooling for holding the modules and allowing the relative movement between submodules.

- Screwdriver to fix the submodules.

- A PLC to control the movement of elements and the lighting of the LED module.

- Power drivers of the module.

- HMI screens to show results and tune parameters.

3.1.1. Image Acquisition Devices

3.1.2. Position Adjustment Devices

3.2. Software Architecture

3.2.1. Image Processing

- Calibrations.

- -

- Photometric. This calibration establishes a correlation between the gray level of the image and a standardised illuminance value. A procedure is established using a standard module to apply corrections to the intensity values acquired by the vision sensor.

- -

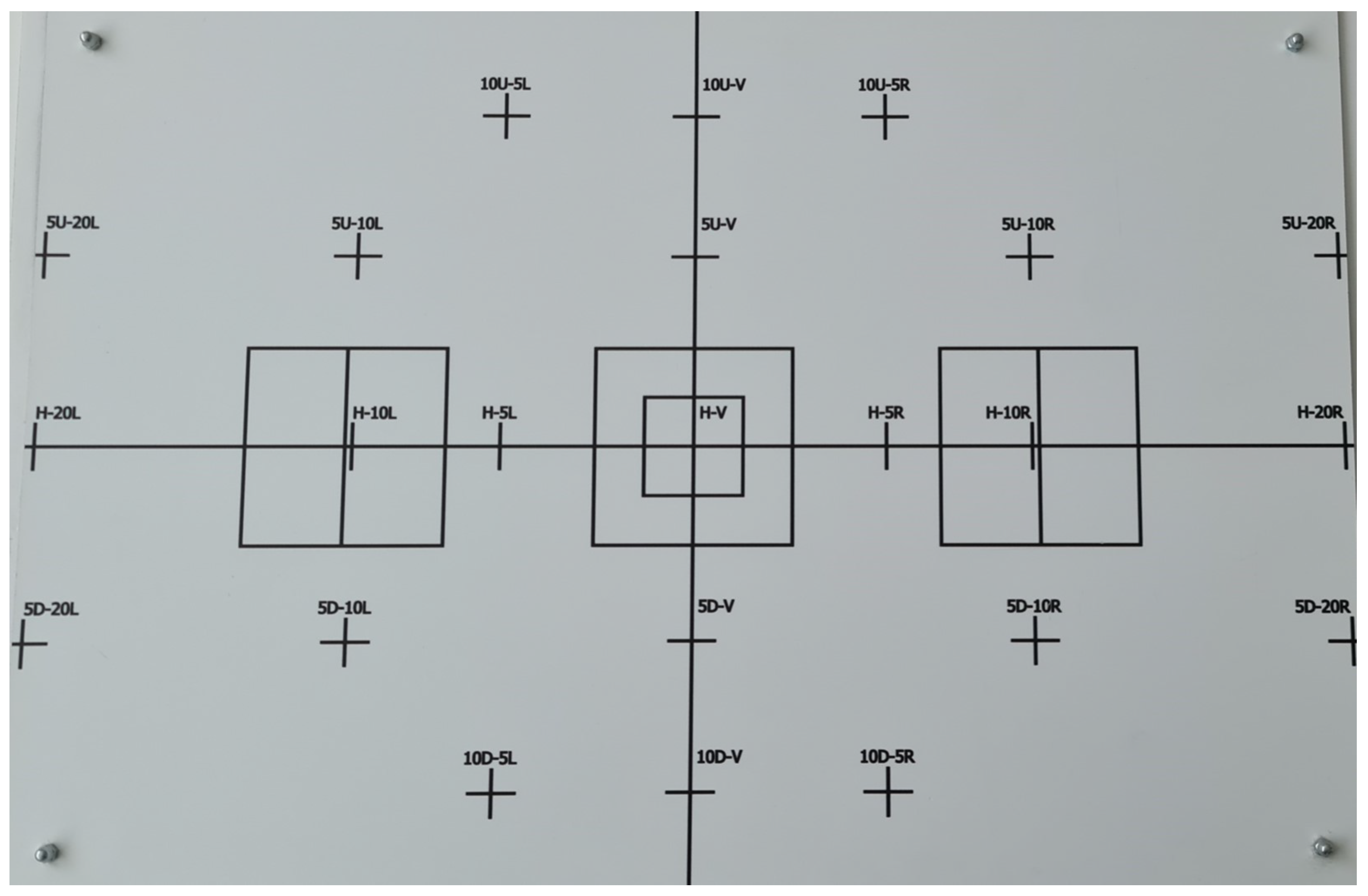

- Geometric. This calibration determines the relationship between the pixels in an image and sexagesimal degrees in spherical coordinates. To achieve this, a calibration pattern (Figure 9) is placed on the background panel of the photometric tunnel. The calibration pattern is placed at a distance of 700 mm and the length of the square in the center measures 43 mm. The pattern is acquired by the vision sensor and processed to obtain the length of the square in pixels (170 pixels). The desired pixel–degree ratio can be obtained from:where is the number of pixels between two points in the image, and is the angle formed by these two points in spherical coordinates.

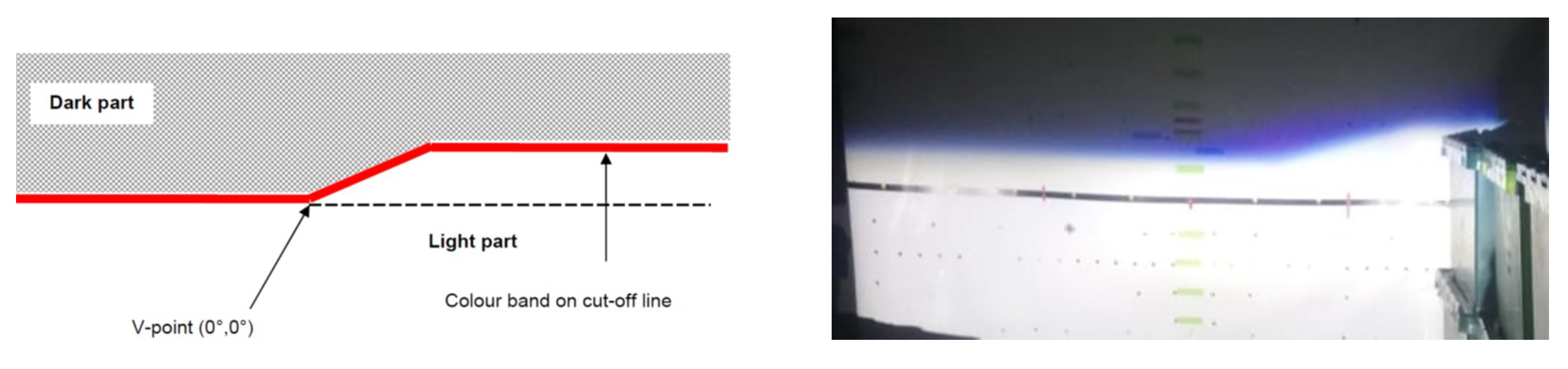

- Cut-off measurements. For these measurements, the V point in the horizontal part of the cut-off line has to be located (Figure 10b). Traditional image processing algorithms are used for this. As the gray level image shows a bimodal histogram with a homogeneous background, the Otsu algorithm is used for segmentation [28]. Then, via the Hough transform, the cut-off line shape is extracted [29]. The lower intersection point is the desired V Point.

- -

- Sharpness. It is determined by vertically scanning three sections placed through the horizontal part of the cut-off line (at H 1.5, 2.5, and 3.5, Left or Right, depending on LHD/RHD from the V point). During the scanning, the gradient G is determined using the formula:where E is the illuminance, is the vertical position in degrees, and is the scan resolution, also in degrees. The sharpness of the cut-off line is the point with the highest gradient with respect to the H-H axis.

- -

- Chromatism. The low beam color has to be inside the specific limits defined in the CIE diagram. Figure 10b shows the limit specified by the customer in the CIE diagram. RGB values of the pixels inside the ROI in the cut-off line are changed to the XYZ CIE coordinates. Only X and Y coordinates are taken into account to place the RBG values in the CIE diagram. The customer defines the black line in the CIE diagram and a specified percentage of points should remain on the left (% blue) and the others should remain on the right (% red).

3.2.2. Optimal Position Adjustment

- Step 0: Check if the LED module model has a previously learned optimal position. To do this, a query is made on the database of learned positions. If the model already has a registered position, this is the initial one. If not, it is initialised to an intermediate position. The position vector is initialised as follows:where n is the initial position (learned or intermediate).

- Step 1: Set the LED module to the position . First time . If is outside the position range allowed by the tooling, the module is adjusted in the intermediate tooling position. For this module, it is not possible to reach an optimal position, so go to Step 4. If it is within the range, go to Step 2.

- Step 2: Acquire and process the cut-off shape image to obtain the cut-off measurements: , , and .

- Step 3: If and and , the module has been correctly adjusted and assembled and the position is recorded in the database; if so, go to Step 4. If not , then go to Step 1.

- Step 4: Completion stage. Result notification via HMI.

4. Experimental Case of Study: BiLED Module

4.1. Calibration Phase

4.2. Production Phase

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HB | High-beam |

| ECE | Economic Commission for Europe |

| GUI | Graphical User Interface |

| LED | Light Emitting Diode |

| LB | Low-beam |

| LHD | Left Hand Traffic |

| MVS | Machine Vision System |

| PLC | Programmable Logic Controller |

| RHD | Right Hand Traffic |

| ROI | Region Of Interest |

| UML | Unified Modelling Language |

| WLLED | White Light LED |

Appendix A

Appendix A.1

| Module | Cut-Off Sharpness | % Blue | % Red | Optimal Position |

|---|---|---|---|---|

| 1 | 0.130 | 79.270 | 5.830 | - |

| 2 | 0.090 | 78.110 | 18.500 | 4 |

| 3 | 0.092 | 81.100 | 15.350 | 4 |

| 4 | 0.110 | 82.180 | 6.430 | - |

| 5 | 0.120 | 80.340 | 5.410 | - |

| 6 | 0.100 | 80.940 | 6.530 | - |

| 7 | 0.100 | 79.870 | 6.060 | - |

| 8 | 0.110 | 82.940 | 6.270 | - |

| 9 | 0.097 | 84.030 | 12.560 | 4 |

| 10 | 0.100 | 82.880 | 13.850 | 4 |

| 11 | 0.110 | 84.130 | 13.860 | 4 |

| 12 | 0.097 | 76.510 | 21.460 | 4 |

| 13 | 0.103 | 80.890 | 15.840 | 4 |

| 14 | 0.107 | 82.760 | 15.560 | 4 |

| 15 | 0.090 | 82.750 | 14.470 | 4 |

| 16 | 0.086 | 75.450 | 23.250 | 5 |

| 17 | 0.079 | 73.280 | 25.670 | 5 |

| 18 | 0.085 | 82.310 | 16.080 | 5 |

| 19 | 0.092 | 76.670 | 22.040 | 5 |

| 20 | 0.093 | 80.920 | 17.610 | 5 |

| 21 | 0.094 | 67.570 | 26.420 | - |

| 22 | 0.096 | 84.110 | 12.910 | 4 |

| 23 | 0.089 | 81.930 | 15.580 | 5 |

| 24 | 0.099 | 80.720 | 17.490 | 5 |

| 25 | 0.086 | 74.300 | 23.410 | 6 |

| 26 | 0.099 | 82.920 | 14.980 | 4 |

| 27 | 0.110 | 79.850 | 17.490 | 5 |

| 28 | 0.083 | 80.420 | 18.820 | 5 |

| 29 | 0.093 | 73.240 | 24.760 | 5 |

| 30 | 0.097 | 80.290 | 17.530 | 5 |

| 31 | 0.101 | 84.060 | 12.970 | 4 |

| 32 | 0.084 | 79.080 | 19.740 | 5 |

| 33 | 0.083 | 74.250 | 25.250 | 5 |

| 34 | 0.080 | 81.460 | 14.020 | 5 |

| 35 | 0.112 | 83.930 | 12.870 | 4 |

| 36 | 0.103 | 81.250 | 17.130 | 4 |

| 37 | 0.086 | 75.740 | 20.800 | 5 |

| 38 | 0.100 | 68.550 | 28.350 | - |

| 39 | 0.091 | 78.320 | 17.330 | 5 |

| 40 | 0.076 | 76.280 | 21.030 | 5 |

| 41 | 0.099 | 81.200 | 17.430 | 6 |

| 42 | 0.076 | 80.840 | 13.410 | 5 |

| 43 | 0.078 | 72.060 | 23.380 | 5 |

| 44 | 0.087 | 74.680 | 24.220 | 5 |

| 45 | 0.079 | 66.120 | 25.870 | - |

| 46 | 0.083 | 74.600 | 21.830 | 6 |

| 47 | 0.089 | 71.520 | 25.920 | - |

| 48 | 0.080 | 79.290 | 16.360 | 6 |

| 49 | 0.089 | 79.650 | 19.140 | 5 |

| 50 | 0.078 | 74.450 | 22.460 | 5 |

| 51 | 0.078 | 78.340 | 19.200 | 5 |

| 52 | 0.078 | 79.350 | 18.850 | 5 |

| 53 | 0.089 | 75.200 | 22.500 | 5 |

| 54 | 0.077 | 73.920 | 24.350 | 5 |

| 55 | 0.083 | 76.400 | 21.030 | 5 |

| 56 | 0.085 | 75.390 | 24.840 | 7 |

| 57 | 0.081 | 72.430 | 22.710 | 5 |

| 58 | 0.082 | 79.670 | 19.420 | 5 |

Appendix A.2

| Module | Cut-Off Sharpness | % Blue | % Red | Optimal Position |

|---|---|---|---|---|

| 1 | 0.092 | 83.060 | 8.310 | 3 |

| 2 | 0.098 | 84.290 | 7.560 | 4 |

| 3 | 0.096 | 85.390 | 9.420 | - |

| 4 | 0.095 | 82.680 | 8.620 | 4 |

| 5 | 0.110 | 84.060 | 7.490 | 3 |

| 6 | 0.123 | 82.790 | 7.380 | 3 |

| 7 | 0.115 | 87.100 | 9.150 | 4 |

| 8 | 0.090 | 84.310 | 7.780 | 4 |

| 9 | 0.097 | 87.280 | 8.360 | 4 |

| 10 | 0.092 | 86.100 | 9.020 | 4 |

| 11 | 0.105 | 85.490 | 8.990 | 4 |

| 12 | 0.082 | 86.610 | 8.050 | 4 |

| 13 | 0.105 | 82.250 | 7.570 | 4 |

| 14 | 0.094 | 86.300 | 8.250 | 4 |

| 15 | 0.101 | 86.060 | 8.050 | 4 |

| 16 | 0.150 | 84.020 | 8.510 | - |

| 17 | 0.099 | 84.220 | 8.380 | 4 |

| 18 | 0.078 | 86.190 | 9.030 | - |

| 19 | 0.101 | 83.800 | 7.630 | 4 |

| 20 | 0.086 | 86.210 | 7.890 | 4 |

| 21 | 0.085 | 85.520 | 8.390 | 4 |

| 22 | 0.092 | 86.130 | 9.880 | - |

| 23 | 0.109 | 85.070 | 7.860 | 3 |

| 24 | 0.103 | 84.280 | 7.990 | 3 |

| 25 | 0.100 | 84.760 | 7.560 | 4 |

| 26 | 0.089 | 83.620 | 7.190 | 3 |

| 27 | 0.108 | 83.660 | 7.610 | 4 |

| 28 | 0.099 | 82.170 | 7.170 | 4 |

| 29 | 0.098 | 84.000 | 8.260 | 3 |

| 30 | 0.117 | 83.800 | 8.970 | 4 |

| 31 | 0.104 | 83.310 | 8.250 | 4 |

| 32 | 0.121 | 82.980 | 7.640 | 4 |

| 33 | 0.116 | 82.890 | 8.100 | 4 |

| 34 | 0.097 | 85.400 | 8.230 | 3 |

| 35 | 0.112 | 83.740 | 8.210 | 4 |

| 36 | 0.105 | 84.740 | 7.540 | 3 |

| 37 | 0.108 | 84.960 | 8.310 | 3 |

Appendix A.3

| Module | Cut-Off Sharpness | % Blue | % Red | Optimal Position |

|---|---|---|---|---|

| 1 | 0.131 | 82.720 | 7.450 | - |

| 2 | 0.130 | 80.730 | 6.930 | - |

| 3 | 0.130 | 81.820 | 7.420 | - |

| 4 | 0.119 | 84.450 | 10.740 | - |

| 5 | 0.128 | 81.020 | 6.930 | - |

| 6 | 0.127 | 81.890 | 7.400 | - |

| 7 | 0.127 | 84.290 | 8.260 | 3 |

| 8 | 0.134 | 83.640 | 9.500 | 4 |

| 9 | 0.151 | 83.520 | 11.500 | - |

| 10 | 0.132 | 84.920 | 10.040 | - |

| 11 | 0.135 | 83.030 | 9.000 | 3 |

| 12 | 0.136 | 81.470 | 8.570 | 3 |

| 13 | 0.128 | 84.530 | 9.550 | 4 |

| 14 | 0.127 | 85.010 | 9.400 | - |

| 15 | 0.130 | 82.980 | 7.950 | - |

| 16 | 0.136 | 84.160 | 11.380 | - |

| 17 | 0.131 | 84.000 | 9.060 | 5 |

| 18 | 0.124 | 85.530 | 9.740 | - |

| 19 | 0.137 | 84.960 | 9.520 | - |

| 20 | 0.141 | 83.800 | 9.890 | - |

| 21 | 0.133 | 84.430 | 9.750 | 5 |

| 22 | 0.133 | 85.600 | 10.130 | - |

| 23 | 0.127 | 85.600 | 9.670 | - |

| 24 | 0.145 | 81.810 | 8.890 | 4 |

| 25 | 0.142 | 82.650 | 9.300 | 5 |

| 26 | 0.141 | 85.590 | 10.140 | - |

| 27 | 0.151 | 81.480 | 9.120 | 4 |

| 28 | 0.131 | 85.880 | 10.790 | - |

| 29 | 0.147 | 81.230 | 8.640 | 4 |

| 30 | 0.141 | 84.090 | 9.190 | 5 |

| 31 | 0.132 | 86.430 | 10.070 | - |

| 32 | 0.129 | 84.420 | 9.830 | - |

| 33 | 0.130 | 82.270 | 9.010 | 5 |

| 34 | 0.157 | 82.940 | 9.460 | - |

| 35 | 0.139 | 84.950 | 10.280 | - |

| 36 | 0.142 | 83.630 | 9.430 | 5 |

| 37 | 0.135 | 83.590 | 10.140 | - |

| 38 | 0.142 | 81.540 | 8.140 | 4 |

| 39 | 0.122 | 79.970 | 9.410 | - |

References

- Ma, S.H.; Lee, C.H.; Yang, C.H. Achromatic LED-based projection lens design for automobile headlamp. Optik 2019, 191, 89–99. [Google Scholar] [CrossRef]

- Van Derlofske, J.F.; McColgan, M.W. White LED sources for vehicle forward lighting. Solid State Light. II 2002, 4776, 195. [Google Scholar] [CrossRef]

- Long, X.; He, J.; Zhou, J.; Fang, L.; Zhou, X.; Ren, F.; Xu, T. A review on light-emitting diode based automotive headlamps. Renew. Sustain. Energy Rev. 2015, 41, 29–41. [Google Scholar] [CrossRef]

- VA. Nichia Breaks 100 lm/W Barrier for a White LED. Available online: https://www.ledsmagazine.com/architectural-lighting/indoor-lighting/article/16699406/nichia-breaks-100-lmw-barrier-for-a-white-led (accessed on 2 June 2023).

- Pohlmann, W.; Vieregge, T.; Rode, M. High performance LED lamps for the automobile: Needs and opportunities. Manuf. LEDs Light. Displays 2007, 6797, 67970D. [Google Scholar] [CrossRef]

- Sun, C.C.; Wu, C.S.; Lin, Y.S.; Lin, Y.J.; Hsieh, C.Y.; Lin, S.K.; Yang, T.H.; Yu, Y.W. Review of optical design for vehicle forward lighting based on white LEDs. Opt. Eng. 2021, 60, 1–20. [Google Scholar] [CrossRef]

- EU. Uniform provisions concerning the approval of motor vehicle headlamps emitting an asymmetrical passing-beam or a driving-beam or both and equipped with filament lamps and/or light-emitting diode (LED) modules. Off. J. Eur. Union 2014, 250, 67–128. [Google Scholar]

- Albou, P.; LED Module for Headlamp. SAE Technical Papers; 2003. Available online: https://saemobilus.sae.org/content/2003-01-0556/ (accessed on 20 June 2023).

- Neumann, R.; LED Front Lighting—Optical Concepts, Styling Opportunities and Consumer Expectations. SAE Technical Papers. 2006. Available online: https://saemobilus.sae.org/content/2006-01-0100/ (accessed on 13 May 2023).

- Wu, Y.; Feng, Y.; Peng, S.; Mao, Z.; Chen, B. Generative machine learning-based multi-objective process parameter optimization towards energy and quality of injection molding. Environ. Sci. Pollut. Res. 2023, 30, 51518–51530. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.C.; Wu, T.C.; Chen, Y.S.; Yang, B.Y. A Semi-Analytical Method for Designing a Runner System of a Multi-Cavity Mold for Injection Molding. Polymers 2022, 14, 5442. [Google Scholar] [CrossRef] [PubMed]

- Martínez, S.S.; Ortega, J.G.; García, J.G.; García, A.S.; Estévez, E.E. An industrial vision system for surface quality inspection of transparent parts. Int. J. Adv. Manuf. Technol. 2013, 68, 1123–1136. [Google Scholar] [CrossRef]

- Psarommatis, F.; Sousa, J.; Mendonça, J.P.; Kiritsis, D. Zero-defect manufacturing the approach for higher manufacturing sustainability in the era of industry 4.0: A position paper. Int. J. Prod. Res. 2022, 60, 73–91. [Google Scholar] [CrossRef]

- Satorres Martínez, S.; Illana Rico, S.; Cano Marchal, P.; Martínez Gila, D.M.; Gómez Ortega, J. Zero Defect Manufacturing in the Food Industry: Virgin Olive Oil Production. Appl. Sci. 2022, 12, 5184. [Google Scholar] [CrossRef]

- Brick, P.; Schmid, T. Automotive headlamp concepts with low-beam and high-beam out of a single LED. Illum. Opt. II 2011, 8170, 817008. [Google Scholar] [CrossRef]

- Ying, S.P.; Chen, B.M.; Fu, H.K.; Yeh, C.Y. Single headlamp with low-and high-beam light. Photonics 2021, 8, 32. [Google Scholar] [CrossRef]

- Valeo Service. Lighting systems From light to advanced vision technologies. In Automotive Technology, Naturally; Valeo Service: Paris, France, 2015; pp. 1–100. [Google Scholar]

- Moscow Architectural Institute. Brief Information; Moscow Architectural Institute: Moscow, Russia, 2006. [Google Scholar]

- Tehrani, B.M.; BuHamdan, S.; Alwisy, A. Robotics in assembly-based industrialized construction: A narrative review and a look forward. Int. J. Intell. Robot. Appl. 2023, 7, 556–574. [Google Scholar] [CrossRef]

- Sun, W.; Mu, X.; Sun, Q.; Sun, Z.; Wang, X. Analysis and optimization of assembly precision-cost model based on 3D tolerance expression. Assem. Autom. 2018, 38, 497–510. [Google Scholar] [CrossRef]

- Shi, X.; Tian, X.; Wang, G.; Zhao, D. Semantic-based assembly precision optimization strategy considering assembly process capacity. Machines 2021, 9, 269. [Google Scholar] [CrossRef]

- McKenna, V.; Jin, Y.; Murphy, A.; Morgan, M.; Fu, R.; Qin, X.; McClory, C.; Collins, R.; Higgins, C. Cost-oriented process optimisation through variation propagation management for aircraft wing spar assembly. Robot. Comput.-Integr. Manuf. 2019, 57, 435–451. [Google Scholar] [CrossRef]

- Wang, K.; Liu, D.; Liu, Z.; Wang, Q.; Tan, J. An assembly precision analysis method based on a general part digital twin model. Robot. Comput.-Integr. Manuf. 2021, 68, 102089. [Google Scholar] [CrossRef]

- Pulikottil, T.; Estrada-Jimenez, L.A.; Ur Rehman, H.; Mo, F.; Nikghadam-Hojjati, S.; Barata, J. Agent-based manufacturing—Review and expert evaluation. Int. J. Adv. Manuf. Technol. 2023, 127, 2151–2180. [Google Scholar] [CrossRef]

- Gomez Ortega, J.; Gamez Garcia, J.; Satorres Martinez, S.; Sanchez Garcia, A. Industrial assembly of parts with dimensional variations. Case study: Assembling vehicle headlamps. Robot. Comput.-Integr. Manuf. 2011, 27, 1001–1010. [Google Scholar] [CrossRef]

- Booch, G.; Rumbaugh, J.; Jacobson, I. Unified Modeling Language User Guide, 2nd ed.; Addison-Wesley Longman Publishing Co., Inc.: Boston, MA, USA, 2015; pp. 392–393. ISBN 0-201-57168-4. [Google Scholar]

- Szyperski, C.; Gruntz, D.; Murer, S. Component Software: Beyond Object-Oriented Programming; Addison-Wesley Longman Publishing Co., Inc.: Boston, MA, USA, 2002; pp. 448–449. ISBN 978-0-201-74572-6. [Google Scholar]

- Otsu, N. A threshold selection using an iterative selection method. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Hart, P.E.; Stork, D.G.; Duda, R.O. Pattern Classification; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

| TD-IZQ Model | IO1-TI-IZQ Model | F56-USA-IZQ | |||||||

|---|---|---|---|---|---|---|---|---|---|

| n | |||||||||

| 1 | 0.106 | 7.710 | 83.755 | 0.112 | 8.175 | 85.188 | 0.122 | 8.300 | 81.830 |

| 2 | 0.101 | 8.911 | 84.428 | 0.094 | 9.140 | 86.252 | 0.136 | 8.790 | 83.670 |

| 3 | 0.099 | 9.288 | 86.450 | 0.096 | 7.543 | 80.516 | 0.139 | 8.810 | 82.680 |

| 4 | 0.093 | 7.671 | 83.491 | 0.121 | 7.798 | 80.488 | 0.13 | 8.950 | 82.660 |

| 5 | 0.095 | 8.321 | 83.993 | 0.102 | 8.246 | 85.275 | 0.141 | 8.610 | 82.150 |

| 6 | 0.104 | 8.367 | 85.995 | 0.081 | 8.215 | 85.877 | 0.148 | 8.520 | 80.680 |

| 7 | 0.106 | 8.735 | 86.558 | 0.141 | 7.091 | 79.242 | 0.132 | 9.360 | 83.160 |

| 8 | 0.104 | 8.394 | 86.281 | 0.107 | 7.379 | 79.612 | 0.137 | 9.070 | 83.690 |

| 9 | 0.089 | 13.268 | 84.475 | 0.110 | 7.543 | 81.971 | 0.130 | 9.820 | 84.820 |

| 10 | 0.093 | 8.186 | 82.262 | 0.091 | 7.743 | 82.171 | 0.140 | 9.160 | 82.790 |

| 11 | 0.073 | 21.520 | 78.560 | 0.141 | 9.348 | 82.426 | 0.131 | 8.40 | 83.080 |

| 12 | 0.090 | 11.923 | 85.276 | 0.080 | 9.048 | 88.057 | 0.144 | 9.570 | 84.450 |

| 13 | 0.115 | 9.573 | 86.048 | 0.088 | 8.673 | 87.041 | 0.131 | 9.140 | 83.220 |

| 14 | 0.087 | 19.095 | 80.774 | 0.091 | 6.898 | 82.281 | 0.138 | 8.770 | 82.650 |

| 15 | 0.096 | 8.637 | 84.160 | 0.092 | 7.355 | 81.132 | 0.136 | 8.570 | 82.070 |

| 16 | 0.103 | 8.101 | 83.449 | 0.118 | 6.740 | 82.017 | 0.135 | 8.830 | 83.130 |

| 17 | 0.090 | 10.141 | 87.980 | 0.117 | 7.410 | 81.918 | 0.136 | 9.790 | 83.760 |

| 18 | 0.093 | 7.918 | 83.813 | 0.097 | 8.859 | 86.529 | 0.142 | 8.600 | 81.880 |

| 19 | 0.096 | 9.821 | 85.977 | 0.104 | 7.749 | 82.989 | 0.142 | 8.060 | 81.310 |

| 20 | 0.089 | 8.980 | 84.380 | 0.113 | 7.598 | 81.669 | 0.135 | 8.730 | 83.080 |

| 21 | 0.117 | 8.727 | 79.788 | 0.099 | 8.350 | 85.437 | 0.13 | 8.000 | 82.740 |

| 22 | 0.119 | 7.332 | 82.822 | 0.083 | 7.797 | 81.96 | 0.136 | 9.470 | 83.030 |

| 23 | 0.091 | 13.343 | 84.209 | 0.099 | 8.609 | 86.016 | 0.136 | 8.620 | 82.710 |

| 24 | 0.089 | 18.684 | 80.522 | 0.091 | 6.876 | 81.534 | 0.153 | 9.140 | 82.640 |

| 25 | 0.103 | 14.583 | 83.358 | 0.116 | 7.302 | 81.947 | |||

| 26 | 0.100 | 8.181 | 85.592 | 0.105 | 8.383 | 86.926 | |||

| 27 | 0.112 | 10.786 | 86.113 | 0.093 | 8.247 | 84.69 | |||

| 28 | 0.115 | 8.059 | 85.042 | 0.117 | 6.792 | 81.028 | |||

| 29 | 0.092 | 12.739 | 83.006 | 0.085 | 8.799 | 86.838 | |||

| 30 | 0.088 | 13.322 | 83.622 | 0.111 | 6.761 | 82.624 | |||

| 31 | 0.078 | 25.687 | 70.258 | 0.097 | 7.723 | 82.142 | |||

| 32 | 0.116 | 8.440 | 85.882 | 0.099 | 7.171 | 81.134 | |||

| 33 | 0.106 | 15.711 | 82.083 | 0.103 | 8.274 | 85.487 | |||

| 34 | 0.090 | 14.901 | 82.231 | 0.106 | 7.291 | 82.135 | |||

| 35 | 0.101 | 9.203 | 83.271 | 0.108 | 8.425 | 85.643 | |||

| 36 | 0.091 | 13.371 | 84.116 | 0.125 | 7.253 | 81.102 | |||

| 37 | 0.090 | 12.300 | 83.759 | 0.098 | 8.039 | 85.682 | |||

| 38 | 0.068 | 19.253 | 79.976 | 0.097 | 7.012 | 81.718 | |||

| 39 | 0.093 | 13.674 | 83.290 | 0.089 | 8.771 | 85.739 | |||

| 40 | 0.110 | 9.316 | 85.419 | 0.102 | 6.802 | 80.711 | |||

| 41 | 0.106 | 7.697 | 85.693 | ||||||

| 42 | 0.104 | 6.963 | 81.239 | ||||||

| 43 | 0.117 | 6.572 | 81.038 | ||||||

| 44 | 0.114 | 6.925 | 81.497 | ||||||

| 45 | 0.107 | 6.601 | 81.304 | ||||||

| 46 | 0.117 | 7.239 | 80.902 | ||||||

| 47 | 0.097 | 7.675 | 85.742 | ||||||

| 48 | 0.098 | 8.753 | 85.947 | ||||||

| Model | Cut-Off Sharpness () | Percentage of Red () | Percentage of Blue () |

|---|---|---|---|

| TD-IZQ | (0.068–0.119) | (7.330–25.680) | (70.250–87.980) |

| IO1-TI-IZQ | (0.080–0.141) | (6.570–9.340) | (79.240–88.050) |

| F56-USA-IZQ | (0.122–0.153) | (8.000–9.820) | (80.680–84.820) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Satorres Martínez, S.; Martínez Gila, D.M.; Rico, S.I.; Teba Camacho, D. Machine Vision System for Automatic Adjustment of Optical Components in LED Modules for Automotive Lighting. Sensors 2023, 23, 8988. https://doi.org/10.3390/s23218988

Satorres Martínez S, Martínez Gila DM, Rico SI, Teba Camacho D. Machine Vision System for Automatic Adjustment of Optical Components in LED Modules for Automotive Lighting. Sensors. 2023; 23(21):8988. https://doi.org/10.3390/s23218988

Chicago/Turabian StyleSatorres Martínez, Silvia, Diego Manuel Martínez Gila, Sergio Illana Rico, and Daniel Teba Camacho. 2023. "Machine Vision System for Automatic Adjustment of Optical Components in LED Modules for Automotive Lighting" Sensors 23, no. 21: 8988. https://doi.org/10.3390/s23218988

APA StyleSatorres Martínez, S., Martínez Gila, D. M., Rico, S. I., & Teba Camacho, D. (2023). Machine Vision System for Automatic Adjustment of Optical Components in LED Modules for Automotive Lighting. Sensors, 23(21), 8988. https://doi.org/10.3390/s23218988