Abstract

Despite its undeniable advantages, the operation of a CT scanner also carries risks to human health. The CT scanner is a source of ionizing radiation, which also affects people in its surroundings. The aim of this paper is to quantify the radiation exposure of workers at a 3D CT wood scanning workplace and to determine a monitoring program based on measurements of ionizing radiation levels during the operation of a CT log scanner. The workplace is located in the Biotechnology Park of the National Forestry Centre. The ionizing radiation source is located in a protective cabin as a MICROTEC 3D CT machine with an X-ray lamp as X-ray source. The CT scanner is part of the 3D CT scanning line and its function is continuous quality scanning or detection of internal defects of the examined wood. The measurement of leakage radiation during scanning is performed with a metrologically verified meter. The measured quantity is the ambient dose equivalent rate . The results of the measurements at the selected measurement sites have shown that, after installation of additional safety barriers, the CT scanner for the logs complies with the most strict criteria in terms of radiation protection. Workers present at the workplace during the operation of the CT scanner are not exposed to radiation higher than the background radiation level.

1. Introduction

In recent decades, there has been a growing development of non-destructive quality testing of various materials. This scientific field is called defectoscopy. The role of defectoscopy is to detect defects in a material or product using a set of methods or by monitoring physical parameters. Based on the type of waves that interact with the material, these methods are divided into ultrasonic, infrared, visual and X-ray, and magnetic defectoscopy.

X-ray defectoscopy has started to be applied and developed especially in the medical field of radiology, where X-rays are used to scan living structures. By improving this concept and using computer technology, the first commercial medical CT scanner was developed in 1972 [1]. With gradual development, X-ray scanners also began to find applications in industry for checking defects in castings and welds as well as for scanning baggage at airports. The first tests and modifications for non-medical use of a CT scanner began at the Los Alamos Laboratory, where a research and development program was established for this purpose in 1977 [2]. Today, CT scanners have a wide range of applications mainly in research, reverse engineering, measurement and digitization [3]. An example is the use of CT scanning to detect the distribution of rejuvenation products of porous asphalt [4]. The authors Liang et al., 2020, used industrial CT scanning technology to test the compaction quality of cement-stabilized macadam [5]. The use of CT scanning in investigating the health status of tree seedlings is interesting [6]. A case study from 2016 was undertaken to compare a medical CT scanner with an industrial CT scanner [7].

In the 1980s, Microtec began to develop and use computer tomography technology to scan tree trunks. The aim was to know the internal features of the wood before cutting plans were made. Today we can say that the company has been successful in its efforts and nowadays there are several CT scanners for logs in operation and installed in wood processing plants all over the world. This basic idea has enabled the development in the application of CT scanning in the forestry and timber sector. CT scanners can be used to optimize the position of a trunk during cutting. Research has confirmed a 13% increase in economic value [8]. The application of fast and continuous scanning of timber logs was demonstrated by Ursella et al. The scanning speed reached up to 160 m/min [9]. Another example is the demonstration that the introduction of furniture production optimization using CT scanning can increase the economic value by 11% [10]. The introduction of CT scanning technology is also related to the development of software tools for the automatic detection of wood defects, the use of neural networks [11] and the principles of computer vision [12,13].

Despite its undeniable advantages, the operation of a CT scanner also carries risks to human health. A CT scanner is a source of ionizing radiation and working near it is an activity causing radiation exposure. Today, industrial CT scanning technology is so well developed, we can say that it is a very safe technology using which a worker is exposed to a very small dose of radiation [14,15]. It has been shown the benefits obtained outweigh the risks when CT scanners are used in medicine [16,17,18]. The question is whether this is also the case for industrial applications.

Radiation protection is a system of technical and organizational measures to protect people from the effects of ionizing radiation [19]. The system of variables used in radiation protection is dynamically evolving and current information is published in the ICRU (International Commission on Radiation Units and Measurements) and ICRP (International Commission on Radiological Protection) materials. The quantities used can be divided into operational quantities, radiation protection quantities and basic physical quantities. Operational quantities are used for direct measurement and include the ambient dose equivalent to that used in this work. They have been defined to provide a reasonable estimate of the second group, the radiation protection quantities. These are not directly measurable, but are used to estimate the health effects of ionizing radiation and are therefore used to set exposure limits. This includes the effective dose, for which limit values are set in current legislation. The relationship between these quantities is defined by relating these quantities to the basic physical quantities, fluence, kerma in the air and absorbed dose, by means of conversion factors. For photon radiation, the conversion factors are related to the kerma in the air. For each exposure situation assessed, the value of the measured operational quantity shall always be greater than, or at least equal to, the calculated value of the radiation protection quantity, while the disparity shall not be large. According to ICRU report No. 57 [20], for photon radiation in the energy range 60 keV–10 MeV the ratio between the effective dose and the ambient dose equivalent is in the range 0.75–0.92, and for low energy radiation this ratio is even lower. To demonstrate compliance with the limits expressed in radiation protection quantities, it is therefore possible to directly use the operational quantities as a conservative estimate.

While reducing the radiation dose per scan is particularly relevant in clinical and biological CT, the effects of X-ray exposure on the scanned object are often negligible in industrial CT [15]. General principles of radiation protection, justification, optimization and dose limitation [21] thus apply only to the potential public and occupational exposure.

The first principle of justification, to ensure that the individual or societal benefit resulting from the practice outweighs the health detriment that it may cause, can be documented by the benefit of optimization of log sawing based on the CT scan data. A large published review [22] states 3% to 28% lumber value improvement based on the knowledge of position and size of internal log defects, such as knots and decay, depending on the wood species. Such benefit can hardly be achieved using alternative methods while related radiation exposure risks can be optimized.

In the second principle of optimization, with the given source of ionizing radiation, several methods can be applied to optimize the exposure. The three main methods used to control the exposure to ionizing radiation are time, distance and shielding.

Typical CT scanning devices will have a shielding of the radiation source of some kind, to ensure the directional and energy properties of the emitting radiation. The scanning chamber itself will furthermore shield the radiation. Properties of the shielding can be optimized in order to achieve the desired shielding effect, while keeping in mind technical requirements such as access to the device.

Time is in many situations the most effective method to optimize the exposure. In case of industrial CT scanners, it would be applied as a combination of work planning and application of operating procedures for the workers involved. The scanning process is controlled remotely from the control room; the only relevant workplace is log manipulation.

Distance is applied directly with the use of a remote control and operation of the scanning unit. Furthermore, the concept of controlled area and supervised area allows to define areas where certain exposure can be expected and to apply relevant measures to control the presence of persons.

The third principle, dose limitation, is required by the relevant legislation. In the European Union according to Directive 2013/59/EURATOM, the limit on the effective dose for occupational exposure shall be 20 mSv in any single year [23]. This is often transposed to national legislation, as is the case for Slovakia [21].

This paper is focused on the issue of radiation protection of the wood log scanning line, which includes the unique computer tomography technology. This technology makes it possible to create a 3D model of a log of wood and display its internal defects. This model subsequently serves to optimize cutting plans in order to maximize yield. There are currently 14 CT log scanners installed in the world, and the 15th one mentioned in this study is operated in a research and development environment, where it serves as a tool for increasing the competitiveness of the forestry sector. The chosen form of the case study demonstrates a specific situation in operation and applies the general principles of radiation protection in practice. Currently, such a case study has not been published and can be of benefit to both the scientific and application communities.

The aim of this paper is to quantify the radiation exposure of workers at a 3D CT wood scanning workplace based on measurements of ionizing radiation levels during the operation of a log CT scanner, to compare it with limit values, and to determine a monitoring program.

2. Materials and Methods

2.1. Description of the 3D CT Scanning Workplace

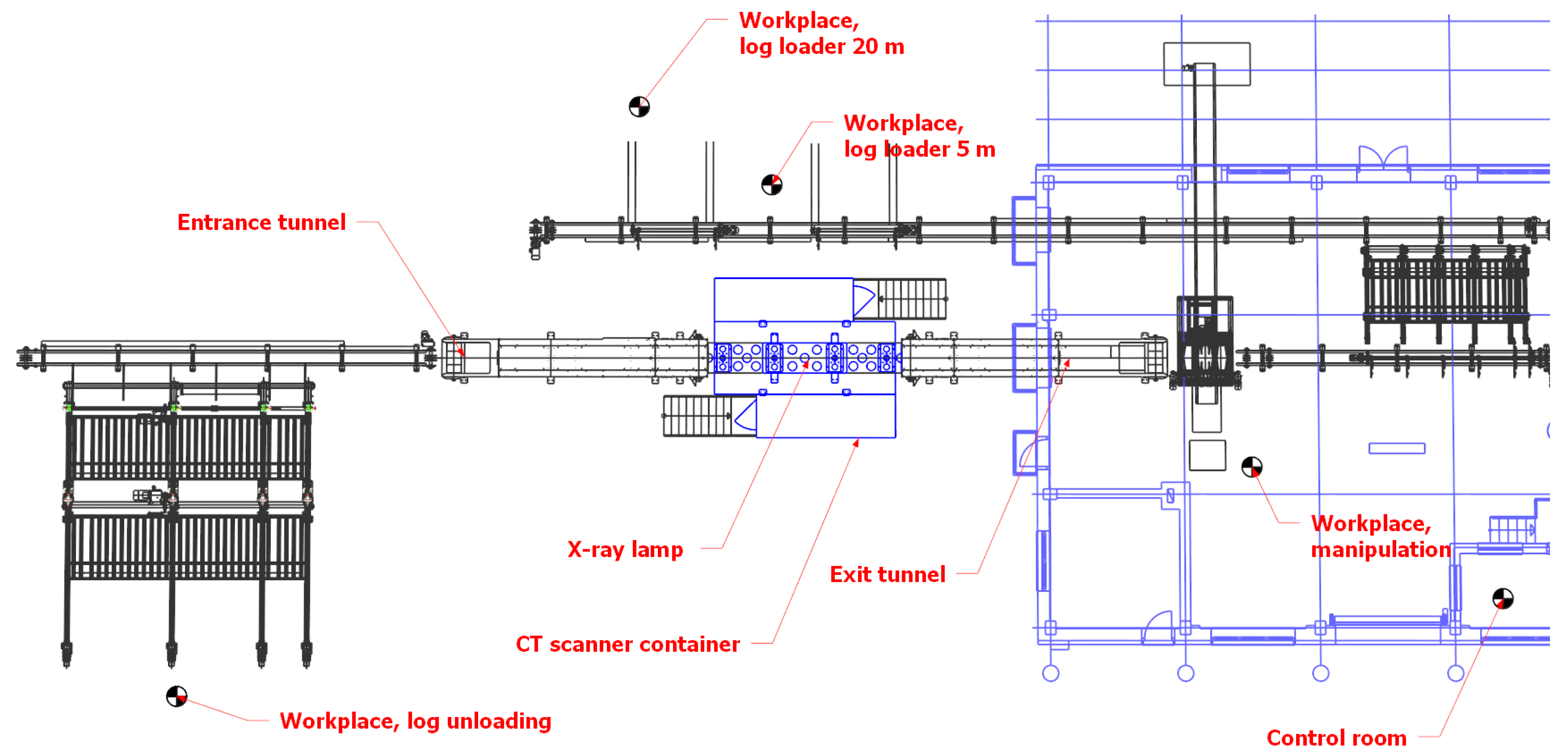

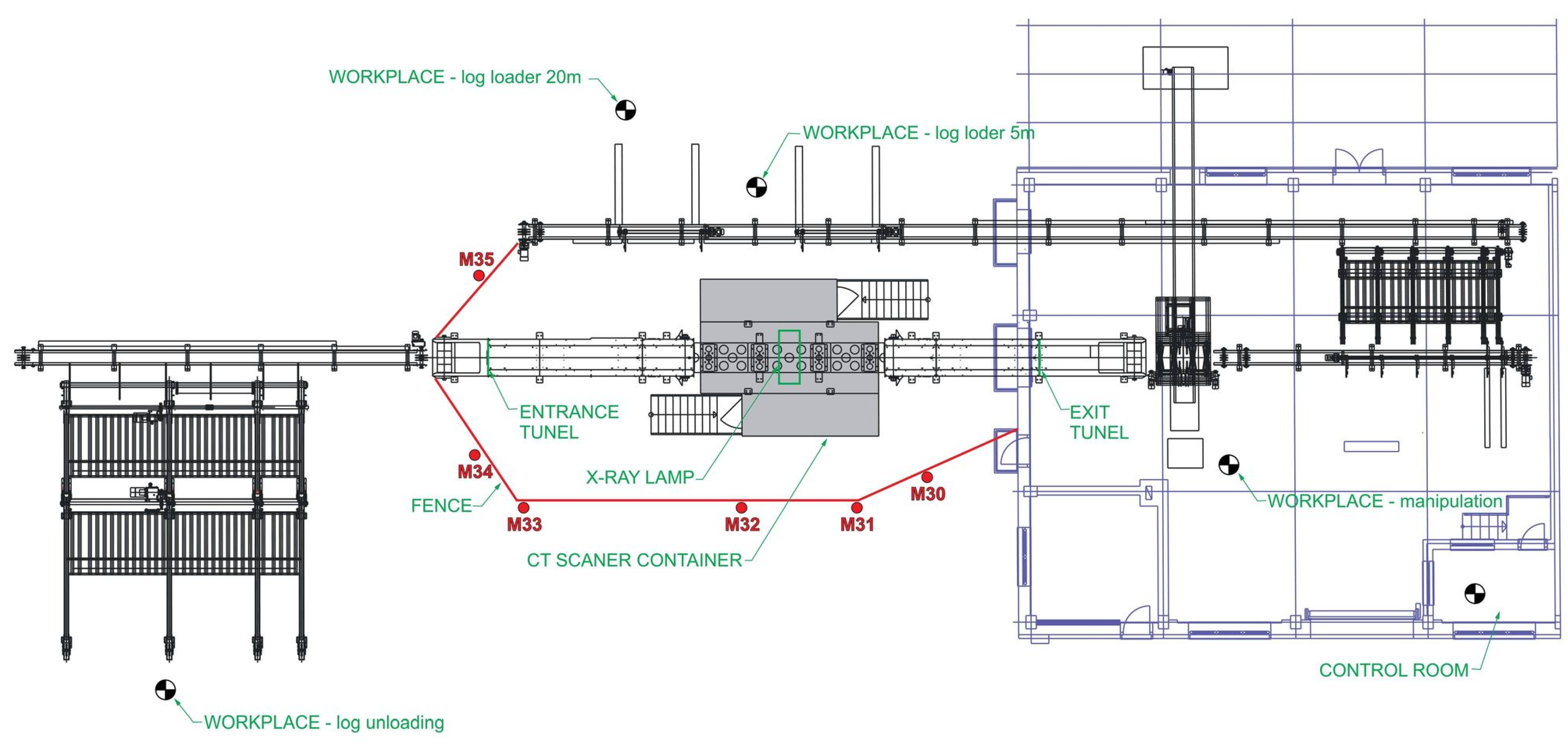

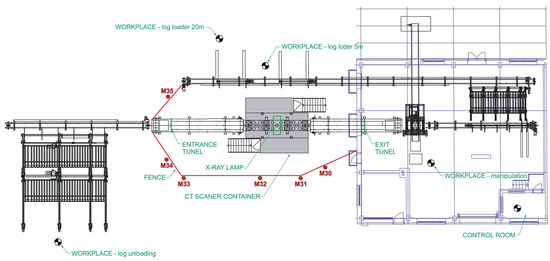

The workplace is located in the Biotechnology Park of the National Forest Centre. The ionizing radiation source is an X-ray tube placed in a protective cabin as a 3D CT device MICROTEC (Brixen, Italy). The CT scanner is part of the 3D CT scanning line (Figure 1) and its function is continuous quality scanning or detection of internal defects of the wood under examination. The examined logs are loaded mechanically on a conveyor with a feed speed of 5 m/min, which allows scanning the material along its entire length. The inlet and outlet openings of the CT scanner’s protective cabin are protected by slats of lead rubber declared by the manufacturer as the equivalent of 4 mm Pb at 225 kV.

Figure 1.

Schematic of the 3D CT scanning line.

After entering the protected scanning cabin through the scanning portal, the tree trunk is tomographically scanned. The results of the diagnostics are displayed directly on a PC in the control room. The vault is located in a specially protected area of the 3D CT scanning workstation.

The CT scanner is capable of measuring quality, deformation and other values through the penetration of X-rays with a voltage of up to 225 kV. A narrow fan-shaped moving beam of radiation is detected by the sensor array. The device can be accessed from both sides. Access is restricted and secured against unwanted entry by barriers with safety components. The operation is fully automatic, but the device requires the presence of an operator to monitor, control and intervene in the management of the operation system (Figure 1).

The workplace itself and the surrounding area are marked with a label, showing the symbol of the ionizing radiation source according to the relevant legislation of the country where the radiation source is operated.

2.2. Method

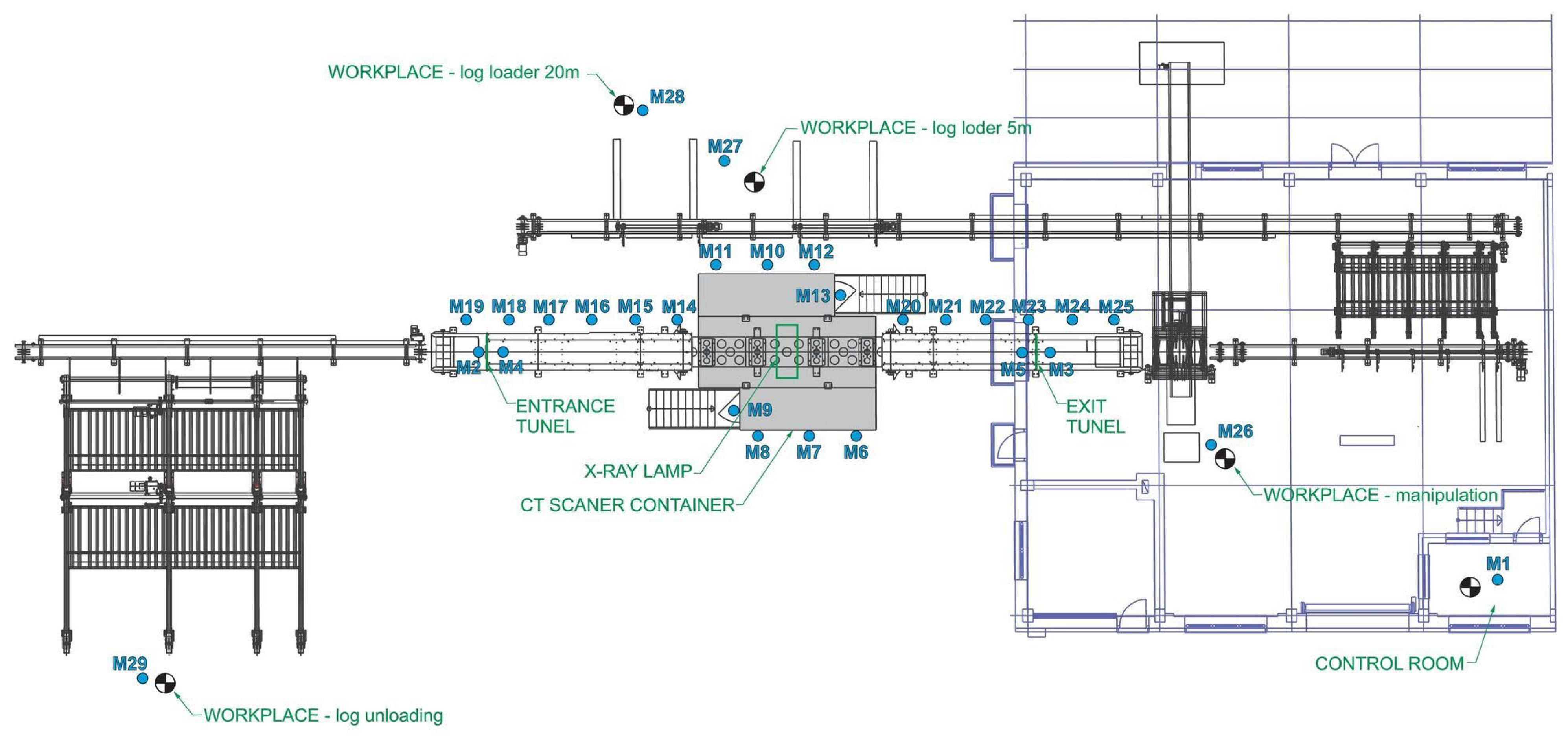

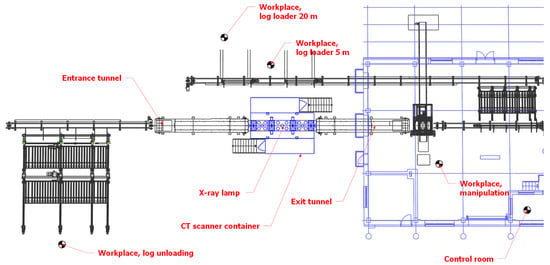

The measurement of leakage radiation during scanning was performed with a metrologically verified instrument. The measured value was the ambient dose equivalent rate . The measurement was carried out on 7th of October 2022. In the first step, the ambient dose equivalent rate of the background was measured, i.e., with the CT scanner switched off. In the second step, measurement locations were selected at which the value was subsequently measured during the log scanning process. The following Figure 2 shows the layout of the 3D CT wood scanning workstation with the operator staff positions and measurement points M1 to M29 marked.

Figure 2.

Layout of the 3D CT wood scanning workplace and selected measuring points M1 to M29.

2.3. Methodology for Calculating the Effective Dose Value E

The effective dose E is the sum of the weighted equivalent HT doses in all organs or tissues of the body due to internal and external exposure multiplied by the appropriate tissue weighting factor WT

where WT is the tissue weighting factor of the tissue or organ T, WR is the radiation weighting factor of the ionizing radiation R and DT,R is the mean absorbed radiation dose R in the tissue T.

The tissue weighting factors WT of an organ or tissue T represent the relative contribution of that organ to the total health damage caused by the stochastic effects of ionizing radiation. The unit of the effective dose is Sievert (Sv). One Sievert is equivalent to one joule per kilogram.

2.4. Measuring Equipment

Two independent measuring devices were used for the measurement of the leakage radiation. Both devices are calibrated. Full specifications of the measuring devices are listed in the Table 1.

Table 1.

Technical parameters of the measuring devices.

APVL Thermo Scientific (Saint-Cyr-sur-Loire, France), FH 40 G-L10 Ω ambient dose equivalent rate meter : Measurement working range for of 10 nSv/h–100 mSv. Energy range 30 keV–4.4 MeV. Data error: typically <5%, maximum 20%, for 137Cs radiation (E = 662 keV). Directional dependence <20% over the range −75°, +75° with regard to the longitudinal axis of the instrument.

Thermo Scientific, RadEye G 20-10 (Loughborough, UK), ambient dose equivalent rate meter : Measuring working range for dose equivalent 10 nSv/h–2 mSv. Energy range 17 keV–1.3 MeV. Data error: typically <5%, maximum 20%, for 137Cs radiation (E = 662 keV). The instrument is equipped with a telescopic rod, for making measurements in inaccessible places.

Measurement quality was ensured in several ways. High-end measuring devices designed for this purpose were used for the measurement. The measuring devices were calibrated by competent authorities and metrologically verified. The measurement was carried out by a person with the appropriate accreditation. The measurement itself took place simultaneously on two measuring devices, with one measuring device serving as a control for the measured values.

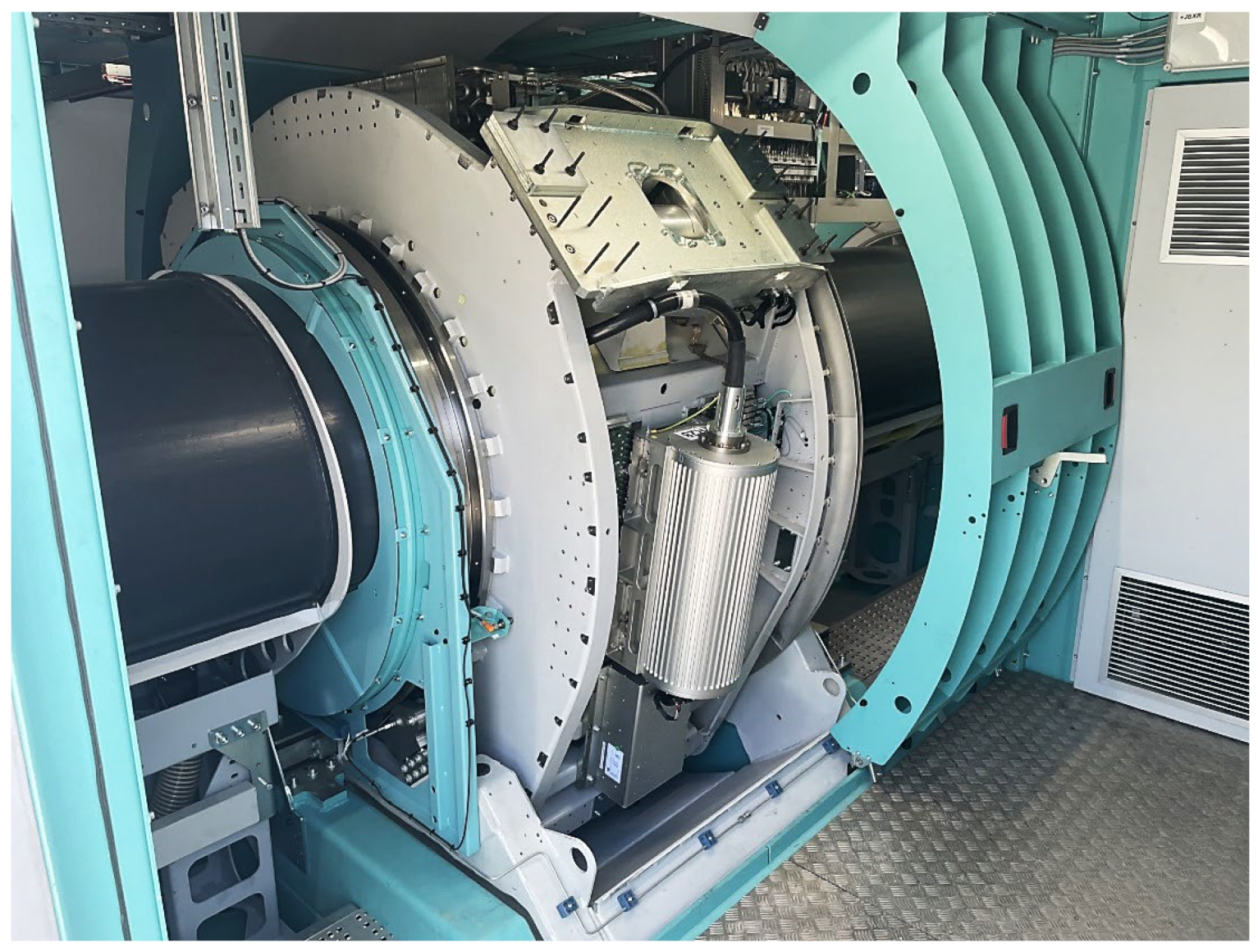

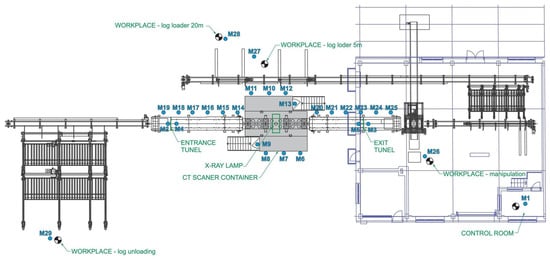

2.5. The Source of Radiation

The source of ionizing radiation was an MXR-225FB X-ray lamp placed in the rotating portal for the purpose of continuous CT scanning of tree trunks. CT scans of tree trunks were taken in order to detect internal wood defects. The following Table 2 lists the technical parameters of the radiation source.

Table 2.

Technical parameters of the radiation source.

Figure 3 shows the radiation source, an X-ray tube placed in a rotating portal that rotates around the object being scanned.

Figure 3.

Radiation source located in the rotating portal of a CT scanner.

3. Results

The measured background value of the ambient dose equivalent rate at the 3D CT wood scanning workstation is 0.13 μSv/h. Table 3 shows the measured values of the ambient dose equivalent rate at different workplace locations of the 3D CT wood scanning workstation compared with the occupational exposure limit. Table 4 shows the measured values of the ambient dose equivalent rate at all measured locations of the 3D CT wood scanning workstation, compared to the exposure limit value for non-exposed outside workers as well as for the supervised area. The CT equipment was in working mode during the measurement—scanning of logs with a diameter of 35 cm was in progress.

Table 3.

Measured ambient dose equivalent rates at workstation sites compared with occupational exposure limit.

Table 4.

Measured ambient dose equivalent rates at selected measurement sites compared with supervised area effective dose limit.

The measured values show that the ambient dose equivalent rate at measurement points M1, M28 and M29 was the same as the ambient dose equivalent rate of the background. Measurement sites M26 and M27 showed an increased value of 0.02 μSv/h and 0.04 μSv/h compared to the background.

The highest ambient dose equivalent rate values were obtained at measurement points M4 and M5, which are the log inlet and outlet of the CT scanner, and measurement points M14 and M20, which are the interfaces between the shielded part of the CT scanner container and the inlet and outlet scanning tunnels. As the distance from these points increases, the measured ambient dose equivalent rate values decrease (measurements from M14 to M19 and measurements from M20 to M25).

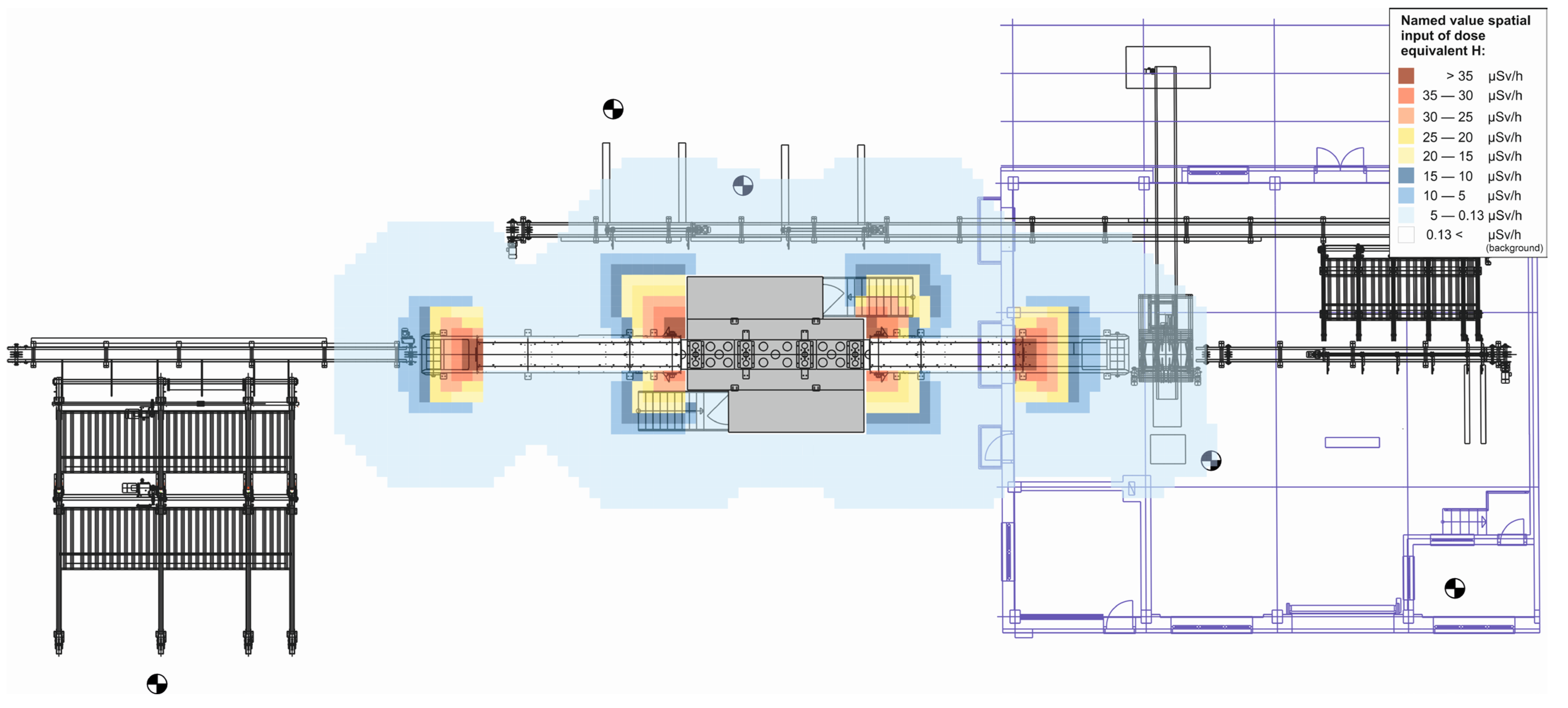

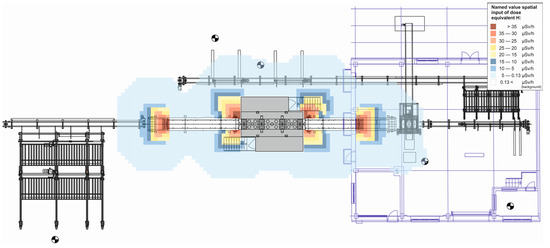

Based on the measured values of the ambient dose equivalent at the measurement points, a 3D CT radiation exposure map of the log scanning workplace was interpolated (Figure 4).

Figure 4.

Map of ionizing radiation exposure of a 3D CT scanning workstation for logs.

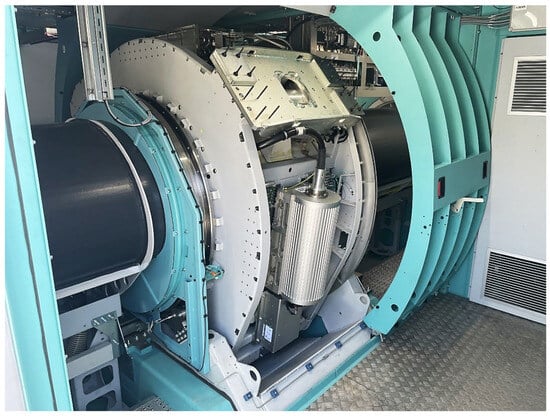

Given the ambient dose equivalent rate values reached at the measurement sites that are accessible to non-exposed outside workers during CT scanner operation, there is a risk that they could be exposed to ionizing radiation that comes close to or exceeds the limit (see Table 5 for a comparison with the annual limit of 1 mSv effective dose). It is therefore necessary to establish safety measures to prevent people accessing these sites. These were implemented in the form of a fence defining the supervised area (Figure 5). The legislation requirements for establishment of a supervised area in the Slovak legislation [21] are defined as a possibility to exceed the annual effective dose 1 mSv. Subsequently, control measurements of the ambient dose equivalent rate at the boundary of the fence were made at measurement points M30 to M35.

Table 5.

Measured ambient dose equivalent rate values at the CT scanner fence boundary.

Figure 5.

Definition of the supervised area by fencing—red.

Table 5 shows the measured ambient dose equivalent rate values at the fence boundary.

The results show that the implemented safety measures (establishment of supervised area) fulfil their function, since no person can be exposed to ionizing radiation exceeding the annual limit of 1 mSv effective dose per year at any point accessible to outside workers during the operation of the CT scanner. To the above results it should be noted that the doses were calculated for a 500 h time exposure for the outside workers. This exposure time is conservatively overestimated. The overestimation is based on the fact that the CT scanner will not be operating continuously and the expected working time of the X-ray tube will not exceed the 500 h estimate. Furthermore, it is neither expected, nor necessary, for any person to stay in the area near the protective fence during the operation of the CT scanner. In reality, the real exposure time will be considerably shorter and thus the results of the received dose at the individual measurement points will be lower. The real annual exposure time will be monitored in the future and the results will be re-evaluated according to the observed data.

4. Discussion

The operating CT scanner for logs of wood is comparable in design to CT scanners used in medicine. The difference is in the adaptation of the dimensions of the device so that the wood logs can be scanned. In terms of physical principle, the operation of the CT scanner is the same as that of medical CT scanners. In contrast to the use of CT scanners in medicine, when scanning logs of wood we do not have to take the need to minimize the exposure of the scanned subject to ionizing radiation into account. A CT log scanner can operate at full power, which is approximately double that of a medical CT scanner. A medical CT scanner has a limit for X-ray voltages of 120 to 130 kV, in the case of an industrial CT scanner the X-ray voltages can reach 225 kV [7].

The International Commission on Radiological Protection (ICRP) provides guidance and recommendations on radiation protection. When it comes to industrial CT scanner use, several ICRP publications may be relevant. The ICRP Publication 103 (2007)—“The 2007 Recommendations of the International Commission on Radiological Protection.” [24]—provides the foundational recommendations on radiation protection, including dose limits and principles for radiation protection. It lays the groundwork for understanding radiation protection in various contexts, including industrial applications. The ICRP Publication 129 (2021)—“Radiological Protection in Cone Beam Computed Tomography.” [25]—may be particularly relevant to industrial CT scanner use, as it addresses the radiation protection aspects of cone beam computed tomography, a technology similar to traditional CT scanning. The ICRP Publication 75,—“General Principles for the Radiation Protection of Workers.” [26]—provides fundamental principles for radiation protection and is applicable to various contexts, including industrial uses of radiation-emitting devices like CT scanners. While it may not be specific to CT scanners, it offers general guidelines for the protection of workers in radiation environments.

In the protection of individuals, whether residents or workers, the protection against ionizing radiation in the operation of an industrial CT scanner is very effective. A full range of protective features such as spacing, demarcation of space and shielding barriers can be used to effectively prevent the penetration of ionizing radiation. As a result, the industrial CT scanning worker may not be exposed to ionizing radiation above the background level.

There are risks associated with a failure or crash of the CT scanner. The risk of radiation exposure in the case of CT scanners is minimized by the very nature of the radiation source. The X-ray tube is a source of radiation only if it is powered by electricity. In the case of a failure or breakage of the safety barrier, the electric current is interrupted and the X-ray tube becomes harmless from the aspect of the risk of radiation exposure. This same advantage is also present if the X-ray tube is stolen. It can be concluded that the operation of a CT scanner is less risky than the operation with a radionuclide radiation source in terms of control of the radiation source.

Today, there are many professional and scientific articles available that focus on the issue of radiation risk from computed tomography. These publications are mainly focused on the area of medical use and risk optimization for patients undergoing such tests. The modification of CT scanner performance for each patient was addressed by Bora et al., 2014 [27]. Optimization of radiation exposure from CT scans performed in pediatrics has been addressed by Brody et al., 2007, and Frush et al., 2003 [28,29].

In order to ensure a high level of radiation protection at the CT scanner workstation, the type and energy spectrum of the radiation must be taken into account. In the area to be monitored this is scattered X-ray radiation. The energy spectrum depends on the shielding material, the voltage on the electrode and the low-energy radiation filters used [22].

There are few publications focusing on the safety of CT scanning in industry. Zhou et al., 2016, conducted a study on the radiation protection of industrial computed tomography workstations [30]. In a large book publication, Industrial X-ray Computed Tomography, by Carmignato et al., 2018, the issue of safety and risk associated with CT scanner operation is not covered [31]. For these reasons, this case study can provide valuable information for the design and provision of other industrial computed tomography workplaces from the perspective of human protection from ionizing radiation.

5. Conclusions

For the purpose of assessment and subsequent optimization of the effective dose of ionizing radiation at the workplace of 3D CT scanning of logs, the individuals assessed were a professional representative from the number of workers working with the ionizing radiation source and a maintenance person from the number of workers working with ionizing radiation sources. On the basis of the results, it can be concluded that for an operation of 500 h per year with an ionizing radiation source with an ambient dose equivalent rate of approximately 0.19 μSv/h, the limit value of 1 mSv annual effective dose for a non-exposed classified worker working with ionizing radiation sources will not be exceeded in normal operation. The above applies only in the case of staying and working at the workplace workstations and locations outside the CT scanner log fence.

For the purpose of assessment and subsequent optimization of the effective dose of ionizing radiation at the 3D CT scanning workplace for the population, we consider an ambient dose equivalent rate value of about 0.02 μSv/h (subtracting terrestrial and cosmic background) at a distance of 3 m from the CT scanner for 500 h per year. The resulting effective dose to the resident is less than 10 μSv/year.

The above assessment of the radiation exposure of the 3D CT scanning of logs to workers and the general public during operation shows that it will not be necessary to demonstrate optimization of radiation protection for this activity. When comparing the cost of additional protection from ionizing radiation with the benefit of these measures, the cost of an adequate protective barrier (Pb, Fe) that would have to cover the CT scanner logs significantly outweighs the benefits of the additional protective barrier (Pb, Fe). The measurement has proven that the existing shielding is sufficient to achieve a high level of radiation protection. In addition to increasing costs, additional shielding would also limit the technological performance in terms of accessibility of the device for inspection and maintenance, thus reducing the overall efficiency of the operation of the 3D CT scanner for logs.

Author Contributions

Conceptualization, T.G. and J.H.; methodology, J.H. and M.V.; software, V.O.; validation, J.H. and T.G.; formal analysis, M.N.; resources, T.G.; data curation, V.O. and J.D.; writing—original draft preparation, T.G. and M.V.; writing—review and editing, T.G., M.N. and M.V.; visualization, V.O.; supervision, J.H. and J.D.; project administration, M.N.; funding acquisition, M.N. and T.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Slovak Research and Development Agency under the project contract no. APVV-21-0032 “Certification of log quality based on internal wood defects”, and APVV-20-0118 “3D CT detection and beech log yield optimization”, the Scientific Grant Agency of Ministry of Education, Science, Research and Sport of the Slovak Republic (grant number VEGA 1/0714/21) and Cultural and educational grant agency (KEGA 023ŽU-4/2021).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Alexander, R.E.; Gunderman, R.B. EMI and the first CT scanner. J. Am. Coll. Radiol. 2010, 7, 778–781. [Google Scholar] [CrossRef]

- Kruger, R.P.; Wecksung, G.W.; Morris, R.A. Industrial applications of computed tomography at Los Alamos Scientific Laboratory. Opt. Eng. 1980, 19, 273–282. [Google Scholar] [CrossRef][Green Version]

- Castillo, M. The industry of CT scanning. Am. J. Neuroradiol. 2012, 33, 583–585. [Google Scholar] [CrossRef]

- Zhang, Y.; Verwaal, W.; Van de Ven, M.F.C.; Molenaar, A.A.A.; Wu, S.P. Using high-resolution industrial CT scan to detect the distribution of rejuvenation products in porous asphalt concrete. Constr. Build. Mater. 2015, 100, 1–10. [Google Scholar] [CrossRef]

- Liang, C.; Wang, Y.; Tan, G.; Zhang, L.; Zhang, Y.; Yu, Z. Analysis of internal structure of cement-stabilized macadam based on industrial CT scanning. Adv. Mater. Sci. Eng. 2020, 2020, 1–10. [Google Scholar] [CrossRef]

- Dutilleul, P.; Lontoc-Roy, M.; Prasher, S.O. Branching out with a CT scanner. Trends Plant Sci. 2005, 10, 411–412. [Google Scholar] [CrossRef] [PubMed]

- du Plessis, A.; le Roux, S.G.; Guelpa, A. Comparison of medical and industrial X-ray computed tomography for non-destructive testing. Case Stud. Nondestruct. Test. Eval. 2016, 6, 17–25. [Google Scholar] [CrossRef]

- Fredriksson, M. Log sawing position optimization using computed tomography scanning. Wood Mater. Sci. Eng. 2014, 9, 110–119. [Google Scholar] [CrossRef]

- Ursella, E.; Giudiceandrea, F.; Boschetti, M. A Fast and Continuous CT scanner for the optimization of logs in a sawmill. J. Nondestruct. Test. 2018, 2, 1–5. [Google Scholar]

- Fredriksson, M. Optimizing sawing of boards for furniture production using CT log scanning. J. Wood Sci. 2015, 61, 474–480. [Google Scholar] [CrossRef]

- Pan, L.; Rogulin, R.; Kondrashev, S. Artificial neural network for defect detection in CT images of wood. Comput. Electron. Agric. 2021, 187, 106312. [Google Scholar] [CrossRef]

- Longuetaud, F.; Leban, J.M.; Mothe, F.; Kerrien, E.; Berger, M.O. Automatic detection of pith on CT images of spruce logs. Comput. Electron. Agric. 2004, 44, 107–119. [Google Scholar] [CrossRef]

- Giudiceandrea, F.; Katsevich, A.; Ursela, E. A reconstruction algorithm is a key enabling technology for a new ultrafast CT scanner. SIAM News 2016, 49, 470. [Google Scholar]

- Smith-Bindman, R. Is computed tomography safe. N. Engl. J. Med. 2010, 363, 1–4. [Google Scholar] [CrossRef]

- De Chiffre, L.; Carmignato, S.; Kruth, J.P.; Schmitt, R.; Weckenmann, A. Industrial applications of computed tomography. CIRP Ann. 2014, 63, 655–677. [Google Scholar] [CrossRef]

- Power, S.P.; Moloney, F.; Twomey, M.; James, K.; O’Connor, O.J.; Maher, M.M. Computed tomography and patient risk: Facts, perceptions and uncertainties. World J. Radiol. 2016, 8, 902. [Google Scholar] [CrossRef] [PubMed]

- Fayngersh, V.; Passero, M. Estimating radiation risk from computed tomography scanning. Lung 2009, 187, 143–148. [Google Scholar] [CrossRef]

- Thrall, J.H. Radiation exposure in CT scanning and risk: Where are we? Radiology 2012, 264, 325–328. [Google Scholar] [CrossRef] [PubMed]

- Klekner, V. (Ed.) Principy a Praxe Radiační Ochrany; AZIN CZ: Praha, Czech Republic, 2000; ISBN 80-238-3703-6. [Google Scholar]

- ICRU. International Commission on Radiation Units and Measurements. In Conversion Coefficients for Use in Radiological Protection against External Radiation; ICRU Report 57; International Commission on Radiation Units and Measurements: Bethesda, MD, USA, 1998. [Google Scholar]

- Act No. 87/2018 Coll. on radiation protection and the amendment of some laws Slovak Republic. Available online: https://www.slov-lex.sk/static/pdf/2018/87/ZZ_2018_87_20230415.pdf (accessed on 10 July 2023).

- Wei, Q.; Leblon, B.; La Rocque, A. On the use of X-ray computed tomography for determining wood properties: A review. Can. J. For. Res. 2011, 41, 2120–2140. [Google Scholar] [CrossRef]

- Council of the European Union. European Council Directive 2013/59/Euratom on basic safety standards for protection against the dangers arising from exposure to ionising radiation and repealing Directives 89/618/Euratom, 90/641/Euratom, 96/29/Euratom, 97/43/Euratom and 2003/122/Euratom; Official Journal of the EU: Brussels, Belgium, 2014; pp. L13:1–L13:73. Available online: http://data.europa.eu/eli/dir/2013/59/oj (accessed on 10 July 2023).

- ICRP. Recommendations of the International Commission on Radiological Protection (Users Edition); ICRP Publication: Ottawa, ON, Canada, 2007. [Google Scholar]

- ICRP. Radiological Protection in Cone Beam Computed Tomography (CBCT); ICRP Publication 129: Ottawa, ON, Canada, 2015. [Google Scholar]

- ICRP. General Principles for the Radiation Protection of Workers; ICRP Publication 75: Ottawa, ON, Canada, 1997. [Google Scholar]

- Bora, A.; Açikgöz, G.; Yavuz, A.; Bulut, M.D. Computed tomography: Are we aware of radiation risks in computed tomography? East. J. Med. 2014, 19, 164. [Google Scholar]

- Brody, A.S.; Frush, D.P.; Huda, W.; Brent, R.L. Radiation risk to children from computed tomography. Pediatrics 2007, 120, 677–682. [Google Scholar] [CrossRef] [PubMed]

- Frush, D.P.; Donnelly, L.F.; Rosen, N.S. Computed tomography and radiation risks: What pediatric health care providers should know. Pediatrics 2003, 112, 951–957. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.F.; Zhou, X.J.; Li, X.B.; Li, P. Radiation protection in the design of γ-ray industrial computed tomography systems. Nucl. Sci. Tech. 2016, 27, 1–7. [Google Scholar] [CrossRef]

- Carmignato, S.; Wim, D.; Richard, L. Industrial X-ray Computed Tomography; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 1–372. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).