Multi-Task Learning of Scanning Electron Microscopy and Synthetic Thermal Tomography Images for Detection of Defects in Additively Manufactured Metals

Abstract

:1. Introduction

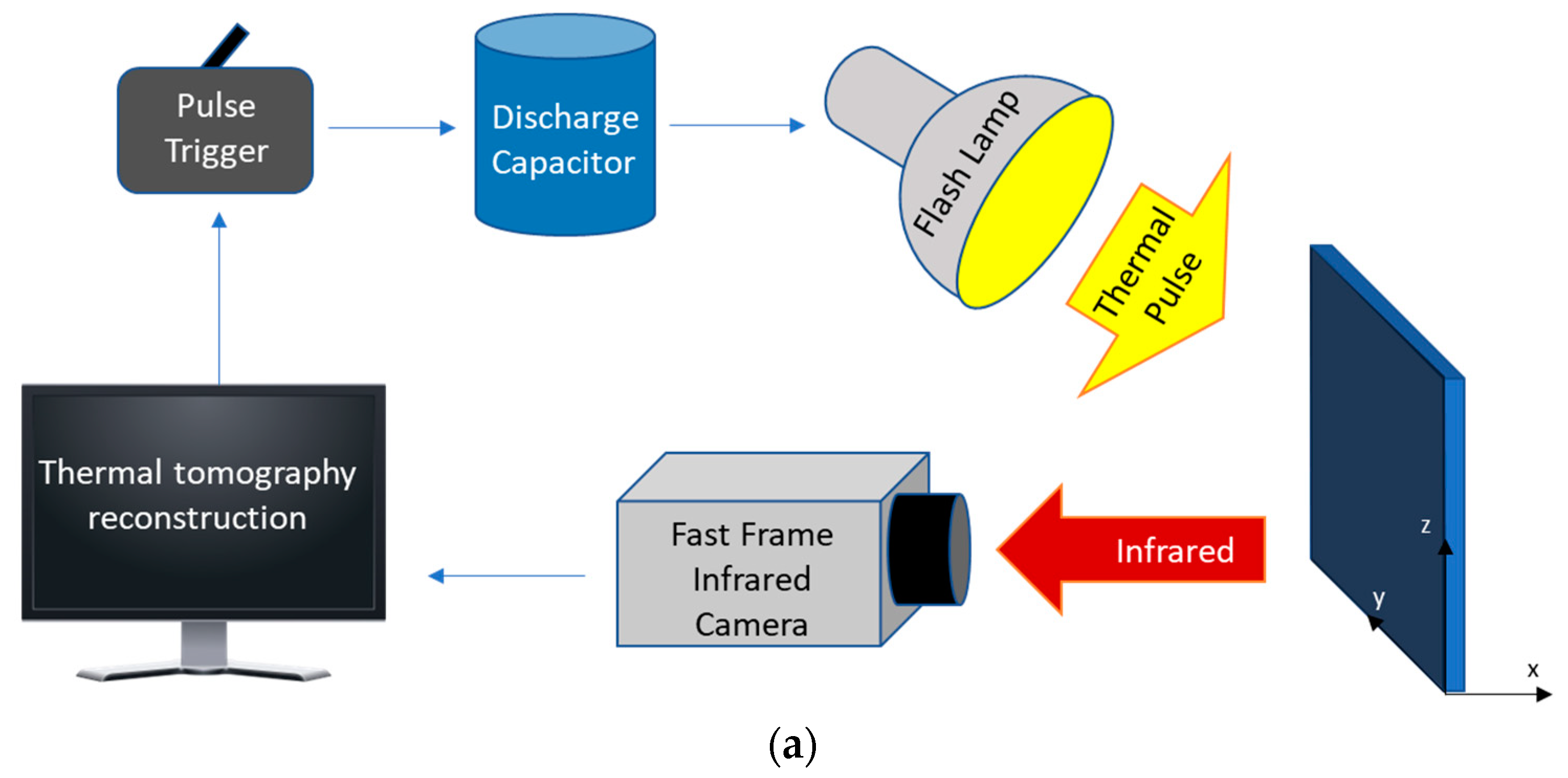

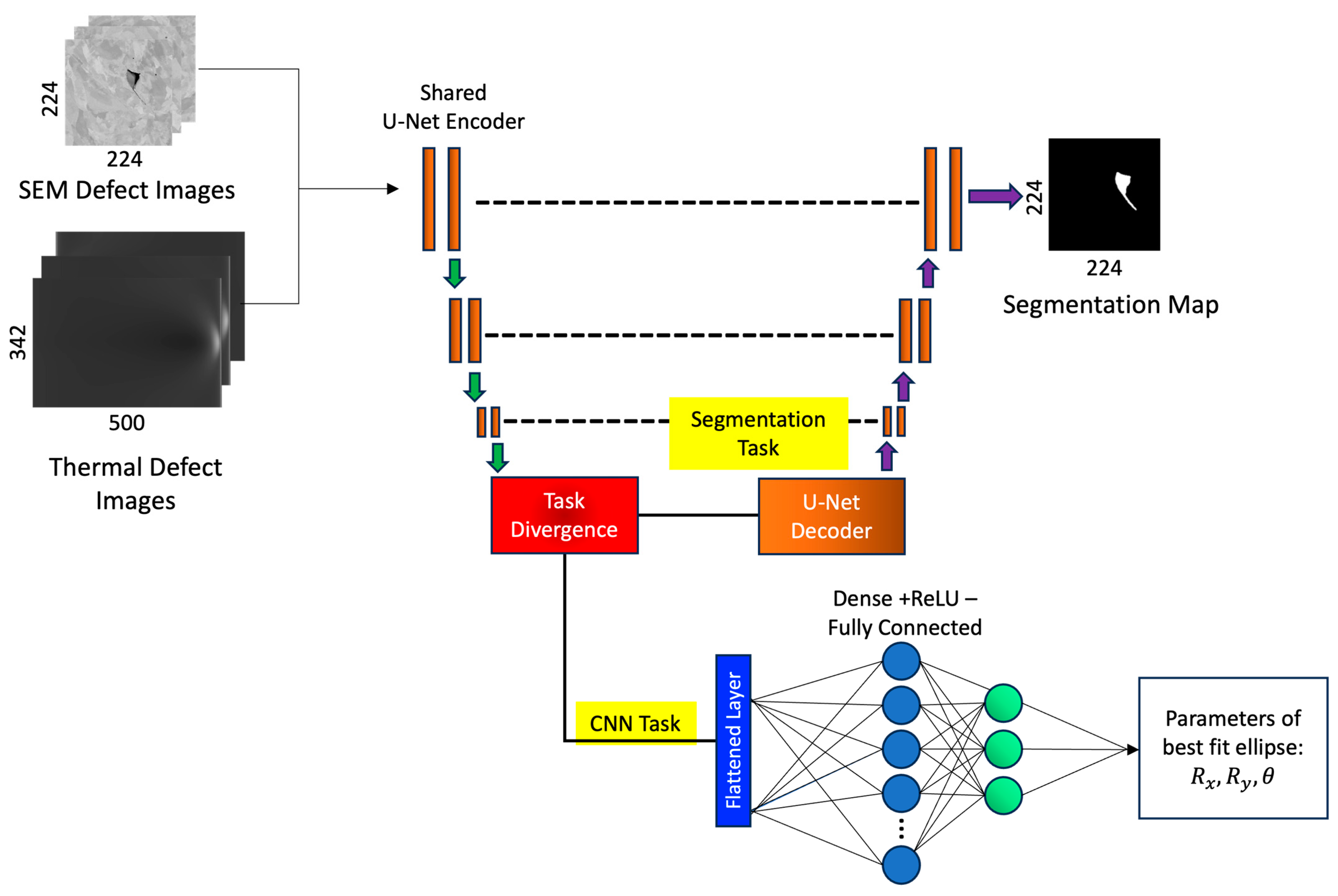

2. Multi-Task Learning Network for Classification and Segmentation of Images

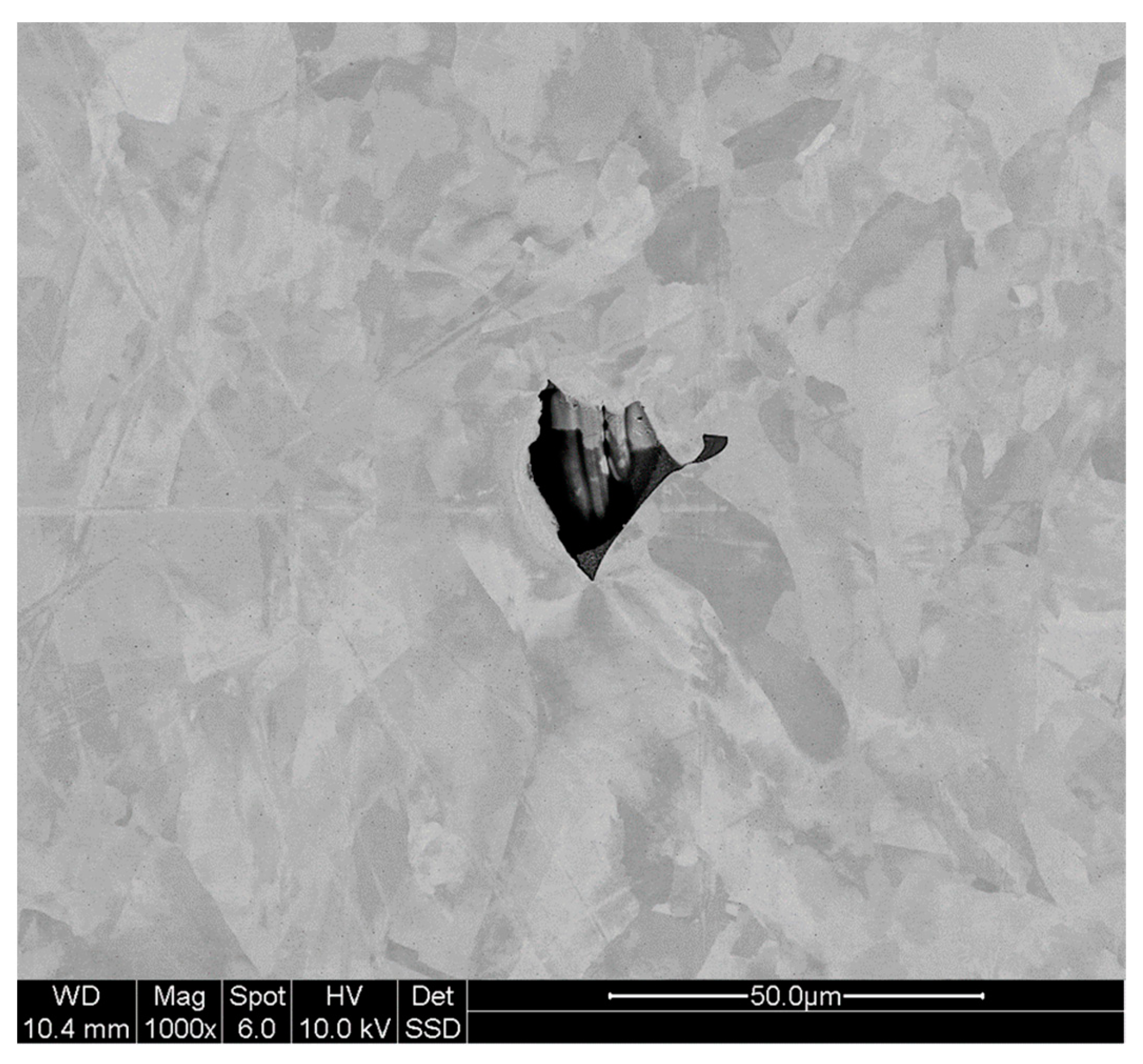

2.1. Datasets of Synthetic Thermal Tomography and Scanning Electron Microscopy Images

2.2. Multi-Task Network Architecture

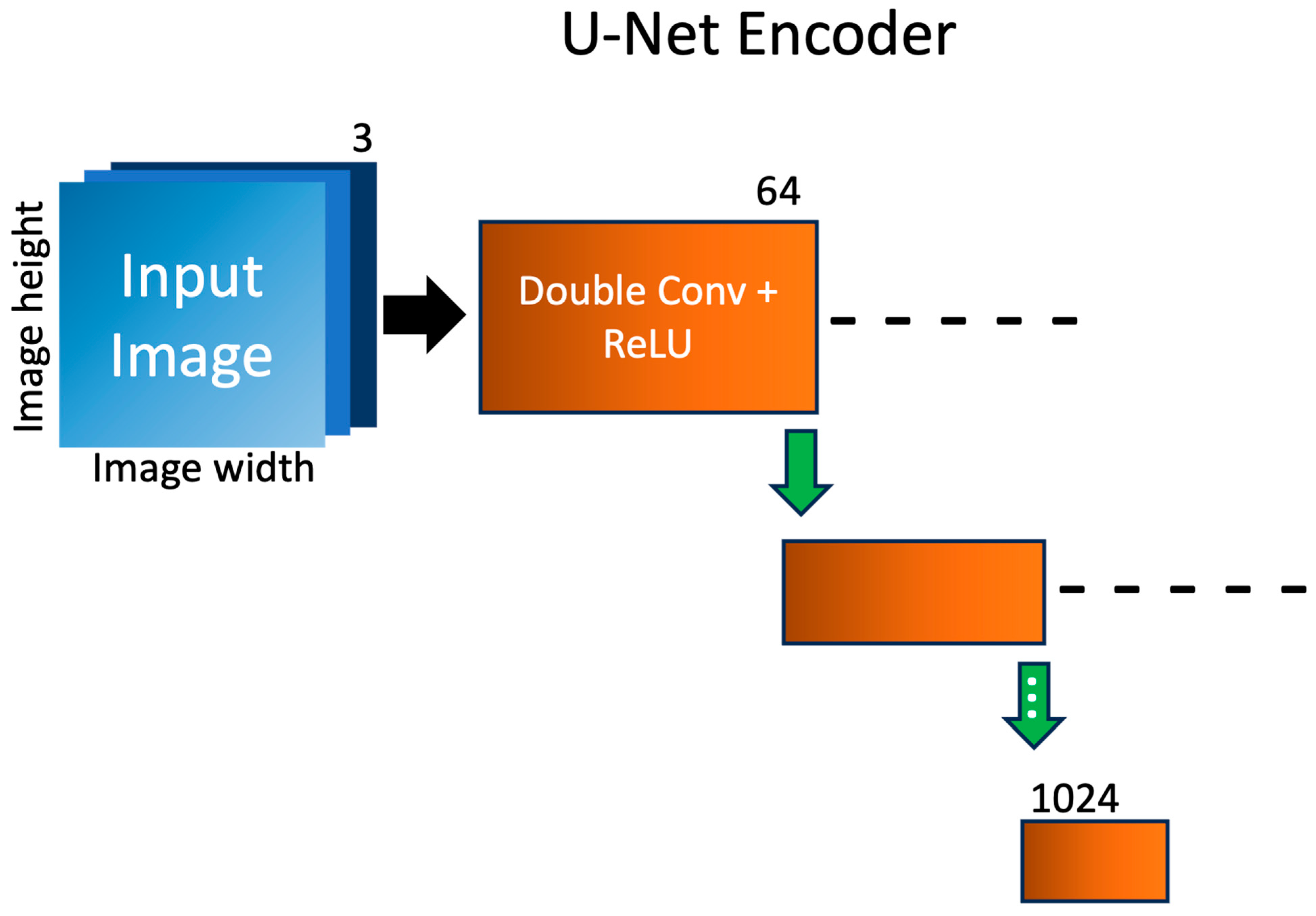

2.3. U-Net Shared Encoder

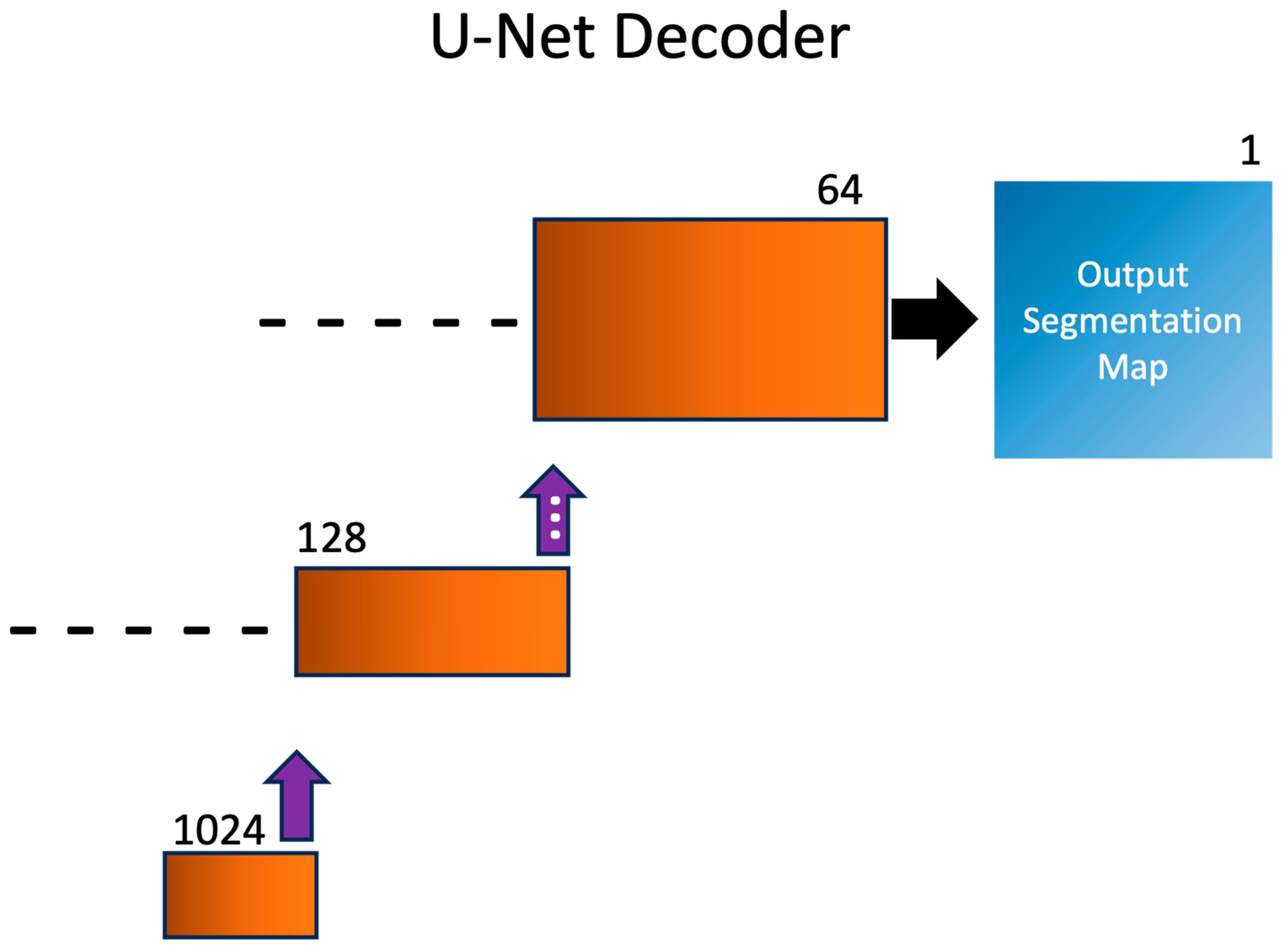

2.4. U-Net Segmentation Decoder

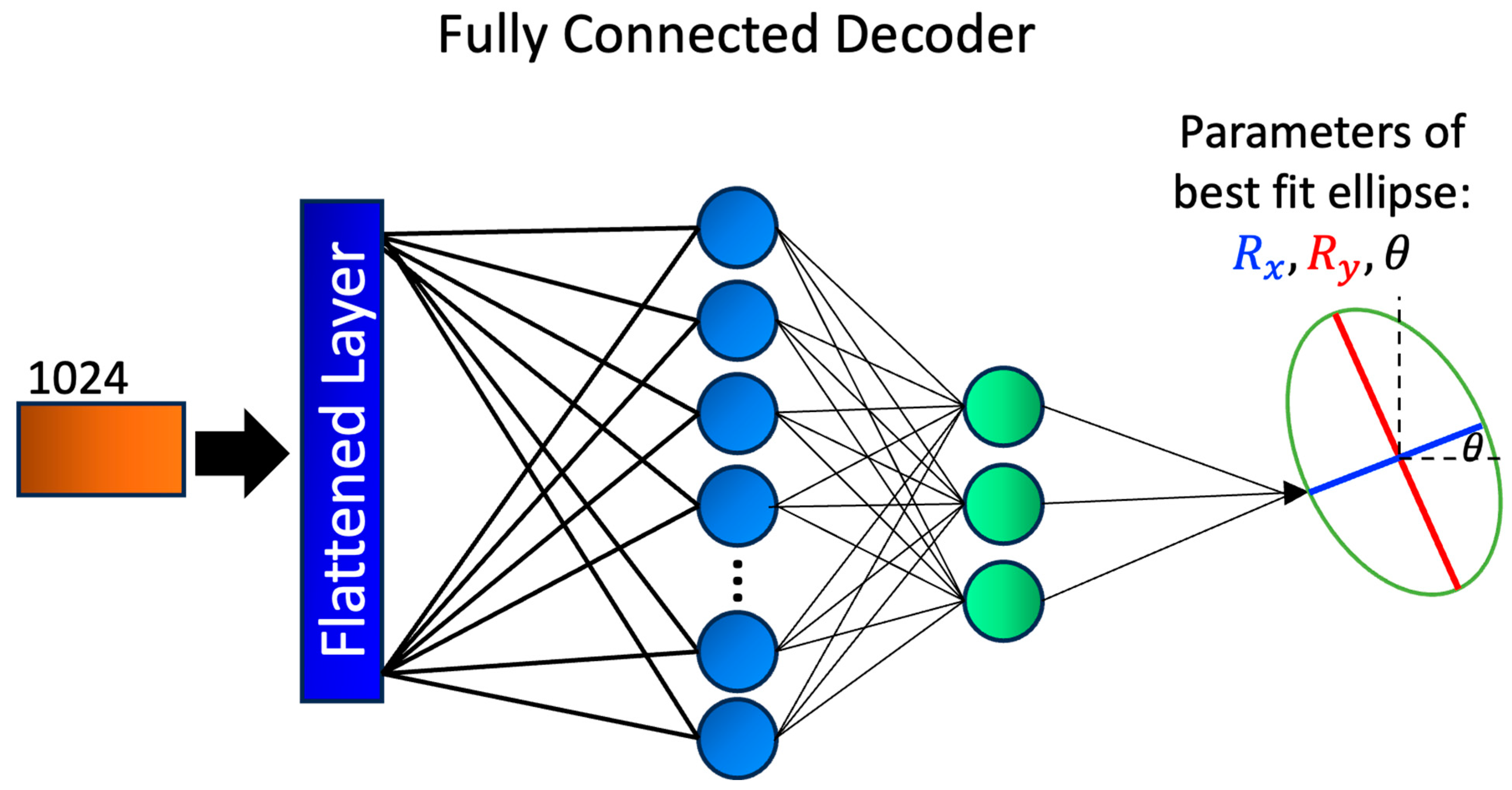

2.5. Fully Connected Layer Decoder

2.6. Loss Functions and Evaluation Metrics

3. Multi-Task Learning Image Analysis Results

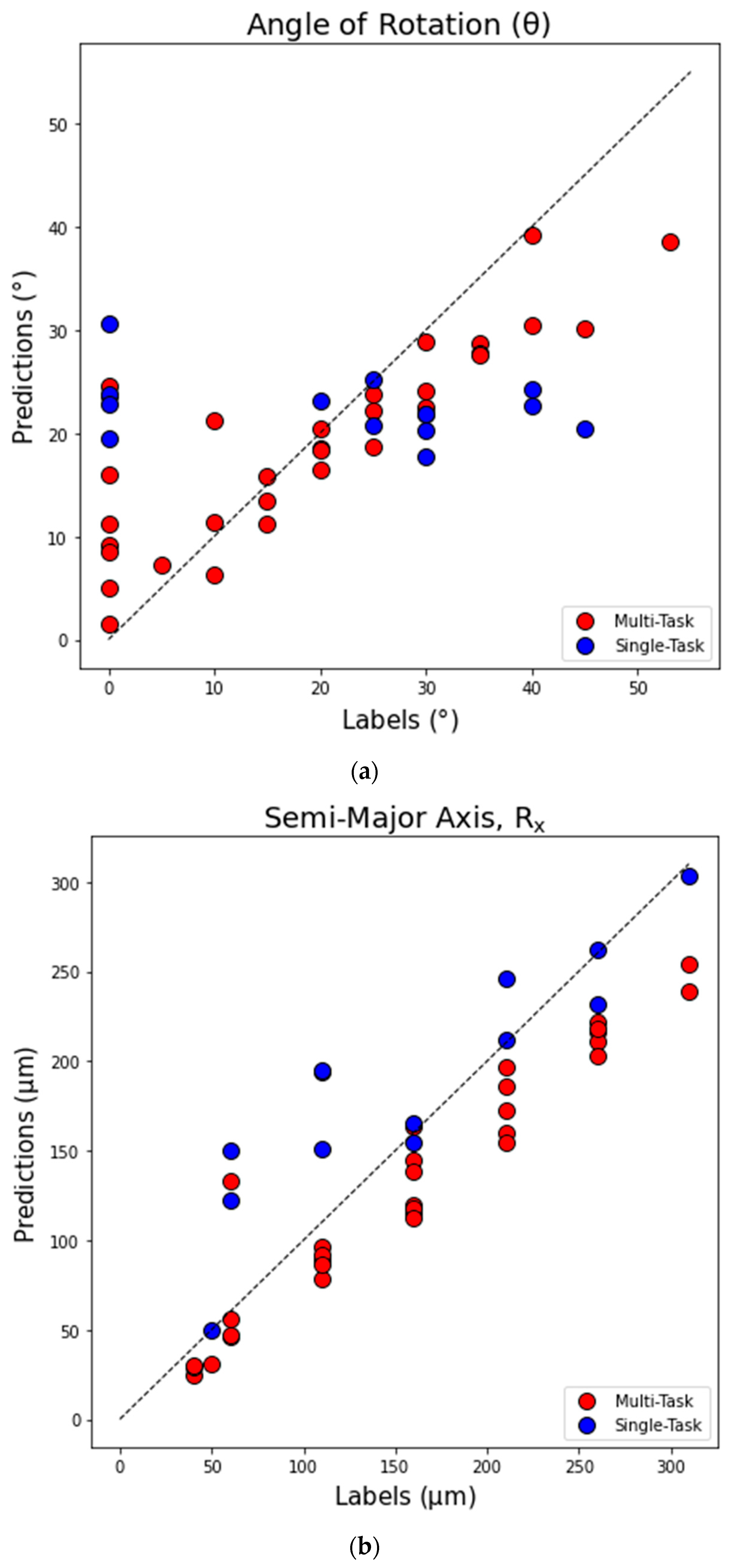

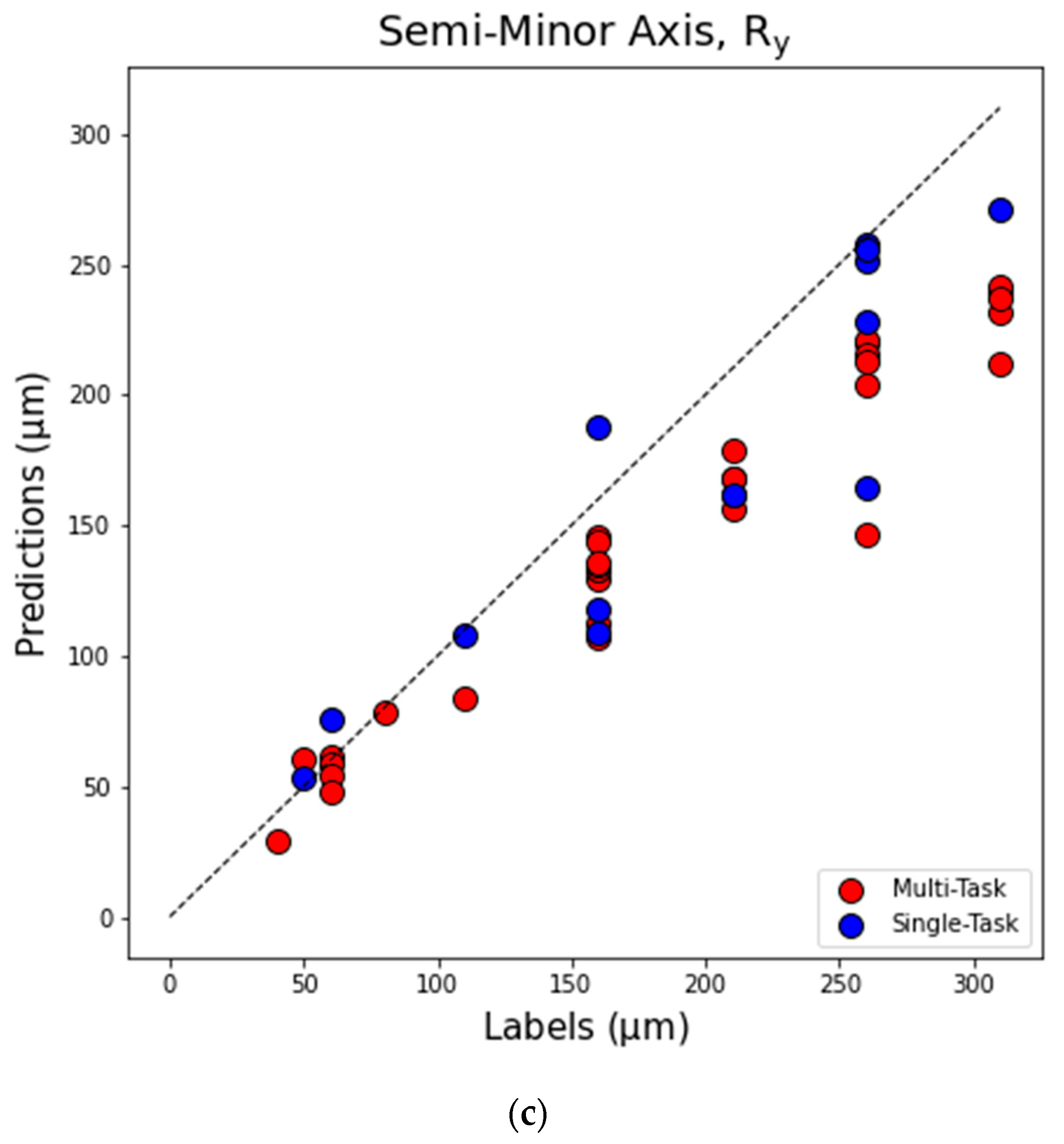

3.1. Classification of the Synthetic TT Images

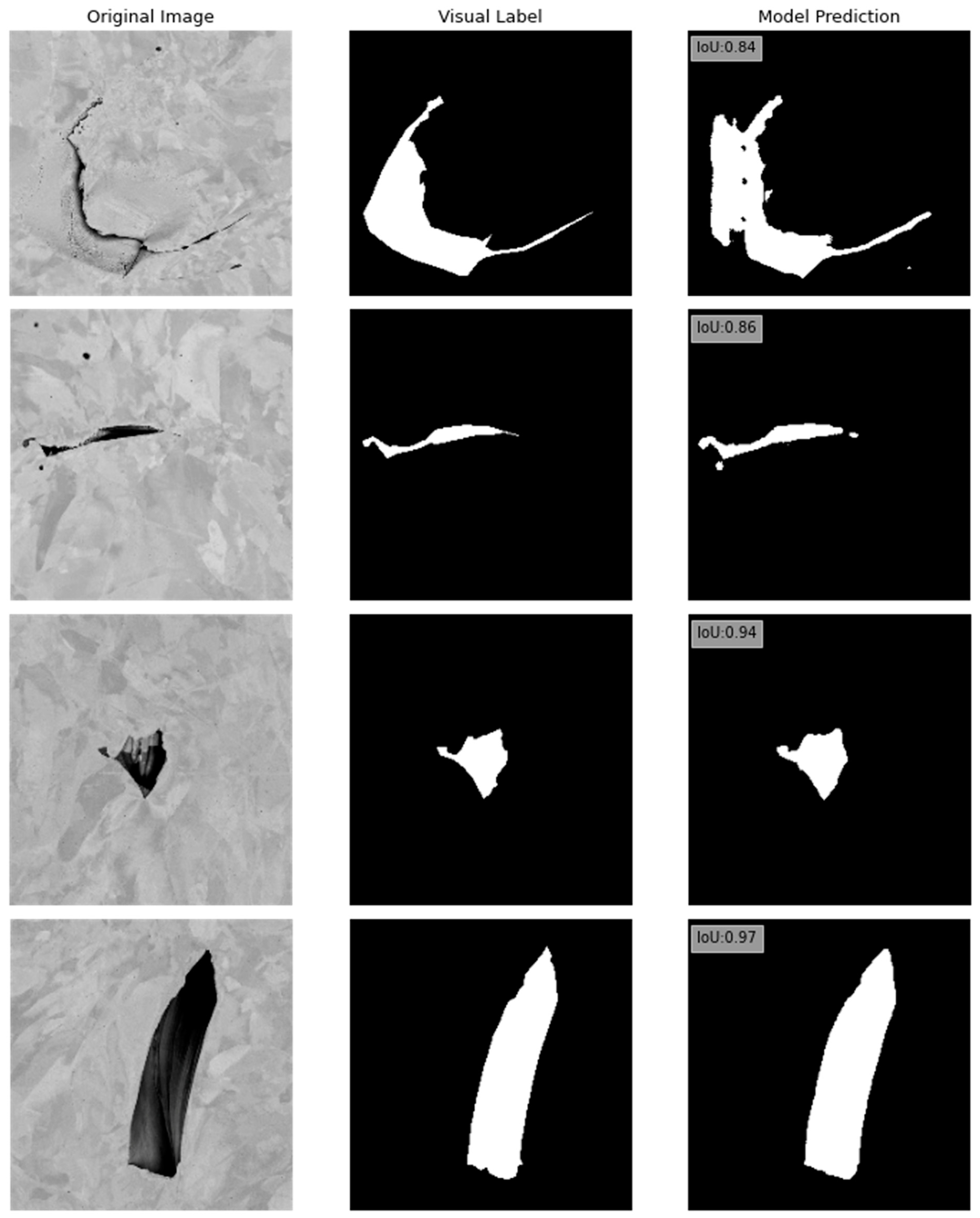

3.2. Segmentation of SEM Images

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lou, X.; Gandy, D. Advanced Manufacturing for Nuclear Energy. JOM 2019, 71, 2834–2836. [Google Scholar] [CrossRef]

- Hensley, C.; Sisco, K.; Beauchamp, S.; Godfrey, A.; Rezayat, H.; McFalls, T.; Galicki, D.; List, F.; Carver, K.; Stover, C.; et al. Qualification Pathways for Additively Manufactured Components for Nuclear Applications. J. Nucl. Mater. 2021, 548, 152846. [Google Scholar] [CrossRef]

- Sun, C.; Wang, Y.; McMurtrey, M.D.; Jerred, N.D.; Liou, F.; Li, J. Additive Manufacturing for Energy: A Review. Appl. Energy 2021, 282, 116041. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser Powder-Bed Fusion Additive Manufacturing: Physics of Complex Melt Flow and Formation Mechanisms of Pores, Spatter and Denudation Zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Brennan, M.C.; Keist, J.S.; Palmer, T.A. Defects in Metal Additive Manufacturing Processes. J. Mater. Eng. Perform. 2021, 30, 4808–4818. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Withers, P.J.; Todd, I.; Prangnell, P.B. The Influence of Porosity on Fatigue Crack Initiation in Addi-tively Manufactured Titanium Components. Sci. Rep. 2017, 7, 7308. [Google Scholar] [CrossRef]

- Sangid, M.D.; Ravi, P.; Prithivirajan, V.; Miller, N.A.; Kenesei, P.; Park, J.-S. ICME Approach to Determining Critical Pore Size of IN718 Produced by Selective Laser Melting. JOM 2019, 72, 465–474. [Google Scholar] [CrossRef]

- Haley, J.; Leach, C.; Jordan, B.; Dehoff, R.; Paquit, V. In-situ Digital Image Correlation and Thermal Monitoring in Directed Energy Deposition Additive Manufacturing. Opt. Express 2021, 29, 9927–9941. [Google Scholar] [CrossRef]

- Mohammadi, G.M.; Mahmoud, D.; Elbestawi, M. On the Application of Machine Learning for Defect Detection in L-PBF Additive Manufacturing. Opt. Laser Technol. 2021, 143, 107338. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. A Multi-Scale Convolutional Neural Network for Autonomous Anomaly Detection and Classification in a Laser Powder Bed Fusion Additive Manufacturing Process. Addit. Manuf. 2018, 24, 273–286. [Google Scholar] [CrossRef]

- Kwon, O.; Kim, H.G.; Ham, M.J.; Kim, W.; Kim, G.-H.; Cho, J.-H.; Kim, N.I.; Kim, K. A Deep Neural Network for Classification of MeltPool Images in Metal Additive Manufacturing. J. Intell. Manuf. 2020, 31, 375–386. [Google Scholar] [CrossRef]

- Cui, W.; Zhang, Y.; Zhang, X.; Li, L.; Liou, F. Metal Additive Manufacturing Parts Inspection Using Convolutional Neural Network. Appl. Sci. 2020, 10, 545. [Google Scholar] [CrossRef]

- Ziabari, A.; Venkatakrishnan, S.V.; Snow, Z.; Lisovich, A.; Sprayberry, M.; Brackman, P.; Frederick, C.; Bhattad, P.; Graham, S.; Bingham, P.; et al. Enabling rapid X-ray CT Characterisation for Additive manufacturing using CAD Models and Deep Learning-Based Reconstruction. Npj Comput. Mater. 2023, 9, 91. [Google Scholar] [CrossRef]

- Chen, Y.; Peng, X.; Kong, L.; Dong, G.; Remani, A.; Leach, R. Defect Inspection Technologies for Additive Manufacturing. Int. J. Extrem. Manuf. 2021, 3, 022002. [Google Scholar] [CrossRef]

- Zheng, Z.; Peng, L.; Wang, D. Defect Analysis of 316 L Stainless Steel Prepared by LPBF Additive Manufacturing Processes. Coatings 2021, 11, 1562. [Google Scholar] [CrossRef]

- DeCost, B.L.; Lei, B.; Francis, T.; Holm, E.A. High Throughput Quantitative Metallography for Complex Microstructures Using Deep Learning: A Case Study in Ultrahigh Carbon Steel. Microsc. Microanal. 2019, 25, 21–29. [Google Scholar] [CrossRef] [PubMed]

- Azimi, S.M.; Britz, D.; Engstler, M.; Fritz, M.; Mücklich, F. Advanced Steel Microstructural Classification by Deep Learning Methods. Sci. Rep. 2018, 8, 2128. [Google Scholar] [CrossRef]

- Sainju, R.; Roberts, G.; Chen, W.-Y.; Hutchinson, B.; Yang, Q.; Ding, C.; Edwards, D.J.; Li, M.; Zhu, Y. Deep Learning for Automated Quantification of Irradiation Defects in TEM Data: Relating Pixel-Level Errors to Defect Properties. Microsc. Microanal. 2023, 29, 1559–1560. [Google Scholar] [CrossRef]

- Lu, Q.Y.; Wong, C.H. Application of non-destructive testing techniques for post-process control of additively manufactured parts. Virtual Phys. Prototyp. 2017, 12, 301–321. [Google Scholar] [CrossRef]

- Hassani, S.; Dackermann, U.A. Systematic Review of Advanced Sensor Technologies for Non-Destructive Testing and Structural Health Monitoring. Sensors 2023, 23, 2204. [Google Scholar] [CrossRef]

- Zhang, X.; Saniie, J.; Bakhtiari, S.; Heifetz, A. Compression of Pulsed Infrared Thermography Data with Unsupervised Learning for Nondestructive Evaluation of Additively Manufactured Metals. IEEE Access 2021, 10, 9094–9107. [Google Scholar] [CrossRef]

- Zhang, X.; Saniie, J.; Cleary, W.; Heifetz, A. Quality Control of Additively Manufactured Metallic Structures with Machine Learning of Thermography Images. JOM 2020, 72, 4682–4694. [Google Scholar] [CrossRef]

- Moradi, M.; Ghorbani, R.; Sfarra, S.; Tax, D.M.J.; Zarouchas, D. A Spatiotemporal Deep Neural Network Useful for Defect Identification and Reconstruction of Artworks Using Infrared Thermography. Sensors 2022, 22, 9361. [Google Scholar] [CrossRef]

- Venegas, P.; Ivorra, E.; Ortega, M.; Sáez de Ocáriz, I. Towards the Automation of Infrared Thermography Inspections for Industrial Maintenance Applications. Sensors 2022, 22, 613. [Google Scholar] [CrossRef]

- Alhammad, M.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Torbali, M.E.; Genest, M.; Zhang, H.; Zolotas, A.; Maldgue, X.P.V. Automated Impact Damage Detection Technique for Composites Based on Thermographic Image Processing and Machine Learning Classification. Sensors 2022, 22, 9031. [Google Scholar] [CrossRef]

- Fang, Q.; Ibarra-Castanedo, C.; Garrido, I.; Duan, Y.; Maldague, X. Automatic Detection and Identification of Defects by Deep Learning Algorithms from Pulsed Thermography Data. Sensors 2023, 23, 4444. [Google Scholar] [CrossRef] [PubMed]

- Szymanik, B. An Evaluation of 3D-Printed Materials’ Structural Properties Using Active Infrared Thermography and Deep Neural Networks Trained on the Numerical Data. Materials 2022, 15, 3727. [Google Scholar] [CrossRef] [PubMed]

- Szymanik, B.; Psuj, G.; Hashemi, M.; Lopato, P. Detection and Identification of Defects in 3D-Printed Dielectric Structures via Thermographic Inspection and Deep Neural Networks. Materials 2021, 14, 4168. [Google Scholar] [CrossRef]

- Heifetz, A.; Shribak, D.; Zhang, X.; Saniie, J.; Fisher, Z.L.; Liu, T.; Sun, J.G.; Elmer, T.; Bakhtiari, S.; Cleary, W. Thermal Tomography 3D Imaging of Additively Manufactured Metallic Structures. AIP Adv. 2020, 10, 105318. [Google Scholar] [CrossRef]

- Zhang, X.; Saniie, J.; Heifetz, A. Detection of Defects in Additively Manufactured Stainless Steel 316L with Compact Infrared Camera and Machine Learning Algorithms. JOM 2020, 72, 4244–4253. [Google Scholar] [CrossRef]

- Ankel, V.; Shribak, D.; Chen, W.-Y.; Heifetz, A. Classification of Computed Thermal Tomography Images with Deep Learning Convolutional Neural Network. J. Appl. Phys. 2022, 131, 244901. [Google Scholar] [CrossRef]

- Caruana, R. Multitask Learning. Mach. Learn. 1997, 28, 41–75. [Google Scholar] [CrossRef]

- Hille, K.; Gust, K.; Bitz, U.; Kammer, T. Associations between Music Education, Intelligence, and Spelling Ability in Ele-mentary School. Adv. Cogn. Psychol. 2011, 7, 1–6. [Google Scholar] [CrossRef]

- François, C.; Grau-Sánchez, J.; Duarte, E.; Rodriguez-Fornells, A. Musical Training as an Alternative and Effective Method for Neuro-Education and Neuro-Rehabilitation. Front. Psychol. 2015, 6, 475. [Google Scholar] [CrossRef]

- Beck, M.M.; Lind, R.R.; Geertsen, S.S.; Ritz, C.; Lundbye-Jensen, J.; Wienecke, J. Motor-Enriched Learning Activities Can Improve Mathematical Performance in Preadolescent Children. Front. Hum. Neurosci. 2016, 10, 645. [Google Scholar] [CrossRef]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional Networks for Biomedical Image Segmentation. arXiv 2015, arXiv:1505.04597. [Google Scholar] [CrossRef]

- Chowdary, J.; Yogarajah, P.; Chaurasia, P.; Guruviah, V. A Multi-Task Learning Framework for Automated Segmentation and Classification of Breast Tumors from Ultrasound Images. Ultrason. Imaging 2022, 44, 3–12. [Google Scholar] [CrossRef]

- Huang, H.; Yang, G.; Zhang, W.; Xu, X.; Yang, W.; Jiang, W.; Lai, X. A Deep Multi-Task Learning Framework for Brain Tumor Segmentation. Front. Oncol. 2021, 11, 690244. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Anwer, N.; Huang, Q.; Mathieu, L. Machine Learning in Tolerancing for Additive Manufacturing. CIRP Ann. 2018, 67, 157–160. [Google Scholar] [CrossRef]

- Yang, Y.; Shao, C. Hybrid Multi-Task Learning-Based Response Surface Modeling in Manufacturing. J. Manuf. Syst. 2021, 59, 607–616. [Google Scholar] [CrossRef]

- Shao, C.; Ren, J.; Wang, H.; Jin, J.; Hu, S.J. Improving Machined Surface Shape Prediction by Integrating Multi-Task Learning With Cutting Force Variation Modeling. J. Manuf. Sci. Eng. 2016, 139, 4034592. [Google Scholar] [CrossRef]

- Sebastian, U.; Ilkin, A.; Frank, S.; Constanze, T.; Matthias, W. A Review of Synthetic and Augmented Training Data for Machine Learning in Ultrasonic Nondestructive Evaluation. Ultrasonics 2023, 134, 107041. [Google Scholar]

- Liu, K.; Wang, F.; He, Y.; Liu, Y.; Yang, J.; Yao, Y. Data-Augmented Manifold Learning Thermography for Defect Detection and Evaluation of Polymer Composites. Polymers 2023, 15, 173. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Tang, Y.; Lou, W.; Liu, Y.; Yang, J.; Yao, Y. A Thermographic Data Augmentation and Signal Separation Method for Defect Detection. Meas. Sci. Technol. 2021, 32, 045401. [Google Scholar] [CrossRef]

- Li, X.; Ying, X.; Zhu, W.; Liu, W.; Hou, B.; Zhou, L. Nondestructive Detection and Analysis Based on Data Enhanced Thermography. Meas. Sci. Technol. 2022, 33, 064006. [Google Scholar] [CrossRef]

- Wei, Z.; Osman, A.; Valeske, B.; Maldague, X. Pulsed Thermography Dataset for Training Deep Learning Models. Appl. Sci. 2023, 13, 2901. [Google Scholar] [CrossRef]

- Fang, Q.; Ibarra-Castanedo, C.; Maldague, X. Automatic Defects Segmentation and Identification by Deep Learning Algorithm with Pulsed Thermography: Synthetic and Experimental Data. Big Data Cogn. Comput. 2021, 5, 9. [Google Scholar] [CrossRef]

- Long, J.; Shelhamer, E.; Darrell, T. Fully Convolutional Networks for Semantic Segmentation. In Proceedings of the 2015 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Boston, MA, USA, 7–12 June 2015; pp. 3431–3440. [Google Scholar]

- Wong, V.; Ferguson, M.; Law, K.; Lee, Y.-T.T.; Witherell, P. Segmentation of Additive Manufacturing Defects Using U-NET. J. Comput. Inf. Sci. Eng. 2021, 22, 1–44. [Google Scholar] [CrossRef]

- Open Source Data Labeling. Available online: https://labelstud.io/ (accessed on 14 November 2022).

- Kingma, D.P.; Ba, J. Adam: A Method for Stochastic Optimization. arXiv 2017, arXiv:1412.6980. [Google Scholar] [CrossRef]

- Yang, L.; Zhuo, W.; Qi, L.; Shi, Y.; Gao, Y. ST++: Make Self-Training Work Better for Semi-Supervised Semantic Segmentation. arXiv 2022, arXiv:2106.05095. [Google Scholar] [CrossRef]

| Loss | Single-Task | Multi-Task |

|---|---|---|

| Train MSE | 12.56 | 84.23 |

| Validation MSE | 21.66 | 42.06 |

| Test MSE | 98.48 | 38.54 |

| Train AE | 0.259 | 0.09 |

| Validation AE | 0.20 | 0.64 |

| Test AE | 0.23 | 0.47 |

| Variable | θ | Rx | Ry | |||

|---|---|---|---|---|---|---|

| Network | Single-Task | Multi-Task | Single-Task | Multi-Task | Single-Task | Multi-Task |

| Pearson r | −0.34 | 0.82 | 0.89 | 0.96 | 0.92 | 0.97 |

| −0.28 | 0.8 | 0.92 | 0.96 | 0.93 | 0.96 | |

| Dataset | Metric | Single-Task | Multi-Task |

|---|---|---|---|

| Training | BCE | 0.03 | 0.01 |

| Validation | BCE | 0.03 | 0.02 |

| Testing | BCE | 0.31 | 0.03 |

| Training | IoU | 0.88 | 0.92 |

| Validation | IoU | 0.79 | 0.92 |

| Testing | IoU | 0.81 | 0.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scott, S.; Chen, W.-Y.; Heifetz, A. Multi-Task Learning of Scanning Electron Microscopy and Synthetic Thermal Tomography Images for Detection of Defects in Additively Manufactured Metals. Sensors 2023, 23, 8462. https://doi.org/10.3390/s23208462

Scott S, Chen W-Y, Heifetz A. Multi-Task Learning of Scanning Electron Microscopy and Synthetic Thermal Tomography Images for Detection of Defects in Additively Manufactured Metals. Sensors. 2023; 23(20):8462. https://doi.org/10.3390/s23208462

Chicago/Turabian StyleScott, Sarah, Wei-Ying Chen, and Alexander Heifetz. 2023. "Multi-Task Learning of Scanning Electron Microscopy and Synthetic Thermal Tomography Images for Detection of Defects in Additively Manufactured Metals" Sensors 23, no. 20: 8462. https://doi.org/10.3390/s23208462

APA StyleScott, S., Chen, W.-Y., & Heifetz, A. (2023). Multi-Task Learning of Scanning Electron Microscopy and Synthetic Thermal Tomography Images for Detection of Defects in Additively Manufactured Metals. Sensors, 23(20), 8462. https://doi.org/10.3390/s23208462