Inferential Composition Control of a Distillation Column Using Active Disturbance Rejection Control with Soft Sensors

Abstract

:1. Introduction

2. An Overview of Active Disturbance Rejection Control and Inferential Control

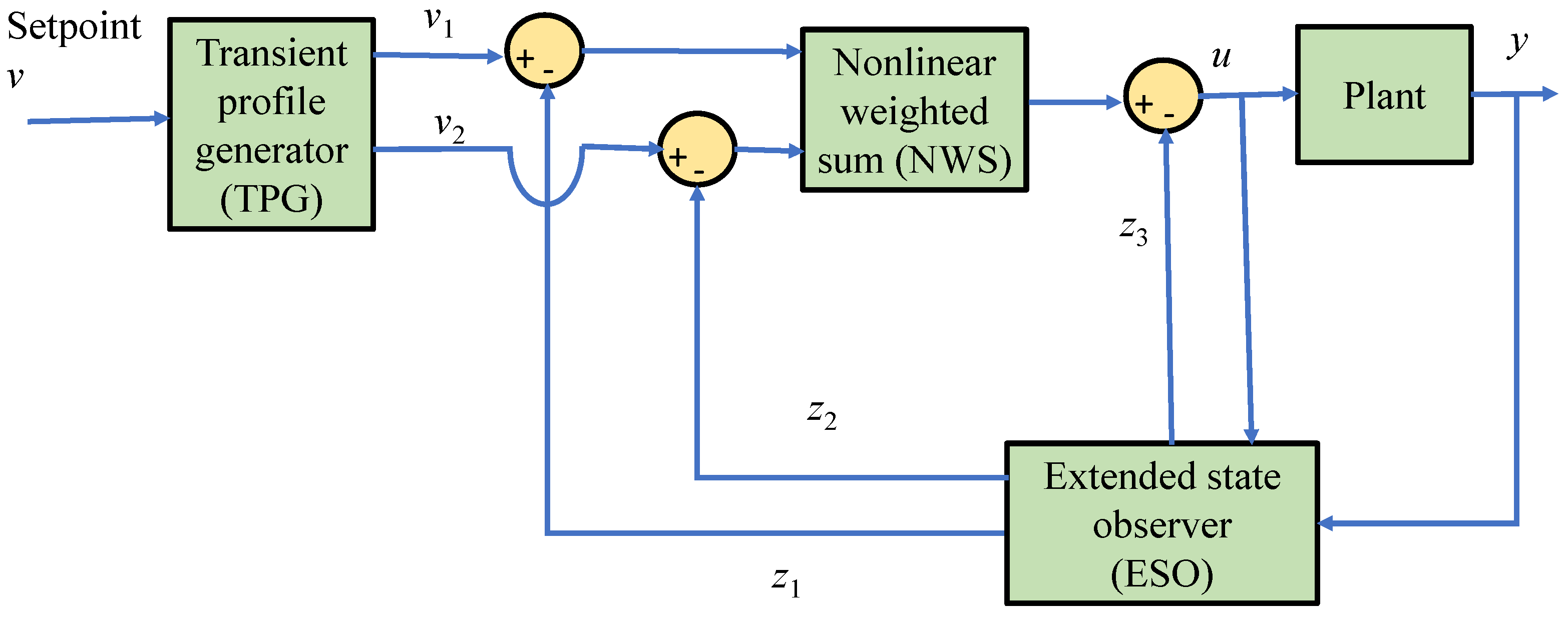

2.1. Active Disturbance Rejection Control

2.2. Overview of Inferential Control

- They provide more insight into the process through catching the information hidden in data;

- They provide enhanced monitoring and control of industrial processes with the consequences of reducing environmental impact, enhancing productivity and energy efficiency, and improving business profitability through decreasing the production cost related to off-specification products;

- They can be simply implemented on existing hardware. Moreover, on-line model identification algorithms can be utilized to adapt the model when plant characteristics change; and

- They entail little or no capital costs such as installation cost, commissioning and management of the required infrastructure.

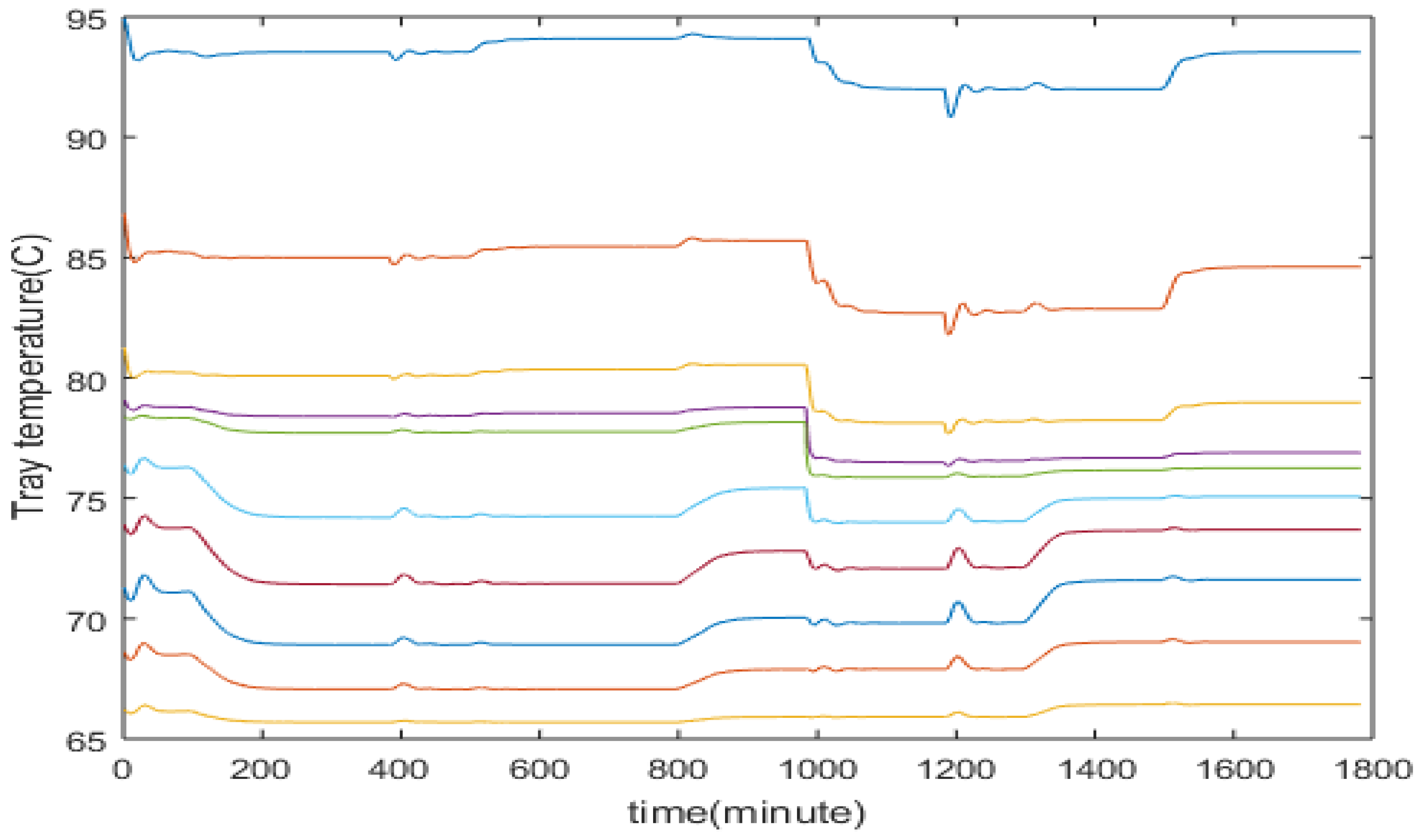

3. A Binary Distillation Column for Methanol-Water Separation

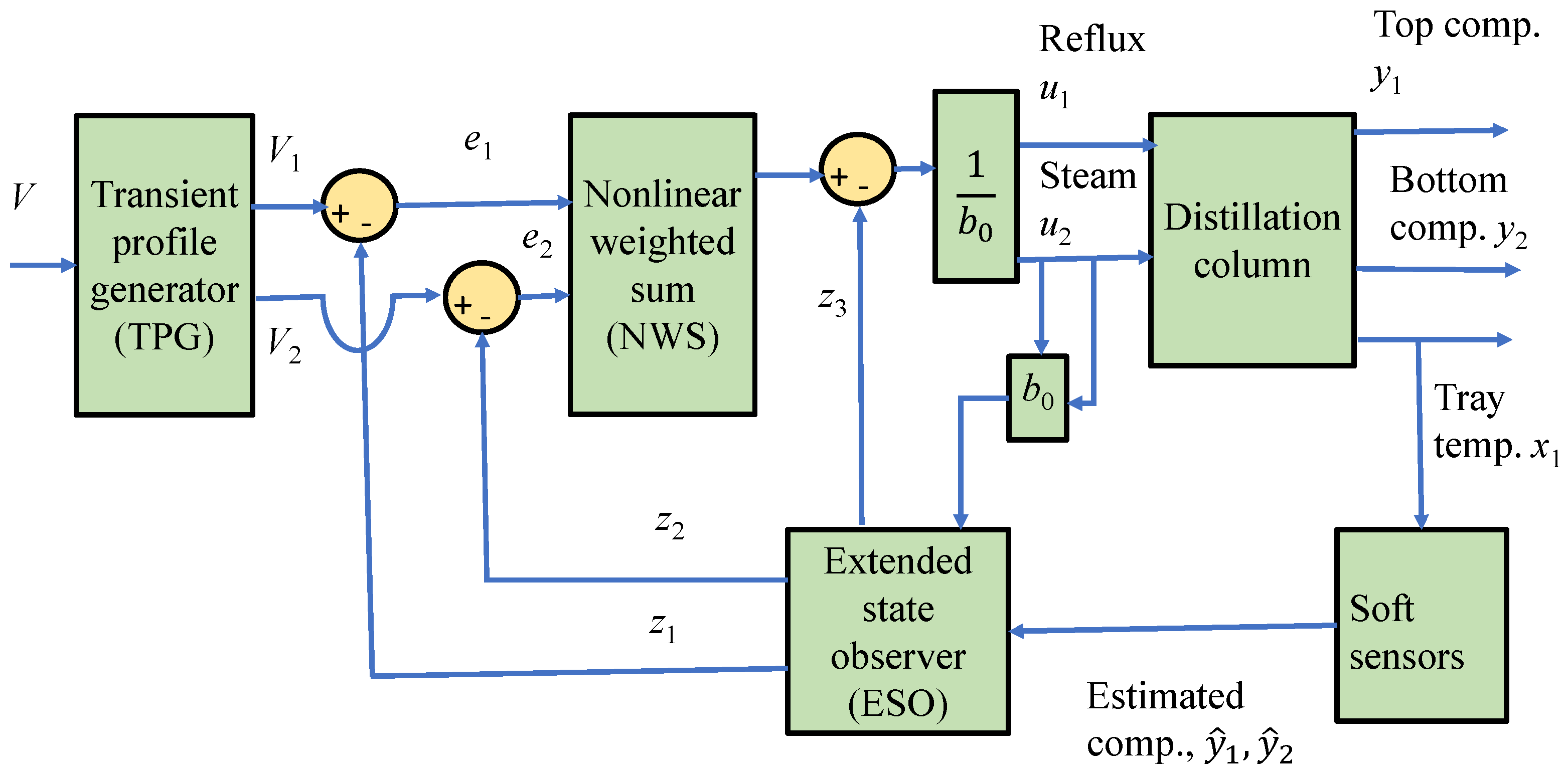

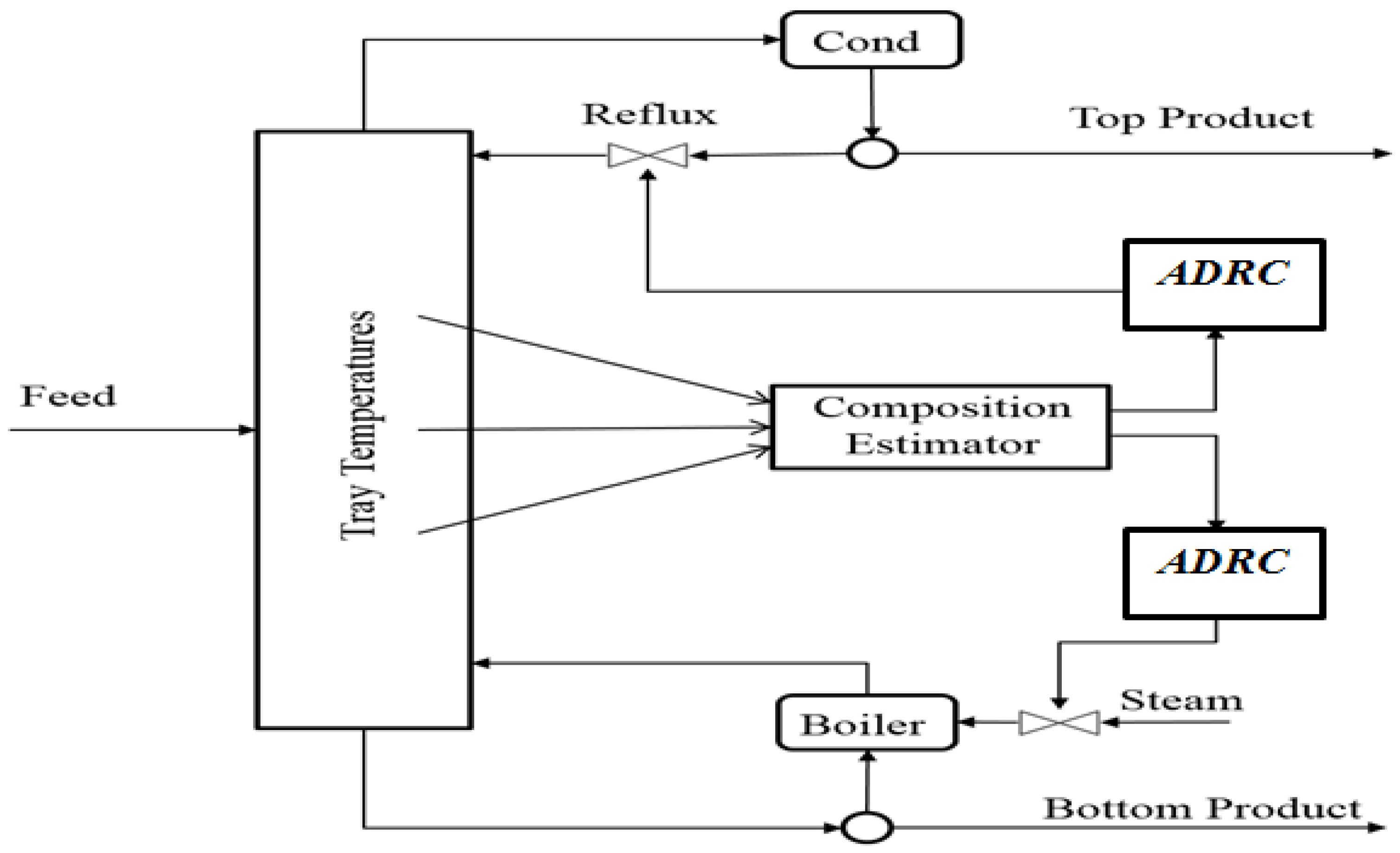

4. Inferential ADRC Scheme

5. PCR Model-Based Software Sensors

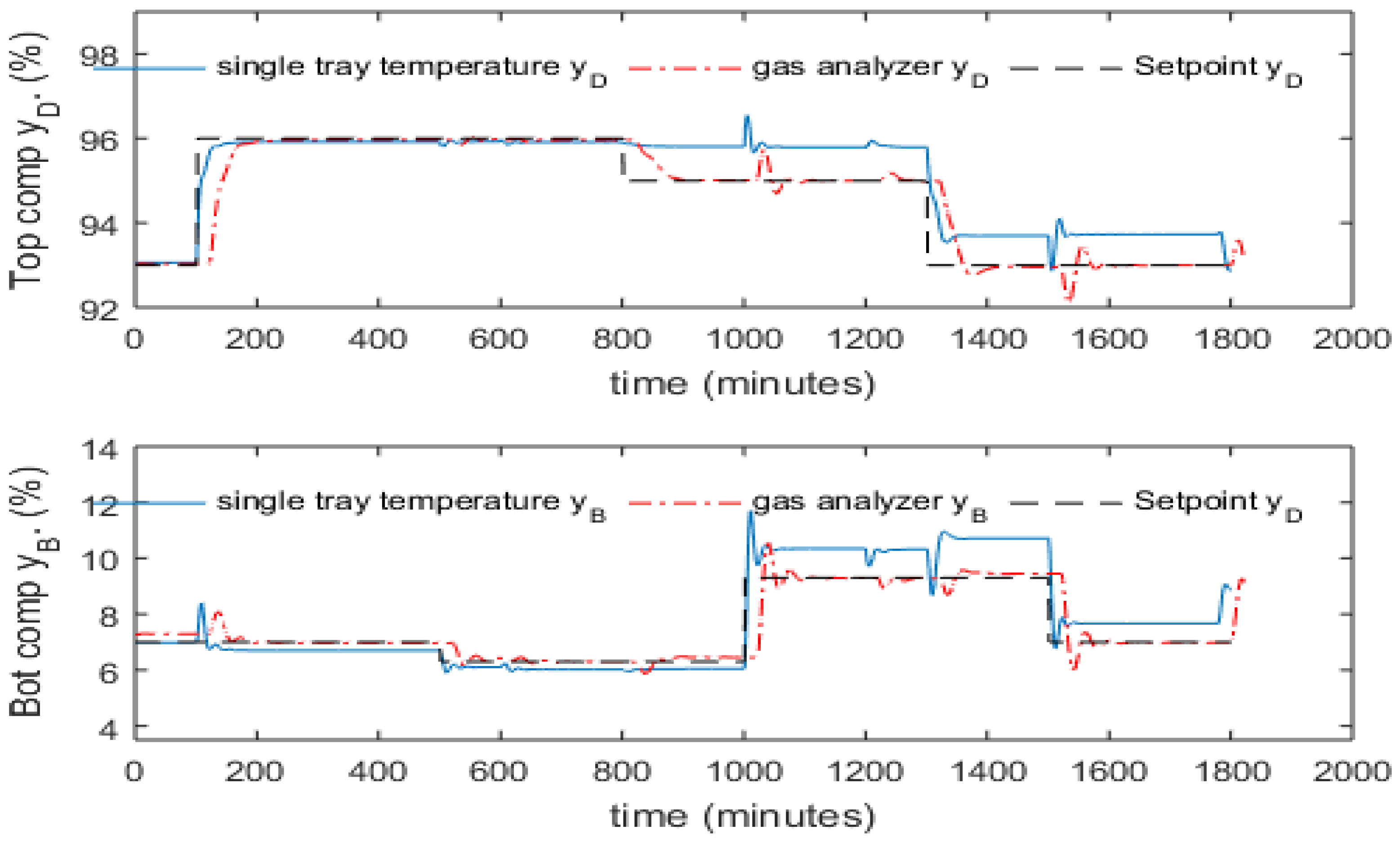

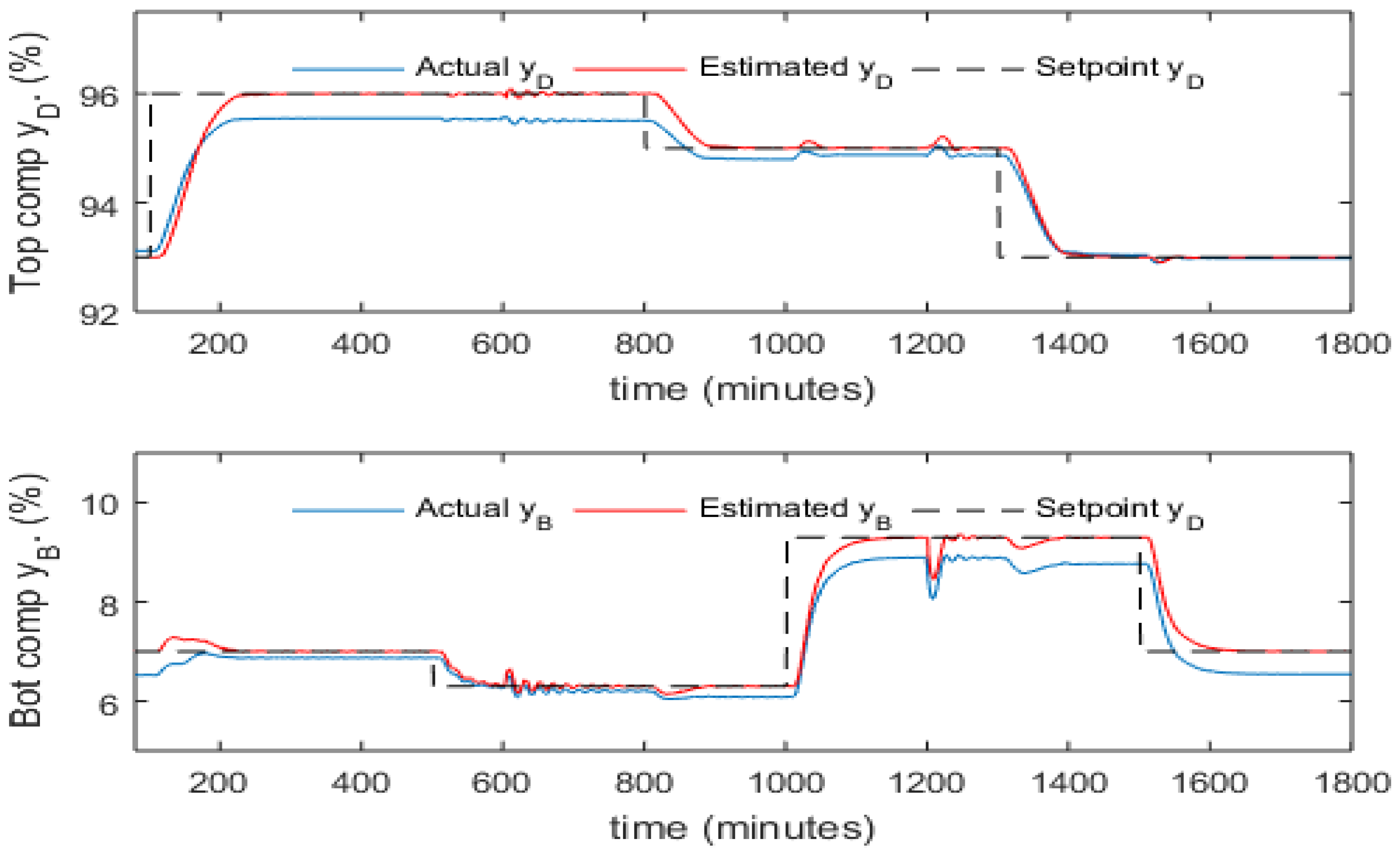

5.1. Static PCR Models

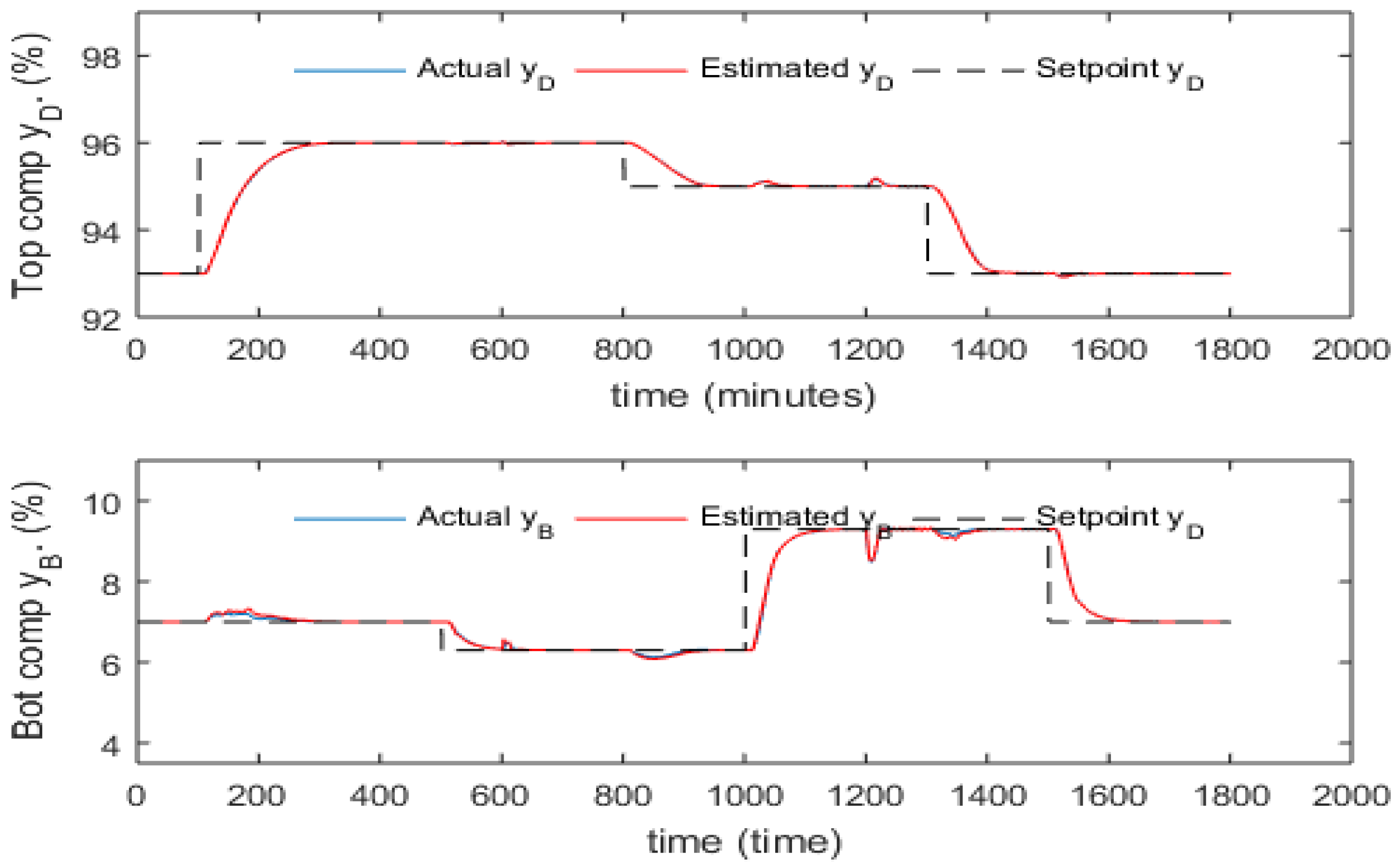

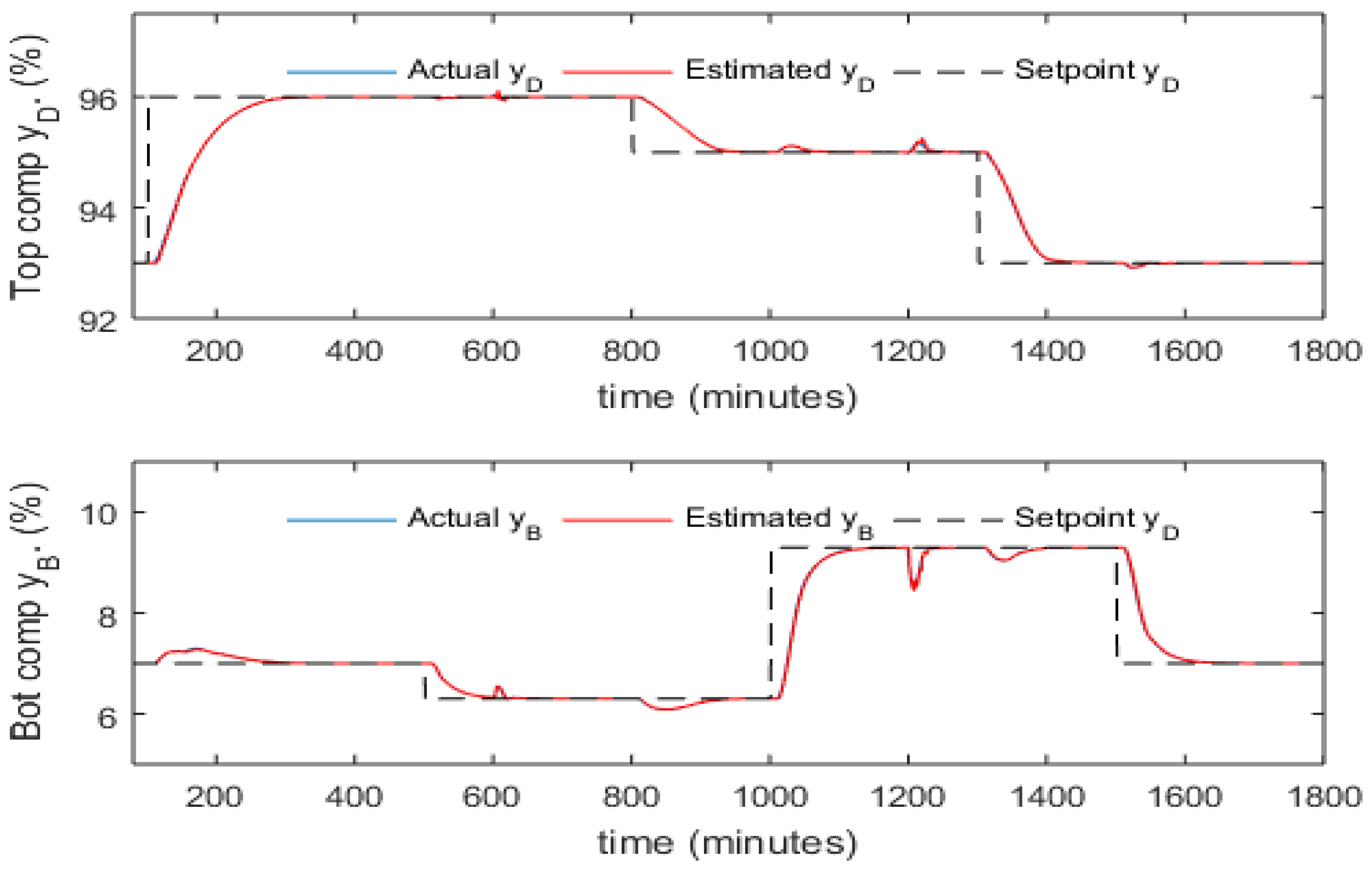

5.2. Dynamic PCR Models

6. Inferential ADRC Scheme Based on PCR Models

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| t | t − 1 | t − 2 | t − 3 | t − 4 | t − 5 | |

|---|---|---|---|---|---|---|

| T1 | −0.037 | 0.006 | 0.077 | 0.091 | 0.039 | −0.151 |

| T2 | 0.012 | −0.039 | −0.030 | −0.061 | 0.031 | −0.001 |

| T3 | 0.115 | 0.059 | 0.031 | −0.021 | −0.002 | −0.030 |

| T4 | 0.051 | 0.014 | −0.003 | −0.035 | −0.009 | −0.020 |

| T5 | 0.046 | −0.022 | −0.021 | −0.044 | −0.052 | −0.016 |

| T6 | −0.083 | −0.045 | 0.056 | 0.068 | 0.065 | 0.016 |

| T7 | −0.138 | −0.069 | 0.020 | 0.044 | 0.071 | 0.055 |

| T8 | −0.171 | −0.110 | −0.042 | −0.023 | 0.004 | 0.007 |

| T9 | −0.175 | −0.103 | −0.015 | 0.013 | 0.068 | 0.100 |

| T10 | −0.219 | −0.146 | −0.088 | −0.071 | −0.047 | −0.017 |

| t | t − 1 | t − 2 | t − 3 | t − 4 | t − 5 | |

|---|---|---|---|---|---|---|

| T1 | −0.569 | −0.453 | −0.307 | −0.140 | 0.032 | 0.191 |

| T2 | −0.122 | −0.084 | −0.037 | 0.042 | 0.154 | 0.261 |

| T3 | 0.056 | 0.052 | 0.047 | 0.060 | 0.100 | 0.142 |

| T4 | 0.019 | −0.004 | −0.041 | −0.076 | −0.093 | −0.097 |

| T5 | 0.083 | 0.059 | 0.020 | −0.033 | −0.084 | −0.122 |

| T6 | 0.113 | 0.065 | 0.016 | −0.028 | −0.005 | −0.062 |

| T7 | 0.002 | −0.027 | −0.047 | −0.053 | −0.041 | −0.015 |

| T8 | 0.032 | 0.014 | 0.004 | 0.007 | 0.026 | 0.055 |

| T9 | −0.008 | −0.033 | −0.048 | −0.048 | −0.027 | 0.008 |

| T10 | 0.017 | 0.001 | −0.004 | 0.003 | 0.028 | 0.067 |

References

- Fazlali, A.; Hosseini, S.; Yasini, B.; Moghadassi, A. Optimization of operating conditions of distillation columns: An energy saving option in refinery industry. Songklanakarin J. Sci. Technol. 2009, 31, 661–664. [Google Scholar]

- Hewitt, G.; Quarain, J.; Morell, M. More efficient distillation. Chem. Eng. 1999, 16–18. Available online: https://www.osti.gov/etdeweb/biblio/20016386 (accessed on 29 November 2022).

- Kiss, A.; Bildea, C. A control perspective on process intensification in dividing-wall columns. Chem. Eng. Process. Process Intensif. 2011, 50, 281–292. [Google Scholar] [CrossRef]

- Kiss, A. Distillation technology-still young and full of breakthrough opportunities. J. Chem. Technol. Biotechnol. 2013, 89, 479–498. [Google Scholar] [CrossRef]

- Brockett, R. New Issues in the Mathematics of Control; Springer: Berlin/Heidelberg, Germany, 2001; pp. 189–220. [Google Scholar]

- Han, J. Auto-disturbances-rejection controller and its application. Control Decis. 1998, 13, 20–23. [Google Scholar]

- Han, J. A class of extended state observers for uncertain systems. Control Decis. 1995, 10, 85–88. [Google Scholar]

- Han, J. Active Disturbance Rejection Control Technique—The Technique for Estimating and Compensating the Uncertainties; National Defence Industry Press: Beijing, China, 2008. [Google Scholar]

- Han, J. From PID to active disturbance rejection control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

- Gao, Z. Scaling and bandwidth-parameterization based controller tuning. In Proceedings of the 2003 American Control Conference, Denver, CO, USA, 4–6 June 2003; pp. 4989–4996. [Google Scholar]

- Gao, Z. Active disturbance rejection control—A paradigm shift in feedback control system design. In Proceedings of the 2006 American Control Conference, Minneapolis, MN, USA, 14–16 June 2006; pp. 2399–2405. [Google Scholar]

- Gao, Z.; Huang, Y.; Han, J. An alternative paradigm for control system design. In Proceedings of the 40th IEEE Conference on Decision and Control, Orlando, FL, USA, 4–7 December 2001; pp. 4578–4585. [Google Scholar]

- Mejdell, T.; Skogestad, S. Estimation of distillation compositions from multiple temperature measurements using partial-least-squares regression. Ind. Eng. Chem. Res. 1991, 30, 2543–2555. [Google Scholar] [CrossRef]

- Kister, H. Distillation Operation; McGraw Hill: New York, NY, USA, 1990. [Google Scholar]

- Fortuna, L.; Graziani, S.; Xibilia, M. Soft sensors for product quality monitoring in debutanizer distillation columns. Control Eng. Pract. 2005, 13, 499–508. [Google Scholar] [CrossRef]

- Tham, M.; Montague, G.; Morris, A.J.; Lant, P. Soft-sensors for process estimation and inferential control. J. Process Control 1991, 1, 3–14. [Google Scholar] [CrossRef]

- Weber, R.; Brosilow, C. The use of secondary measurements to improve control. AIChE J. 1972, 18, 614–623. [Google Scholar] [CrossRef]

- Joseph, B.; Brosilow, C. Inferential control of processes: Part III. Construction of optimal and suboptimal dynamic estimators. AIChE J. 1978, 24, 500–509. [Google Scholar] [CrossRef]

- Corrigan, J.; Zhang, J. Developing accurate data-driven soft-sensors through integrating dynamic kernel slow feature analysis with neural networks. J. Process Control 2021, 106, 208–220. [Google Scholar] [CrossRef]

- Kresta, J.; Marlin, T.; MacGregor, J. Development of inferential process models using PLS. Comput. Chem. Eng. 1994, 18, 597–611. [Google Scholar] [CrossRef]

- Mejdell, T.; Skogestad, S. Composition estimator in a pilot-plant distillation column using multiple temperatures. Ind. Eng. Chem. Res. 1991, 30, 2555–2564. [Google Scholar] [CrossRef]

- Mejdell, T.; Skogestad, S. Output estimation using multiple secondary measurements: High-purity distillation. AIChE J. 1993, 39, 1641–1653. [Google Scholar] [CrossRef]

- Zhang, J. Inferential feedback control of distillation composition based on PCR and PLS models. In Proceedings of the American Control Conference 2001, Arlington, VA, USA, 25–27 June 2001; pp. 1196–1201. [Google Scholar]

- Zhang, J. Offset-free inferential feedback control of distillation compositions based on PCR and PLS models. Chem. Eng. Technol. 2006, 29, 560–566. [Google Scholar] [CrossRef]

- Al-Kalbani, F.; Al Hosni, S.M.; Zhang, J. Active disturbance rejection control of a methanol-water separation distillation column. In Proceedings of the 8th IEEE GCC Conference and Exhibition, Muscat, Oman, 1–4 February 2015. [Google Scholar] [CrossRef]

- Dias, T.; Oliveira, R.; Saraiva, P.M.; Reis, M.S. Linear and non-linear soft sensors for predicting the research octane number (RON) through integrated synchronization, resolution selection and modelling. Sensors 2022, 22, 3734. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yang, C.; Sun, Y. Sintering quality prediction model based on semi-supervised dynamic time feature extraction framework. Sensors 2022, 22, 5861. [Google Scholar] [CrossRef] [PubMed]

- Severino, A.G.V.; de Lima, J.M.M.; de Araújo, F.M.U. Industrial soft sensor optimized by improved PSO: A deep representation-learning approach. Sensors 2022, 22, 6887. [Google Scholar] [CrossRef] [PubMed]

- Paepae, T.; Bokoro, P.N.; Kyamakya, K. A virtual sensing concept for Nitrogen and Phosphorus monitoring using machine learning techniques. Sensors 2022, 22, 7338. [Google Scholar] [CrossRef] [PubMed]

- Al-Kalbani, F.; Zhang, J. Inferential active disturbance rejection control of a distillation column. In Proceedings of the 9th IFAC International Symposium on Advanced Control of Chemical Processes (ADCHEM2015), Whistler, BC, Canada, 7–10 June 2015; pp. 403–408. [Google Scholar]

| Variables | Nominal Values |

|---|---|

| Top composition (y1) | 93% (wt) methanol |

| Bottom composition (y2) | 7% (wt) methanol |

| Reflux flow rate (u1) | 10.108 g/s |

| Steam flow rate (u2) | 13.814 g/s |

| Feed composition (d1) | 50.12% (wt) methanol |

| Feed flow rate (d2) | 18.23 g/s |

| No. of PCs | Top Composition | Bottom Composition | ||

|---|---|---|---|---|

| Training Data | Testing Data | Training Data | Testing Data | |

| 1 | 410.00 | 230.00 | 1400 | 280.30 |

| 2 | 32.00 | 10.00 | 679.90 | 82.27 |

| 3 | 31.00 | 10.00 | 89.39 | 19.71 |

| 4 | 4.00 | 0.78 | 68.10 | 8.50 |

| 5 | 3.50 | 0.48 | 49.35 | 6.71 |

| 6 | 3.15 | 0.32 | 40.86 | 5.45 |

| 7 | 3.14 | 0.32 | 35.64 | 6.43 |

| 8 | 3.07 | 0.36 | 27.82 | 3.36 |

| 9 | 2.93 | 0.38 | 20.21 | 2.66 |

| 10 | 2.85 | 0.34 | 17.86 | 1.94 |

| Model Orders | Model Output | SSE | No. of Principal Components |

|---|---|---|---|

| 1 | Top composition | 0.662 | 11 |

| Bot composition | 13.04 | 11 | |

| 2 | Top composition | 0.361 | 14 |

| Bot composition | 9.958 | 7 | |

| 3 | Top composition | 0.045 | 32 |

| Bot composition | 2.970 | 7 | |

| 4 | Top composition | 0.140 | 50 |

| Bot composition | 2.542 | 7 | |

| 5 | Top composition | 0.122 | 17 |

| Bot composition | 1.323 | 7 | |

| 6 | Top composition | 0.145 | 42 |

| Bot composition | 4.722 | 8 | |

| 7 | Top composition | 0.141 | 54 |

| Bot composition | 3.958 | 8 |

| Control Schemes | Top Comp. | Bottom Comp. | |

|---|---|---|---|

| Inferential ADRC with static PCR model | Without mean updating | 54,542 | 6946.9 |

| With mean updating | 1.6889 | 1.8309 | |

| Inferential ADRC with 5th order dynamic PCR model | Without mean updating | 165.52 | 219.59 |

| With mean updating | 0.1856 | 0.1551 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Kalbani, F.; Zhang, J. Inferential Composition Control of a Distillation Column Using Active Disturbance Rejection Control with Soft Sensors. Sensors 2023, 23, 1019. https://doi.org/10.3390/s23021019

Al Kalbani F, Zhang J. Inferential Composition Control of a Distillation Column Using Active Disturbance Rejection Control with Soft Sensors. Sensors. 2023; 23(2):1019. https://doi.org/10.3390/s23021019

Chicago/Turabian StyleAl Kalbani, Fahad, and Jie Zhang. 2023. "Inferential Composition Control of a Distillation Column Using Active Disturbance Rejection Control with Soft Sensors" Sensors 23, no. 2: 1019. https://doi.org/10.3390/s23021019

APA StyleAl Kalbani, F., & Zhang, J. (2023). Inferential Composition Control of a Distillation Column Using Active Disturbance Rejection Control with Soft Sensors. Sensors, 23(2), 1019. https://doi.org/10.3390/s23021019