Ultraviolet Photodetector Based on a Beta-Gallium Oxide/Nickel Oxide/Beta-Gallium Oxide Heterojunction Structure

Abstract

:1. Introduction

2. Experimental

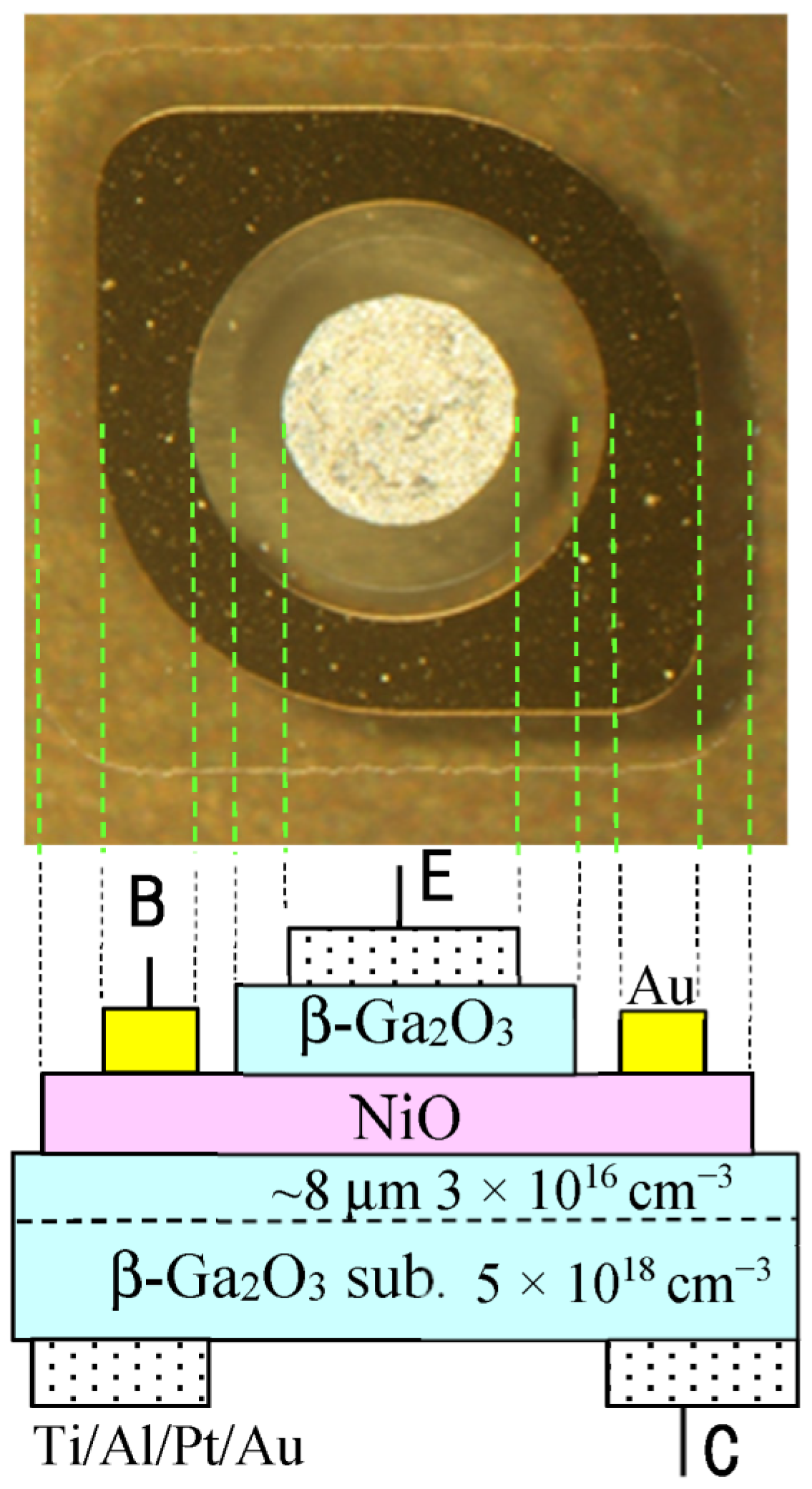

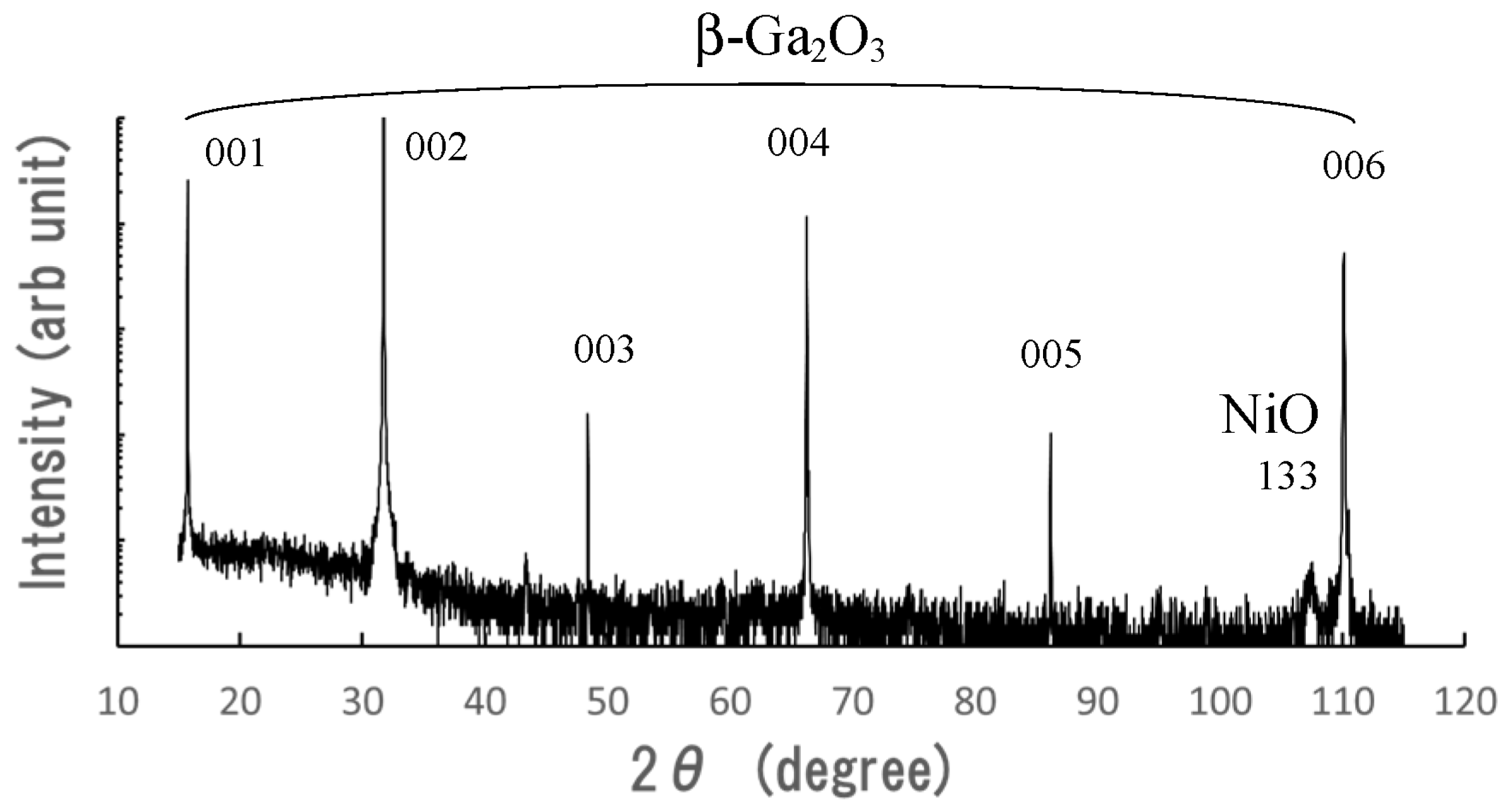

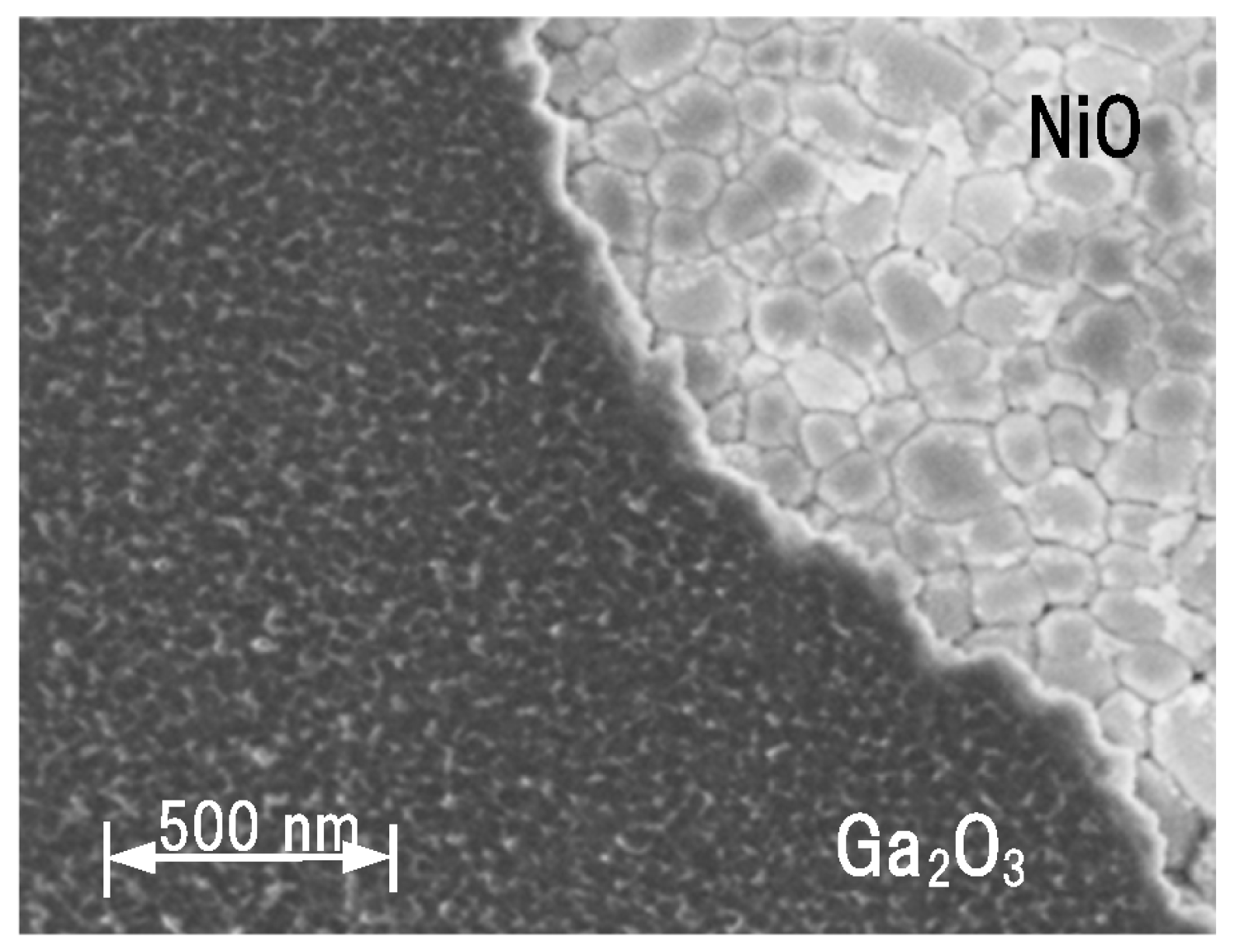

2.1. Device Structure and Fabrication

2.2. Measurements

3. Results and Discussion

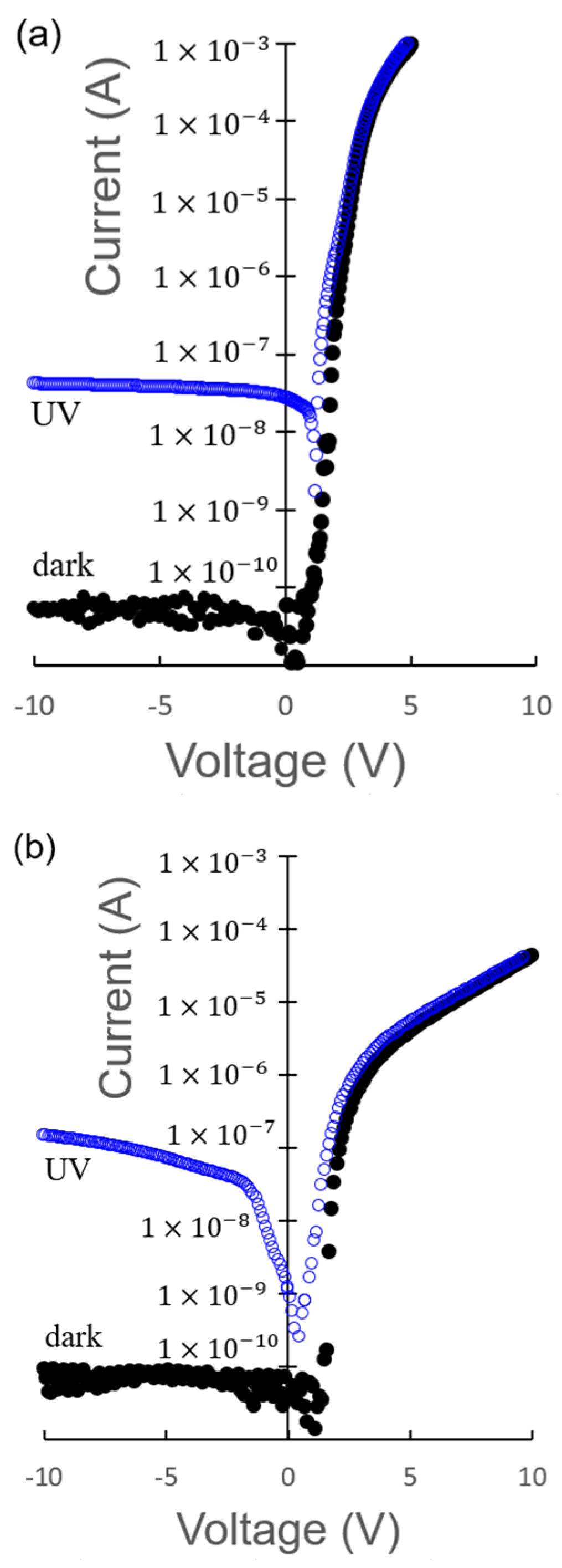

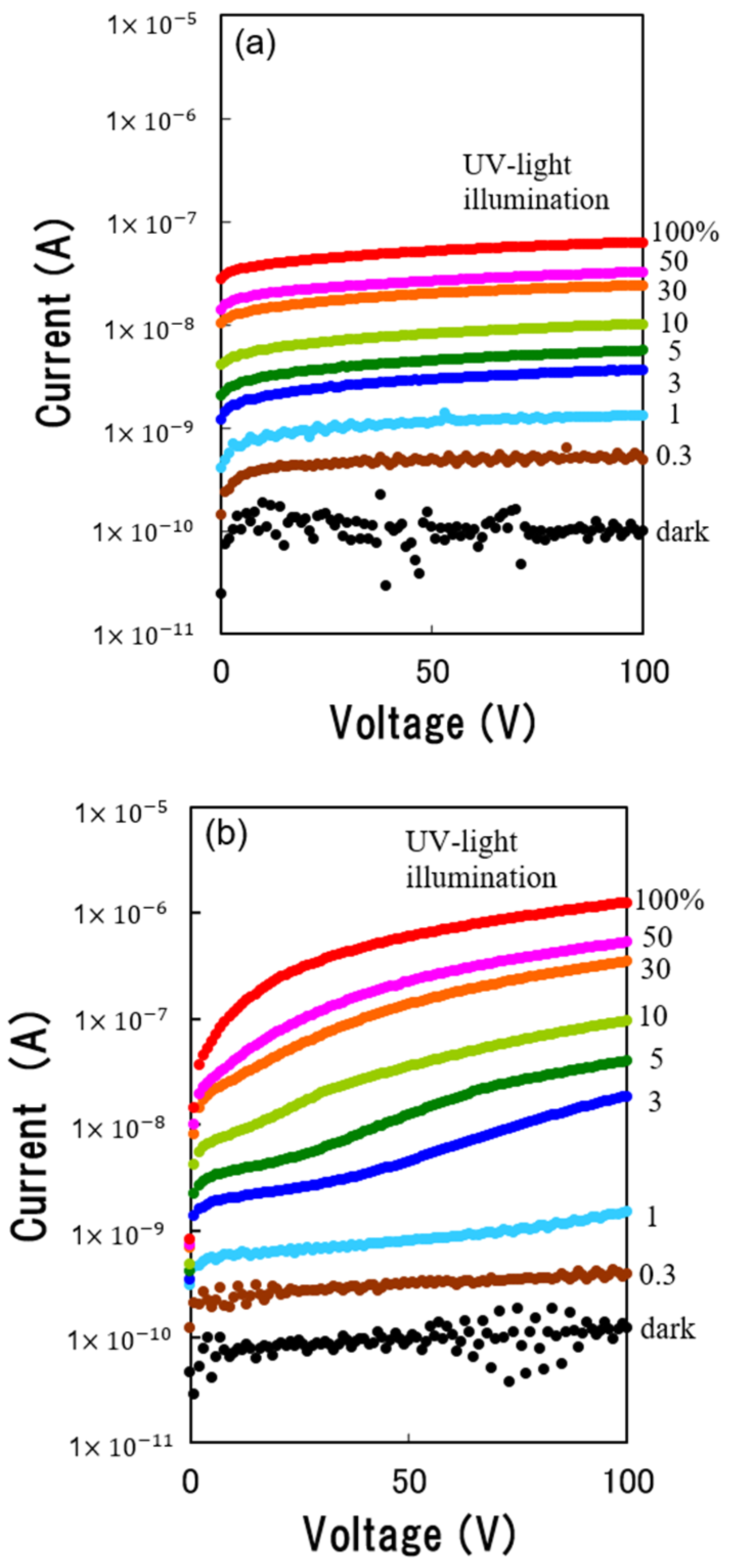

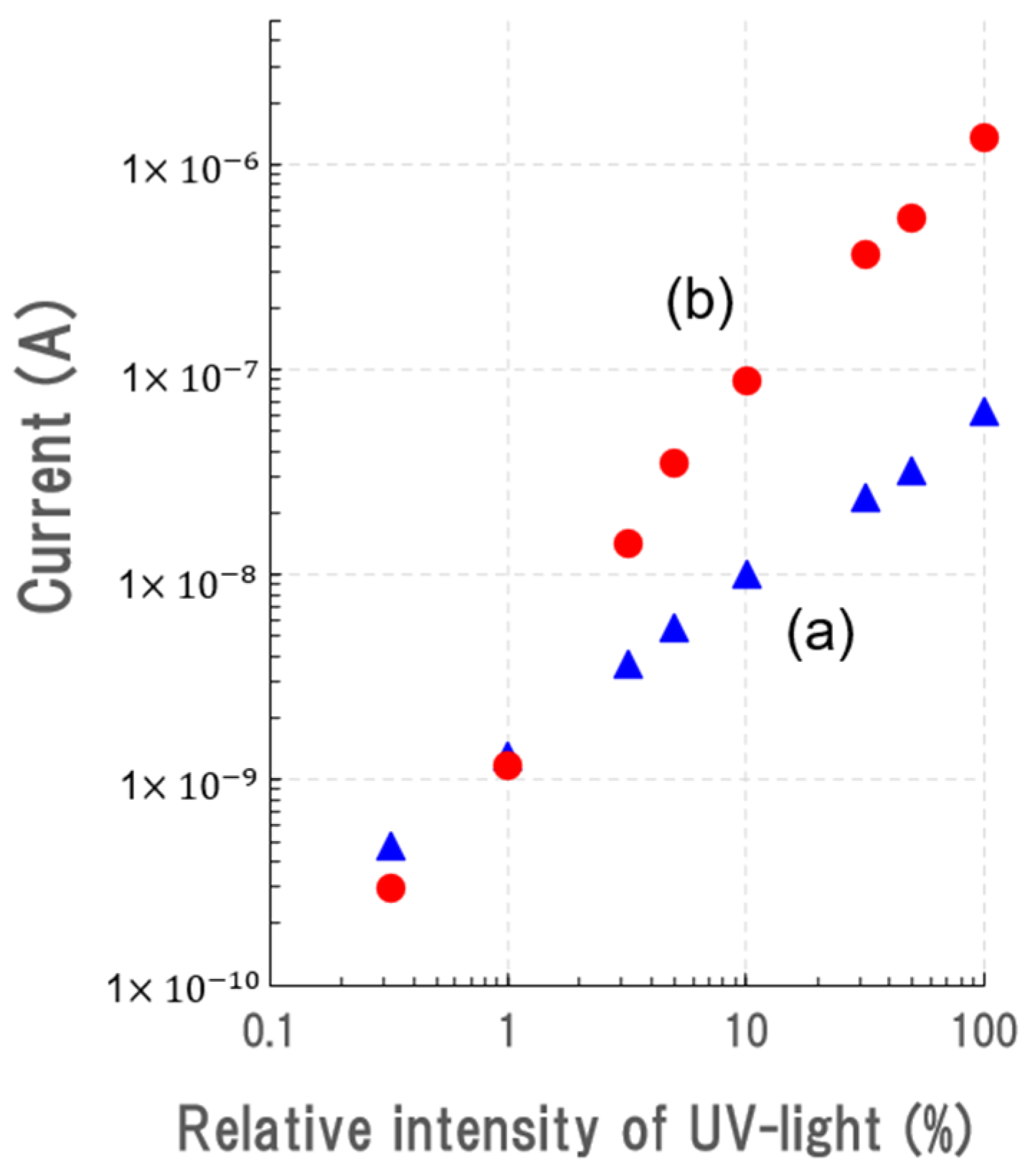

3.1. Current–Voltage Characteristics

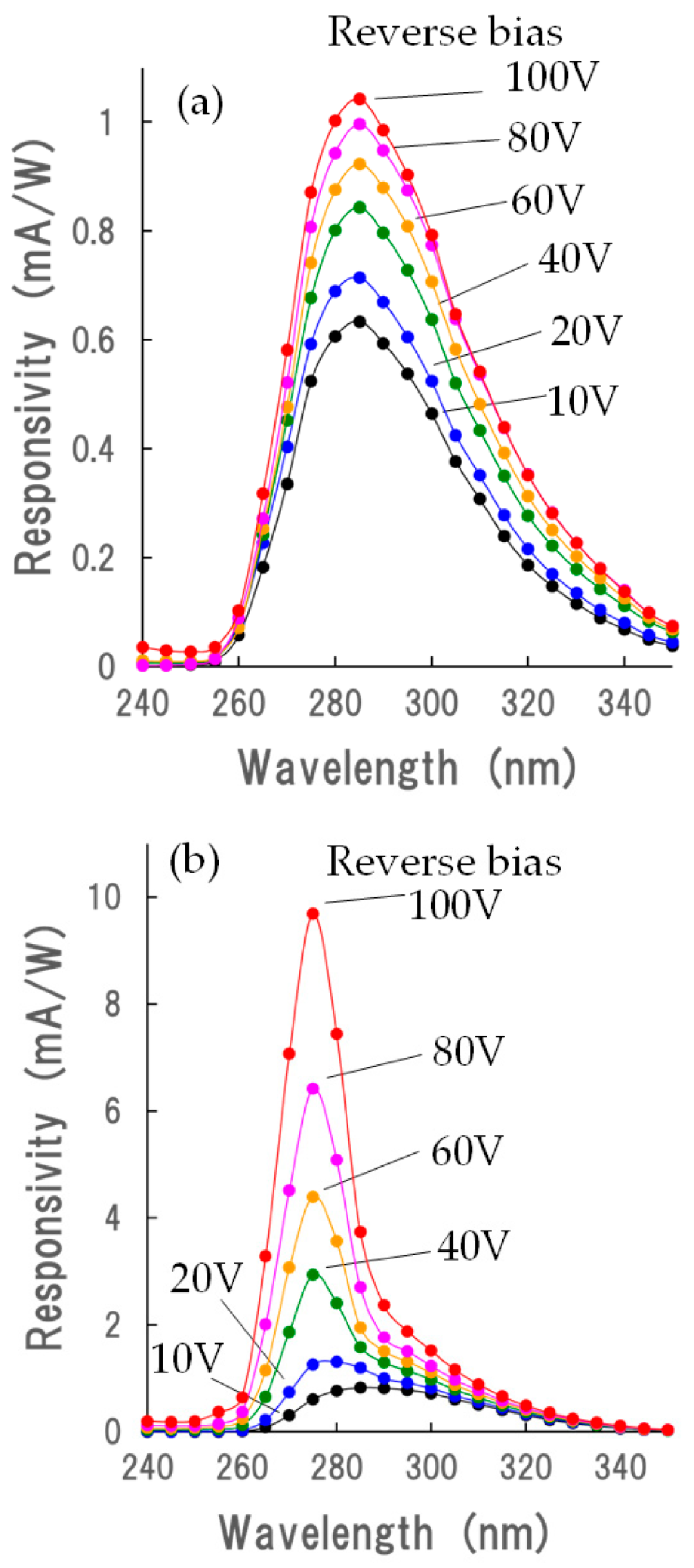

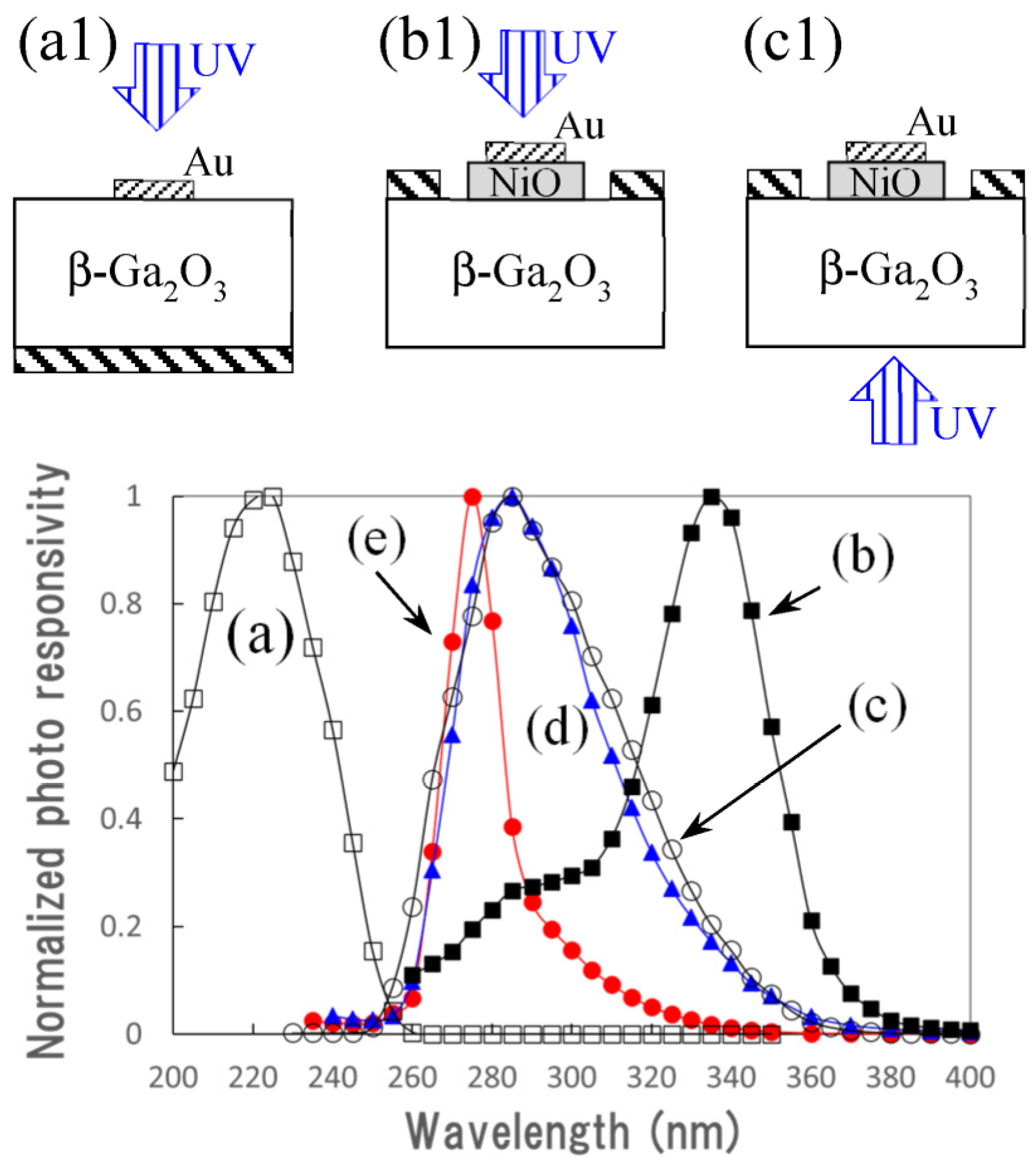

3.2. Photo Responsivity

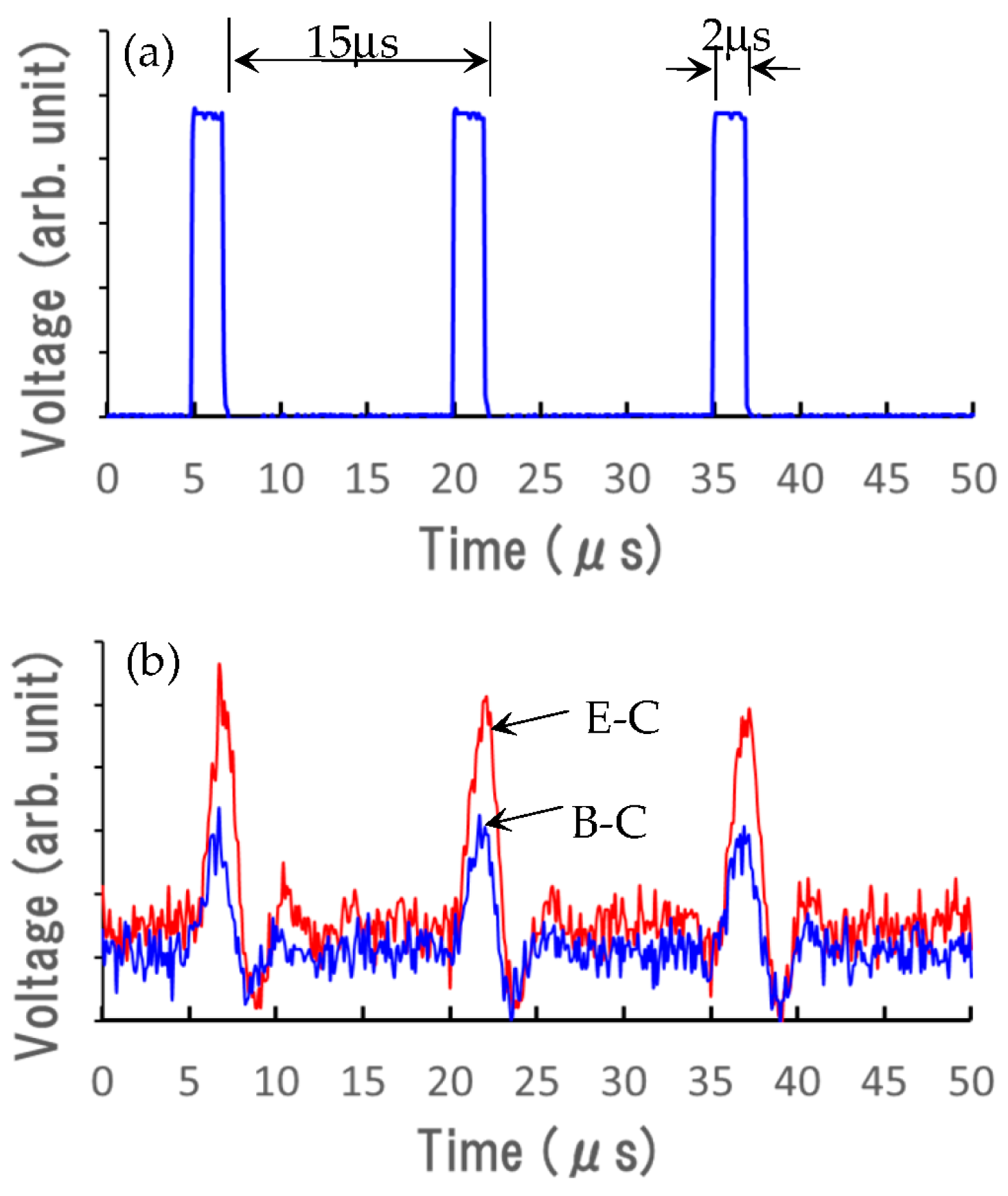

3.3. Transient Response

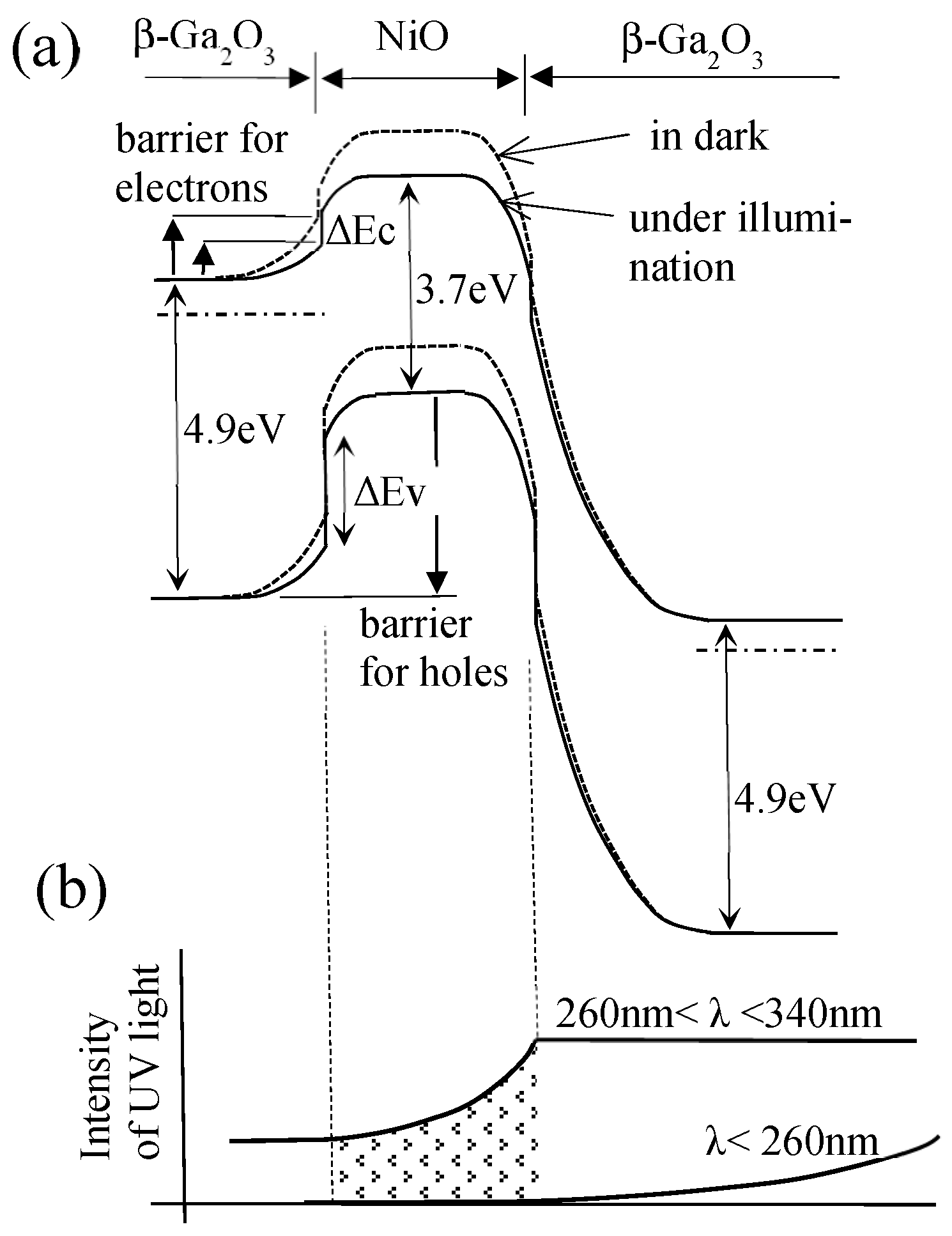

4. Discussion

5. Conclusions

Supplementary Materials

Funding

Data Availability Statement

Conflicts of Interest

References

- Sasaki, K.; Kuramata, A.; Yamakoshi, S.; Higashiwaki, M.; Masui, T. Ga2O3 Schottky Barrier Diodes Fabricated by Using Single-Crystal β-Ga2O3 (010) Substrates. IEEE Electron Device Lett. 2013, 34, 493. [Google Scholar] [CrossRef]

- Wong, M.H.; Nakata, Y.; Kuramata, A.; Yamakoshi, S.; Higashiwaki, M. Enhancement-mode Ga2O3 MOSFETs with Si-ion-implanted source and drain. Appl. Phys. Express 2017, 10, 041101.1. [Google Scholar] [CrossRef]

- Pearton, S.J.; Ren, F.; Tadjer, M.; Kim, J. Perspective: Ga2O3 for ultra-high power rectifiers and MOSFETS. J. Appl. Phys. 2018, 124, 220901. [Google Scholar] [CrossRef]

- Oshima, T.; Okuno, T.; Arai, N.; Suzuki, N.; Ohira, S.; Fujita, S. Vertical Solar-Blind Deep-Ultraviolet Schottky Photodetectors Based on β-Ga2O3 Substrates. Appl. Phys. Express 2008, 1, 011202. [Google Scholar] [CrossRef]

- Peng, B.; Yuan, L.; Zhang, H.; Cheng, H.; Zhang, Y.; Zhang, Y.; Jia, R. Fast-response self-powered solar-blind photodetector based on Pt/β-Ga2O3 Schottky barrier diodes. Optik 2021, 245, 167715. [Google Scholar] [CrossRef]

- Kokubun, Y.; Kubo, S.; Nakagomi, S. All-oxide p–n heterojunction diodes comprising p-type NiO and n-type β-Ga2O3. Appl. Phys. Express 2016, 9, 091101. [Google Scholar] [CrossRef]

- Nakagomi, S.; Kubo, S.; Kokubun, Y. The orientational relationship between monoclinic β-Ga2O3 and cubic NiO. J. Cryst. Growth 2016, 445, 73. [Google Scholar] [CrossRef]

- Lu, X.; Zhou, X.; Jiang, H.; Ng, K.W.; Chen, Z.; Pei, Y.; Lau, K.M.; Wang, G. 1-kV Sputtered p-NiO/n-Ga2O3 Heterojunction Diodes with an Ultra-Low Leakage Current Below 1 μ A/cm2. IEEE Electron Device Lett. 2020, 41, 449. [Google Scholar] [CrossRef]

- Li, J.S.; Chiang, C.C.; Xia, X.; Yoo, T.J.; Ren, F.F.; Kim, H.; Pearton, S.J. Demonstration of 4.7 kV breakdown voltage in NiO/β-Ga2O3 vertical rectifiers. Appl. Phys. Lett. 2022, 121, 042105. [Google Scholar] [CrossRef]

- Jia, M.; Wang, F.; Tang, L.; Xiang, J.; Teng, K.S.; Lau, S.P. High-Performance Deep Ultraviolet Photodetector Based on NiO/β-Ga2O3 Heterojunction. Nanoscale Res. Lett. 2020, 15, 47. [Google Scholar] [CrossRef]

- Li, K.H.; Alfaraj, N.; Kang, C.H.; Braic, L.; Hedhili, M.N.; Guo, Z.; Ng, T.K.; Ooi, B.S. Deep-Ultraviolet Photodetection Using Single-Crystalline β-Ga2O3/NiO Heterojunctions. ACS Appl. Mater. Interfaces 2019, 11, 35095. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Yu, M.; Wang, Z.; Yuan, L.; Huang, Y.; Zhang, L.; Zhang, Y.; Jia, R. Improved Photoresponse Performance of Self-Powered β-Ga₂O₃/NiO Heterojunction UV Photodetector by Surface Plasmonic Effect of Pt Nanoparticles. IEEE Trans. Electron Devices 2020, 67, 3199. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, C.; Guo, D.; Li, P.; Wang, S.; Liu, A.; Li, C.; Wu, F.; Tang, W. All-Oxide NiO/Ga2O3 p–n Junction for Self-Powered UV Photodetector. ACS Appl. Electron. Mater. 2020, 2, 2032. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, S.; Zhang, H.; Ye, L.; Xiong, Y.; Yu, P.; Li, W.; Yang, X.; Li, H.; Kong, C. Ultrasensitive fully transparent amorphous Ga2O3 solar-blind deep-ultraviolet photodetector for corona discharge detection. J. Phys. D Appl. Phys. 2022, 55, 305104. [Google Scholar] [CrossRef]

- Hu, S.; Han, D.; Jiang, K.; Liu, N.; Wang, W.; Zhang, J.; Liu, K.; Zhang, T.; Zhang, W.; Ye, J. Influence of oxygen vacancy and metal–semiconductor contact on the device performance of amorphous gallium oxide photodetectors. Appl. Phys. Express 2023, 16, 021005. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Fu, R.; Ma, J.; Xu, H.; Li, B.; Liu, Y.J. High performance solar-blind ultraviolet photodetector based on ITO/β-Ga2O3 heterostructure. Phys. D Appl. Phys. 2022, 55, 324002. [Google Scholar] [CrossRef]

- He, H.; Wu, C.; Hu, H.; Wang, S.; Zhang, F.; Guo, D.; Wu, F. Bandgap Engineering and Oxygen Vacancy Defect Electroactivity Inhibition in Highly Crystalline N-Alloyed Ga2O3 Films through Plasma-Enhanced Technology. J. Phys. Chem. Lett. 2023, 14, 6444–6450. [Google Scholar] [CrossRef]

- Cheng, Y.; Ye, J.; Lai, L.; Fang, S.; Guo, D. Ambipolarity Regulation of Deep-UV Photocurrent by Controlling Crystalline Phases in Ga2O3 Nanostructure for Switchable Logic Applications. Adv. Electron. Mater. 2023, 9, 2201216. [Google Scholar] [CrossRef]

- Ashok, P.; Dhar, J.C. High Performance Self-Powered UV Photodetector Based on -GaO Nanowire/CHNHPbI Heterostructure. IEEE Photonics Technol. Lett. 2022, 34, 1321–1324. [Google Scholar] [CrossRef]

- Pasupuleti, K.S.; Reddeppa, M.; Park, B.G.; Oh, J.E.; Kim, S.G.; Kim, M.D. Efficient Charge Separation in Polypyrrole/GaN-Nanorod-Based Hybrid Heterojunctions for High-Performance Self-Powered UV Photodetection. Phisica Status Solidi Rapid Res. Lett. 2021, 15, 2000518. [Google Scholar] [CrossRef]

- Kokubun, Y.; Nakagomi, S. Electrical Conductivity Studies in Sol–Gel-Derived Li-Doped NiO Epitaxial Thin Films. Phys. Status Solidi B 2020, 257, 2000330. [Google Scholar] [CrossRef]

- Kokubun, Y.; Miura, K.; Endo, F.; Nakagomi, S. Sol-gel prepared β-Ga2O3 thin films for ultraviolet photodetectors. Appl. Phys. Lett. 2007, 90, 031912. [Google Scholar] [CrossRef]

| UV Photodetectors | ||

|---|---|---|

| Structure | Photoresponsivity | References |

| Transparent amorphous Ga2O3 | 2.66 A/W 5.78 A/W | [14] [15] |

| ITO/β-Ga2O3 | 1720.2 A/W | [16] |

| ITO/NiO/β-Ga2O3 | 27.43 A/W | [10] |

| β-Ga2O3/NiO | 415 mA/W | [11] |

| β-Ga2O3/NiO with Pt nanoparticles | 4.27 mA/W | [12] |

| β-Ga2O3/NiO | 57 μA/W | [13] |

| β-Ga2O3NW/CH3NH3PbI3/NiO NW | 254 mA/W | [17] |

| β-Ga2O3/NiO/β-Ga2O3 | 10 mA/W | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakagomi, S. Ultraviolet Photodetector Based on a Beta-Gallium Oxide/Nickel Oxide/Beta-Gallium Oxide Heterojunction Structure. Sensors 2023, 23, 8332. https://doi.org/10.3390/s23198332

Nakagomi S. Ultraviolet Photodetector Based on a Beta-Gallium Oxide/Nickel Oxide/Beta-Gallium Oxide Heterojunction Structure. Sensors. 2023; 23(19):8332. https://doi.org/10.3390/s23198332

Chicago/Turabian StyleNakagomi, Shinji. 2023. "Ultraviolet Photodetector Based on a Beta-Gallium Oxide/Nickel Oxide/Beta-Gallium Oxide Heterojunction Structure" Sensors 23, no. 19: 8332. https://doi.org/10.3390/s23198332

APA StyleNakagomi, S. (2023). Ultraviolet Photodetector Based on a Beta-Gallium Oxide/Nickel Oxide/Beta-Gallium Oxide Heterojunction Structure. Sensors, 23(19), 8332. https://doi.org/10.3390/s23198332