Analysis of the Response Signals of an Electronic Nose Sensor for Differentiation between Fusarium Species

Abstract

:1. Introduction

2. Materials and Methods

2.1. Electronic Nose Device

2.2. Measurements with the Electronic Nose

2.2.1. Measurement Cycle

2.2.2. Series of Measurements

2.3. Collecting Signals and Extracting Modeling Features

- (A)

- When the sensor chamber is open and the sensors respond to the change in conditions from clean air to the presence of the odor;

- (B)

- After reaching a steady state, the heating voltage decreases, which lowers the sensor temperature, and the response to this type of change is recorded;

- (C)

- After reaching steady state, the heating voltage of the sensor is increased to the nominal voltage;

- (D)

- When the sensor chamber is closed and the sensors respond to the change in gas composition from the presence of the measured odor to clean air conditions.

- First, the magnitude of the normalized response at a selected time point;

- Second, the slope of the response curve at that time point (the slope was calculated using ±2 data points around the time point under consideration);

- Third, the area under the curve up to the selected time point.

2.4. Samples Preparation

2.5. Classification Analysis

2.5.1. Random Forest Classification Model

2.5.2. Models for Performance Measures

2.5.3. Software Packages

3. Results

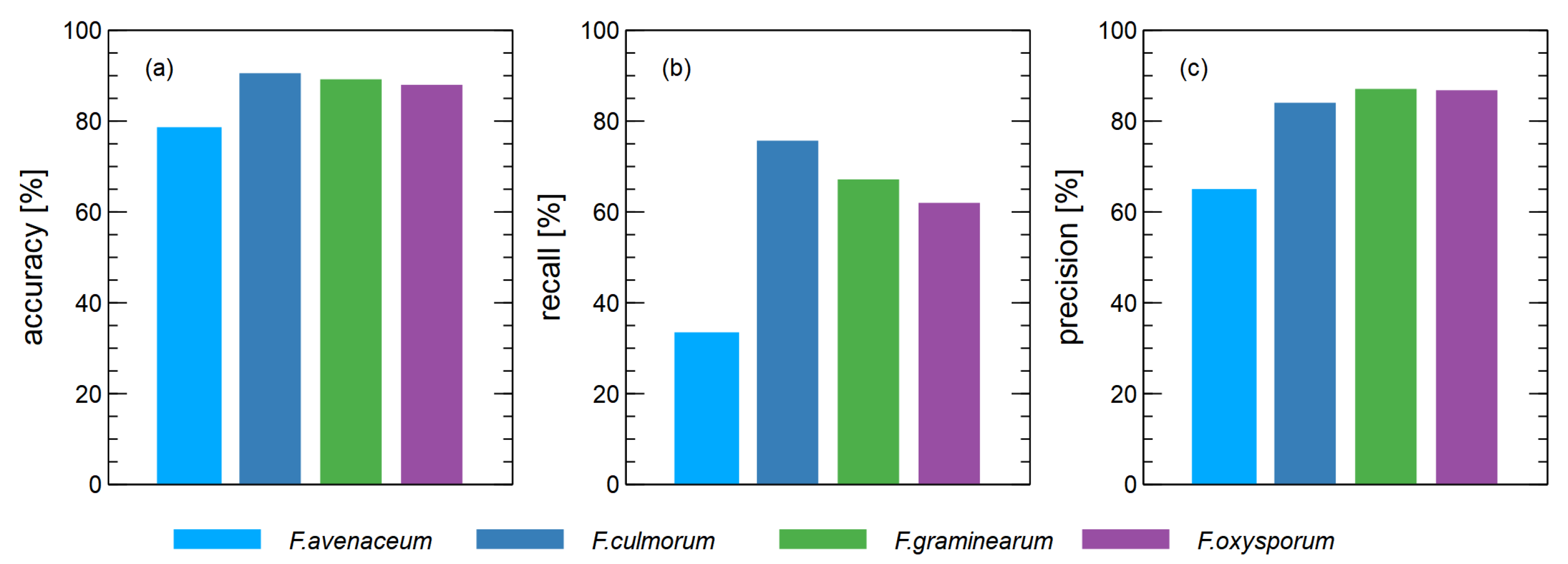

3.1. Recognition of Fusarium Species

3.2. Various Modes of Electronic Nose Response

3.3. Electronic Nose Signals Collection Time

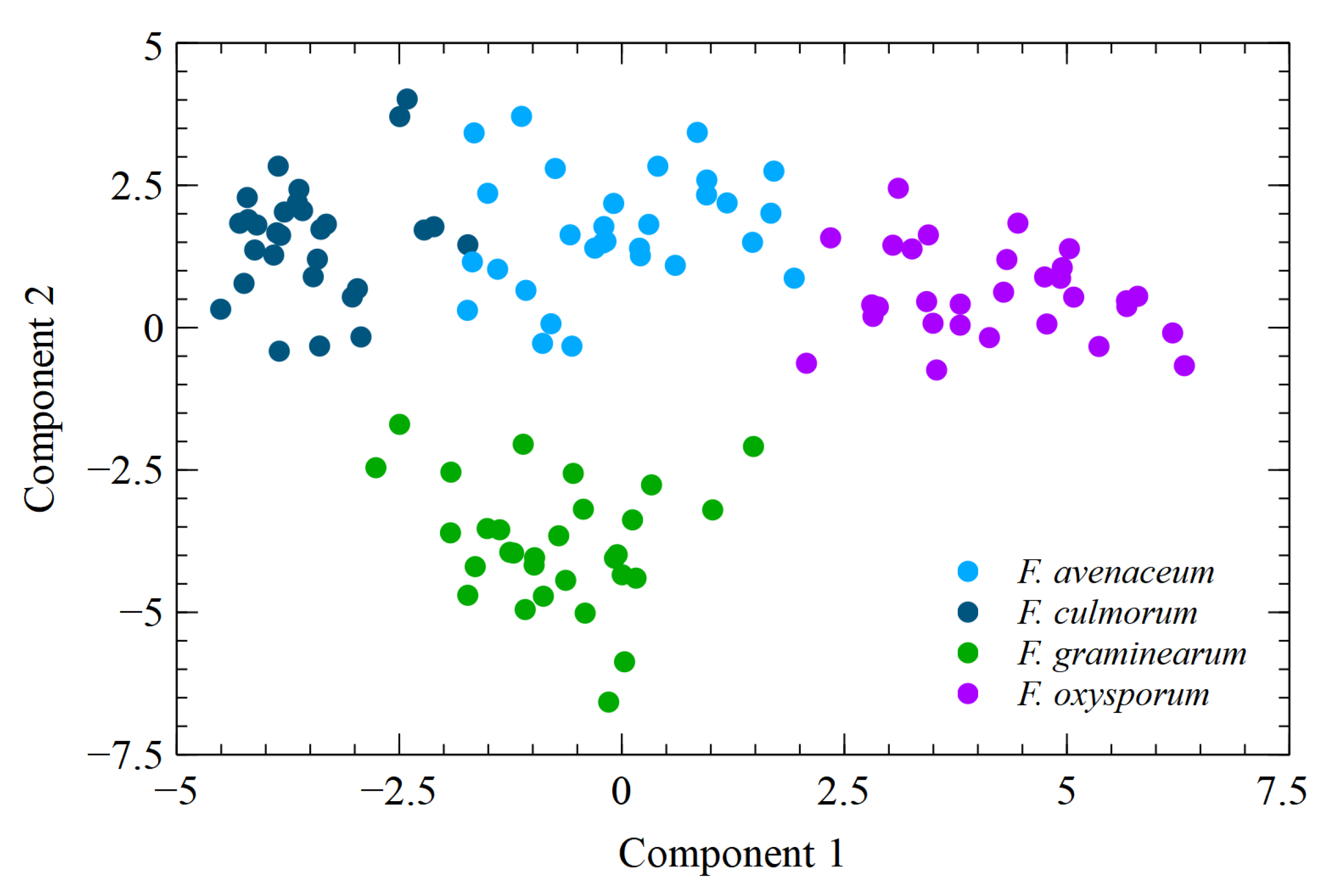

3.4. Linear Discrimination Analysis

4. Discussion

4.1. Differentiation between Fusarium Species via Electronic Nose Measurements

4.2. Choice of the Operating Mode of the Electronic Nose Sensor

4.3. Electronic Nose Data Collection Time

4.4. Chemical Compounds Produced by Fusarium

4.5. Future Applications

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Inhibition of Fusarium Mycelium Development by the Presence of Bacillus Bacteria

Appendix B. TGS Sensors Used in the Electronic Nose Construction

| Sensor | Target Gas Detection |

|---|---|

| TGS 2600 | Highly sensitive to low concentrations of gaseous air contaminants such as hydrogen and carbon monoxide (for example, that in cigarette smoke). Can detect hydrogen at a level of several ppm. |

| TGS 2602 | Highly sensitive to low concentrations of odorous gases such as ammonia and HS generated from waste materials in office and home environments. Highly sensitive to low concentrations of VOCs such as toluene emitted from wood finishing and construction products. |

| TGS 2603 | Highly sensitive to low concentrations of odorous gases such as amine-series and sulfurous odors generated from waste materials or spoiled foods such as fish. |

| TGS 2610 | Uses filter material, eliminating the influence of interference gases such as alcohol. Highly selective of LP gas. |

| TGS 2611 | Uses filter material, eliminating the influence of interference gases such as alcohol. Highly selective of methane gas. |

| TGS 2612 | Highly sensitive to methane, propane, and butane. Targeted for LNG and LPG monitoring. Low sensitivity to alcohol vapors (a typical interference gas in the residential environment). The sensor is often used in consumer market gas alarms. |

Appendix C. Electronic Nose Sensor’s Response

References

- Persaud, K.; Dodd, G. Analysis of discrimination mechanisms in the mammalian olfactory system using a model nose. Nature 1982, 299, 352–355. [Google Scholar] [CrossRef] [PubMed]

- Hunter, G.W.; Akbar, S.; Bhansali, S.; Daniele, M.; Erb, P.D.; Johnson, K.; Liu, C.C.; Miller, D.; Oralkan, O.; Hesketh, P.J.; et al. Editors’ Choice—Critical Review—A Critical Review of Solid State Gas Sensors. J. Electrochem. Soc. 2020, 167, 037570. [Google Scholar] [CrossRef]

- Kuchmenko, T.A.; Lvova, L.B. A Perspective on Recent Advances in Piezoelectric Chemical Sensors for Environmental Monitoring and Foodstuffs Analysis. Chemosensors 2019, 7, 39. [Google Scholar] [CrossRef]

- Liu, T.; Li, D.; Chen, J. An active method of online drift-calibration-sample formation for an electronic nose. Measurement 2021, 171, 108748. [Google Scholar] [CrossRef]

- Cheng, L.; Meng, Q.H.; Lilienthal, A.J.; Qi, P.F. Development of compact electronic noses: A review. Meas. Sci. Technol. 2021, 32, 062002. [Google Scholar] [CrossRef]

- Figaro Engineering Inc. MOS Type Sensors Operating Principle. Available online: https://www.figarosensor.com/technicalinfo/principle/mos-type.html (accessed on 26 December 2022).

- Burlachenko, J.; Kruglenko, I.; Snopok, B.; Persuad, K. Sample handling for electronic nose technology: State of the art and future trends. TrAC Trends Anal. Chem. 2016, 82, 222–236. [Google Scholar] [CrossRef]

- Huang, J.R.; Gu, C.P.; Meng, F.L.; Li, M.Q.; Liu, J.H. Detection of volatile organic compounds by using a single temperature-modulated SnO2 gas sensor and artificial neural network. Smart Mater. Struct. 2007, 16, 701–705. [Google Scholar] [CrossRef]

- Hossein-Babaei, F.; Amini, A. Recognition of complex odors with a single generic tin oxide gas sensor. Sensors Actuators Chem. 2014, 194, 156–163. [Google Scholar] [CrossRef]

- Yuan, Z.; Han, E.; Meng, F.; Zuo, K. Detection and Identification of Volatile Organic Compounds Based on Temperature-Modulated ZnO Sensors. IEEE Trans. Instrum. Meas. 2020, 69, 4533–4544. [Google Scholar] [CrossRef]

- Liu, H.; Wu, R.; Guo, Q.; Hua, Z.; Wu, Y. Electronic Nose Based on Temperature Modulation of MOS Sensors for Recognition of Excessive Methanol in Liquors. ACS Omega 2021, 6, 30598–30606. [Google Scholar] [CrossRef]

- Liu, H.; He, Y.; Nagashima, K.; Meng, G.; Dai, T.; Tong, B.; Deng, Z.; Wang, S.; Zhu, N.; Yanagida, T.; et al. Discrimination of VOCs molecules via extracting concealed features from a temperature-modulated p-type NiO sensor. Sensors Actuators Chem. 2019, 293, 342–349. [Google Scholar] [CrossRef]

- Amini, A.; Bagheri, M.A.; Montazer, G.A. Improving gas identification accuracy of a temperature-modulated gas sensor using an ensemble of classifiers. Sensors Actuators Chem. 2013, 187, 241–246. [Google Scholar] [CrossRef]

- Gosangi, R.; Gutierrez-Osuna, R. Active temperature modulation of metal-oxide sensors for quantitative analysis of gas mixtures. Sensors Actuators Chem. 2013, 185, 201–210. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, L.; Tian, F.; Zhang, D. Temperature Modulated Gas Sensing E-Nose System for Low-Cost and Fast Detection. IEEE Sensors J. 2016, 16, 464–474. [Google Scholar] [CrossRef]

- Krivetskiy, V.; Efitorov, A.; Arkhipenko, A.; Vladimirova, S.; Rumyantseva, M.; Dolenko, S.; Gaskov, A. Selective detection of individual gases and CO/H2 mixture at low concentrations in air by single semiconductor metal oxide sensors working in dynamic temperature mode. Sensors Actuators Chem. 2018, 254, 502–513. [Google Scholar] [CrossRef]

- Oates, M.J.; Fox, P.; Sanchez-Rodriguez, L.; Carbonell-Barrachina, Á.A.; Ruiz-Canales, A. DFT based classification of olive oil type using a sinusoidally heated, low cost electronic nose. Comput. Electron. Agric. 2018, 155, 348–358. [Google Scholar] [CrossRef]

- Iwata, T.; Saeki, M.; Okura, Y.; Yoshikawa, T. Gas discrimination based on enhanced gas-species related information obtained by a single gas sensor with novel temperature modulation. Sensors Actuators Chem. 2022, 354, 131225. [Google Scholar] [CrossRef]

- Meng, F.; Mi, C.; Luan, X.; Ji, H.; Zhu, H.; Yuan, Z. Detection of Drug-Producing Chemicals Based on Gas Sensor Array With Dynamic Temperature Modulation. IEEE Sensors J. 2023, 23, 8109–8119. [Google Scholar] [CrossRef]

- Ma, L.; Geiser, D.; Proctor, R.; Rooney, A.; O’Donnell, K.; Trail, F.; Gardiner, D.; Manners, J.; Kazan, K. Fusarium pathogenomics. Annu. Rev. Microbiol. 2013, 67, 399–416. [Google Scholar] [CrossRef]

- Khan, N.; Martínez-Hidalgo, P.; Ice, T.A.; Maymon, M.; Humm, E.A.; Nejat, N.; Sanders, E.; Kaplan, D.; Hirsch, A.M. Antifungal activity of Bacillus species against Fusarium and analysis of the potential mechanisms used in biocontrol. Front. Microbiol. 2018, 9, 2363. [Google Scholar] [CrossRef]

- Khedher, S.B.; Mejdoub-Trabelsi, B.; Tounsi, S. Biological potential of Bacillus subtilis V26 for the control of Fusarium wilt and tuber dry rot on potato caused by Fusarium species and the promotion of plant growth. Biol. Control 2021, 152, 104444. [Google Scholar] [CrossRef]

- Stocka, N. Wykorzystanie Bakterii z Rodzaju Bacillus w Ochronie Biologicznej Powietrza Zanieczyszczonego Grzybami z Rodzaju Fusarium [The use of Bacillus Bacteria in Biological Control of Air Polluted with Fusarium Fungi]. Ph.D. Thesis, Faculty of Civil Engineering and Environmental Sciences, Białystok University of Technology, Białystok, Poland, 2023. [Google Scholar]

- Vikram, A.; Hamzehzarghani, H.; Kushalappa, A. Volatile metabolites from the headspace of onion bulbs inoculated with postharvest pathogens as a tool for disease discrimination. Can. J. Plant Pathol. 2005, 27, 194–203. [Google Scholar] [CrossRef]

- Falasconi, M.; Gobbi, E.; Pardo, M.; Torre, M.D.; Bresciani, A.; Sberveglieri, G. Detection of toxigenic strains of Fusarium verticillioides in corn by electronic olfactory system. Sensors Actuators Chem. 2005, 108, 250–257. [Google Scholar] [CrossRef]

- Presicce, D.S.; Forleo, A.; Taurino, A.M.; Zuppa, M.; Siciliano, P.; Laddomada, B.; Logrieco, A.; Visconti, A. Response evaluation of an E-nose towards contaminated wheat by Fusarium poae fungi. Sensors Actuators Chem. 2006, 118, 433–438. [Google Scholar] [CrossRef]

- Perkowski, J.; Busko, M.; Chmielewski, J.; Goral, T.; Tyrakowska, B. Content of trichodiene and analysis of fungal volatiles (electronic nose) in wheat and triticale grain naturally infected and inoculated with Fusarium culmorum. Int. J. Food Microbiol. 2008, 126, 127–134. [Google Scholar] [CrossRef]

- Eifler, J.; Martinelli, E.; Santonico, M.; Capuano, R.; Schild, D.; Natale, C.D. Differential Detection of Potentially Hazardous Fusarium Species in Wheat Grains by an Electronic Nose. PLoS ONE 2011, 6, e21026. [Google Scholar] [CrossRef]

- Nordström, I.; Sherwood, P.; Bohman, B.; Woodward, S.; Peterson, D.L.; Niño-Sánchez, J.; Sánchez-Gómez, T.; Díez, J.J.; Cleary, M. Utilizing volatile organic compounds for early detection of Fusarium circinatum. Sci. Rep. 2022, 12. [Google Scholar] [CrossRef]

- Feng, H.; Viejo, C.G.; Vaghefi, N.; Taylor, P.W.J.; Tongson, E.; Fuentes, S. Early Detection of Fusarium oxysporum Infection in Processing Tomatoes (Solanum lycopersicum) and Pathogen–Soil Interactions Using a Low-Cost Portable Electronic Nose and Machine Learning Modeling. Sensors 2022, 22, 8645. [Google Scholar] [CrossRef]

- Labanska, M.; van Amsterdam, S.; Jenkins, S.; Clarkson, J.P.; Covington, J.A. Preliminary Studies on Detection of Fusarium Basal Rot Infection in Onions and Shallots Using Electronic Nose. Sensors 2022, 22, 5453. [Google Scholar] [CrossRef]

- Leggieri, M.C.; Mazzoni, M.; Bertuzzi, T.; Moschini, M.; Prandini, A.; Battilani, P. Electronic Nose for the Rapid Detection of Deoxynivalenol in Wheat Using Classification and Regression Trees. Toxins 2022, 14, 617. [Google Scholar] [CrossRef]

- Borowik, P.; Grzywacz, T.; Tarakowski, R.; Tkaczyk, M.; Ślusarski, S.; Dyshko, V.; Oszako, T. Development of a Low-Cost Electronic Nose with an Open Sensor Chamber: Application to Detection of Ciboria batschiana. Sensors 2023, 23, 627. [Google Scholar] [CrossRef] [PubMed]

- Borowik, P.; Adamowicz, L.; Tarakowski, R.; Wacławik, P.; Oszako, T.; Ślusarski, S.; Tkaczyk, M. Application of a Low-Cost Electronic Nose for Differentiation between Pathogenic Oomycetes Pythium intermedium and Phytophthora plurivora. Sensors 2021, 21, 1326. [Google Scholar] [CrossRef] [PubMed]

- Borowik, P.; Adamowicz, L.; Tarakowski, R.; Wacławik, P.; Oszako, T.; Ślusarski, S.; Tkaczyk, M. Development of a Low-Cost Electronic Nose for Detection of Pathogenic Fungi and Applying It to Fusarium oxysporum and Rhizoctonia solani. Sensors 2021, 21, 5868. [Google Scholar] [CrossRef] [PubMed]

- Borowik, P.; Tarakowski, R.; Tkaczyk, M.; Ślusarski, S.; Oszako, T. Application of a Low-Cost Electronic Nose to Detect of Forest Tree Pathogens: Fusarium oxysporum and Phytophthora plurivora. IEEE Access 2022, 10, 93475–93487. [Google Scholar] [CrossRef]

- Cervera Gómez, J.; Pelegri-Sebastia, J.; Lajara, R. Circuit Topologies for MOS-Type Gas Sensor. Electronics 2020, 9, 525. [Google Scholar] [CrossRef]

- Yan, J.; Guo, X.; Duan, S.; Jia, P.; Wang, L.; Peng, C.; Zhang, S. Electronic Nose Feature Extraction Methods: A Review. Sensors 2015, 15, 27804–27831. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- ur Rehman, A.; Bermak, A. Heuristic Random Forests (HRF) for Drift Compensation in Electronic Nose Applications. IEEE Sensors J. 2019, 19, 1443–1453. [Google Scholar] [CrossRef]

- Men, H.; Fu, S.; Yang, J.; Cheng, M.; Shi, Y.; Liu, J. Comparison of SVM, RF and ELM on an Electronic Nose for the Intelligent Evaluation of Paraffin Samples. Sensors 2018, 18, 285. [Google Scholar] [CrossRef]

- Li, Q.; Gu, Y.; Wang, N.F. Application of Random Forest Classifier by Means of a QCM-Based E-Nose in the Identification of Chinese Liquor Flavors. IEEE Sensors J. 2017, 17, 1788–1794. [Google Scholar] [CrossRef]

- Qiu, S.; Wang, J. Effects of storage temperature and time on internal quality of satsuma mandarin (Citrus unshiu marc.) by means of E-nose and E-tongue based on two-way MANOVA analysis and random forest. Innov. Food Sci. Emerg. Technol. 2015, 31, 139–150. [Google Scholar] [CrossRef]

- Qiu, S.; Wang, J.; Gao, L. Discrimination and Characterization of Strawberry Juice Based on Electronic Nose and Tongue: Comparison of Different Juice Processing Approaches by LDA, PLSR, RF, and SVM. J. Agric. Food Chem. 2014, 62, 6426–6434. [Google Scholar] [CrossRef]

- Hastie, T.; Tibshirani, R.; Friedman, J. The Elements of Statistical Learning. Data Mining, Inference, and Prediction; Springer Series in Statistics; Springer: New York, NY, USA, 2009. [Google Scholar]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Rodriguez Gamboa, J.C.; da Silva, A.J.; Araujo, I.S.C.; Albarracin, E.E.S.; Duran, A.C.W. Validation of the rapid detection approach for enhancing the electronic nose systems performance, using different deep learning models and support vector machines. Sensors Actuators Chem. 2021, 327, 128921. [Google Scholar] [CrossRef]

- Okorski, A.; Polak-Śliwińska, M.; Karpiesiuk, K.; Pszczółkowska, A.; Kozera, W. Real time PCR: A good tool to estimate mycotoxin contamination in pig diets. World Mycotoxin J. 2017, 10, 219–228. [Google Scholar] [CrossRef]

- Okorski, A.; Pszczółkowska, A.; Markuszewki, B.; Olszewski, J.; Sięda, M.; Makowczenko, K.G.; Paukszto, Ł.; Jastrzębski, J.P. First Report of a Fusarium Wilt of Black Currant Caused by Fusarium avenaceum in Northeastern Poland. Plant Dis. 2020, 104, 593. [Google Scholar] [CrossRef]

- Okorski, A.; Milewska, A.; Pszczółkowska, A.; Karpiesiuk, K.; Kozera, W.; Dąbrowska, J.A.; Radwińska, J. Prevalence of Fusarium fungi and Deoxynivalenol Levels in Winter Wheat Grain in Different Climatic Regions of Poland. Toxins 2022, 14, 102. [Google Scholar] [CrossRef]

- Buśko, M.; Kulik, T.; Ostrowska, A.; Góral, T.; Perkowski, J. Quantitative volatile compound profiles in fungal cultures of three different Fusarium graminearum chemotypes. FEMS Microbiol. Lett. 2014, 359, 85–93. [Google Scholar] [CrossRef]

- Loulier, J.; Lefort, F.; Stocki, M.; Asztemborska, M.; Szmigielski, R.; Siwek, K.; Grzywacz, T.; Hsiang, T.; Ślusarski, S.; Oszako, T.; et al. Detection of Fungi and Oomycetes by Volatiles Using E-Nose and SPME-GC/MS Platforms. Molecules 2020, 25, 5749. [Google Scholar] [CrossRef]

- Freire, E.; Campos, V.; Pinho, R.; Oliveira, D.; Faria, M.; Pohlit, A.; Noberto, N.; Rezende, E.; Pfenning, L.; Silva, J. Volatile substances produced by Fusarium oxysporum from coffee rhizosphere and other microbes affect Meloidogyne incognita and Arthrobotrys conoides. J. Nematol. 2012, 44, 321. [Google Scholar]

- Sherif, M.; Becker, E.M.; Herrfurth, C.; Feussner, I.; Karlovsky, P.; Splivallo, R. Volatiles Emitted from Maize Ears Simultaneously Infected with Two Fusarium Species Mirror the Most Competitive Fungal Pathogen. Front. Plant Sci. 2016, 7, 1460. [Google Scholar] [CrossRef] [PubMed]

- Boeker, P. On ‘Electronic Nose’ methodology. Sensors Actuators Chem. 2014, 204, 2–17. [Google Scholar] [CrossRef]

- Okorski, A.; Pszczółkowska, A.; Okorska, S.; Fordoński, G. First Report of Fagus sylvatica Infection by Fusarium avenaceum in Forest Container Nurseries in Northeastern Poland. Plant Dis. 2015, 99, 420. [Google Scholar] [CrossRef] [PubMed]

- Pszczółkowska, A.; Okorski, A.; Paukszto, Ł.; Jastrzębski, J. First report of anthracnose disease caused by Colletotrichum fioriniae on blueberry in western Poland. Plant Dis. 2016, 100, 2167. [Google Scholar] [CrossRef]

- Inbaia, S.; Farooqi, A.; Ray, R.V. Aggressiveness and mycotoxin profile of Fusarium avenaceum isolates causing Fusarium seedling blight and Fusarium head blight in UK malting barley. Front. Plant Sci. 2023, 14, 1121553. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Duan, Z.; Zhang, B.; Zhao, Y.; Yuan, Z.; Zhang, Y.; Wu, Y.; Jiang, Y.; Tai, H. Local Gaussian process regression with small sample data for temperature and humidity compensation of polyaniline-cerium dioxide NH3 sensor. Sensors Actuators Chem. 2023, 378, 133113. [Google Scholar] [CrossRef]

| Predicted | |||

|---|---|---|---|

| Positive | Negative | ||

| actual | positive | (true positive) | (false negative) |

| negative | (false positive) | (true negative) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borowik, P.; Dyshko, V.; Tarakowski, R.; Tkaczyk, M.; Okorski, A.; Oszako, T. Analysis of the Response Signals of an Electronic Nose Sensor for Differentiation between Fusarium Species. Sensors 2023, 23, 7907. https://doi.org/10.3390/s23187907

Borowik P, Dyshko V, Tarakowski R, Tkaczyk M, Okorski A, Oszako T. Analysis of the Response Signals of an Electronic Nose Sensor for Differentiation between Fusarium Species. Sensors. 2023; 23(18):7907. https://doi.org/10.3390/s23187907

Chicago/Turabian StyleBorowik, Piotr, Valentyna Dyshko, Rafał Tarakowski, Miłosz Tkaczyk, Adam Okorski, and Tomasz Oszako. 2023. "Analysis of the Response Signals of an Electronic Nose Sensor for Differentiation between Fusarium Species" Sensors 23, no. 18: 7907. https://doi.org/10.3390/s23187907

APA StyleBorowik, P., Dyshko, V., Tarakowski, R., Tkaczyk, M., Okorski, A., & Oszako, T. (2023). Analysis of the Response Signals of an Electronic Nose Sensor for Differentiation between Fusarium Species. Sensors, 23(18), 7907. https://doi.org/10.3390/s23187907