Fabrication of Ultra-Stable and Customized High-Temperature Speckle Patterns Using Air Plasma Spraying and Flexible Speckle Templates

Abstract

:1. Introduction

2. Methods for Fabricating Ultra-Stable and Customized High-Temperature Speckle Patterns

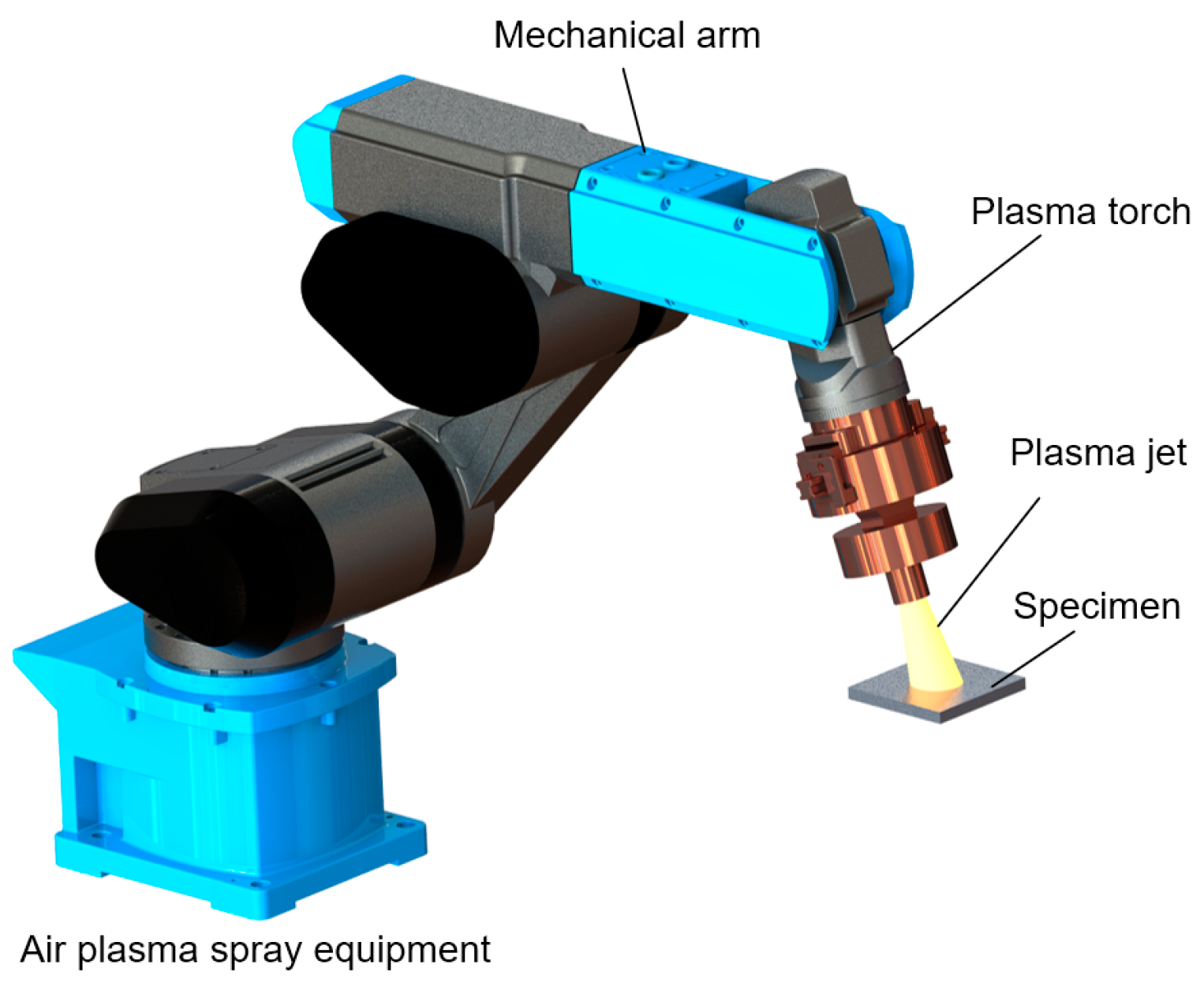

2.1. Air Plasma Spray

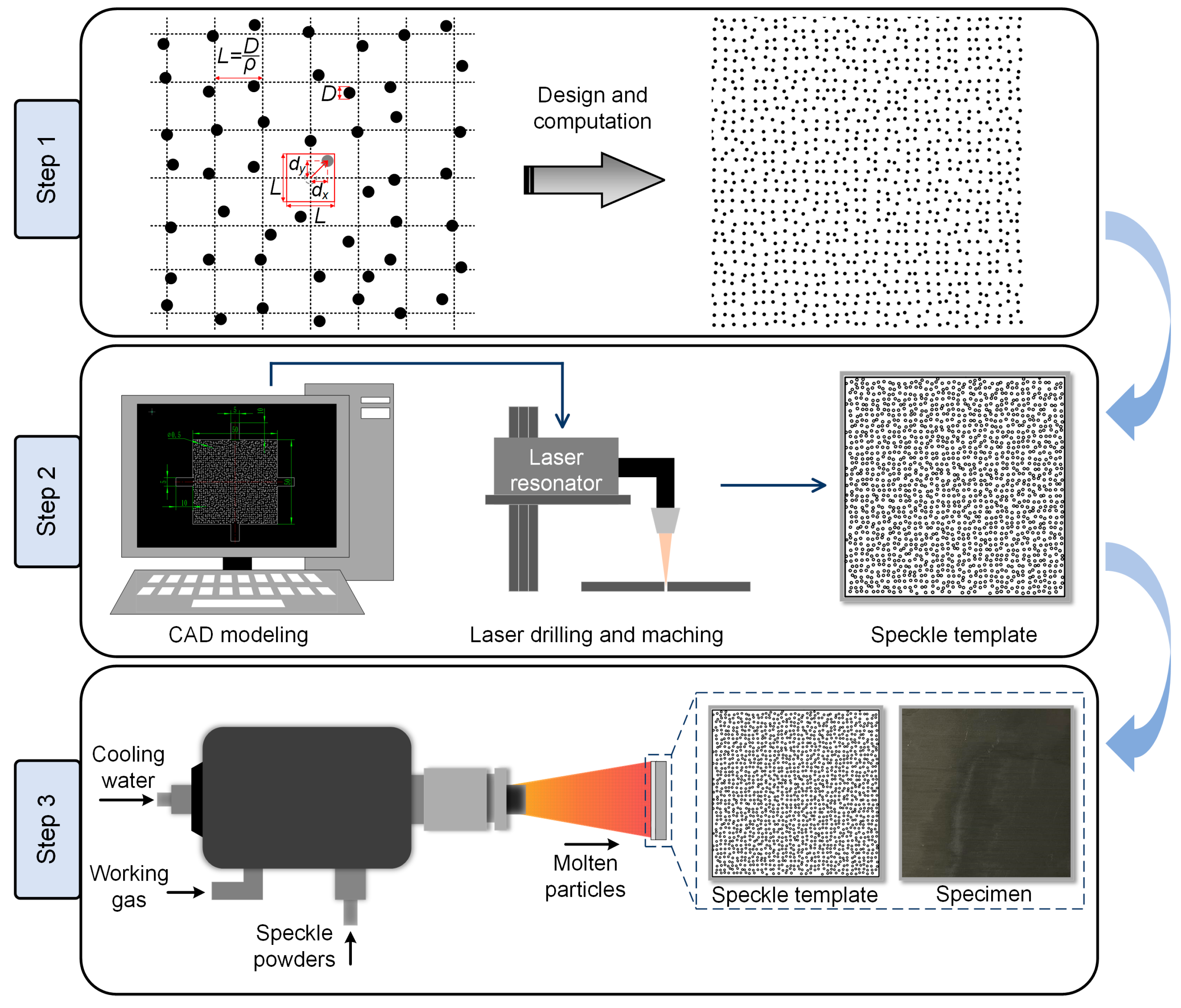

2.2. High-Temperature Speckle Pattern Fabrication Using Air Plasma Spray and Flexible Speckle Templates

3. Validations of APS-Based High-Temperature Speckle Patterns

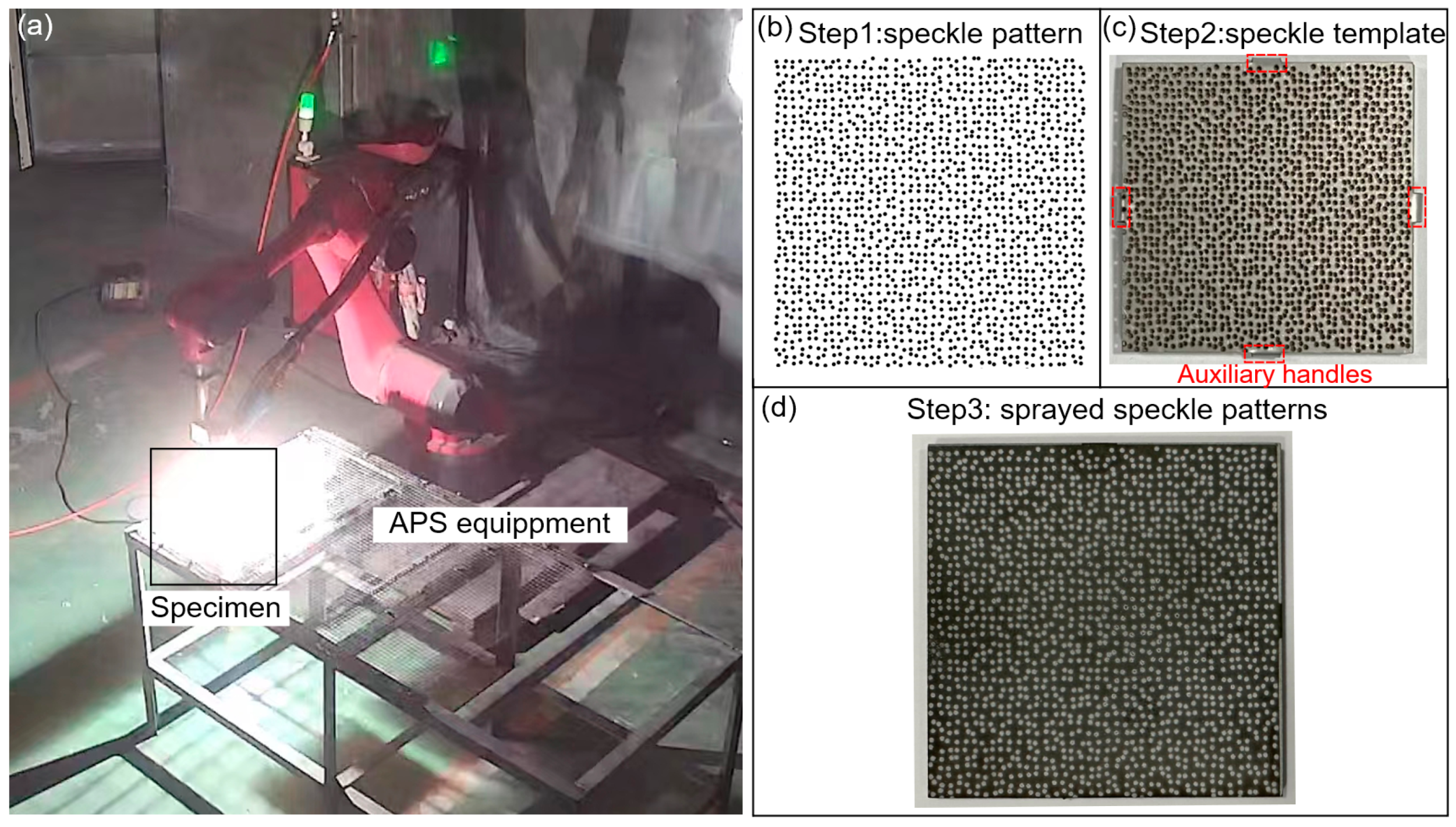

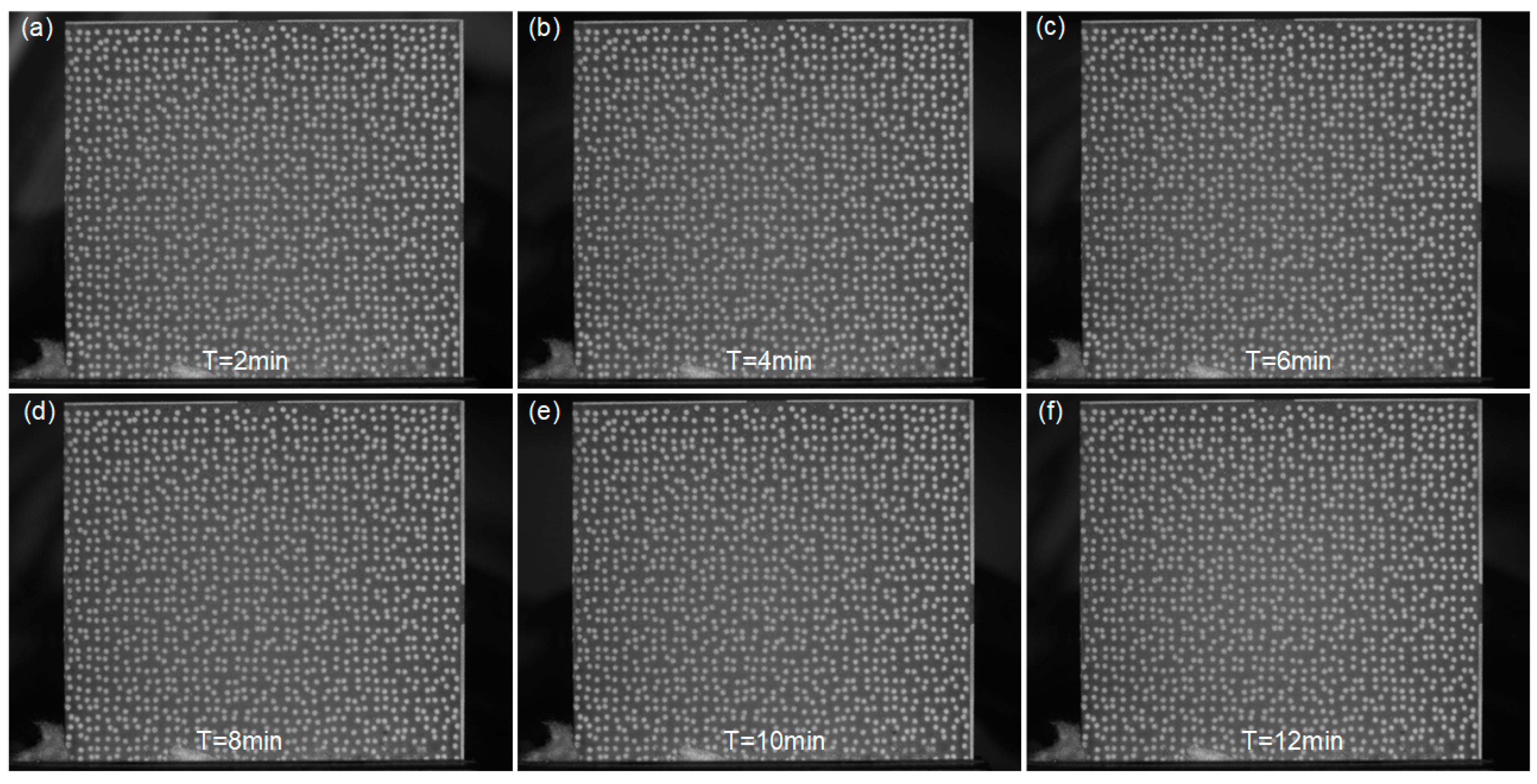

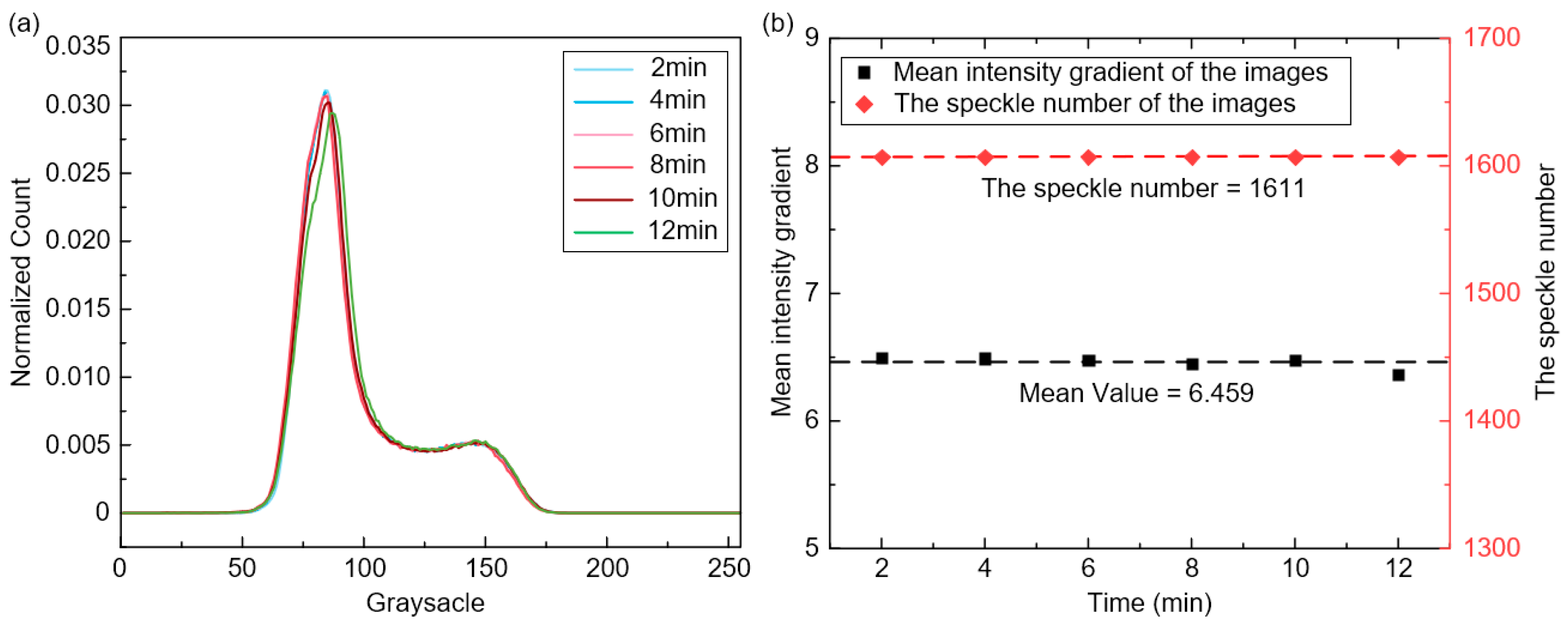

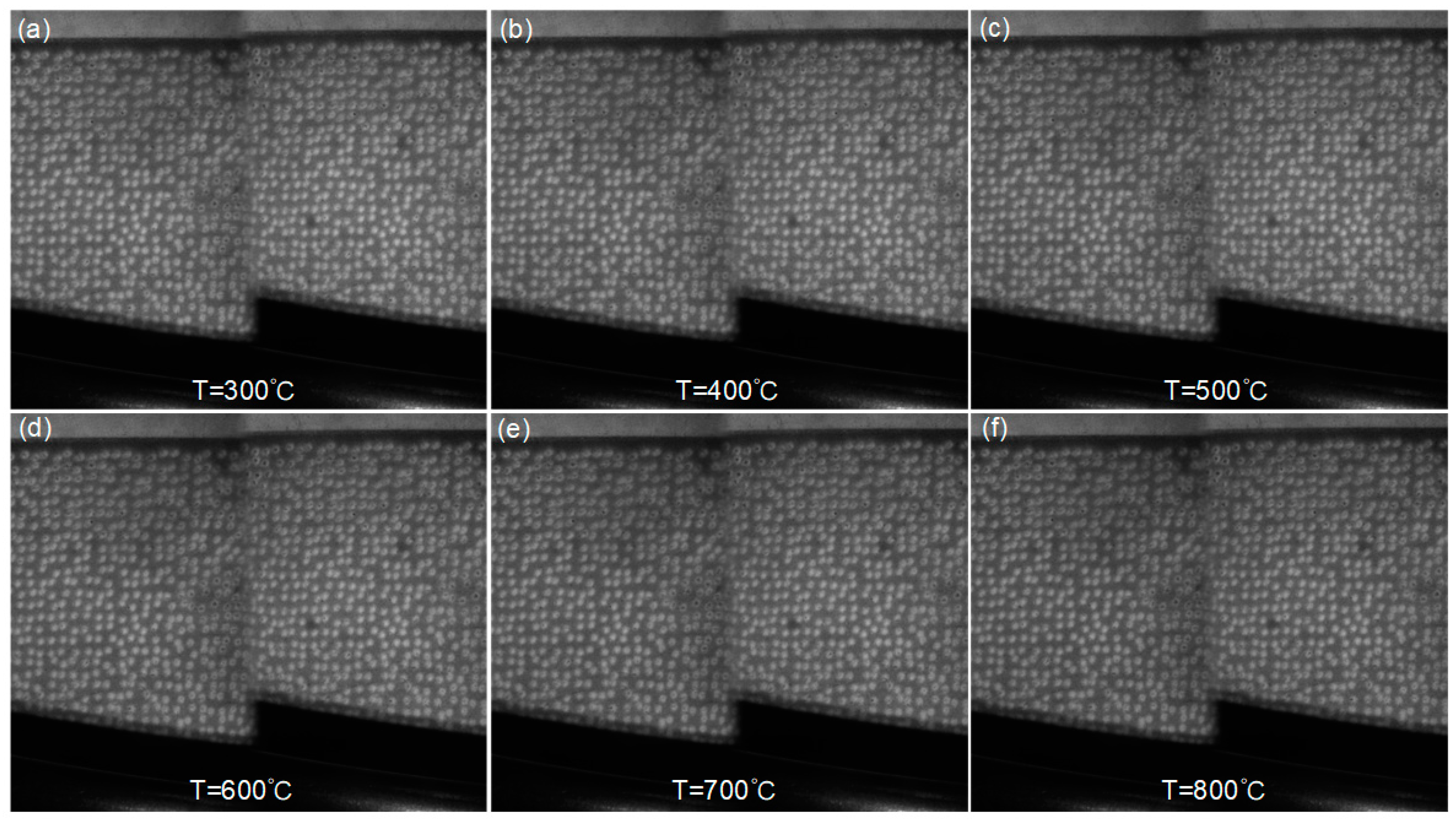

3.1. Fabrication and Characterization of APS-Based Speckle Patterns

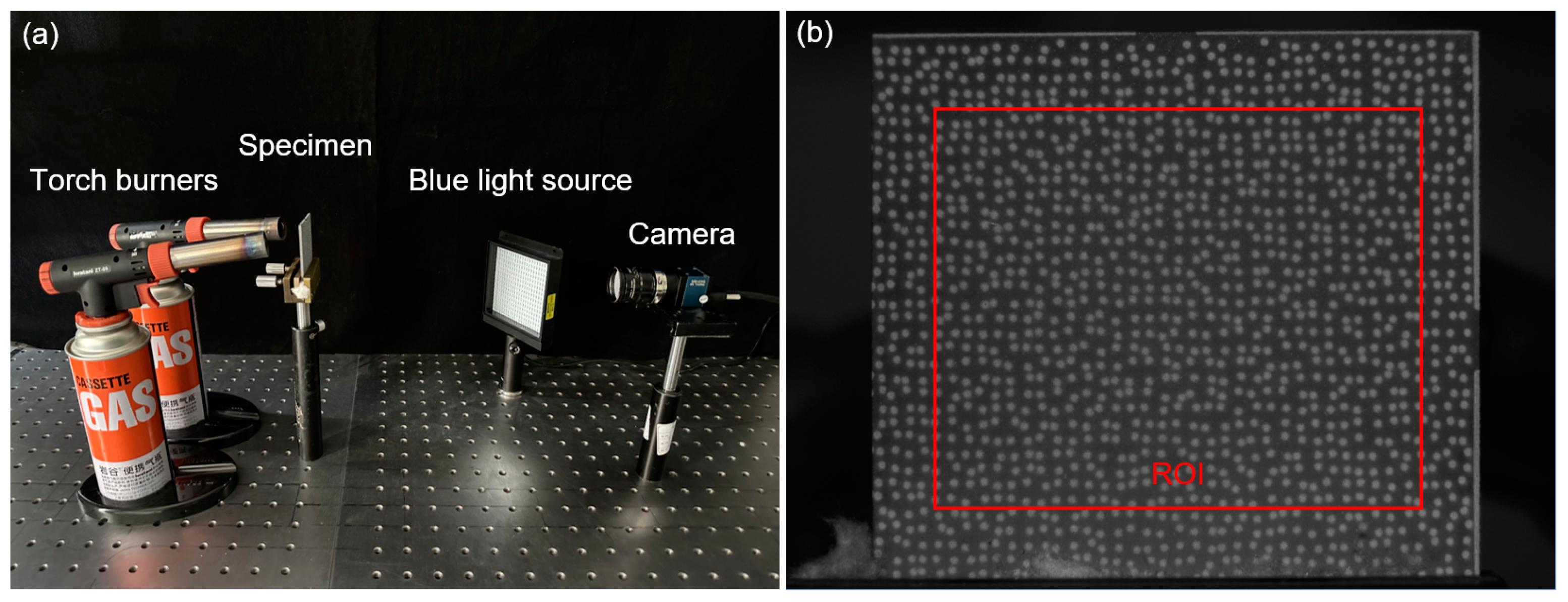

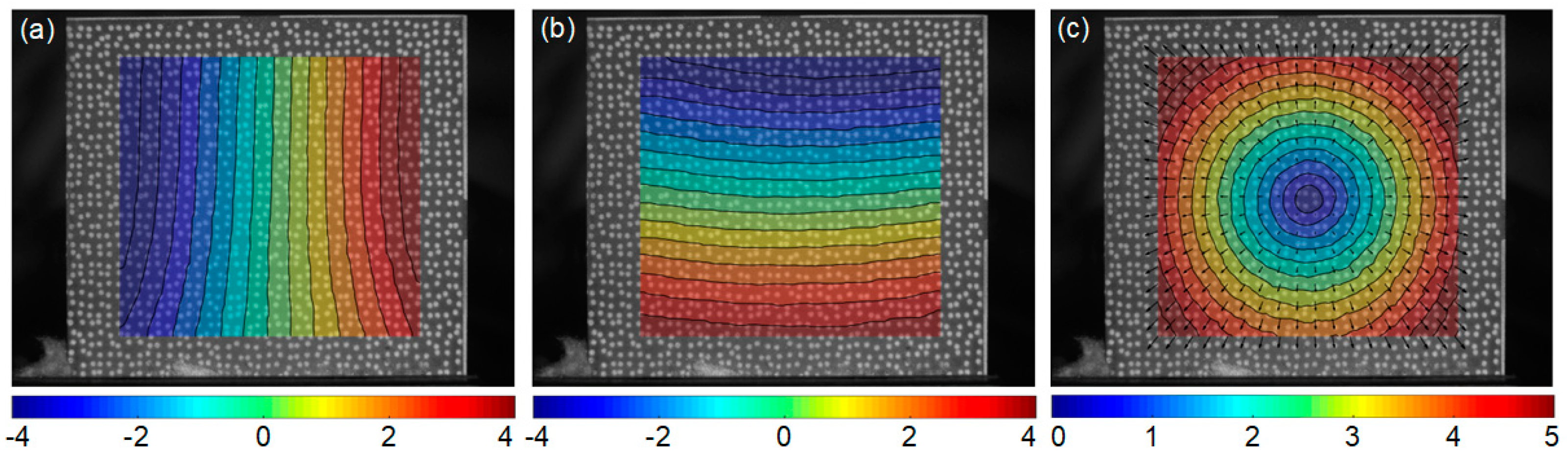

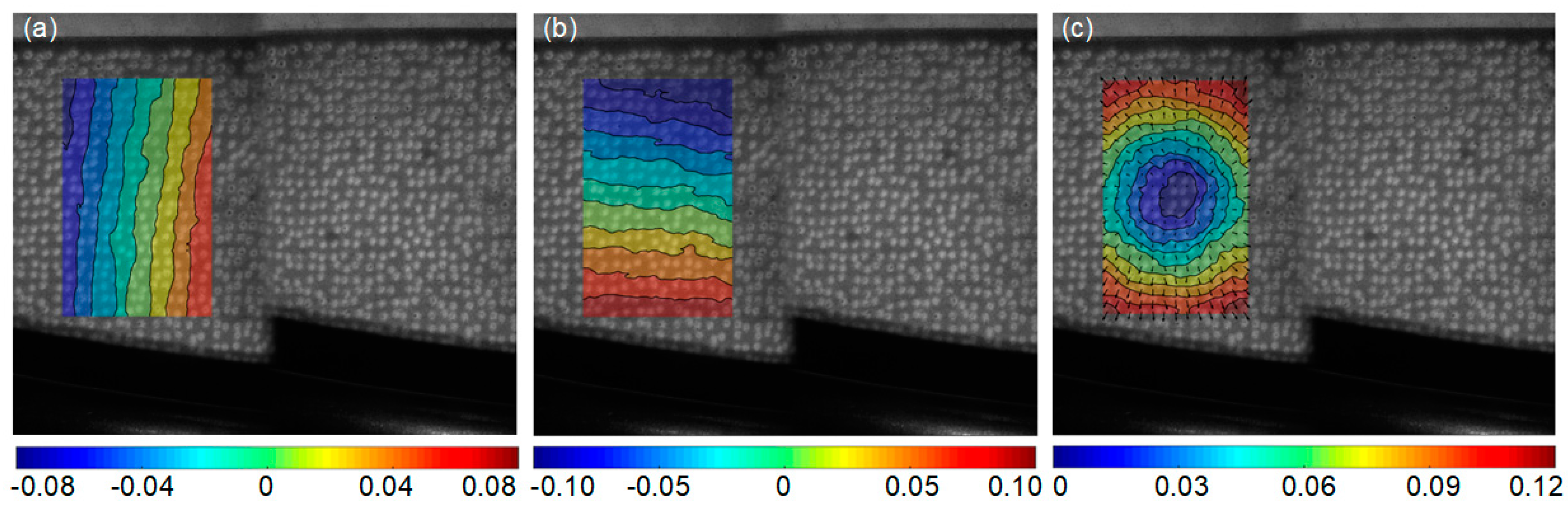

3.2. Thermal Deformation Measurement of a Planar Sample with APS-Based Speckle Pattern

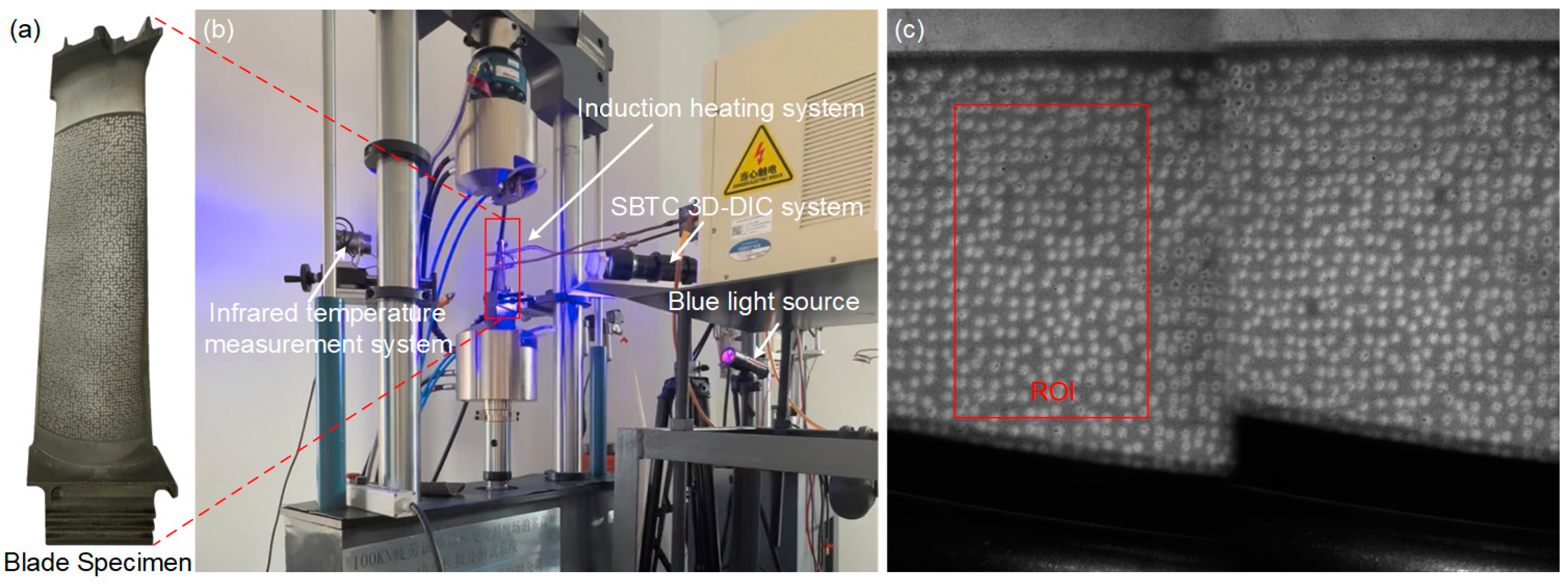

4. Application to Thermal Deformation of a Turbine Blade under Induction Heating

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sziroczak, D.; Smith, H. A Review of Design Issues Specific to Hypersonic Flight Vehicles. Prog. Aerosp. Sci. 2016, 84, 1–28. [Google Scholar] [CrossRef]

- Clarke, D.R.; Oechsner, M.; Padture, N.P. Thermal-Barrier Coatings for More Efficient Gas-Turbine Engines. MRS Bull. 2012, 37, 891–898. [Google Scholar] [CrossRef]

- Rajendran, R. Gas Turbine Coatings—An Overview. Eng. Fail. Anal. 2012, 26, 355–369. [Google Scholar] [CrossRef]

- Codrington, J.; Nguyen, P.; Ho, S.Y.; Kotousov, A. Induction Heating Apparatus for High Temperature Testing of Thermo-Mechanical Properties. Appl. Therm. Eng. 2009, 29, 2783–2789. [Google Scholar] [CrossRef]

- Quinta Da Fonseca, J.; Mummery, P.M.; Withers, P.J. Full-Field Strain Mapping by Optical Correlation of Micrographs Acquired during Deformation. J. Microsc. 2005, 218, 9–21. [Google Scholar] [CrossRef] [PubMed]

- Lyons, J.S.; Liu, J.; Sutton, M.A. High-Temperature Deformation Measurements Using Digital-Image Correlation. Exp. Mech. 1996, 36, 64–70. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, X.; Yu, L.; Pan, B. Automated Camera Exposure Control for Accuracy-Enhanced Stereo-Digital Image Correlation Measurement. Sensors 2022, 22, 9641. [Google Scholar] [CrossRef]

- Turner, J.L.; Russell, S.S. Application of Digital Image Analysis to Strain Measurement at Elevated Temperature. Strain 1990, 26, 55–59. [Google Scholar] [CrossRef]

- Doitrand, A.; Estevez, R.; Thibault, M.; Leplay, P. Fracture and cohesive parameter identification of refractories by digital image correlation up to 1200 °C. Exp. Mech. 2020, 60, 577–590. [Google Scholar] [CrossRef]

- Yu, L.; Pan, B. Time-Gated Active Imaging Digital Image Correlation for Deformation Measurement at High Temperatures. Extrem. Mech. Lett. 2022, 54, 101767. [Google Scholar] [CrossRef]

- Yu, L.; Pan, B. Overview of High-Temperature Deformation Measurement Using Digital Image Correlation. Exp. Mech. 2021, 61, 1121–1142. [Google Scholar] [CrossRef]

- Berke, R.B.; Lambros, J. Ultraviolet Digital Image Correlation (UV-DIC) for High Temperature Applications. Rev. Sci. Instrum. 2014, 85, 045121. [Google Scholar] [CrossRef]

- Wang, W.; Xu, C.; Jin, H.; Meng, S.; Zhang, Y.; Xie, W. Measurement of High Temperature Full-Field Strain up to 2000 °C Using Digital Image Correlation. Meas. Sci. Technol. 2017, 28, 035007. [Google Scholar] [CrossRef]

- Pan, Z.; Huang, S.; Su, Y.; Qiao, M.; Zhang, Q. Strain Field Measurements over 3000 °C Using 3D-Digital Image Correlation. Opt. Lasers Eng. 2020, 127, 105942. [Google Scholar] [CrossRef]

- Su, H.; Fang, X.; Qu, Z.; Zhang, C.; Yan, B.; Feng, X. Synchronous Full-Field Measurement of Temperature and Deformation of C/SiC Composite Subjected to Flame Heating at High Temperature. Exp. Mech. 2016, 56, 659–671. [Google Scholar] [CrossRef]

- Dong, Y.; Pan, B. In-Situ 3D Shape and Recession Measurements of Ablative Materials in an Arc-Heated Wind Tunnel by UV Stereo-Digital Image Correlation. Opt. Lasers Eng. 2019, 116, 75–81. [Google Scholar] [CrossRef]

- Meyer, P.; Waas, A.M. Measurement of In Situ-Full-Field Strain Maps on Ceramic Matrix Composites at Elevated Temperature Using Digital Image Correlation. Exp. Mech. 2015, 55, 795–802. [Google Scholar] [CrossRef]

- Zheng, Q.; Mashiwa, N.; Furushima, T. Evaluation of Large Plastic Deformation for Metals by a Non-Contacting Technique Using Digital Image Correlation with Laser Speckles. Mater. Des. 2020, 191, 108626. [Google Scholar] [CrossRef]

- Brillaud, J.; Lagattu, F. Limits and Possibilities of Laser Speckle and White-Light Image-Correlation Methods: Theory and Experiments. Appl. Opt. 2002, 41, 6603. [Google Scholar] [CrossRef]

- Grant, B.M.B.; Stone, H.J.; Withers, P.J.; Preuss, M. High-Temperature Strain Field Measurement Using Digital Image Correlation. J. Strain Anal. Eng. Des. 2009, 44, 263–271. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, G.; Cao, Q.; Ruan, M.; Liu, S.; Pan, H.; Liu, L. Deformation Measurement in Al Thin Films at Elevated Temperatures by Digital Image Correlation with Speckles Prepared by Femtosecond Laser. Opt. Laser Technol. 2022, 155, 108339. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Z.; Xie, H. A Real Time Deformation Evaluation Method for Surface and Interface of Thermal Barrier Coatings during 1100 °C Thermal Shock. Meas. Sci. Technol. 2012, 23, 105604. [Google Scholar] [CrossRef]

- Leplay, P.; Lafforgue, O.; Hild, F. Analysis of Asymmetrical Creep of a Ceramic at 1350 Degrees C by Digital Image Correlation. J. Am. Ceram. Soc. 2015, 98, 2240–2247. [Google Scholar] [CrossRef]

- Pan, B.; Wu, D.; Wang, Z.; Xia, Y. High-Temperature Digital Image Correlation Method for Full-Field Deformation Measurement at 1200 °C. Meas. Sci. Technol. 2011, 22, 015701. [Google Scholar] [CrossRef]

- Novak, M.D.; Zok, F.W. High-Temperature Materials Testing with Full-Field Strain Measurement: Experimental Design and Practice. Rev. Sci. Instrum. 2011, 82, 115101. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Liang, J.; Tang, Z.; Cao, B.; Yu, M. High-Temperature Digital Image Correlation Method for Full-Field Deformation Measurement Captured with Filters at 2600 °C Using Spraying to Form Speckle Patterns. Opt. Eng. 2014, 53, 063101. [Google Scholar] [CrossRef]

- Lugscheider, E.; Barimani, C.; Eckert, P.; Eritt, U. Modeling of the APS Plasma Spray Process. Comput. Mater. Sci. 1996, 7, 109–114. [Google Scholar] [CrossRef]

- Vardelle, A.; Moreau, C.; Themelis, N.J.; Chazelas, C. A Perspective on Plasma Spray Technology. Plasma Chem. Plasma Process. 2015, 35, 491–509. [Google Scholar] [CrossRef]

- Mazzoleni, P.; Matta, F.; Zappa, E.; Sutton, M.A.; Cigada, A. Gaussian Pre-Filtering for Uncertainty Minimization in Digital Image Correlation Using Numerically-Designed Speckle Patterns. Opt. Lasers Eng. 2015, 66, 19–33. [Google Scholar] [CrossRef]

- Chen, Z.; Shao, X.; Xu, X.; He, X. Optimized Digital Speckle Patterns for Digital Image Correlation by Consideration of Both Accuracy and Efficiency. Appl. Opt. 2018, 57, 884–893. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, Q. Glare: A Free and Open-Source Software for Generation and Assessment of Digital Speckle Pattern. Opt. Lasers Eng. 2022, 148, 106766. [Google Scholar] [CrossRef]

- Su, Y.; Gao, Z.; Fang, Z.; Liu, Y.; Wang, Y.; Zhang, Q.; Wu, S. Theoretical Analysis on Performance of Digital Speckle Pattern: Uniqueness, Accuracy, Precision, and Spatial Resolution. Opt. Express 2019, 27, 22439–22474. [Google Scholar] [CrossRef]

- Zhou, P. Subpixel Displacement and Deformation Gradient Measurement Using Digital Image/Speckle Correlation (DISC). Opt. Eng. 2001, 40, 1613. [Google Scholar] [CrossRef]

- Lecompte, D.; Smits, A.; Bossuyt, S.; Sol, H.; Vantomme, J.; Van Hemelrijck, D.; Habraken, A.M. Quality Assessment of Speckle Patterns for Digital Image Correlation. Opt. Lasers Eng. 2006, 44, 1132–1145. [Google Scholar] [CrossRef]

- Pan, B.; Lu, Z.; Xie, H. Mean Intensity Gradient: An Effective Global Parameter for Quality Assessment of the Speckle Patterns Used in Digital Image Correlation. Opt. Lasers Eng. 2010, 48, 469–477. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Q.; Xie, H. Fabrication of Heat-Resistant Grids and Their Application to Deformation Measurements Using a Sampling Moiré Method. Meas. Sci. Technol. 2021, 32, 105008. [Google Scholar] [CrossRef]

- Luo, H.; Yu, L.; Pan, B. Design and Validation of a Compact Bi-Prism- Based Single-Bilateral-Telecentric-Camera Stereo-DIC System. IEEE Trans. Instrum. Meas. 2022, 71, 1007510. [Google Scholar] [CrossRef]

- Schreier, H.; Orteu, J.-J.; Sutton, M.A. Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications; Springer: Boston, MA, USA, 2009. [Google Scholar]

- Pan, B.; Asundi, A.; Xie, H.; Gao, J. Digital Image Correlation Using Iterative Least Squares and Pointwise Least Squares for Displacement Field and Strain Field Measurements. Opt. Lasers Eng. 2009, 47, 865–874. [Google Scholar] [CrossRef]

- Aeronautical Materials Handbook Redaction Committee. China Aeronautical Materials Handbook; Standards Press of China: Beijing, China, 2002. [Google Scholar]

| Parameter | Unit | Value |

|---|---|---|

| Plasma arc current | A | 620 |

| Plasma arc voltage | V | 75 |

| Flow rate of primary gas (Ar) | L/min | 55 |

| Flow rate of secondary gas (H2/N2) | L/min | 8 |

| Flow rate of speckle powders | g/min | 40 |

| Spray distance | mm | 85 |

| Spray speed | m/s | 350 |

| Torch traverse speed | mm/s | 500 |

| Ni | Cr | C | Mn | Ca | S | P | Mo |

| 50.0~55.0 | 17.0~21.0 | 0.02~0.06 | ≤0.35 | ≤0.01 | ≤0.35 | ≤0.015 | 2.80~3.30 |

| Al | Ti | B | Nb | Co | Cu | Fe | |

| 0.30~0.70 | 0.75~1.15 | ≤0.006 | 5.00~5.50 | 2.80~3.30 | ≤0.30 | Bal |

| Temperature/°C | Reference Value of CTE [36] | εxx/με | Measured CTE | Relative Error | εyy/με | Measured CTE | Relative Error |

|---|---|---|---|---|---|---|---|

| 200 | 13.0 | 2533 | 12.66 | 2.56% | 2568 | 12.84 | 1.23% |

| 300 | 13.5 | 4127 | 13.75 | 1.92% | 4194 | 13.98 | 3.58% |

| 400 | 14.1 | 5733 | 14.33 | 1.65% | 5819 | 14.54 | 3.19% |

| 500 | 14.4 | 7221 | 14.44 | 0.29% | 7271 | 14.54 | 0.98% |

| 600 | 14.8 | 8917 | 14.86 | 0.42% | 8971 | 14.95 | 1.02% |

| 700 | 15.4 | 10,736 | 15.33 | 0.41% | 10,779 | 15.38 | 0.01% |

| C | Cr | Ni | Co | W | Mo | Al | Ti |

| 0.07~0.15 | 9.5~11.0 | Bal | 9.5~10.5 | 4.5~5.5 | 3.5~4.2 | 5.0~6.0 | 2.0~3.0 |

| B | Zr | Mn | Si | P | S | ||

| 0.01~0.02 | ≤0.10 | ≤0.50 | ≤0.50 | ≤0.02 | ≤0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, N.; Yu, L.; Wang, Q.; Pan, B. Fabrication of Ultra-Stable and Customized High-Temperature Speckle Patterns Using Air Plasma Spraying and Flexible Speckle Templates. Sensors 2023, 23, 7656. https://doi.org/10.3390/s23177656

Lu N, Yu L, Wang Q, Pan B. Fabrication of Ultra-Stable and Customized High-Temperature Speckle Patterns Using Air Plasma Spraying and Flexible Speckle Templates. Sensors. 2023; 23(17):7656. https://doi.org/10.3390/s23177656

Chicago/Turabian StyleLu, Ning, Liping Yu, Qianqian Wang, and Bing Pan. 2023. "Fabrication of Ultra-Stable and Customized High-Temperature Speckle Patterns Using Air Plasma Spraying and Flexible Speckle Templates" Sensors 23, no. 17: 7656. https://doi.org/10.3390/s23177656

APA StyleLu, N., Yu, L., Wang, Q., & Pan, B. (2023). Fabrication of Ultra-Stable and Customized High-Temperature Speckle Patterns Using Air Plasma Spraying and Flexible Speckle Templates. Sensors, 23(17), 7656. https://doi.org/10.3390/s23177656