Predicting the Early-Age Time-Dependent Behaviors of a Prestressed Concrete Beam by Using Physics-Informed Neural Network

Abstract

1. Introduction

2. Materials and Methods

2.1. Governing Equations

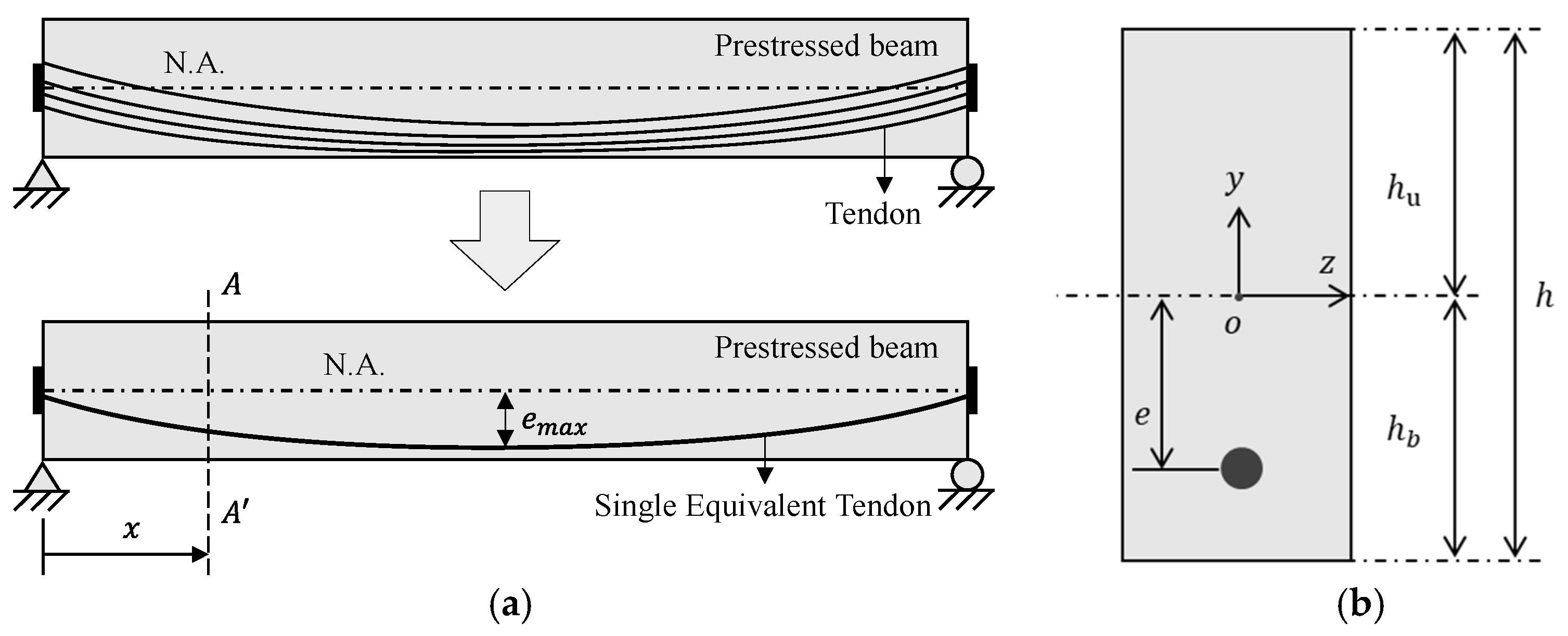

2.1.1. Problem Definition and Assumptions

2.1.2. Governing Equations for Time-Dependent Behaviors of a PSC Beam

2.1.3. Dimensionless Governing Equations

otherwise mentioned hereafter. For example, substituting and into Equation (1) results in:

otherwise mentioned hereafter. For example, substituting and into Equation (1) results in:2.2. Formulation

2.2.1. Deriving Integro-Differential Equation for

2.2.2. Forward Finite Difference Equation

2.3. PINN for Solving the Integro-Differential Governing Equation

2.3.1. Approximate Integro-Differential Equation of Equation (28) for Using the PINN

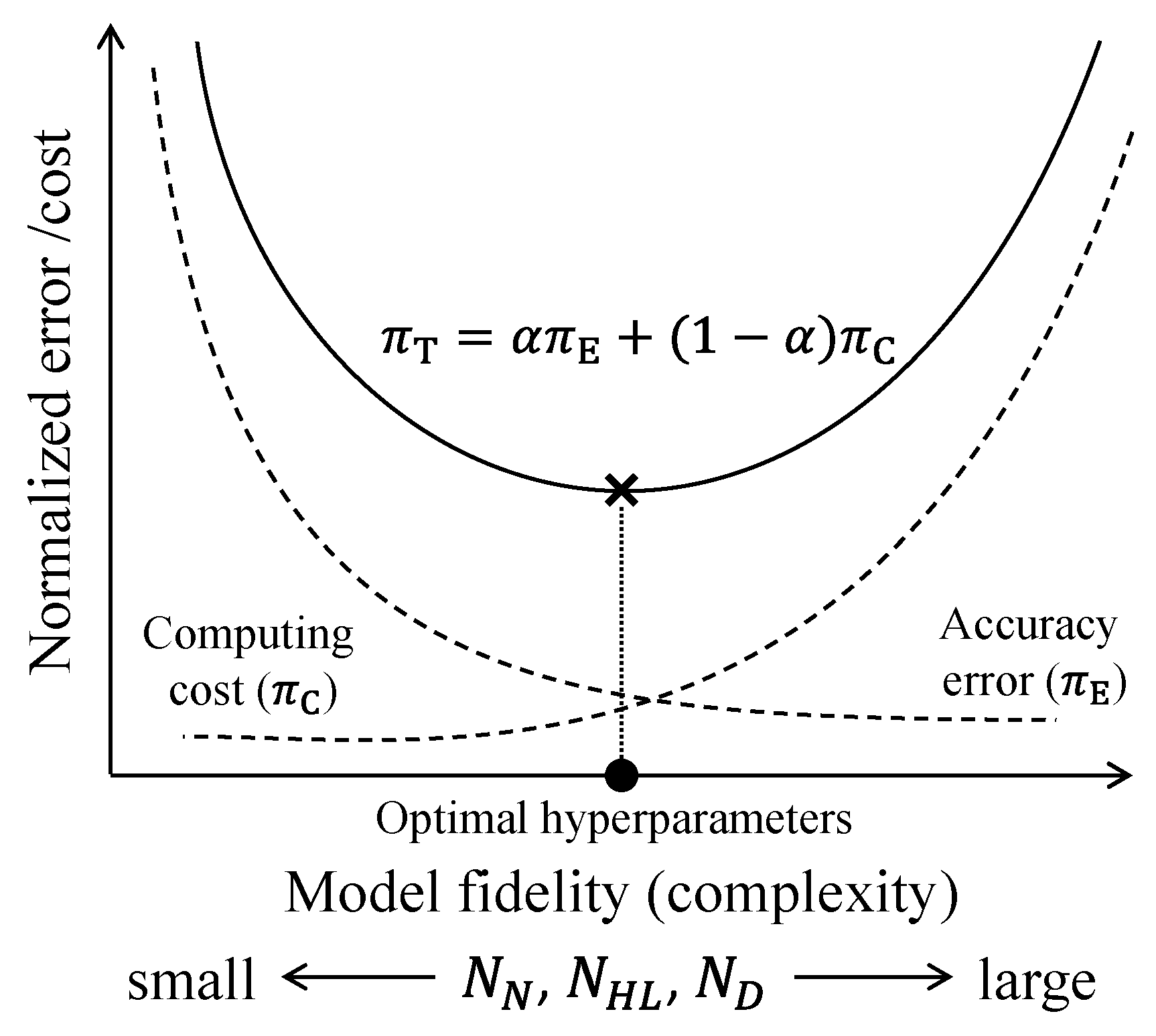

2.3.2. Optimal Hyperparameter Combinations for the PINN to Solve Equation (34)

3. Results and Discussion

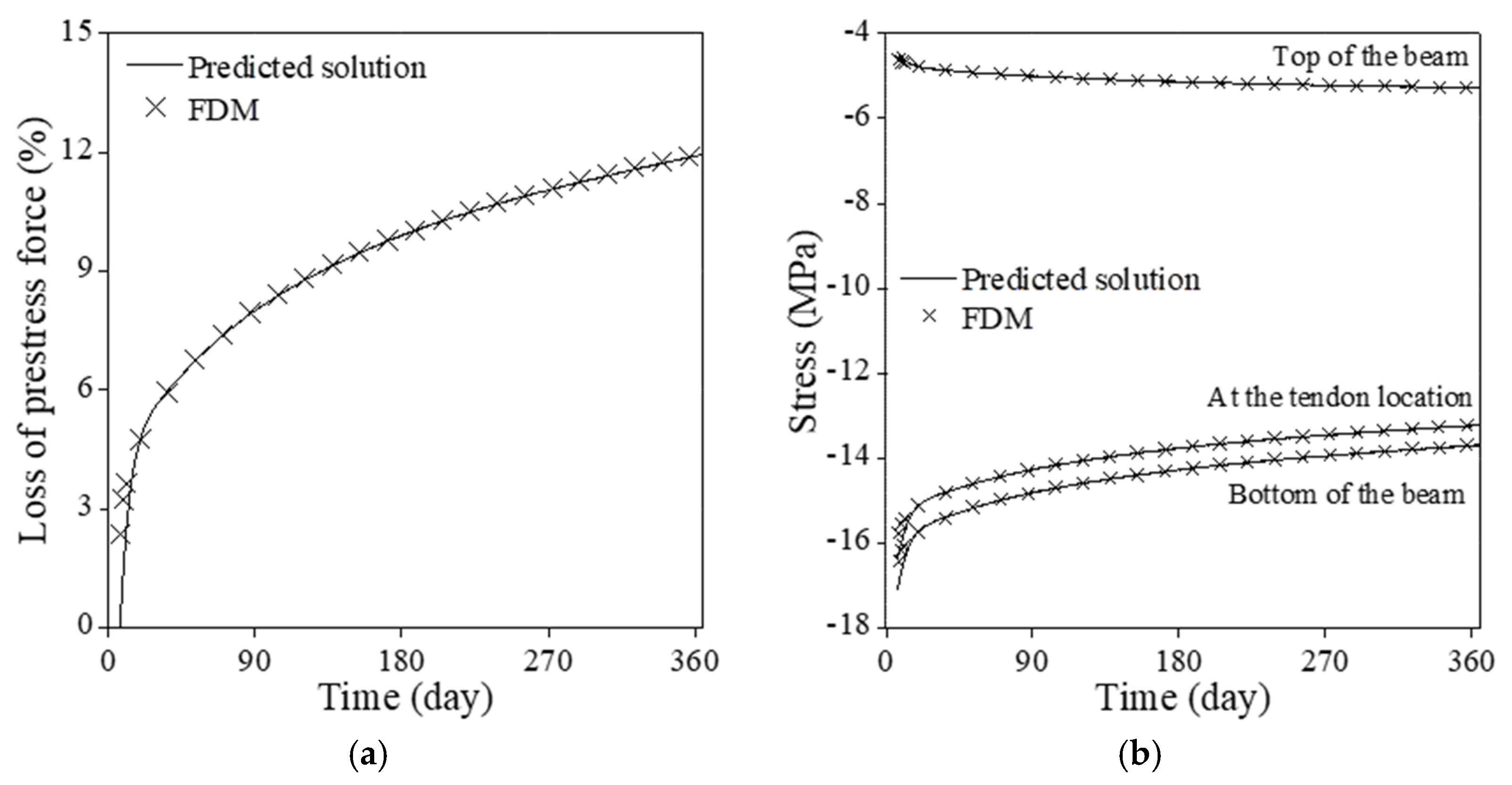

3.1. Numerical Verification

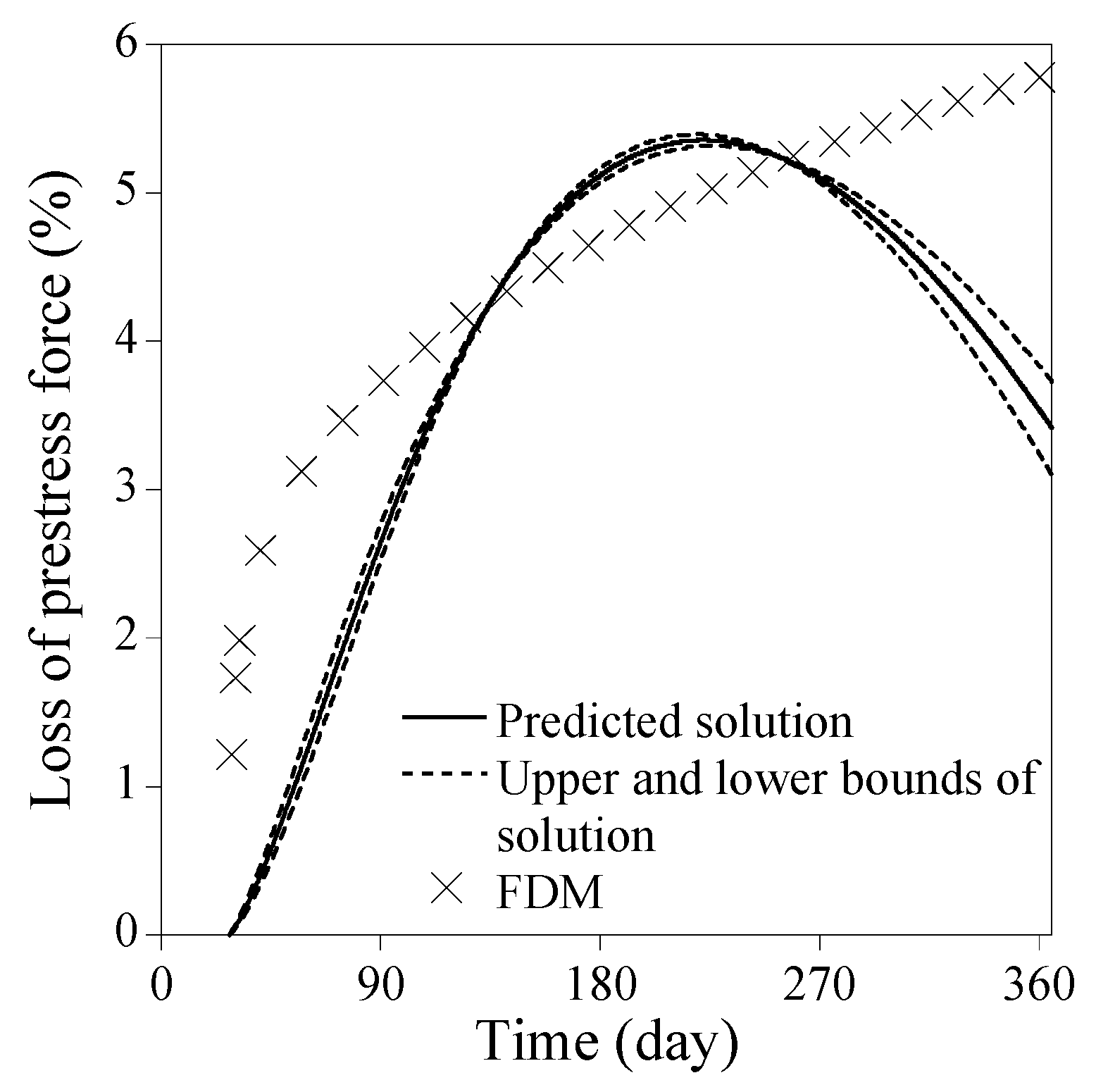

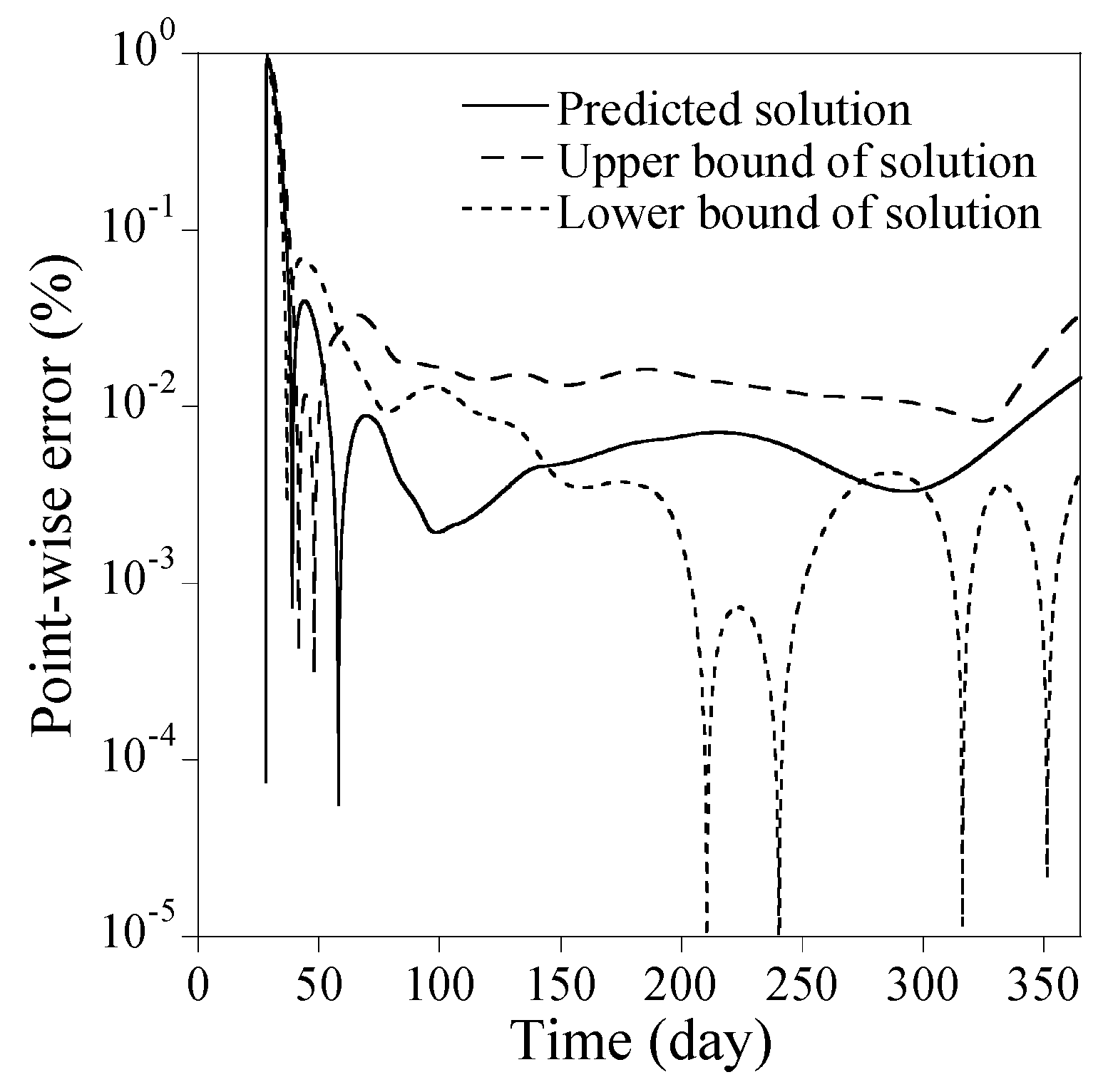

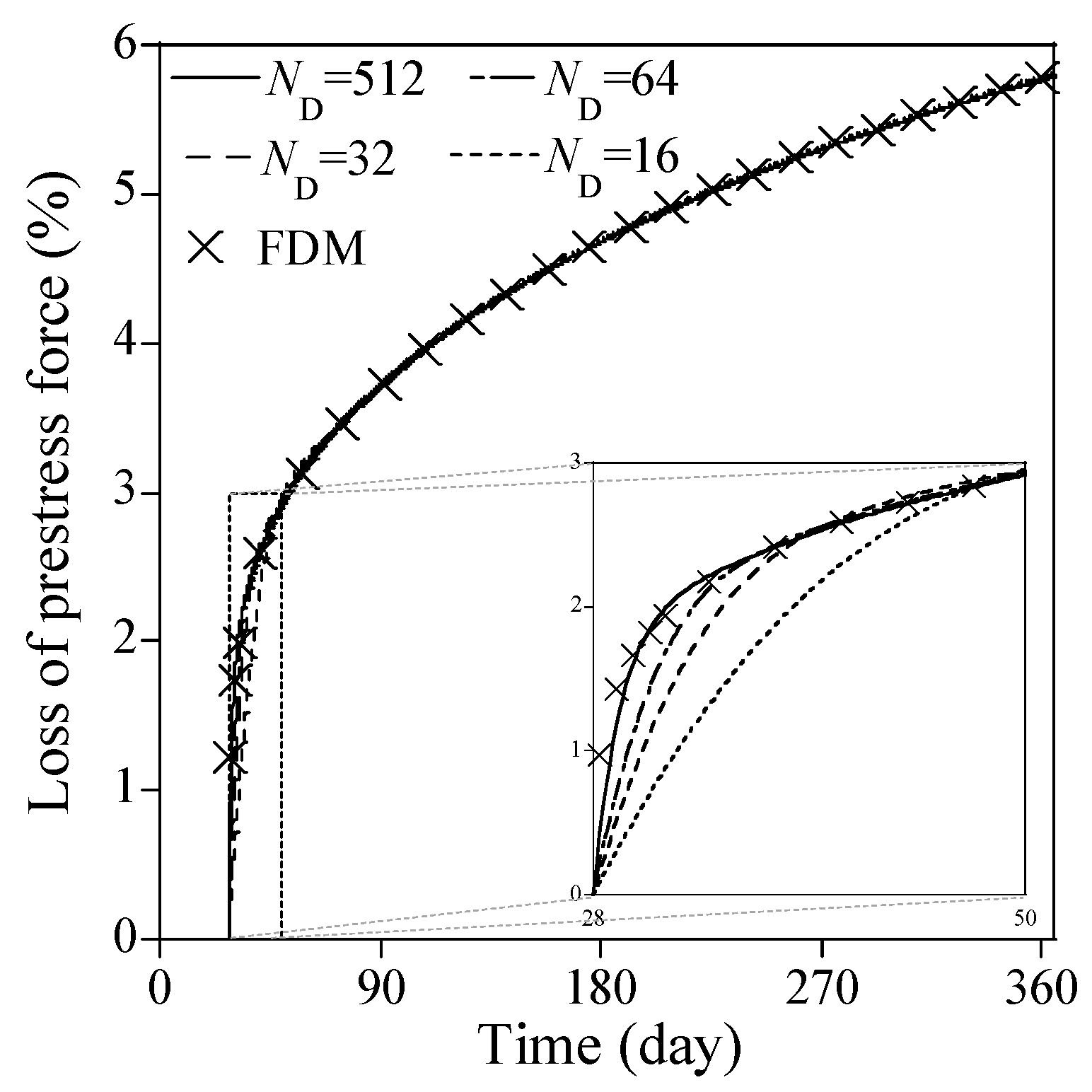

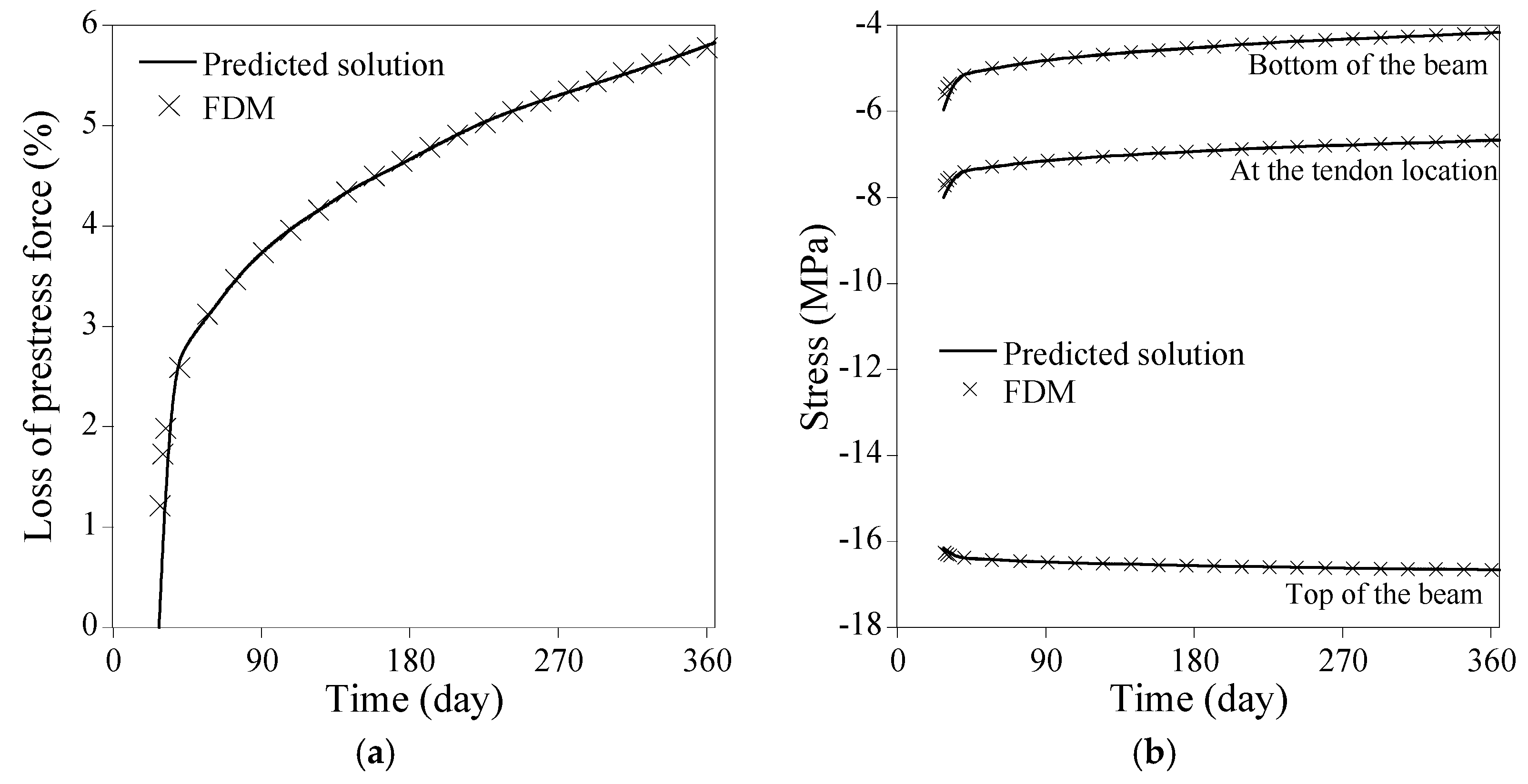

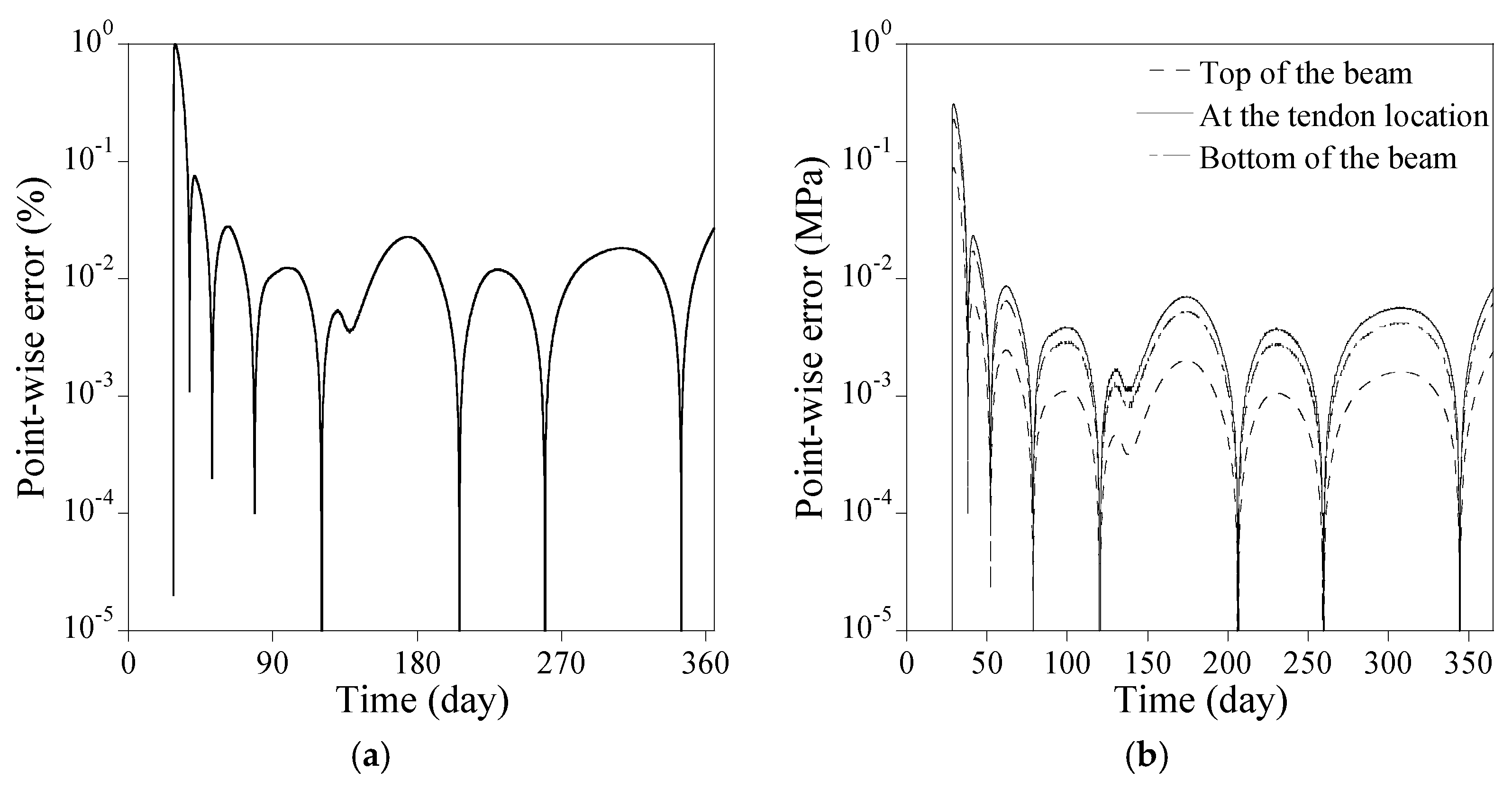

3.1.1. Rectangular Cross Section

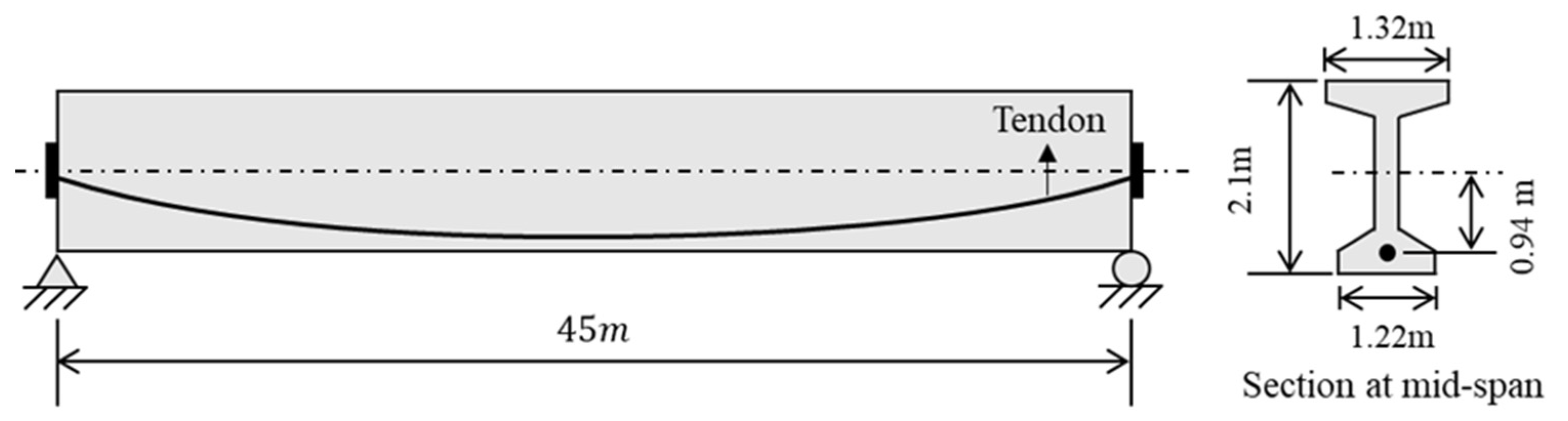

3.1.2. Conventional PSC I-Beam Section

4. Conclusions

- The dimensionless integro-differential governing equation is derived for the PINN. The governing equation accounts for time-dependent coupling among the effective prestress force and several factors including concrete creep and shrinkage, tendon relaxation, and changes in concrete elastic modulus.

- The fidelity of the PINN is determined by three primary hyperparameters: the number of nodes, the number of hidden layers, and the number of domains. Among these primary hyperparameters, the number of domains is the most critical factor for the accuracy and consistency of predicted solutions from the PINN. Optimal hyperparameter combinations for the PINN were determined by considering the trade-off between solution accuracy and computation time.

- The numerical results from the PINN with an optimal hyperparameter combination yielded satisfactory results, with absolute differences at 365 days in loss of prestress force being 0.027% and in all stresses at the top and bottom of the beam and the tendon location being less than 0.2% for PSC beams with a rectangular and an I-shaped section.

- The proposed PINN approach can effectively predict time-dependent behaviors of PSC beams, offering a promising alternative to conventional numerical methods. The proposed PINN can address the limitations of conventional machine learning by training deep neural networks that satisfy the governing equation associated with the complicated time-dependent behaviors of the PSC beam.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Notations

| Time (day) beginning from the initial prestress transfer | |

| The age of concrete at | |

| Elastic modulus of concrete at time | |

| Elastic modulus of concrete at (i.e., | |

| Elastic modulus of concrete at the age of 28 days (i.e., | |

| Elastic modulus of the tendon | |

| Modular ratio at time (i.e., ) | |

| Gross section area of tendons | |

| Net section area of concrete of PSC beam | |

| Vertical coordinate with the origin at the centroid of the net concrete section of the beam | |

| Height of the PSC beam | |

| Vertical distance from the centroid of the net concrete section of the beam | |

| Characteristic compressive strength of concrete | |

| Characteristic ultimate strength of concrete | |

| Yield stress of the tendon | |

| Initial stress of the tendon | |

| Specific weight of concrete per unit volume | |

| Initial effective prestress force of tendon after elastic shortening of concrete at | |

| Effective prestress force of tendon at time | |

| Bending moment induced by the self-weight of the beam | |

| Axial-bending stress at location and time | |

| Elastic strain of concrete at location and time | |

| Creep strain of concrete at location and time | |

| Shrinkage strain of concrete at time . | |

| Net strain of concrete at location and time | |

| Net strain of tendon at time | |

| Elastic strain of tendon at time | |

| Relaxed strain of tendon at time | |

| Creep coefficient at time for the unit strain of which the corresponding stress is applied at time | |

| Creep coefficient at time for unit strain of which the corresponding stress is applied at time (i.e., ) | |

| Relaxation function of the tendon at time | |

| The ratio of to at time (i.e., | |

| Prestress transfer coefficient at time , i.e., or | |

| Elastic strain of concrete at the location of the tendon due to self-weight of the beam at time (i.e., ) | |

| Symbol for defining the associated dimensionless variables normalized by , and for forces, strains, and stresses, respectively. |

Appendix A. Numerical Procedures to Calculate from the Finite Difference Equation (33)

- (1)

- For , Equation (33) is expressed for as follows:

- (2)

- For , Equation (33) is written for as

- (3)

- , Equation (33) is expressed for as follows

References

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics informed deep learning (Part I): Data-driven solutions of nonlinear partial differential equations. arXiv 2017, arXiv:1711.10561. [Google Scholar]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics informed deep learning (Part II): Data-driven discovery of nonlinear partial differential equations. arXiv 2017, arXiv:1711.10566. [Google Scholar]

- Fujita, K. Physics-informed neural network method for modelling beam-wall interactions. Electron. Lett. 2022, 58, 390–392. [Google Scholar] [CrossRef]

- Tartakovsky, A.M.; Marrero, C.O.; Perdikaris, P.; Tartakovsky, G.D.; Barajas-Solano, D. Learning parameters and constitutive relationships with physics informed deep neural networks. arXiv 2018, arXiv:1808.03398. [Google Scholar]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 2019, 378, 686–707. [Google Scholar] [CrossRef]

- Raissi, M.; Yazdani, A.; Karniadakis, G.E. Hidden fluid mechanics: Learning velocity and pressure fields from flow visualizations. Science 2020, 367, 1026–1030. [Google Scholar] [CrossRef]

- He, Q.; Barajas-Solano, D.; Tartakovsky, G.; Tartakovsky, A.M. Physics-informed neural networks for multi-physics data assimilation with application to subsurface transport. Adv. Water Resour. 2020, 141, 103610. [Google Scholar] [CrossRef]

- Karimpouli, S.; Tahmasebi, P. Physics informed machine learning: Seismic wave equation. Geosci. Front. 2020, 11, 1993–2001. [Google Scholar] [CrossRef]

- Yang, L.; Meng, X.; Karniadakis, G.E. B-PINNs: Bayesian physics-informed neural networks for forward and inverse PDE problems with noisy data. J. Comput. Phys. 2021, 425, 109913. [Google Scholar] [CrossRef]

- Jagtap, A.D.; Kharazmi, E.; Karniadakis, G.E. Conservative physics-informed neural networks on discrete domains for conservation laws: Applications to forward and inverse problems. Comput. Methods Appl. Mech. Eng. 2020, 365, 113028. [Google Scholar] [CrossRef]

- Yucesan, Y.A.; Viana, F.A. Wind turbine main bearing fatigue life estimation with physics-informed neural networks. In Proceedings of the Annual Conference of the PHM Society, Scottsdale, AZ, USA, 21–26 September 2019; Volume 11, pp. 1–14. [Google Scholar]

- Chen, Y.; Lu, L.; Karniadakis, G.E.; Dal Negro, L. Physics-informed neural networks for inverse problems in nano-optics and metamaterials. Opt. Express 2020, 28, 11618–11633. [Google Scholar] [CrossRef] [PubMed]

- Goswami, S.; Anitescu, C.; Chakraborty, S.; Rabczuk, T. Transfer learning enhanced physics informed neural network for phase-field modeling of fracture. Theor. Appl. Fract. Mech. 2020, 106, 102447. [Google Scholar] [CrossRef]

- Kadeethum, T.; Jørgensen, T.M.; Nick, H.M. Physics-informed neural networks for solving nonlinear diffusivity and Biot’s equations. PLoS ONE 2020, 15, e0232683. [Google Scholar] [CrossRef] [PubMed]

- Tartakovsky, A.M.; Marrero, C.O.; Perdikaris, P.; Tartakovsky, G.D.; Barajas-Solano, D. Physics-informed deep neural networks for learning parameters and constitutive relationships in subsurface flow problems. Water Resour. Res. 2020, 56, e2019WR026731. [Google Scholar] [CrossRef]

- Mao, Z.; Jagtap, A.D.; Karniadakis, G.E. Physics-informed neural networks for high-speed flows. Comput. Methods Appl. Mech. Eng. 2020, 360, 112789. [Google Scholar] [CrossRef]

- Jin, X.; Cai, S.; Li, H.; Karniadakis, G.E. NSFnets (Navier-Stokes flow nets): Physics-informed neural networks for the incompressible Navier-Stokes equations. J. Comput. Phys. 2021, 426, 109951. [Google Scholar] [CrossRef]

- Jagtap, A.D.; Mao, Z.; Adams, N.; Karniadakis, G.E. Physics-informed neural networks for inverse problems in supersonic flows. J. Comput. Phys. 2022, 466, 111402. [Google Scholar] [CrossRef]

- Kissas, G.; Yang, Y.; Hwuang, E.; Witschey, W.R.; Detre, J.A.; Perdikaris, P. Machine learning in cardio-vascular flows modeling: Predicting arterial blood pressure from non-invasive 4D flow MRI data using physics-informed neural networks. Comput. Methods Appl. Mech. Eng. 2020, 358, 112623. [Google Scholar] [CrossRef]

- Haghighat, E.; Raissi, M.; Moure, A.; Gomez, H.; Juanes, R. A deep learning framework for solution and discovery in solid mechanics. arXiv 2020, arXiv:2003.02751. [Google Scholar]

- Rao, C.; Sun, H.; Liu, Y. Physics-informed deep learning for computational elastodynamics without labeled data. J. Eng. Mech. 2021, 147, 04021043. [Google Scholar] [CrossRef]

- Alkhadhr, S.; Almekkawy, M. Wave equation modeling via physics-informed neural networks: Models of soft and hard constraints for initial and boundary conditions. Sensors 2023, 23, 2792. [Google Scholar] [CrossRef]

- Tarkhov, D.; Lazovskaya, T.; Malykhina, G. Constructing physics-informed neural networks with architecture based on analytical modification of numerical methods by solving the problem of modelling processes in a chemical reactor. Sensors 2023, 23, 663. [Google Scholar] [CrossRef] [PubMed]

- Boushaba, A.; Cauet, S.; Chamroo, A.; Etien, E.; Rambault, L. Comparative study between physics-informed CNN and PCA in induction motor broken bars MCSA detection. Sensors 2022, 22, 9494. [Google Scholar] [CrossRef] [PubMed]

- Shukla, K.; Jagtap, A.D.; Blackshire, J.L.; Sparkman, D.; Karniadakis, G.E. A physics-informed neural network for quantifying the microstructural properties of polycrystalline nickel using ultrasound data: A promising approach for solving inverse problems. IEEE Signal Process. Mag. 2021, 39, 68–77. [Google Scholar] [CrossRef]

- Jagtap, A.D.; Mitsotakis, D.; Karniadakis, G.E. Deep learning of inverse water waves problems using multi-fidelity data: Application to Serre–Green–Naghdi equations. Ocean Eng. 2022, 248, 110775. [Google Scholar] [CrossRef]

- Yuan, L.; Ni, Y.Q.; Deng, X.Y.; Hao, S. A-PINN: Auxiliary physics informed neural networks for forward and inverse problems of nonlinear integro-differential equations. J. Comput. Phys. 2022, 462, 111260. [Google Scholar] [CrossRef]

- Pang, G.; Lu, L.; Karniadakis, G.E. fPINNs: Fractional physics-informed neural networks. SIAM J. Sci. Comput. 2019, 41, A2603–A2626. [Google Scholar] [CrossRef]

- Nabian, M.A.; Meidani, H. A deep neural network surrogate for high-dimensional random partial differential equations. arXiv 2018, arXiv:1806.02957. [Google Scholar]

- Zhang, D.; Lu, L.; Guo, L.; Karniadakis, G.E. Quantifying total uncertainty in physics-informed neural networks for solving forward and inverse stochastic problems. J. Comput. Phys. 2019, 397, 108850. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, D.; Karniadakis, G.E. Physics-informed generative adversarial networks for stochastic differential equations. SIAM J. Sci. Comput. 2020, 42, A292–A317. [Google Scholar] [CrossRef]

- Zhang, D.; Guo, L.; Karniadakis, G.E. Learning in modal space: Solving time-dependent stochastic PDEs using physics-informed neural networks. SIAM J. Sci. Comput. 2020, 42, A639–A665. [Google Scholar] [CrossRef]

- Mishra, S.; Molinaro, R. Estimates on the generalization error of physics-informed neural networks for approximating a class of inverse problems for PDEs. IMA J. Numer. Anal. 2022, 42, 981–1022. [Google Scholar] [CrossRef]

- Hu, Z.; Jagtap, A.D.; Karniadakis, G.E.; Kawaguchi, K. When do extended physics-informed neural networks (XPINNs) improve generalization? SIAM J. Sci. Comput. 2022, 44, A3158–A3182. [Google Scholar] [CrossRef]

- De Ryck, T.; Jagtap, A.D.; Mishra, S. Error estimates for physics-informed neural networks approximating the Navier–Stokes equations. IMA J. Numer. Anal. 2023, drac085. [Google Scholar] [CrossRef]

- Karniadakis, G.E.; Kevrekidis, I.G.; Lu, L.; Perdikaris, P.; Wang, S.; Yang, L. Physics-informed machine learning. Nat. Rev. Phys. 2021, 3, 422–440. [Google Scholar] [CrossRef]

- Lu, L.; Meng, X.; Mao, Z.; Karniadakis, G.E. DeepXDE: A deep learning library for solving differential equations. SIAM Rev. 2021, 63, 208–228. [Google Scholar] [CrossRef]

- Amini, D.; Haghighat, E.; Juanes, R. Physics-informed neural network solution of thermo–hydro–mechanical processes in porous media. J. Eng. Mech. 2022, 148, 04022070. [Google Scholar] [CrossRef]

- Jagtap, A.D.; Karniadakis, G.E. Extended Physics-Informed Neural Networks (XPINNs): A generalized space-time domain decomposition based deep learning framework for nonlinear partial differential equations. Commun. Comput. Phys. 2020, 28, 2002–2041. [Google Scholar]

- Shukla, K.; Jagtap, A.D.; Karniadakis, G.E. Parallel physics-informed neural networks via domain decomposition. J. Comput. Phys. 2021, 447, 110683. [Google Scholar] [CrossRef]

- Hu, Z.; Jagtap, A.D.; Karniadakis, G.E.; Kawaguchi, K. Augmented physics-informed neural networks (APINNs): A gating network-based soft domain decomposition methodology. arXiv 2022, arXiv:2211.08939. [Google Scholar]

- Penwarden, M.; Jagtap, A.D.; Zhe, S.; Karniadakis, G.E.; Kirby, R.M. A unified scalable framework for causal sweeping strategies for Physics-Informed Neural Networks (PINNs) and their temporal decompositions. arXiv 2023, arXiv:2302.14227. [Google Scholar]

- Jagtap, A.D.; Kawaguchi, K.; Karniadakis, G.E. Adaptive activation functions accelerate convergence in deep and physics-informed neural networks. J. Comput. Phys. 2020, 404, 109136. [Google Scholar] [CrossRef]

- Jagtap, A.D.; Kawaguchi, K.; Em Karniadakis, G. Locally adaptive activation functions with slope recovery for deep and physics-informed neural networks. Proc. R. Soc. A 2020, 476, 20200334. [Google Scholar] [CrossRef]

- Jagtap, A.D.; Shin, Y.; Kawaguchi, K.; Karniadakis, G.E. Deep Kronecker neural networks: A general framework for neural networks with adaptive activation functions. Neurocomputing 2022, 468, 165–180. [Google Scholar] [CrossRef]

- Jagtap, A.D.; Karniadakis, G.E. How important are activation functions in regression and classification? A survey, performance comparison, and future directions. arXiv 2022, arXiv:2209.02681. [Google Scholar] [CrossRef]

- Maroliya, M.K. Comparative study of flexural behavior of reinforced concrete beam and prestressed concrete beam. Int. J. Eng. Res. Appl. (IJERA) 2012, 2, 230–233. [Google Scholar]

- Porco, F.; Fiore, A.; Porco, G.; Uva, G. Monitoring and safety for prestressed bridge girders by SOFO sensors. J. Civ. Struct. Health Monit. 2013, 3, 3–18. [Google Scholar] [CrossRef]

- Garber, D.B.; Gallardo, J.M.; Deschenes, D.J.; Bayrak, O. Experimental investigation of prestress losses in full-scale bridge girders. ACI Struct. J. 2015, 112, 553–564. [Google Scholar] [CrossRef]

- Butler, L.J.; Gibbons, N.; He, P.; Middleton, C.; Elshafie, M.Z. Evaluating the early-age behaviour of full-scale prestressed concrete beams using distributed and discrete fibre optic sensors. Constr. Build. Mater. 2016, 126, 894–912. [Google Scholar] [CrossRef]

- Yang, I.H. Uncertainty and sensitivity analysis of time-dependent effects in concrete structures. Eng. Struct. 2007, 29, 1366–1374. [Google Scholar] [CrossRef]

- Caro, L.A.; Martí-Vargas, J.R.; Serna, P. Time-dependent evolution of strand transfer length in pretensioned prestressed concrete members. Mech. Time-Depend. Mater. 2013, 17, 501–527. [Google Scholar] [CrossRef]

- Ranzi, G.; Al-Deen, S.; Ambrogi, L.; Uy, B. Long-term behaviour of simply-supported post-tensioned composite slabs. J. Constr. Steel Res. 2013, 88, 172–180. [Google Scholar] [CrossRef]

- Li, D.; Kaewunruen, S. Effect of extreme climate on topology of railway prestressed concrete sleepers. Climate 2019, 7, 17. [Google Scholar] [CrossRef]

- Zawam, M.; Soudki, K.; West, J.S. Factors affecting the time-dependent behaviour of GFRP prestressed concrete beams. J. Build. Eng. 2019, 24, 100715. [Google Scholar] [CrossRef]

- Joyklad, P.; Ali, N.; Chaiyasarn, K.; Suparp, S.; Hussain, Q. Time-dependent behavior of full-scale precast post-tensioned (PCPT) girders: Experimental and finite element analysis. Case Stud. Constr. Mater. 2022, 17, e01310. [Google Scholar] [CrossRef]

- Robertson, I.N. Prediction of vertical deflections for a long-span prestressed concrete bridge structure. Eng. Struct. 2005, 27, 1820–1827. [Google Scholar] [CrossRef]

- Au, F.T.; Si, X.T. Accurate time-dependent analysis of concrete bridges considering concrete creep, concrete shrinkage and cable relaxation. Eng. Struct. 2011, 33, 118–126. [Google Scholar] [CrossRef]

- Lou, T.; Karavasilis, T.L. Time-dependent assessment and deflection prediction of prestressed concrete beams with unbonded CFRP tendons. Compos. Struct. 2018, 194, 365–376. [Google Scholar] [CrossRef]

- Páez, P.M.; Sensale, B. Improved prediction of long-term prestress loss in unbonded prestressed concrete members. Eng. Struct. 2018, 174, 111–125. [Google Scholar] [CrossRef]

- Gilbert, R.I.; Mickleborough, N.C. Design of Prestressed Concrete; CRC Press: Boca Raton, FL, USA, 1990. [Google Scholar]

- Liu, R.; Ye, H.; Liu, Y.; Zhao, H.; Correia, J.A.; Xin, H. Numerical simulation of concrete creep behaviour using integral creep algorithm with alternating stresses. Structures 2021, 29, 1979–1987. [Google Scholar] [CrossRef]

- Comité Euro-International du Béton. CEB-FIP Model Code 1990: Design Code; Thomas Telford: London, UK, 1993. [Google Scholar]

- Magura, D.D.; Sozen, M.A.; Siess, C.P. A study of stress relaxation in prestressing reinforcement. Civ. Eng. Stud. SRS-237 1962. [Google Scholar] [CrossRef]

| Material Properties | Specification |

|---|---|

| 33,600 MPa | |

| 200 GPa | |

| 0.72 m2 | |

| 0.0864 m4 | |

| 1% | |

| 0.3 | |

| 32 MPa | |

| 36 MPa | |

| 1580 MPa | |

| 0.7 | |

| 25 kN/m3 |

| Hyperparameter | Combinations |

|---|---|

| 16, 32, 64, 128 | |

| 5, 6, 7, 8 | |

| 2, 4, 8, 16, 32, 64, 128, 256, 512 | |

| Activation function | elu |

| Optimizer | Adam + L-BFGS |

| Learning rate | 0.001 |

| Maximum iteration | 10,000 for Adam optimizer |

| Number of Gauss quadrature points | 40 |

| Material Properties | Specification |

|---|---|

| 35,385 MPa | |

| 200 GPa | |

| 1.084 m2 | |

| 0.6454 m4 | |

| 0.972% | |

| 0.445 | |

| 40 MPa | |

| 44 MPa | |

| 1580 MPa | |

| 0.7 | |

| 25 kN/m3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, H.-W.; Hwang, J.-H. Predicting the Early-Age Time-Dependent Behaviors of a Prestressed Concrete Beam by Using Physics-Informed Neural Network. Sensors 2023, 23, 6649. https://doi.org/10.3390/s23146649

Park H-W, Hwang J-H. Predicting the Early-Age Time-Dependent Behaviors of a Prestressed Concrete Beam by Using Physics-Informed Neural Network. Sensors. 2023; 23(14):6649. https://doi.org/10.3390/s23146649

Chicago/Turabian StylePark, Hyun-Woo, and Jin-Ho Hwang. 2023. "Predicting the Early-Age Time-Dependent Behaviors of a Prestressed Concrete Beam by Using Physics-Informed Neural Network" Sensors 23, no. 14: 6649. https://doi.org/10.3390/s23146649

APA StylePark, H.-W., & Hwang, J.-H. (2023). Predicting the Early-Age Time-Dependent Behaviors of a Prestressed Concrete Beam by Using Physics-Informed Neural Network. Sensors, 23(14), 6649. https://doi.org/10.3390/s23146649