Research on the Flow Parameters of Waste Motion in a Rotary Kiln with the Use of the Tracer Method

Abstract

1. Introduction

2. Research on the Flow Parameters Using the Tracer Method

2.1. Properties of the Tested Materials

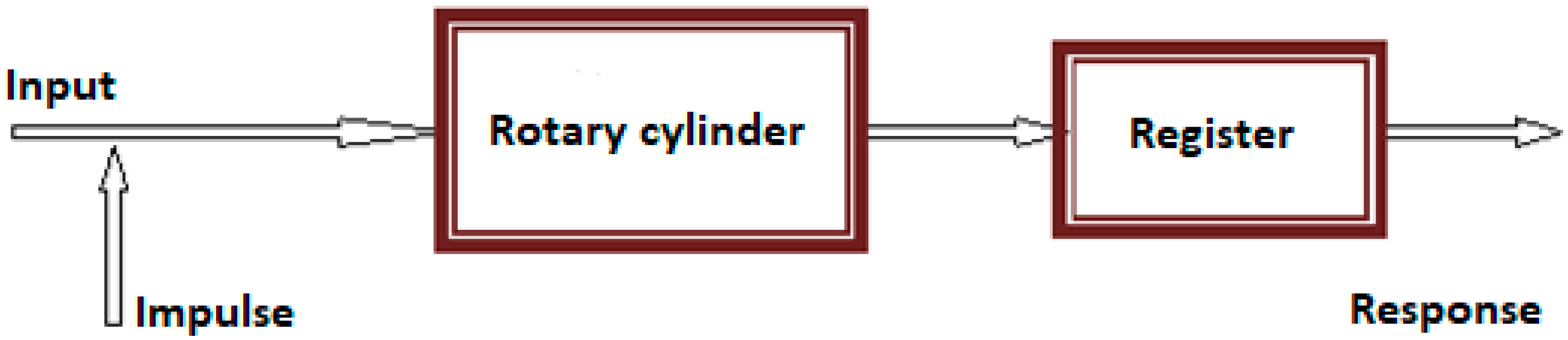

2.2. The Laboratory Stand

- -

- Length: L = 0.85 m,

- -

- Internal diameter: d = 0.19 m,

- -

- Length/internal diameter: L/d = 4.47,

- -

- Cross-sectional area: p = 0.028 m2.

2.3. The Tracer Method

2.4. The Course of the Tests

- -

- The cylinder rotational speed,

- -

- The angle of inclination to the ground,

- -

- The type of feed material (variation in rheological properties).

- -

- The introduction of batches of the material in order to reach a steady state,

- -

- The introduction of two batches of material,

- -

- The introduction of the tracer batch,

- -

- The batch of material was continuously introduced until the lack of presence of the tracer in the received material.

3. Algorithm for Determining the Residence Time Distribution

3.1. Introduction to the Algorithm

- E(t) represents specifying the molar (mass) fraction of particles with a residence time and within a certain range in the stream leaving the device,

- F(t) represents the distribution function of the residence time distribution, also called the residence time distribution.

- = 0 ( = ∞)—perfect mixing (tank reactor),

- = ∞ ( = 0)—no mixing (tube reactor).

3.2. Algorithm for the RTD Calculation

- Variant 1: Assumed that the sum of the relative measured masses was equal to the sum of the values determined by the regression function E(), as expressed by the following equation:

- Variant 2: Assumed that the sum of the values determined by the regression function E() was a consequence of the relative notation: mass of the received tracer and residence time. Therefore, this algorithm took into account the following condition:where n—the number of values of E(θj) determined by the regression function.

- Variant 3: The combination of the conditions presented above was the assumption included in the equation:

- -

- for the variant 1 ⇒ α (a)

- -

- for the variant 2 ⇒ α (a)

- -

- for the variant 3 ⇒ α (a)

4. Results and Discussion

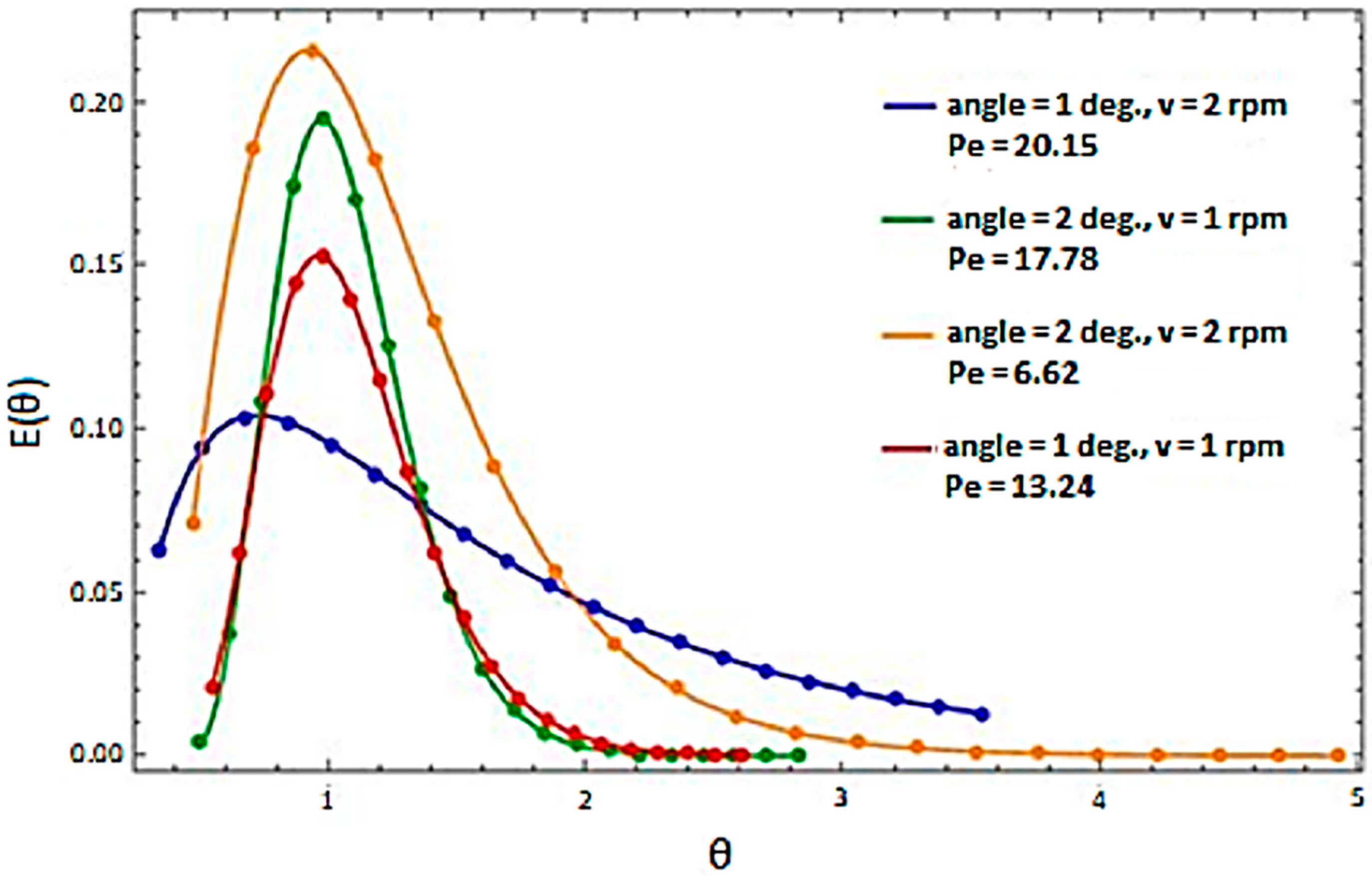

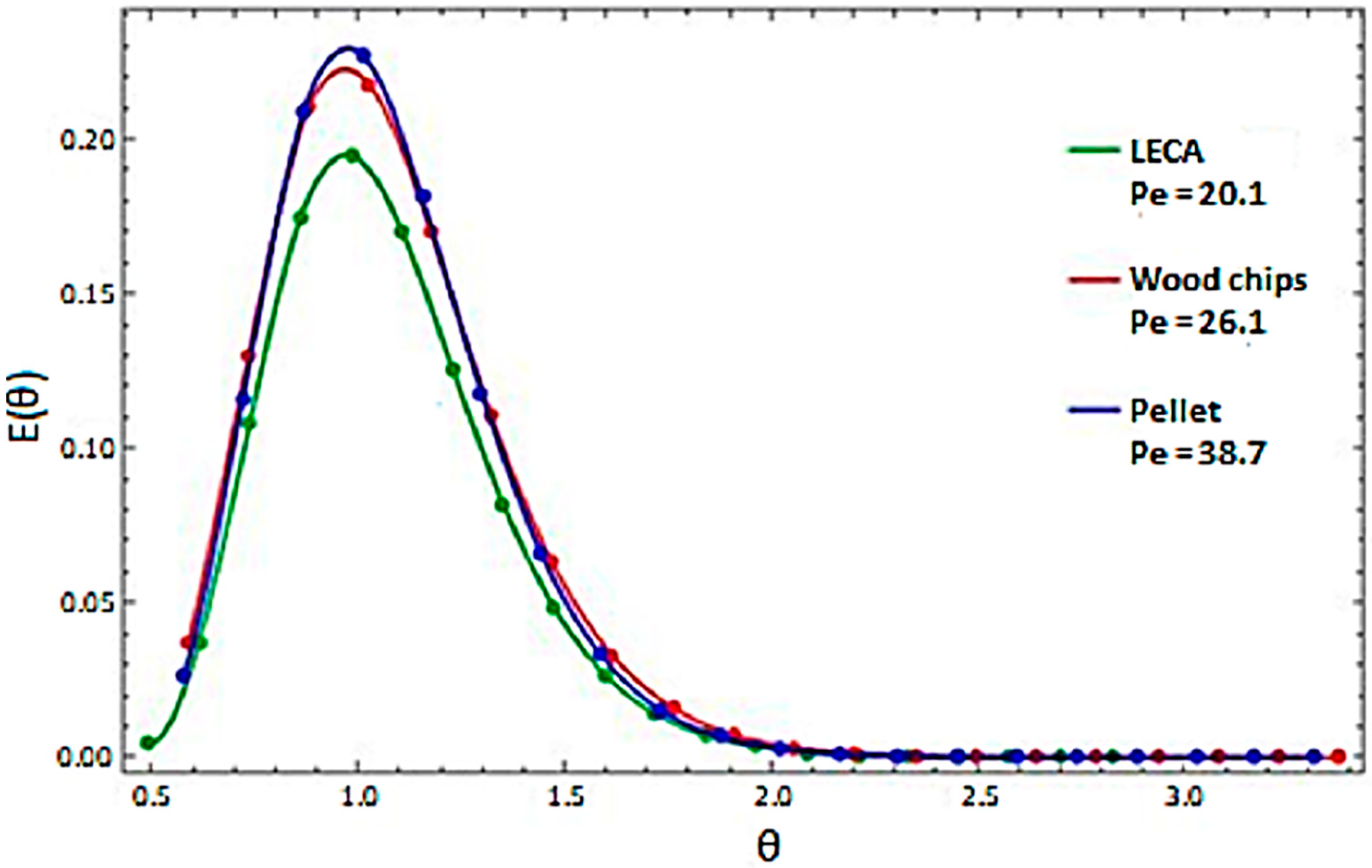

4.1. Results of the Experiment with the Use of Tracer Method

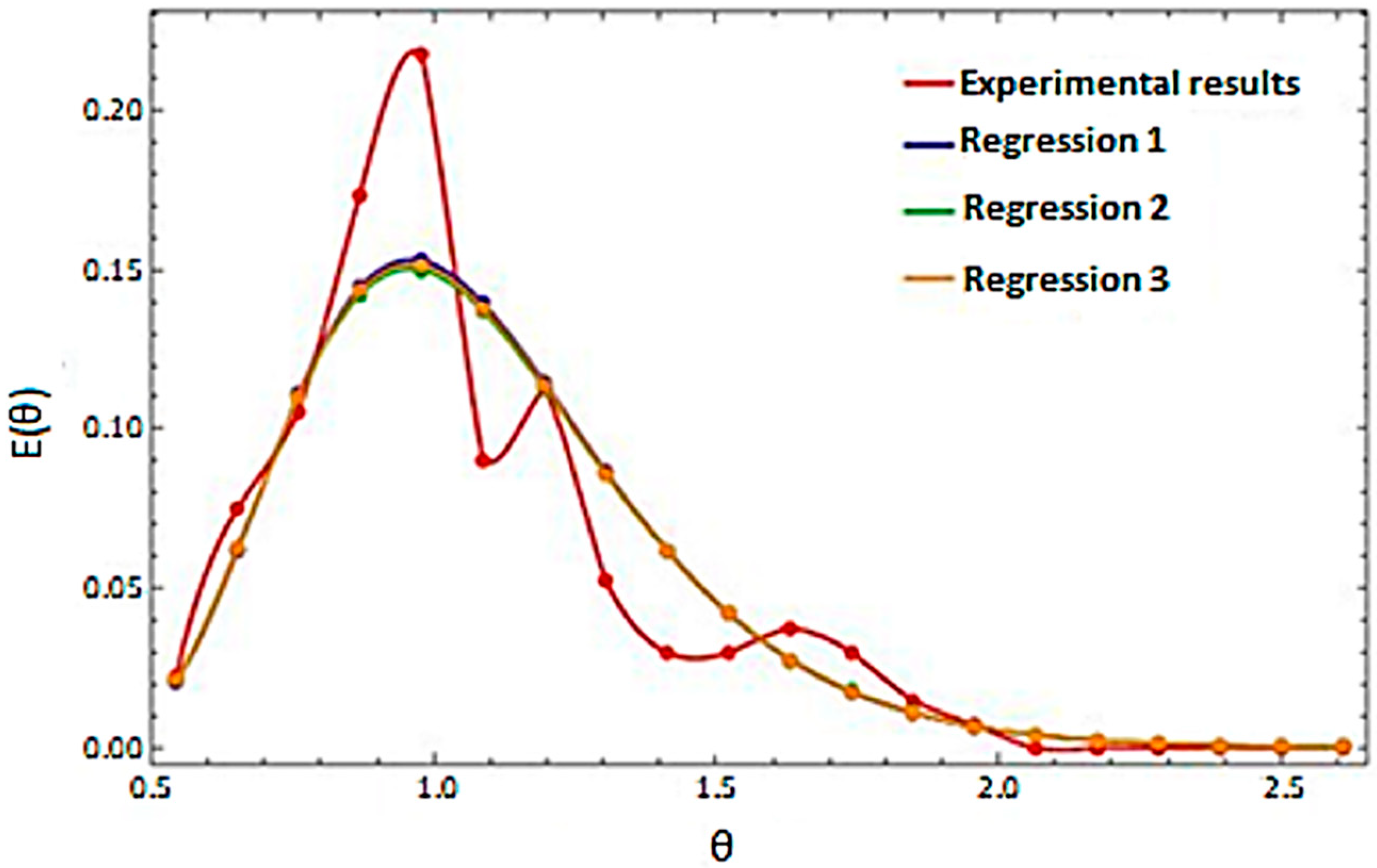

4.2. The Results Obtained from the RTD Algorithm

4.3. Linear Regression

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gan, Y.; Cui, S.; Ma, X.; Guo, H.; Wang, Y. Preparation of Cu-Al/SiO2 Porous Material and Its Effect on NO Decomposition in a Cement Kiln. Materials 2020, 13, 145. [Google Scholar] [CrossRef] [PubMed]

- Colin, B.; Dirion, J.-L.; Arlabosse, P.; Salvador, S. Wood chips flow in a rotary kiln: Experiments and modeling. Chem. Eng. Res. Des. 2015, 98, 179–187. [Google Scholar] [CrossRef]

- Beckmann, M.; Fontana, A.; Gehrmann, H.-J. Mathematical Modeling and Experimental Investigation of the Pyrolysis of Waste in Rotary Kilns. In Proceedings of the 4th International Symposium on Waste Treatment Technologies—Thermal, Non-Thermal and Gas Clean-Up, Sheffield, UK, 29 June–2 July 2003. [Google Scholar]

- Descoins, N.; Dirion, J.-L.; Howes, T. Solid transport in a pyrolysis pilot-scale rotary kiln: Preliminary results—Stationary and dynamic results. Chem. Eng. Process. Process Intensif. 2005, 44, 315–321. [Google Scholar] [CrossRef]

- World Counts. Available online: https://www.theworldcounts.com/challenges/waste/hazardous-waste-statistics (accessed on 20 March 2023).

- Poranek, N.; Łaźniewska-Piekarczyk, B.; Lombardi, L.; Czajkowski, A.; Bogacka, M.; Pikoń, K. Green Deal and Circular Economy of Bottom Ash Waste Management in Building Industry—Alkali (NaOH) Pre-Treatment. Materials 2022, 15, 3487. [Google Scholar] [CrossRef] [PubMed]

- Poranek, N.; Łaźniewska-Piekarczyk, B.; Czajkowski, A.; Pikoń, K. MSWIBA Formation and Geopolymerisation to Meet the United Nations Sustainable Development Goals (SDGs) and Climate Mitigation. Buildings 2022, 12, 1083. [Google Scholar] [CrossRef]

- Li, S.-Q.; Chi, Y.; Li, R.-D.; Yan, J.-H.; Cen, K.-F. Axial transport and residence time of MSW in rotary kilns: Part II. Theoretical and optimal analyses. Powder Technol. 2002, 126, 228–240. [Google Scholar] [CrossRef]

- Klose, W.; Schinkel, A.-P. Energy and mass transport process in the granular bed of an indirectly heated rotary kiln. China Particuology 2004, 2, 107–112. [Google Scholar] [CrossRef]

- Parveen, N.; Zaidi, S.; Danish, M. Development and analyses of data-driven models for predicting the bed depth profile of solids flowing in a rotary kiln. Adv. Powder Technol. 2020, 31, 678–694. [Google Scholar] [CrossRef]

- Wajda, A.; Brociek, R.; Pleszczyński, M. Optimization of Energy Recovery from Hazardous Waste in a Waste Incineration Plant with the Use of an Application. Processes 2022, 10, 462. [Google Scholar] [CrossRef]

- Gehrmann, H.J. Mathematische Modellierung und experimentelle Untersuchungen zur Pyrolyse von Abfallen in Drehrohrsystemen. Ph.D. Dissertation, Bauhaus-Universitat Weimar, Weimar, Germany, 2005. [Google Scholar]

- Henein, H. Bed Behaviour in Rotary Cylinders with Applications to Rotary Kilns. Ph.D. Dissertation, The University of British Columbia, Vancouver, BC, Canada, 1980. [Google Scholar]

- Szarawara, J.; Skrzypek, J.; Gawdzik, A. Podstawy Inżynierii Reaktorów Chemicznych; Wydawnictwo Naukowo-Techniczne: Warszawa, Poland, 1991. [Google Scholar]

- Jaworski, T. Modelowanie Procesu Transportu Masy na Rusztach Urządzeń do Termicznego Przekształcania Odpadów Stałych; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2012. [Google Scholar]

- Saemann, W.C. Passage of solids through rotary kilns: Factors affecting time of passage. Chem. Eng. Prog. 1951, 47, 508–514. [Google Scholar]

- Danckwerts, P.V. Continuous flow systems—Distribution of residence times. Chem. Eng. Sci. 1953, 2, 3857–3866. [Google Scholar] [CrossRef]

- Rogers, R.; Gardner, P.P. A Monte Carlo method for simulating dispersion and transport through horizontal rotating cylinder. Powder Technol. 1979, 23, 159–167. [Google Scholar] [CrossRef]

- Gupta, S.D.; Khakhar, D.V. Axial transport of granular solids in horizontal rotating cylinders: Part 1. Theory. Powder Technol. 1991, 67, 145–151. [Google Scholar] [CrossRef]

- Boateng, A.A.; Barr, P.V. Modeling of particle mixing and segregation in the transverse plane of a rotary kiln. Chem. Eng. Sci. 1996, 51, 4167–4181. [Google Scholar] [CrossRef]

- Paredes, I.J.; Yohannes, B.; Emady, H.N.; Muzzio, F.J.; Maglio, A.; Borghard, W.G.; Glasser, B.J.; Cuitiño, A.M. Measurement of the residence time distribution of a cohesive powder in a flighted rotary kiln. Chem. Eng. Sci. 2018, 191, 56–66. [Google Scholar] [CrossRef]

- Pichler, M.; Haddadi, B.; Jordan, C.; Norouzi, H.; Harasek, M. Influence of particle residence time distribution on the biomass pyrolysis in a rotary kiln. J. Anal. Appl. Pyrolysis 2021, 158, 105171. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, Y.; Li, H.; Li, X.; Gao, X. A simple step-change method to determine mean residence time in rotary kiln and a predictive model at low inclination. Powder Technol. 2018, 333, 30–37. [Google Scholar] [CrossRef]

- Aureli, R.; Brandizzi, N.; Magistris, G.D.; Brociek, R. A Customized Approach to Anomalies Detection by using Autoencoders. In Proceedings of the 2021 Scholar’s Yearly Symposium of Technology, Engineering and Mathematics, SYSTEM 2021, Catania 2021, CEUR Workshop Proceeding 2021, Plovdiv, Bulgaria, 27–29 May 2021; Volume 3092, pp. 53–59, code 177420. [Google Scholar]

- Brociek, R.; Słota, D. Application of intelligent algorithm to solve the fractional heat conduction inverse problem. In Proceedings of the 21st International Conference on Information and Software Technologies, ICIST 2015, Druskininkai, Lithuania, 15–16 October 2015; Volume 538, pp. 356–365, Part of the Communications in Computer and Information Science Book Series; code 153159. [Google Scholar] [CrossRef]

- Brociek, R.; Słota, D. Application of real ant colony optimization algorithm to solve space and time fractional heat conduction inverse problem. Inf. Technol. Control 2017, 46, 5–16. [Google Scholar] [CrossRef]

- Shi, X.; Huang, G.; Hao, X.; Yang, Y.; Li, Z. A Synchronous Prediction Model Based on Multi-Channel CNN with Moving Window for Coal and Electricity Consumption in Cement Calcination Process. Sensors 2021, 21, 4284. [Google Scholar] [CrossRef]

- Jin, X.; Xia, C.; Xu, H.; Wang, J.; Zeng, P. Mixed Criticality Scheduling for Industrial Wireless Sensor Networks. Sensors 2016, 16, 1376. [Google Scholar] [CrossRef]

- Paredes, I.J.; Yohannes, B.; Emady, H.; Glasser, B.J.; Borghard, W.G.; Muzzio, F.; Cuitiño, A.M.; Beeckman, J.; Ilias, S.; Podsiadlo, P.; et al. The effect of operating conditions on the residence time distribution and axial dispersion coefficient of a cohesive powder in a rotary kiln. Chem. Eng. Sci. 2017, 158, 50–57. [Google Scholar] [CrossRef]

- Liu, P.; Li, B.; Cheung, S.C.P.; Wu, W. Material and energy flows in rotary kiln-electric furnace smelting of ferronickel alloy with energy saving. Appl. Therm. Eng. 2016, 109, 542–559. [Google Scholar] [CrossRef]

- Richers, U. Thermische Behandlung von Abfällen in Drehrohröfen-eine Darstellung anhand der Literatur, Institut für Technische Chemie Projekt Schadstoff- und Abfallarme Verfahren; Forschungszentrum Karlsruhe GmbH: Karlsruhe, Germany, 1995. [Google Scholar]

- Stegowski, Z. Badania Znacznikowe i Modelowanie Komputerowe Wybranych Układów Przepływowych; Wydawnicwto Wydział Fizyki i Informatyki Stosowanej AGH: Kraków, Poland, 2010. [Google Scholar]

- Mieszkowski, H. Pomiary Cieplne i Energetyczne; WNT: Warszawa, Poland, 1981. [Google Scholar]

- Burghardt, A.; Bartelmus, G. Chemical Reaction Engineering. Reactors for Homogeneous Systems; PWN: Warszawa, Poland, 2001. [Google Scholar]

- Levenspiel, O. Chemical Reaction Engineering; John Wiley & Sons: Hoboken, NJ, USA, 1991. [Google Scholar]

| Parameter | Unit | Pellet | LECA | Wood Bark | Wood Chips | Wood Bark + Leca |

|---|---|---|---|---|---|---|

| Bulk density | kg/m3 | 610 | 278 | 147 | 209 | 198 |

| Apparent density | kg/m3 | 978 | 664 | 216 | 620 | 345 |

| Porosity | - | 0.38 | 0.55 | 0.32 | 0.66 | 0.43 |

| Angle of repose | ° | 45 | 34 | 27 | 42 | 30 |

| Size | mm | 20 × 6 | 8–16 | - | 30 × 5 | - |

| Material | Rotational Speed [rpm] | Angle of Inclination [°] |

|---|---|---|

| Pellet | 1; 1.5; 2 | 1; 2; 3 |

| LECA | 1; 1.5; 2 | 1; 2; 3 |

| Wood bark | 1; 1.5; 2 | 1; 2; 3 |

| Wood chips | 1; 1.5; 2 | 1; 2; 3 |

| Wood bark + LECA | 1; 1.5; 2 | 1; 2; 3 |

| Variant: LECA, Angle 3°, v = 1 rpm | |||||||

| Time [min] | Tracer Mass [g] | Material Mass [g] | Tracer Share [%] | Time [min] | Tracer Mass [g] | Material Mass [g] | Tracer Share [%] |

| 1 | 0 | 290 | 0 | 10 | 14 | 258 | 5.26 |

| 2 | 0 | 288 | 0 | 11 | 18 | 250 | 6.77 |

| 3 | 0 | 284 | 0 | 12 | 14 | 262 | 5.26 |

| 4 | 4 | 278 | 1.50 | 13 | 10 | 276 | 3.76 |

| 5 | 12 | 272 | 4.51 | 14 | 8 | 278 | 3.01 |

| 6 | 52 | 212 | 19.55 | 15 | 6 | 274 | 2.26 |

| 7 | 60 | 202 | 22.56 | 16 | 6 | 278 | 2.26 |

| 8 | 26 | 232 | 9.77 | 17 | 2 | 282 | 0.75 |

| 9 | 34 | 214 | 12.78 | 18 | 0 | 286 | 0 |

| Variant: Mixture, Angle 3°, v = 1 rpm | |||||||

| Time [min] | Tracer Mass [g] | Material Mass [g] | Tracer Share [%] | Time [min] | Tracer Mass [g] | Material Mass [g] | Tracer Share [%] |

| 1 | 0 | 252 | 0 | 10 | 28 | 234 | 10.85 |

| 2 | 0 | 256 | 0 | 11 | 20 | 236 | 7.75 |

| 3 | 0 | 256 | 0 | 12 | 12 | 242 | 4.65 |

| 4 | 2 | 252 | 0.77 | 13 | 10 | 246 | 3.88 |

| 5 | 18 | 236 | 6.98 | 14 | 6 | 248 | 2.33 |

| 6 | 26 | 230 | 10.08 | 15 | 6 | 250 | 2.33 |

| 7 | 26 | 228 | 10.08 | 16 | 4 | 252 | 1.54 |

| 8 | 52 | 202 | 20.16 | 17 | 0 | 254 | 0 |

| 9 | 48 | 208 | 18.60 | ||||

| Variant: Wood Chips, Angle 3°, v = 1 rpm | |||||||

| Time [min] | Tracer Mass [g] | Material Mass [g] | Tracer Share [%] | Time [min] | Tracer Mass [g] | Material Mass [g] | Tracer Share [%] |

| 1 | 0 | 246 | 0 | 9 | 28 | 218 | 11.48 |

| 2 | 0 | 244 | 0 | 10 | 16 | 226 | 6.56 |

| 3 | 0 | 246 | 0 | 11 | 8 | 236 | 3.28 |

| 4 | 0 | 248 | 0 | 12 | 0 | 242 | 0 |

| 5 | 6 | 240 | 2.46 | 13 | 6 | 238 | 2.46 |

| 6 | 30 | 212 | 12.30 | 14 | 0 | 244 | 0 |

| 7 | 90 | 156 | 36.89 | 15 | 2 | 242 | 0.82 |

| 8 | 58 | 186 | 23.77 | 16 | 0 | 250 | 0 |

| Data | tśr, min | PeL, - | Ϭ, - |

|---|---|---|---|

| Experiment results | 9.67 | 13.74 | 2.81 |

| Regression 1 | 9.20 | 13.24 | 4.08 |

| Regression 2 | 9.19 | 13.09 | 4.10 |

| Regression 3 | 9.20 | 13.17 | 4.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaworski, T.; Wajda, A. Research on the Flow Parameters of Waste Motion in a Rotary Kiln with the Use of the Tracer Method. Sensors 2023, 23, 6526. https://doi.org/10.3390/s23146526

Jaworski T, Wajda A. Research on the Flow Parameters of Waste Motion in a Rotary Kiln with the Use of the Tracer Method. Sensors. 2023; 23(14):6526. https://doi.org/10.3390/s23146526

Chicago/Turabian StyleJaworski, Tomasz, and Agata Wajda. 2023. "Research on the Flow Parameters of Waste Motion in a Rotary Kiln with the Use of the Tracer Method" Sensors 23, no. 14: 6526. https://doi.org/10.3390/s23146526

APA StyleJaworski, T., & Wajda, A. (2023). Research on the Flow Parameters of Waste Motion in a Rotary Kiln with the Use of the Tracer Method. Sensors, 23(14), 6526. https://doi.org/10.3390/s23146526