Research on a Space–Time Continuous Sensing System for Overburden Deformation and Failure during Coal Mining

Abstract

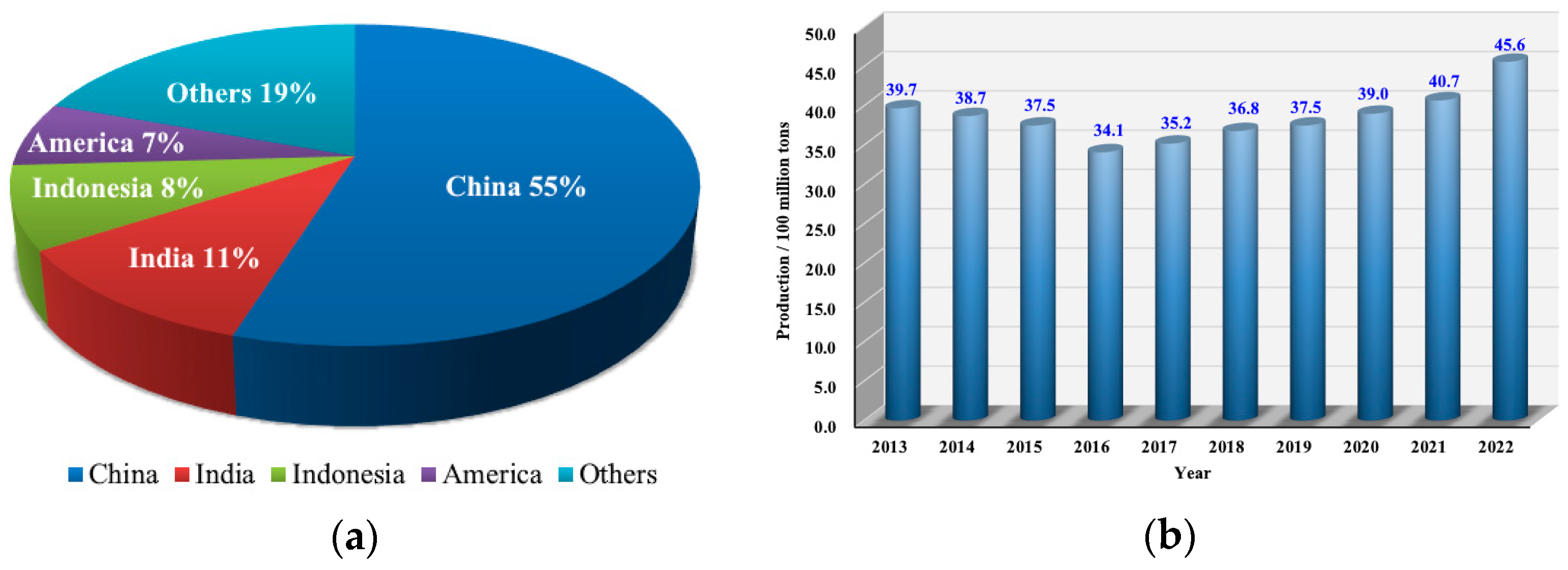

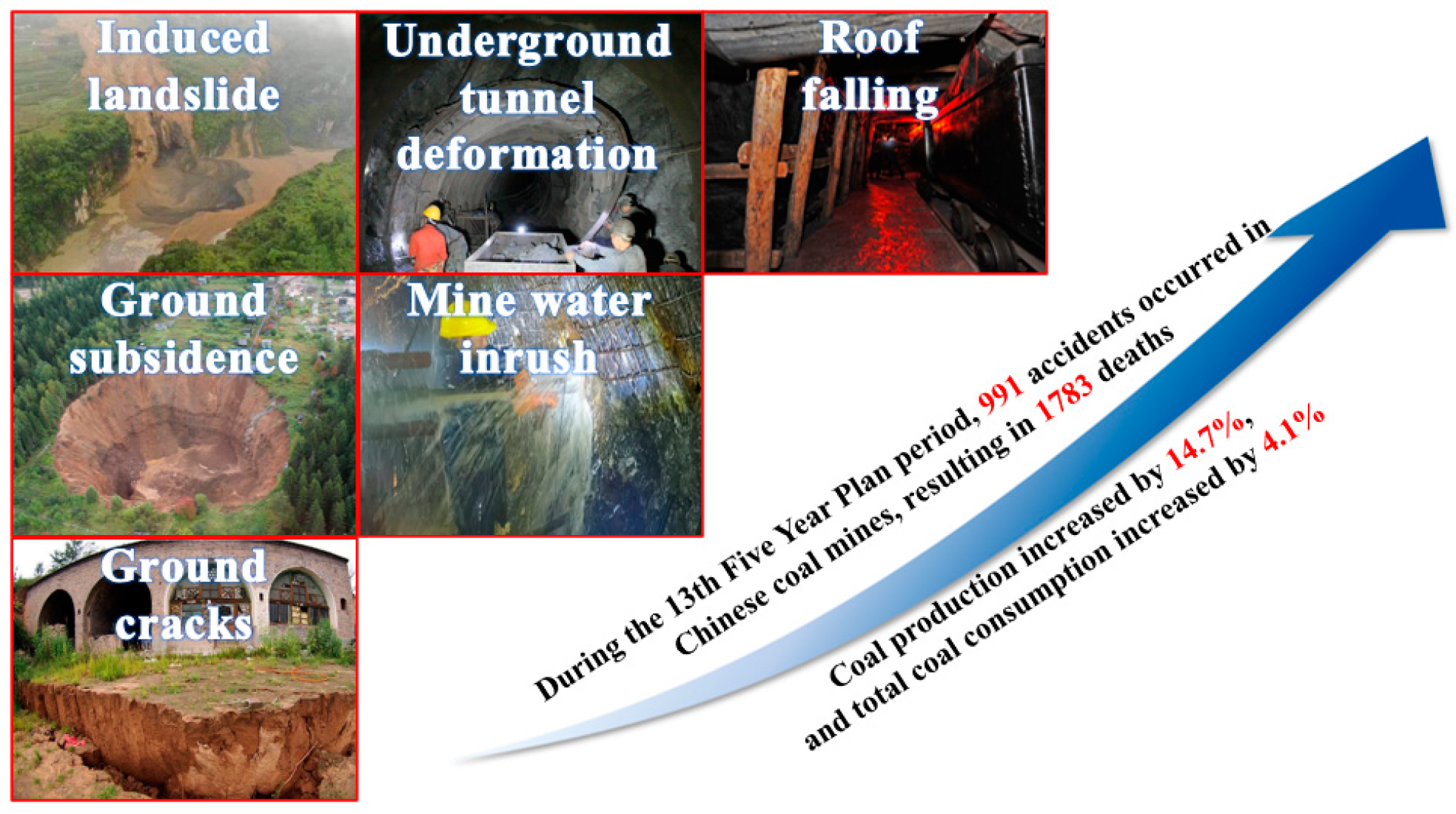

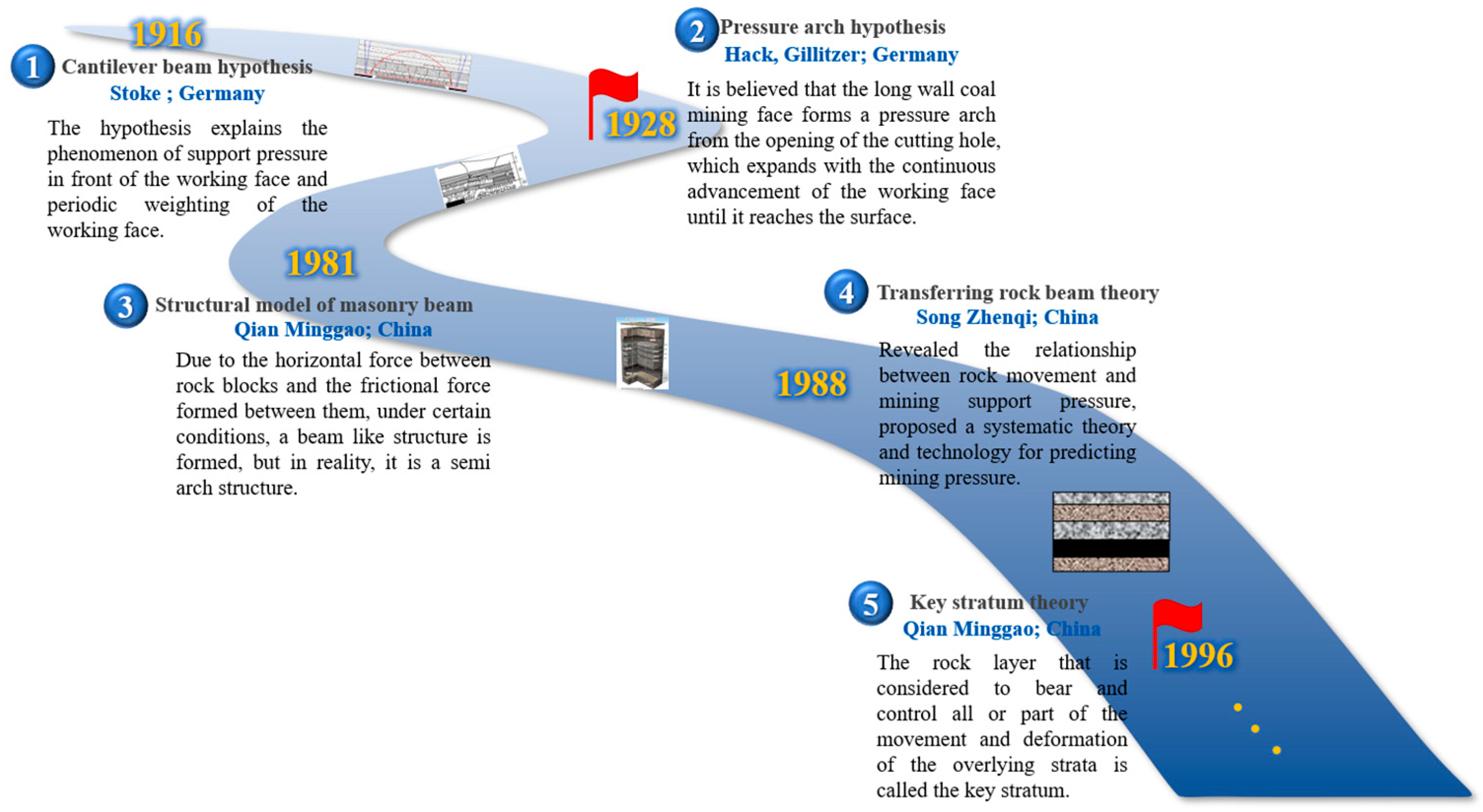

1. Introduction

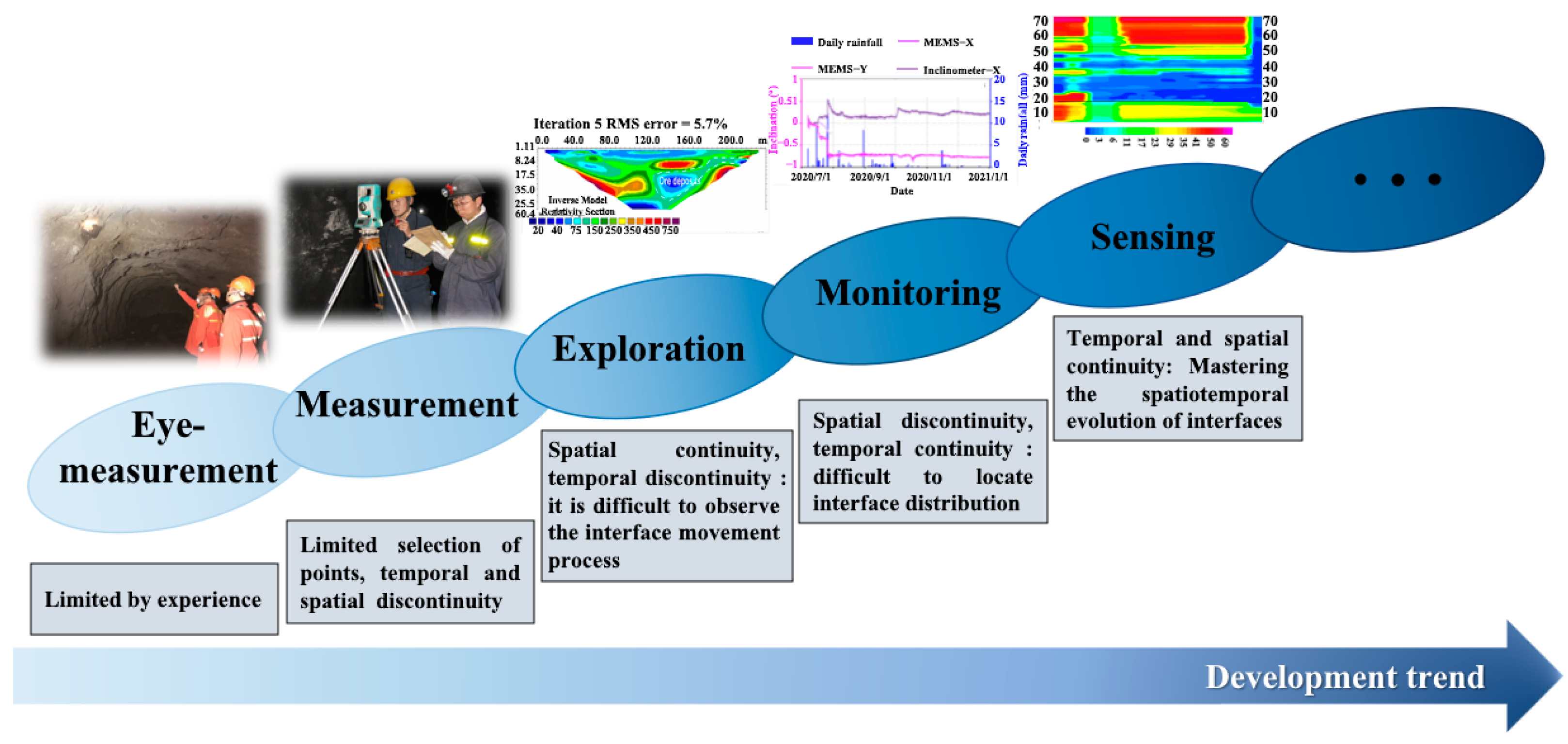

2. Research on Space–Time Continuous Sensing of Overburden Deformation and Failure

2.1. Typical Modes of Overburden Deformation and Failure

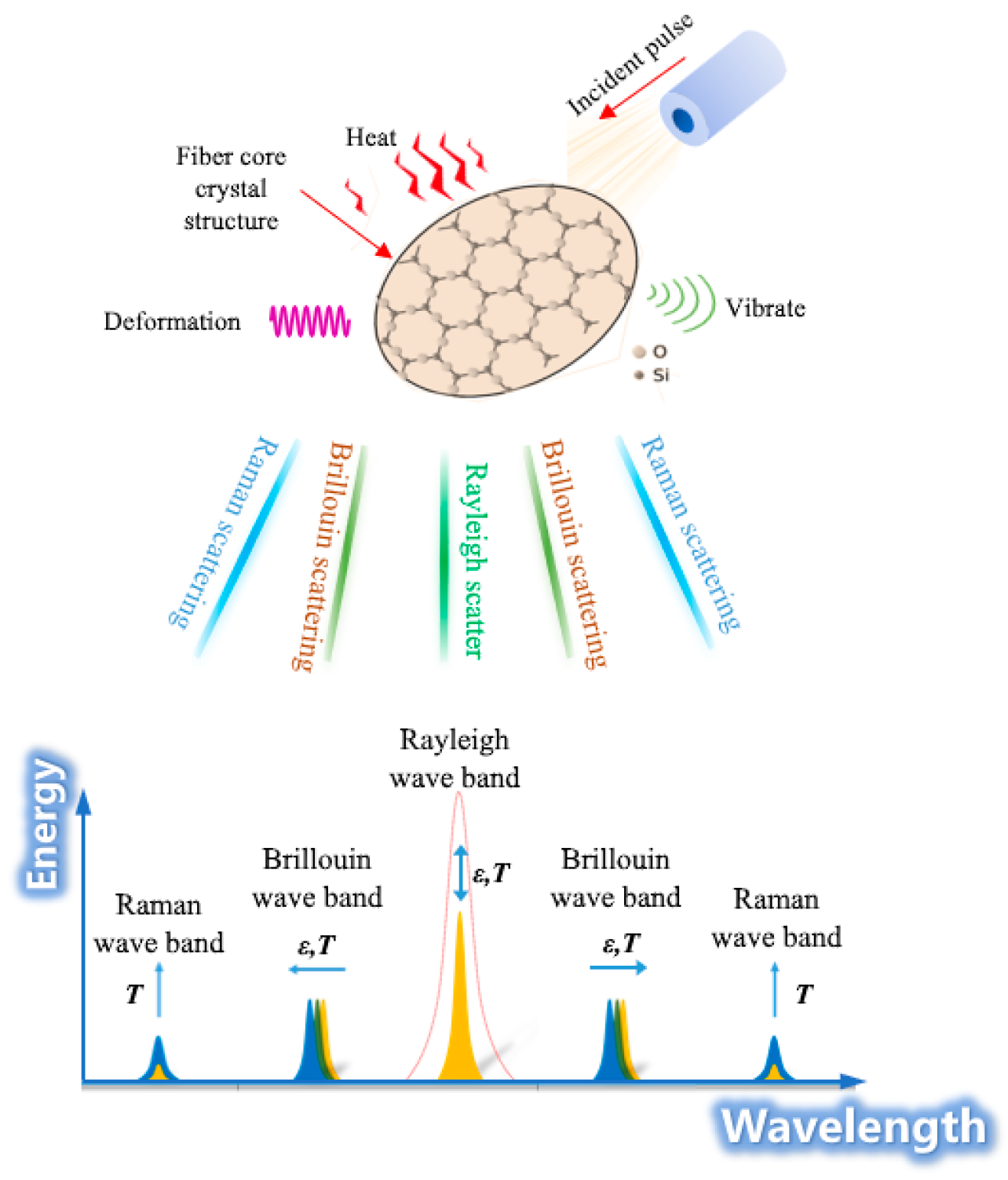

2.2. Space–Time Continuous Sensing Based on DFOS Technology

2.2.1. The Principle of DFOS Technology

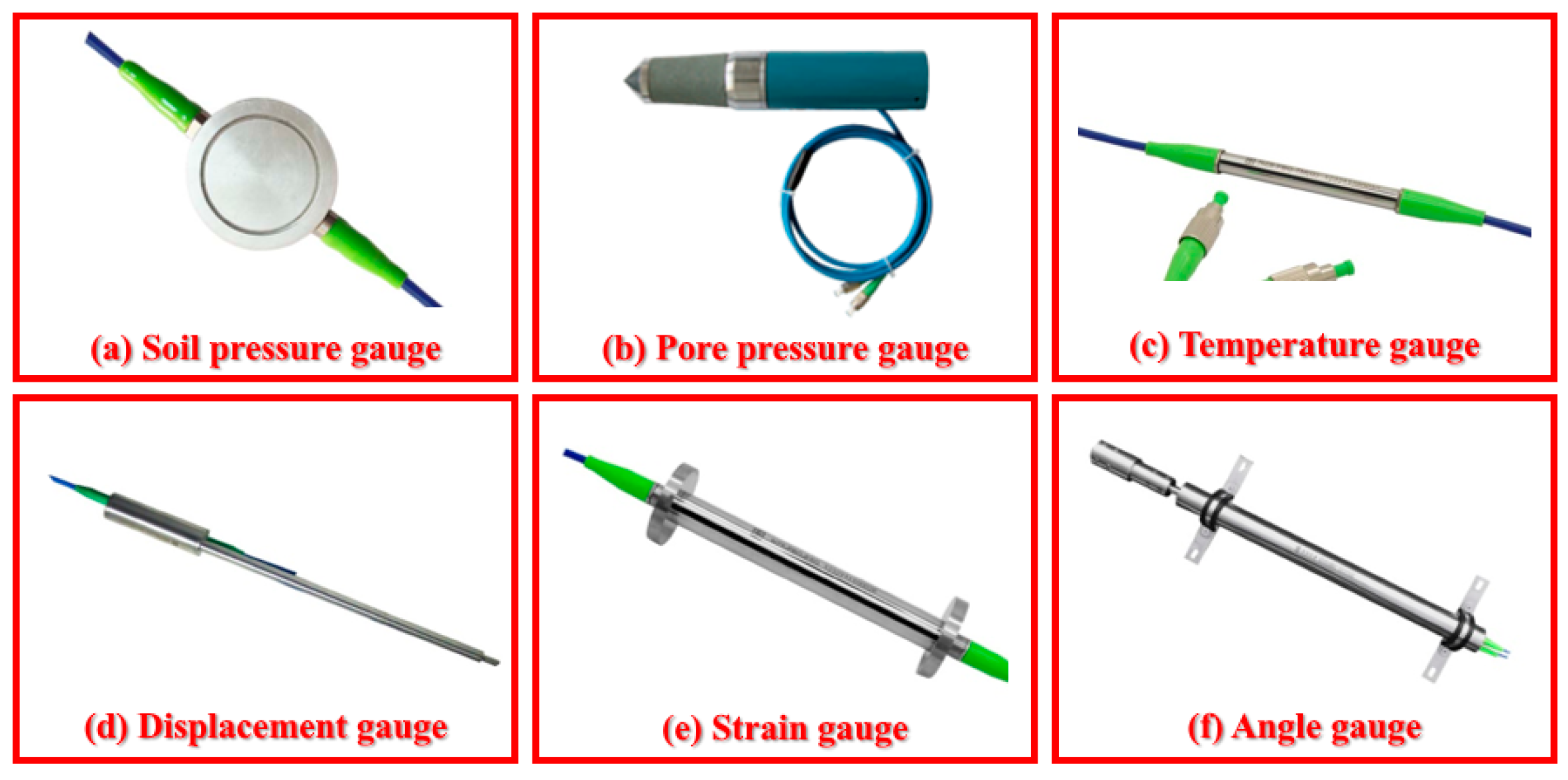

2.2.2. Sensing Cables and Sensors in Mine Engineering Monitoring

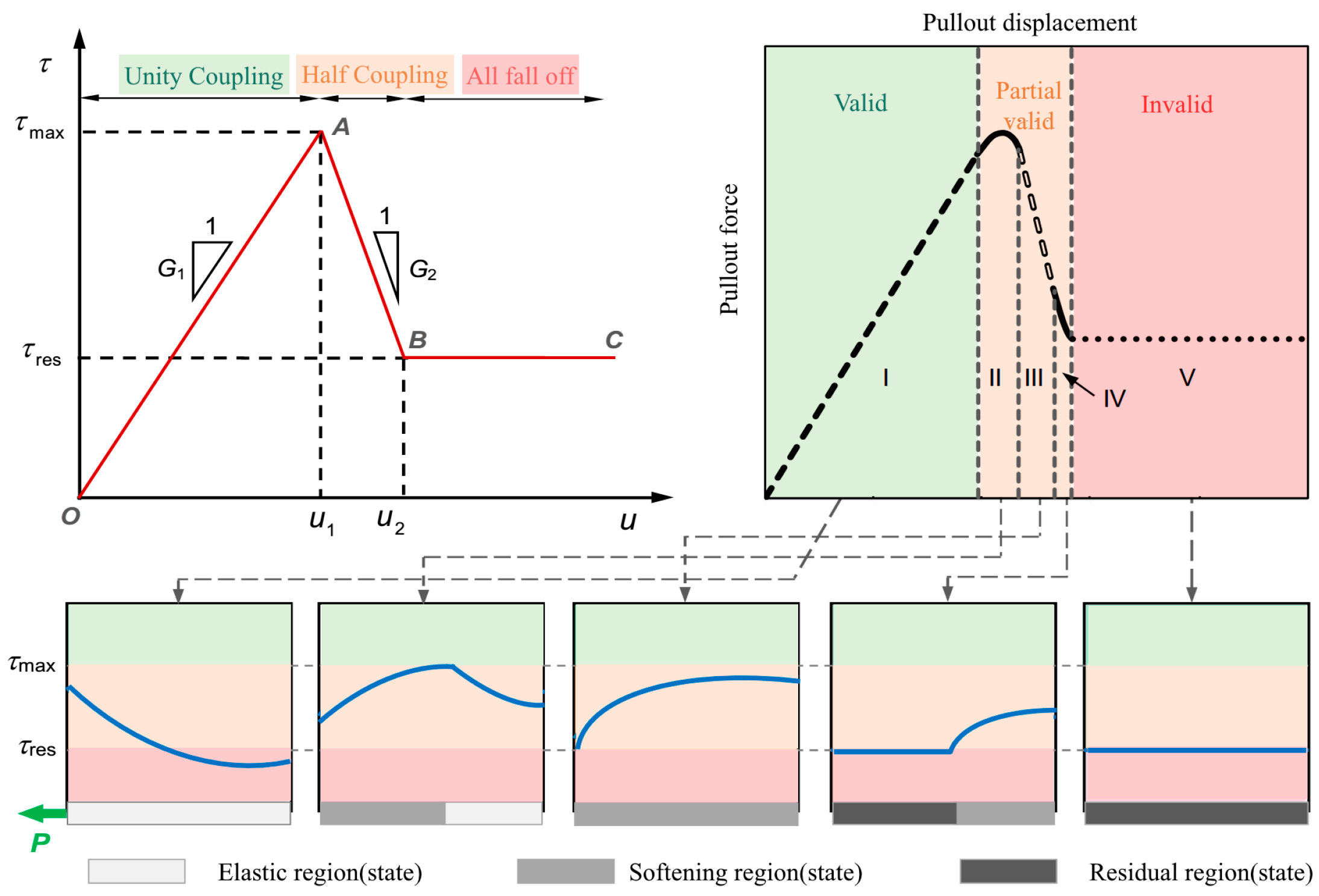

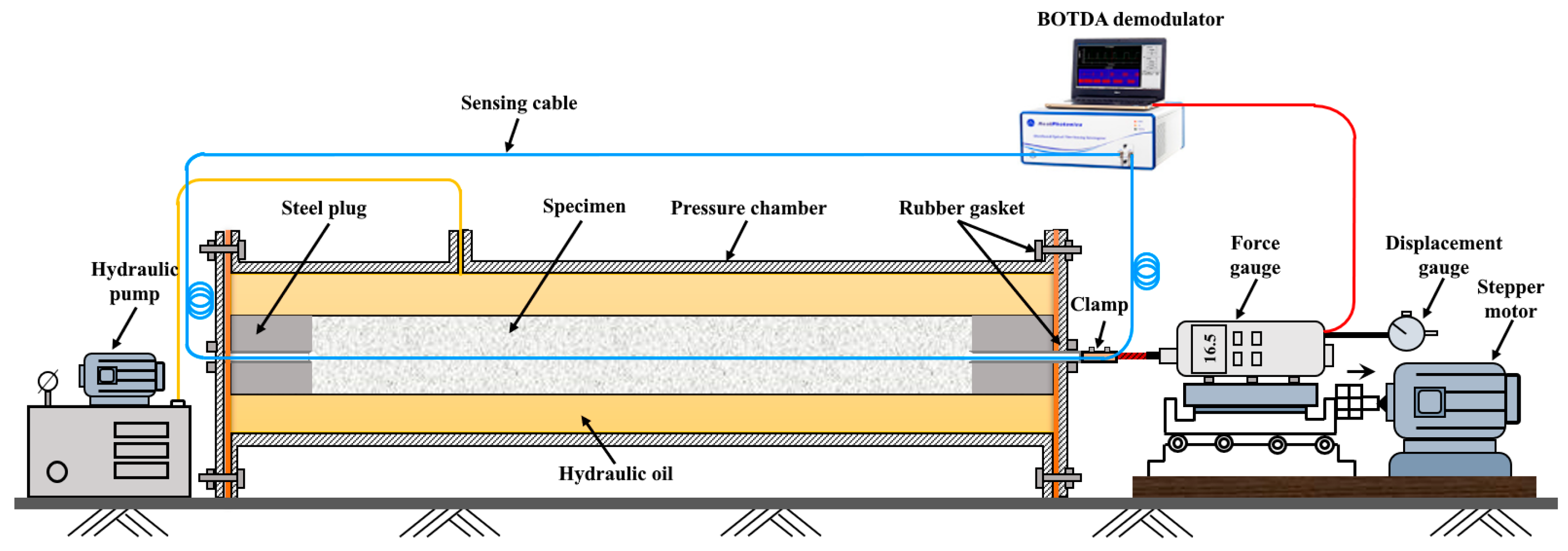

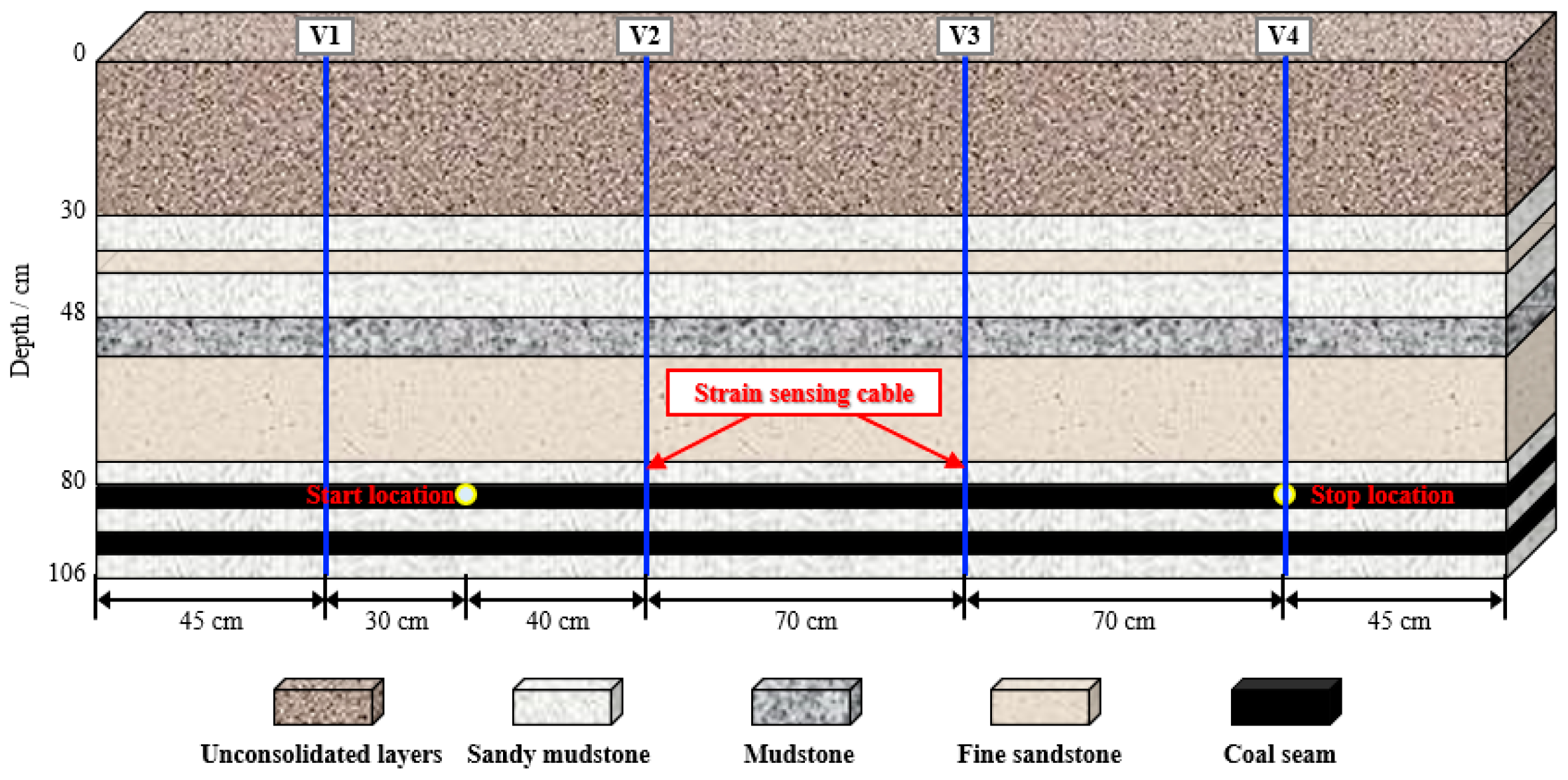

2.2.3. The Cable–Rock Mass Coupling Test

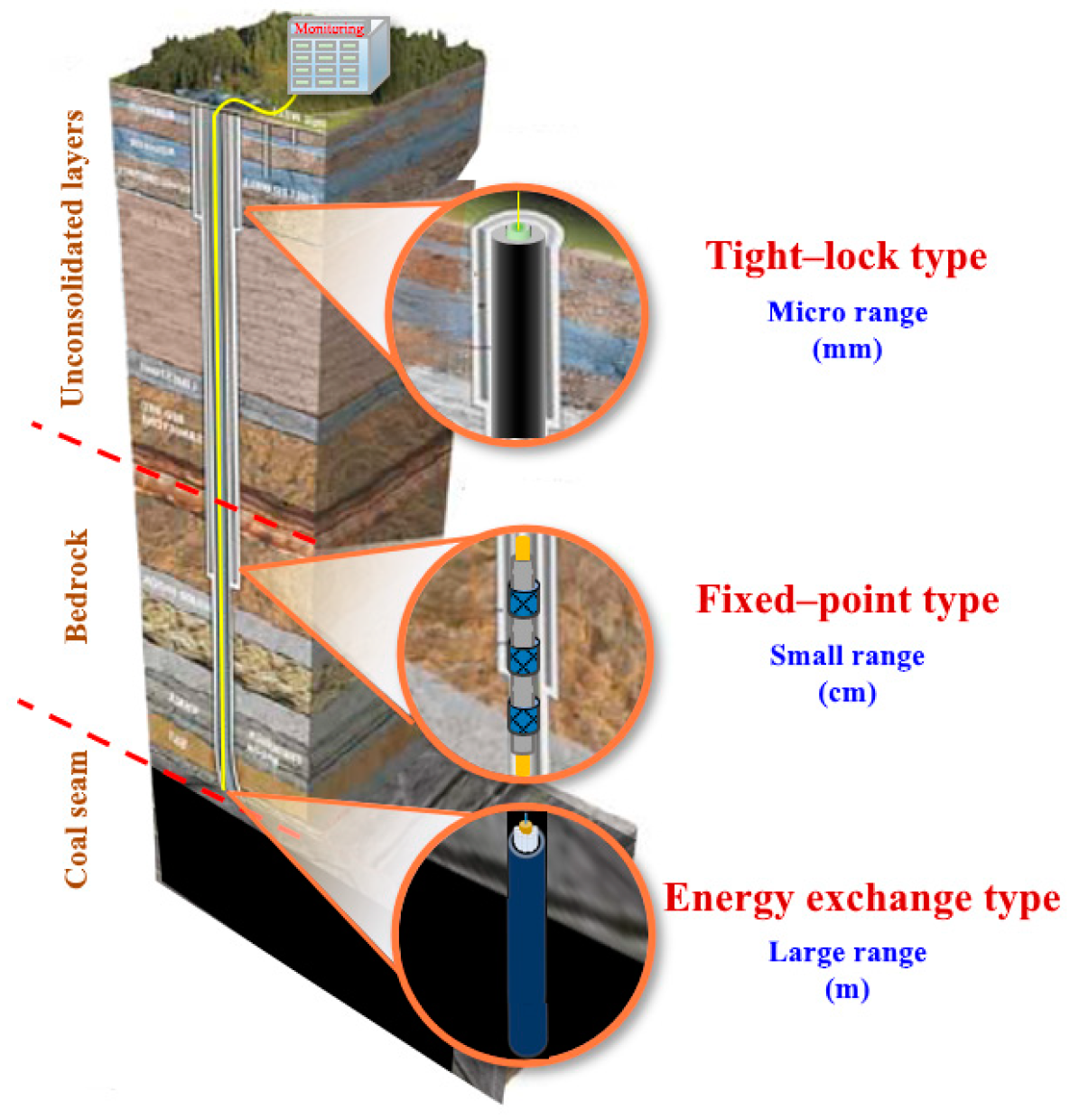

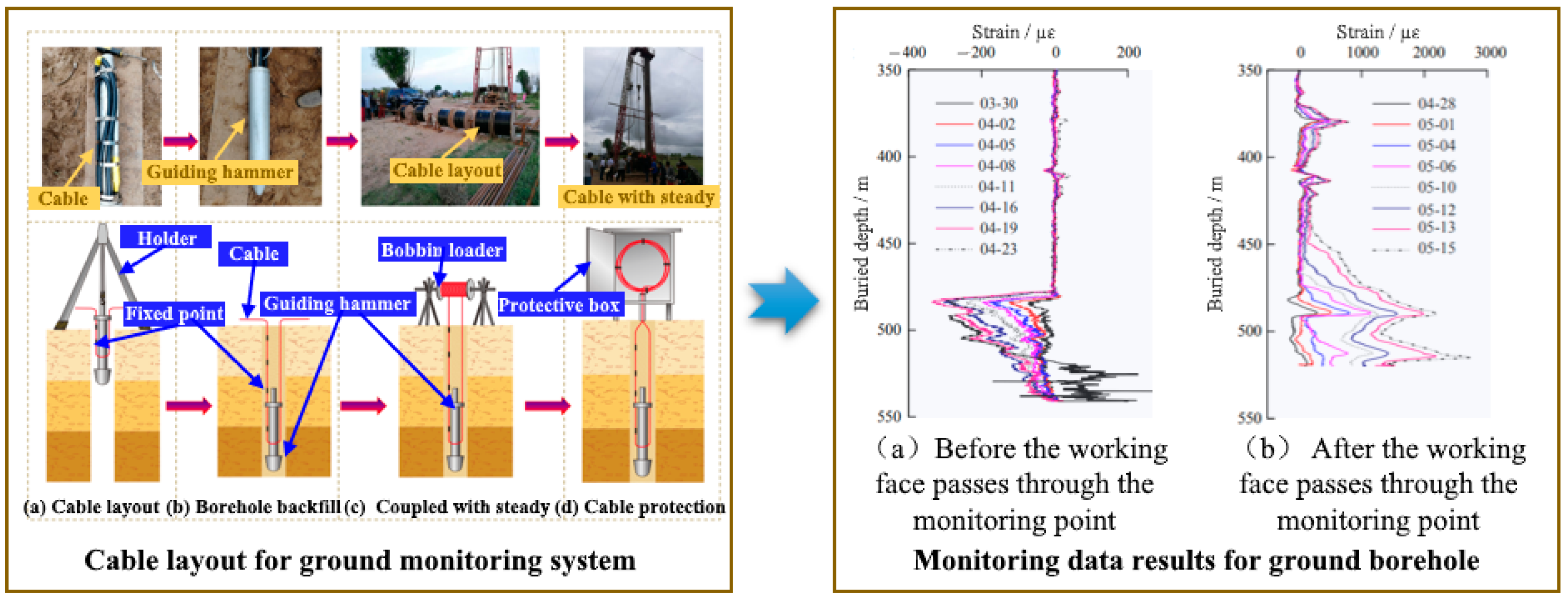

2.2.4. The Cable Layout for Ground and Underground Monitoring

2.3. Applied Case Analysis

3. The Development Trend

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peng, S.P. China coal resource exploitation and environmental protection. Sci. Technol. Rev. 2009, 27, 3. [Google Scholar]

- Huang, Q.X. Green mining of coal resources. Shaanxi Coal 2008, 1, 18–21. [Google Scholar]

- Zhang, T.; Gan, Q.; Zhao, Y.X.; Zhu, G.P.; Nie, X.D.; Yang, K.; Li, J.Z. Investigations into mining-induced stress–fracture–seepage field coupling effect considering the response of key stratum and composite aquifer. Rock Mech. Rock Eng. 2019, 52, 4017–4031. [Google Scholar] [CrossRef]

- Liu, H.H.; Zheng, L.G.; Zheng, J.T. Relationships between permeability, porosity and effective stress for low-permeability sedimentary rock. Int. J. Rock Mech. Min. Sci. 2015, 78, 304–318. [Google Scholar]

- Cheng, G.; Shi, B.; Zhu, H.H.; Zhang, C.C.; Wu, J.H. A field study on distributed fiber optic deformation monitoring of overlying strata during coal mining. J. Civ. Struct. Health Monit. 2015, 5, 553–562. [Google Scholar] [CrossRef]

- Shi, B. On field and their coupling in engineering geology. J. Eng. Geol. 2013, 21, 673–680. [Google Scholar]

- Peng, W.Q. Study on the Failure of Overlying Rock in Mining Shallow Thick Coal Seam by Slicing Method. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2006. [Google Scholar]

- Qian, M.G. Conditions required for equilibrium of overlying strata at working areas. J. China Inst. Min. Technol. 1981, 2, 31–40. [Google Scholar]

- Qian, M.G. A study of the behavior of overlying strata in longwall mining and its application to strata control. Dev. Geotech. Eng. 1981, 32, 13–17. [Google Scholar]

- Qian, M.G.; Zhang, D.L.; Li, L.J.; Kang, L.X.; Xu, J.L. “S–R” stability for the voussoir beam and its application. Ground Press. Strat. Control 1994, 21, 6–11. [Google Scholar]

- Qian, M.G.; Zhu, D.R.; Wang, Z.T. The fracture type of main roof and their effects on roof pressure in coal face. J. China Inst. Min. Technol. 1986, 15, 9–18. [Google Scholar]

- Beijing Mining Research Institute of Chinese Coal Science Research Institute. The Laws of Ground Subsidence Andoverburden Failure and It’s Applications on Coal Mines; China Coal Industry Publishing House: Beijing, China, 1981. [Google Scholar]

- Song, Z.Q. Practical Mine Pressure Control; China University of Mining and Technology Press: Xuzhou, China, 1988. [Google Scholar]

- Gao, Y.F. “Four-zone” model of rockmass movement and back analysis of dynamic displacement. J. China Coal Soc. 1996, 21, 51–56. [Google Scholar]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Theoretical study of key stratum in ground control. J. China Coal Soc. 1996, 21, 225–230. [Google Scholar]

- Jiang, F.X.; Song, Z.Q.; Song, Y. Basic structure forms of main roof. Chin. J. Rock Mech. Eng. 1993, 12, 366–379. [Google Scholar]

- Dou, L.M.; He, H. Study of OX–F–T spatial structure evolution of overlying strata coal mines. Chin. J. Rock Mech. Eng. 2012, 31, 453–460. [Google Scholar]

- Chai, J.; Ouyang, Y.B.; Liu, J.X.; Zhang, D.D.; Du, W.G.; Lei, W.L. Experimental study on a new method to forecasting goaf pressure based key strata deformation detected using optic fiber sensors. Opt. Fiber Technol. 2021, 67, 102706. [Google Scholar] [CrossRef]

- Chai, J.; Du, W.G.; Yuan, Q.; Zhang, D. Analysis of test method for physical model test of mining based on optical fiber sensing technology detection. Opt. Fiber Technol. 2019, 48, 84–94. [Google Scholar] [CrossRef]

- Zhu, L.; Gu, W.Z.; Pan, H.; Liu, Z.C.; Chai, J.; Ouyang, Y.B. Calculation model of overburden rock failure volume in mined-out area based on Brillouin optical time-domain analysis technology. Opt. Fiber Technol. 2021, 66, 102640. [Google Scholar] [CrossRef]

- Cheng, G.; Xu, W.T.; Shi, B.; Wu, J.H.; Sun, B.Y.; Zhu, H.H. Experimental study on the deformation and failure mechanism of overburden rock during coal mining using a comprehensive intelligent sensing method. J. Rock Mech. Geotech. Eng. 2022, 14, 1626–1641. [Google Scholar] [CrossRef]

- Xu, J.L.; Qian, M.G. Method to distinguish key strata in overburden. J. China Univ. Min. Technol. 2000, 5, 21–25. [Google Scholar]

- Shi, H.; Jiang, F.X. Mechanical analysis of rupture regularity of hard and massive overlying strata of longwall face. Chin. J. Rock Mech. Eng. 2004, 23, 3066–3069. [Google Scholar]

- Jiang, Y.D.; Yang, Y.M.; Ma, Z.Q.; Li, Y.W. Breakage mechanism of roof strata above widespread mined-out area with roadway mining method and feasibility analysis of upward mining. J. China Coal Soc. 2016, 41, 801–807. [Google Scholar]

- Shi, B.; Zhang, D.; Zhu, H.H.; Zhang, C.C.; Gu, K.; Sang, H.W.; Han, H.M.; Sun, M.Y.; Liu, Y. DFOS applications to geo-engineering monitoring. Photonic Sens. 2021, 11, 158–186. [Google Scholar] [CrossRef]

- Zhu, H.H.; Liu, W.; Wang, T.; Su, J.W.; Shi, B. Distributed acoustic sensing for monitoring linear infrastructures: Current status and trends. Sensors 2022, 22, 7550. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, B.; Zeni, L.; Minardo, A.; Zhu, H.H.; Jia, L.X. An Fiber Bragg Grating-based monitoring system for slope deformation study in geotechnical centrifuge. Sensors 2019, 19, 1591. [Google Scholar] [CrossRef]

- Zhang, L.; Cui, Y.F.; Zhu, H.H.; Wu, H.; Han, H.M.; Yan, Y.; Shi, B. Shear deformation calculation of landslide using distributed strain sensing technology considering the coupling effect. Landslides 2023. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, H.H.; Han, H.M.; Shi, B. Fiber optic monitoring of an anti-slide pile in a retrogressive landslide. J. Rock Mech. Geotech. Eng. 2023. [Google Scholar] [CrossRef]

- Shi, B.; Zhu, H.H.; Zhang, C.C.; Sun, M.Y.; Zhang, W.; Zhang, T.Y. Rock and soil disaster sensing and application. Sci. Sin. Technol. 2023. [Google Scholar] [CrossRef]

- Zhang, C.C.; Shi, B.; Zhang, S.; Gu, K.; Wei, G.Q. Microanchored borehole fiber optics allows strain profiling of the shallow subsurface. Sci. Rep. 2021, 11, 9173. [Google Scholar] [CrossRef]

- Cheng, G.; Wang, Z.X.; Zhu, H.H.; Li, D.Y.; Xu, W.T.; Zhang, L. Experimental study on overlying strata deformation and failure using distributed intelligent sensing. advances in geoengineering along the belt and road. BRWSG 2021. Lect. Notes Civ. Eng. 2022, 230, 315–328. [Google Scholar]

- Zhang, C.C.; Shi, B.; Gu, K.; Liu, S.P.; Wu, J.H.; Zhang, S.; Zhang, L.; Jiang, H.T.; Wei, G.Q. Vertically distributed sensing of deformation using fiber optic sensing. Geophys. Res. Lett. 2018, 45, 11732–11741. [Google Scholar] [CrossRef]

- Zhang, L.; Cheng, G.; Wu, J.H.; Minardo, A.D.; Song, Z.P. Study on slope failure evolution under surcharge loading and toe cutting with BOTDA technology. Opt. Fiber Technol. 2021, 66, 102644. [Google Scholar] [CrossRef]

- Horiguchi, T.; Shimizu, K.; Kurashima, T.; Tateda, M.; Koyamada, Y. Development of a distributed sensing technique using Brillouin scattering. J. Lightwave Technol. 1995, 13, 1296–1302. [Google Scholar] [CrossRef]

- Zhu, H.H.; Shi, B.; Zhang, J.; Yan, J.F.; Zhang, C.C. Distributed fiber optic monitoring and stability analysis of a model slope under surcharge loading. J. Mt. Sci. 2014, 11, 979–989. [Google Scholar] [CrossRef]

- Shi, B. On the ground sensing system and ground sensing engineering. J. Eng. Geol. 2017, 25, 582–591. [Google Scholar]

- Piao, C.D.; Shi, B.; Wei, G.Q.; Yu, L.; Chen, E.Y. BOTDA distributed measurement and analysis of mining overburden separation. J. Min. Saf. Eng. 2015, 32, 376–381. [Google Scholar]

- Sun, B.Y.; Zhang, P.S.; Fu, M.R. Comparative study on the “optic-electric” monitoring method for the deformation and failure of surrounding rock in stopes. Nat. Hazards 2022, 110, 407–427. [Google Scholar] [CrossRef]

- Liu, Y.; Li, W.P.; He, J.H.; Liu, S.W.; Cai, L.Y.; Cheng, G. Application of Brillouin optical time domain reflectometry to dynamic monitoring of overburden deformation and failure caused by underground mining. Int. J. Rock Mech. Min. Sci. 2018, 106, 133–143. [Google Scholar] [CrossRef]

- Meng, F.F.; Piao, C.D.; Shi, B.; Sasaoka, T.; Shimada, H. Calculation model of overburden subsidence in mined-out area based on Brillouin optical time-domain reflectometer technology. Int. J. Rock Mech. Min. Sci. 2021, 138, 104620. [Google Scholar] [CrossRef]

- Karhmis, M.; Triplett, T.; Haycocks, C.; Goodman, G. Mining subsidence and its prediction in appalachian coalfield. In Rock Mechanics: Theory, Experiment, Practice, Proceedings of the 24th US Symposium Rock Mechanics, College Station, TX, USA, 20–23 June 1983; OnePetro: Richardson, TX, USA, 1983. [Google Scholar]

- Palchik, V. Influence of physical characteristics of weal rock mass on height of caved zone over abandoned subsurface coal mines. Environ. Geol. 2002, 42, 92–101. [Google Scholar] [CrossRef]

- State Administration of Safety Supervision, State Administration of Coal Mine Safety Supervision, State Energy Administration, State Railway Administration. Specification for Coal Pillar Setting and Mining of Buildings, Water Bodies, Railways and Main Roadways; China Coal Industry Publishing House: Beijing, China, 2017. [Google Scholar]

- Li, Q.S.; Li, X.B.; Xu, J.L.; Xu, Z.H.; Zhang, C. Research advances in mining fractures evolution law of rock strata and ecological treatment technology. Coal Sci. Technol. 2022, 50, 28–47. [Google Scholar] [CrossRef]

- Chai, J.; Qiu, B.; Li, Y.; Zhu, L. Simulation experiment of embedded fiber Bragg grating monitoring in rock deformation through borehole. J. Min. Saf. Eng. 2012, 29, 44–47. [Google Scholar]

- Wang, H.Q.; Zhu, J.J.; Fu, H.Q.; Feng, G.C.; Wang, C.C. Modeling and robust estimation for the residual motion error in airborne sar interferometry. IEEE Geosci. Remote Sens. Lett. 2019, 16, 65–69. [Google Scholar] [CrossRef]

- Xie, H.P.; Zhou, H.W.; Wang, J.A.; Li, L.Z.; Kwasniewski, M.A. Application of FLAC to predict ground surface displacement due to coal extraction and its comparative analysis. Chin. J. Rock Mech. Eng. 1999, 18, 397–401. [Google Scholar]

- Xu, Y.C.; Zhang, Y.Z. Deformation characteristics of the thick unconsolidated layers due to mining by UDEC. J. China Coal Soc. 2002, 27, 268–272. [Google Scholar]

- Zhang, P.S.; Liu, S.D.; Shu, Y.F. Analysis on dynamic testing results of distortion and collapsing of the top rock by geophysical method during mining of coal seam. J. China Coal Soc. 2011, 36, 218–222. [Google Scholar]

- Ou, Y.C.; Zhang, P.S.; Wang, W. Study on the evolution rule of land damage based on electrical resistivity imaging technology in mining face. Geotech. Geol. Eng. 2019, 37, 4259–4268. [Google Scholar] [CrossRef]

- Cheng, G.; Wang, Z.X.; Shi, B.; Zhu, H.H.; Li, G.Q.; Tian, L.Q. Research on multi-field fiber optic neural sensing and safety guarantee system constructing for mining overburden deformation. Coal Sci. Technol. 2023, 1–12. Available online: http://kns.cnki.net/kcms/detail/11.2402.TD.20230208.1353.001.html (accessed on 1 May 2023).

| Cable Type | Diameter (mm) | Tensile Strength (N) | Range | Unit Weight (kg/km) | Characteristics |

|---|---|---|---|---|---|

GFRP Cable | 5.8 | 3000 | −1~1% | 28 | Fine measurement, low shear strength and wear resistance, high requirements for layout environment. |

Metal-based cable | 5.0 | 3500 | −1~1% | 38 | High shear strength, wear resistance, good environmental adaptability, and general measurement accuracy. |

Fixed-point cable | 5.0 | 1000 | 0~3% | 36 | The measurement range is extensive and can reach the meter level, suitable for segmented fine monitoring of large deformation. |

Steel wire armored temperature cable | 8.0 | 1800 | −40~85 °C | 45 | Good environmental adaptability, strong anti-damage ability, and general temperature sensitivity. |

Plastic armored temperature cable | 3.0 | 400 | −20~85 °C | 27 | It has good coupling with the rock and soil, high sensitivity for temperature, general tensile capacity, and a narrow temperature tolerance range. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, G.; Wang, Z.; Shi, B.; Zhu, W.; Li, T. Research on a Space–Time Continuous Sensing System for Overburden Deformation and Failure during Coal Mining. Sensors 2023, 23, 5947. https://doi.org/10.3390/s23135947

Cheng G, Wang Z, Shi B, Zhu W, Li T. Research on a Space–Time Continuous Sensing System for Overburden Deformation and Failure during Coal Mining. Sensors. 2023; 23(13):5947. https://doi.org/10.3390/s23135947

Chicago/Turabian StyleCheng, Gang, Zhenxue Wang, Bin Shi, Wu Zhu, and Tianbin Li. 2023. "Research on a Space–Time Continuous Sensing System for Overburden Deformation and Failure during Coal Mining" Sensors 23, no. 13: 5947. https://doi.org/10.3390/s23135947

APA StyleCheng, G., Wang, Z., Shi, B., Zhu, W., & Li, T. (2023). Research on a Space–Time Continuous Sensing System for Overburden Deformation and Failure during Coal Mining. Sensors, 23(13), 5947. https://doi.org/10.3390/s23135947