A Deep Learning Method for Rolling Bearing Fault Diagnosis Based on Attention Mechanism and Graham Angle Field

Abstract

1. Introduction

- This method can cover a large amount of feature information, and, in the image conversion process, the rectangular coordinate system is transformed into a polar coordinate system, and the two-dimensional image is regenerated from the converted polar coordinate system image, which can almost completely retain its temporal correlation.

- An improved ResNet50 model based on the attention mechanism is proposed to extract the temporal and spatial features of the image, and, finally, a classifier is used to classify and diagnose faults.

- On the basis of ablation experiment verification, it is proved that the method has excellent fault diagnosis performance.

2. Literature Review

Data Feature Extraction in Fault Diagnosis

3. Materials and Methods

3.1. GAF Timing Recoding

- Step 1:

- Normalization

- Step 2:

- Timing Recoding

- Step 3:

- Image Conversion

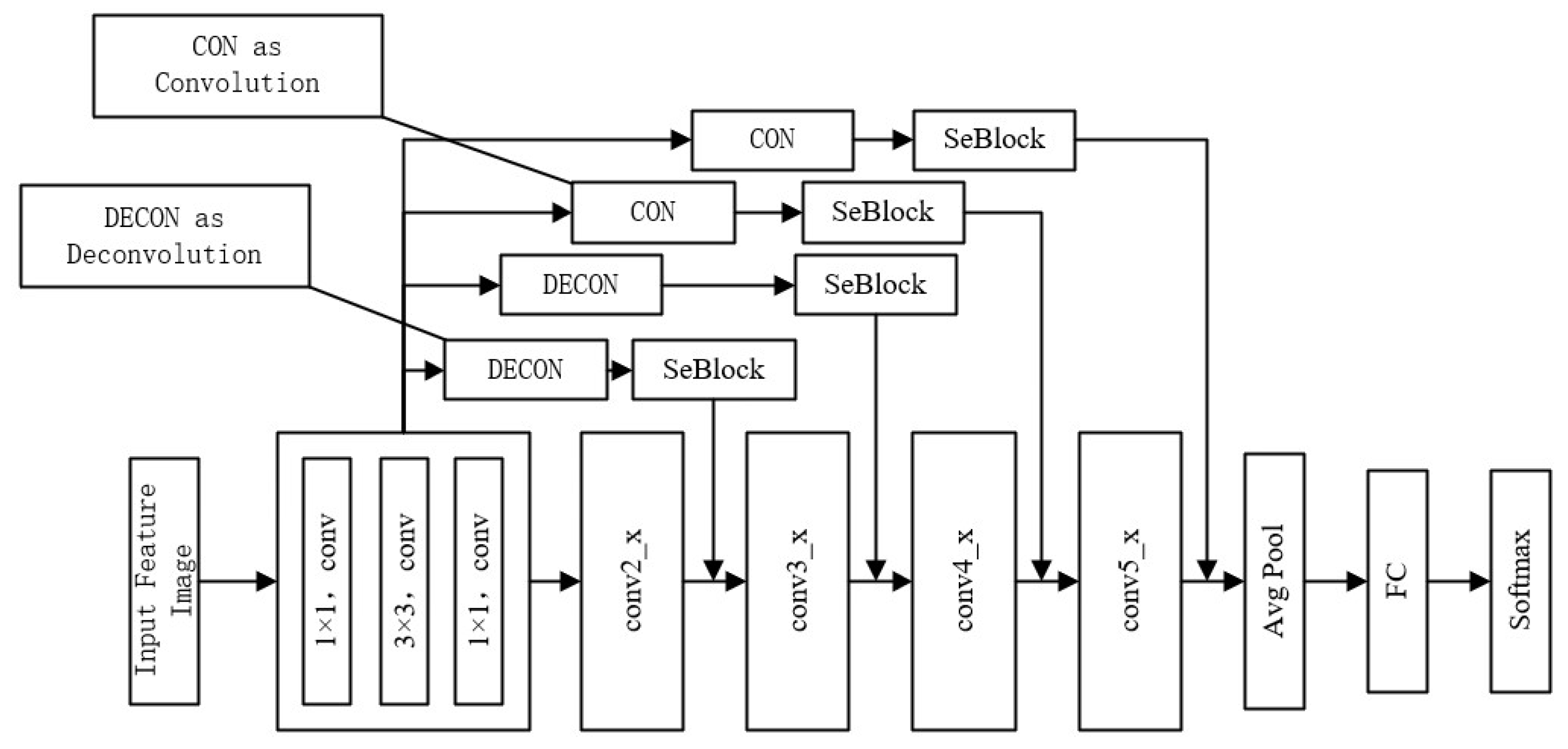

3.2. Improved ResNet50 Model Based on Attention Mechanism

3.3. SeBlock Module Based on Attention Mechanism

3.4. Classification Network Model Based on Attention Mechanism

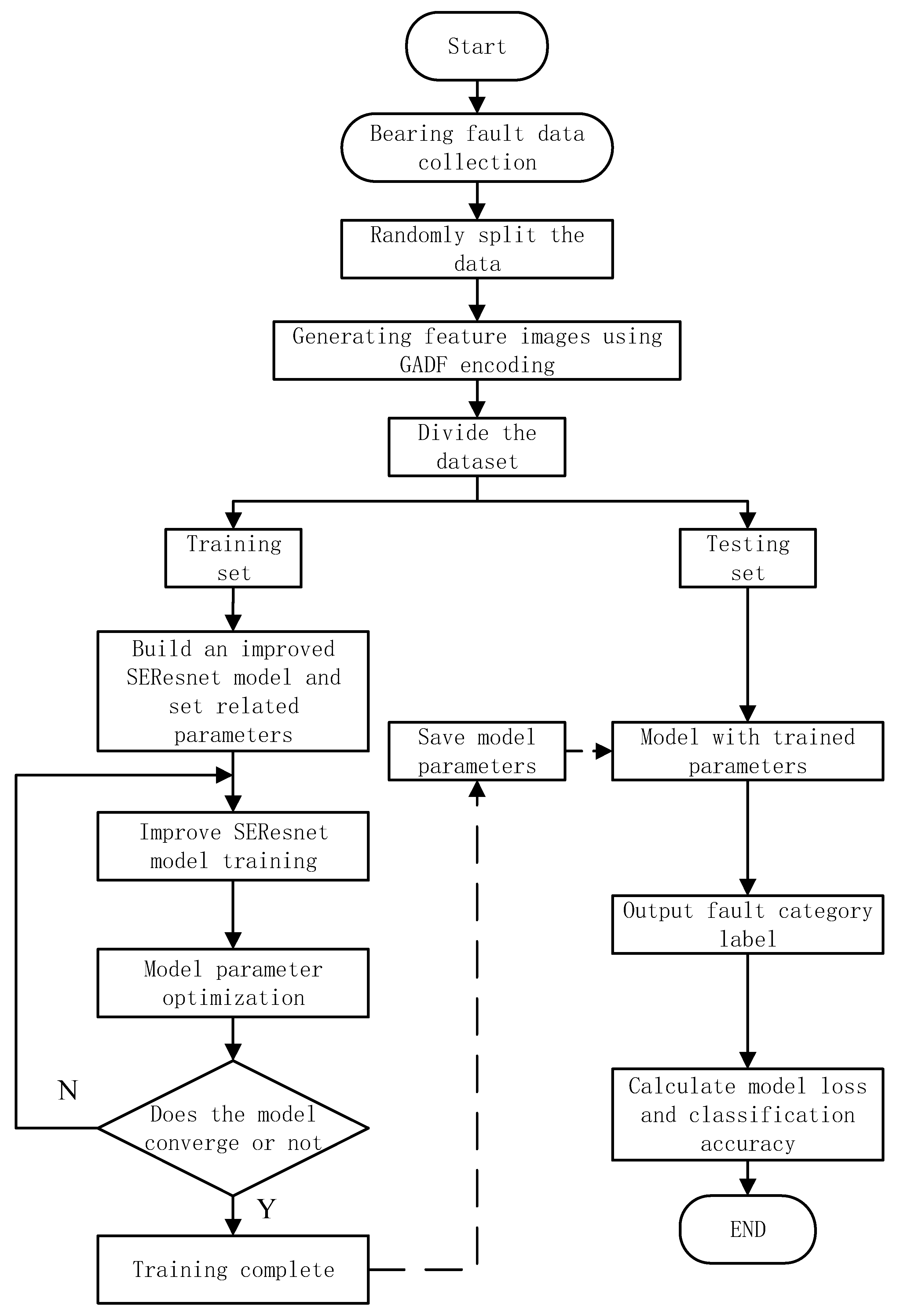

3.5. Fault Diagnosis Method of Rolling Bearing Based on GAF-SEResNet

- Step 1:

- Collect the original vibration signal of the bearing and generate corresponding data files for model training.

- Step 2:

- The collected signal is divided into data according to the sample length by overlapping sampling, and corresponding data samples are generated.

- Step 3:

- Reconstruct the generated data sample into a two-dimensional feature image according to the GADF encoding method, and construct an image dataset accordingly.

- Step 4:

- Divide the feature image dataset into a training set and a test set according to a certain ratio.

- Step 5:

- Build an improved SEResNet neural network model and initialize network parameters.

- Step 6:

- Input the training set into the model for pre-training, and optimize the model parameters until the optimal value is reached, then proceed to Step 7, otherwise re-execute Step 5, adjust the model parameters until the optimization effect reaches the best, and save the current model.

- Step 7:

- Input the test set data into the trained improved SEResNet model for rolling bearing fault diagnosis, and then obtain the bearing fault classification result and classification accuracy.

4. Experimental Research and Analysis

4.1. Experimental Dataset

4.1.1. Data Processing

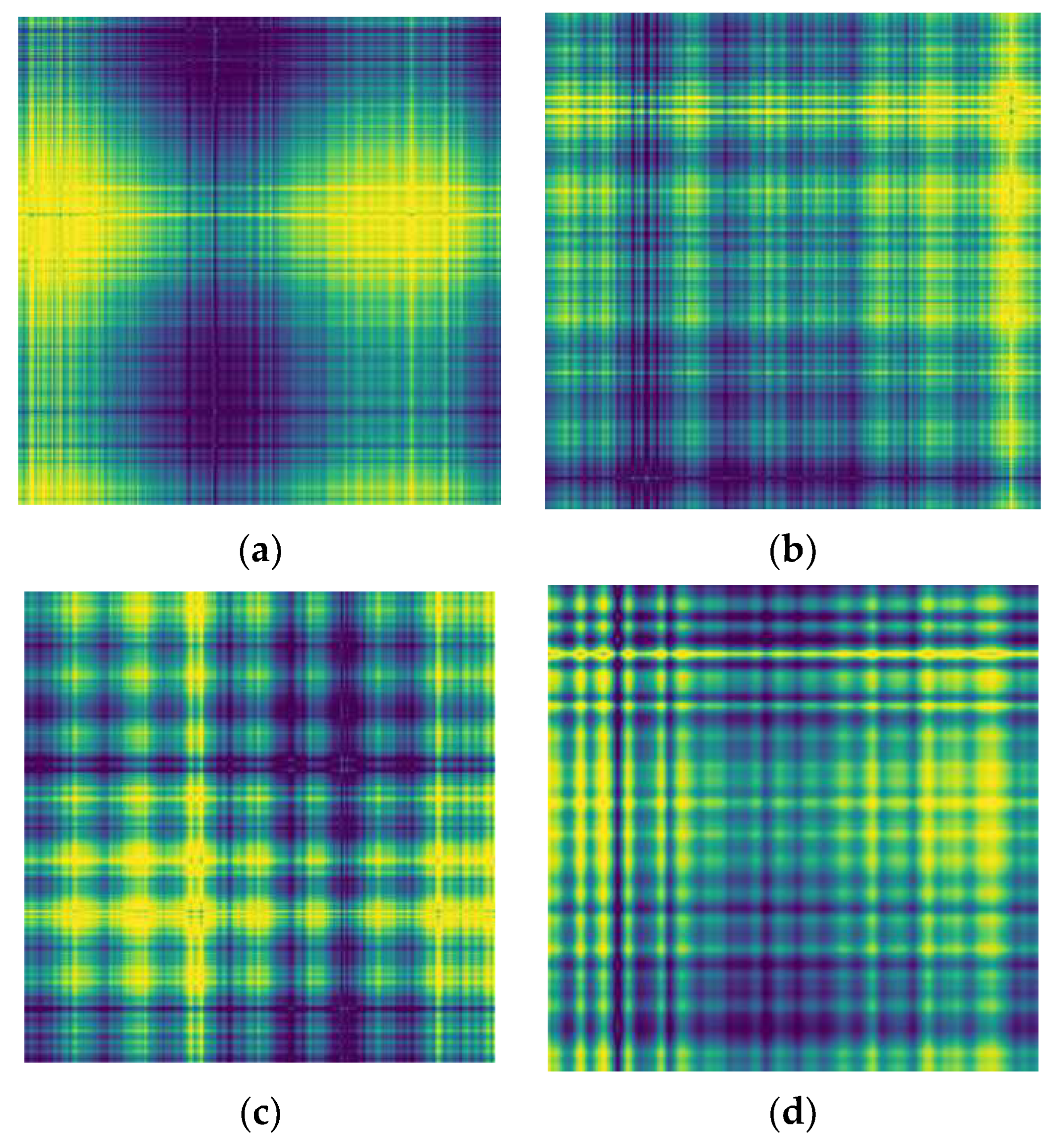

4.1.2. Feature Image Generation

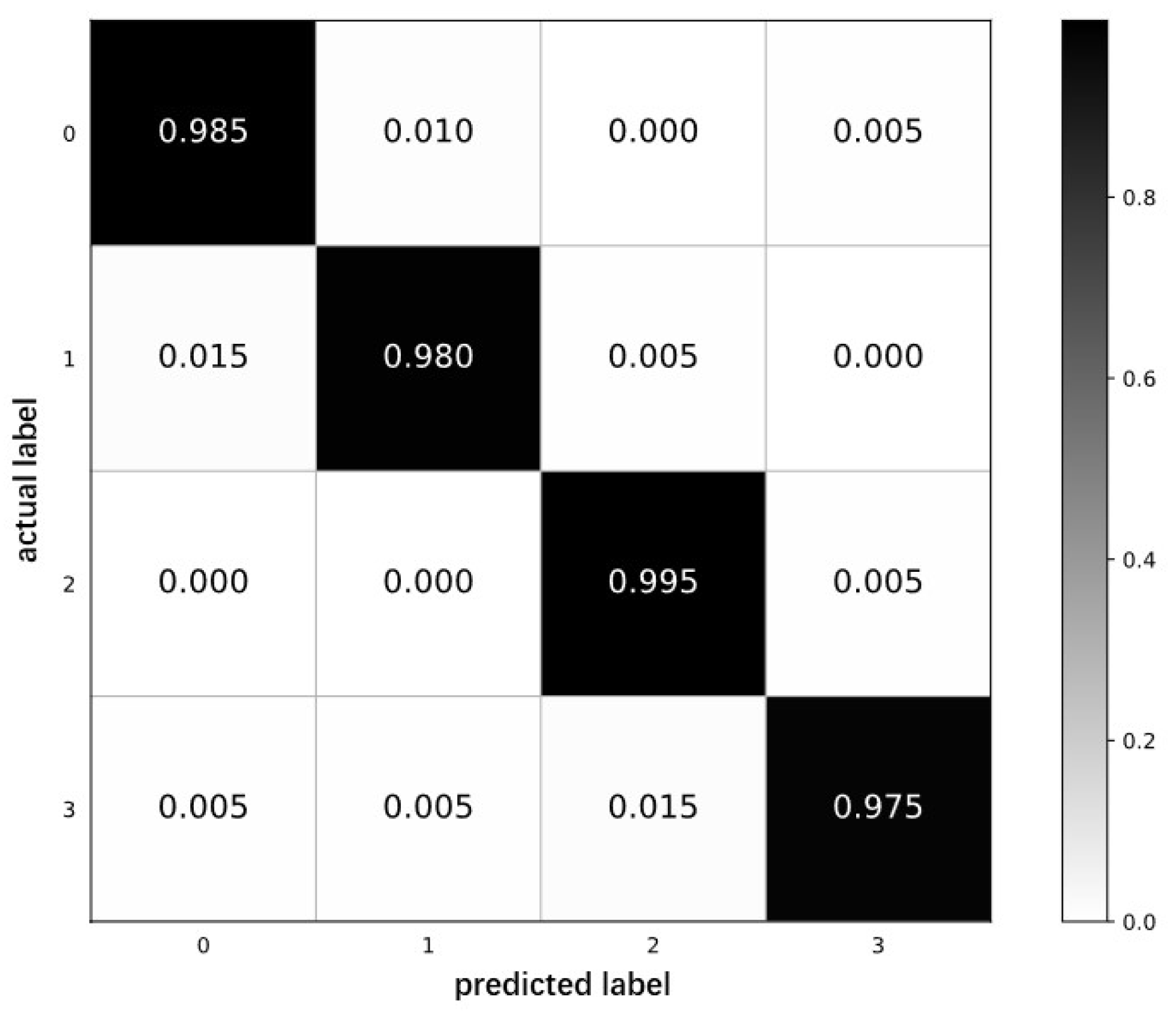

4.2. Model Training and Analysis of Training Results

4.3. Comparative Analysis with Other Image Coding Methods

4.4. Comparative Analysis with Other Algorithm Models

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rai, A.; Upadhyay, S.H. A review on signal processing techniques utilized in the fault diagnosis of rolling element bearings. Tribol. Int. 2016, 96, 289–306. [Google Scholar] [CrossRef]

- Lu, C.; Wang, Z.-Y.; Qin, W.-L.; Ma, J. Fault diagnosis of rotary machinery components using a stacked denoising autoencoder-based health state identification. Signal Process. 2017, 130, 377–388. [Google Scholar] [CrossRef]

- Tao, H.; Wang, P.; Chen, Y.; Stojanovic, V.; Yang, H. An unsupervised fault diagnosis method for rolling bearing using STFT and generative neural networks. J. Frankl. Inst. 2020, 357, 7286–7307. [Google Scholar] [CrossRef]

- Ren, Z.; Zhou, S.; Chunhui, E.; Gong, M.; Li, B.; Wen, B. Crack fault diagnosis of rotor systems using wavelet transforms. Comput. Electr. Eng. 2015, 45, 33–41. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, L.; Wang, Q.; An, G.; Guo, M.; Lian, H. Application to induction motor faults diagnosis of the amplitude recovery method combined with FFT. Mech. Syst. Signal Process. 2010, 24, 2961–2971. [Google Scholar] [CrossRef]

- Sun, M.; Wang, H.; Liu, P.; Huang, S.; Fan, P. A sparse stacked denoising autoencoder with optimized transfer learning applied to the fault diagnosis of rolling bearings. Measurement 2019, 146, 305–314. [Google Scholar] [CrossRef]

- Unal, M.; Onat, M.; Demetgul, M.; Kucuk, H. Fault diagnosis of rolling bearings using a genetic algorithm optimized neural network. Measurement 2014, 58, 187–196. [Google Scholar] [CrossRef]

- Tang, G.; Wang, Y.; Huang, Y.; Wang, H. Multiple time-frequency curve classification for tacho-less and resampling-less compound bearing fault detection under time-varying speed conditions. IEEE Sens. J. 2020, 21, 5091–5101. [Google Scholar] [CrossRef]

- Jin, Z.; He, D.; Wei, Z. Intelligent fault diagnosis of train axle box bearing based on parameter optimization VMD and improved DBN. Eng. Appl. Artif. Intell. 2022, 110, 104713. [Google Scholar] [CrossRef]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A new convolutional neural network-based data-driven fault diagnosis method. IEEE Trans. Ind. Electron. 2017, 65, 5990–5998. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Li, Q. Intelligent fault diagnosis of rolling bearings under imbalanced data conditions using attention-based deep learning method. Measurement 2022, 189, 110500. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, F.; Chen, W.; Jiang, Y.; Song, D. Fault state recognition of rolling bearing based fully convolutional network. Comput. Sci. Eng. 2018, 21, 55–63. [Google Scholar] [CrossRef]

- Ciregan, D.; Meier, U.; Schmidhuber, J. Multi-column deep neural networks for image classification. In Proceedings of the 2012 IEEE Conference on Computer Vision and Pattern Recognition, Providence, RI, USA, 16–21 June 2012; pp. 3642–3649. [Google Scholar]

- Blum, A.L.; Langley, P. Selection of relevant features and examples in machine learning. Artif. Intell. 1997, 97, 245–271. [Google Scholar] [CrossRef]

- Verstraete, D.; Ferrada, A.; Droguett, E.L.; Meruane, V.; Modarres, M. Deep learning enabled fault diagnosis using time-frequency image analysis of rolling element bearings. Shock. Vib. 2017, 2017, 5067651. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- Shuang, L.; Meng, L. Bearing fault diagnosis based on PCA and SVM. In Proceedings of the 2007 International Conference on Mechatronics and Automation, Harbin, China, 5–8 August 2007; pp. 3503–3507. [Google Scholar]

- Jia, F.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal Process. 2016, 72, 303–315. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Wang, F.; Zhao, H. An enhancement deep feature fusion method for rotating machinery fault diagnosis. Knowl.-Based Syst. 2017, 119, 200–220. [Google Scholar] [CrossRef]

- Liu, H.; Li, L.; Ma, J. Rolling bearing fault diagnosis based on STFT-deep learning and sound signals. Shock. Vib. 2016, 2016, 6127479. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Guo, L.; Lin, J.; Xing, S. A neural network constructed by deep learning technique and its application to intelligent fault diagnosis of machines. Neurocomputing 2018, 272, 619–628. [Google Scholar] [CrossRef]

- Guo, X.; Chen, L.; Shen, C. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Measurement 2016, 93, 490–502. [Google Scholar] [CrossRef]

- Zhang, W.; Peng, G.; Li, C.; Chen, Y.; Zhang, Z. A new deep learning model for fault diagnosis with good anti-noise and domain adaptation ability on raw vibration signals. Sensors 2017, 17, 425. [Google Scholar] [CrossRef] [PubMed]

- Shao, H.; Jiang, H.; Zhang, X.; Niu, M. Rolling bearing fault diagnosis using an optimization deep belief network. Meas. Sci. Technol. 2015, 26, 115002. [Google Scholar] [CrossRef]

- Chen, Z.; Li, W. Multisensor feature fusion for bearing fault diagnosis using sparse autoencoder and deep belief network. IEEE Trans. Instrum. Meas. 2017, 66, 1693–1702. [Google Scholar] [CrossRef]

- Lu, C.; Wang, Y.; Ragulskis, M.; Cheng, Y. Fault diagnosis for rotating machinery: A method based on image processing. PLoS ONE 2016, 11, e0164111. [Google Scholar] [CrossRef] [PubMed]

- Yin, H.; Li, Z.; Zuo, J.; Liu, H.; Yang, K.; Li, F. Wasserstein generative adversarial network and convolutional neural network (WG-CNN) for bearing fault diagnosis. Math. Probl. Eng. 2020, 2020, 2604191. [Google Scholar] [CrossRef]

- Wang, Z.; Oates, T. Imaging time-series to improve classification and imputation. arXiv 2015, arXiv:1506.00327. [Google Scholar]

- Setiawan, F.; Yahya, B.N.; Lee, S.L. Deep activity recognition on imaging sensor data. Electron. Lett. 2019, 55, 928–931. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Hu, J.; Shen, L.; Sun, G. Squeeze-and-excitation networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–22 June 2018; pp. 7132–7141. [Google Scholar]

- Smith, W.A.; Randall, R.B. Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mech. Syst. Signal Process. 2015, 64, 100–131. [Google Scholar] [CrossRef]

- Tang, X.; Xu, Z.; Wang, Z. A novel fault diagnosis method of rolling bearing based on integrated vision transformer model. Sensors 2022, 22, 3878. [Google Scholar] [CrossRef]

- Fan, H.-W.; Ma, N.-G.; Zhang, X.-H.; Xue, C.-Y.; Ma, J.-T.; Yan, Y. New intelligent fault diagnosis approach of rolling bearing based on improved vibration gray texture image and vision transformer. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 09544062221085871. [Google Scholar]

- Han, K.; Wang, Y.; Tian, Q.; Guo, J.; Xu, C.; Xu, C. Ghostnet: More features from cheap operations. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 13–19 June 2020; pp. 1580–1589. [Google Scholar]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

| Serial | Layout | Output Dimension | Hierarchical Design |

|---|---|---|---|

| 1 | Input | - | |

| 2 | Conv1 | ||

| 3 | BN, ReLU | - | |

| 4 | Max Pool | ||

| 5 | Conv2_x | ||

| 6 | Conv3_x | ||

| 7 | Conv4_x | ||

| 8 | Conv5_x | ||

| 9 | ReLU | - | |

| 10 | Avg pool | ||

| 11 | Fc | - | |

| 12 | softmax | - |

| Fault Location | Damage Diameter/mm | Training Sample | Test Sample | Label |

|---|---|---|---|---|

| Normal | 0 | 800 | 200 | 0 |

| Inner Circle | 0.1778 | 800 | 200 | 1 |

| Outer Ring | 0.1778 | 800 | 200 | 2 |

| Rolling Element | 0.1778 | 800 | 200 | 3 |

| Layout | Number of Parameters/Pieces | Training Time/ms | Accuracy/% |

|---|---|---|---|

| TFR | 25,046,021 | 14,285 | 96.36 |

| GI | 24,629,431 | 14,325 | 95.42 |

| GADF | 25,328,635 | 13,862 | 98.37 |

| Method | Number of Parameters/Pieces | Training Time/ms | Accuracy/% |

|---|---|---|---|

| 1DCNN + Signal | 15,467,261 | 6458 | 78.56 |

| GADF + VGG16 | 136,145,681 | 34,436 | 85.72 |

| GADF + GhostNet | 4,724,368 | 3524 | 91.54 |

| GADF + ResNet50 | 26,541,072 | 15,241 | 93.22 |

| GADF-SEResNet | 25,328,635 | 13,862 | 98.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Wang, K.; Chen, C.; Ji, W. A Deep Learning Method for Rolling Bearing Fault Diagnosis Based on Attention Mechanism and Graham Angle Field. Sensors 2023, 23, 5487. https://doi.org/10.3390/s23125487

Lu J, Wang K, Chen C, Ji W. A Deep Learning Method for Rolling Bearing Fault Diagnosis Based on Attention Mechanism and Graham Angle Field. Sensors. 2023; 23(12):5487. https://doi.org/10.3390/s23125487

Chicago/Turabian StyleLu, Jingyu, Kai Wang, Chen Chen, and Weixi Ji. 2023. "A Deep Learning Method for Rolling Bearing Fault Diagnosis Based on Attention Mechanism and Graham Angle Field" Sensors 23, no. 12: 5487. https://doi.org/10.3390/s23125487

APA StyleLu, J., Wang, K., Chen, C., & Ji, W. (2023). A Deep Learning Method for Rolling Bearing Fault Diagnosis Based on Attention Mechanism and Graham Angle Field. Sensors, 23(12), 5487. https://doi.org/10.3390/s23125487