Magnetoresistance and Magnetic Relaxation of La-Sr-Mn-O Films Grown on Si/SiO2 Substrate by Pulsed Injection MOCVD

Abstract

1. Introduction

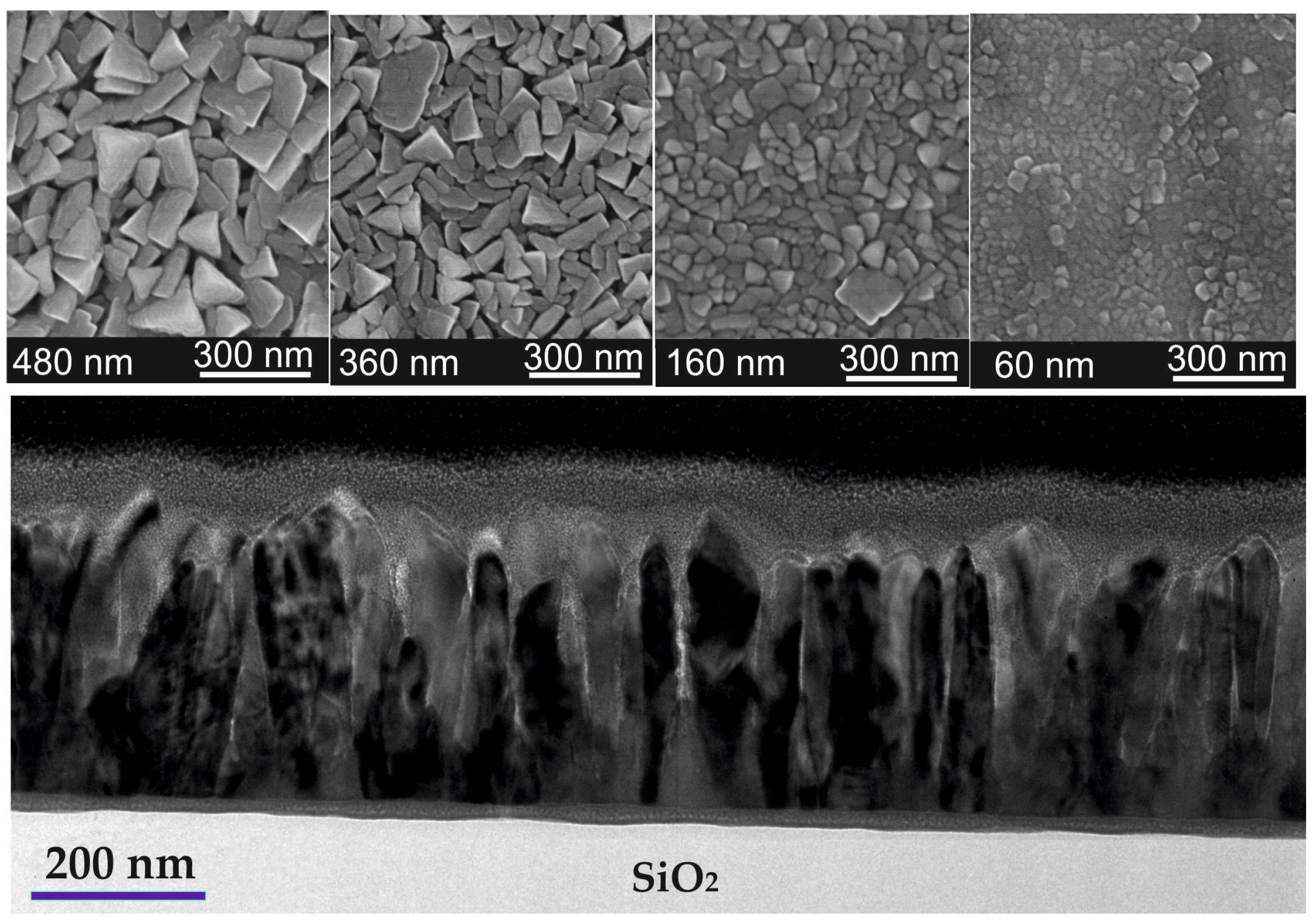

2. Materials and Methods

2.1. Film Preparation

2.2. Characterization

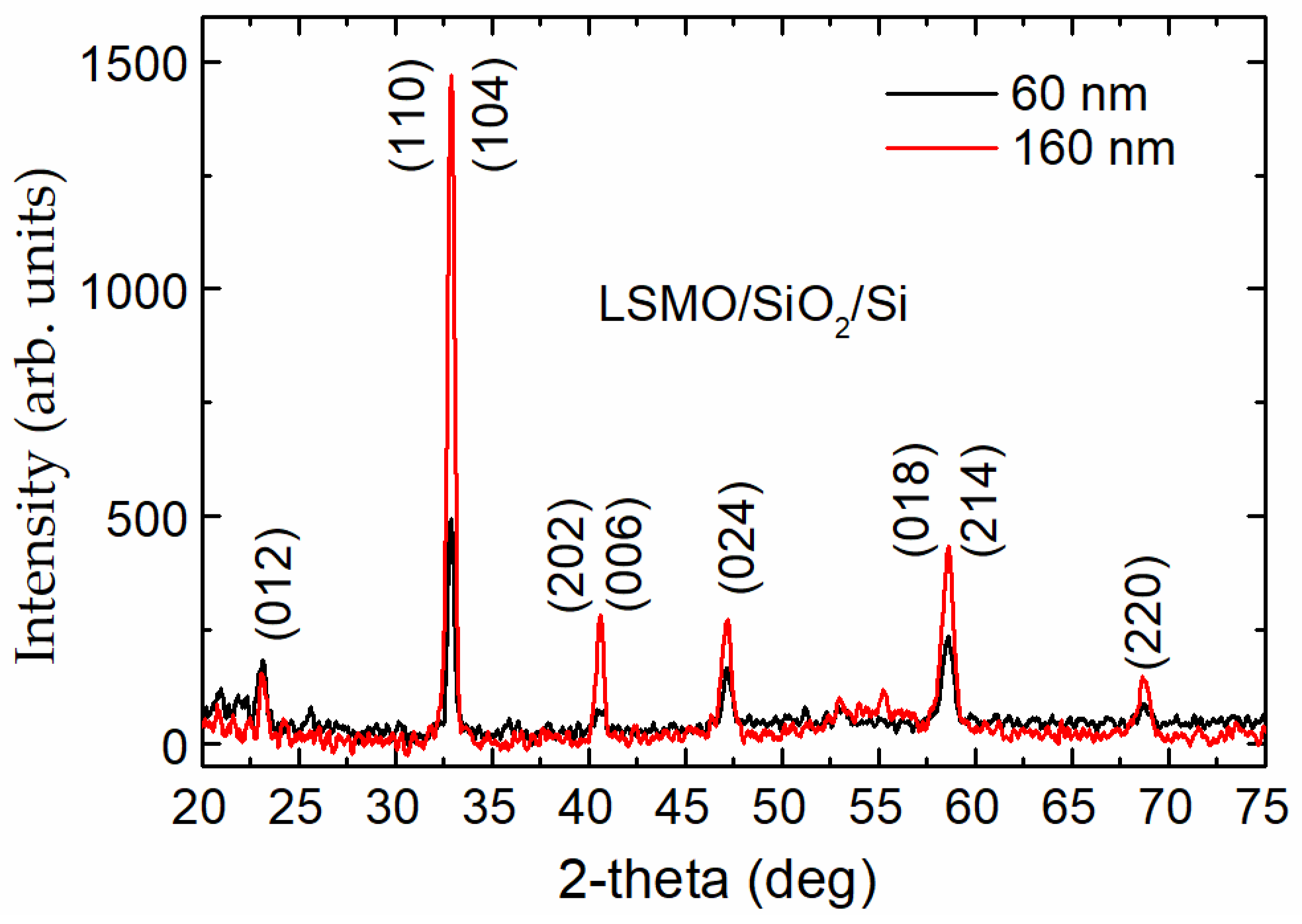

3. Results and Discussion

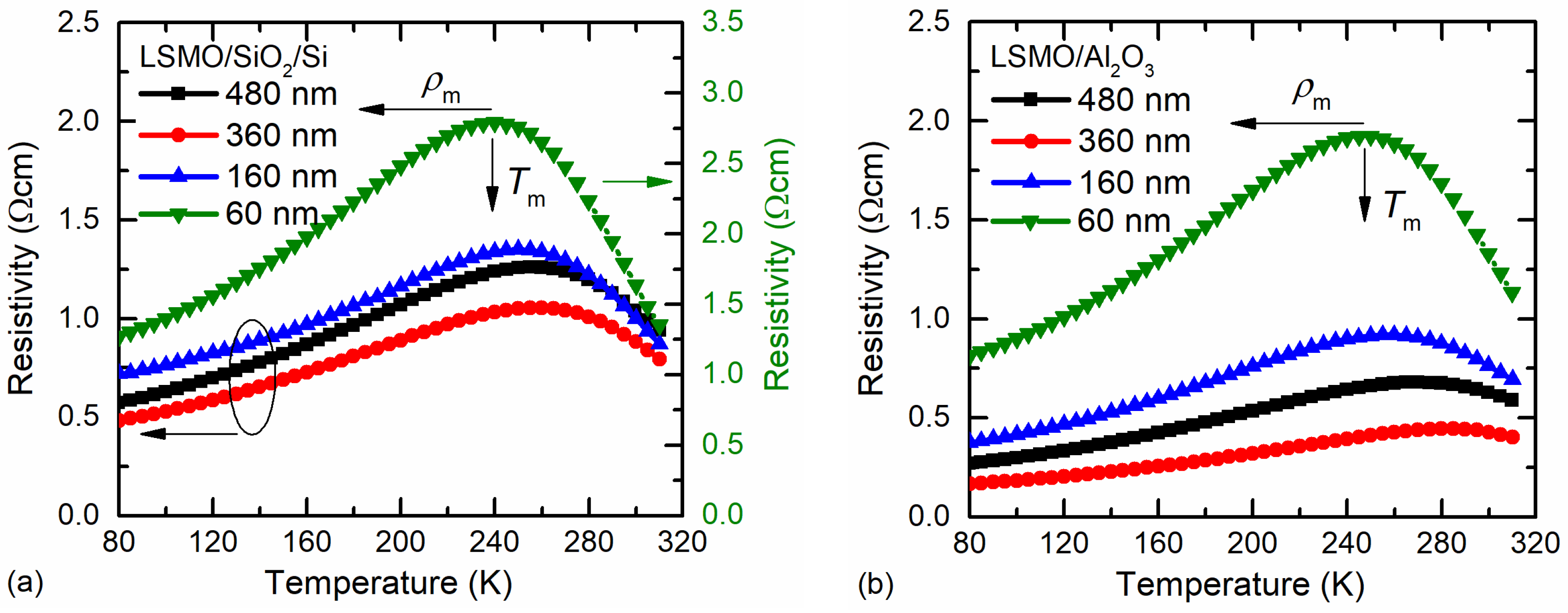

3.1. Resistivity of LSMO/SiO2/Si Films: Comparison with LSMO/Al2O3 Films

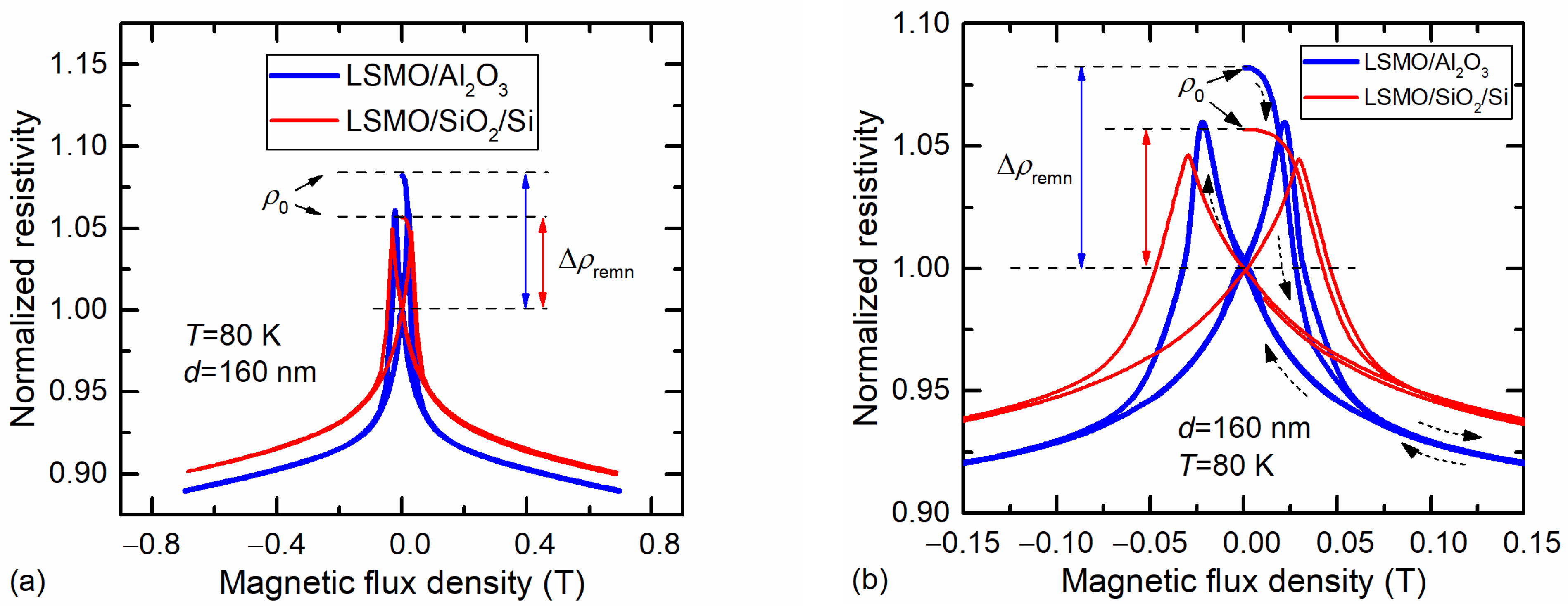

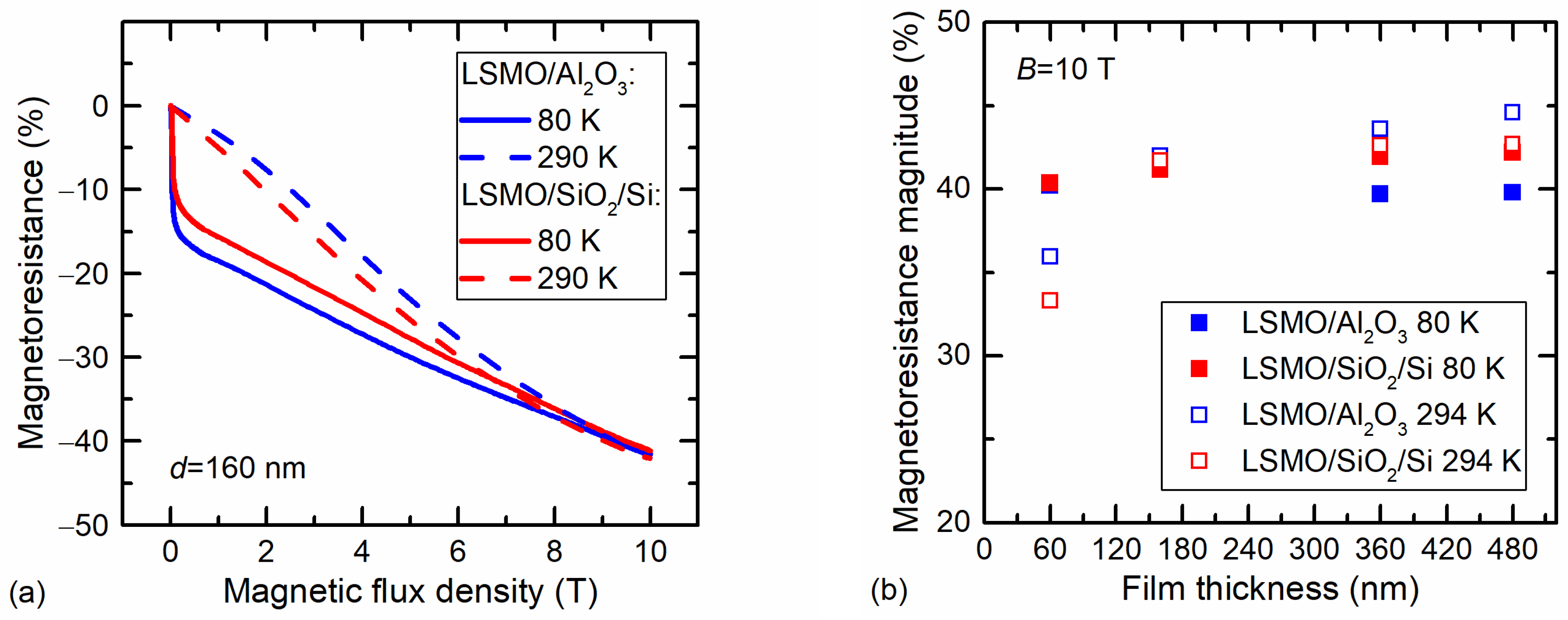

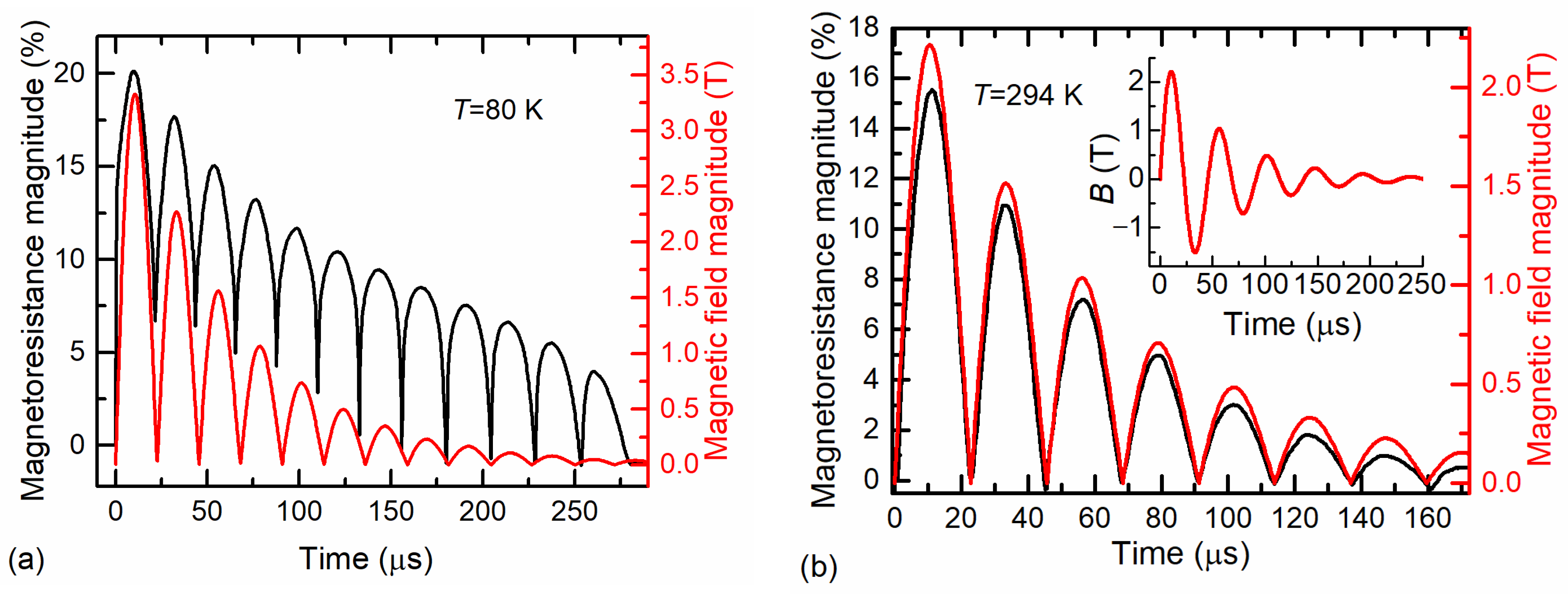

3.2. Magnetoresistance of LSMO Films

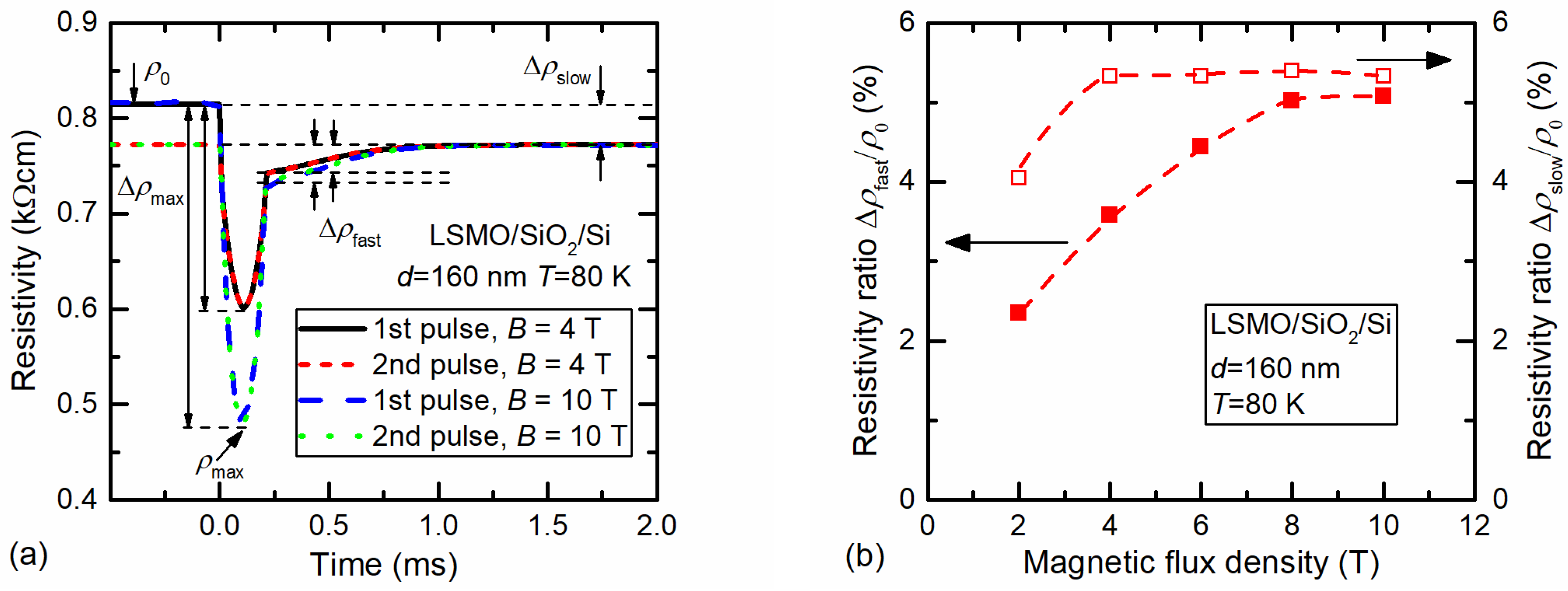

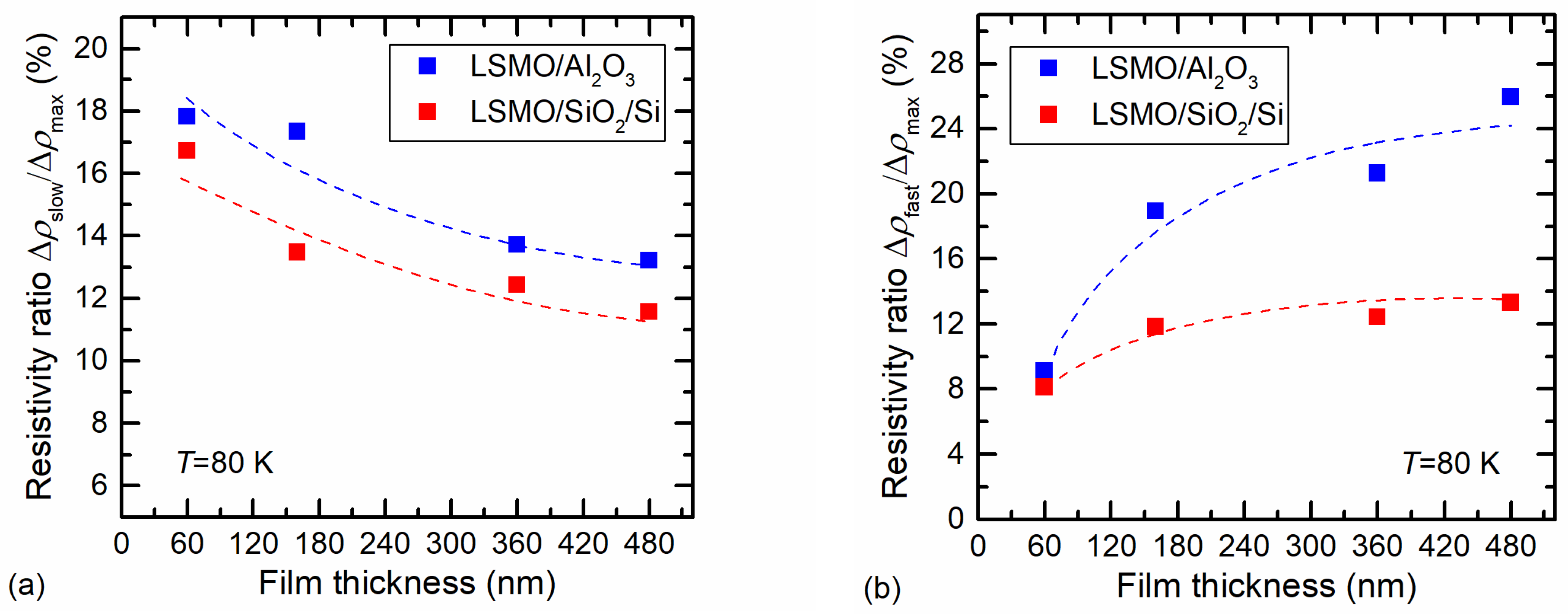

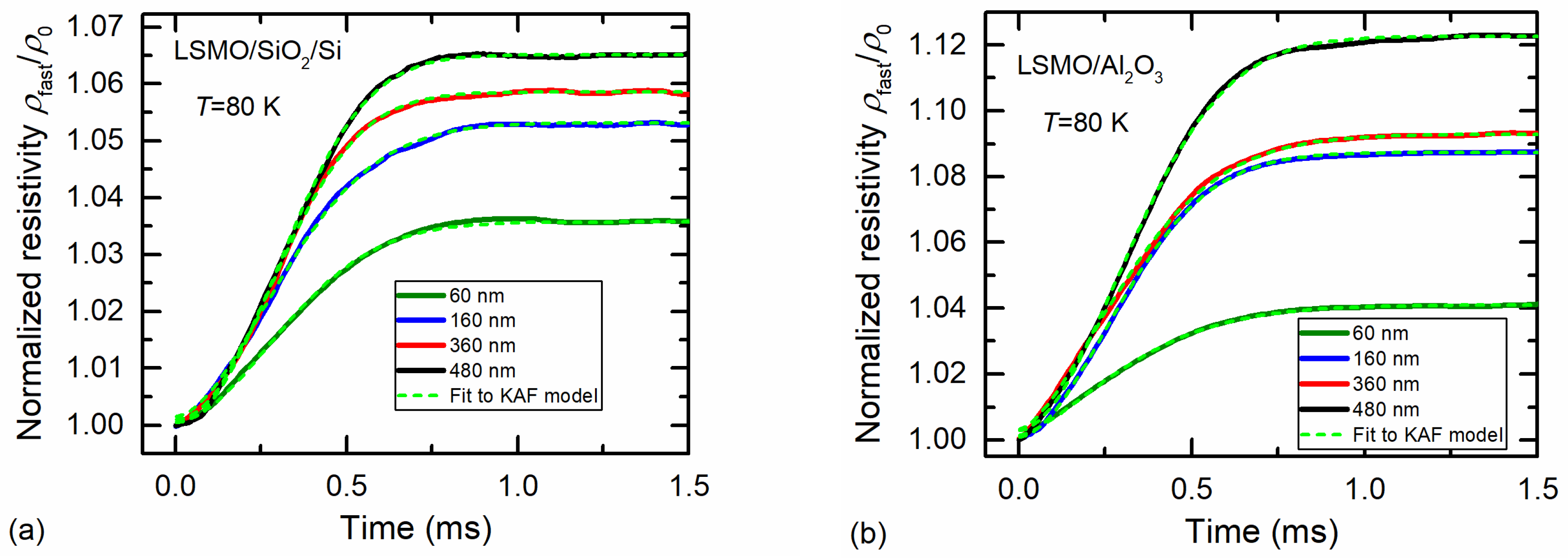

3.3. Resistance Relaxation of LSMO Films

3.4. Testing of Magnetic-Field Sensor Based on LSMO/SiO2/Si Film

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jogschies, L.; Klaas, D.; Kruppe, R.; Rittinger, J.; Taptimthong, P.; Wienecke, A.; Rissing, L.; Wurz, M.C. Recent developments of magnetoresistive sensors for industrial applications. Sensors 2015, 15, 28665. [Google Scholar] [CrossRef] [PubMed]

- Žurauskienė, N. Engineering of Advanced Materials for High Magnetic Field Sensing: A Review. Sensors 2023, 23, 2939. [Google Scholar] [CrossRef] [PubMed]

- Yole Intelligence. Magnetic Sensor 2022 Report; Yole Group: Lyon, France, 2022; Available online: https://www.yolegroup.com/product/report/magnetic-sensor-2022/# (accessed on 16 March 2023).

- Zheng, C.; Zhu, K.; Cardoso de Freitas, S.; Chang, J.-Y.; Davies, J.E.; Eames, P.; Freitas, P.P.; Kazakova, O.; Kim, C.G.; Leung, C.-W.; et al. Magnetoresistive sensor development roadmap (non-recording applications). IEEE Trans. Magn. 2019, 55, 0800130. [Google Scholar] [CrossRef]

- Battesti, R.; Beard, J.; Böser, S.; Bruyant, N.; Budker, D.; Crooker, S.A.; Daw, E.J.; Flambaum, V.V.; Inada, T.; Irastorza, I.G.; et al. High Magnetic Fields for Fundamental Physics. Phys. Rep. 2018, 765–766, 1–39. [Google Scholar] [CrossRef]

- Coey, J.M.D.; Viret, M.; von Molnár, S. Mixed-Valence Manganites. Adv. Phys. 2009, 58, 571–697. [Google Scholar] [CrossRef]

- Zhao, B.; Hu, X.; Dong, F.; Wang, Y.; Wang, H.; Tan, W.; Huo, D. The Magnetic Properties and Magnetocaloric Effect of Pr0.7Sr0.3MnO3 Thin Film Grown on SrTiO3 Substrate. Materials 2022, 16, 75. [Google Scholar] [CrossRef]

- Israel, C.; Calderón, M.J.; Mathur, N.D. The Current Spin on Manganites. Mater. Today 2007, 10, 24–32. [Google Scholar] [CrossRef]

- Dong, C.; Chen, R.; Liu, Y.; Liu, C.; Zhu, H.; Ke, J.; Liu, W.; Yang, M.; Wang, J. Field-Induced Magnetic Phase Transitions and Rich Phase Diagram of HoMnO3 Single Crystal. Crystals 2019, 9, 419. [Google Scholar] [CrossRef]

- Millis, A.J.; Littlewood, P.B.; Shraiman, B.I. Double Exchange Alone Does Not Explain the Resistivity of La1−XSrxMnO3. Phys. Rev. Lett. 1995, 74, 5144–5147. [Google Scholar] [CrossRef]

- Ziese, M. Extrinsic Magnetotransport Phenomena in Ferromagnetic Oxides. Rep. Prog. Phys. 2002, 65, 143–249. [Google Scholar] [CrossRef]

- Pękała, M.; Pękała, K.; Drozd, V. Magnetotransport Study of Nanocrystalline and Polycrystalline Manganites La0.8Sr0.2MnO3 in High Magnetic Fields. J. Appl. Phys. 2015, 117, 175902. [Google Scholar] [CrossRef]

- Zurauskiene, N.; Balevicius, S.; Stankevic, V.; Kersulis, S.; Schneider, M.; Liebfried, O.; Plausinaitiene, V.; Abrutis, A. B-Scalar Sensor Using CMR Effect in Thin Polycrystalline Manganite Films. IEEE Trans. Plasma Sci. 2011, 39, 411–416. [Google Scholar] [CrossRef]

- Balevičius, S.; Žurauskienė, N.; Stankevič, V.; Keršulis, S.; Plaušinaitienė, V.; Abrutis, A.; Zherlitsyn, S.; Herrmannsdörfer, T.; Wosnitza, J.; Wolff-Fabris, F. Nanostructured Thin Manganite Films in Megagauss Magnetic Field. Appl. Phys. Lett. 2012, 101, 092407. [Google Scholar] [CrossRef]

- Stankevič, T.; Medišauskas, L.; Stankevič, V.; Balevičius, S.; Žurauskienė, N.; Liebfried, O.; Schneider, M. Pulsed Magnetic Field Measurement System Based on Colossal Magnetoresistance-B-Scalar Sensors for Railgun Investigation. Rev. Sci. Instrum. 2014, 85, 044704. [Google Scholar] [CrossRef] [PubMed]

- Haran, T.L.; Hoffman, R.B.; Lane, S.E. Diagnostic capabilities for electromagnetic railguns. IEEE Trans. Plasma Sci. 2013, 41, 1526–1532. [Google Scholar] [CrossRef]

- Bellmann, J.; Lueg-Althoff, J.; Schulze, S.; Gies, S.; Beyer, E.; Erman Tekkaya, A. Measurement and Analysis Technologies for Magnetic Pulse Welding: Established Methods and New Strategies. Adv. Manuf. 2016, 4, 322–339. [Google Scholar] [CrossRef]

- Sirena, M.; Steren, L.B.; Guimpel, J. Magnetic Relaxation in Bulk and Film Manganite Compounds. Phys. Rev. B 2001, 64, 104409. [Google Scholar] [CrossRef]

- Kozlova, N.; Dörr, K.; Eckert, D.; Handstein, A.; Skourski, Y.; Walter, T.; Müller, K.-H.; Schultz, L. Slow Relaxation of Grain Boundary Resistance in a Ferromagnetic Manganite. J. Appl. Phys. 2003, 93, 8325–8327. [Google Scholar] [CrossRef]

- Žurauskienė, N.; Rudokas, V.; Keršulis, S.; Stankevič, V.; Pavilonis, D.; Plaušinaitienė, V.; Vagner, M.; Balevičius, S. Magnetoresistance and Its Relaxation of Nanostructured La-Sr-Mn-Co-O Films: Application for Low Temperature Magnetic Sensors. J. Magn. Magn. Mater. 2021, 539, 168340. [Google Scholar] [CrossRef]

- Xi, H.; Gao, K.-Z.; Ouyang, J.; Shi, Y.; Yang, Y. Slow Magnetization Relaxation and Reversal in Magnetic Thin Films. J. Phys. Condens. Matter 2008, 20, 295220. [Google Scholar] [CrossRef]

- Bakaul, S.R.; Miao, B.F.; Lin, W.; Hu, W.; David, A.; Ding, H.F.; Wu, T. Domain-Related Origin of Magnetic Relaxation in Compressively Strained Manganite Thin Films. Appl. Phys. Lett. 2012, 101, 012408. [Google Scholar] [CrossRef]

- Williams, G.; Watts, D.C. Non-Symmetrical Dielectric Relaxation Behaviour Arising from a Simple Empirical Decay Function. Trans. Faraday Soc. 1970, 66, 80–85. [Google Scholar] [CrossRef]

- Macdonald, J.R.; Phillips, J.C. Topological Derivation of Shape Exponents for Stretched Exponential Relaxation. J. Chem. Phys. 2005, 122, 074510. [Google Scholar] [CrossRef]

- Costa, T.; Cardoso, F.A.; Germano, J.; Freitas, P.P.; Piedade, M.S. A CMOS Front-End with Integrated Magnetoresistive Sensors for Biomolecular Recognition Detection Applications. IEEE Trans. Biomed. Circuits Syst. 2017, 11, 988–1000. [Google Scholar] [CrossRef]

- Khan, M.A.; Sun, J.; Li, B.; Przybysz, A.; Kosel, J. Magnetic sensors-A review and recent technologies. Eng. Res. Express 2021, 3, 022005. [Google Scholar] [CrossRef]

- Camacho, R.; Sánchez Llamazares, J.L.; Curiel, M.; Sánchez Llamazares, J.L.; Siqueiros, J.M.; Raymond Herrera, O. Superparamagnetic State in La0.7Sr0.3MnO3 Thin Films Obtained by Rf-Sputtering. Sci. Rep. 2020, 10, 2568. [Google Scholar] [CrossRef] [PubMed]

- Shim, I.-B.; Kim, C.-S.; Park, K.-T.; Oh, Y.-J. Role of intermediate layer for La2/3Sr1/3MnO3/SiO2/Si(1 0 0) granular thin films. J. Magn. Magn. Mater. 2001, 226–230, 1672–1674. [Google Scholar] [CrossRef]

- Kang, Y.-M.; Ulyanov, A.N.; Lee, S.-Y.; Yoo, S.-I. Low field magnetoresistance properties of (La0.75Sr0.25)1.05Mn0.95O3 polycrystalline thin films on a-SiO2/Si substrates prepared by ex-situ solid phase crystallization. Met. Mater. Int. 2011, 17, 1045–1053. [Google Scholar] [CrossRef]

- Zurauskiene, N.; Stankevic, V.; Kersulis, S.; Vagner, M.; Plausinaitiene, V.; Dobilas, J.; Vasiliauskas, R.; Skapas, M.; Koliada, M.; Pietosa, J.; et al. Enhancement of Room-Temperature Low-Field Magnetoresistance in Nanostructured Lanthanum Manganite Films for Magnetic Sensor Applications. Sensors 2022, 22, 4004. [Google Scholar] [CrossRef]

- Lukose, R.; Plausinaitiene, V.; Vagner, M.; Zurauskiene, N.; Kersulis, S.; Kubilius, V.; Motiejuitis, K.; Knasiene, B.; Stankevic, V.; Saltyte, Z.; et al. Relation between Thickness, Crystallite Size and Magnetoresistance of Nanostructured La1−xSrxMnyO3±δ Films for Magnetic Field Sensors. Beilstein J. Nanotechnol. 2019, 10, 256–261. [Google Scholar] [CrossRef]

- Stankevič, V.; Keršulis, S.; Dilys, J.; Bleizgys, V.; Viliūnas, M.; Vertelis, V.; Maneikis, A.; Rudokas, V.; Plaušinaitienė, V.; Žurauskienė, N. Measurement System for Short-Pulsed Magnetic Fields. Sensors 2023, 23, 1435. [Google Scholar] [CrossRef] [PubMed]

- Zurauskiene, N.; Balevicius, S.; Stankevic, V.; Kersulis, S.; Klimantavicius, J.; Plausinaitiene, V.; Kubilius, V.; Skapas, M.; Juskenas, R.; Navickas, R. Magnetoresistive Properties of Thin Nanostructured Manganite Films Grown by Metalorganic Chemical Vapour Deposition onto Glass-Ceramics Substrates. J. Mater. Sci. 2018, 53, 12996–13009. [Google Scholar] [CrossRef]

- Stankevic, V.; Zurauskiene, N.; Kersulis, S.; Plausinaitiene, V.; Lukose, R.; Klimantavicius, J.; Tolvaišienė, S.; Skapas, M.; Selskis, A.; Balevicius, S. Nanostructured Manganite Films Grown by Pulsed Injection MOCVD: Tuning Low- and High-Field Magnetoresistive Properties for Sensors Applications. Sensors 2022, 22, 605. [Google Scholar] [CrossRef] [PubMed]

- Grainys, A.; Novickij, J.; Stankevič, T.; Stankevič, V.; Novickij, V.; Žurauskienė, N. Single Pulse Calibration of Magnetic Field Sensors Using Mobile 43 KJ Facility. Meas. Sci. Rev. 2015, 15, 244–247. [Google Scholar] [CrossRef]

- Zurauskiene, N.; Pavilonis, D.; Balevicius, S.; Stankevic, V.; Maneikis, A.; Plausinaitiene, V.; Novickij, J. Fast Resistance Relaxation in Nanostructured La–Ca–Mn–O Films in Pulsed Magnetic Fields. IEEE Trans. Plasma Sci. 2015, 43, 3445–3450. [Google Scholar] [CrossRef]

- Hwang, H.Y.; Cheong, S.-W.; Ong, N.P.; Batlogg, B. Spin-Polarized Intergrain Tunneling inLa2/3Sr1/3MnO3. Phys. Rev. Lett. 1996, 77, 2041–2044. [Google Scholar] [CrossRef]

- Lee, S.; Hwang, H.Y.; Shraiman, B.I.; Ratcliff, W.D., II; Cheong, S.-W. Intergrain magnetoresistance via second-order tunneling in perovskite manganites. Phys. Rev. Lett. 1999, 82, 4508–4511. [Google Scholar] [CrossRef]

- Li, J.; Wang, P.; Xiang, J.Y.; Zhu, X.H.; Peng, W.; Chen, Y.F.; Zheng, D.N.; Li, Z.W. Large Low-Field Magnetoresistance Observed in Twinned La2∕3Ca1∕3MnO3 Thin Films Epitaxially Grown on Yttria-Stabilized Zirconia-Buffered Silicon on Insulator Substrates. Appl. Phys. Lett. 2005, 86, 112514. [Google Scholar] [CrossRef]

- Wagner, P.; Gordon, I.; Trappeniers, L.; Vanacken, J.; Herlach, F.; Moshchalkov, V.V.; Bruynseraede, Y. Spin Dependent Hopping and Colossal Negative Magnetoresistance in EpitaxialNd0.52Sr0.48MnO3 Films in Fields up to 50 T. Phys. Rev. Lett. 1998, 81, 3980–3983. [Google Scholar] [CrossRef]

- Zurauskiene, N.; Balevicius, S.; Pavilonis, D.; Stankevic, V.; Plausinaitiene, V.; Zherlitsyn, S.; Herrmannsdorfer, T.; Law, J.M.; Wosnitza, J. Magnetoresistance and Resistance Relaxation of Nanostructured La-Ca-MnO Films in Pulsed Magnetic Fields. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Kolmogorov, A. On the Statistical Theory of Metal Crystallization. Izv. Akad. Nauk. SSSR Ser. Mat. 1937, 1, 335–360. [Google Scholar]

- Avrami, M. Kinetics of Phase Change. II Transformation-time Relations for Random Distribution of Nuclei. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Fatuzzo, E. Theoretical Considerations on the Switching Transient in Ferroelectrics. Phys. Rev. 1962, 127, 1999–2005. [Google Scholar] [CrossRef]

- Zurauskiene, N.; Juskenas, R.; Pavilonis, D.; Klimantavicius, J.; Balevicius, S.; Stankevic, V.; Vasiliauskas, R.; Plausinaitiene, V.; Abrutis, A.; Skapas, M. Magnetoresistance Relaxation Anisotropy of Nanostructured La-Sr(Ca)-Mn-O Films Induced by High-Pulsed Magnetic Fields. IEEE Trans. Plasma Sci. 2017, 45, 2773–2779. [Google Scholar] [CrossRef]

| Substrate | Film Thickness, nm | ρm, Ω cm | Tm, K |

|---|---|---|---|

| Si/SiO2 | 60 | 2.79 | 240 |

| 160 | 1.36 | 250 | |

| 360 | 1.06 | 260 | |

| 480 | 1.26 | 257 | |

| Al2O3 | 60 | 1.92 | 248 |

| 160 | 0.93 | 260 | |

| 360 | 0.44 | 285 | |

| 480 | 0.68 | 272 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Žurauskienė, N.; Rudokas, V.; Tolvaišienė, S. Magnetoresistance and Magnetic Relaxation of La-Sr-Mn-O Films Grown on Si/SiO2 Substrate by Pulsed Injection MOCVD. Sensors 2023, 23, 5365. https://doi.org/10.3390/s23125365

Žurauskienė N, Rudokas V, Tolvaišienė S. Magnetoresistance and Magnetic Relaxation of La-Sr-Mn-O Films Grown on Si/SiO2 Substrate by Pulsed Injection MOCVD. Sensors. 2023; 23(12):5365. https://doi.org/10.3390/s23125365

Chicago/Turabian StyleŽurauskienė, Nerija, Vakaris Rudokas, and Sonata Tolvaišienė. 2023. "Magnetoresistance and Magnetic Relaxation of La-Sr-Mn-O Films Grown on Si/SiO2 Substrate by Pulsed Injection MOCVD" Sensors 23, no. 12: 5365. https://doi.org/10.3390/s23125365

APA StyleŽurauskienė, N., Rudokas, V., & Tolvaišienė, S. (2023). Magnetoresistance and Magnetic Relaxation of La-Sr-Mn-O Films Grown on Si/SiO2 Substrate by Pulsed Injection MOCVD. Sensors, 23(12), 5365. https://doi.org/10.3390/s23125365