Multivariable Signal Processing for Characterization of Failure Modes in Thin-Ply Hybrid Laminates Using Acoustic Emission Sensors

Abstract

1. Introduction

2. Experimental Procedures

2.1. Materials and Design

2.2. Manufacturing Procedures

2.3. Test Procedures

2.4. AE Device

3. Results and Discussion

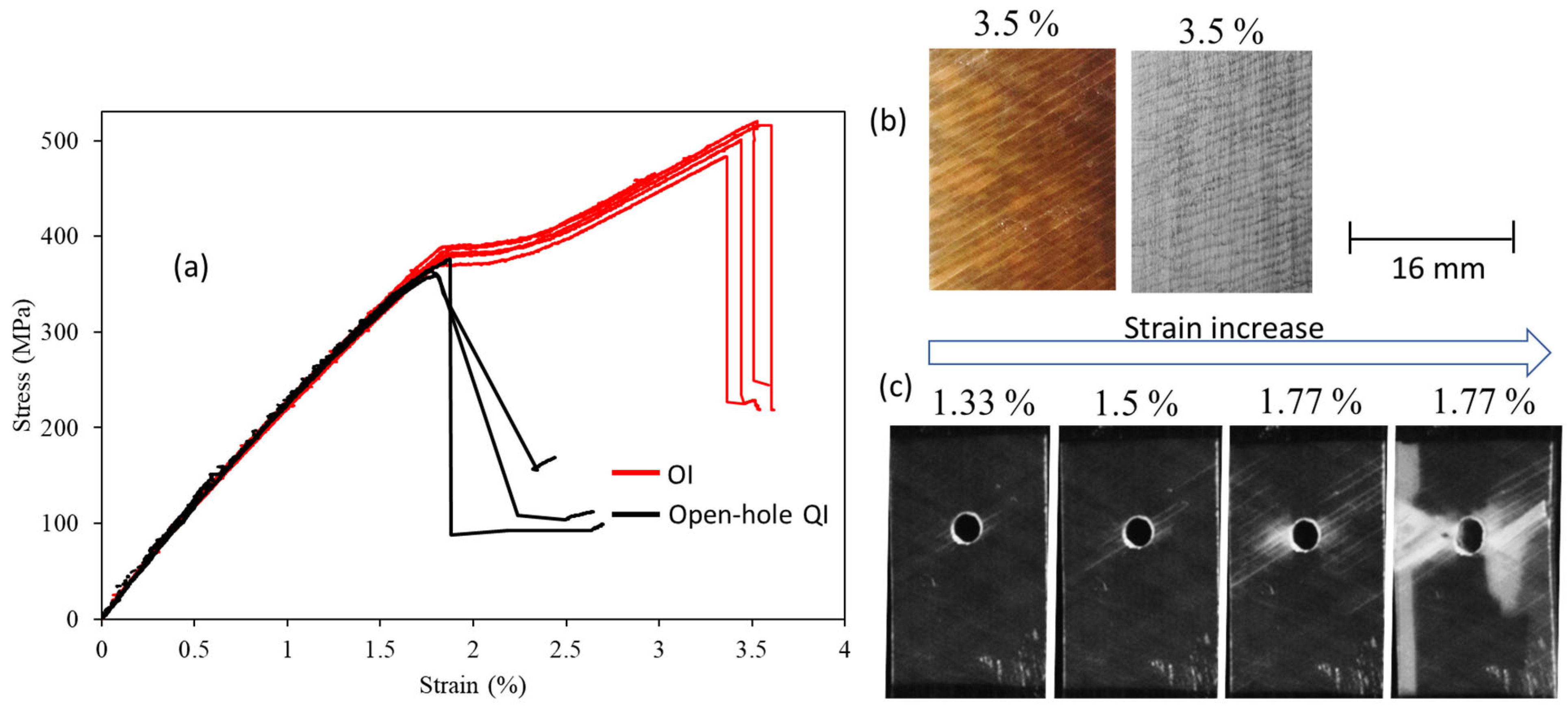

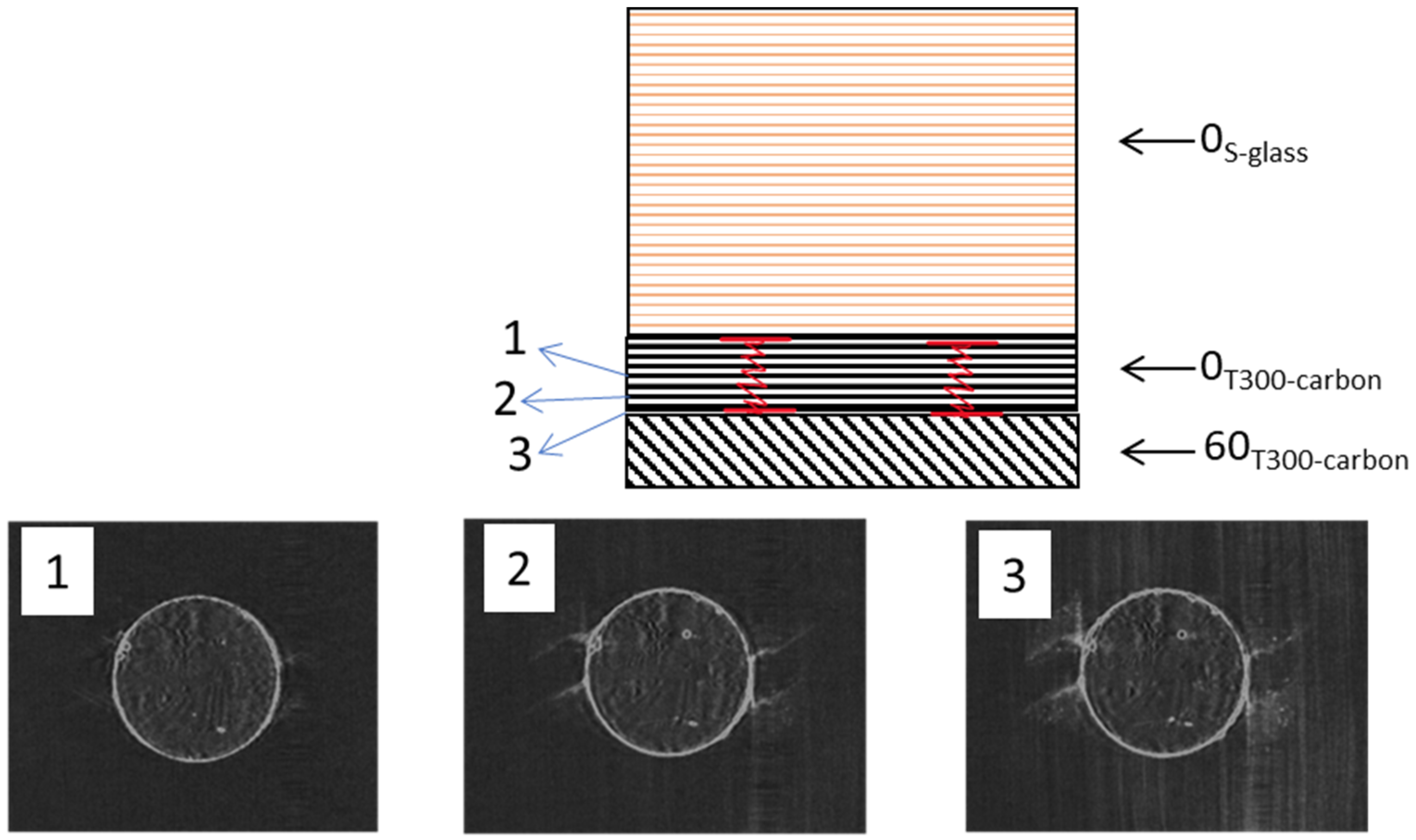

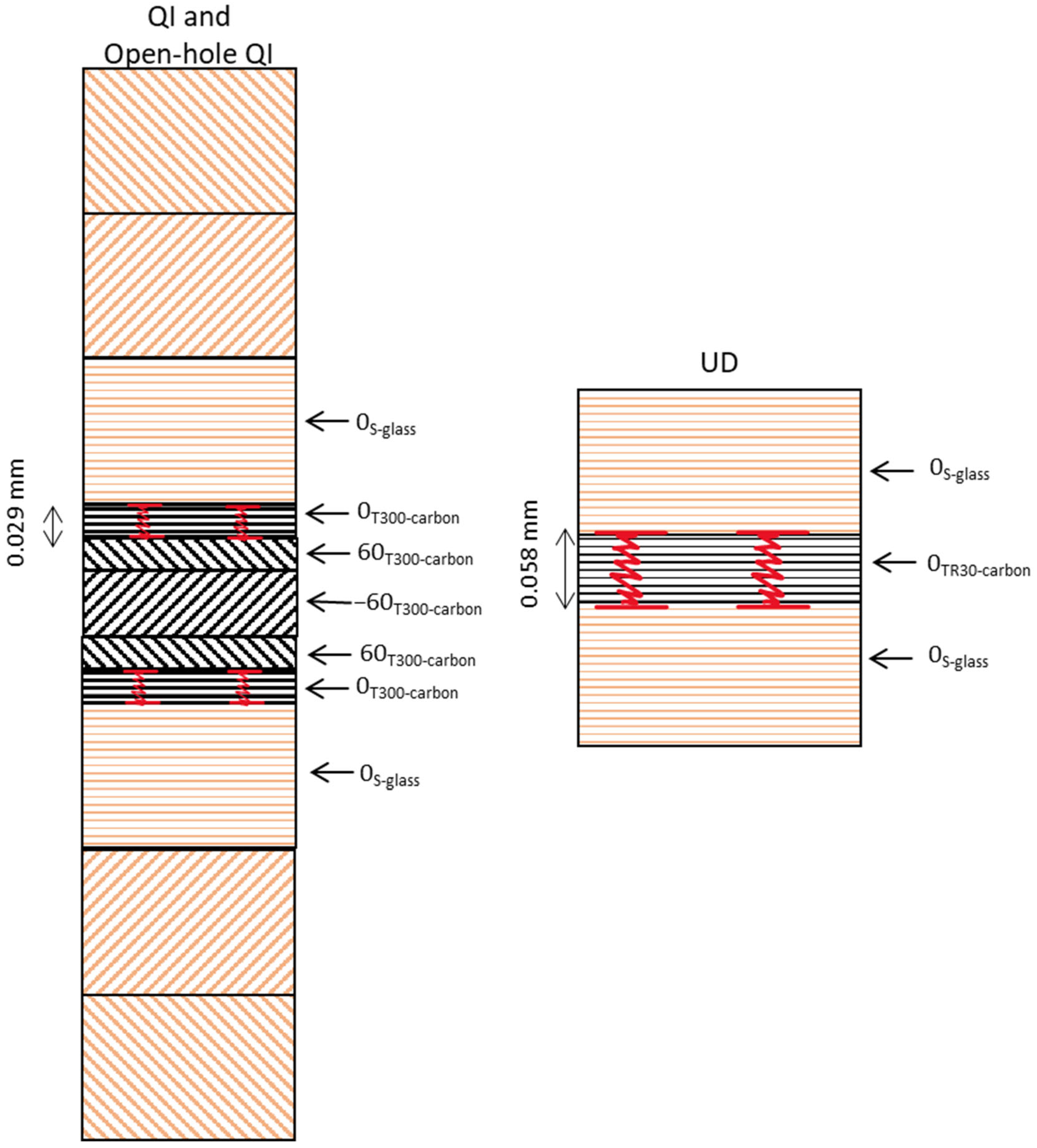

3.1. Mechanical Behavior and Resulted Failure Mechanisms

3.2. AE Results

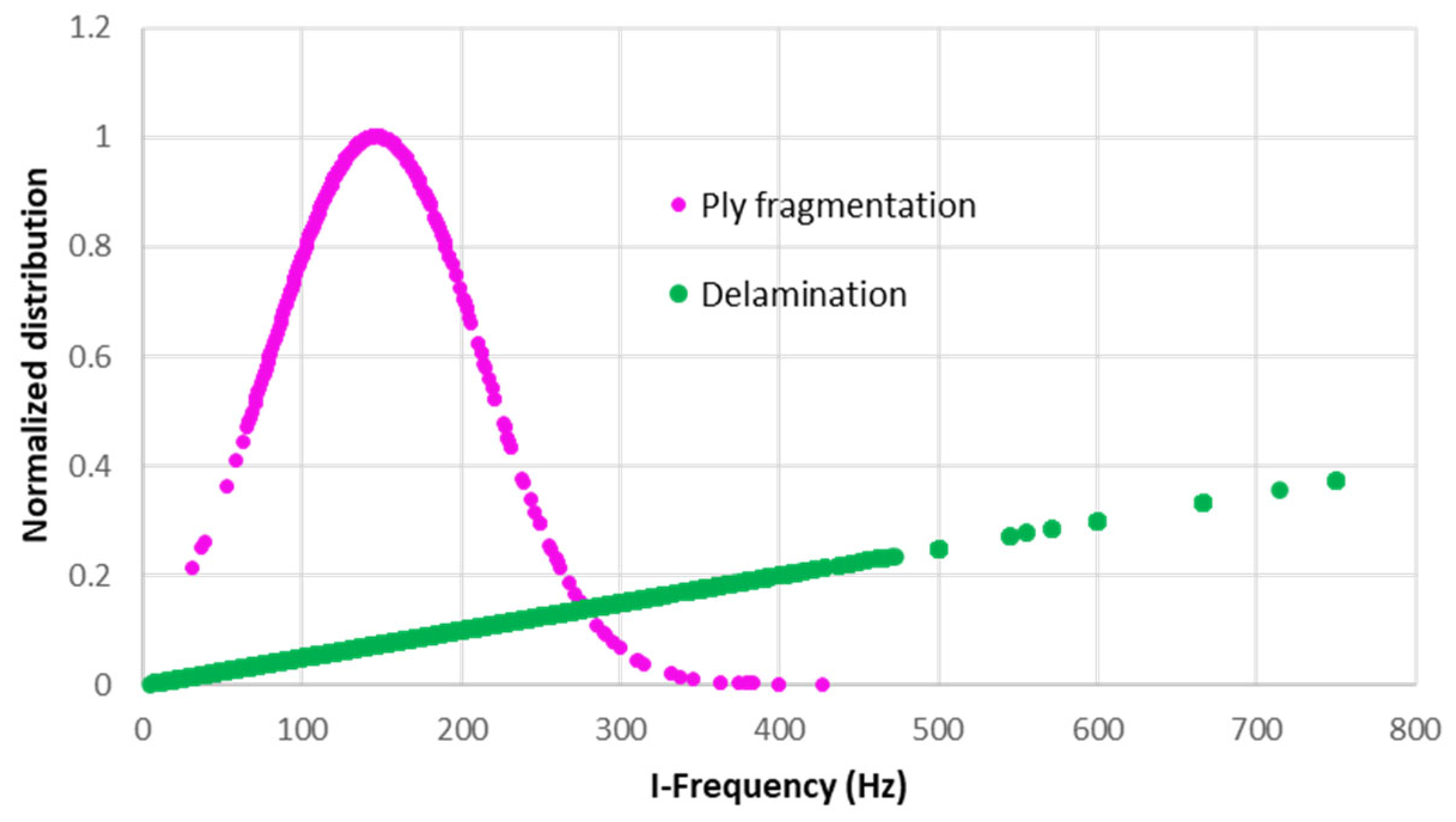

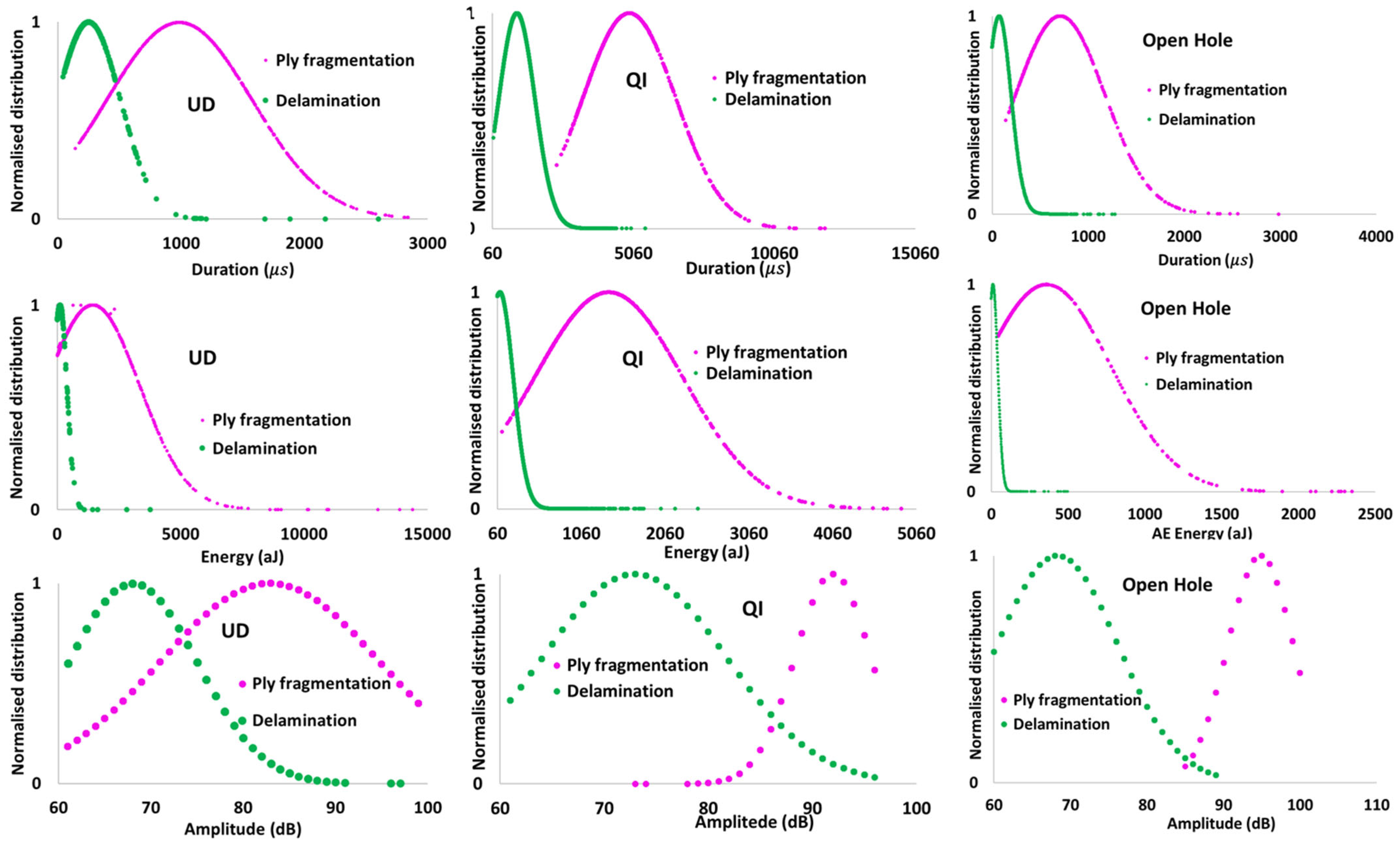

3.3. Clustering of the AE Signals and Their Correlation with the Failure Mechanisms

4. Conclusions

- CT-scan and visual images confirmed that the fragmentations and dispersed delamination were the dominant failure modes observed in the tested specimens. These failure mechanisms resulted in a successful pseudo-ductile behaviour for the UD and QI laminates, as well as notch-insensitivity in the open-hole QI laminate.

- The AE signals generated from the UD laminate have a higher energy level than the QI and open-hole laminates, which is due to the thicker block of adjacent 0° carbon plies, causing larger fragmentations.

- Applying GMM to cluster the AE signals uncovered two distinct types of events: those with high energy, amplitude, and duration, which were linked to carbon ply fragmentation, and those with low values of those parameters, which were connected to delamination of the glass/carbon interface. It was also found that, in contrast to the literature, high-frequency AE signals are not necessarily linked with carbon fibre fragmentation, and they are also linked with delamination, with no distinguishable ranges.

- The proposed clustering method and AE-based approach were found to be a simple yet robust tool for characterizing failure mechanisms in hybrid laminates and can serve as an early warning and failure detection method. However, it should be noted that the AE characteristics may vary depending on the stacking sequence and configurations, making it challenging to generalize the clustering criteria for different PDH configurations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Czél, G.; Wisnom, M.R. Demonstration of pseudo-ductility in high performance glass/epoxy composites by hybridisation with thin-ply carbon prepreg. Compos. Part A Appl. Sci. Manuf. 2013, 52, 23–30. [Google Scholar] [CrossRef]

- Czél, G.; Jalalvand, M.; Wisnom, M.R. Design and characterisation of advanced pseudo-ductile unidirectional thin-ply carbon/epoxy-glass/epoxy hybrid composites. Compos. Struct. 2016, 143, 362–370. [Google Scholar] [CrossRef]

- Czél, G.; Jalalvand, M.; Fotouhi, M.; Longana, M.L.; Nixon-Pearson, O.J.; Wisnom, M.R. Pseudo-ductility and reduced notch sensitivity in multi-directional all-carbon/epoxy thin-ply hybrid composites. Compos. Part A Appl. Sci. Manuf. 2018, 104, 151–164. [Google Scholar] [CrossRef]

- Jalalvand, M.; Czél, G.; Wisnom, M.R. Damage analysis of pseudo-ductile thin-ply UD hybrid composites—A new analytical method. Compos. Part A Appl. Sci. Manuf. 2015, 69, 83–93. [Google Scholar] [CrossRef]

- Fotouhi, M.; Jalalvand, M.; Wisnom, M.R. High performance quasi-isotropic thin-ply carbon/glass hybrid composites with pseudo-ductile behaviour in all fibre orientations. Compos. Sci. Technol. 2017, 152, 101–110. [Google Scholar] [CrossRef]

- Fotouhi, M.; Jalalvand, M.; Wisnom, M.R. Notch insensitive orientation-dispersed pseudo-ductile thin-ply carbon/glass hybrid laminates. Compos. Part A Appl. Sci. Manuf. 2018, 110, 29–44. [Google Scholar] [CrossRef]

- Ramirez-Jimenez, C.R.; Papadakis, N.; Reynolds, N.; Gan, T.; Purnell, P.; Pharaoh, M. Identification of failure modes in glass/polypropylene composites by means of the primary frequency content of the acoustic emission event. Compos. Sci. Technol. 2004, 64, 1819–1827. [Google Scholar] [CrossRef]

- Pashmforoush, F.; Khamedi, R.; Fotouhi, M.; Hajikhani, M.; Ahmadi, M. Damage classification of sandwich composites using acoustic emission technique and k-means genetic algorithm. J. Nondestr. Eval. 2014, 33, 481–492. [Google Scholar] [CrossRef]

- Fotouhi, M.; Ahmadi, M. Acoustic emission based study to characterize the initiation of mode I delamination in composite materials. J. Thermoplast. Compos. Mater. 2014, 29, 519–537. [Google Scholar] [CrossRef]

- Benmedakhene, S.; Kenane, M.; Benzeggagh, M.L. Initiation and growth of delamination in glass/epoxy composites subjected to static and dynamic loading by acoustic emission monitoring. Compos. Sci. Technol. 1999, 59, 201–208. [Google Scholar] [CrossRef]

- Bohse, J. Acoustic emission characteristics of micro-failure processes in polymer blends and composites. Compos. Sci. Technol. 2000, 60, 1213–1226. [Google Scholar] [CrossRef]

- Saeedifar, M.; Fotouhi, M.; Najafabadi, M.A.; Toudeshky, H.H.; Minak, G. Prediction of quasi-static delamination onset and growth in laminated composites by acoustic emission. Compos. Part B Eng. 2016, 85, 113–122. [Google Scholar] [CrossRef]

- Lomov, S.V.; Bogdanovich, A.E.; Ivanov, D.S.; Mungalov, D.; Karahan, M.; Verpoest, I. A comparative study of tensile properties of non-crimp 3D orthogonal weave and multi-layer plain weave E-glass composites. Part 1: Materials, methods and principal results. Compos. A Appl. Sci. Manuf. 2009, 40, 1134–1143. [Google Scholar] [CrossRef]

- Fotouhi, M.; Pashmforoush, F.; Ahmadi, M.; Refahi, A. Monitoring the initiation and growth of delamination in composite materials using acoustic emission under quasi-static three-point bending test. J. Reinf. Plast. Compos. 2011, 30, 1481–1493. [Google Scholar] [CrossRef]

- Godin, N.; Huguet, S.; Gaertner, R.; Salmon, L. Clustering of acoustic emission signals collected during tensile tests on unidirectional glass/polyester composite using supervised and unsupervised classifiers. NDT&E Int. 2004, 37, 253–264. [Google Scholar]

- Fotouhi, M.; Saeedifar, M.; Sadeghi, S.; Ahmadi, M.; Minak, G. Investigation of the damage mechanisms for mode I delamination growth in foam core sandwich composites using Acoustic Emission. Struct. Health Monit. 2015, 14, 265–280. [Google Scholar] [CrossRef]

- Fotouhi, M.; Suwarta, P.; Jalalvand, M.; Czel, G.; Wisnom, M.R. Detection of fibre fracture and ply fragmentation in thin-ply UD carbon/glass hybrid laminates using acoustic emission. Compos. Part A Appl. Sci. Manuf. 2016, 86, 66–76. [Google Scholar] [CrossRef]

- Fotouhi, M.; Suwarta, P.; Jalalvand, M.; Czél, G.; Wisnom, M.R. Acoustic emission monitoring of thin ply hybrid composites under repeated quasi-static tensile loading. FME Trans. 2018, 46, 238–244. [Google Scholar] [CrossRef]

- Fotouhi, M.; Fuller, J.; Longana, M.; Jalalvand, M.; Wisnom, M.R. The high strain rate tension behaviour of pseudo-ductile high performance thin ply composites. Compos. Struct. 2019, 215, 365–376. [Google Scholar] [CrossRef]

- Huang, M.; Jiang, L.; Liaw, P.K.; Brooks, C.R.; Seeley, R.; Klarstrom, D.L. Using acoustic emission in fatigue and fracture materials research. Nondestruct. Eval. Overv. 1998, 50, 11. [Google Scholar]

- Fotouhi, M.; Sadeghi, S.; Jalalvand, M.; Ahmadi, M. Analysis of the damage mechanisms in mixed-mode delamination of laminated composites using acoustic emission data clustering. J. Thermoplast. Compos. Mater. 2017, 30, 318–340. [Google Scholar] [CrossRef]

- Ni, L.; Jinhang, S. The analysis and research of clustering algorithm based on PCA. In Proceedings of the 13th IEEE International Conference on Electronic Measurement & Instruments (ICEMI), Yangzhou, China, 20–23 October 2017; pp. 361–365. [Google Scholar] [CrossRef]

- Fotouhi, S.; Khoshravan Azar, M.R.; Fotouhi, M. Achieving robust acoustic emission-based damage characterisation of scaled laminated composites under indentation. Express Polym. Lett. 2021, 15, 839–852. [Google Scholar] [CrossRef]

- Refahi Oskouei, A.; Heidary, H.; Ahmadi, M.; Farajpur, M. Unsupervised acoustic emission data clustering for the analysis of damage mechanisms in glass/polyester composites. Mater. Des. 2012, 37, 416–422. [Google Scholar] [CrossRef]

- Pashmforoush, F.; Fotouhi, M.; Ahmadi, M. Acoustic emission-based damage classification of glass/polyester composites using harmony search k-means algorithm. J. Reinf. Plast. Compos. 2012, 31, 671–680. [Google Scholar] [CrossRef]

- Saeedifar, M.; Zarouchas, D. Damage characterization of laminated composites using acoustic emission: A review. Compos. Part B Eng. 2020, 195, 108039. [Google Scholar] [CrossRef]

| Prepreg Type | TR30/epoxy [6] | S-glass/913epoxy [6] | T300/epoxy [17] |

|---|---|---|---|

| Fibre modulus (GPa) | 234 | 88 | 230 |

| Prepreg fibre direction Modulus, E11 (GPa) | 101.7 | 45.7 | 101.7 |

| Fibre failure strain (%) | 1.9 | 5.5 | 1.5 |

| Cured nominal thickness (mm) | 0.029 | 0.155 | 0.029 |

| Fibre mass per unit area (g/m2) | 21.2 | 190 | 22 |

| Fibre volume fraction (%) | 41 | 50 | 43 |

| Supplier | Sky Flex | Hexcel | Sky Flex |

| Number of Fragmentation | Average Energy (aJ) | Average Duration (μs) | Average Amplitude (dB) | |

|---|---|---|---|---|

| UD | 684 | 1902 | 988 | 83 |

| QI | 765 | 1266 | 4921 | 92 |

| Open Hole | 511 | 465 | 710 | 95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fotouhi, S.; Assaad, M.; Nasor, M.; Imran, A.; Ashames, A.; Fotouhi, M. Multivariable Signal Processing for Characterization of Failure Modes in Thin-Ply Hybrid Laminates Using Acoustic Emission Sensors. Sensors 2023, 23, 5244. https://doi.org/10.3390/s23115244

Fotouhi S, Assaad M, Nasor M, Imran A, Ashames A, Fotouhi M. Multivariable Signal Processing for Characterization of Failure Modes in Thin-Ply Hybrid Laminates Using Acoustic Emission Sensors. Sensors. 2023; 23(11):5244. https://doi.org/10.3390/s23115244

Chicago/Turabian StyleFotouhi, Sakineh, Maher Assaad, Mohamed Nasor, Ahmed Imran, Akram Ashames, and Mohammad Fotouhi. 2023. "Multivariable Signal Processing for Characterization of Failure Modes in Thin-Ply Hybrid Laminates Using Acoustic Emission Sensors" Sensors 23, no. 11: 5244. https://doi.org/10.3390/s23115244

APA StyleFotouhi, S., Assaad, M., Nasor, M., Imran, A., Ashames, A., & Fotouhi, M. (2023). Multivariable Signal Processing for Characterization of Failure Modes in Thin-Ply Hybrid Laminates Using Acoustic Emission Sensors. Sensors, 23(11), 5244. https://doi.org/10.3390/s23115244