Research on Surface Tracking and Constant Force Control of a Grinding Robot

Abstract

1. Introduction

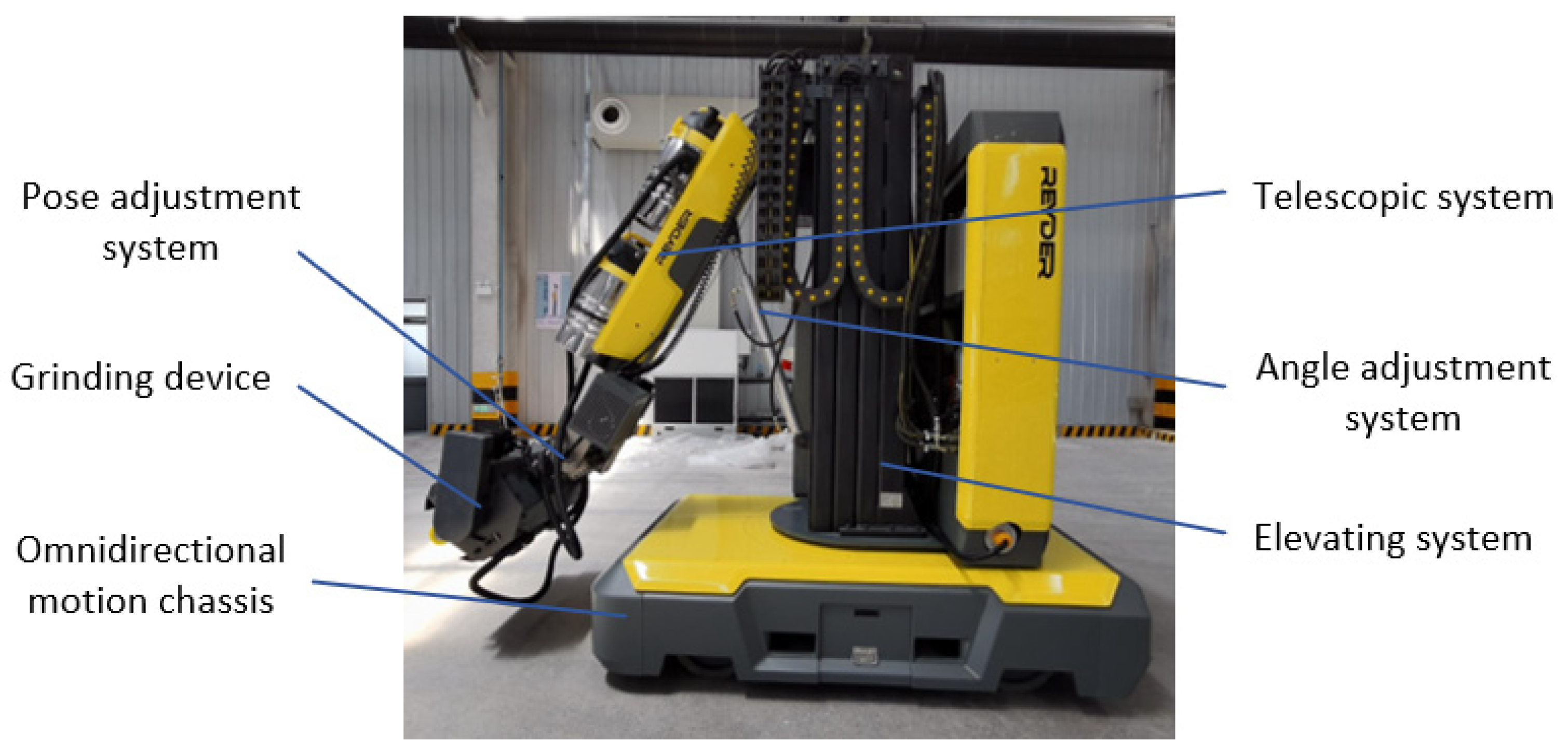

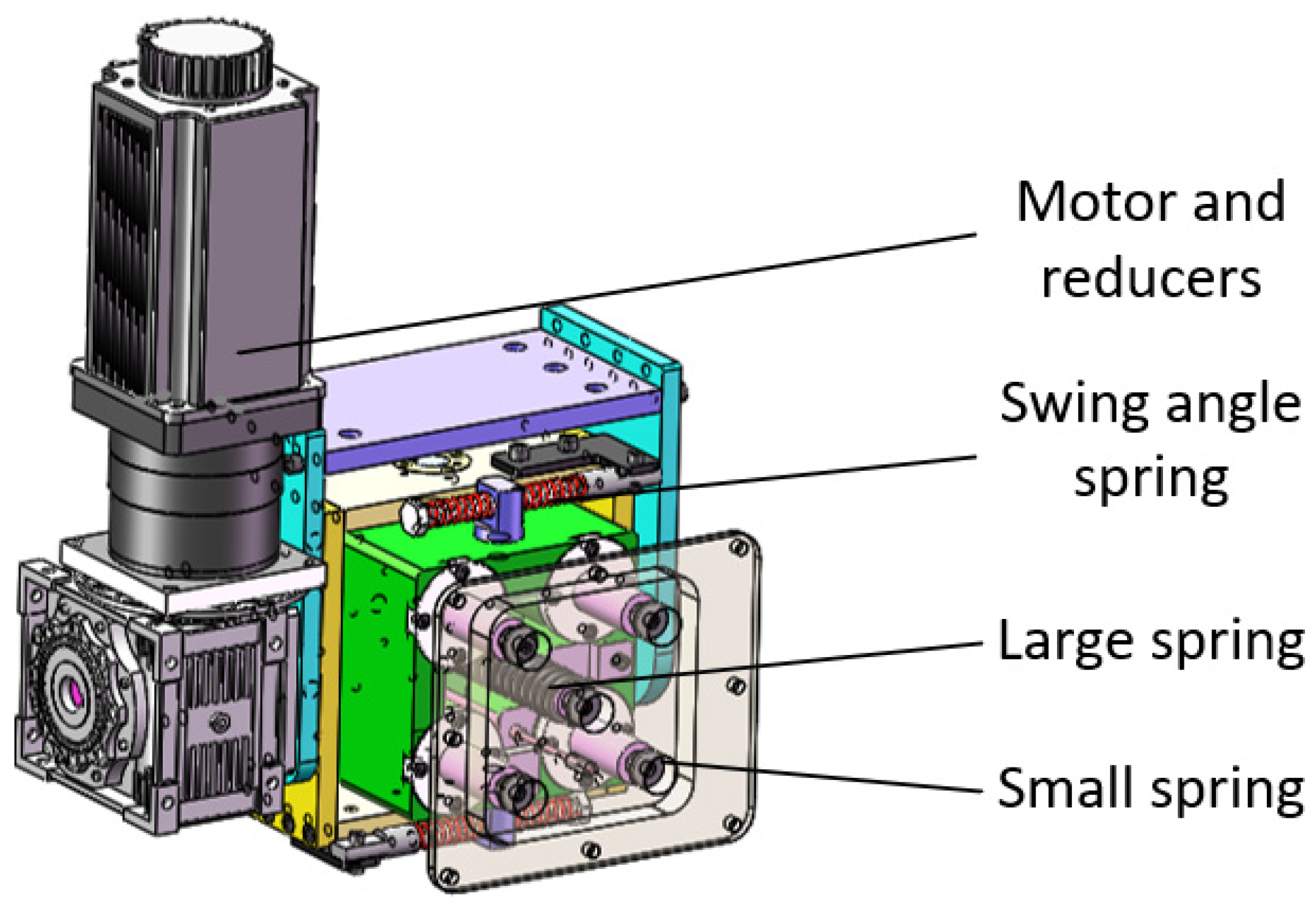

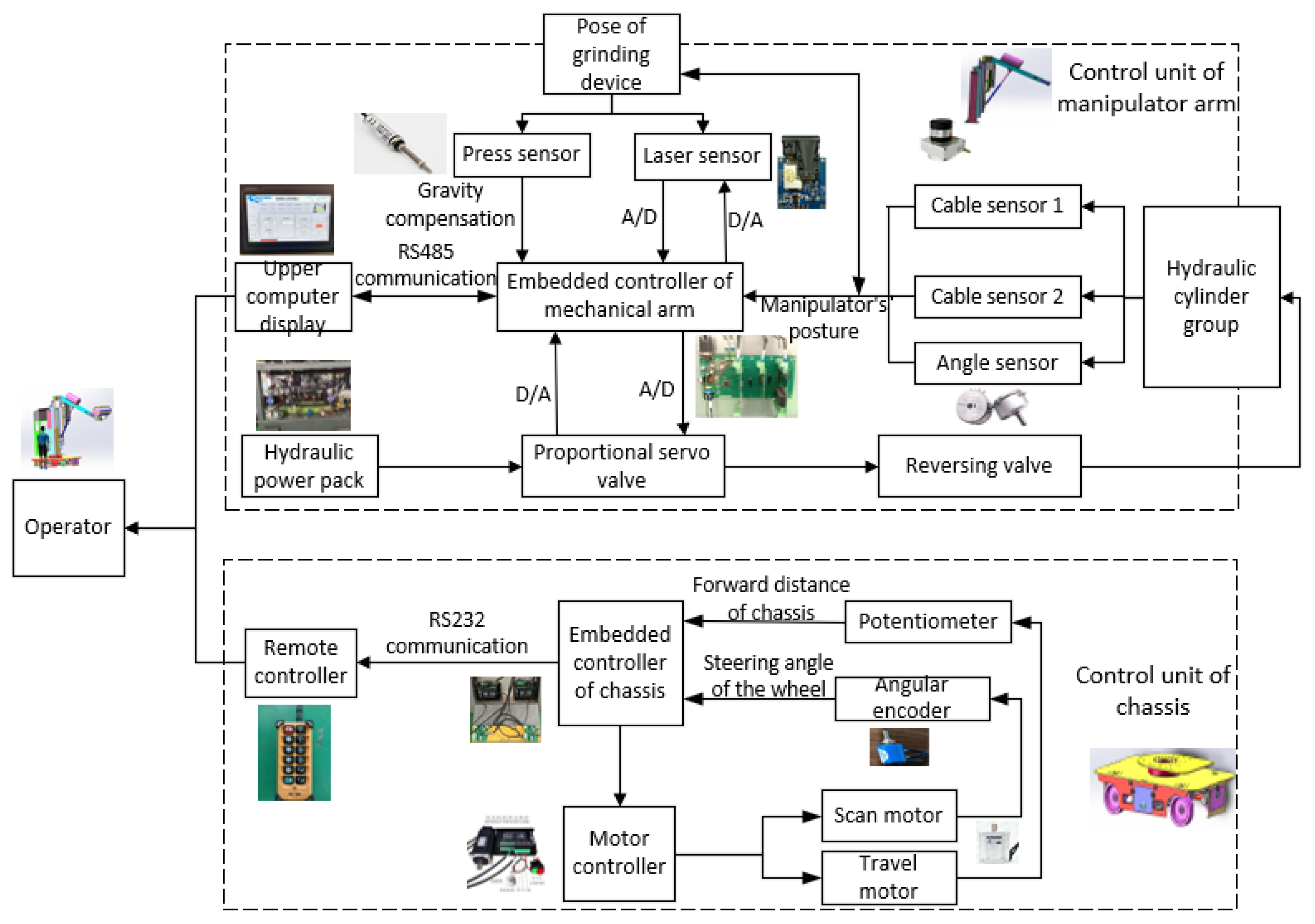

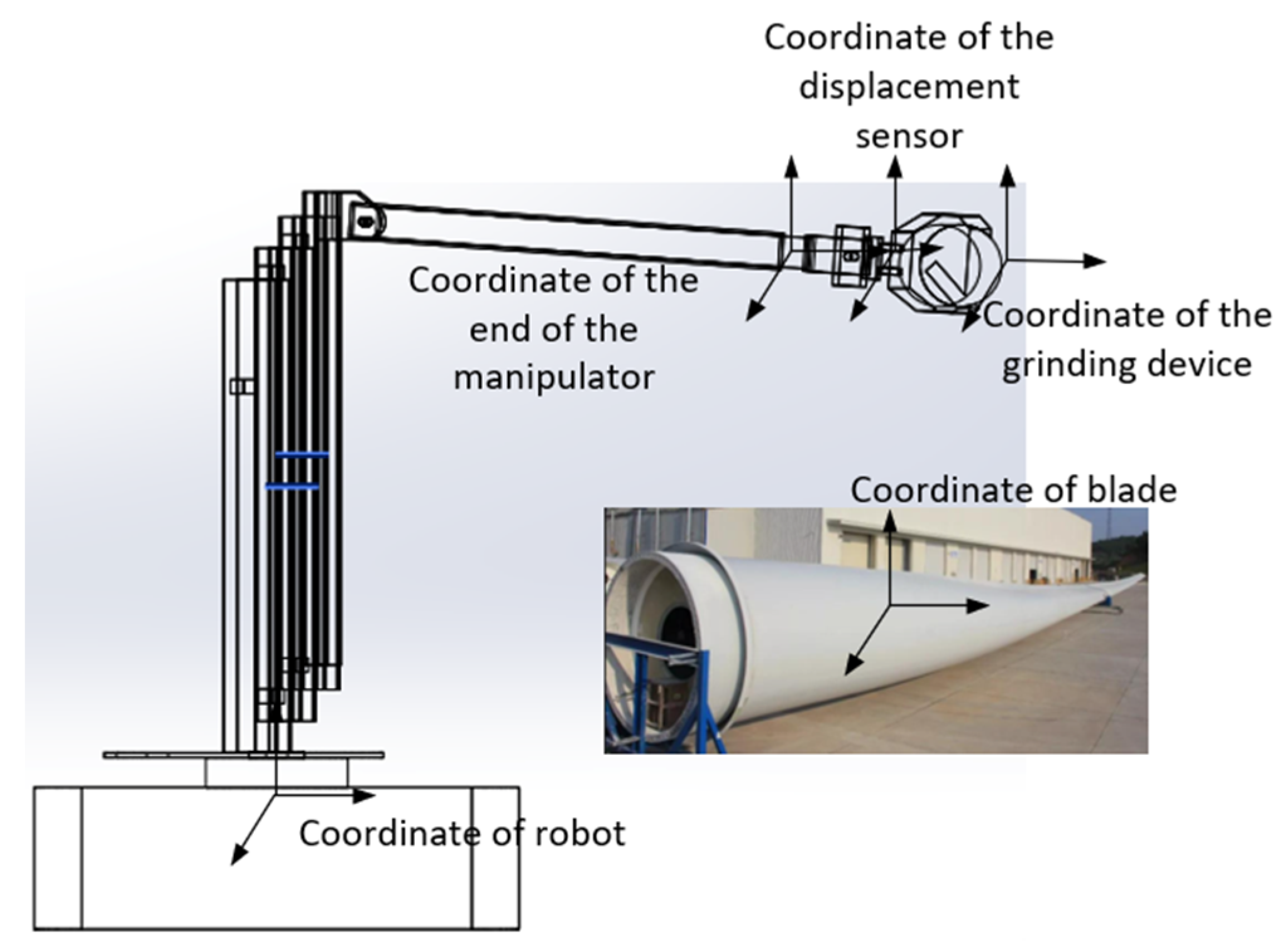

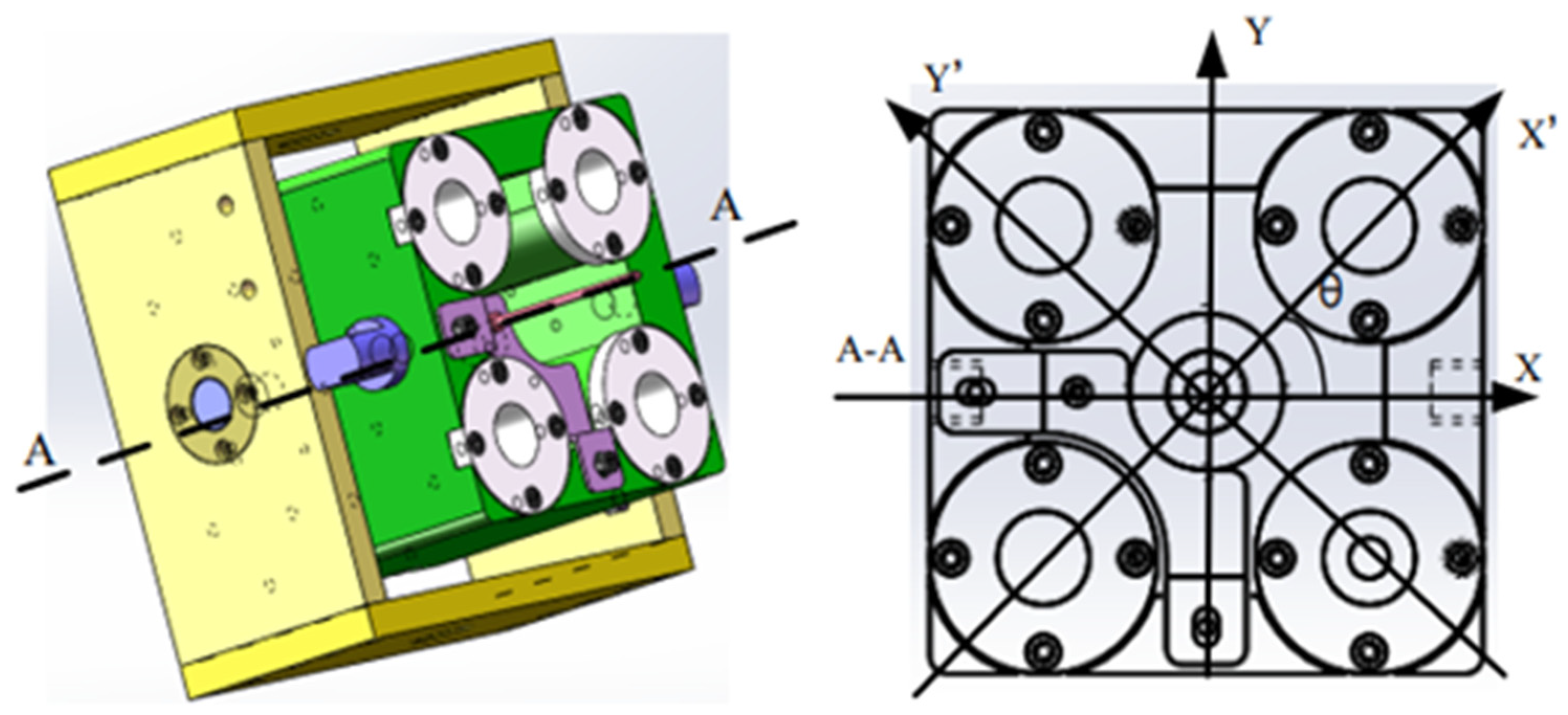

2. Grinding Robot

2.1. Structure of the Grinding Robot

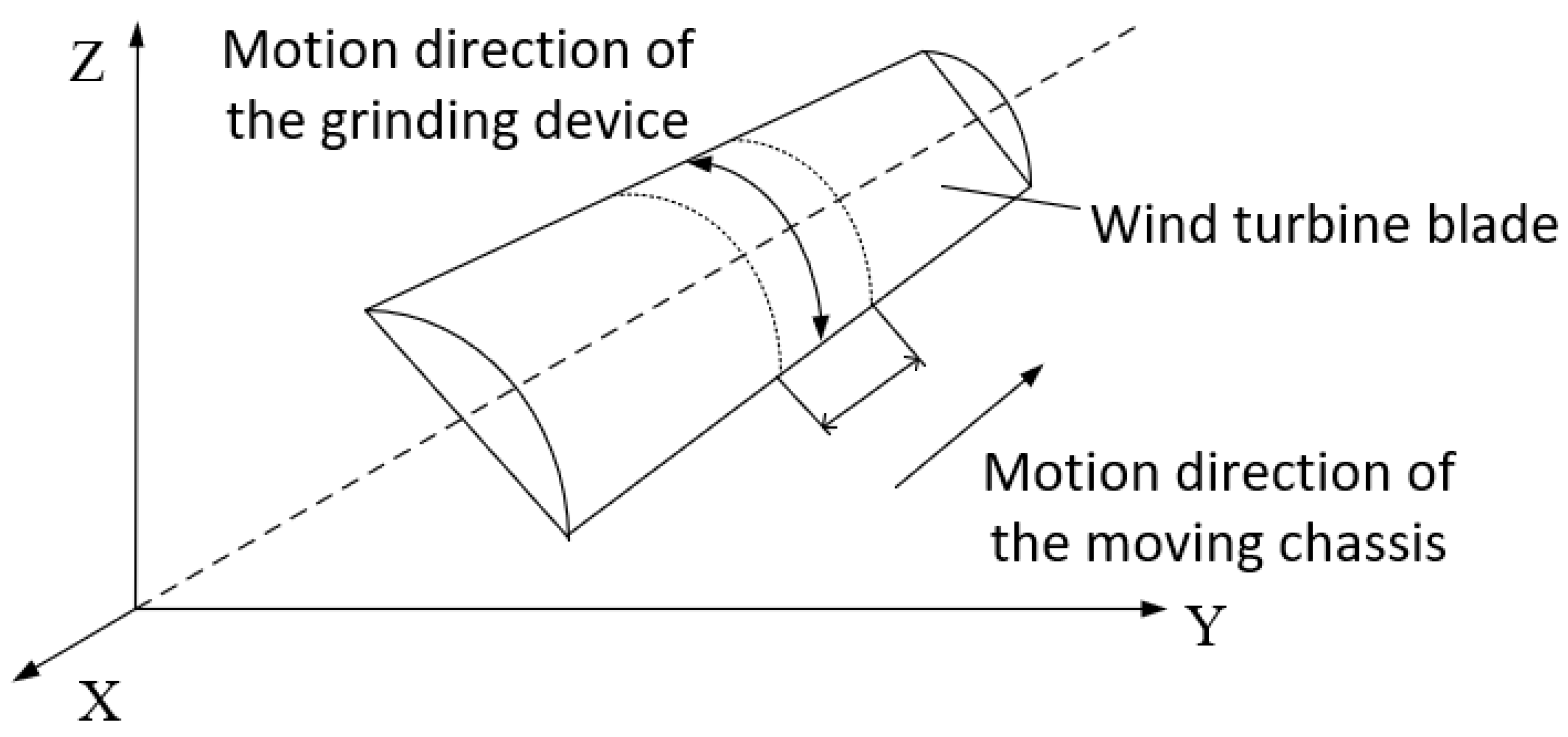

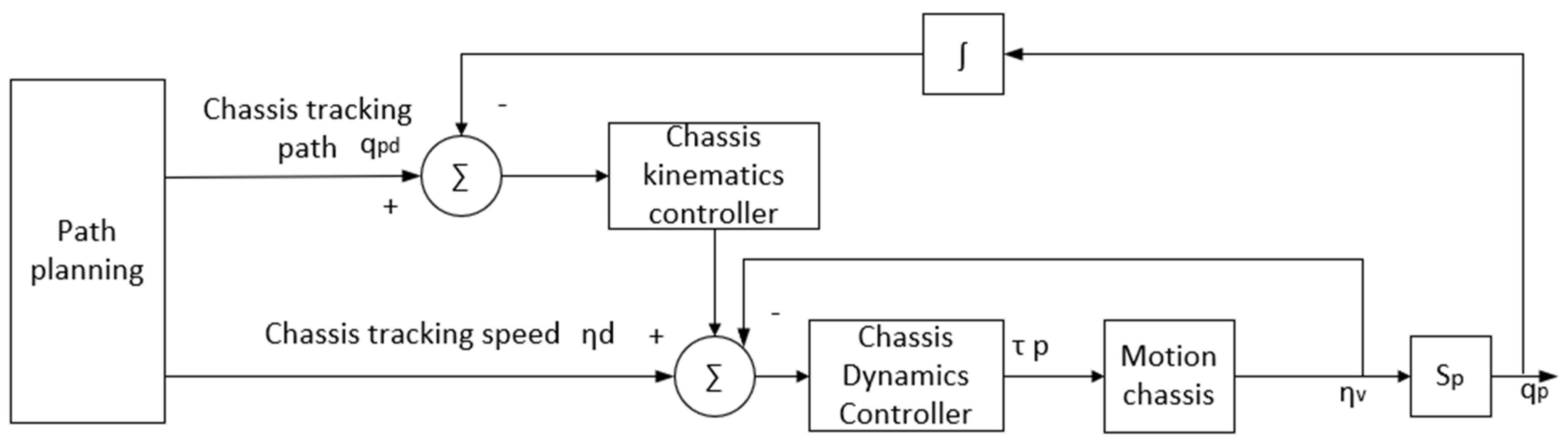

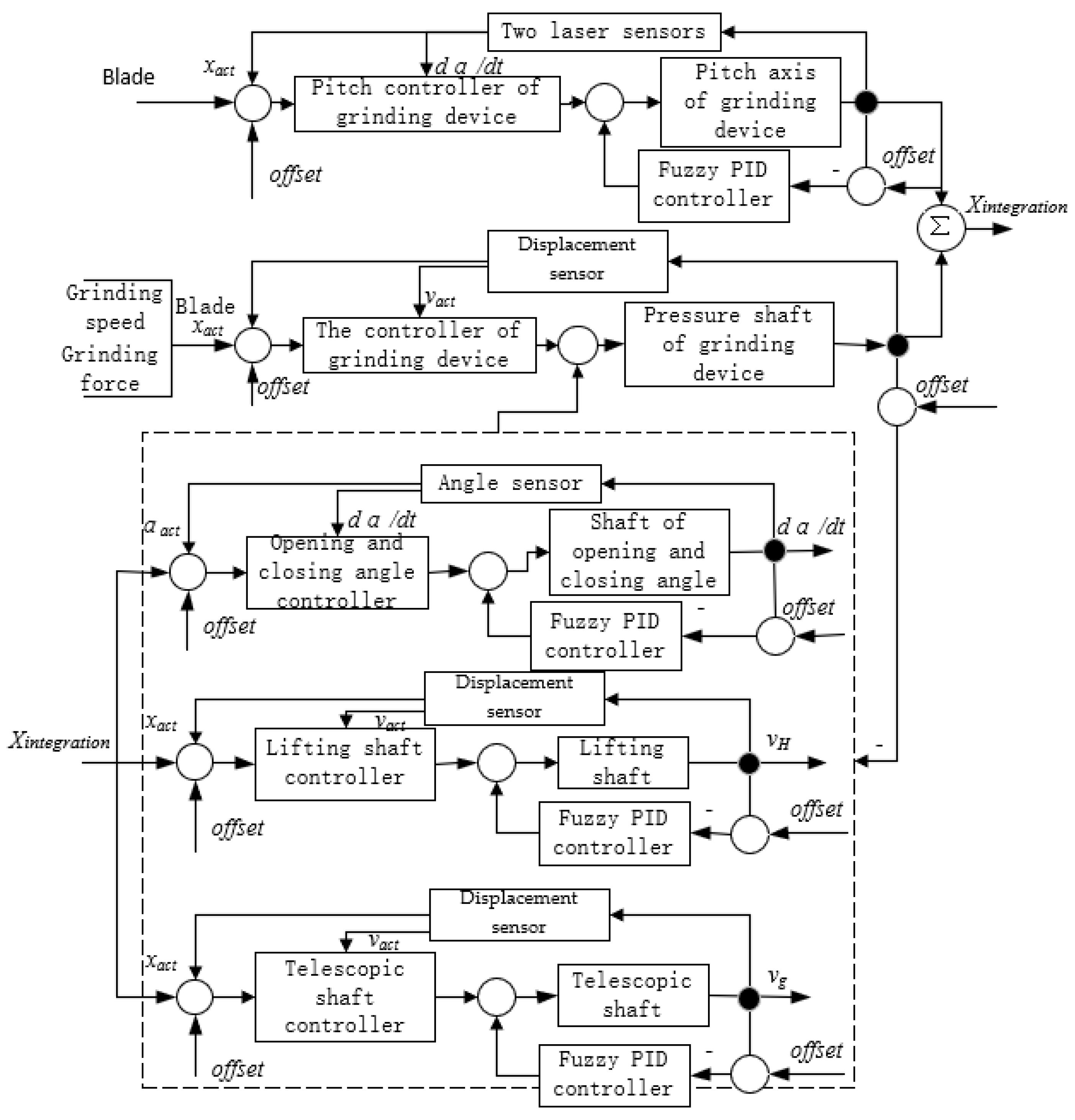

2.2. Motion Planning and Control Scheme

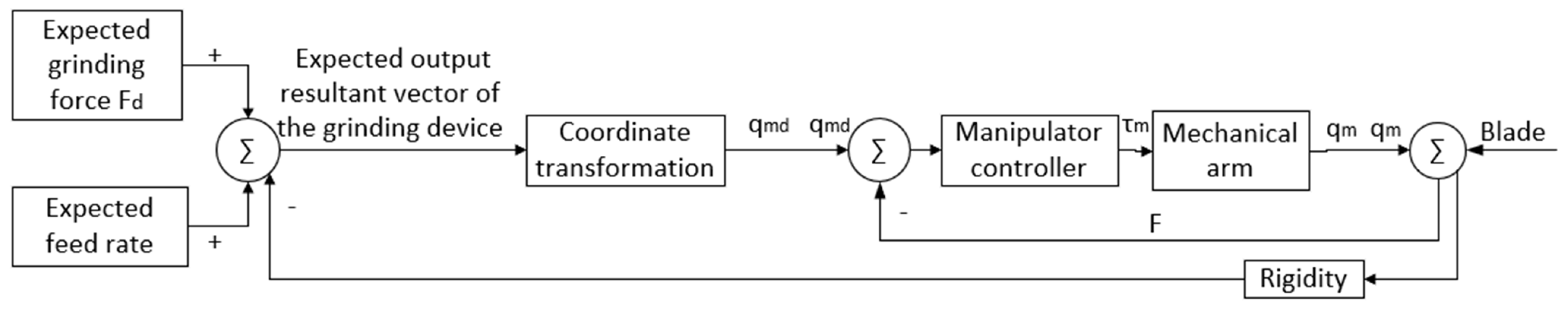

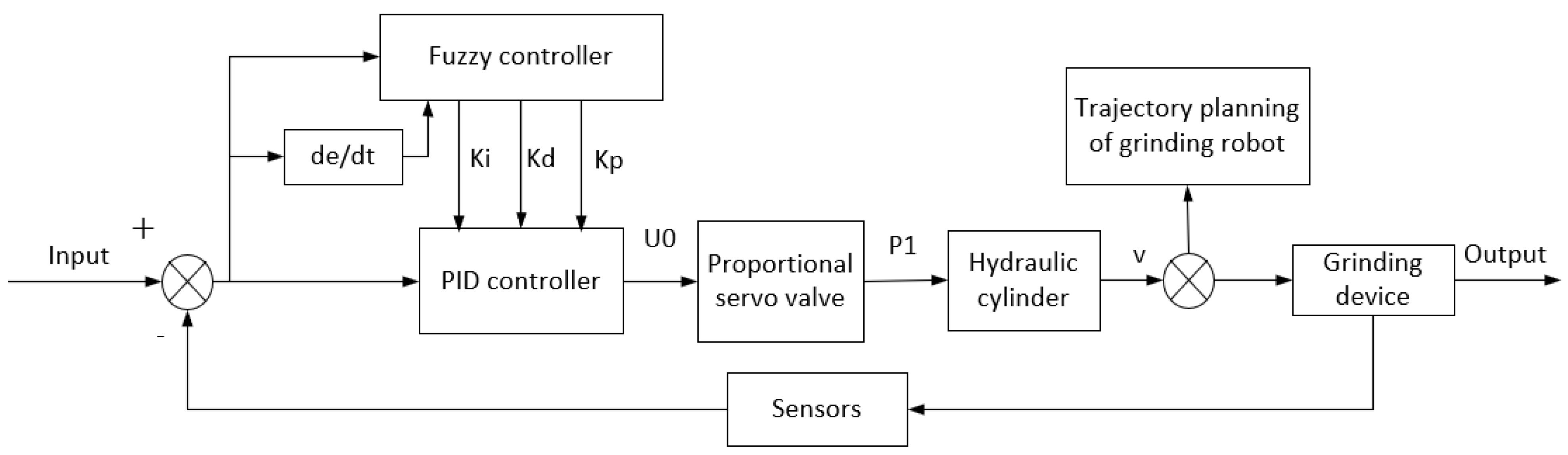

3. Control Strategy of Grinding Robot

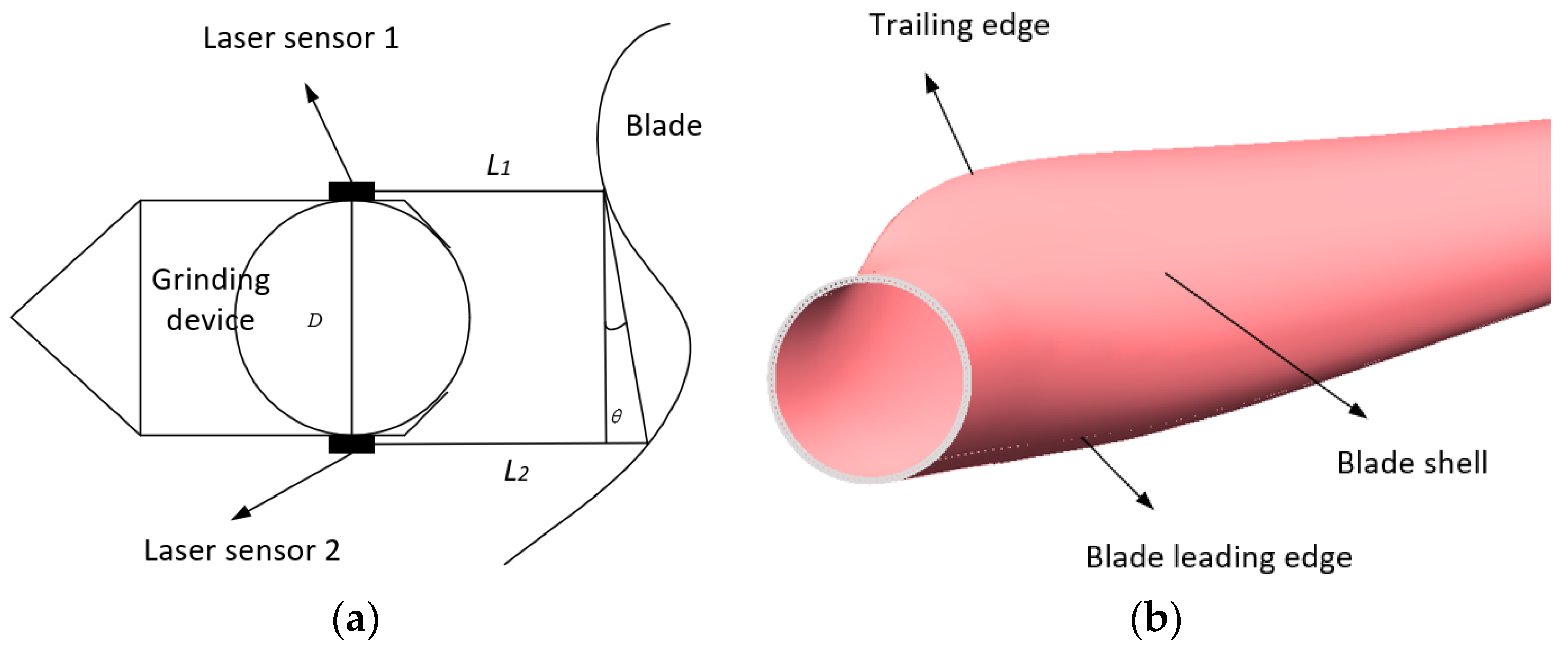

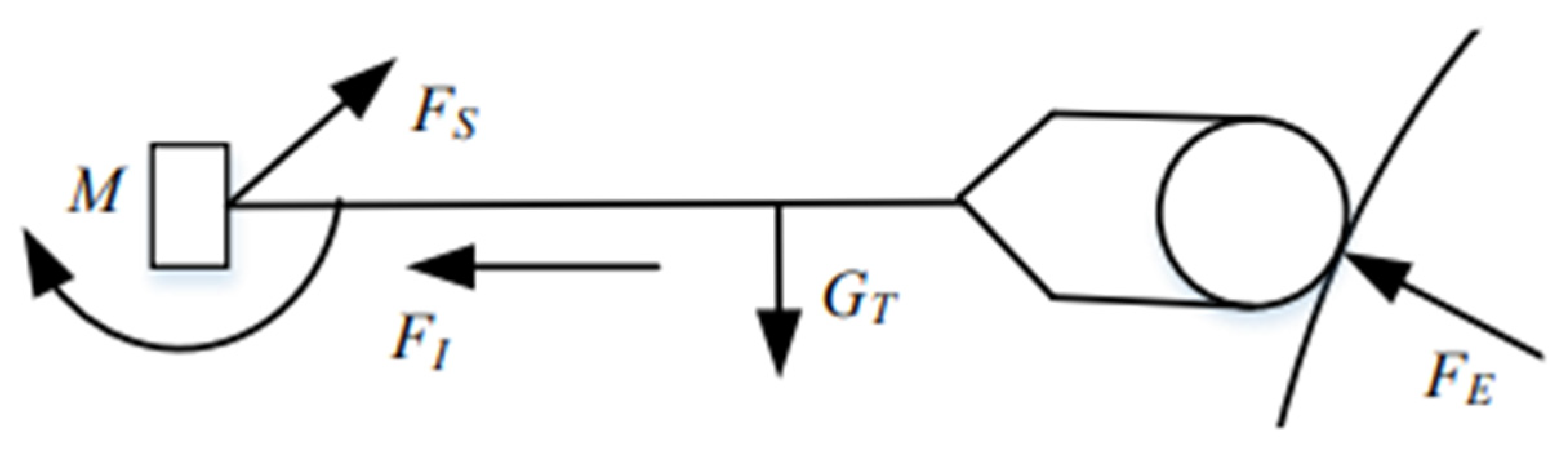

3.1. Surface Tracking Control Strategy

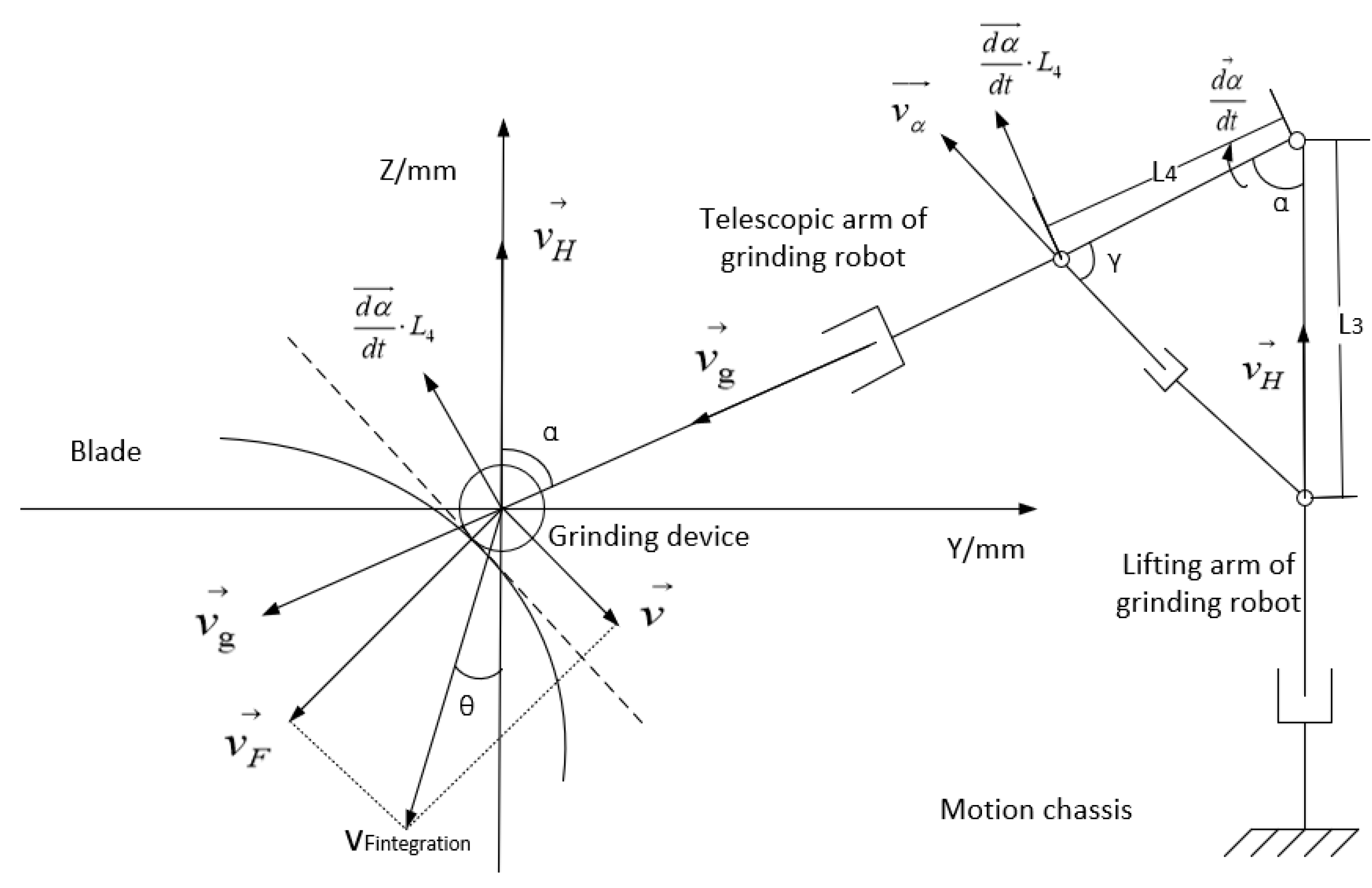

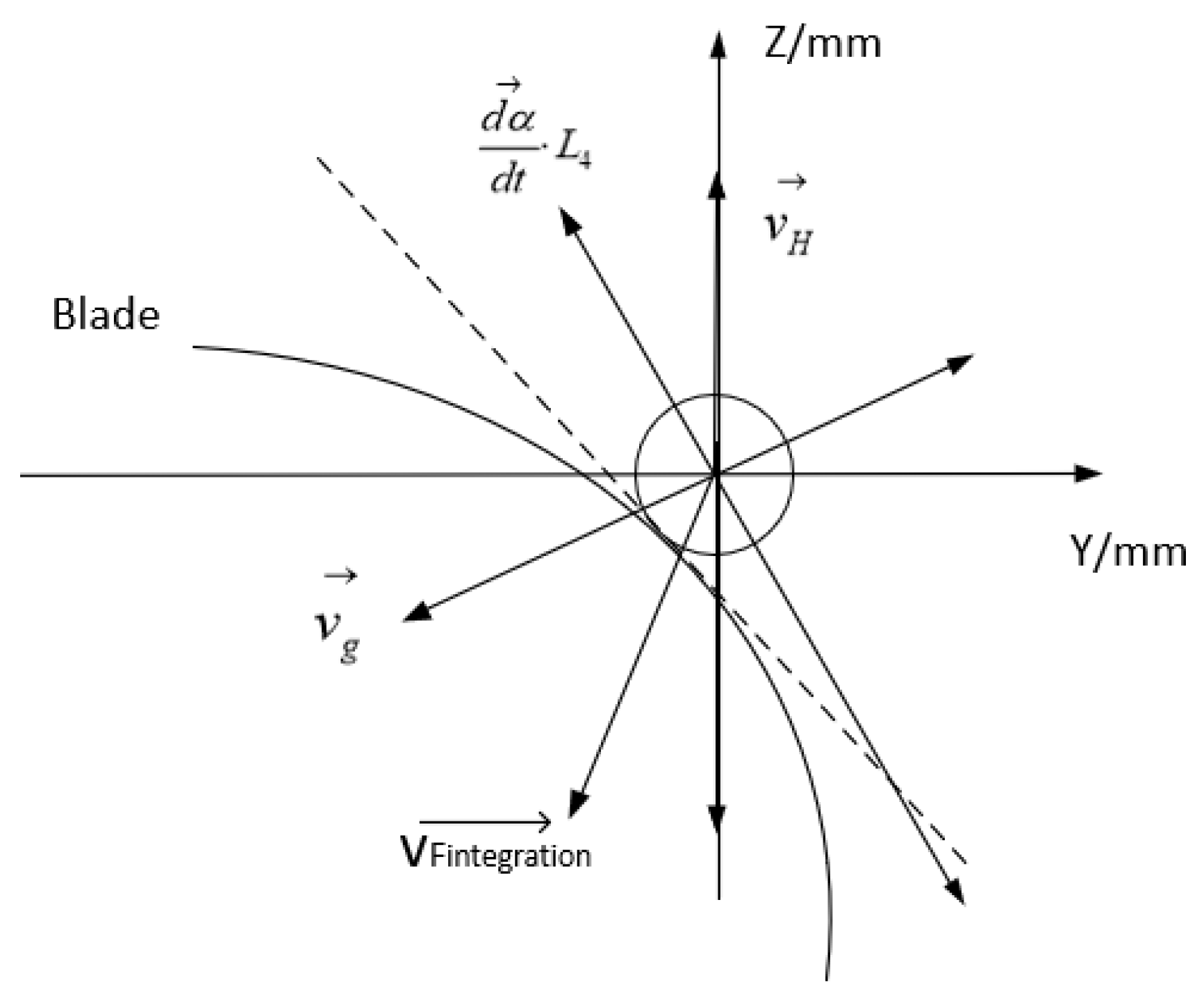

3.1.1. Surface Tracking of Blade Surface

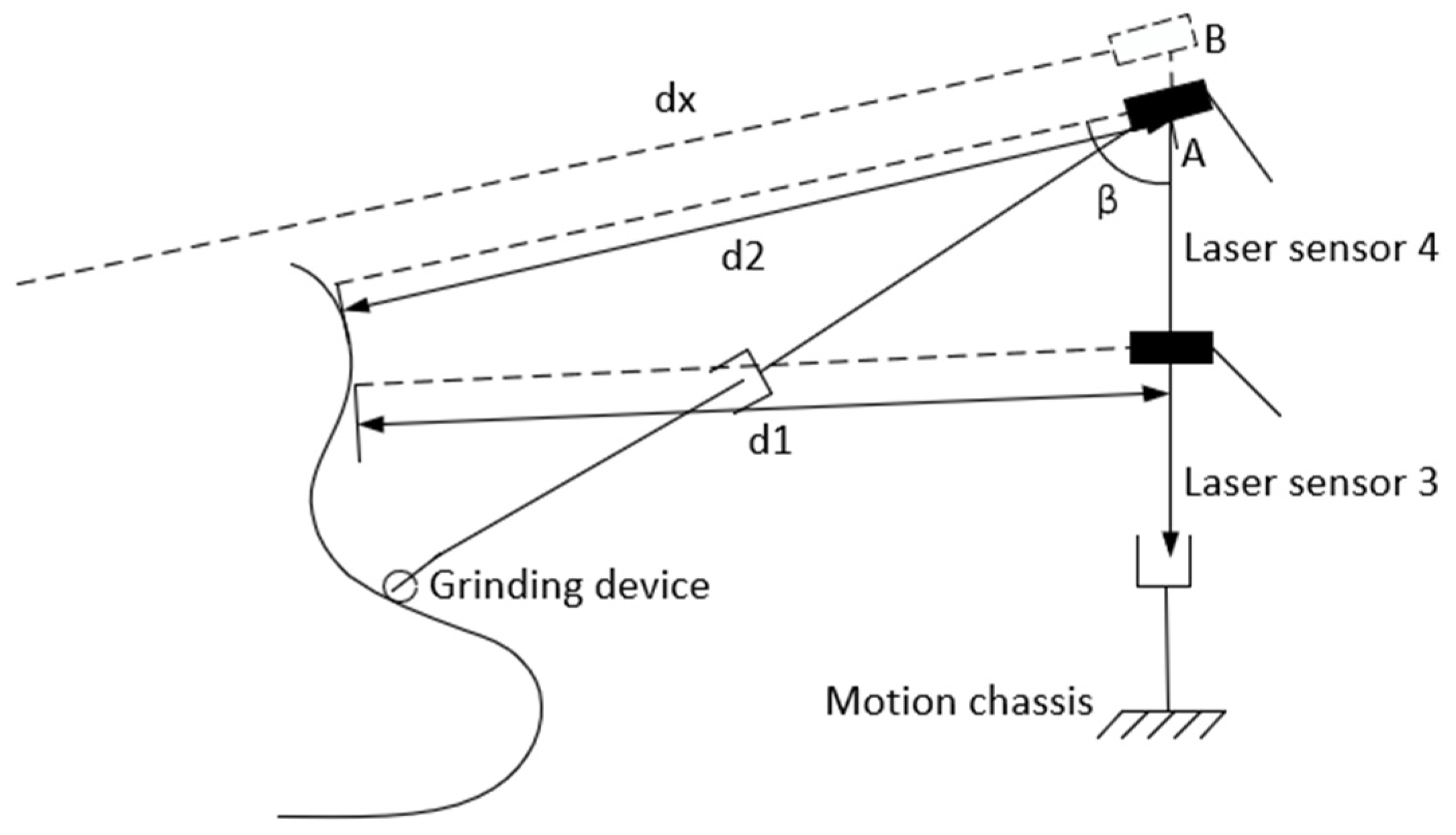

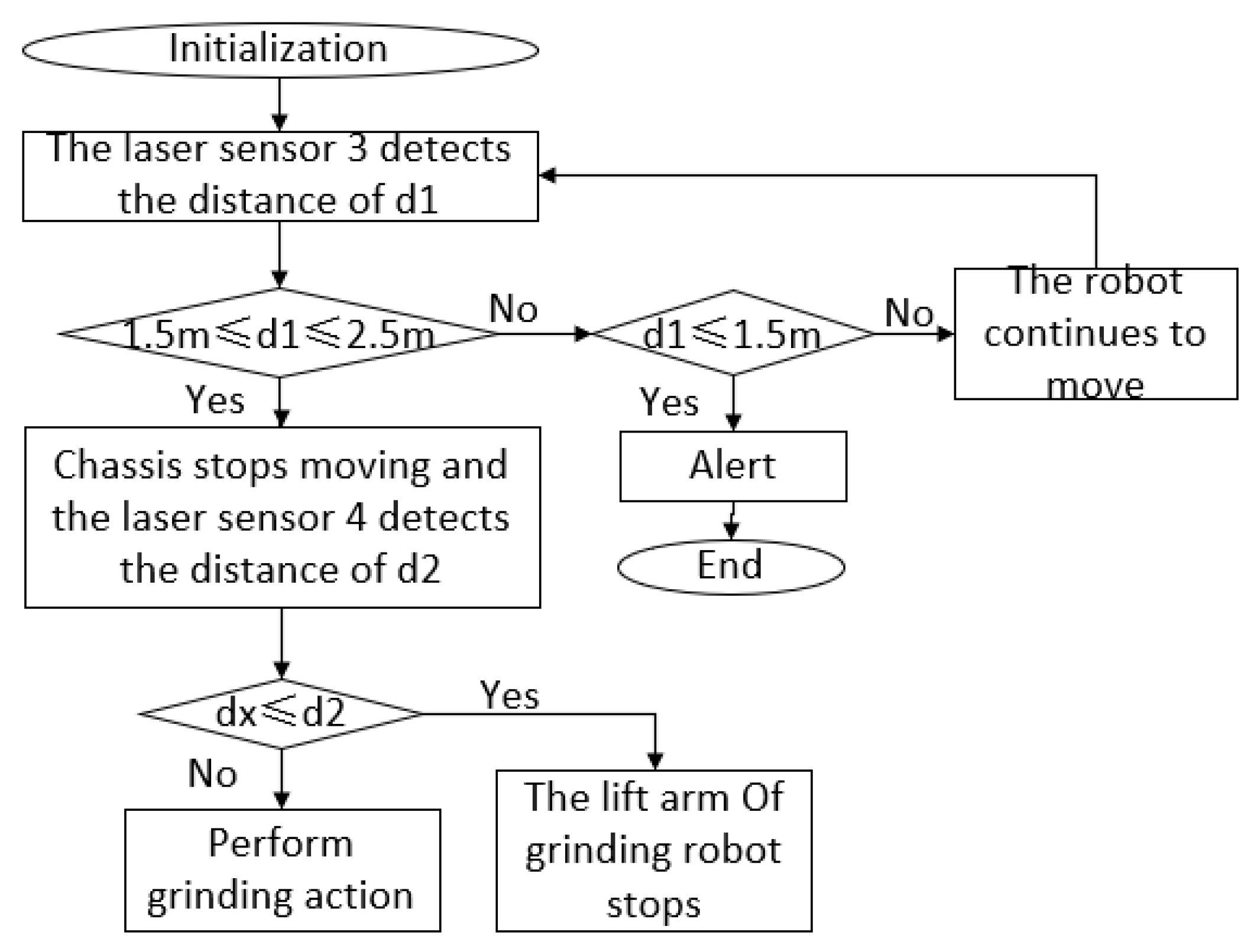

3.1.2. Adjustment of the Robot’s Position

3.2. Constant Force Grinding Control Strategy

3.3. Control Strategy of Mechanical Arm Power System

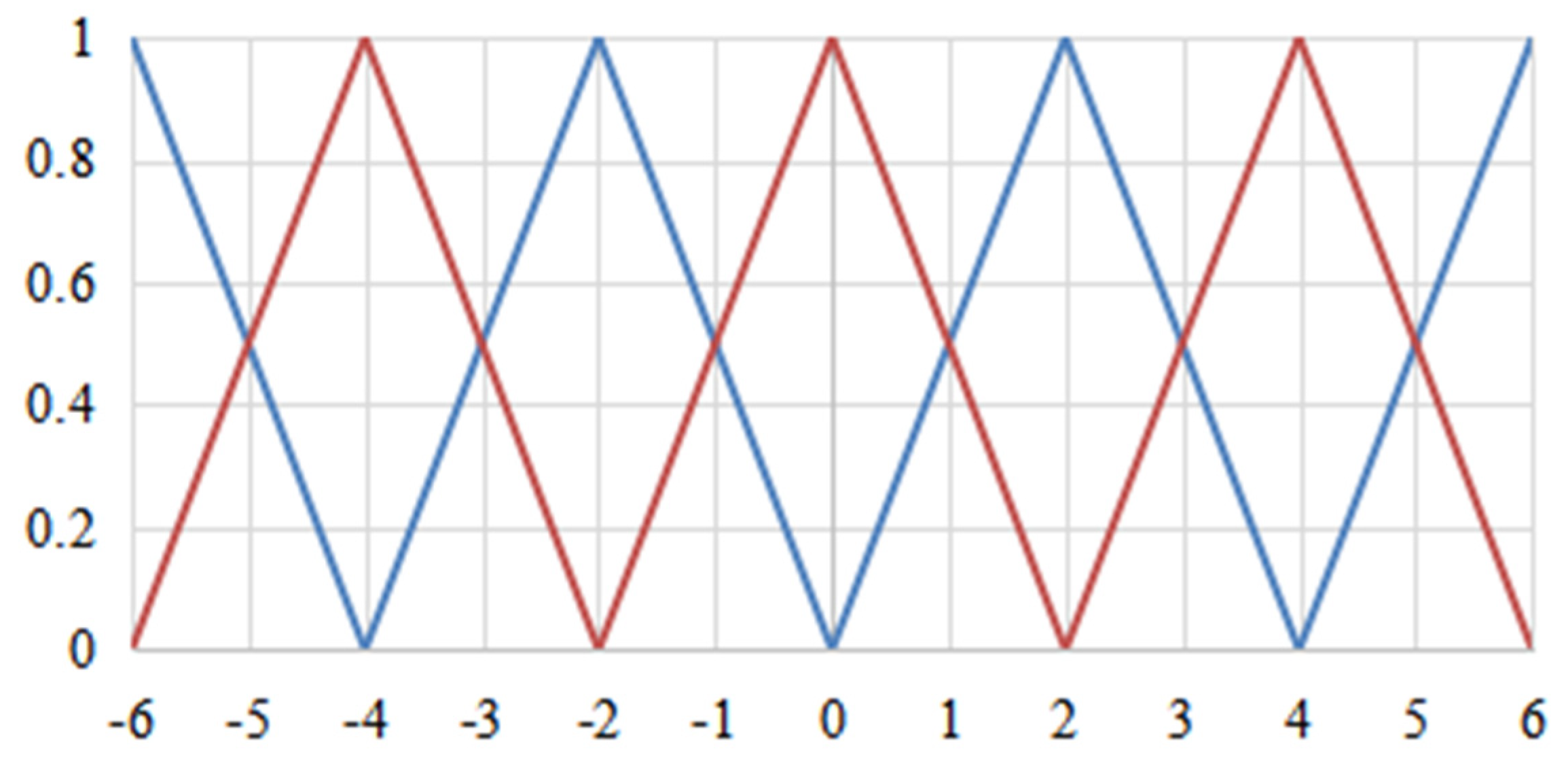

3.3.1. Fuzzy Input Value

3.3.2. Establish Fuzzy Rule Table

3.3.3. Demoulding Processing

3.4. Analysis of Gravity Compensation

- The grinding device performs a profiling movement on the blade’s surface when it is not in contact with the blade and the grinding force is zero, after which time the measurements of the pressure sensor and the manipulator in each attitude are collected;

- The force and attitude information collected are substituted into Equation (33) to obtain the installation deflection angle;

- The above two steps are repeated to collect multiple different sets of information and thus obtain multiple installation deflection angles, which can be used to calculate the average installation deflection angle ;

- The deflection angle obtained in the previous step is substituted into Equation (34) to determine whether the result is 0; if it is not 0, the above steps are repeated until the contact force obtained is 0.

4. Experiments

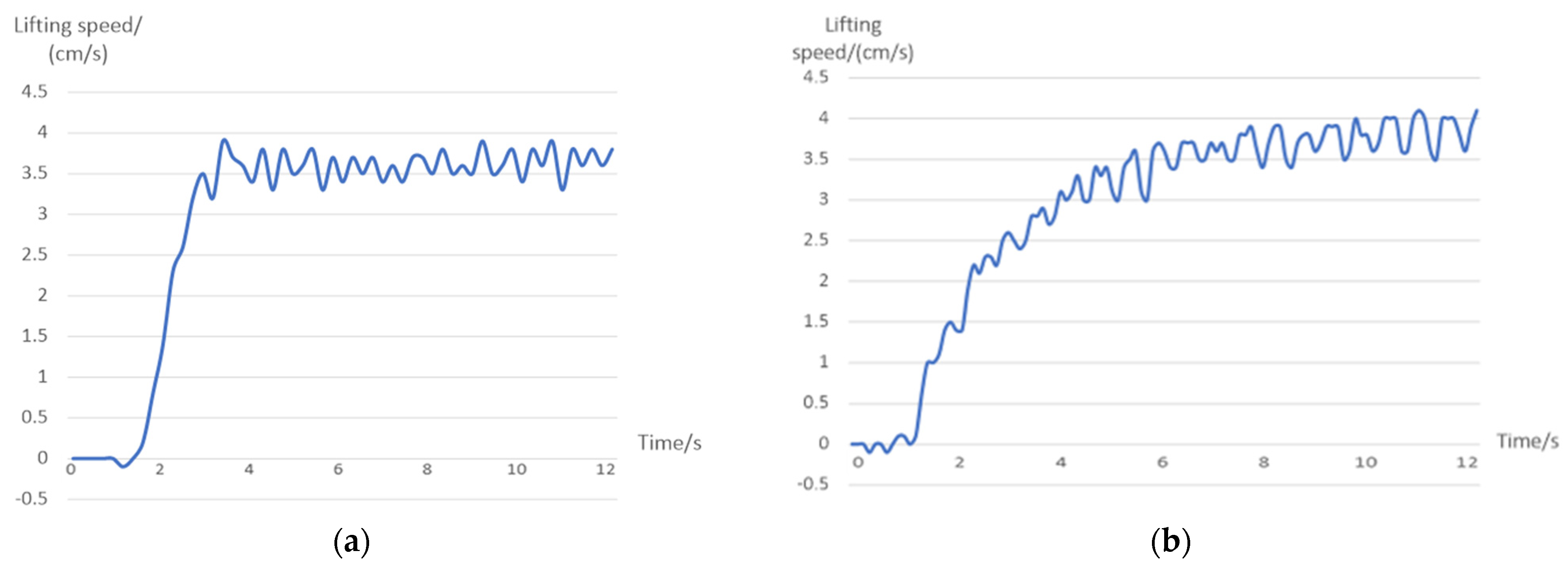

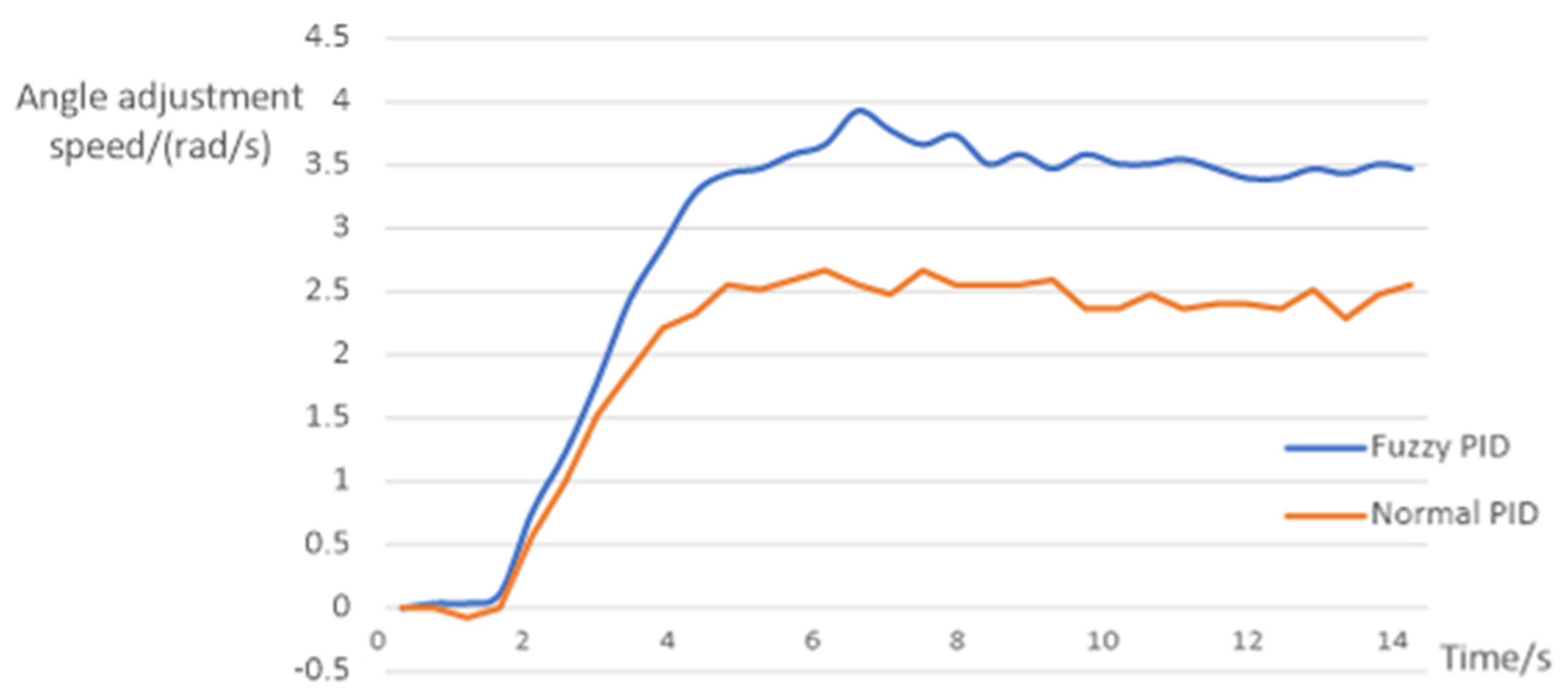

4.1. Control Algorithm Comparison Experiment

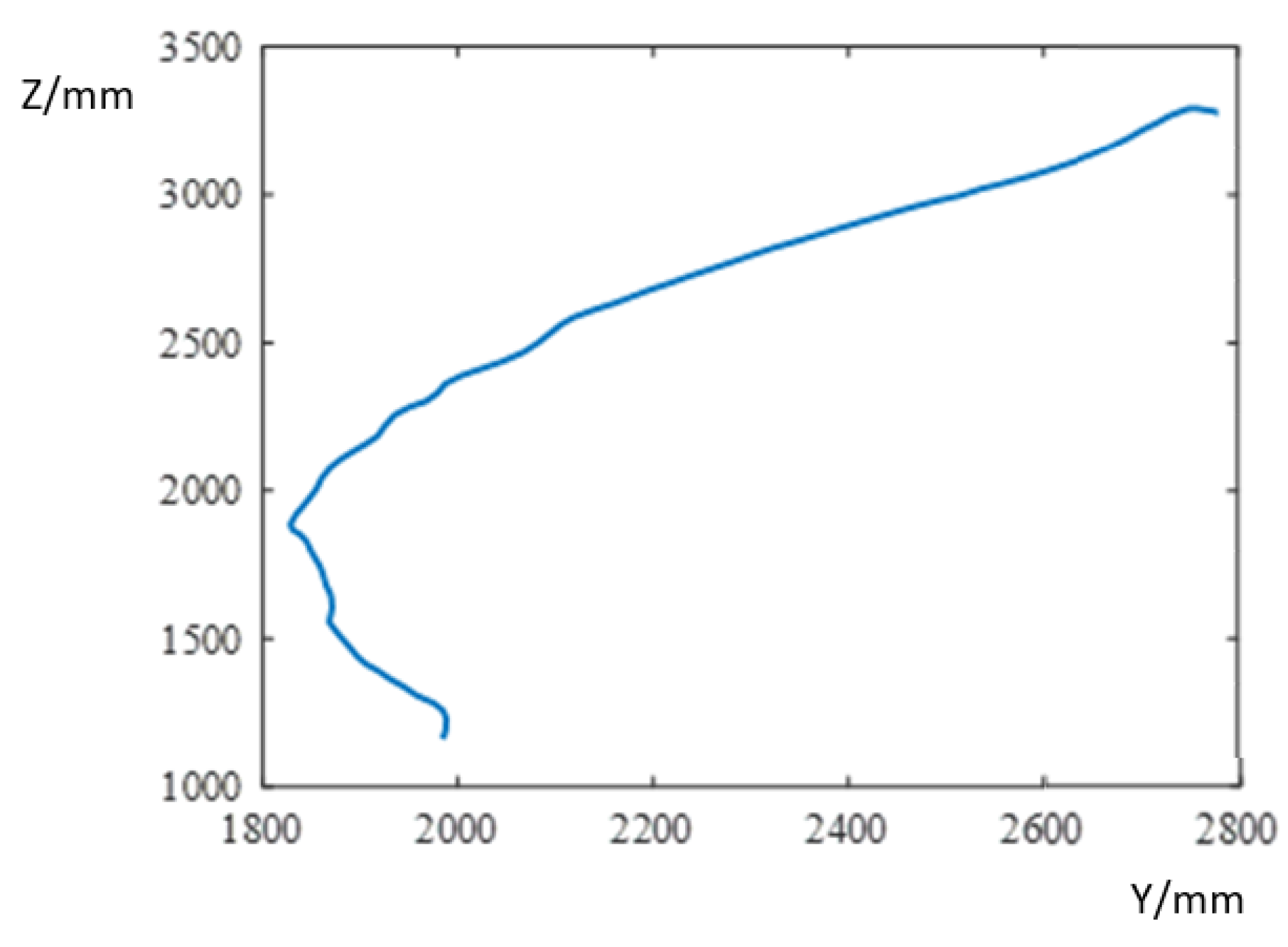

4.2. Surface Tracking Experiment

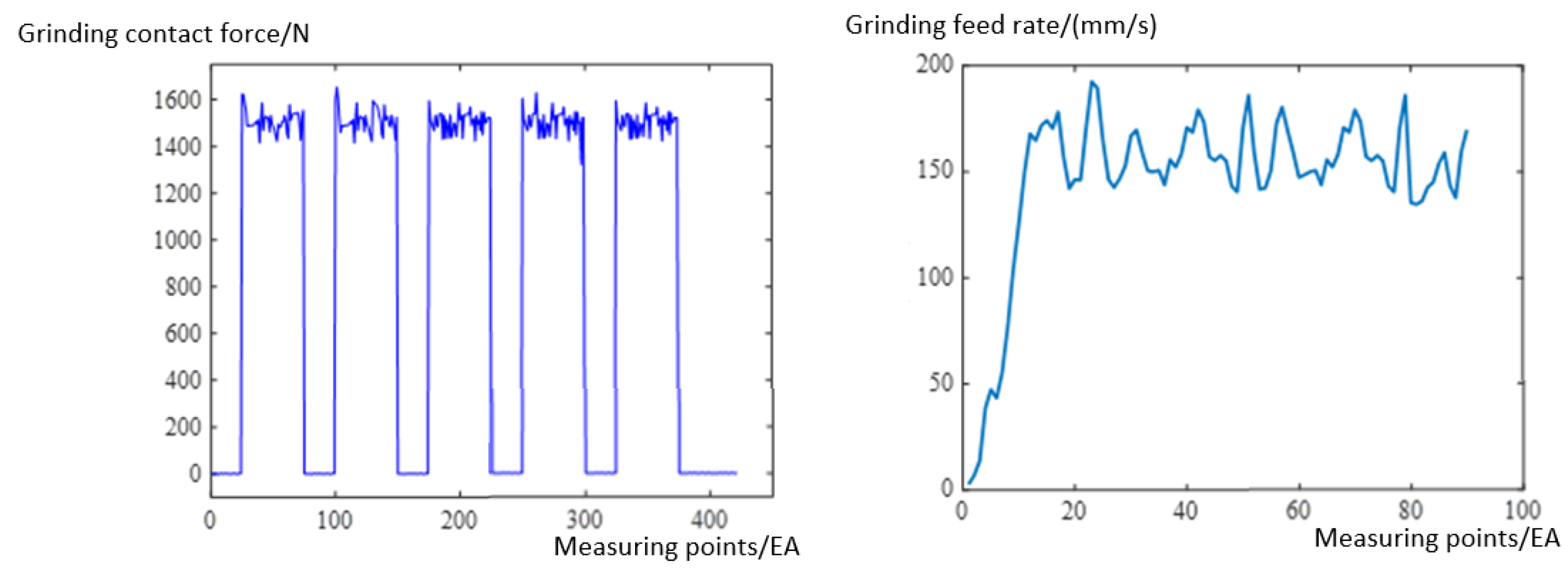

4.3. Grinding Force Tracking Experiment

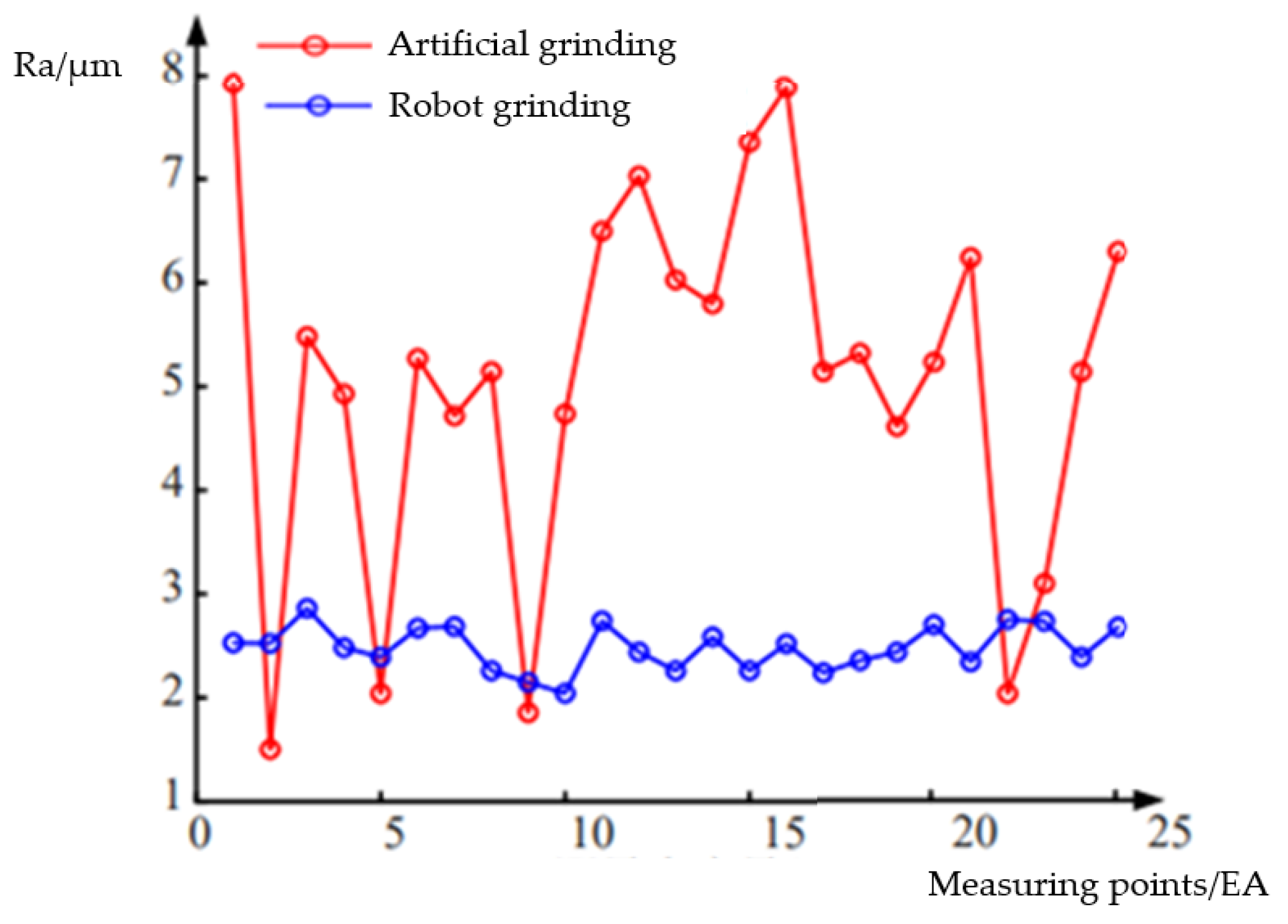

4.4. Field Processing Experiment

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dai, J.C.; Yang, X.; Wen, L. Development of wind power industry in China: A comprehensive assessment. Renew. Sustain. Energy Rev. 2018, 97, 156–164. [Google Scholar] [CrossRef]

- Liu, Y.D.; Wang, J. The SWOT Analysis and Countermeasure Research on the Development of Wind Power Industry in China. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Chengdu, China, 9–11 July 2021. [Google Scholar]

- Chen, G.W.; Huang, X.M.; Zhang, L.A.; Wang, J.H.; Liu, W.S. Study on sand grinding technology of wind turbine blade surface. Acta Energ. Sol. Sin. 2021, 42, 302–307. [Google Scholar]

- Yan, C.; Chen, X.L.; Li, G.L.; Li, C.L. Design and development of an efficient and adaptive grinding head system for a new type of wind turbine blade automatic grinding robot. Compos. Sci. Eng. 2021, 12, 114–119. [Google Scholar]

- Xu, Z.L.; Lu, S.; Yang, J.; Feng, Y.H.; Shen, C.T. A wheel-type in-pipe robot for grinding weld beads. Adv. Manuf. 2017, 5, 182–190. [Google Scholar] [CrossRef]

- Ma, W.C. Design and Research on Constant Force Control Device for Robot Grinding. Master’s Thesis, Huazhong University of Science & Technology, Wuhan, China, May 2019. [Google Scholar]

- Xiao, M. Research on Constant Force Control Methods in Robot Grinding Process. Ph.D. Thesis, South China University of Technology, Guangzhou, China, May 2020. [Google Scholar]

- Zhang, T.; Yu, Y.; Zou, Y.B. An Adaptive Sliding-Mode Iterative Constant-force Control Method for Robotic Belt Grinding Based on a One-Dimensional Force Sensor. Sensors 2019, 19, 1635. [Google Scholar] [CrossRef] [PubMed]

- Kuo, Y.L.; Huang, S.Y.; Lan, C.C. Sensorless force control of automated grinding/deburring using an adjustable force regulation mechanism. IEEE Int. Conf. Robot. Autom. 2019, 2019, 9489–9495. [Google Scholar]

- Shen, Y.; Lu, Y.; Zhuang, C. A fuzzy-based impedance control for force tracking in unknown environment. J. Mech. Sci. Technol. 2022, 36, 5231–5242. [Google Scholar] [CrossRef]

- Wahballa, H.; Duan, J.; Dai, Z. Constant force tracking using online stiffness and reverse damping force of variable impedance controller for robotic polishing. Int. J. Adv. Manuf. Technol. 2022, 121, 5855–5872. [Google Scholar] [CrossRef]

- Yao, M.Y.; Zheng, C.W.; Wang, Z.H.; Qian, J.Z.; Xi, Q.; Kuang, S.L. Research on the method of skateboard edge grinding by combination of robot and pneumatic constant force grinding device. In Proceedings of the Fourth International Conference on Mechanical, Electric and Industrial Engineering (MEIE2021), Kunming, China, 22–24 May 2021. [Google Scholar]

- Sun, M.J.; Guo, K.; Sun, J. Research on robot grinding force control method. Intell. Robot. Appl. 2021, 13014, 821–829. [Google Scholar]

- Dai, S.J.; Li, S.N.; Ji, W.B.; Sun, Z.L.; Zhao, Y.F. Force tracking control of grinding end effector based on backstepping + PID. Ind. Robot. Int. J. 2021, 49, 34–46. [Google Scholar] [CrossRef]

- Xu, X.H.; Chen, W. Hybrid active/passive force control strategy for grinding marks suppression and profile accuracy enhancement in robotic belt grinding of turbine blade. Robot. Comput. Integr. Manuf. 2021, 67, 102047. [Google Scholar] [CrossRef]

- Zhang, T.; Yuan, C.; Zou, Y.B. Online Optimization Method of Controller Parameters for Robot Constant Force Grinding Based on Deep Reinforcement Learning Rainbow. J. Intell. Robot. Syst. 2022, 105, 85. [Google Scholar] [CrossRef]

- Zhao, W.; Xiao, J.L.; Liu, S.J.; Dou, S.X.; Liu, H.T. Robotic direct grinding for unknown workpiece contour based on adaptive constant force control and human–robot collaboration. Ind. Robot. 2022, 50, 376–384. [Google Scholar] [CrossRef]

- Wang, G.; Deng, Y.; Zhou, H.; Yue, X. PD-adaptive variable impedance constant force control of macro-mini robot for compliant grinding and polishing. Int. J. Adv. Manuf. Technol. 2023, 124, 2149–2170. [Google Scholar] [CrossRef]

- Han, J.L.; Shan, X.L.; Liu, H.T.; Xiao, J.L.; Huang, T. Fuzzy gain scheduling PID control of a hybrid robot based on dynamic characteristics. Mech. Mach. Theory 2023, 184, 105283. [Google Scholar] [CrossRef]

- Li, D.W.; Yang, J.X.; Zhao, H.; Ding, H. Contact force plan and control of robotic grinding towards ensuring contour accuracy of curved surfaces. Int. J. Mech. Sci. 2022, 227, 107449. [Google Scholar] [CrossRef]

- Jia, W.D.; Jiang, Z.F.; Dai, Y. Constant Force Control Method of Grinding Device. Lect. Notes Comput. Sci. 2022, 13457, 378–387. [Google Scholar]

- Zhao, X.W.; Lu, H.; Yu, W.F.; Tao, B.; Ding, H. Vision-based Mobile Robotic Grinding for Large-scale Workpiece and Its Accuracy Analysis. IEEE/ASME Trans. Mechatron. 2022, 28, 895–906. [Google Scholar] [CrossRef]

- Dai, S.J.; Zhang, W.H.; Ji, W.B.; Zhao, Y.F.; Zheng, H.W.; Mu, J.H.; Li, P.W.; Deng, R.Q. Research on constant force grinding control of aero-engine blades based on extended state observer. Ind. Robot 2022, 49, 1077–1088. [Google Scholar] [CrossRef]

- Xiao, M.; Zhang, T.; Zou, Y.B.; Chen, S.Y. Robotic constant force grinding control based on grinding model and iterative algorithm. Ind. Robot 2020, 48, 270–279. [Google Scholar] [CrossRef]

- Zhang, X.X. Hybrid Coutour Force/Position Control of Industrial Robot Based on Variable-Gain Iterative Learning. Ph.D. Thesis, China University of Geosciences, Wuhan, China, May 2022. [Google Scholar]

- Li, J.; Guan, Y.; Chen, H.; Wang, B.; Zhang, T. Robotic Polishing of Unknown-Model Workpieces With Constant Normal Contact Force Control. IEEE/ASME Trans. Mechatron. 2023, 28, 1093–1103. [Google Scholar] [CrossRef]

- Zhang, T.; Yuan, C.; Zou, Y.B. Research on the algorithm of constant force grinding controller based on reinforcement learning PPO. Int. J. Adv. Manuf. Technol. 2023, 1–14. [Google Scholar] [CrossRef]

- Peterson, M.B. Design considerations for effective wear control. In Wear Control Handbook; American Society of Mechanical Engineering: New York, NY, USA, 1980; pp. 413–474. [Google Scholar]

- Tsai, M.J.; Huang, J.F.; Kao, W.L. Robotic polishing of precision molds with uniform material removal control. Int. J. Mach. Tools Manuf. 2009, 49, 885–895. [Google Scholar] [CrossRef]

- Lai, H.S.; Wu, L.; Chen, X.D.; Yang, Z.Q. Research on the force control of the robot and surface tracking with unknown parameters. Manuf. Technol. Mach. Tool 2018, 6, 21–25. [Google Scholar]

- Xiong, M.Q. Research on Key Techniques of Robot Force/Position Control Grinding and Polishing. Master’s Thesis, Changchun University of Science and Technology, Changchun, China, June 2020. [Google Scholar]

- Zhang, T.; Xiao, M.; Zou, Y.B.; Xiao, J.D. Research on robot constant force control of surface tracking based on reinforcement learning. J. Zhejiang Univ. Eng. Sci. 2019, 53, 1865–1873. [Google Scholar] [CrossRef]

| Kp Ki Kd | ec | |||||||

|---|---|---|---|---|---|---|---|---|

| NB | NM | NS | ZO | PS | PM | PB | ||

| e | NB | PB NB PS | PB NB NS | PM NM NB | PM NM NB | PS NS NB | ZO ZO NM | ZO ZO PS |

| NM | PB NB PS | PB NB NS | PM NM NB | PS NS NM | PS NS NM | ZO ZO NS | NS ZO PS | |

| NS | PM NB ZO | PM NM NS | PM NS NM | PS NS NM | ZO ZO NS | NS PS NS | NS PS ZO | |

| ZO | PM NM ZO | PM NM NS | PS NS NS | ZO ZONS | NS PS NS | NM PM NS | NS PS ZO | |

| PS | PS NM ZO | PS NS ZO | ZO ZO ZO | NS PS ZO | NS PS ZO | NM PM ZO | NB PB ZO | |

| PM | PS ZO PB | ZO ZO NS | NS PS PS | NM PS PS | NM PM PS | NM PB PS | NB PB PB | |

| PB | ZO ZO PB | ZO ZO PM | NM PS PM | NM PM PM | NM PM PS | NB PB PS | NB PB PB | |

| Control Mode | Maximum Overshoot | Rise Time | Peak Time | Steady State Error | Accommodation Time |

|---|---|---|---|---|---|

| fuzzy PID control | 3.58% | 700 ms | 1500 ms | ±0.5 cm/s | 3100 ms |

| proportional servo valve control | 5.58% | 1500 ms | 2700 ms | ±2 cm/s | 5300 ms |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, X.; Li, M.; Dong, Y.; Feng, S. Research on Surface Tracking and Constant Force Control of a Grinding Robot. Sensors 2023, 23, 4702. https://doi.org/10.3390/s23104702

Shi X, Li M, Dong Y, Feng S. Research on Surface Tracking and Constant Force Control of a Grinding Robot. Sensors. 2023; 23(10):4702. https://doi.org/10.3390/s23104702

Chicago/Turabian StyleShi, Xiaohua, Mingyang Li, Yuehu Dong, and Shangyu Feng. 2023. "Research on Surface Tracking and Constant Force Control of a Grinding Robot" Sensors 23, no. 10: 4702. https://doi.org/10.3390/s23104702

APA StyleShi, X., Li, M., Dong, Y., & Feng, S. (2023). Research on Surface Tracking and Constant Force Control of a Grinding Robot. Sensors, 23(10), 4702. https://doi.org/10.3390/s23104702