Driver Assisted Lane Keeping with Conflict Management Using Robust Sliding Mode Controller

Abstract

1. Introduction

1.1. State of the Art

1.2. Proposed Methodology

1.3. Contribution

- The introduction of a shared control parameter into the control design to minimize conflict between the human driver and automated driving system.

- The design of a novel higher-order sliding mode control algorithm with linear and nonlinear terms.

- The addressing of multiple objectives of lane position error reduction, enhancement of driver satisfaction, and conflict management.

2. Problem Formulation: Driver Adapted Lane Keeping

2.1. DiL Modeling: Vehicle-Road-Driver Dynamics

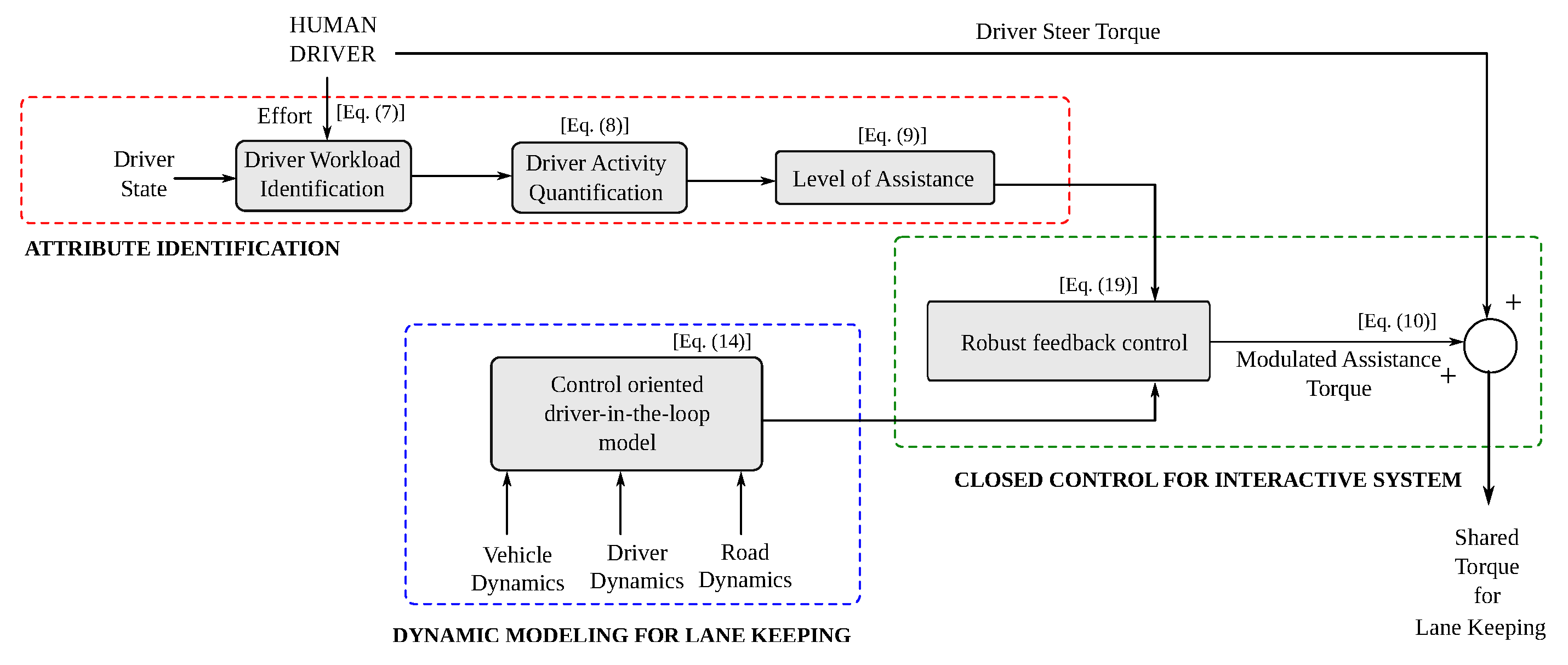

2.2. HMI Management: Driver Workload-Level of Assistance

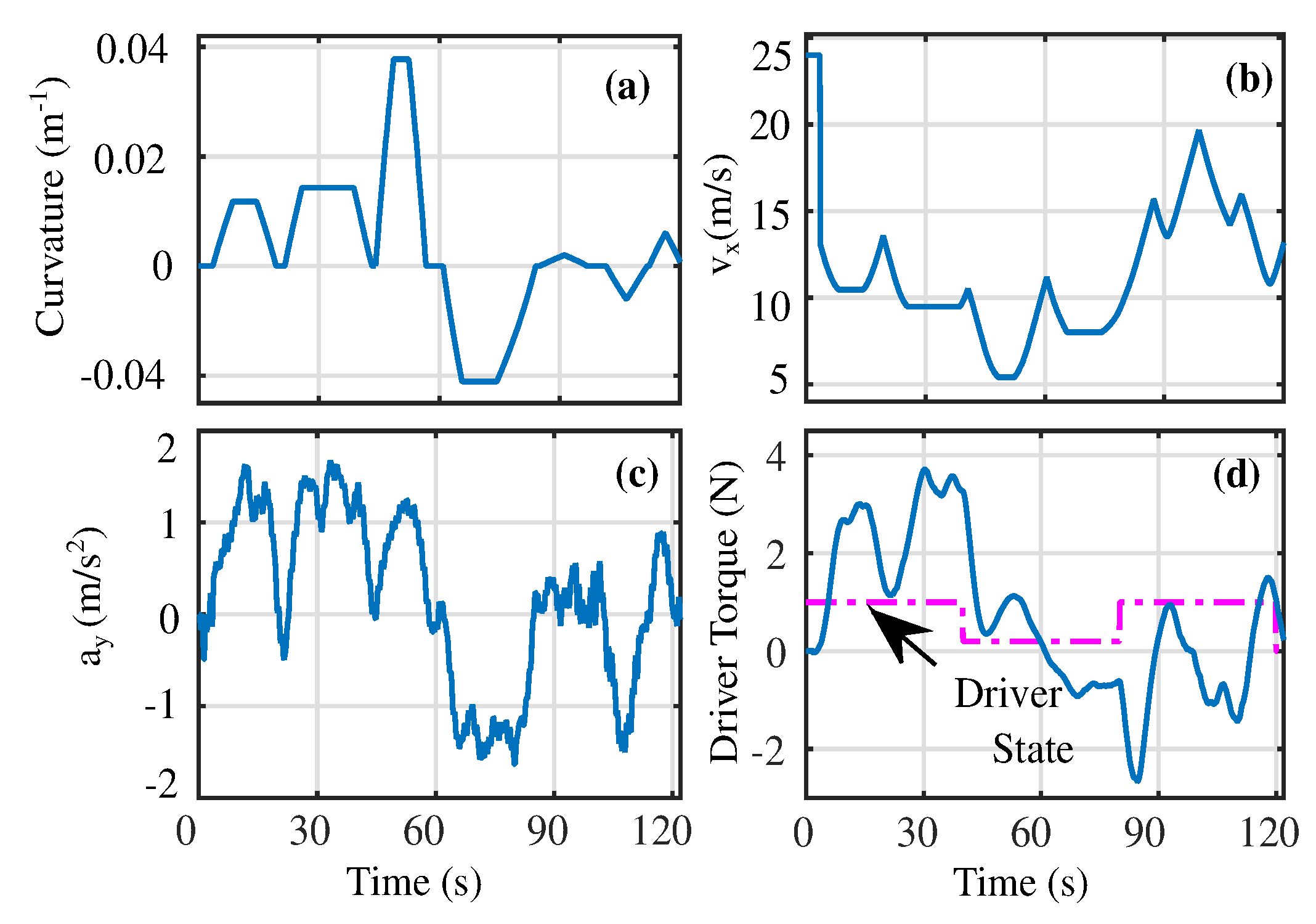

- Identification of driver workload: The measured driver torque at the steering wheel is typically dependent on many factors such as road curvature, lateral acceleration, the preview time, and the far point distance, and dynamics of the human arm among others. In this work, the adaptive driver torque for various drivers/driving scenarios is computed using a simple rule-based logic with the inputs being lateral acceleration and predicted road curvature [43]. With the increase in lateral acceleration and road curvature, the value of the increases, to show more physical workload of the driver. Mathematically, the normalized maximum driver torque is represented in Equation (10).Similarly, the mental workload is accounted for by the driver state which categorizes the driver’s involvement into different levels such as attentive, sleepy, drowsy, and distracted. With the increase in the driver is more involved in the driving task and vice-versa. In the case when , the driver is completely distracted, and when , the driver is actively involved in the driving task. For practical purposes, the DS is obtained from the driver monitoring unit (DMU) installed in vehicles comprising of a vision system to monitor driver activity [44]. It is of note that, although different states of driver are monitored, generally the output of the DMU is binary indicating an active driver or a distracted driver [28].

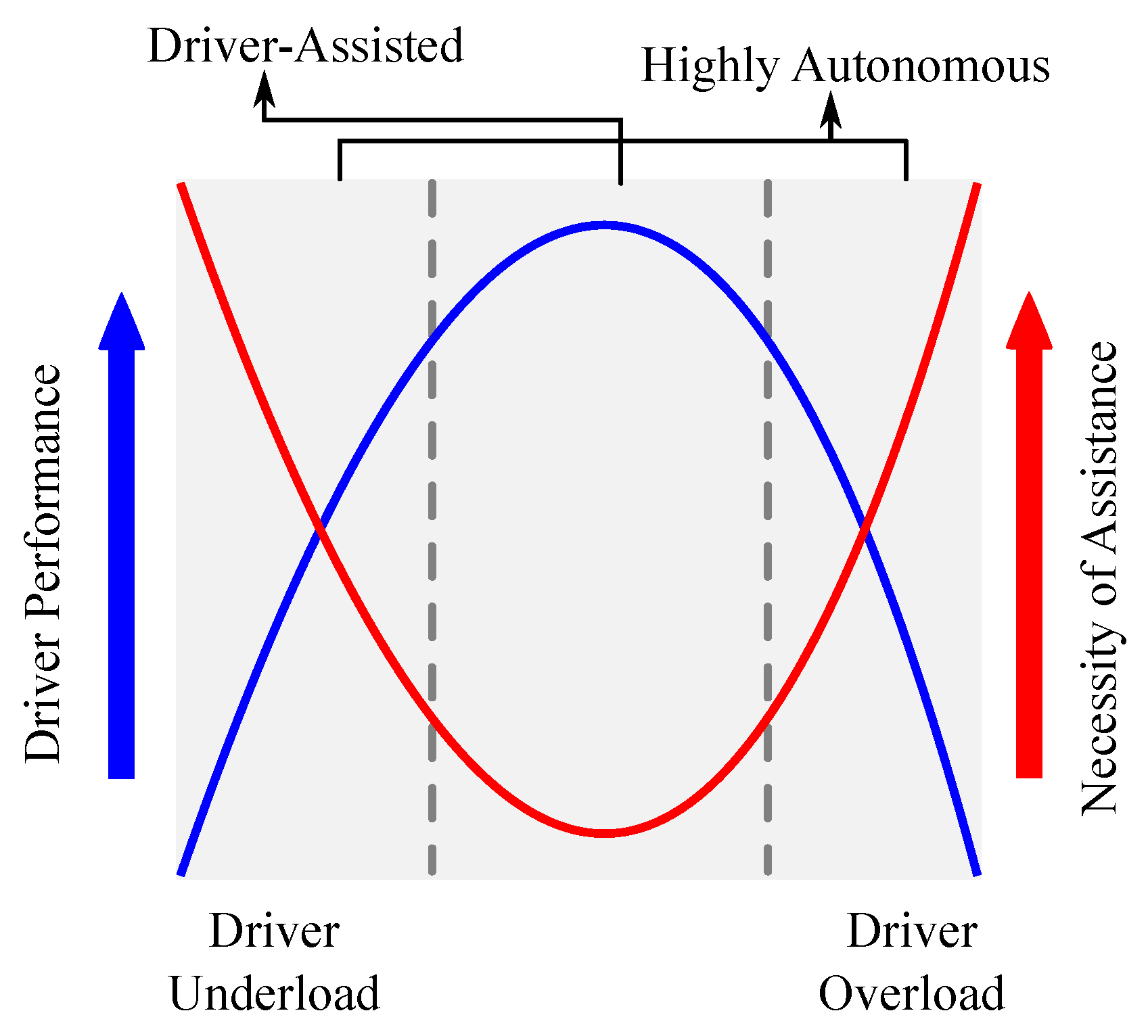

- Mapping driver workload to activity: In the context of driver workload, effective driver performance decreases with an increase in workload levels. Similarly, for low activity (corresponding low workload) level, also the performance of the driver is low, as the driver is not significantly involved in the driving task. Analytically, this relationship is expressed as in Equation (11).where indicates driver activity, , , and selected appropriately to consider the degree of influence of the physical and cognitive components on the driver activity. This relationship is presented graphically in form of a U-shaped function in [27].

- Activity-based level of assistance generation: The level of assistance (LOA) required to complete a driving task can be determined similarly to [27], by using the inverse-U relationship between driver performance and LOA. Considering the objective of providing high assistance to the driver during under-load and over-load (i.e., low activity) regions, an analytical mapping for driver performance-LOA is defined as in Equation (12).The time-varying parameter represents a modulation factor that relates the driver workload-based performance with the LOA for task completion. The parameters , , are chosen to replicate the U-shaped relationship as discussed in [27] and shown in Figure 2. A minimum assistance level of is used to consider the influence of sensor noise, drift, etc.

3. Robust DiL Lane Keeping Control: A HOSM Approach

3.1. Control Oriented DiL Modeling

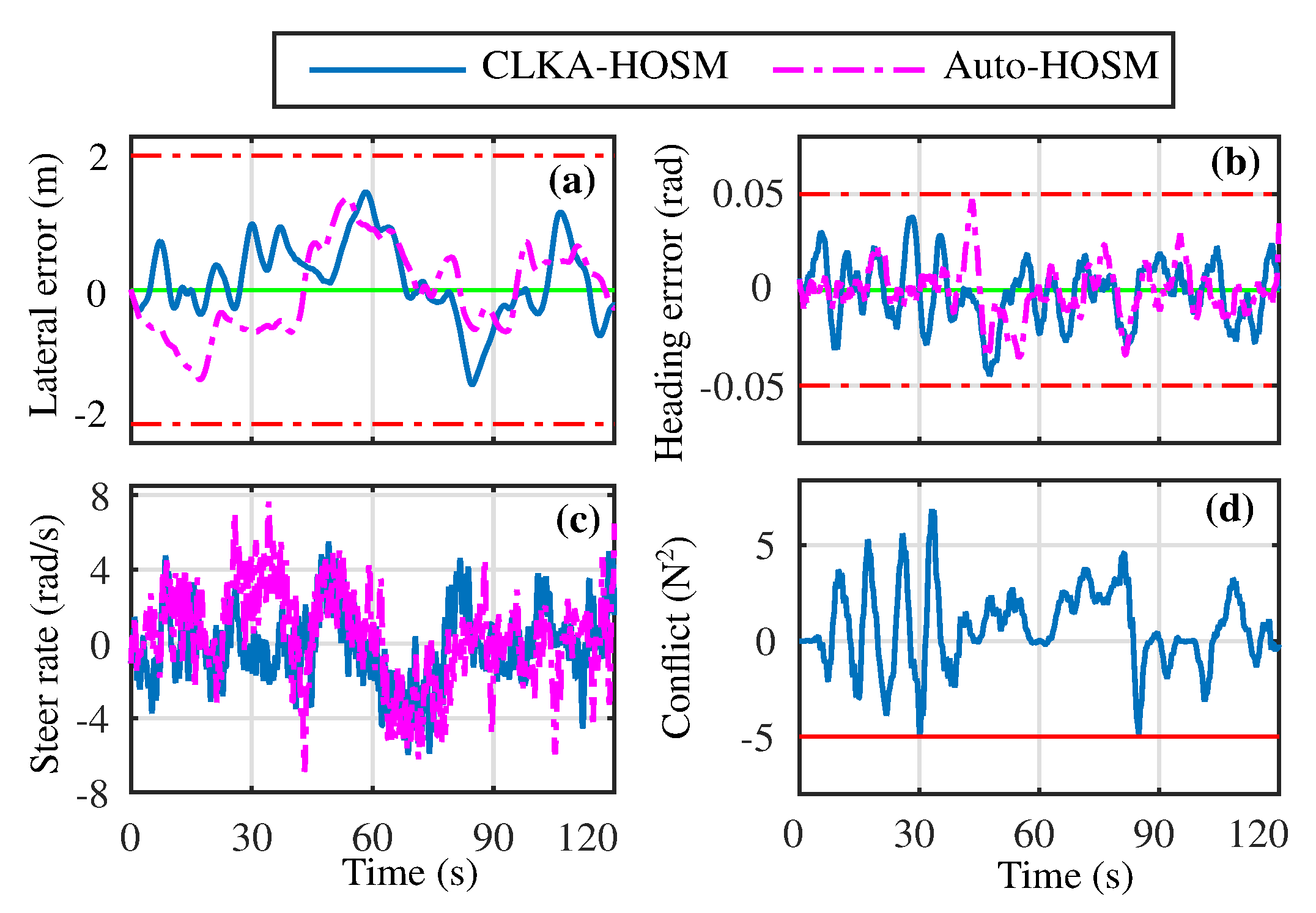

3.2. Control Objectives for LKA

- Minimization of lane tracking errors: The lane tracking errors as given in Equation (8) comprise the errors lateral deviation and the heading angle. To quantify the lane error at a look-ahead distance, the parameter is defined as in Equation (19).The control objective is then to ensure that the front wheels of the vehicle are simultaneously located in strip ( m) along the lane center line. In other words, the following condition in Equation (20).where denotes the width of the vehicle.

- Improvement of driver comfort: The comfort of the driver while navigating the road can be understood as a measure of the vibrations or oscillations at the steering wheel. As such, the steering rate or the lateral acceleration can be used as a measure to quantify the driver comfort [45].

- Conflict Minimization: The mismatch of control actions between the human driver and the autonomous controller categorized as conflict, must be minimized for having a good shared control performance [5]. This can be achieved by passing over the authority to the human driver. Accordingly, the following fictional state is introduced to achieve the above action in Equation (21).where is any positive parameter reflecting the level of sharing, and represents the driver torque measured at the steering wheel. In case of conflict, the value of . In such a case, it can be deduced that . Hence, by the appropriate design of the parameter , the influence of the assistance torque can be reduced.

3.3. Robust HOSM Controller

4. Validation and Results

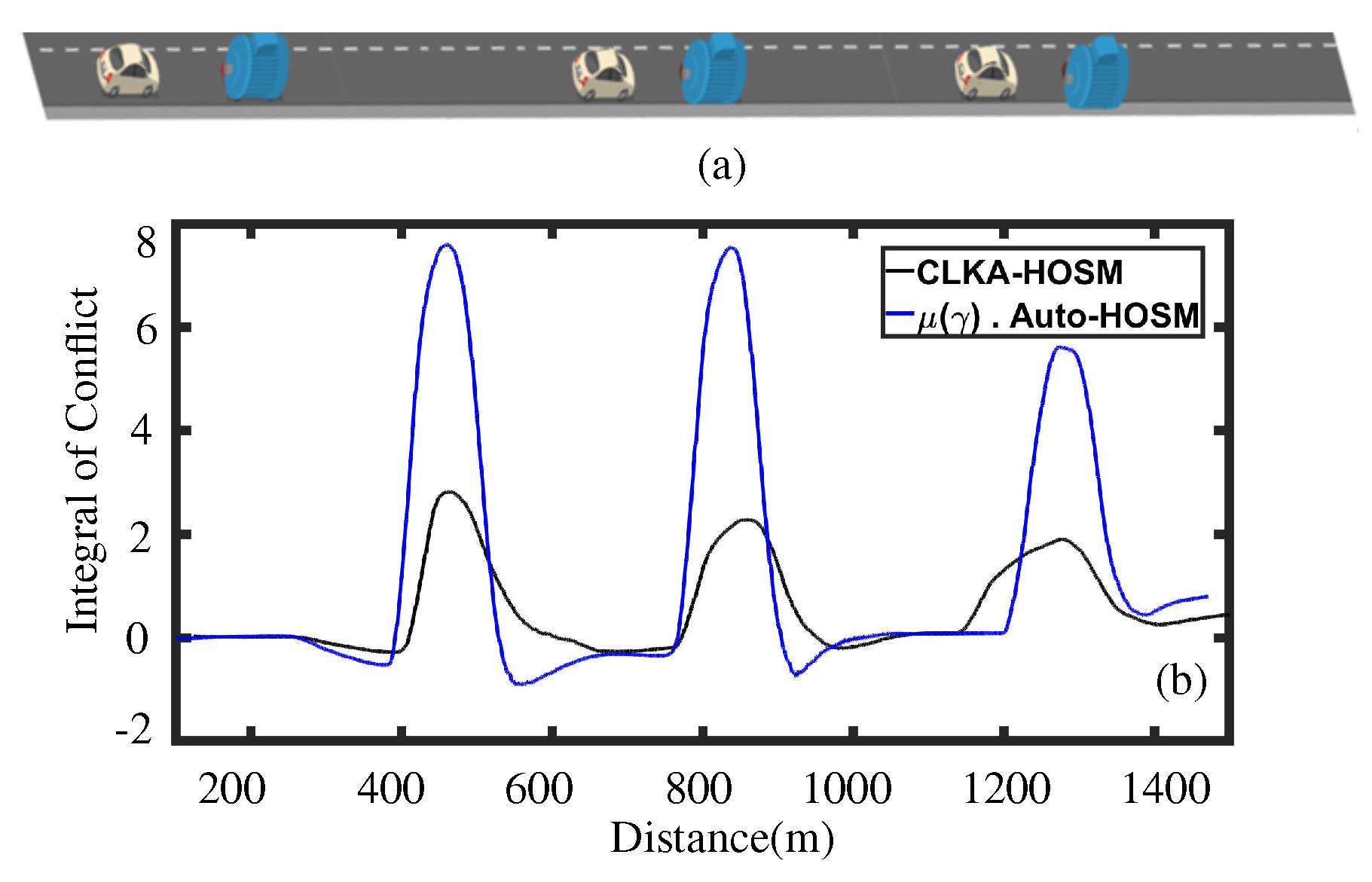

4.1. Simulation Studies

- Auto-HOSM: Autonomous controller (i.e., ) with proposed HOSM control law.

- CLKA-HOSM: Shared controller with proposed HOSM control law.

- AFac: Denotes the ratio between efforts generated by the automation and human driver for completing the driving task i.e., in Equation (36).If the values of AFac , the assistance provided by the automation is less than that of the driver, and inversely for AFac .

- SW: This indicates the steering workload and is representative of the effort generated by both agents simultaneously for completing the driving task i.e., in Equation (37).A larger magnitude of negative steering workload indicates that the assistance provided by the automation to the human driver is not good for shared control.

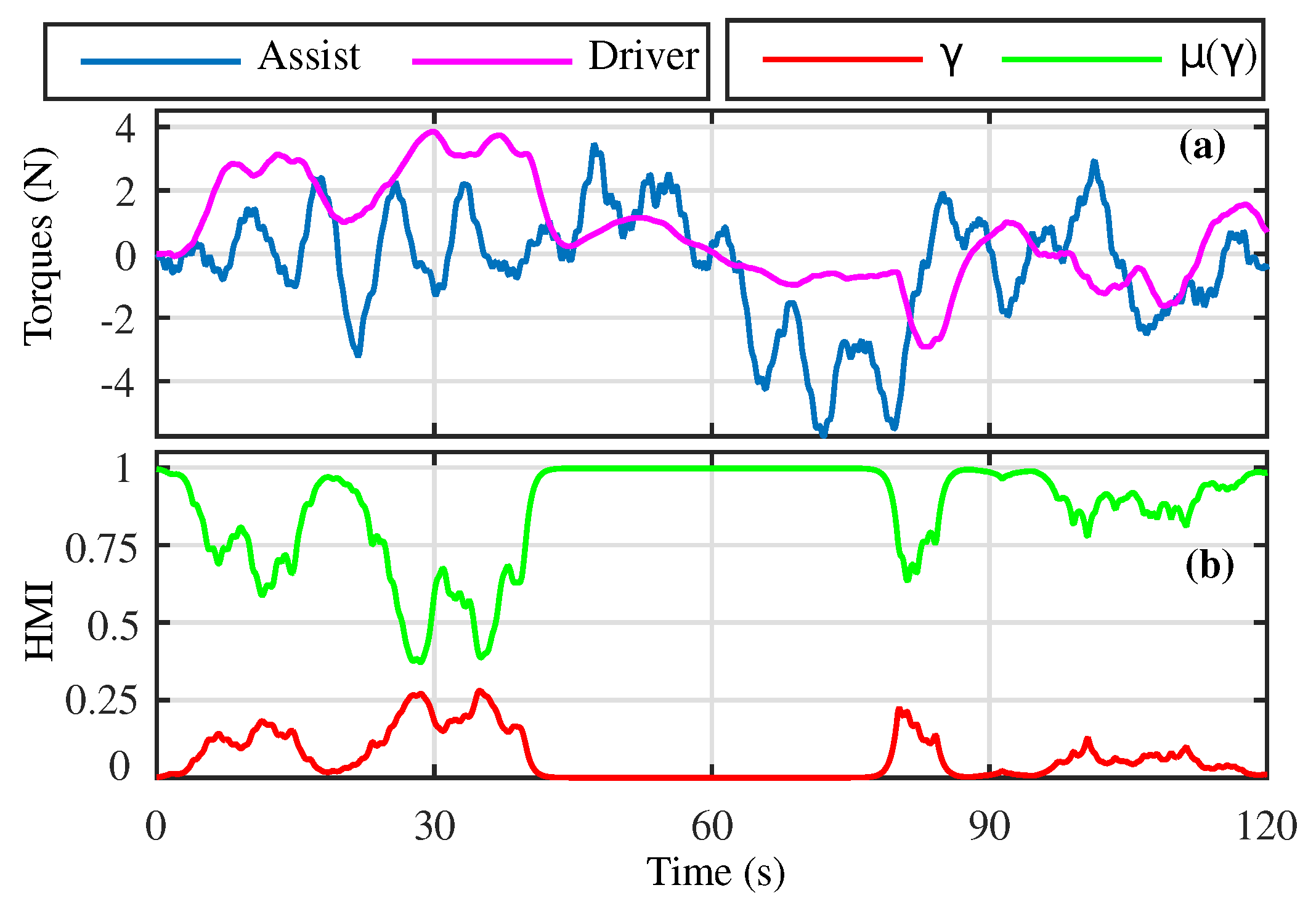

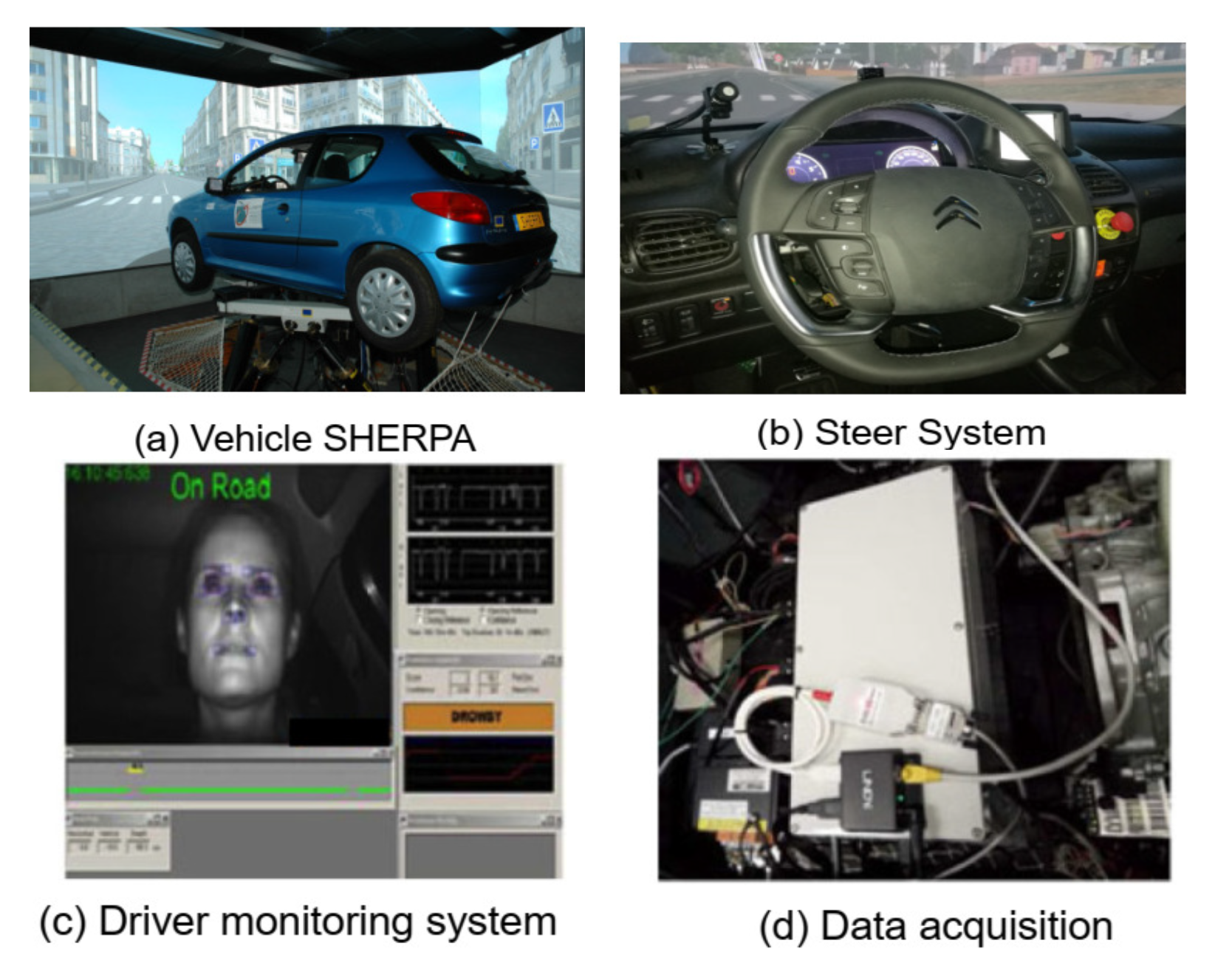

4.2. Experimental Results: SHERPA Vehicle Simulator

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Description | Value |

| M | total mass of the vehicle | 2025 [kg] |

| distance from CoG to front axle | [m] | |

| distance from CoG to rear axle | [m] | |

| tire length contact | [m] | |

| look-ahead distance | 5 [m] | |

| vehicle yaw moment of inertia | 2800 [kgm] | |

| steering moment of inertia | [kgm] | |

| steering gear ratio | [-] | |

| steering system damping | [N/rad] | |

| front cornering stiffness | 42,500 [N/rad] | |

| rear cornering stiffness | 57,000 [N/rad] | |

| rate driver’s—vehicle’s wheel angles | ||

| width of the vehicle | ||

| side slip angle | ||

| steering angle | ||

| steering angle | ||

| steering rate | ||

| heading angle | ||

| front friction force | ||

| rear friction force | ||

| longitudinal velocity | ||

| front slip angle | ||

| rear slip angle | ||

| self-aligning torque | ||

| uncertainty of tire friction force | ||

| level of assistance | ||

| lateral deviation error | ||

| orientation error w.r.t the lane center-line | ||

| driver torque | ||

| automation assistance torque | ||

| rate driver workload-based performance—LOA | ||

| feedback control torque | ||

| anticipatory gain | ||

| compensatory gain | ||

| near visual points of the driver | ||

| far visual points of the driver | ||

| the level of sharing | ||

| driver torque measured at the steering wheel | ||

| conflict dynamics | ||

| linear error surface of the SMC | ||

| ratio between automation and human | ||

| Acronyms | ||

| Symbol | Description | |

| ADAS | Advanced driver assist system | |

| LKA | Lane keeping assistance | |

| ACC | Adaptive cruise control | |

| CA | Collision avoidance | |

| HMI | Human machine interaction | |

| DiL | Driver-in-the-loop | |

| HOSM | High order sliding mode | |

| SMC | Sliding mode control | |

| BT | Brush-Tire | |

| DS | Driver state | |

| DMU | Driver monitoring unit | |

| LOA | Level of assistance | |

| Auto-HOSM | Autonomous controller with proposed HOSM control | |

| CLKA-HOSM | Shared controller with proposed HOSM control | |

| SC-NoK4 | Shared controller with proposed HOSM control with | |

| PSO | Particle swarm optimization | |

| SW | Steering workload | |

| IOC | Integral of conflict | |

| SHERPA | Simulateur Hybride d’Etude et de Recherche Pour l’Automobile |

References

- Rajamani, R. Vehicle Dynamics and Control; Springer: Boston, MA, USA, 2012. [Google Scholar]

- Flemisch, F.; Kelsch, J.; Loper, C.; Schieben, A.; Schindler, J.; Heesen, M. Cooperative control and active interfaces for vehicle assistance and automation. In Proceedings of the FISITA World Automotive Congress, Munich, Germany, 14–19 September 2008. [Google Scholar]

- Abbink, D.A.; Mulder, M.; Boer, E.R. Haptic shared control: Smoothly shifting control authority? Cogn. Technol. Work 2011, 14, 19–28. [Google Scholar] [CrossRef]

- Saito, T.; Wada, T.; Sonoda, K. Control Authority Transfer Method for Automated-to-Manual Driving Via a Shared Authority Mode. IEEE Trans. Intell. Veh. 2018, 3, 198–207. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Sentouh, C.; Popieul, J.C. Driver-automation cooperative approach for shared steering control under multiple system constraints: Design and experiments. IEEE Trans. Ind. Electron. 2017, 64, 3819–3830. [Google Scholar] [CrossRef]

- Wada, T.; Sonoda, K.; Tada, S. Simultaneous Achievement of Supporting Human Drivers and Improving Driving Skills by Shared and Cooperative Control. IFAC-PapersOnLine 2016, 49, 90–95. [Google Scholar] [CrossRef]

- Saleh, L.; Chevrel, P.; Claveau, F.; Lafay, J.F.; Mars, F. Shared steering control between a driver and an automation: Stability in the presence of driver behavior uncertainty. IEEE Trans. Intell. Transp. Syst. 2013, 14, 974–983. [Google Scholar] [CrossRef]

- Schnelle, S.; Wang, J.; Su, H.; Jagacinski, R. A Driver Steering Model with Personalized Desired Path Generation. IEEE Trans. Syst. Man, Cybern. Syst. 2017, 47, 111–120. [Google Scholar] [CrossRef]

- Sentouh, C.; Chevrel, P.; Mars, F.; Claveau, F. A sensorimotor driver model for steering control. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics, San Antonio, TX, USA, 11–14 October 2009; pp. 2462–2467. [Google Scholar]

- Li, L.; Liu, Y.; Wang, J.; Deng, W.; Oh, H. Human dynamics based driver model for autonomous car. IET Intell. Transp. Syst. 2016, 10, 545–554. [Google Scholar] [CrossRef]

- Tanaka, Y.; Kashiba, Y.; Yamada, N.; Suetomi, T.; Nishikawa, K.; Nouzawa, T.; Tsuji, T. Active-steering control system based on human hand impedance properties. In Proceedings of the 2010 IEEE International Conference on Systems, Man and Cybernetics, Istanbul, Turkey, 10–13 October 2010. [Google Scholar] [CrossRef]

- Sharma, O.; Sahoo, N.C.; Puhan, N.B. Recent advances in motion and behavior planning techniques for software architecture of autonomous vehicles: A state-of-the-art survey. Eng. Appl. Artif. Intell. 2021, 101, 104211. [Google Scholar] [CrossRef]

- Gambhire, S.J.; Kishore, D.R.; Londhe, P.S.; Pawar, S.N. Review of sliding mode based control techniques for control system applications. Int. J. Dyn. Control 2021, 9, 363–378. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, J.; Tian, Y.; Li, L. A Novel Adaptive Steering Torque Control Approach for Human–Machine Cooperation Autonomous Vehicles. IEEE Trans. Transp. Electrif. 2021, 7, 2516–2529. [Google Scholar] [CrossRef]

- Kumar, V.; Naresh, R.; Sharma, V.; Kumar, V. State-of-the-Art Optimization and Metaheuristic Algorithms. In Handbook of Intelligent Computing and Optimization for Sustainable Development; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2022; pp. 509–536. [Google Scholar] [CrossRef]

- Brizuela-Mendoza, J.A.; Sorcia-Vázquez, F.D.J.; Rumbo-Morales, J.Y.; Lozoya-Ponce, R.E.; Rodríguez-Cerda, J.C. Active fault tolerant control based on eigenstructure assignment applied to a 3-DOF helicopter. Asian J. Control 2021, 23, 673–684. [Google Scholar] [CrossRef]

- Rumbo Morales, J.Y.; Brizuela Mendoza, J.A.; Ortiz Torres, G.; Sorcia Vázquez, F.d.J.; Rojas, A.C.; Pérez Vidal, A.F. Fault-Tolerant Control implemented to Hammerstein–Wiener model: Application to Bio-ethanol dehydration. Fuel 2022, 308, 121836. [Google Scholar] [CrossRef]

- Xing, Y.; Lv, C.; Cao, D.; Hang, P. Toward human-vehicle collaboration: Review and perspectives on human-centered collaborative automated driving. Transp. Res. Part C Emerg. Technol. 2021, 128, 103199. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, G.; Wang, R.; Schnelle, S.C.; Wang, J. A Gain-Scheduling Driver Assistance Trajectory-Following Algorithm Considering Different Driver Steering Characteristics. IEEE Trans. Intell. Transp. Syst. 2017, 18, 1097–1108. [Google Scholar] [CrossRef]

- Soualmi, B.; Sentouh, C.; Popieul, J.; Debernard, S. Automation-driver cooperative driving in presence of undetected obstacles. Control Eng. Pract. 2014, 24, 106–119. [Google Scholar] [CrossRef]

- Wang, Z.; Zheng, R.; Nacpil, E.J.C.; Nakano, K. Modeling and analysis of driver behaviour under shared control through weighted visual and haptic guidance. IET Intell. Transp. Syst. 2022, 16, 648–660. [Google Scholar] [CrossRef]

- Mars, F.; Deroo, M.; Hoc, J.M. Analysis of Human-Machine Cooperation When Driving with Different Degrees of Haptic Shared Control. IEEE Trans. Haptics 2014, 7, 324–333. [Google Scholar] [CrossRef]

- Boink, R.; van Paassen, M.M.; Mulder, M.; Abbink, D.A. Understanding and reducing conflicts between driver and haptic shared control. In Proceedings of the 2014 IEEE International Conference on Systems, Man, and Cybernetics (SMC), San Diego, CA, USA, 5–8 October 2014. [Google Scholar] [CrossRef]

- Huang, C.; Lv, C.; Hang, P.; Hu, Z.; Xing, Y. Human–Machine Adaptive Shared Control for Safe Driving Under Automation Degradation. IEEE Intell. Transp. Syst. Mag. 2022, 14, 53–66. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Su, C.; Gong, X.; Huang, J.; Yang, D. Adaptive Authority Allocation Approach for Shared Steering Control System. IEEE Trans. Intell. Transp. Syst. 2022, 23, 19428–19439. [Google Scholar] [CrossRef]

- Deng, H.; Zhao, Y.; Feng, S.; Wang, Q.; Lin, F. Shared Control for Intelligent Vehicle Based on Handling Inverse Dynamics and Driving Intention. IEEE Trans. Veh. Technol. 2022, 71, 2706–2720. [Google Scholar] [CrossRef]

- Flemisch, F.; Nashashibi, F.; Rauch, N.; Schieben, A.; Glaser, S.; Temme, G.; Resende, P.; Vanholme, B.; Löper, C.; Thomaidis, G.; et al. Towards highly automated driving: Intermediate report on the HAVEit-joint system. In Proceedings of the 3rd European Road Transport Research Arena, Brussels, Belgium, 7–10 June 2010. [Google Scholar]

- Sentouh, C.; Nguyen, A.T.; Benloucif, M.A.; Popieul, J.C. Driver-Automation Cooperation Oriented Approach for Shared Control of Lane Keeping Assist Systems. IEEE Trans. Control Syst. Technol. 2019, 27, 1962–1978. [Google Scholar] [CrossRef]

- Shimizu, Y.; Kawai, T.; Yuzuriha, J. Improvement in Driver-Vehicle System Performance by Varying Steering Gain with Vehicle Speed and Steering Angle: VGS (Variable Gear-Ratio Steering System); SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef]

- Izadi, V.; Ghasemi, A.H. Modulation of control authority in adaptive haptic shared control paradigms. Mechatronics 2021, 78, 102598. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Sentouh, C.; Popieul, J.C.; Soualmi, B. Shared Lateral Control with Online Adaptation of the Automation Degree for Driver Steering Assist System: A Weighting Design Approach. In Proceedings of the IEEE 54th Annual Conference on Decision and Control (CDC), Osaka, Japan, 15–18 December 2015; pp. 857–862. [Google Scholar]

- Oufroukh, N.A.; Mammar, S. Integrated driver co-pilote approach for vehicle lateral control. In Proceedings of the 2014 IEEE Intelligent Vehicles Symposium Proceedings, Dearborn, MI, USA, 8–11 June 2014. [Google Scholar] [CrossRef]

- Lv, C.; Wang, H.; Cao, D.; Zhao, Y.; Sullman, M.; Auger, D.J.; Brighton, J.; Matthias, R.; Skrypchuk, L.; Mouzakitis, A. A Novel Control Framework of Haptic Take-Over System for Automated Vehicles. In Proceedings of the 2018 IEEE Intelligent Vehicles Symposium (IV), Changshu, China, 26–30 June 2018. [Google Scholar] [CrossRef]

- Ahn, C.; Peng, H.; Tseng, H.E. Robust estimation of road friction coefficient. In Proceedings of the 2011 American Control Conference, San Francisco, CA, USA, 29 June–1 July 2011. [Google Scholar] [CrossRef]

- Rath, J.J.; Veluvolu, K.C.; Defoort, M.; Soh, Y.C. Higher-order sliding mode observer for estimation of tyre friction in ground vehicles. IET Control Theory Appl. 2014, 8, 399–408. [Google Scholar] [CrossRef]

- Moreno, J.A.; Osorio, M. Strict Lyapunov Functions for the Super-Twisting Algorithm. IEEE Trans. Autom. Control 2012, 57, 1035–1040. [Google Scholar] [CrossRef]

- Ahn, C.; Peng, H.; Tseng, H.E. Robust Estimation of Road Frictional Coefficient. IEEE Trans. Control Syst. Technol. 2013, 21, 2170838. [Google Scholar] [CrossRef]

- Kiencke, U.; Nielsen, L. Automotive Control Systems; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

- Baffet, G.; Charara, A.; Lechner, D.; Thomas, D. Experimental evaluation of observers for tire–road forces, sideslip angle and wheel cornering stiffness. Veh. Syst. Dyn. 2008, 46, 501–520. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Sentouh, C.; Popieul, J.C. Online Adaptation of the Authority Level for Shared Lateral Control of Driver Steering Assist System Using Dynamic Output Feedback Controller. In Proceedings of the 41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; pp. 3767–3772. [Google Scholar]

- Nguyen, A.T.; Rath, J.J.; Lv, C.; Guerra, T.M.; Lauber, J. Human-Machine Shared Driving Control for Semi-Autonomous Vehicles Using Level of Cooperativeness. Sensors 2021, 21, 4647. [Google Scholar] [CrossRef]

- Rath, J.J.; Senouth, C.; Popieul, J.C. Personalised lane keeping assist strategy: Adaptation to driving style. IET Control Theory Appl. 2019, 13, 106–115. [Google Scholar] [CrossRef]

- Bencloucif, M.; Nguyen, A.T.; Sentouh, C.; Popieul, J. Cooperative Trajectory Planning for Haptic Shared Control between Driver and Automation in Highway Driving. IEEE Trans. Indus. Electron. 2019, 66, 9846–9857. [Google Scholar] [CrossRef]

- Dong, J.; Yang, G.H. Control synthesis of T-S fuzzy systems based on a new control scheme. IEEE Trans. Fuzzy Syst. 2011, 19, 323–338. [Google Scholar] [CrossRef]

- Reymond, G.; Kemeny, A.; Droulez, J.; Berthoz, A. Role of Lateral Acceleration in Curve Driving: Driver Model and Experiments on a Real Vehicle and a Driving Simulator. Hum. Factors J. Hum. Factors Ergon. Soc. 2001, 43, 483–495. [Google Scholar] [CrossRef] [PubMed]

- Poli, R.; Kennedy, J.; Blackwell, T. Particle swarm optimization. Swarm Intell. 2007, 1, 33–57. [Google Scholar] [CrossRef]

| Case | (m) | AFac | Neg. SW (Nmrad/s) | (Nm) | |

|---|---|---|---|---|---|

| 0 | 1.219 | 0.735 | 219.3 | 9.132 | |

| 0.5 | 1.624 | 0.843 | 202.1 | 5.242 | |

| 1.5 | 1.275 | 0.819 | 206.6 | 5.22 | |

| 2 | 1.389 | 0.818 | 209.6 | 5.92 | |

| 0.5 | 1.241 | 0.824 | 216.7 | 8.35 | |

| 1.5 | 1.889 | 0.763 | 223.2 | 6.577 | |

| 2 | 1.228 | 0.723 | 219.6 | 8.308 |

| Unct. | Cont. | Neg. SW | AF | ||||

|---|---|---|---|---|---|---|---|

| 5% | C1 | 0.508 | 0.019 | 2.054 | 6.514 | 226.4 | 0.797 |

| C2 | 0.659 | 0.022 | 2.375 | 11.624 | 235.2 | 0.811 | |

| 15% | C1 | 0.554 | 0.016 | 2.378 | 8.352 | 211.5 | 0.722 |

| C2 | 0.585 | 0.016 | 2.252 | 7.599 | 206.8 | 1.01 | |

| 20% | C1 | 0.5221 | 0.0172 | 2.165 | 6.705 | 204.5 | 0.822 |

| C2 | 0.472 | 0.0182 | 2.037 | 7.169 | 208.2 | 0.599 |

| v (m/s) | Friction | (m) | (rad) | (N·m) |

|---|---|---|---|---|

| 14 | 1 | 0.1116 | 0.0024 | 0.2523 |

| 0.6 | 0.1188 | 0.0063 | 0.2679 | |

| 0.4 | 0.1289 | 0.0024 | 0.2557 | |

| 20 | 1 | 0.3213 | 0.0045 | 0.6807 |

| 0.6 | 0.3211 | 0.0044 | 0.6783 | |

| 0.4 | 0.3111 | 0.0044 | 0.6663 | |

| 25 | 1 | 0.5727 | 0.0074 | 1.2104 |

| 0.6 | 0.5824 | 0.0072 | 1.1257 | |

| 0.4 | 0.5792 | 0.0073 | 1.1432 |

| Case | AFac | Neg. SW (Nmrad/s) | (Nm) | |

|---|---|---|---|---|

| 0.5 | 0.5923 | 348.7971 | −61.0736 | |

| 0.8 | 0.4794 | 118.1967 | −70.3217 | |

| 0.5 | 0.9754 | 91.0878 | −35.5465 | |

| 0.8 | 0.9507 | 138.8792 | −36.7558 | |

| 0 | 1.0192 | 106.8268 | −27.2865 | |

| 0.5 | 1.0240 | 108.8057 | −18.0648 | |

| 0.8 | 1.0604 | 108.0537 | −15.0333 | |

| 0.5 | 0.9909 | 40.4668 | −7.5843 | |

| 0.8 | 0.9515 | 36.0443 | −8.4723 | |

| 0.5 | 0.8818 | 14.9646 | −4.8727 | |

| 0.8 | 0.9499 | 18.4843 | −7.2032 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perozzi, G.; Oudainia, M.R.; Sentouh, C.; Popieul, J.-C.; Rath, J.J. Driver Assisted Lane Keeping with Conflict Management Using Robust Sliding Mode Controller. Sensors 2023, 23, 4. https://doi.org/10.3390/s23010004

Perozzi G, Oudainia MR, Sentouh C, Popieul J-C, Rath JJ. Driver Assisted Lane Keeping with Conflict Management Using Robust Sliding Mode Controller. Sensors. 2023; 23(1):4. https://doi.org/10.3390/s23010004

Chicago/Turabian StylePerozzi, Gabriele, Mohamed Radjeb Oudainia, Chouki Sentouh, Jean-Christophe Popieul, and Jagat Jyoti Rath. 2023. "Driver Assisted Lane Keeping with Conflict Management Using Robust Sliding Mode Controller" Sensors 23, no. 1: 4. https://doi.org/10.3390/s23010004

APA StylePerozzi, G., Oudainia, M. R., Sentouh, C., Popieul, J.-C., & Rath, J. J. (2023). Driver Assisted Lane Keeping with Conflict Management Using Robust Sliding Mode Controller. Sensors, 23(1), 4. https://doi.org/10.3390/s23010004