Energy-Saving Optimization Method of Urban Rail Transit Based on Improved Differential Evolution Algorithm

Abstract

:1. Introduction

- (1)

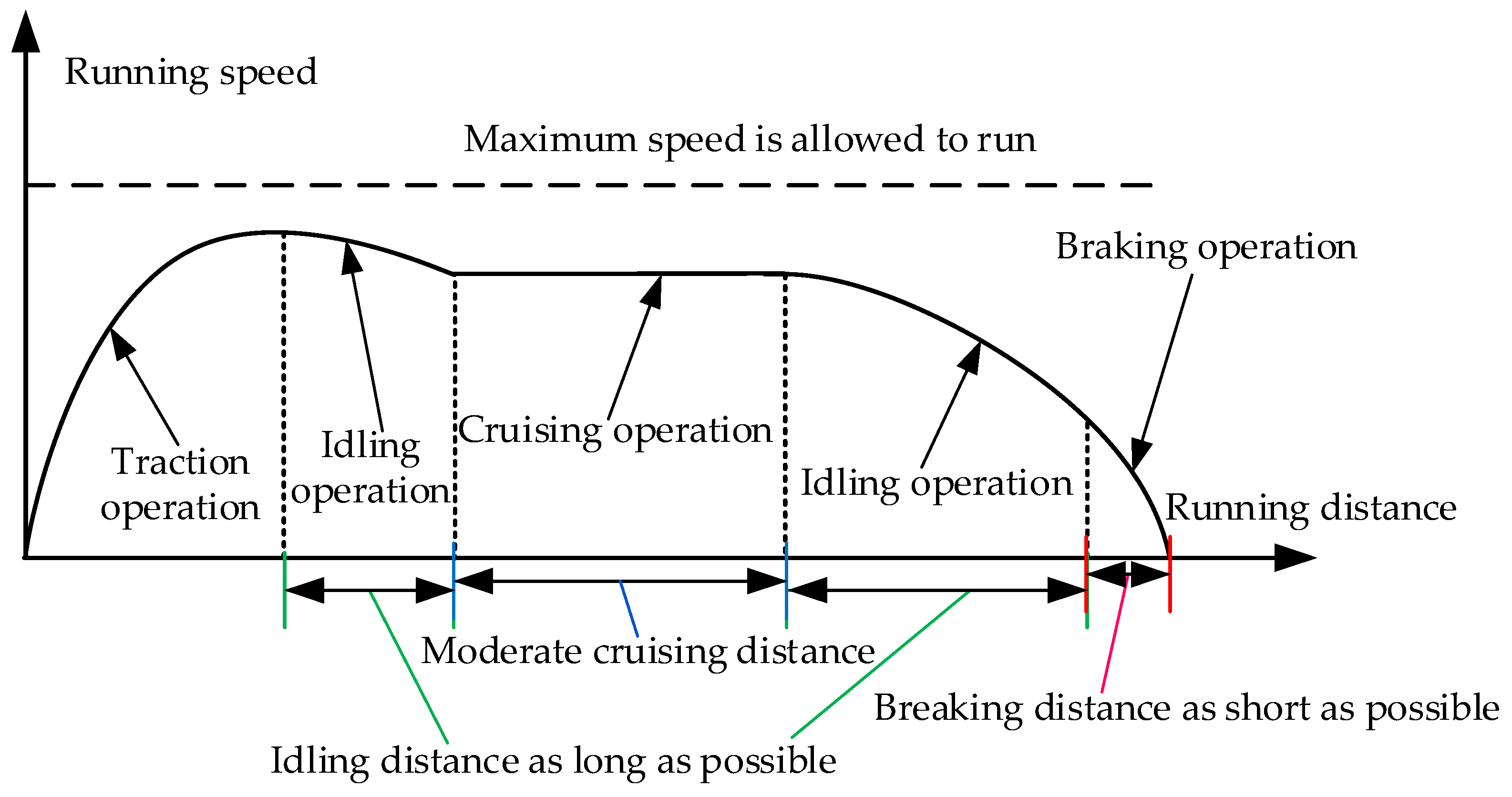

- An optimization model based on the combination of the inertia motion and energy optimization is established by taking the maximum idle distance as the objective and the maximum allowable running speed, passenger comfort, train timetable, maximum allowable acceleration and kinematics equation as constraints.

- (2)

- An improved differential evolution algorithm based on the adaptive dynamic multimodal model is proposed and a comprehensive method for solving multi-objective optimization problems based on the combination of the improved differential evolution algorithm and Q learning algorithm is applied to solve the energy-saving optimization model.

2. Methods

2.1. Basis

2.1.1. Calculation of the Running Resistance

2.1.2. Kinematic Analysis

2.2. Modeling

2.2.1. Modeling Principle

2.2.2. Modeling Implementation

2.3. Solution

2.3.1. Improved Differential Evolution Algorithm Based on the Adaptive Dynamic Multimodal Model

- (1)

- Acquire the knowledge of the population evolution process and judge the individual evolution needs of the population.

- (2)

- Construct the population diversity enhancement strategy to help the population jump out of the stagnant region.

- (3)

- According to the evolution state of the population and individual, the hierarchical mutation method is used to adaptively select the most suitable variation mode of the current individual, and guide the individual to learn knowledge from the global evolution information and neighborhood information of the population.

- (1)

- Set the threshold δ of the change degree of the optimal adaptation value of the population.

- (2)

- If the degree of change of the optimal fitness value of each generation θ is δ, it means that the population may still be rapidly approaching the optimal solution, and the convergence of the population is improved at this time.

- (3)

- If the degree of change of the optimal fitness value of each generation θ < δ, it means that the degree of evolution of the current population search is small, and the diversity of the population is enhanced at this time.

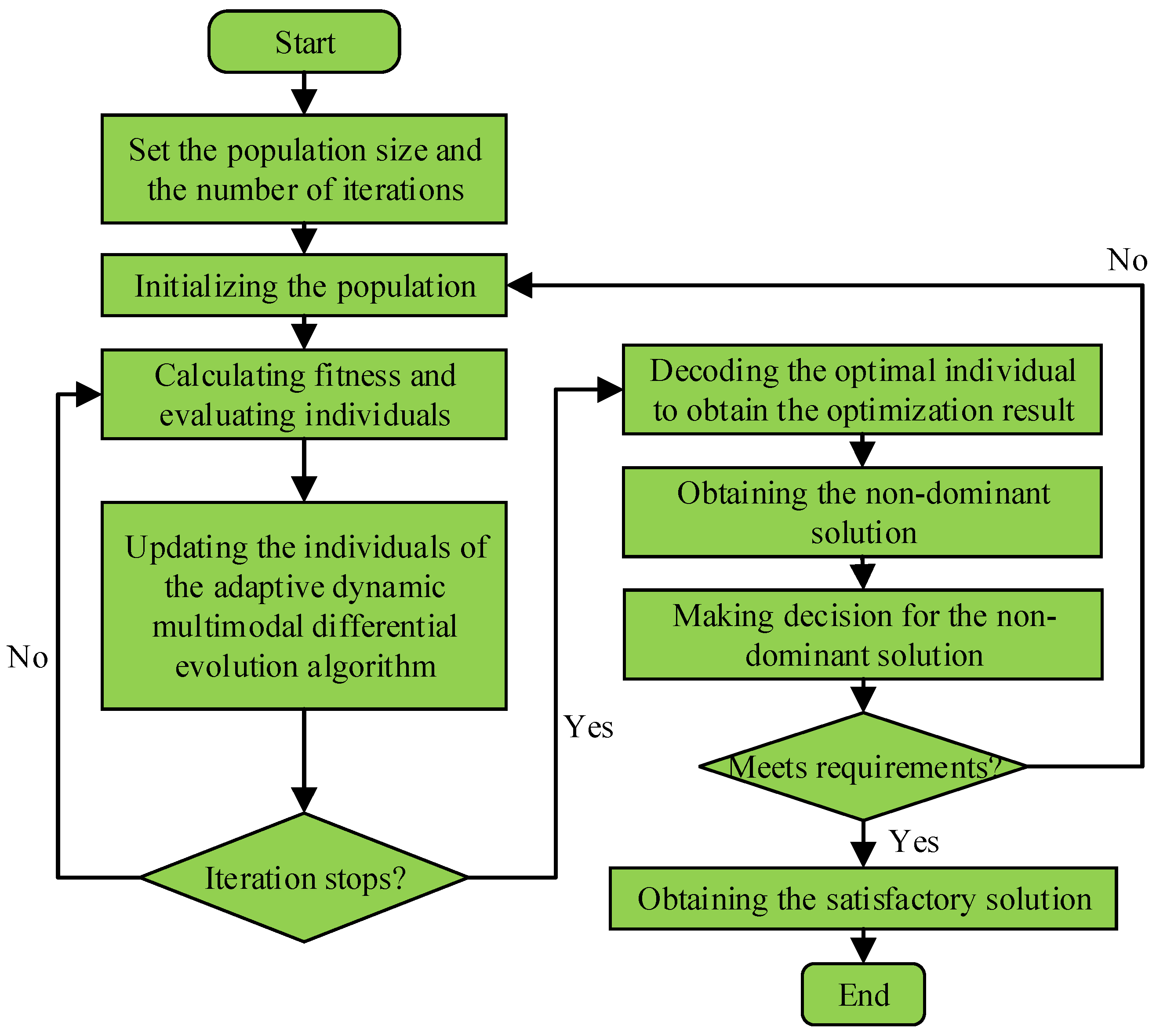

2.3.2. Solution Implementation of the Optimization Model

- (1)

- Setting the population size and number of iterations;

- (2)

- Initializing the population of the adaptive dynamic multimodal differential evolution algorithm;

- (3)

- Calculating fitness and evaluating individuals of the adaptive dynamic multimodal differential evolution algorithm;

- (4)

- Updating the individuals of the adaptive dynamic multimodal differential evolution algorithm;

- (5)

- Determining whether the stop condition of the iteration is satisfied; if so, then turns to (6), and otherwise turns to (3);

- (6)

- Decoding the optimal individual to obtain the optimization result;

- (7)

- Obtaining the non-dominant solution of the optimization problem;

- (8)

- Making a decision for the non-dominant solution by the Q learning algorithm;

- (9)

- Whether the dominant solution meets the requirements of the problem; if so, then turns to (10), and otherwise turns to (2);

- (10)

- Obtaining the satisfactory solution of the optimization problem.

3. Numeric Experiments

3.1. Experiment Setup

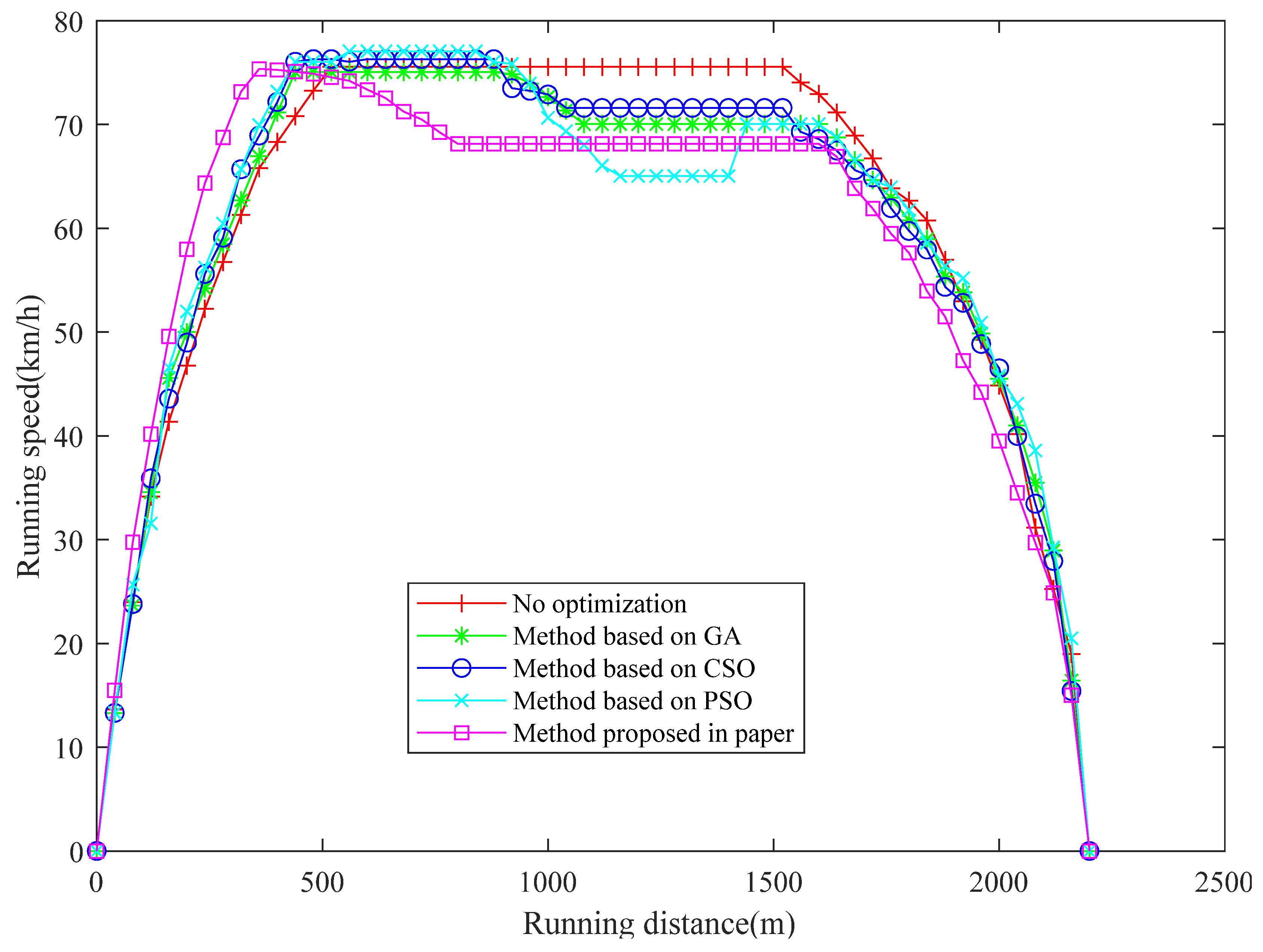

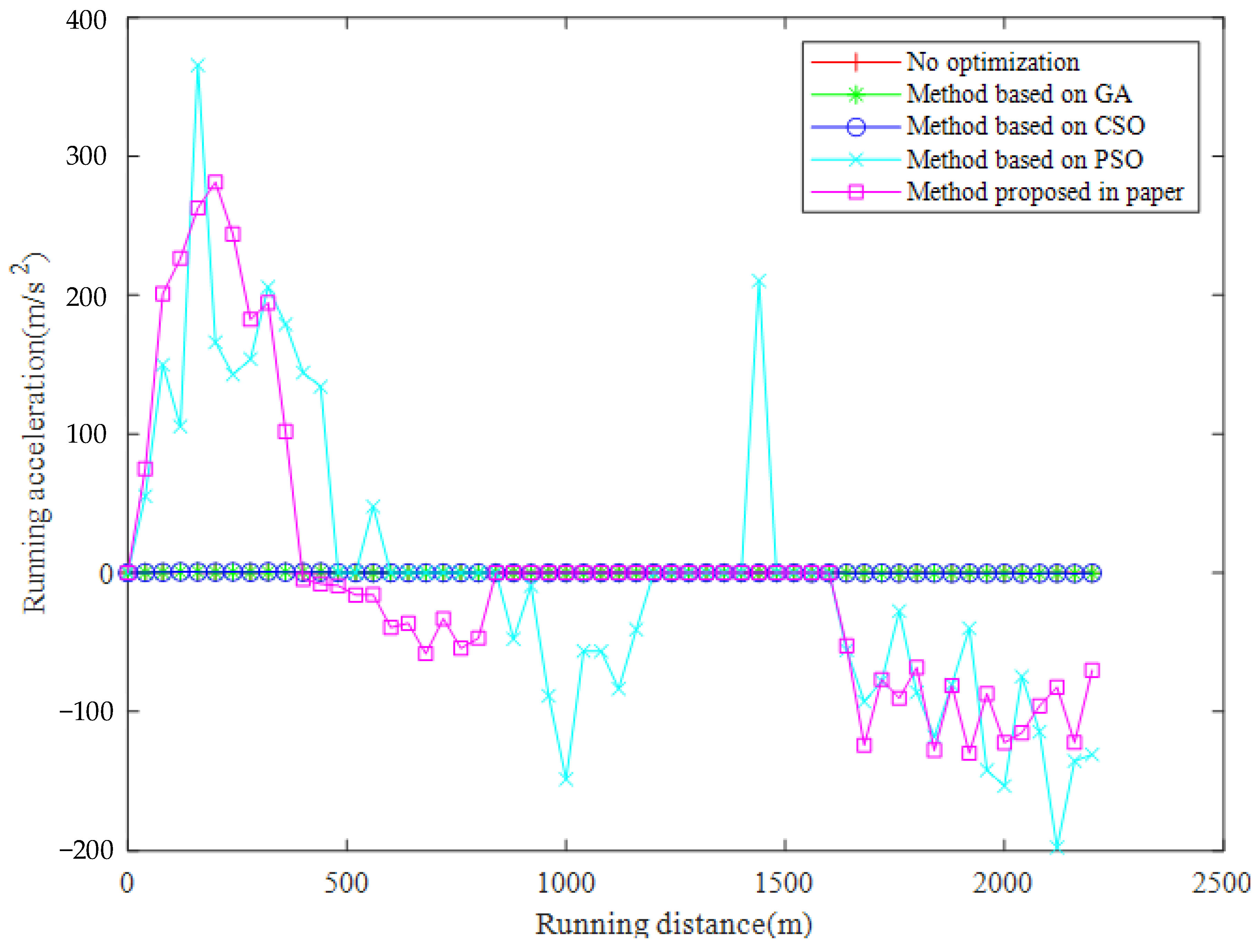

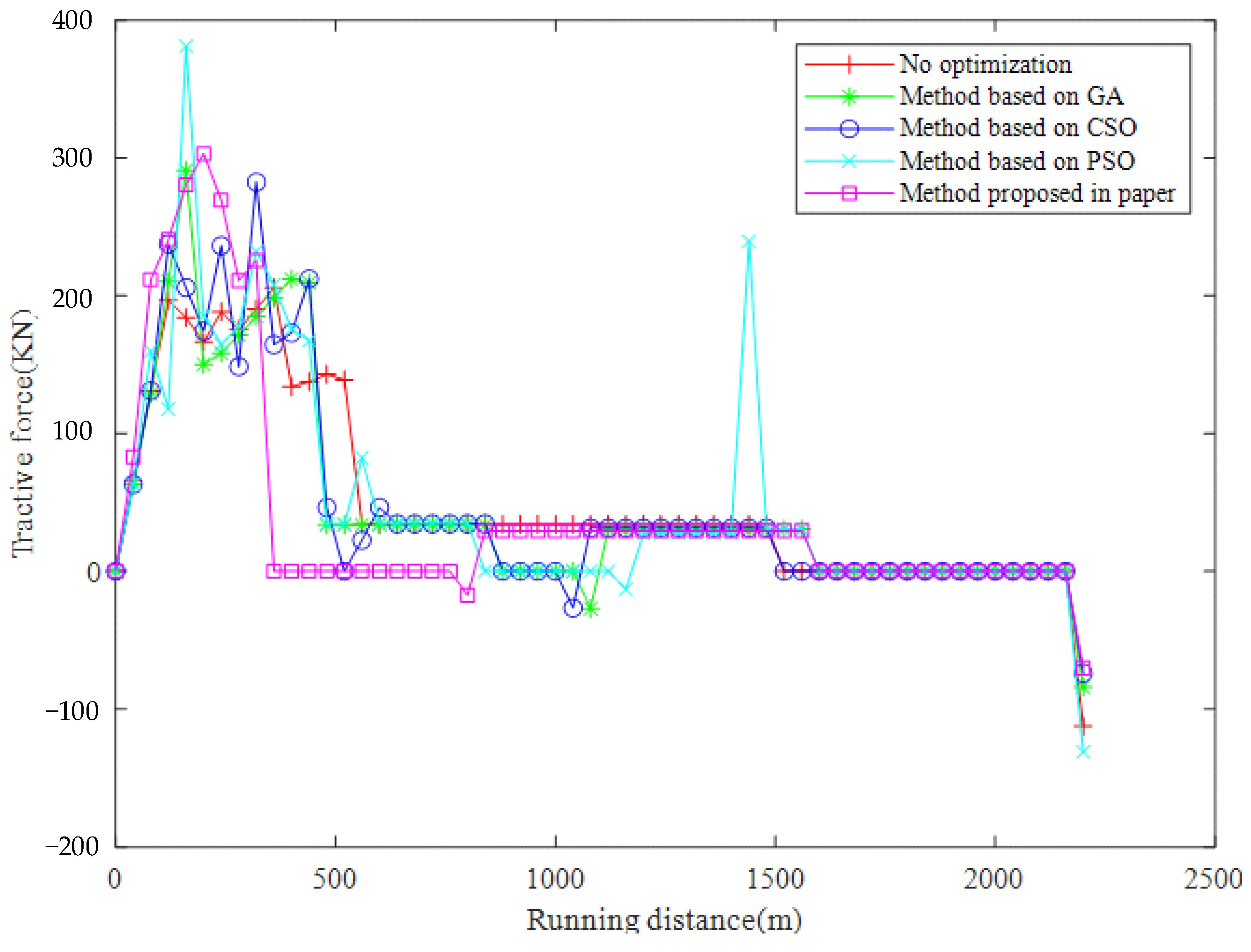

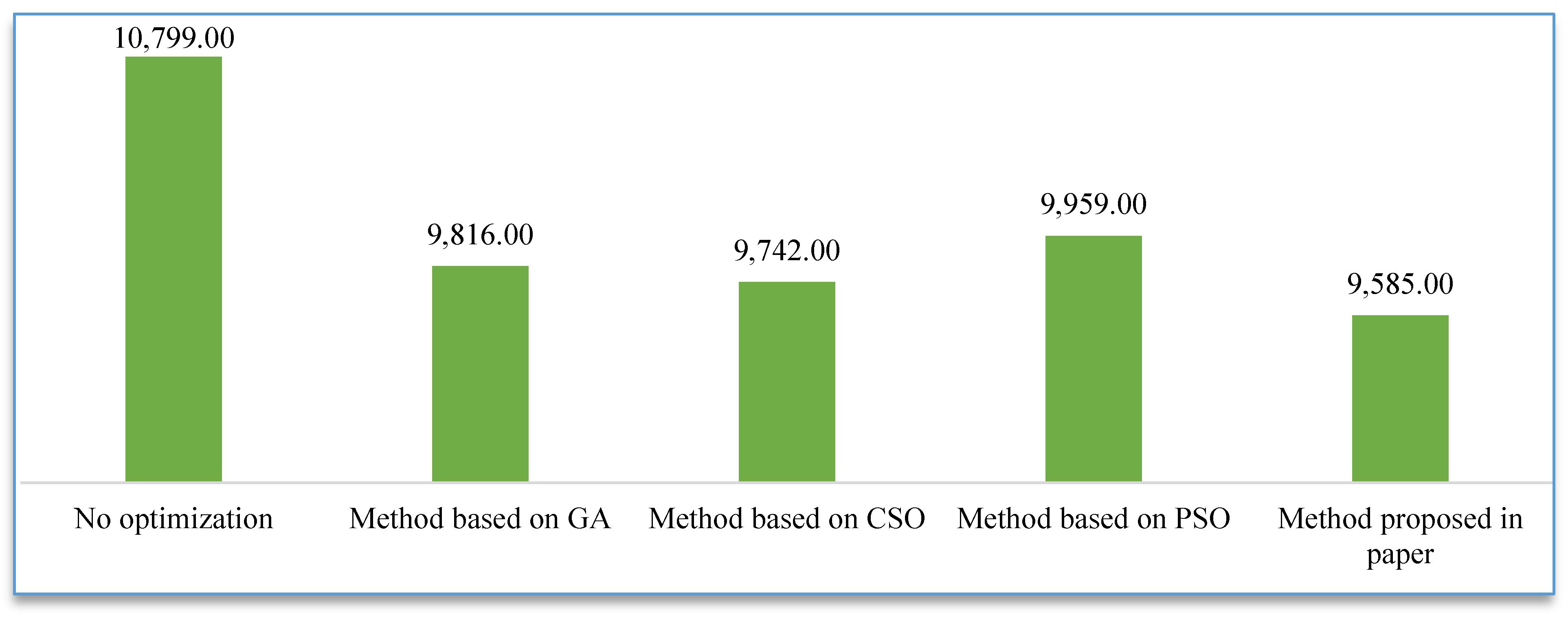

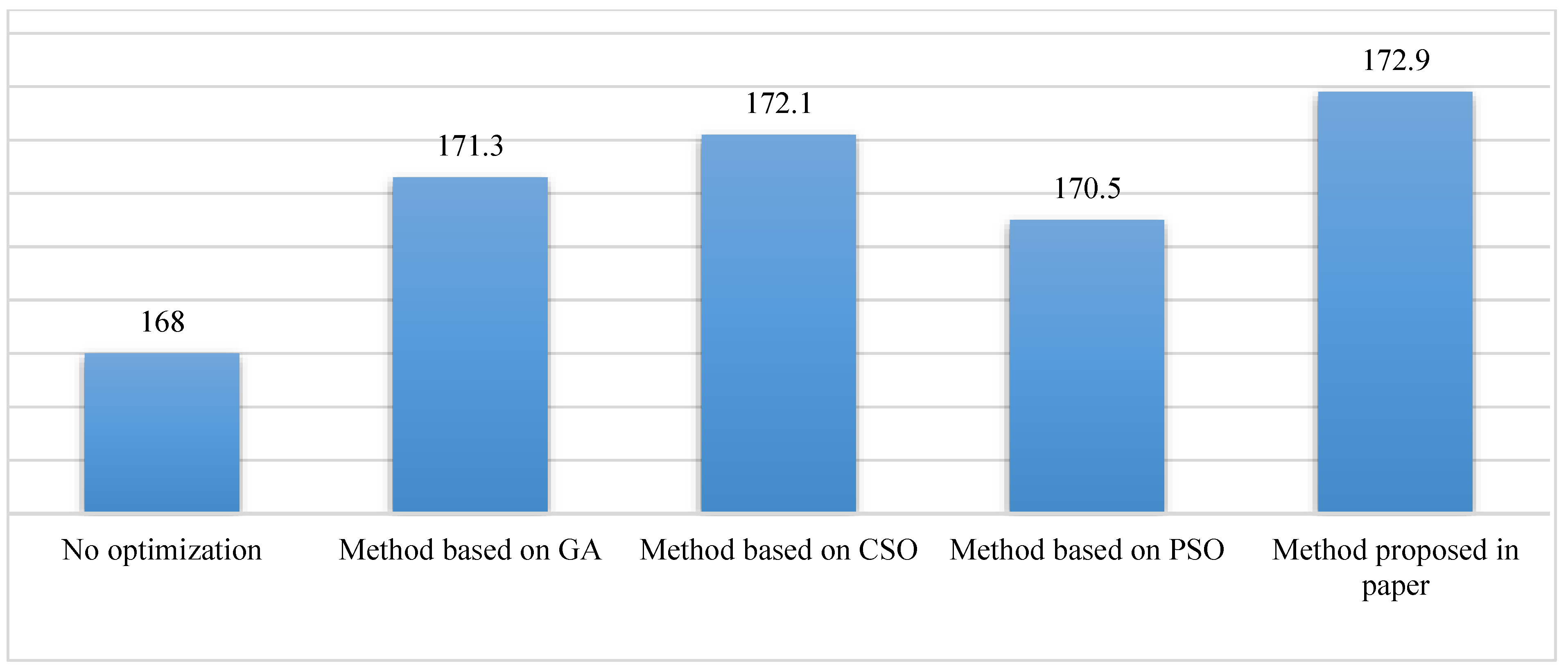

3.2. Experiment Results

3.3. Experimental Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Notations

| Symbol | Unit | Description |

| Unit basic resistance | ||

| An empirical constant | ||

| An empirical constant | ||

| An empirical constant | ||

| Speed of the train | ||

| Unit tunnel-additional resistance | ||

| Length of a tunnel | ||

| Unit curve-additional resistance | ||

| Constant | ||

| Radius of a curve | ||

| Unit ramp-additional resistance | ||

| Motion resistance of train | ||

| Mass of passengers, 1 t = 1000 kg | ||

| Empty mass of train, 1 t = 1000 kg | ||

| Inertial factor | ||

| Gravity acceleration | ||

| Distance between two stations | ||

| The length of the small segment | ||

| Average unit basic resistance | ||

| Average motion resistance | ||

| Average speed of train in | ||

| Kinetic energy of the train | ||

| Total mass of the train, 1 t = 1000 kg | ||

| Coefficient of rotary mass | ||

| Starting speed of train in | ||

| Terminal speed of train in | ||

| Acceleration of train in | ||

| Running time of train in | ||

| External resultant force on the train in sub-segment i | ||

| Tractive force of the train in sub-segment i | ||

| Maximum allowable tractive force of the train | ||

| Maximum acceleration allowed | ||

| Maximum speed allowed | ||

| α, β, γ and λ | Weight coefficients of the optimization objective | |

| The whole optimization objective function | ||

| The most adaptive value of the k generation | ||

| The degree of change of the optimal fitness value | ||

| The enhancement probability | ||

| The enhancement factor | ||

| The probability of replacement | ||

| The j dimension of the i individual | ||

| Value of the basic fitness | ||

| The penalty factor of violating the maximum acceleration limit | ||

| The penalty factor of violating the maximum speed limit | ||

| The penalty factor of violating the passenger comfort constraint | ||

| The penalty factor of violating the tractive force limit | ||

| The control factor of passenger comfort, generally with a value less than 1.2 | ||

| ε, v, ξ, δ and ρ | Constant |

References

- He, D.; Chen, J.; Chen, Y.; Miao, J.; Deng, J.; Chen, J.; Liu, J. Exploration of the correlation between welding flaw geometrical parameters and floating potential based on an ultrasonic duplex finite element model. Measurement 2021, 167, 108269. [Google Scholar] [CrossRef]

- Lin, B.; Yu, S.-P.; Liu, Z.-Y.; Dai, X.-W.; Cui, D.-L.; Han, X.-C. High-speed Train Dynamic Scheduling Method Based on Improved Particle Swarm Optimization Algorithm. Kongzhi Gongcheng Control. Eng. China 2021, 7, 1334. [Google Scholar]

- Zhou, W.; Kang, J.; Qin, J.; Li, S.; Huang, Y. Robust Optimization of High-Speed Railway Train Plan Based on Multiple Demand Scenarios. Mathematics 2022, 10, 1278. [Google Scholar] [CrossRef]

- Nespoulous, J.; Soize, C.; Funfschilling, C.; Perrin, G. Optimisation of Train Speed to Limit Energy consumption. Veh. Syst. Dyn. 2022, 60, 3540–3557. [Google Scholar] [CrossRef]

- Chen, X.; Yao, Y.; Shen, L.; Zhang, X. Multi-objective Optimization of High-speed Train Suspension Parameters for Improving Hunting Stability. Int. J. Rail Transp. 2022, 10, 159–176. [Google Scholar] [CrossRef]

- Arikan, Y.; En, T.; Am, E. A Study of Energy Efficiency in Rail Vehicles. El Cezeri Fen Mühendislik Derg. 2020, 7, 223–235. [Google Scholar]

- Chen, J.; Hu, H.; Ge, Y.; Wang, K.; Huang, W.; He, Z. An Energy Storage System for Recycling Regenerative Braking Energy in High-Speed Railway. IEEE Trans. Power Deliv. 2020, 36, 320–330. [Google Scholar] [CrossRef]

- Shang, F.; Zhan, J.; Chen, Y. An Online Energy-Saving Driving Strategy for Metro Train Operation Based on the Model Predictive Control of Switched-Mode Dynamical Systems. Energies 2020, 13, 4933. [Google Scholar] [CrossRef]

- Xu, Y.; Jia, B.; Li, X.; Li, M.; Ghiasi, A. An integrated micro-macro approach for high-speed railway energy-efficient timetabling problem. Transp. Res. Part C Emerg. Technol. 2020, 112, 88–115. [Google Scholar] [CrossRef]

- Wang, J.; Ghanem, A.; Rakha, H.; Du, J. A rail transit simulation system for multi-modal energy-efficient routing applications. Int. J. Sustain. Transp. 2020, 15, 187–202. [Google Scholar] [CrossRef]

- Cunillera, A.; Fernández-Rodríguez, A.; Cucala, A.P.; Fernández-Cardador, A.; Falvo, M.C. Assessment of the Worthwhileness of Efficient Driving in Railway Systems with High-Receptivity Power Supplies. Energies 2020, 13, 1836. [Google Scholar] [CrossRef]

- Zhu, F.; Yang, Z.; Lin, F.; Xin, Y. Decentralized Cooperative Control of Multiple Energy Storage Systems in Urban Railway based on Multi-Agent Deep Reinforcement Learning. IEEE Trans. Power Electron. 2020, 35, 9368–9379. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, F.; Lin, F. Deep-Reinforcement-Learning-Based Energy Management Strategy for Super capacitor Energy Storage Systems in Urban Rail Transit. IEEE Trans. Intell. Transp. Syst. 2020, 22, 1150–1160. [Google Scholar] [CrossRef]

- Mo, P.; Yang, L.; D’Ariano, A.; Yin, J.; Yao, Y.; Gao, Z. Energy-Efficient Train Scheduling and Rolling Stock Circulation Planning in a Metro Line: A Linear Programming Approach. IEEE Trans. Intell. Transp. Syst. 2020, 21, 3621–3633. [Google Scholar] [CrossRef]

- Zhao, S.; Wu, J.; Li, Z.; Meng, G. Train Operational Plan Optimization for Urban Rail Transit Lines Considering Circulation Balance. Sustainability 2022, 14, 5226. [Google Scholar] [CrossRef]

- Zhou, W.; Oldache, M. Integrated Optimization of Line Planning, Timetabling and Rolling Stock Allocation for Urban Railway Lines. Sustainability 2021, 13, 13059. [Google Scholar] [CrossRef]

- Wang, X.; Tang, T.; Su, S.; Yin, J.; Gao, Z.; Lv, N. An integrated energy-efficient train operation approach based on the space-time-speed network methodology. Transp. Res. Part E Logist. Transp. Rev. 2021, 150, 102323. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.; Zhu, M.; Huang, C.; Li, J.; Xu, Z. Research on Multi-train Energy Saving Optimization Based on Cooperative Multi-objective Particle Swarm Optimization Algorithm. Int. J. Energy Res. 2021, 45, 2644–2667. [Google Scholar] [CrossRef]

- Su, S.; Wang, X.; Tang, T.; Wang, G.; Cao, Y. Energy-efficient Operation by Cooperative Control among Trains: A Multi-agent Reinforcement Learning Approach. Control. Eng. Pract. 2021, 116, 104901. [Google Scholar] [CrossRef]

- Kierzkowski, A.; Haadyn, S. Method for Reconfiguring Train Schedules Taking into Account the Global Reduction of Railway Energy consumption. Energies 2022, 15, 1946. [Google Scholar] [CrossRef]

- Nkurunziza, J.M.V.; Nizeyimana, J.D.; Turabimana, P. Quantitative Estimation of Railway Vehicle Regenerative Energy Saving: A Case of Addis Ababa Light Rail Transit (AALRT). Int. J. Eng. Technol. IJET 2021, 7, 9–19. [Google Scholar] [CrossRef]

- Kardas-Cinal, E. Optimization of Train Energy Cooperation Using Scheduled Service Time Reserve. Energies 2021, 15, 119. [Google Scholar]

- Liao, J.; Zhang, F.; Zhang, S.; Yang, G.; Gong, C. Energy-saving optimization strategy of multi-train metro timetable based on dual decision variables: A case study of Shanghai Metro line one. J. Rail Transp. Plan. Manag. 2021, 17, 100234. [Google Scholar] [CrossRef]

- Yasear, S.A.; Ku-Mahamud, K.R. Review of the Multi-Objective Swarm Intelligence Optimization Algorithms. J. ICT 2021, 2, 171–211. [Google Scholar] [CrossRef]

- Pan, J.S.; Liu, N.; Chu, S.C. A competitive mechanism based multi-objective differential evolution algorithm and its application in feature selection. Knowl.-Based Syst. 2022, 245, 108582. [Google Scholar] [CrossRef]

- Hu, R.; Wu, X.; Qian, B.; Mao, J.; Jin, H. Differential Evolution Algorithm Combined with Uncertainty Handling Techniques for Stochastic Reentrant Job Shop Scheduling Problem. Complexity 2022, 2022, 9924163. [Google Scholar] [CrossRef]

- Tian, Z.; Zhao, H.; Wei, H.; Tan, Y.; Li, Y. Improved opposition-based self-adaptive differential evolution algorithm for vibrational hybrid femtosecond/picosecond coherent anti-Stokes Raman scattering thermometry. Appl. Opt. 2022, 61, 4500–4508. [Google Scholar] [CrossRef]

- Li, C.; Deng, L.; Qiao, L.; Zhang, L. An efficient differential evolution algorithm based on orthogonal learning and elites local search mechanisms for numerical optimization. Knowl. Based Syst. 2022, 235, 107636. [Google Scholar] [CrossRef]

- Li, W.; Ye, X.; Huang, Y.; Mahmoodi, S. Adaptive Dimensional Learning with a Tolerance Framework for the Differential Evolution Algorithm. Complex Syst. Model. Simul. 2022, 2, 59–77. [Google Scholar] [CrossRef]

- Zhang, L.; Tang, L.; Zhang, S.; Wang, Z.; Shen, X.; Zhang, Z. A Self-Adaptive Reinforcement-Exploration Q-Learning Algorithm. Symmetry 2021, 13, 1057. [Google Scholar] [CrossRef]

- Li, F.; Qin, J.; Zheng, W.X. Distributed Q -Learning-Based Online Optimization Algorithm for Unit Commitment and Dispatch in Smart Grid. IEEE Trans. Cybern. 2020, 50, 4146–4156. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q. Study on Optimization of Urban Rail Train Operation Control Curve Based on Improved Multi-Objective Genetic Algorithm. J. Internet Things 2021, 3, 9. [Google Scholar] [CrossRef]

- He, D.; Lu, G.; Yang, Y. Research on Optimization of Train Energy-Saving Based on Improved Chicken Swarm Optimization. IEEE Access 2019, 7, 121675–121684. [Google Scholar] [CrossRef]

- Meng, X.; Wang, Y.; Lin, L.; Li, L.; Jia, L. An Integrated Model of Train Re-Scheduling and Control for High-Speed Railway. Sustainability 2021, 13, 11933. [Google Scholar] [CrossRef]

| Parameter Sequence Number | Parameter Symbol | Parameter Value |

|---|---|---|

| 1 | c1 | 0.0013 |

| 2 | c2 | 0.014 |

| 3 | c3 | 2.4 |

| 4 | c4 | 600 |

| 5 | n | 55 |

| 6 | α | 0.15 |

| 7 | β | 0.1 |

| 8 | γ | 0.65 |

| 9 | 0.1 | |

| 10 | G | 228 t |

| 11 | P | 90 t |

| 12 | S | 2200 m |

| 13 | amax | 1.2 m/s2 |

| 14 | vmax | 80 km/h |

| 15 | FTmax | 330 kN |

| 16 | T | 168 s |

| 17 | CM | 0.5 |

| 18 | CR | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, G.; He, D.; Zhang, J. Energy-Saving Optimization Method of Urban Rail Transit Based on Improved Differential Evolution Algorithm. Sensors 2023, 23, 378. https://doi.org/10.3390/s23010378

Lu G, He D, Zhang J. Energy-Saving Optimization Method of Urban Rail Transit Based on Improved Differential Evolution Algorithm. Sensors. 2023; 23(1):378. https://doi.org/10.3390/s23010378

Chicago/Turabian StyleLu, Guancheng, Deqiang He, and Jinlai Zhang. 2023. "Energy-Saving Optimization Method of Urban Rail Transit Based on Improved Differential Evolution Algorithm" Sensors 23, no. 1: 378. https://doi.org/10.3390/s23010378

APA StyleLu, G., He, D., & Zhang, J. (2023). Energy-Saving Optimization Method of Urban Rail Transit Based on Improved Differential Evolution Algorithm. Sensors, 23(1), 378. https://doi.org/10.3390/s23010378