Research on Pressure-Flow Characteristics of Pilot Stage in Jet Pipe Servo-Valve

Abstract

1. Introduction

2. Mathematical Model

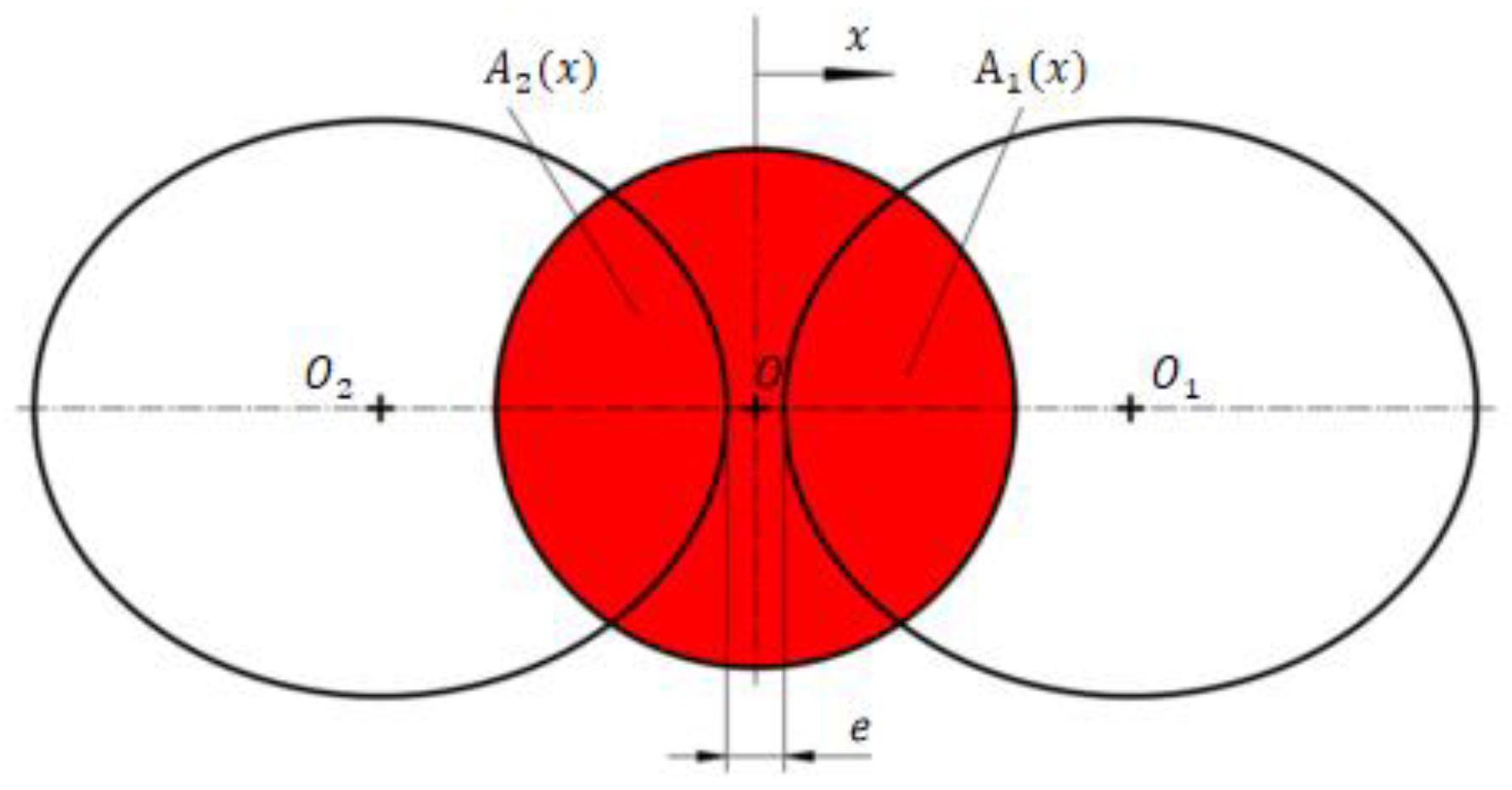

2.1. Flow Area

2.2. Pressure and Flow Characteristics Model

2.2.1. Pipe Flow

- (1)

- —The gravitational potential energy of oil at the inlet of the jet pipe;

- (2)

- —Oil density, ;

- (3)

- —Inlet pressure, MPa;

- (4)

- —The velocity of the oil at the inlet of the jet pipe, approximately considered to be zero;

- (5)

- —The gravitational potential energy of the oil at the nozzle mouth;

- (6)

- —The return pressure, MPa;

- (7)

- —The velocity of the oil at the nozzle mouth, m/s.

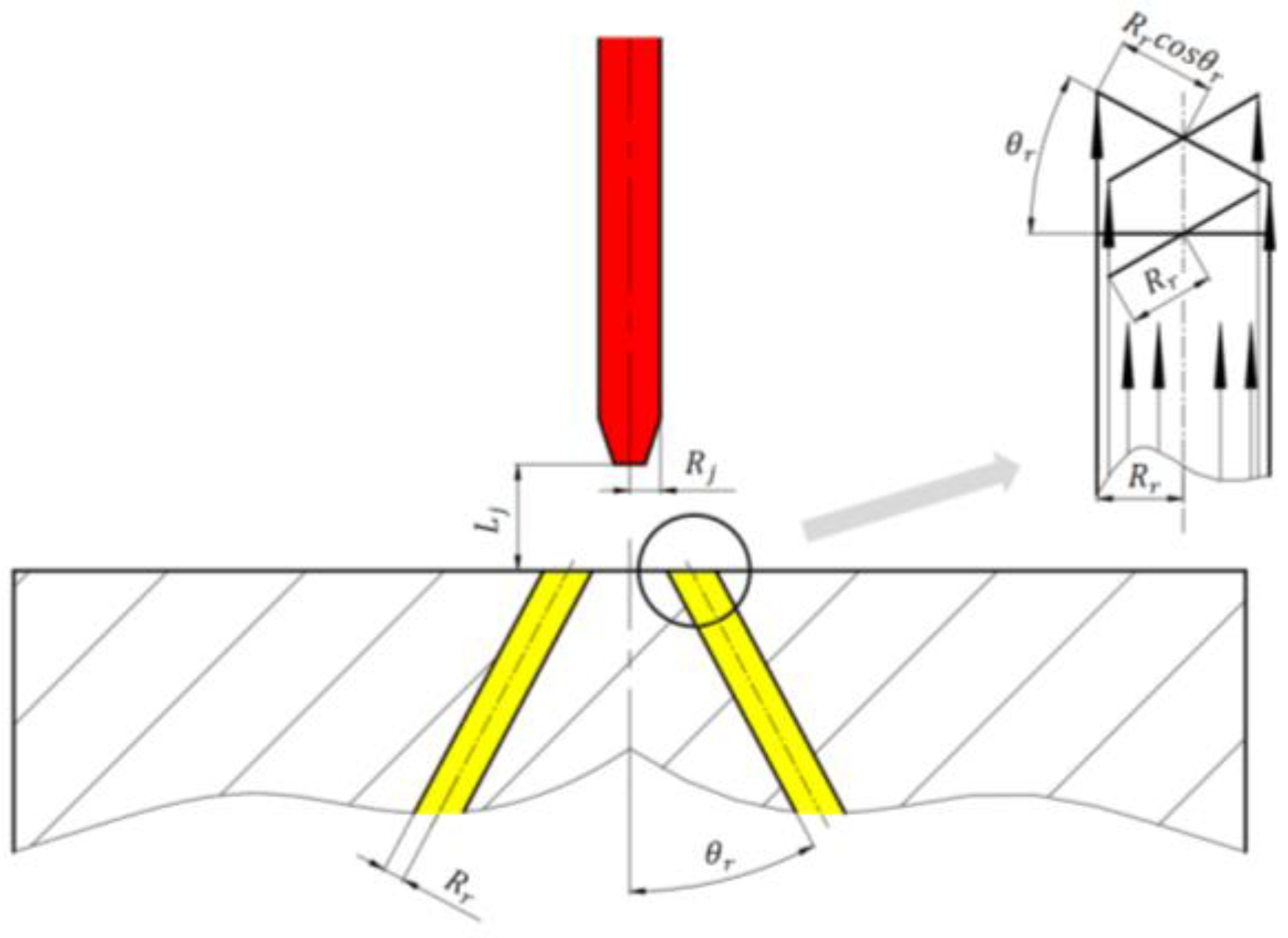

2.2.2. Impact Jet

- (1)

- —Stagnation pressure, MPa;

- (2)

- —Vertical distance from the nozzle to receiving hole, m;

- (3)

- —The size of the free jet zone, i.e., the distance between sections II and III, m.

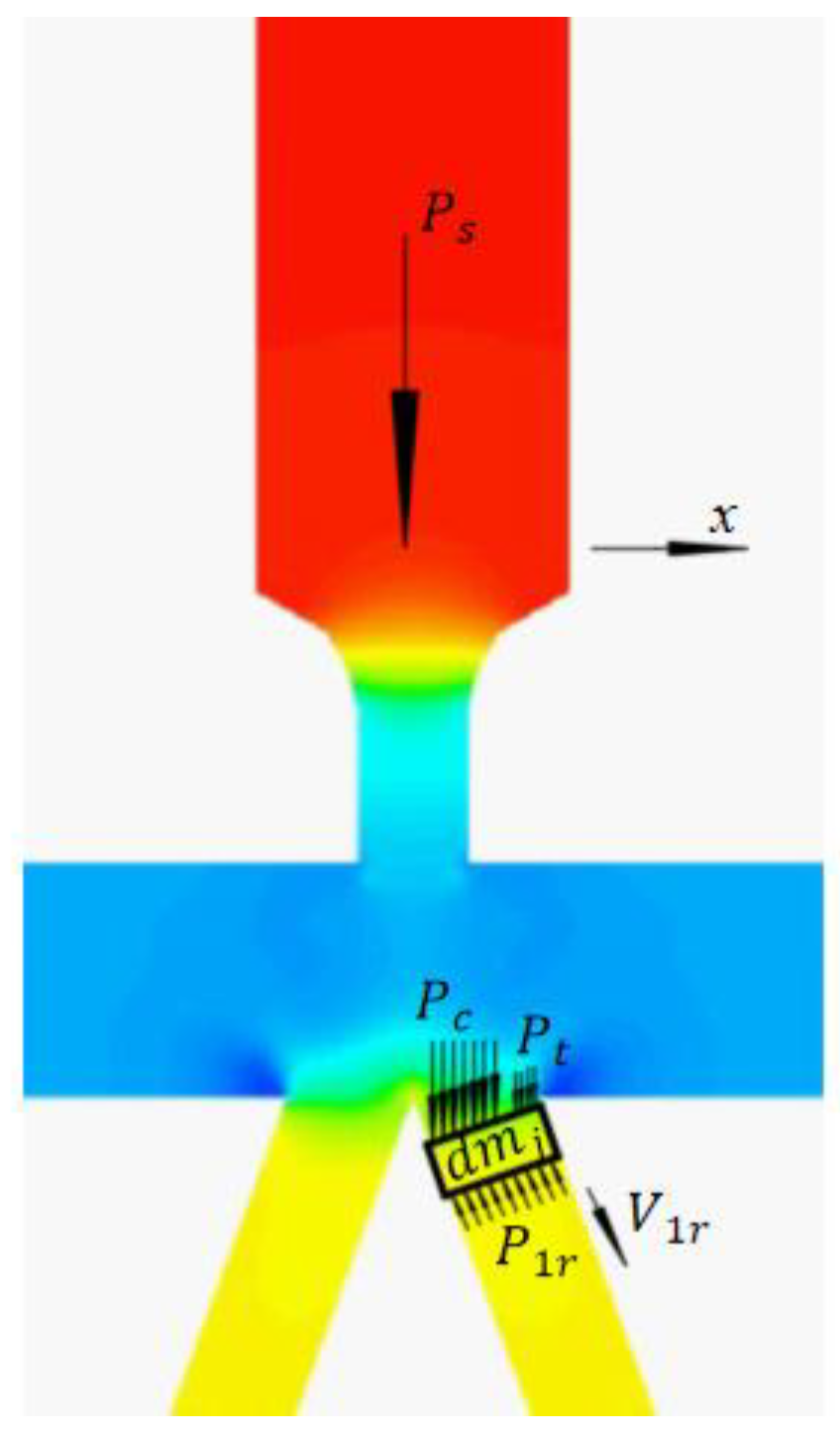

2.2.3. Flow in the Receiving Holes

- The pressure characteristic model

- The flow characteristic model

3. Simulation Research

3.1. Simulation Pre-Processing

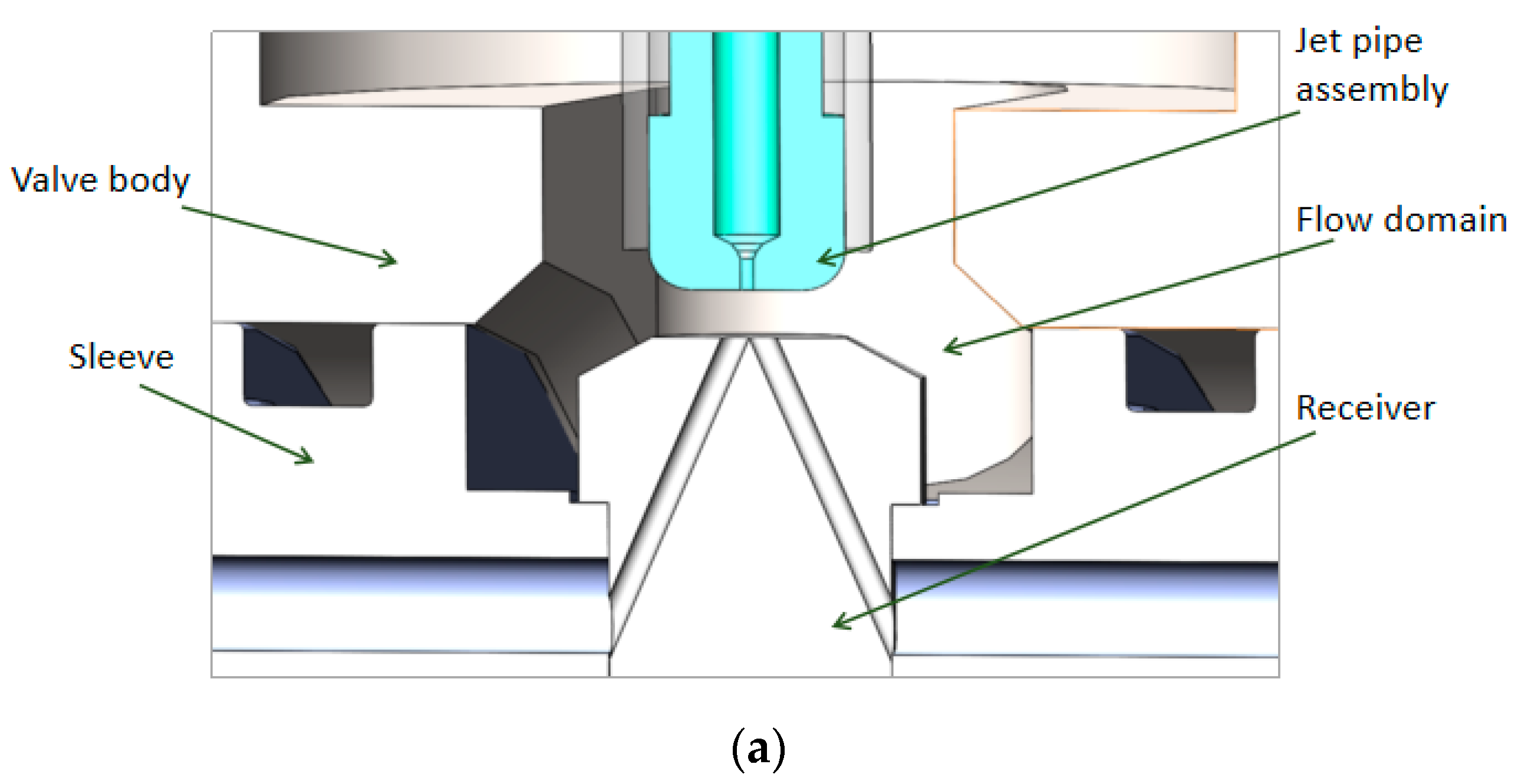

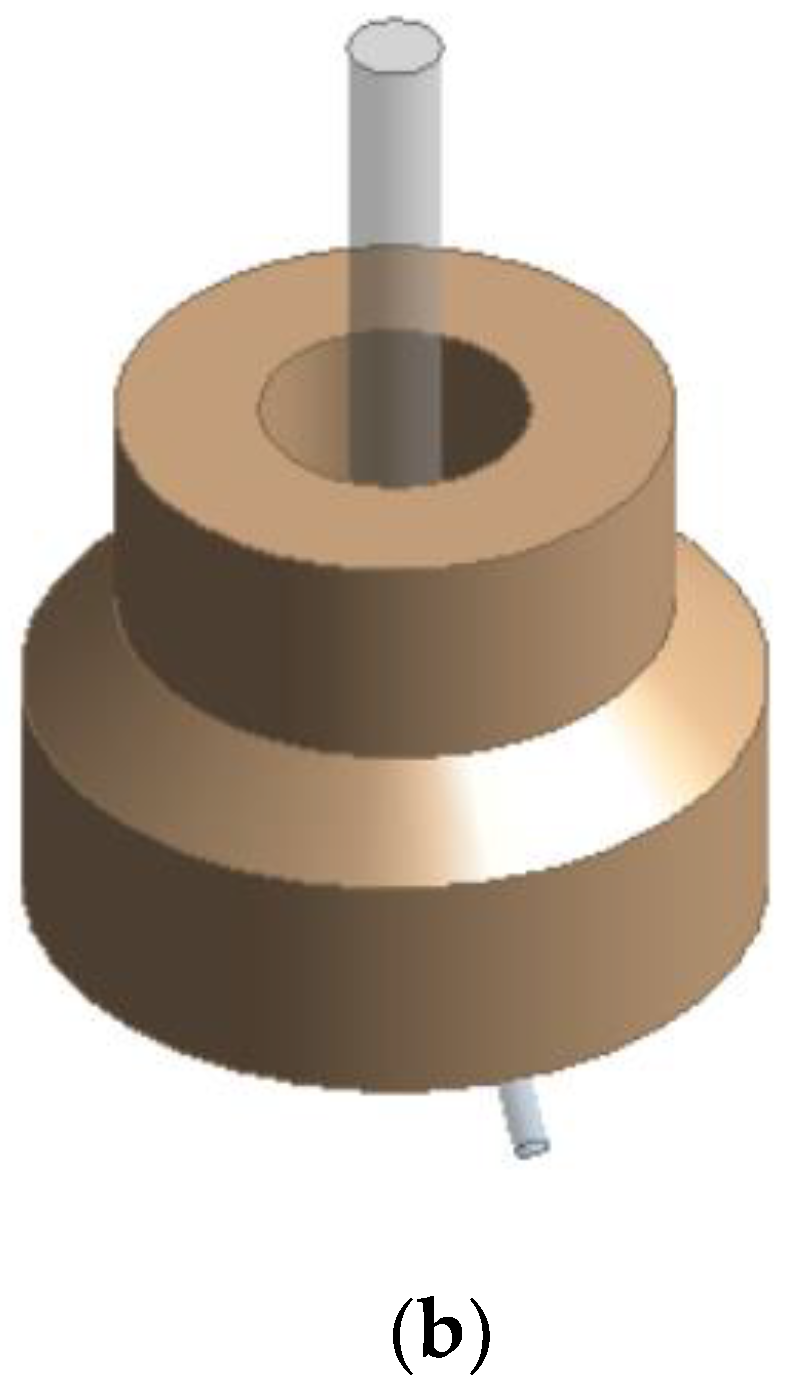

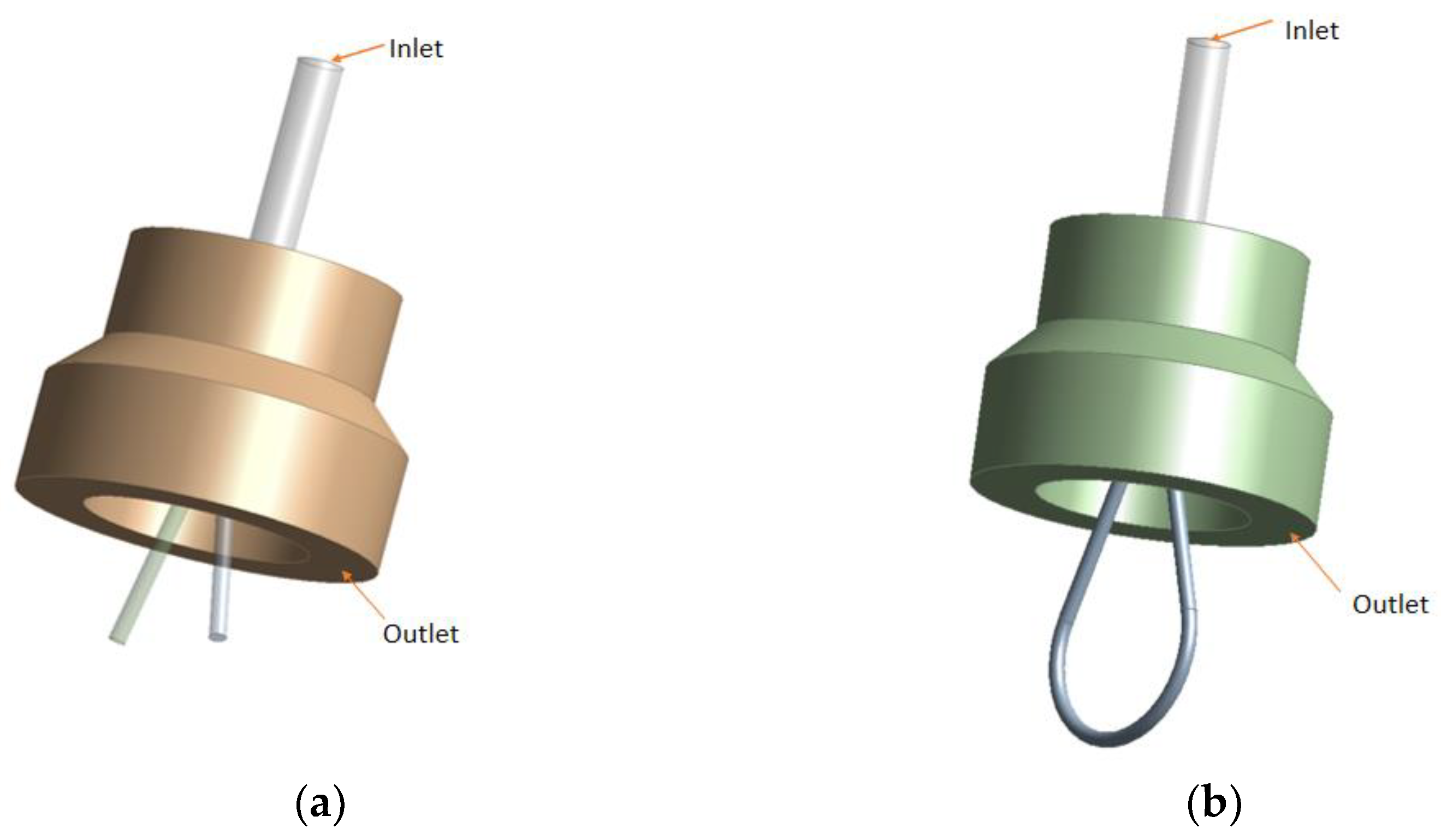

3.1.1. Geometric Model

3.1.2. Model Selection and Boundary Conditions Setup

- Model selection

- Material parameters

- Boundary conditions

3.1.3. Meshing

3.2. The Simulation Results

4. Results and Discussion

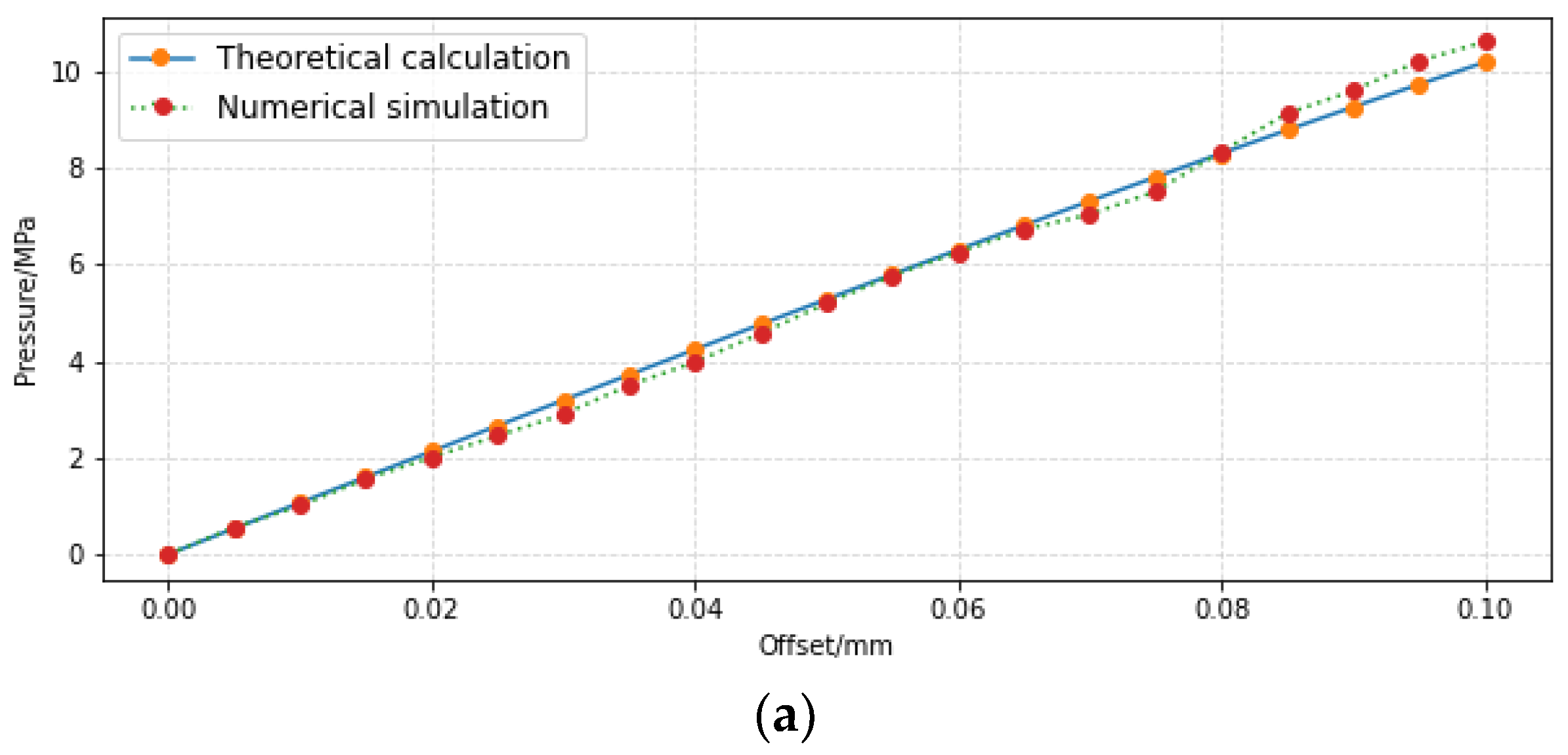

4.1. Comparison between Simulation and Theory

4.2. Experiments

5. Conclusions

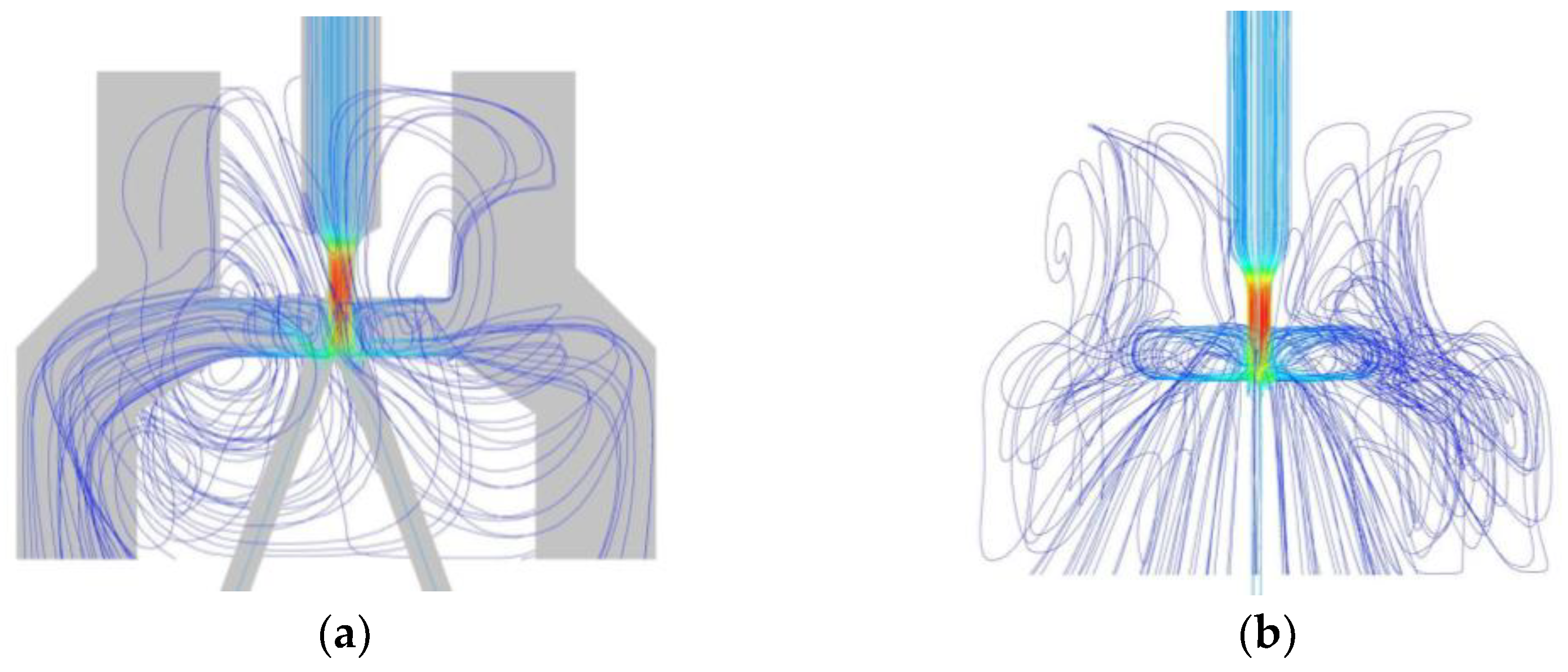

- The flow pattern in the hydraulic amplifier of the jet pipe servo-valve is complex. There are three paths of the oil ejected from the nozzle to return to the oil tank. Some oil flows along the surface of the receiver, like the plate impact jet. Part of the oil entering the receiving holes spills out and flows to the return oil port via the receiver’s upper surface. A vortex ring is formed above the receiver upper surface, then it diffuses to surrounding space, and finally flows to the return oil port or the receiving holes.

- Near the receiving holes, oil flow includes plate impingement jet, oblique impingement jet, vortex ring, and sputtering. In particular, the latter two flow patterns are rarely involved in traditional analysis. This suggests that the reasonability of using the orifice flow formula to analyze and calculate the load flow of the hydraulic amplifier is still to be discussed.

- The calculation results of the pressure characteristic model agree well with the simulation results; this indicates that the pressure characteristic equation has certain accuracy. The calculation results of the modified flow characteristic model are in good agreement with the simulation results; this indicates that the load flow characteristic equation has certain accuracy.

- The experimental data mentioned in references [12] and [20] are used to verify the accuracy of pressure and flow characteristics models. The experimental data agree well with the theoretical data without considering the limit. It shows that the theoretical model can describe the pressure and flow characteristics of jet pipe valve. However, the selection of average pressure, average velocity and even amplification coefficient in the model should be determined according to the actual structural parameters of jet pipe servo-valve.

- Based on impingement jet theory, the flow and pressure characteristics of the pre-stage of the jet pipe servo-valve are studied. Since the flow field information in the impact jet depends on the structure sizes of the jet pipe valve, that is to say, different sizes may lead to different jet distribution in the impinging section. Then the method of determining the average pressure, average flow rate, and even the flow factor will need further research and experiment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maskpey, R.H. A brief history of electrohydraulic servomechanisms. J. Dyn. Sys. Meas. Control 1978, 100, 110–116. [Google Scholar] [CrossRef]

- Tamburrano, P.; Plummer, A.R.; Distaso, E.; Amirante, R. A review of electro-hydraulic servovalve research and development. Int. J. Fluid Power 2018, 20, 1–23. [Google Scholar] [CrossRef]

- Wang, X.J. Characteristics of jet pipe electro-hydraulic servo valve. Chin. Hydraul. Pneum. 1986, 2, 27–28. [Google Scholar]

- Hu, J.J.; Yang, Z.H.; Jin, Y.L.; Huang, Z.; Zhu, Q.; Kong, X.D. Modeling and parameter matching for the pilot stage of jet pipe servo valve. Trans. Beijing Inst. Technol. 2019, 39, 1101–1106. [Google Scholar]

- Somashekhar, S.; Singaperumal, M.; Kumar, R. Modelling the steady-state analysis of a jet pipe electrohydraulic servo valve. IMechE 2006, 220, 109–129. [Google Scholar] [CrossRef]

- Somashekhar, S.; Singaperumal, M.; Kumar, R. Mathematical modelling and simulation of a jet pipe electrohydraulic flow control servo valve. IMechE 2007, 221, 365–382. [Google Scholar] [CrossRef]

- Somashekhar, S. Modeling and simulation of fluid structure interaction in jet pipe electrohydraulic servovalve. IJMECH 2013, 2, 1–14. [Google Scholar]

- Zhao, K.Y.; Wu, Q.X.; Zhang, L.J.; Yuan, Z.H.; Yang, J.Q. Analysis of the jet pipe electro-hydraulic servo valve with finite element methods. In Proceedings of the ICMME, Kuala Lumpur, Malaysia, 28–30 November 2017. [Google Scholar]

- Wu, L.; Chen, K.S.; Gao, Y. Research on cavitation phenomena in pilot stage of jet pipe servo-valve with a rectangular nozzle based on large-eddy simulations. AIP Adv. 2019, 9, 025109. [Google Scholar] [CrossRef]

- Guo, S.R.; Yin, Y.B. Advanced Fluid Power Control, 1st ed.; Shanghai Science and Technology Press: Shanghai, China, 2017; pp. 250–281. [Google Scholar]

- Xuan-Hong-Son, P.; Thien-Phuc, T. Mathematical Model of Steady State Operation in Jet Pipe Electro-Hydraulic Servo Valve. J. Donghua Univ. 2013, 30, 269–275. [Google Scholar]

- Li, Y.S. Mathematical modelling and characteristics of the pilot valve applied to a jet-pipe/deflector-jet servovalve. Sens. Actuators A 2016, 245, 150–159. [Google Scholar] [CrossRef]

- Chen, J. Dynamic Simulation and Optimal Design and Control Method of Jet Pipe Servo Valve. Ph.D. Thesis, Northwestern Polytechnical University, Xi’an, China, 2018. [Google Scholar]

- Beltaos, S.; Rajaratnam, N. Impingement of axisymmetric developing jets. J. Hydraul. Res. 1977, 15, 311–326. [Google Scholar] [CrossRef]

- Ji, H.; Wei, L.J.; Fang, Q.; Qiang, Y.; Jin, Y.L. Investigation to the Flow of the Jet-Pipe Amplifier in a Servovalve. Mach. Tool Hydraul. 2008, 36, 119–121. [Google Scholar]

- Jet Pipe Servovalve Installation and Operation Instruction. Available online: https://www.moog.com/content/dam/moog/literature/ICD/CDS33551_JetPipe.pdf (accessed on 7 May 2022).

- Merritt, H.E. Hydraulic Control Systems, 1st ed.; John Wiley &Sons, Inc.: New York, NY, USA, 1967; pp. 41–43. [Google Scholar]

- Beltaos, S.; Rajaratnam, N. Impinging Circular Turbulent Jets. J. Hydraul. Eng. 1974, 100, 1313–1328. [Google Scholar] [CrossRef]

- Rajaratnam, N.; Zhu, D.Z.; Rai, S.P. Turbulence measurements in the impinging region of a circular jet. Can. J. Civ. Eng. 2010, 37, 782–786. [Google Scholar] [CrossRef]

- Wang, C.H. Hydraulic Control System; China Machine Press: Beijing, China, 2004; pp. 37–40. [Google Scholar]

- Zhou, S.L. Fluid-structure interaction analysis of nozzle flapper assembly and temperature field analysis of the main valve of electro-hydraulic servo valve. Master’s Thesis, Yanshan University, Qing Huangdao, China, 2014. [Google Scholar]

- Yan, H.; Ren, Y.K.; Yao, L.; Dong, L.J. Analysis of the Internal Characteristics of a Deflector Jet Servo Valve. Chin. J. Mech. Eng. 2019, 32, 1–13. [Google Scholar] [CrossRef]

- Yin, Y.B. Theory and Application of Advanced Hydraulic Component, 1st ed.; Shanghai Science and Technology Press: Shanghai, China, 2017; pp. 29–38. [Google Scholar]

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Nozzle radius | 0.12 | mm | |

| Radius of receiving hole | 0.14 | mm | |

| Injection spacing | 0.5 | mm | |

| Angle of receiving hole | 18 | ° | |

| Spacing of receiving hole | e | 0 | mm |

| Project | Value | Unit |

|---|---|---|

| Density | 850 | |

| Specific heat capacity at constant pressure | 1940 | |

| Coefficient of thermal conductivity | 0.123 |

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Nozzle radius | 0.6 | mm | |

| Radius of receiving hole | 0.75 | mm | |

| Supply pressure | 0.6 | MPa | |

| Angle of receiving hole | 15 | ° | |

| Spacing of receiving hole | e | 0.1 | mm |

| Offset (mm) | Flow Rate (L/min) | Pressure (MPa) |

|---|---|---|

| 0 | 0 | 0 |

| 0.2 | 0.75 | 0.2 |

| 0.4 | 1.25 | 0.35 |

| 0.6 | 1.51 | 0.48 |

| 0.8 | 1.58 | 0.56 |

| 1.0 | 1.75 | 0.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.; Kong, X.; Zhang, J.; Du, R. Research on Pressure-Flow Characteristics of Pilot Stage in Jet Pipe Servo-Valve. Sensors 2023, 23, 216. https://doi.org/10.3390/s23010216

Kang S, Kong X, Zhang J, Du R. Research on Pressure-Flow Characteristics of Pilot Stage in Jet Pipe Servo-Valve. Sensors. 2023; 23(1):216. https://doi.org/10.3390/s23010216

Chicago/Turabian StyleKang, Shuangqi, Xiangdong Kong, Jin Zhang, and Ranheng Du. 2023. "Research on Pressure-Flow Characteristics of Pilot Stage in Jet Pipe Servo-Valve" Sensors 23, no. 1: 216. https://doi.org/10.3390/s23010216

APA StyleKang, S., Kong, X., Zhang, J., & Du, R. (2023). Research on Pressure-Flow Characteristics of Pilot Stage in Jet Pipe Servo-Valve. Sensors, 23(1), 216. https://doi.org/10.3390/s23010216