Neural Modelling in the Exploration of the Biomethane Potential from Cattle Manure: A Case Study on Herds Structure from Wielkopolskie, Podlaskie, and Mazowieckie Voivodeships in Poland

Abstract

1. Introduction

2. Materials and Methods

2.1. Obtaining Data for Modelling

- Collection of data from the Agency for Restructuring and Modernization of Agriculture (raw data disclosed by the Agency at the request of A. Wawrzyniak). The data concerned livestock production in rural areas by municipality/province. The data obtained concerned cattle counts in the provinces of Poland selected for the study.

- Calculation of the amount of waste generated from keeping cattle. Calculations performed separately for manure and for slurry. Calculations were made on the basis of literature data [33].

- : amount of manure (tons)

- : amount of slurry (m3)

- x: cattle population (units)

- LSU: Livestock Unit. An index of animals per unit according to Regulation of the Council of Ministers of 12 February 2020 [34].

- O: average amount of manure per year per cattle unit (Mg/LSU·year)

- and are the conversional factorsbased on animal keeping systems in barns as listed in Table 1.

- -

- One ton of manure produces an average of 60 m3 of biogas

- -

- 1 m3 of slurry produces 28 m3 of biogas on average

- -

- The calorific value of biogas is between 19 and 23 (MJ/m3)

- : average amount of biogas containing 60% methane from a unit amount of animal feces (m3∙(tons or m3) −1)

- : estimated amount of slurry (m3)

- : estimated amount of manure (tons)

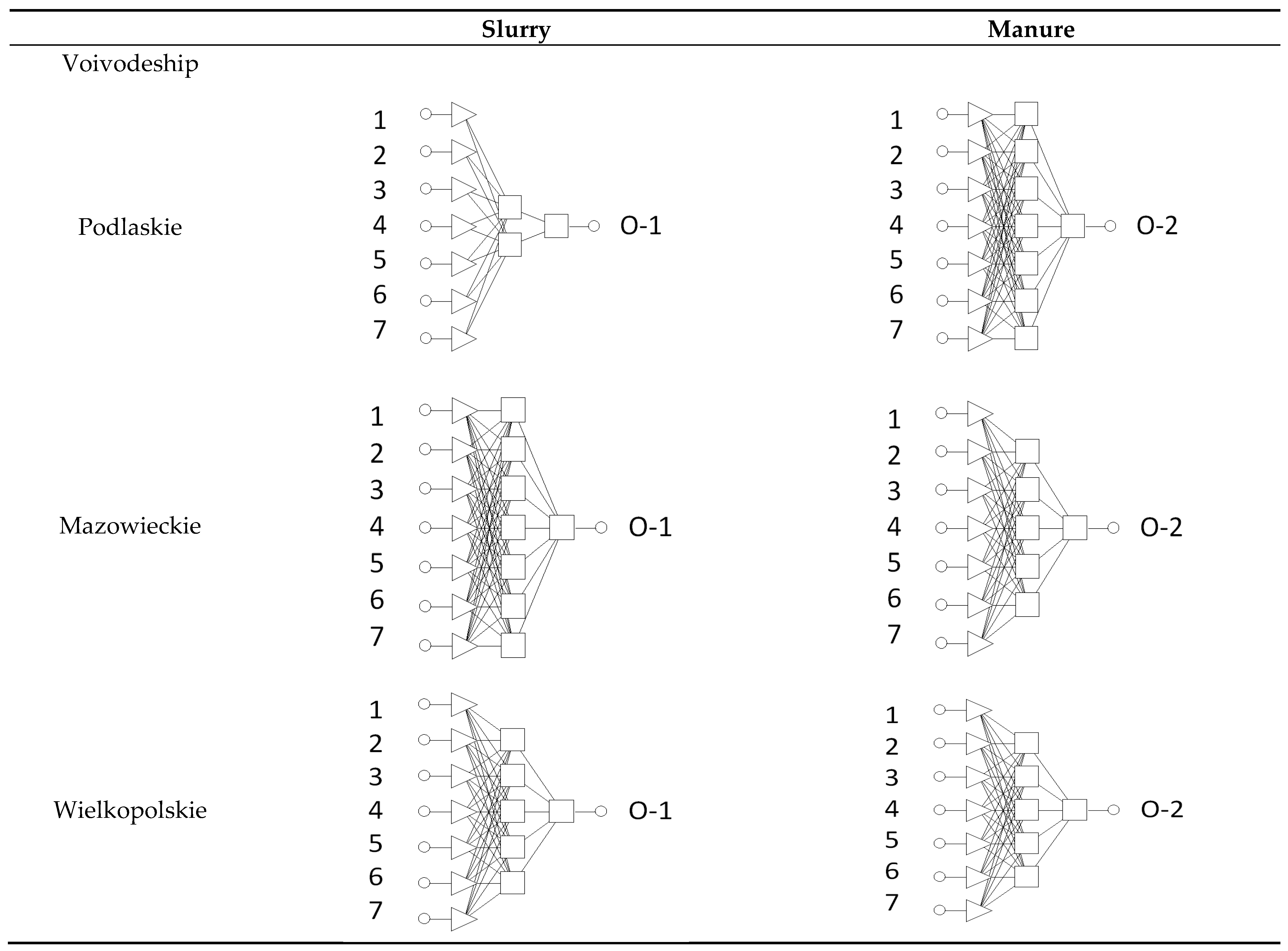

2.2. Simulation Studies

3. Results

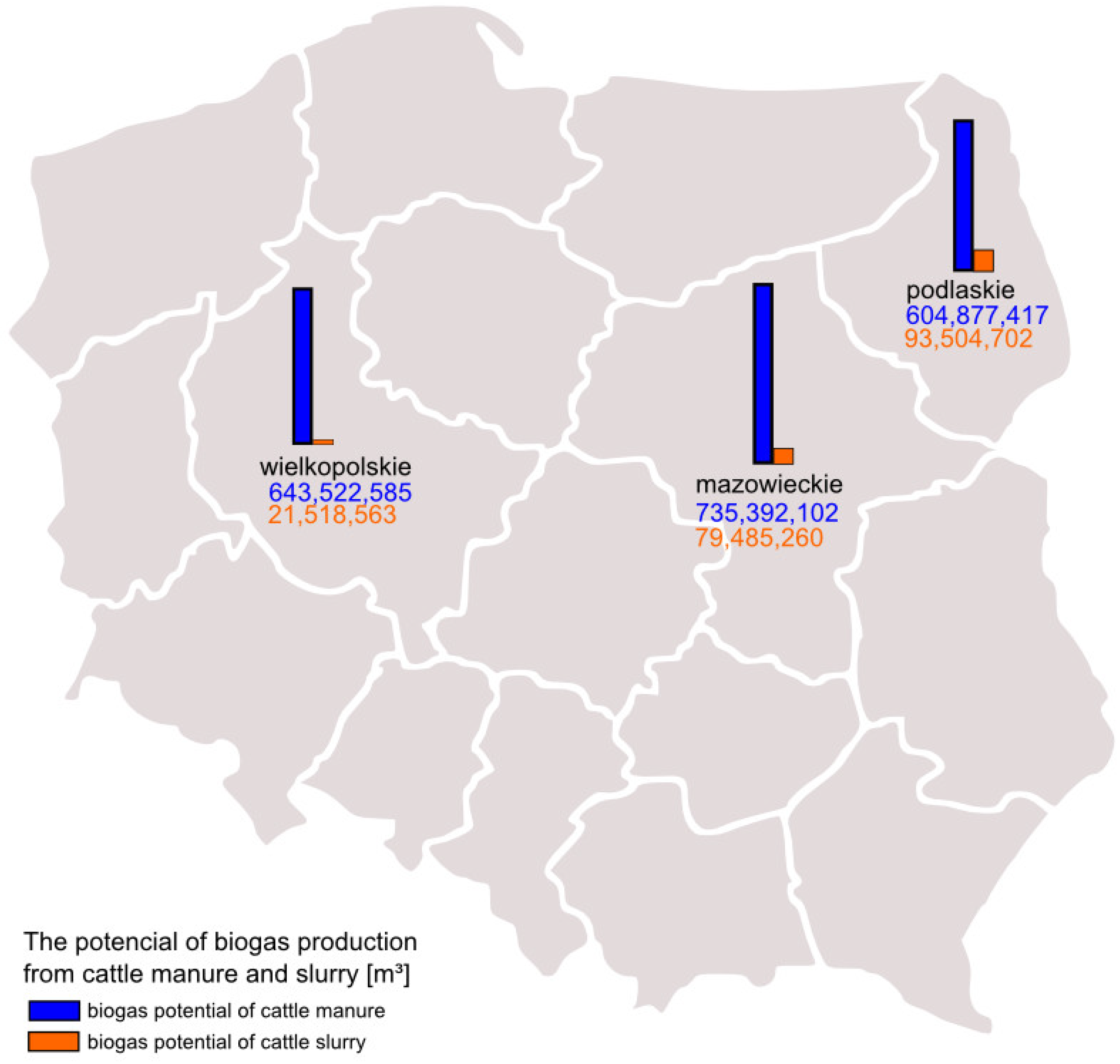

3.1. Biomethane Potential in the Analysed Voivodeships

3.2. Results on ANN Simulation

4. Discussion

4.1. Biomethane Potential in the Analysed Voivodeships

4.2. ANN Simulation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alberici, S.; Grimme, W.; Toop, G. Biomethane production potentials in the EU. In Feasibility of REPower EU 2030 Targets, Production Potentials in the Member States and Outlook to 2050, A Gas for Climate Report; Guidehouse Netherlands B.V.: Utrecht, The Netherlands, 2022; pp. 1–35. Available online: https://www.europeanbiogas.eu/wp-content/uploads/2022/07/GfC_national-biomethane-potentials_070722.pdf (accessed on 5 June 2022).

- Ramos-Suárez, J.L.; Ritterb, A.; Mata González, V.; Camacho Pérez, A. Biogas from animal manure: A sustainable energy opportunity in the Canary Islands. Renew. Sustain. Energy Rev. 2019, 104, 137–150. [Google Scholar] [CrossRef]

- Płatek, W. Methane from biogas as one of methods for natural gas supplying diversification in Poland. Energy Policy J. 2007, 10, 17–329. [Google Scholar]

- Zbytek, Z.; Adamczyk, F. Możliwości wykorzystywania biomasy stałej. Część 1. Uwarunkowania prawne i podział biomasy stałej. [Possibilities of using solid biomass. Part 1. Legal conditions and division of solid biomass]. For. Hortic. Agric. Technol. 2017, 2, 26–28. (In Polish) [Google Scholar]

- Kozłowski, K.; Dach, J.; Lewicki, A.; Malińska, K.; do Carmo, I.E.P. Potential of biogas production from animal manure in Poland. Arch. Environ. Prot. 2019, 45, 99–108. [Google Scholar]

- National Agricultural Census. Statistical Yearbook of Agriculture. 2020; ISSN-2080-8798. Available online: https://stat.gov.pl/obszary-tematyczne/roczniki-statystyczne/roczniki-statystyczne/rocznik-statystyczny-rolnictwa-2020,6,14.html (accessed on 15 June 2022).

- Wawrzyniak, A.; Pochwatka, A.; Lewicki, A.; Sołowiej, P.; Czekała, W. Database system for estimating the biogas potential of cattle and swine feces in Poland. J. Ecol. Eng. 2021, 22, 111–120. [Google Scholar] [CrossRef]

- Koninger, J.; Lugato, E.; Panagos, P.; Kochupillali, M.; Orgiazzi, A.; Briones, J.I.M. Manure management and soil biodiversity: Towards more sustainable food systems in the EU. Agric. Syst. 2021, 194, 103251. [Google Scholar] [CrossRef]

- Eurostat. Treatment of Waste by Waste Category, Hazardousness and Waste Management Operations for Animal Faeces, Manure and Urine. Available online: https://ec.europa.eu/eurostat/databrowser/view/ENV_WASTRT__custom_795114/default/table?lang=en (accessed on 5 June 2022).

- Eurostat. Agri-Environmental Indicator-Livestock Patterns. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Agri-environmental_indicator_-_livestock_patterns#Focus_on_the_agricultural_holdings_with_livestock_in_2016 (accessed on 5 June 2022).

- Horn van, H.H.; Wilkie, C.A.; Powers, J.W.; Nordstedt, A.R. Components of dairy manure management systems. J. Dairy Sci. 1994, 77, 2008–2030. [Google Scholar] [CrossRef]

- Witkowska-Dąbrowska, M. Changes in the amount of greenhouse gases and ammonia emissions to air from agricultural activities in Poland and the EU–analyzes using sustainable development indicators. Probl. World Agric. 2018, 18, 303–314. [Google Scholar] [CrossRef]

- Poland’s National Inventory Report 2019. Greenhouse Gas Inventory for 1988–2017, National Center for Balancing and Management of Emissions. Available online: https://www.kobize.pl/pl/fileCategory/id/16/krajowa-inwentaryzacja-emisji (accessed on 5 June 2022).

- Stolarski, M.J.; Warmiński, K.; Krzyżaniak, M.; Olba–Zięty, E.; Akincza, M. Bioenergy technologies and biomass potential vary in Northern European countries. Renew. Sustain. Energy Rev. 2020, 133, 110238. [Google Scholar] [CrossRef]

- Piechota, G.; Igliński, B. Biomethane in Poland—Current Status, Potential, Perspective and Development. Energies 2021, 14, 1517. [Google Scholar] [CrossRef]

- Bojarski, W.; Pulka, J.; Pochwatka, P.; Bresz, P.; Nowak, M.; Dach, J. Energetic Potential of Dairy Cow Breeding in Poland. In Farm Machinery and Processes Management in Sustainable Agriculture, FMPMSA; Pascuzzi, S., Santoro, F., Eds.; Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2022; Volume 289, pp. 115–121. [Google Scholar] [CrossRef]

- Iweka, S.C.; Owuama, K.C.; Chukwuneke, J.L.; Falowo, O.A. Optymization of biogas yield from anaerobic co-digestion of corn-chaff and cow dung digestate: RSM and python approach. Heliyon 2021, 7, e08255. [Google Scholar] [CrossRef] [PubMed]

- Albari, M.; Abubaker, A.; Darwish, A.A.; Sammeer, A.-D.; Ayadi, O.; Hjouj, D.; Al-Ghussan, L. Optimization of energy production from biogas fuel in a closed landfill using artificial neural networks: A case study of Al Ghabawi Landfill, Jordan. Waste Manag. 2022, 150, 218–226. [Google Scholar] [CrossRef]

- Antwi, P.; Li, J.; Boadi, P.O.; Meng, J.; Shi, E.; Deng, K.; Bondinuba, F.K. Estimation of biogas and methane yields in an UASB treating potato starch processing wastewater with backpropagation artificial neural network. Bioresour. Technol. 2017, 228, 106–115. [Google Scholar] [CrossRef] [PubMed]

- Ghatak, M.; Ghatak, A. Artificial neural network model to predict behaviour of biogas production curve from mixed ligninocellulosic cosubstrates. Fuel 2018, 232, 178–189. [Google Scholar] [CrossRef]

- Yukesh Kannah, R.; Bhava Rohini, K.; Gunasekaran, M.; Gokulakrishnan, K.; Kumar, G.; Rajesh Banu, J. Prediction of effective substrate concentration and its impact of biogas prediction using Artificial Neural Network in Hybrid Upflow anaerobic sludge blanket reactor for treating landfill leachate. Fuel 2022, 313, 122697. [Google Scholar] [CrossRef]

- Neto, J.G.; Ozorio, L.V.; Campos de Abreu, T.C.; dos Santosa, B.F.; Florian Pradelle, F. Modeling of biogas production from food, fruits and vegetables wastes using artificial neural network (ANN). Fuel 2021, 285, 119081. [Google Scholar] [CrossRef]

- Gopal, L.C.; Govindarajan, M.; Kavipriya, M.R.; Mahboob, S.; Al-Ghanim, K.A.; Virik, P.; Zubair, A.; Al-Mulhm, N.; Senthilkumaran, V.; Shankar, V. Optimization strategies for improved biogas production by recycling of waste through response surface methodology and artificial neural network: Sustainable energy perspective research. J. King Saud. Univ.-Sci. 2021, 33, 101241. [Google Scholar] [CrossRef]

- Aklilu, E.G.; Waday, Y.A. Optimizing the process parameters to maximize biogas yield from anaerobic co-digestion of alkali-treated corn stover and poultry manure using artificial neural network and response surface methodology. Biomass Conv. Bioref. 2021. [Google Scholar] [CrossRef]

- Rego, A.S.C.; Augusta, S.; Leite, F.; Leiteb, B.S.; Grillo, A.V.; Santos, B.F. Artificial Neural Network Modelling for Biogas Production in Biodigesters. Chem. Eng. Trans. 2019, 74, 25–30. [Google Scholar]

- Tufaner, F.; Demirci, Y. Prediction of biogas production rate from anaerobic hybrid reactor by artificial neural network and nonlinear regressions models. Clean Technol. Environ. Policy 2020, 22, 713–724. [Google Scholar] [CrossRef]

- Sakiewicz, P.; Piotrowski, K.; Ober, J.; Karwot, J. Innovative artificial neural network approach for integrated biogas–wastewater treatment system modelling: Effect of plant operating parameters on process intensification. Renew. Sustain. Energy Rev. 2020, 124, 109784. [Google Scholar] [CrossRef]

- Tufaner, F.; Avşar, Y.; Gönüllü, M.T. Modeling of biogas production from cattle manure with co-digestion of different organic wastes using an artificial neural network. Clean Technol. Environ. Policy 2017, 19, 2255–2264. [Google Scholar] [CrossRef]

- Almomani, F. Prediction of biogas production from chemically treated co-digested agricultural waste using artificial neural network. Fuel 2020, 280, 118573. [Google Scholar] [CrossRef]

- Okwu, M.O.; Samuel, O.D.; Otanocha, O.B.; Tartibu, L.K.; Omoregbee, H.O.; Mbachu, V.M. Development of ternary models for prediction of biogas yield in a novel modular biodigester: A case of fuzzy Mamdani model (FMM), artificial neural network (ANN), and response surface methodology (RSM). Biomass Conv. Bioref. 2020. [Google Scholar] [CrossRef]

- Chen, W.-Y.; Chan, Y.J.; Lim, J.W.; Liew, C.S.; Mohamad, M.; Ho, C.-D.; Usman, A.; Lisak, G.; Hara, H.; Tan, W.-N. Artificial Neural Network (ANN) Modelling for Biogas Production in Pre-Commercialized Integrated Anaerobic-Aerobic Bioreactors (IAAB). Water 2022, 14, 1410. [Google Scholar] [CrossRef]

- GUS Agricultural Census. Livestock and Selected Elements of Animal Production Method, 1390; GUS Agricultural Census: Warsaw, Poland, 2010. [Google Scholar]

- Regulation of the Council of Ministers of 12 February 2020. Position 243. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20200000243 (accessed on 2 December 2022). (In Polish)

- Myczko, M.; Myczko, R.; Kołodziejczyk, T.; Golimowska, R.; Lenarczyk, J.; Janas, Z.; Kliber, A.; Karłowski, J.; Dolska, M. Budowa i Eksploatacja Biogazowni Rolniczych [Construction and Operation of Agricultural Biogas Plants]. Instytut Technologiczno-Przyrodniczy. Poznań. 2011. Available online: https://www.itp.edu.pl/old/wydawnictwo/indexbf07.html?id=budowa&a=inne (accessed on 5 June 2022). (In Polish).

- Pogłowie Bydła Grudzień. 2018. Available online: https://stat.gov.pl/obszary-tematyczne/rolnictwo-lesnictwo/produkcja-zwierzeca-zwierzeta-gospodarskie/poglowie-bydla-wedlug-stanu-w-grudniu-2018-roku,5,20.html (accessed on 2 December 2022).

- Krajowy Ośrodek Wsparcia Rolnictwa-KOWR. Available online: https://www.kowr.gov.pl/biuro-prasowe/aktualnosci/128-instalacji-biogazu-rolniczego (accessed on 2 December 2022).

- Bilik, K.; Strzelski, J. Dairy cow feeding according to organic standards with regard to studies at the National Research Institute of Animal Production. Wiadomości. Zootech. R. LI 2013, 3, 25–41. (In Polish) [Google Scholar]

- Najważniejsze Zasady Żywienia Jałówek. Tygodnik Poradnik Rolniczy. 26 April 2018. Available online: https://www.tygodnik-rolniczy.pl/articles/polskie-mleko/najwazniejsze-zasady-zywienia-jalowek (accessed on 2 December 2022).

- Żywienie Bydła Opasowego Technologia Produkcji Rolniczej. Kujawsko-Pomorski Agricultural Advisory Centre in Minikowo. 14 April 2020. Available online: https://technologia.kpodr.pl/index.php/2020/04/15/zywienie-bydla-opasowego (accessed on 2 December 2022).

- Kowalski, Z.M.; Kamiński, J. Niektóre problemy żywienia krów wysoko wydajnych. Postępy Nauk. Rol. 2000, 47, 77–98. [Google Scholar]

| Animal Keeping System | ||

|---|---|---|

| Voivodeship | Stands with a Slatted Floor () | Stands with a Solid Floor () |

| Mazowieckie | 0.149 | 0.851 |

| Podlaskie | 0.770 | 0.230 |

| Wielkopolskie | 0.343 | 0.657 |

| Input Variables (Descriptors)-Number of Animals of a Certain Type in the Herd Structure |

| 1 Calves 2 Bulls 6–12 months 3 Bulls 12–24 months 4 Bulls > 24 months 5 Heifers 6–12 months 6 Heifers 12–18 months 7 Dairy Cows months |

| Output (options) |

| O-1 amount of biogas from slurry for examined voivodeship O-2 amount of biogas from manure for examined voivodeship |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | O-1 | O-2 | |

|---|---|---|---|---|---|---|---|---|---|

| No. | Calves DJP | Bulls 6–12 Months | Bulls 12–24 Months | Bulls >24 Months | Heifers 6–12 Months | Heifers 12–18 Months | Dairy Cows | Amount of Biogas from Manure (m3) | Amount of Biogas from Slurry (m3) |

| 1 | 410.25 | 243.3 | 1012.8 | 294 | 545.7 | 1361.6 | 13,527 | 12,653,669 | 1,956,062 |

| 2 | 396.75 | 186.9 | 737.6 | 238 | 547.5 | 1308 | 13,843 | 12,466,307 | 1,927,098 |

| 3 | 174.45 | 148.8 | 620 | 163.8 | 202.5 | 476 | 4511 | 4,641,118 | 717,445 |

| 4 | 69.6 | 66.9 | 257.6 | 67.2 | 100.8 | 195.2 | 1792 | 1,854,335 | 286,652 |

| 5 | 11.25 | 13.5 | 35.2 | 14 | 13.5 | 28.8 | 382 | 376,274 | 58,166 |

| 6 | 286.2 | 223.5 | 808 | 175 | 338.1 | 820 | 8115 | 7,835,354 | 1,211,225 |

| 7 | 96.3 | 87.9 | 391.2 | 81.2 | 106.8 | 195.2 | 2195 | 2,337,194 | 361,294 |

| 8 | 33 | 38.4 | 208 | 65.8 | 24.9 | 76.8 | 542 | 749,772 | 115,903 |

| 9 | 69 | 49.5 | 180.8 | 67.2 | 102 | 201.6 | 2395 | 2,394,325 | 370,126 |

| 10 | 67.35 | 54.3 | 172.8 | 72.8 | 82.5 | 165.6 | 2267 | 2,210,135 | 341,653 |

| … | … | … | … | … | … | … | … | … | … |

| 108 | 476.25 | 257.1 | 1160 | 274.4 | 590.1 | 1567.2 | 13,928 | 13,158,840 | 2,034,153 |

| Learning File | Validation File | Test File | Type of Neural Network | |

|---|---|---|---|---|

| Podlaskie voivodeship | ||||

| slurry | ||||

| S.D. ratio | 0.059180 | 0.03348 | 0.095860 | MLP: 7-2-1 |

| Correlation | 0.998305 | 0.99954 | 0.995798 | |

| manure | ||||

| S.D. ratio | 0.94429 | 0.02336 | 0.0616 | MLP: 7-7-1 |

| Correlation | 0.99902 | 0.999754 | 0.998841 | |

| Mazowieckie voivodeship | ||||

| slurry | ||||

| S.D. ratio | 0.01703 | 0.01429 | 0.02317 | MLP: 7-7-1 |

| Correlation | 0.999863 | 0.9999 | 0.999816 | |

| manure | ||||

| S.D. ratio | 0.010581 | 0.01127 | 0.01075 | MLP: 7-5-1 |

| Correlation | 0.999944 | 0.999945 | 0.999942 | |

| Wielkopolskie voivodeship | ||||

| slurry | ||||

| S.D. ratio | 0.02645 | 0.02817 | 0.02472 | MLP: 7-5-1 |

| Correlation | 0.999653 | 0.999605 | 0.999703 | |

| manure | ||||

| S.D. ratio | 0.01502 | 0.008993 | 0.01077 | MLP: 7-5-1 |

| Correlation | 0.999887 | 0.99996 | 0.999953 | |

| Calves | Bulls 6–12 Months | Bulls 12–24 Months | Bulls > 24 Months | Heifers 6–12 Months | Heifers 12–18 Months | Dairy Cows | |

|---|---|---|---|---|---|---|---|

| Podlaskie voivodeship | |||||||

| Slurry-analysis for training set | |||||||

| Rank | 2 | 5 | 7 | 4 | 3 | 6 | 1 |

| Error | 782,535.2 | 331,844.3 | 234,644.5 | 402,790.21 | 456,897.9 | 315,716.2 | 2,383,259 |

| Quotient | 3.557651 | 1.508668 | 1.066768 | 1.83121 | 2.077201 | 1.435345 | 10.83504 |

| Slurry-analysis for validation set | |||||||

| Rank | 2 | 5 | 7 | 4 | 3 | 6 | 1 |

| Error | 641,876.1 | 244,916.7 | 131,120.5 | 288,690.6 | 350,421.5 | 168,073.5 | 2,344,526 |

| Quotient | 5.280928 | 2.015012 | 1.078772 | 2.375153 | 2.883035 | 1.382797 | 19.28919 |

| Manure-analysis for training set | |||||||

| Rank | 5 | 6 | 4 | 7 | 3 | 2 | 1 |

| Error | 346,955.1 | 174,304.3 | 400,851 | 173,594.9 | 537,229 | 557,505.1 | 2,107,914 |

| Quotient | 2.17774 | 1.094059 | 2.516029 | 1.089607 | 3.372035 | 3.499303 | 13.23078 |

| Manure-analysis for validation set | |||||||

| Rank | 5 | 6 | 4 | 7 | 3 | 2 | 1 |

| Error | 278,951.5 | 89,571.02 | 394,983.2 | 79,676.33 | 454,054.6 | 471,651.7 | 2,006,711 |

| Quotient | 3.609639 | 1.159051 | 5.111093 | 1.031014 | 5.875479 | 6.103185 | 25.96689 |

| Mazowieckie voivodeship | |||||||

| Slurry-analysis for training set | |||||||

| Rank | 6 | 7 | 4 | 5 | 2 | 3 | 1 |

| Error | 103,841.8 | 69,071.22 | 199,142.9 | 164,292.1 | 212,249.7 | 205,649 | 1,830,063 |

| Quotient | 2.397802 | 1.594917 | 4.598388 | 3.793654 | 4.901038 | 4.748621 | 42.25781 |

| Slurry-analysis for validation set | |||||||

| Rank | 6 | 7 | 4 | 5 | 3 | 2 | 1 |

| Error | 96,951.83 | 66,217.75 | 174,988.8 | 156,794.4 | 192,573.9 | 204,318.1 | 1,696,270 |

| Quotient | 2.835091 | 1.936357 | 5.117068 | 4.585022 | 5.631296 | 5.974724 | 49.60278 |

| Manure-analysis for training set | |||||||

| Rank | 4 | 6 | 2 | 5 | 3 | 7 | 1 |

| Error | 110,416.7 | 67,805.55 | 327,842 | 106,089.1 | 200,687 | 58,909.33 | 2,127,190 |

| Quotient | 3.866067 | 2.374104 | 11.47887 | 3.714542 | 7.026739 | 2.062617 | 74.48018 |

| Manure-analysis for validation set | |||||||

| Rank | 5 | 6 | 2 | 4 | 3 | 7 | 1 |

| Error | 85,550.34 | 67,821.77 | 337,742.4 | 112,396.3 | 177,292.7 | 50,618.03 | 1,857,479 |

| Quotient | 3.076455 | 2.438923 | 12.14547 | 4.041856 | 6.37558 | 1.820263 | 66.79635 |

| Wielkopolskie voivodeship | |||||||

| Slurry-analysis for training set | |||||||

| Rank | 6 | 5 | 3 | 4 | 7 | 2 | 1 |

| Error | 164,558.3 | 193,348.8 | 393,748.6 | 218,477.6 | 85,506.16 | 407,828.6 | 1,191,321 |

| Quotient | 2.608864 | 3.065301 | 6.242385 | 3.463685 | 1.355592 | 6.465605 | 18.88689 |

| Slurry-analysis for validation set | |||||||

| Rank | 6 | 5 | 2 | 4 | 7 | 3 | 1 |

| Error | 154,924.7 | 199,205.6 | 361,707.1 | 212,250.6 | 83,400.45 | 357,936.4 | 1,010,796 |

| Quotient | 2.609011 | 3.354724 | 6.091332 | 3.574408 | 1.404506 | 6.027831 | 17.02231 |

| Manure-analysis for training set | |||||||

| Rank | 6 | 5 | 2 | 4 | 7 | 3 | 1 |

| Error | 126,985.5 | 149,031.5 | 450,806.2 | 165,423.2 | 79,804.95 | 209,430.4 | 1,260,193 |

| Quotient | 3.629729 | 4.259889 | 12.88576 | 4.728427 | 2.28113 | 5.98632 | 36.02112 |

| Manure-analysis for validation set | |||||||

| Rank | 6 | 5 | 2 | 4 | 7 | 3 | 1 |

| Error | 121,494.7 | 158,065.2 | 514,812.5 | 184,429.8 | 78,210.54 | 261,297 | 1,466,372 |

| Quotient | 4.614739 | 6.003798 | 19.55415 | 7.005207 | 2.970675 | 9.924857 | 55.69727 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wawrzyniak, A.; Przybylak, A.; Sujak, A.; Boniecki, P. Neural Modelling in the Exploration of the Biomethane Potential from Cattle Manure: A Case Study on Herds Structure from Wielkopolskie, Podlaskie, and Mazowieckie Voivodeships in Poland. Sensors 2023, 23, 164. https://doi.org/10.3390/s23010164

Wawrzyniak A, Przybylak A, Sujak A, Boniecki P. Neural Modelling in the Exploration of the Biomethane Potential from Cattle Manure: A Case Study on Herds Structure from Wielkopolskie, Podlaskie, and Mazowieckie Voivodeships in Poland. Sensors. 2023; 23(1):164. https://doi.org/10.3390/s23010164

Chicago/Turabian StyleWawrzyniak, Agnieszka, Andrzej Przybylak, Agnieszka Sujak, and Piotr Boniecki. 2023. "Neural Modelling in the Exploration of the Biomethane Potential from Cattle Manure: A Case Study on Herds Structure from Wielkopolskie, Podlaskie, and Mazowieckie Voivodeships in Poland" Sensors 23, no. 1: 164. https://doi.org/10.3390/s23010164

APA StyleWawrzyniak, A., Przybylak, A., Sujak, A., & Boniecki, P. (2023). Neural Modelling in the Exploration of the Biomethane Potential from Cattle Manure: A Case Study on Herds Structure from Wielkopolskie, Podlaskie, and Mazowieckie Voivodeships in Poland. Sensors, 23(1), 164. https://doi.org/10.3390/s23010164