Research on Fuel Offset Control of High-Pressure Common-Rail Diesel Engine Based on Crankshaft Segment Signals

Abstract

:1. Introduction

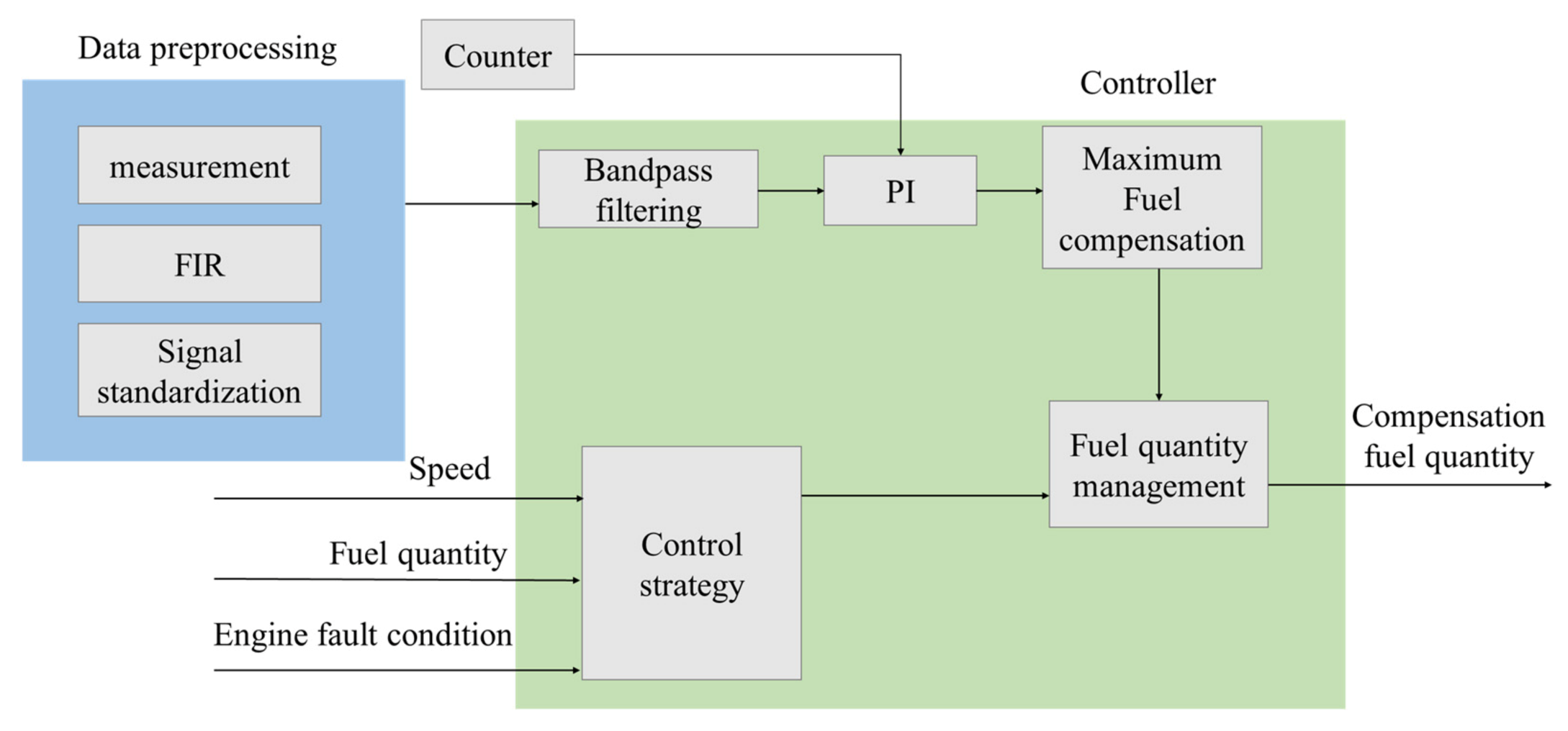

- The characteristics of the crankshaft segment signal were analyzed. It is found that the degree of nonuniformity in engine operation can be represented by the amplitudes of the lower-order nondominant harmonics of the crankshaft segment signal below the firing frequency. It is a new method to measure the operating nonuniformity. It replaces the method of crankshaft angular speed. The crankshaft segment signal can be used as the basis of fuel quantity offset.

- A method based on band-pass filtering synthetic waveform to extract the signal of nonuniform engine operation was proposed. The crankshaft segment signal extracted by this method can reduce the interference caused by the external torque factor of the engine, and the obtained parameters can more accurately reflect the nonuniformity of the engine. Compared with the crankshaft angular speeds, the result obtained by this method is more accurate. ECU is simpler and faster in calculating crankshaft segment signals.

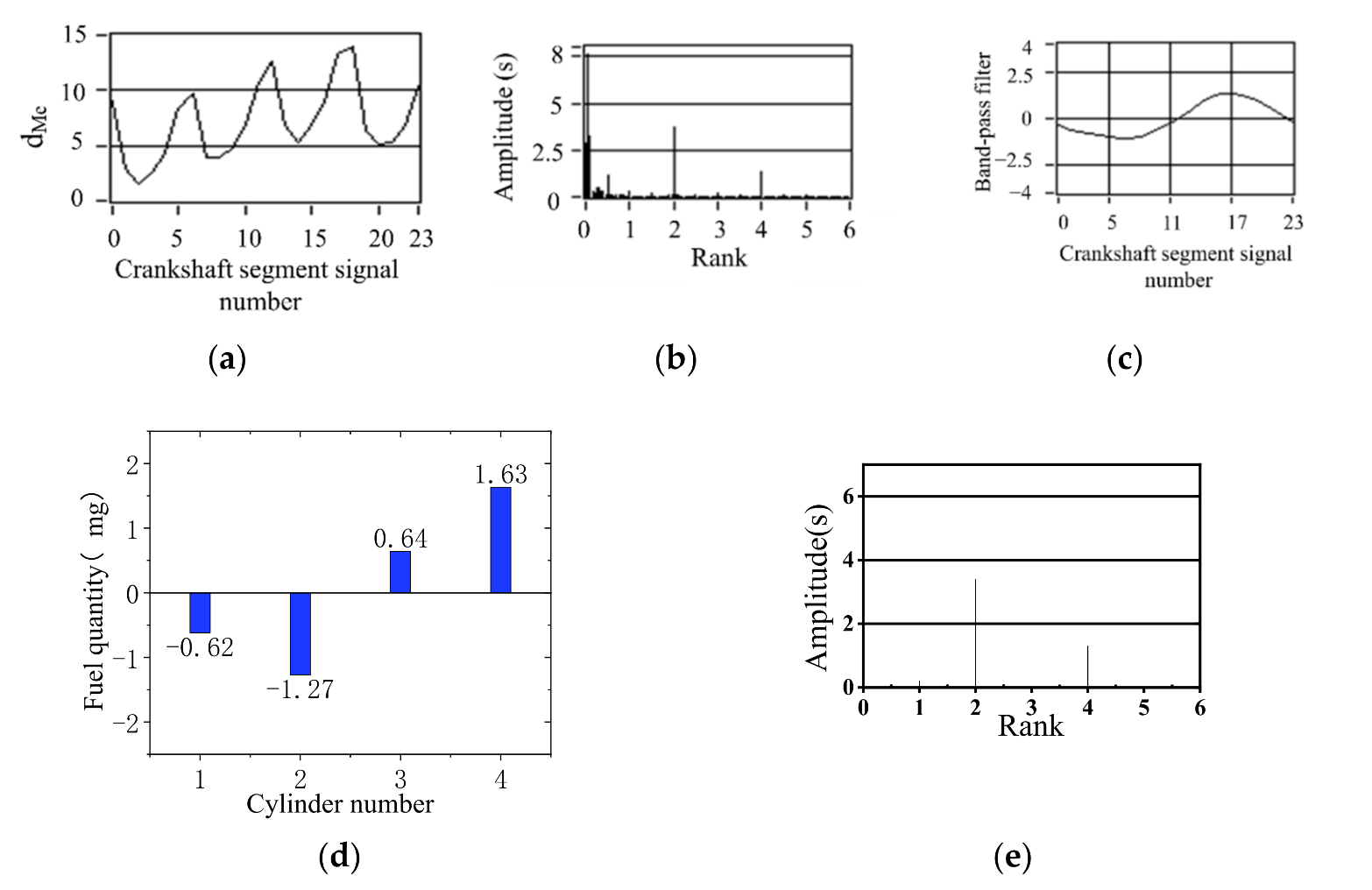

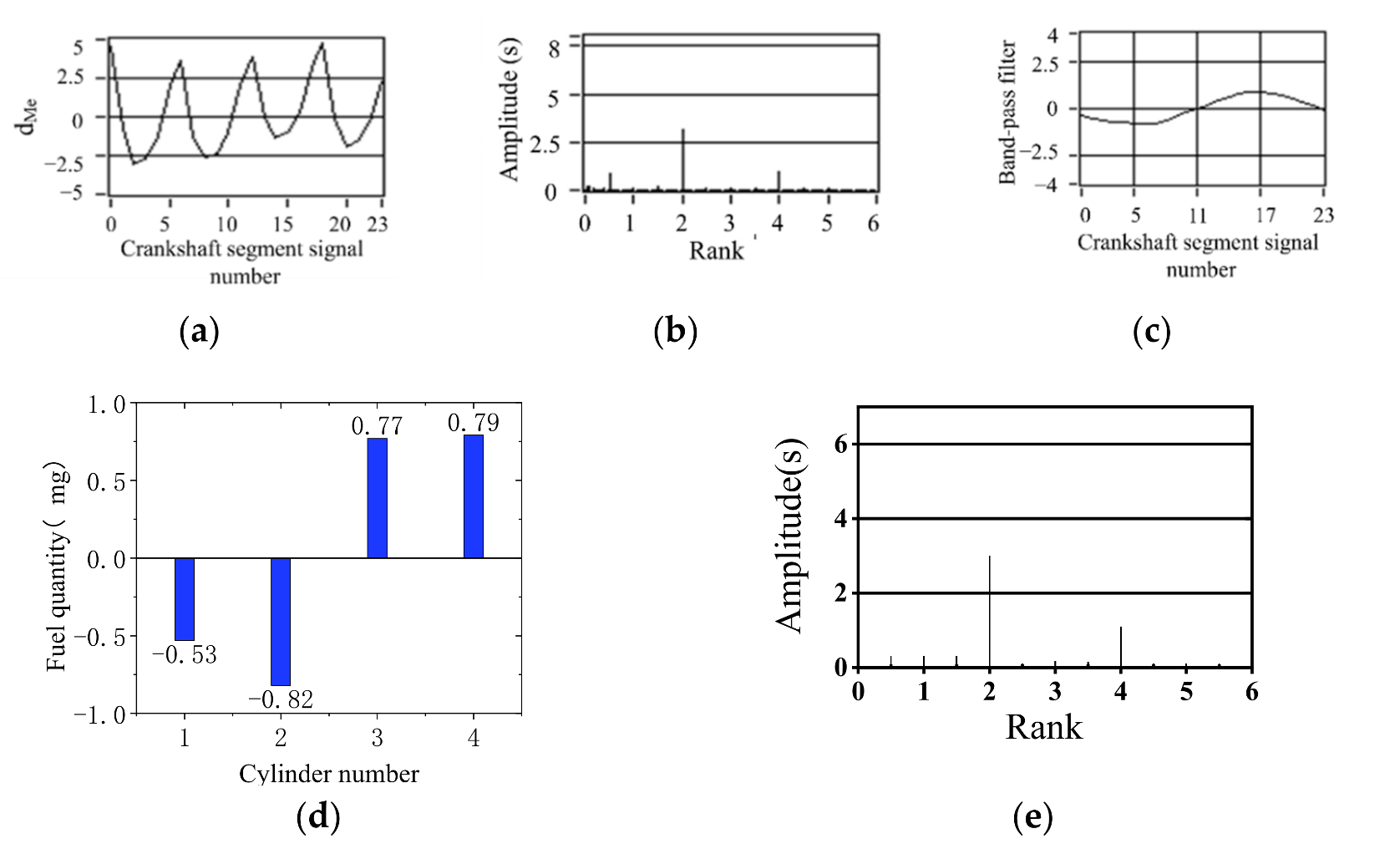

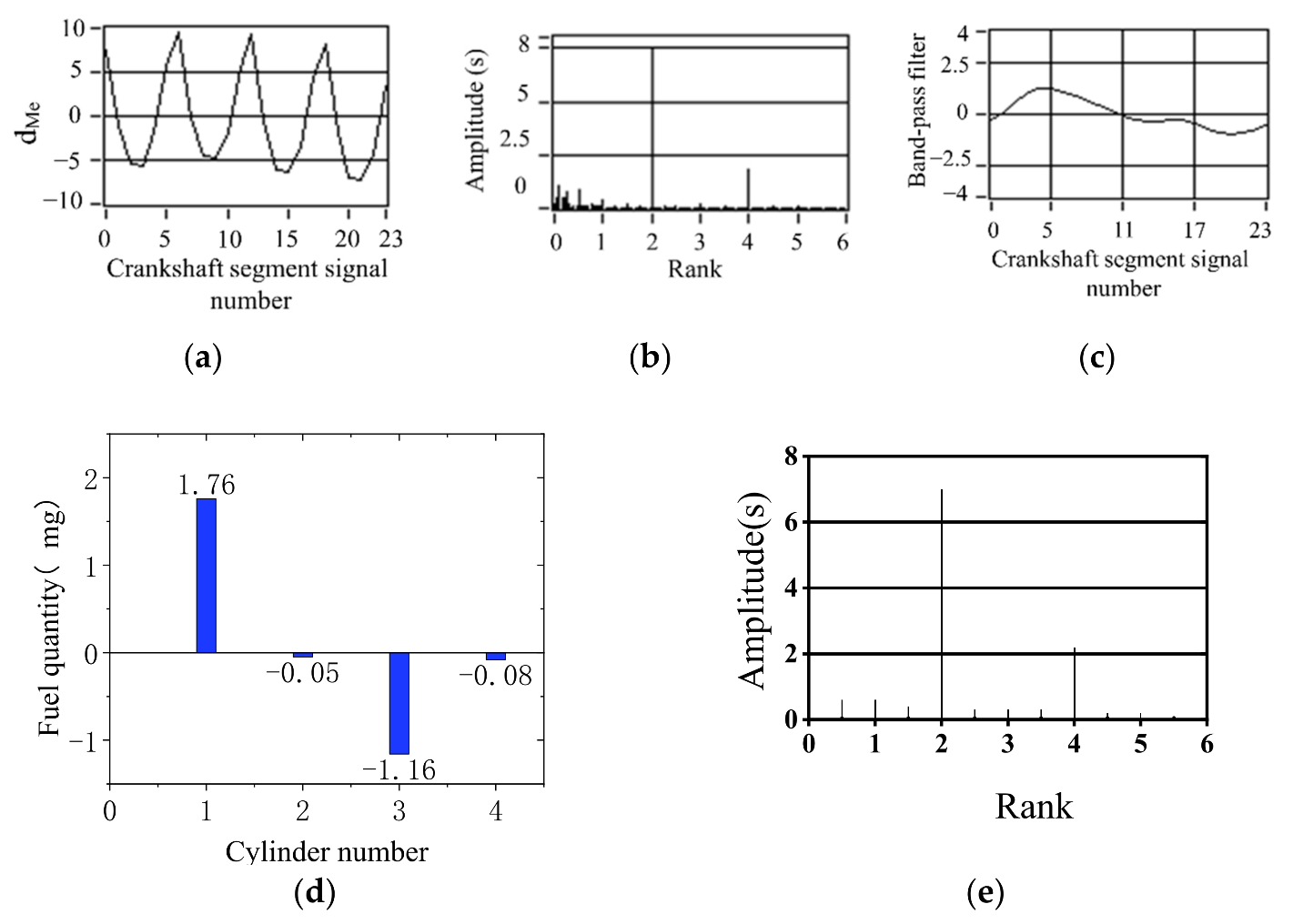

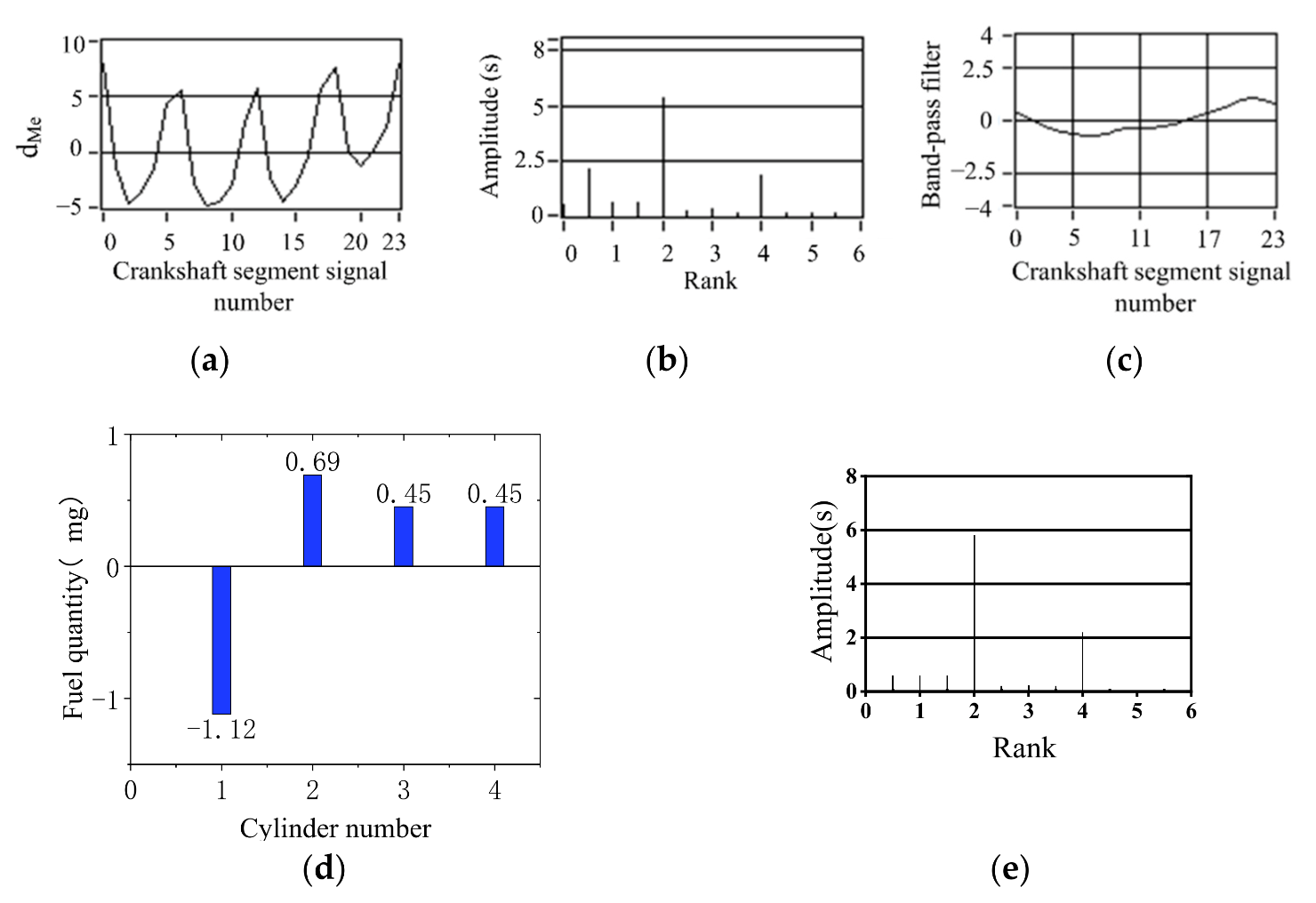

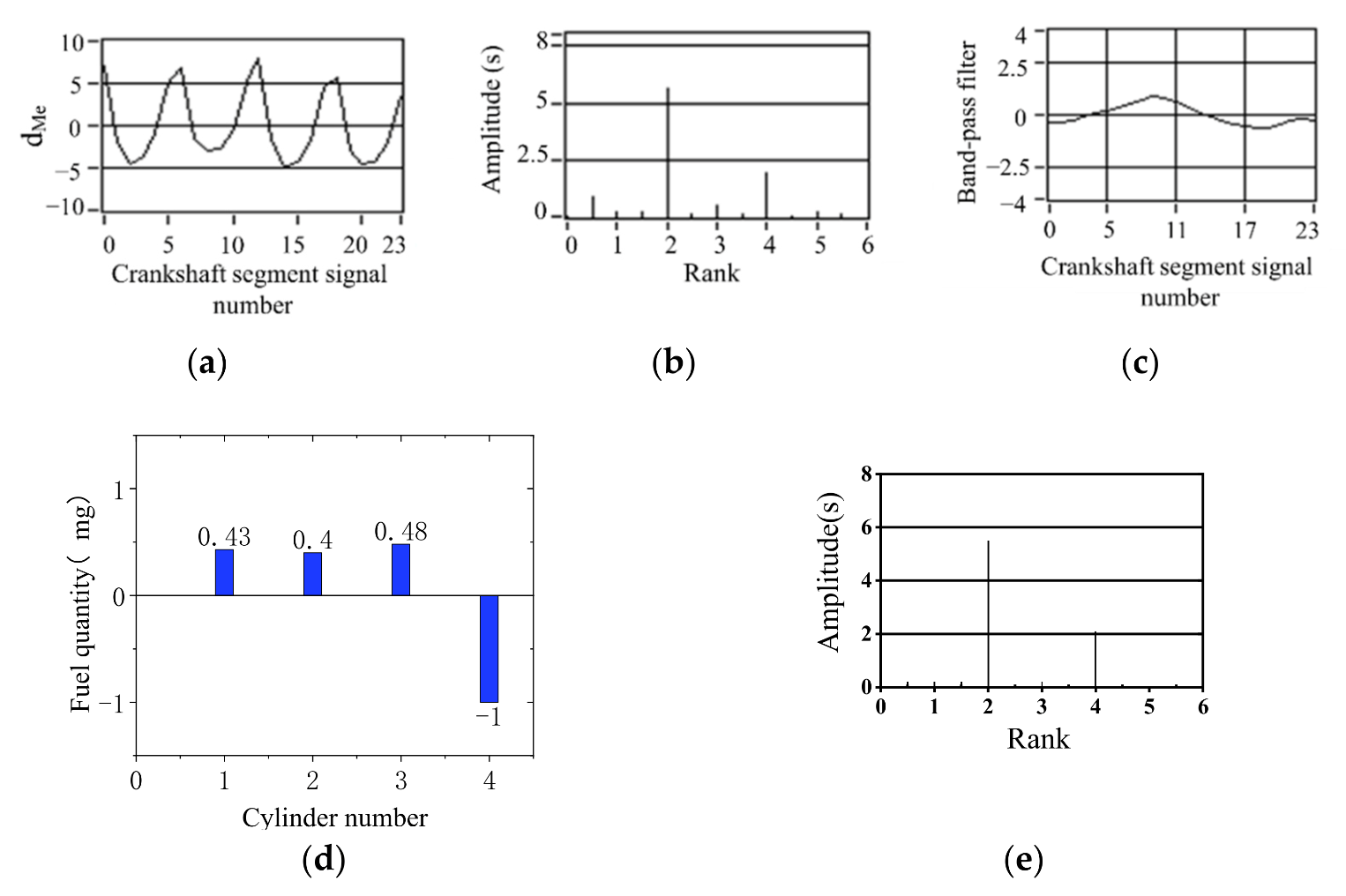

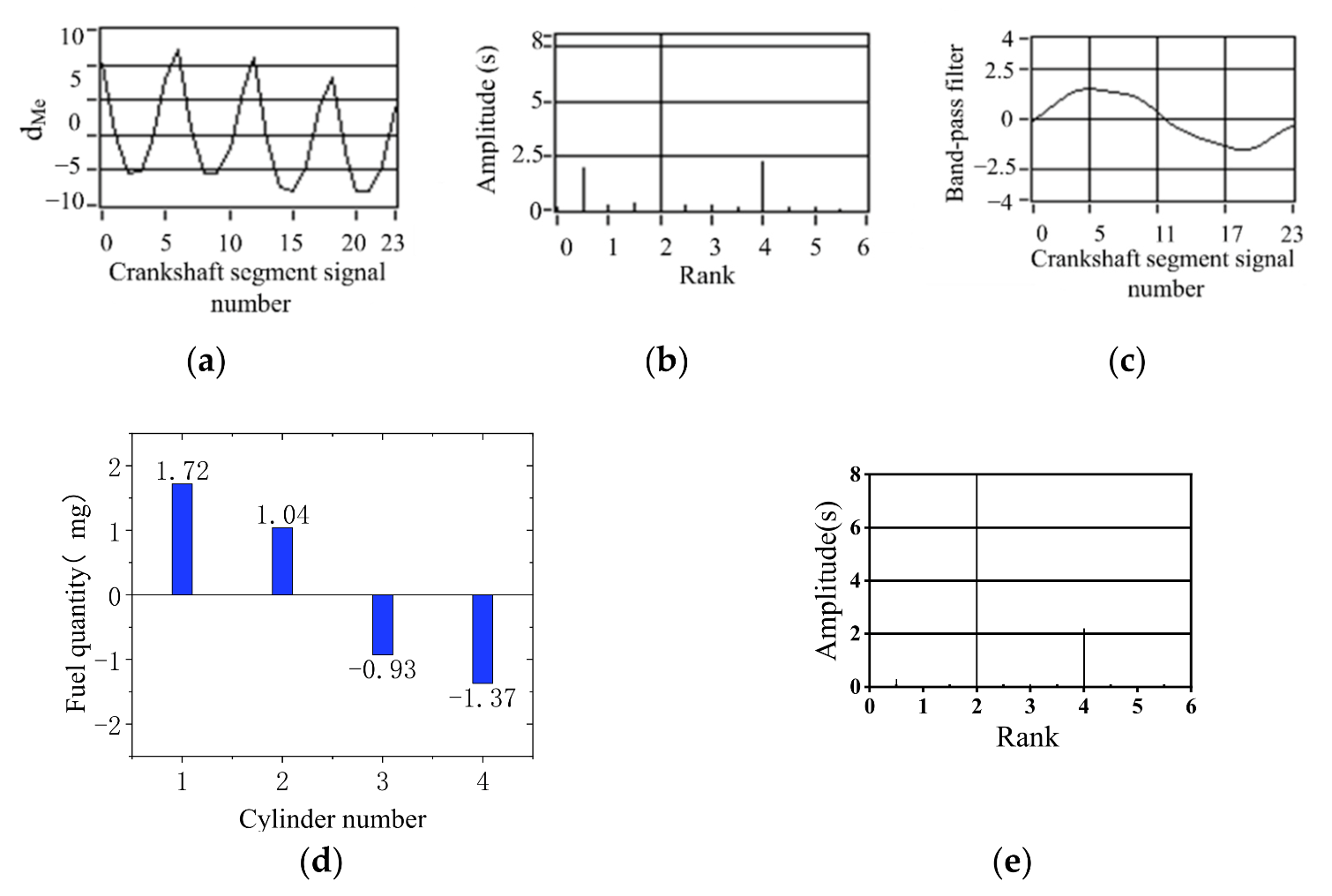

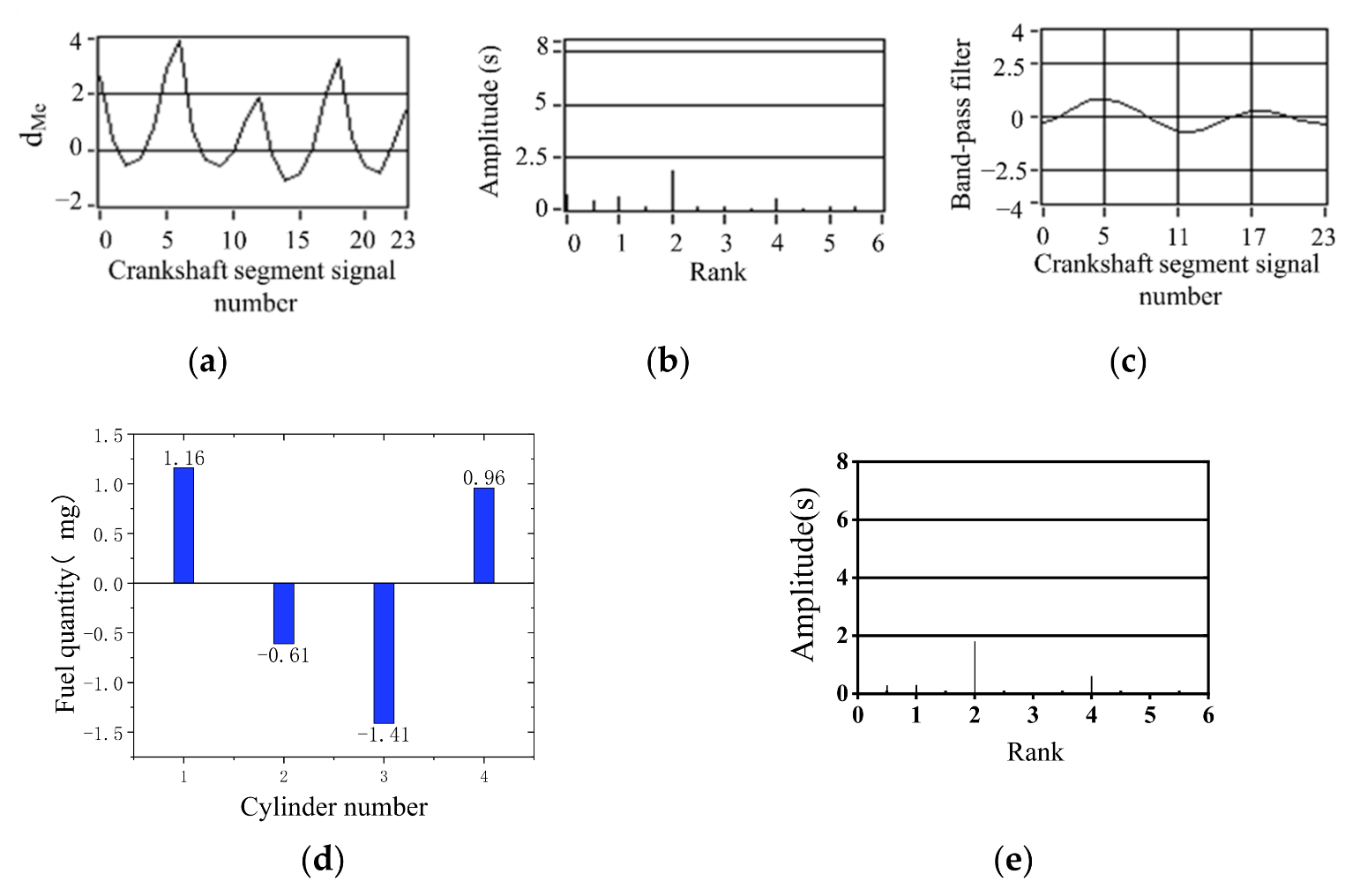

- In order to make the diesel engine operate uniformly, fuel offset is carried out for the nonuniform phenomenon, fuel offset is carried out for the nonuniformity phenomenon, the FOC control strategy based on the characteristics of crankshaft segment signals is proposed, and the fuel compensation value is obtained. The proposed fuel offset control method based on crankshaft segment signals can realize the online control and automatic calibration of diesel engine operating uniformity.

2. Crankshaft Segment Signals Acquisition and Analysis

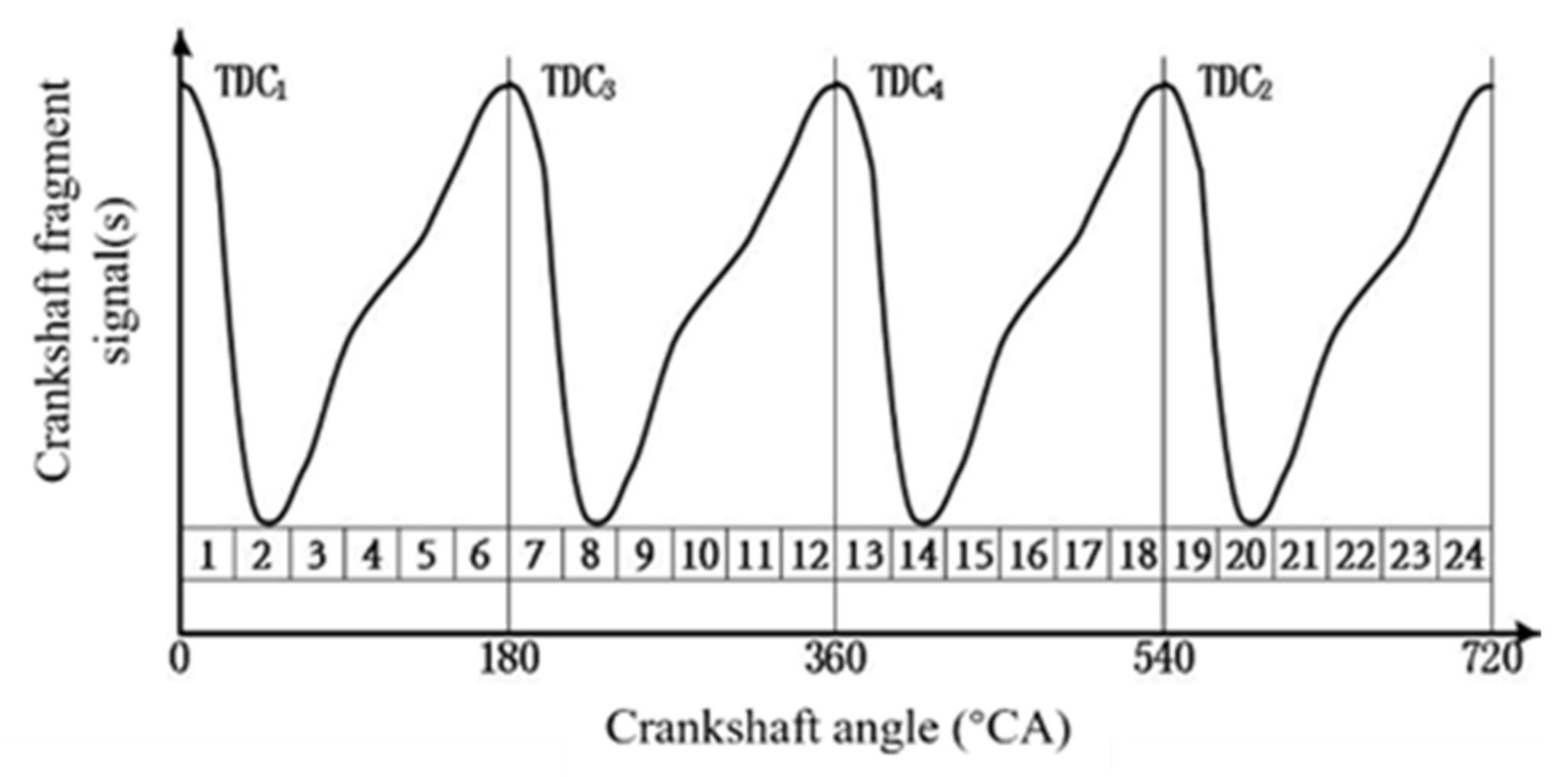

2.1. Crankshaft Segment Signal Acquisition and Processing

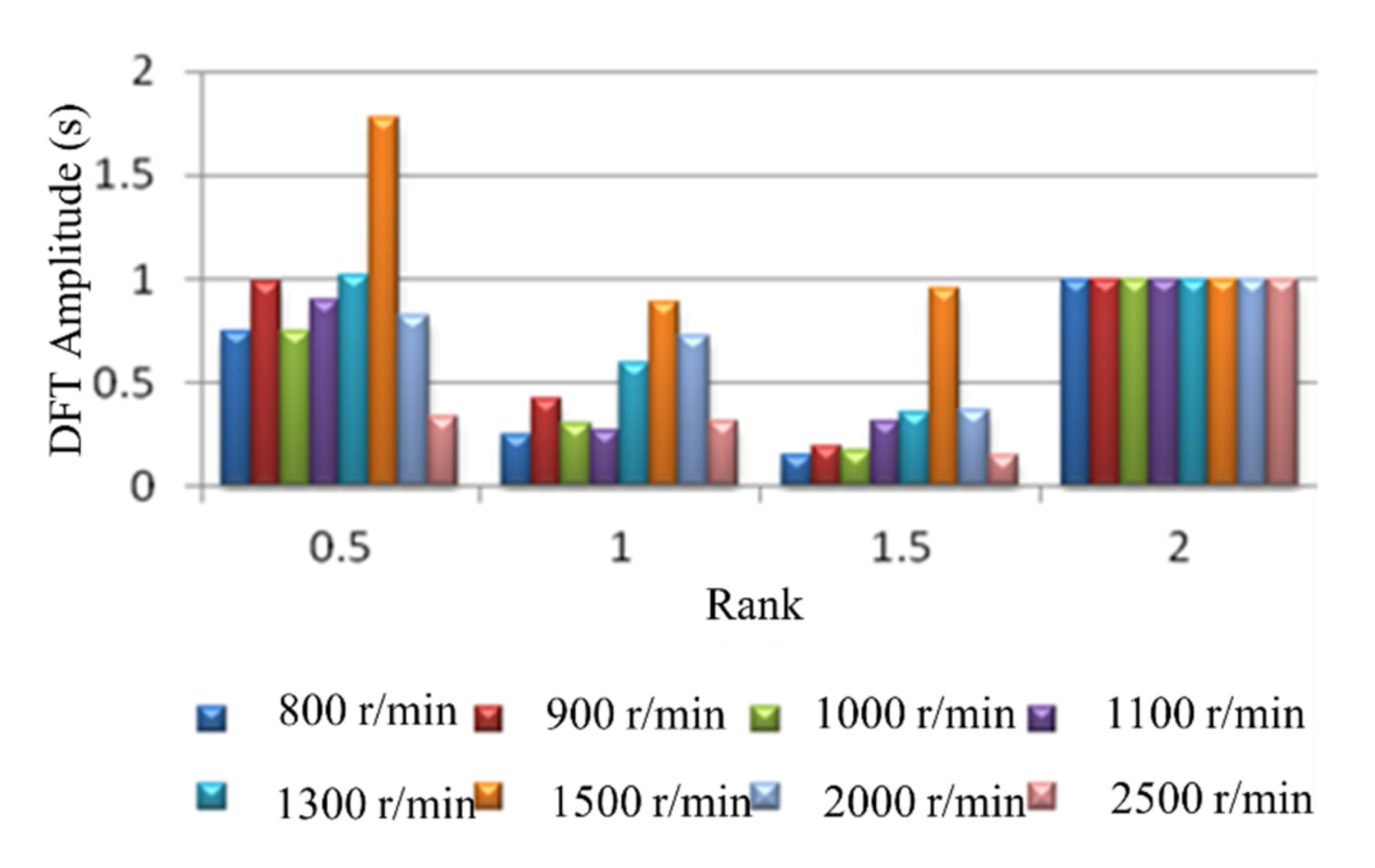

2.2. Characteristic Analysis of Crankshaft Segment Signals

3. Quantification of Engine Operating Nonuniformity and FOC Control Principle

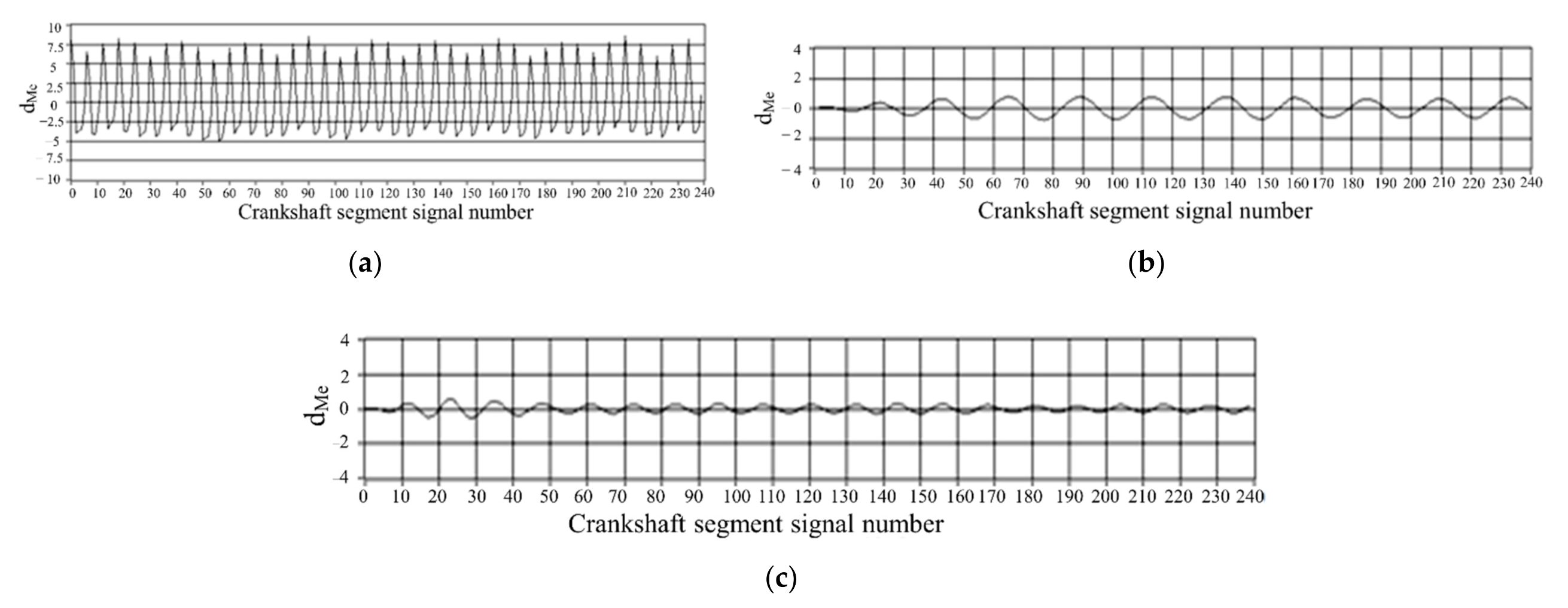

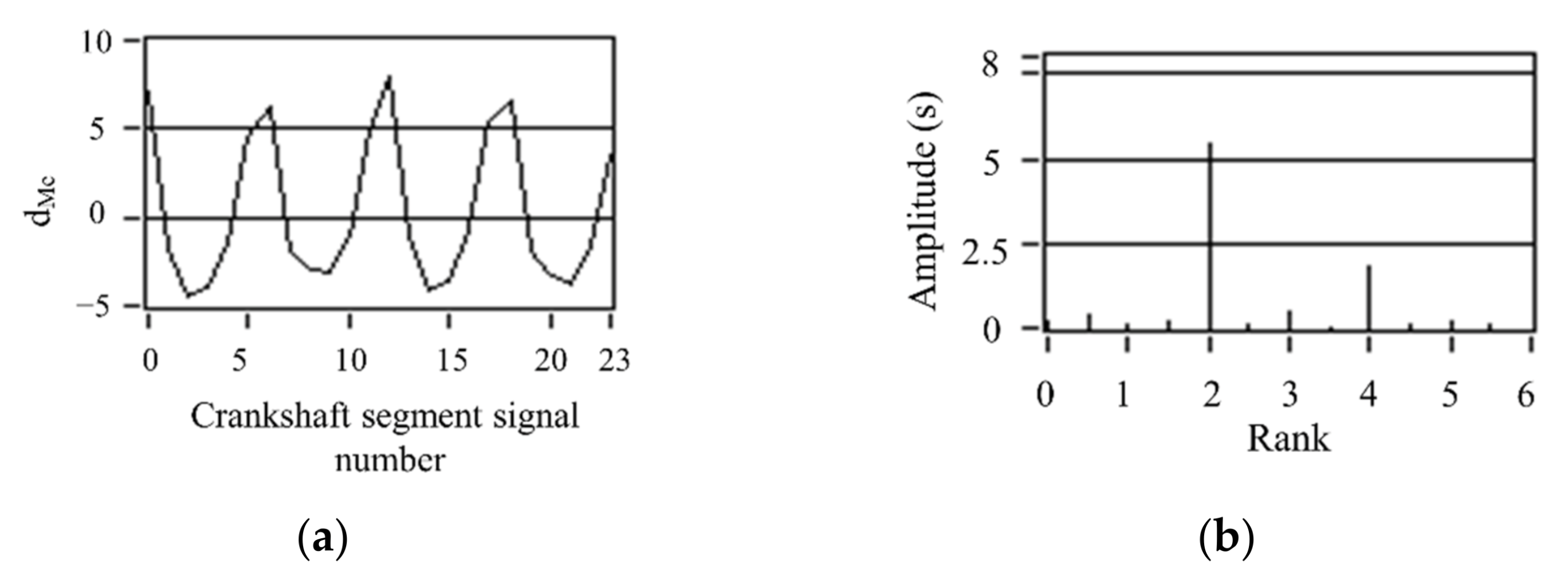

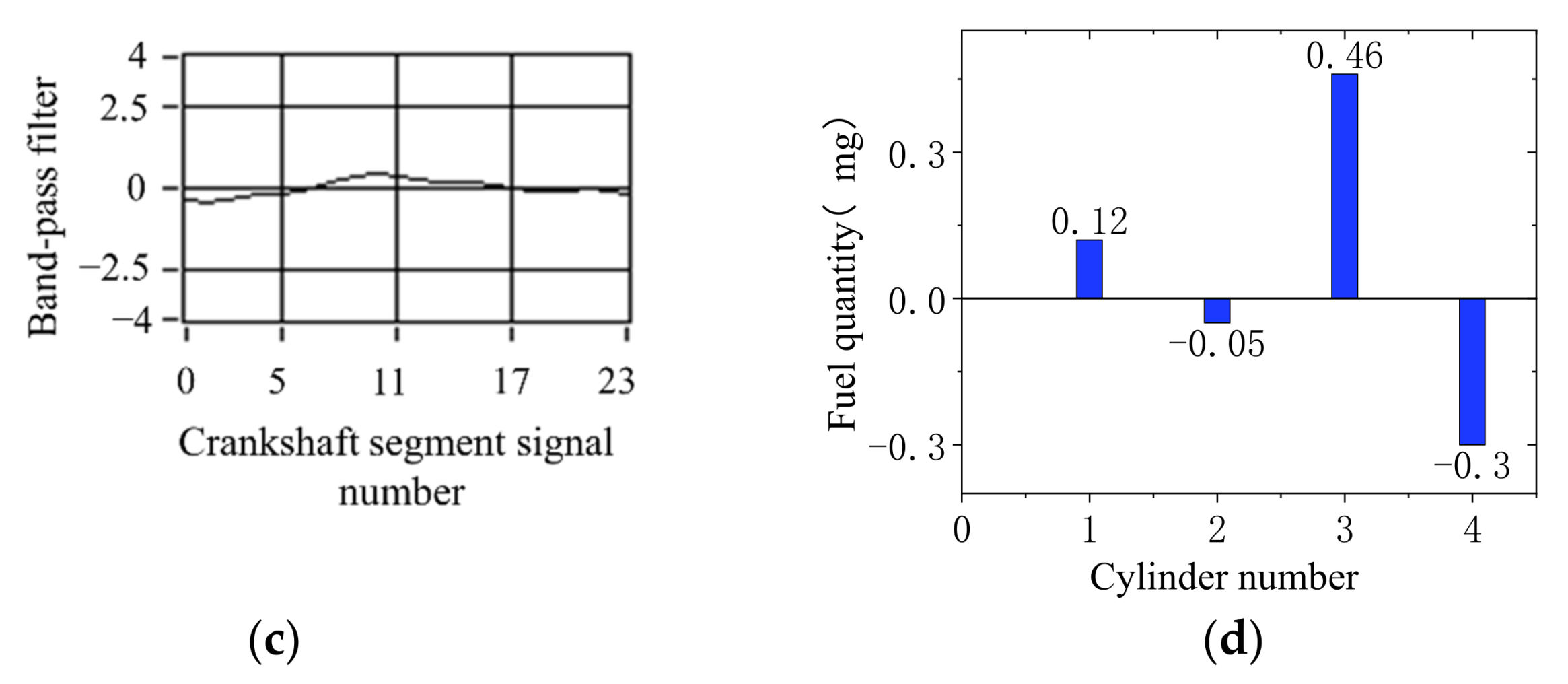

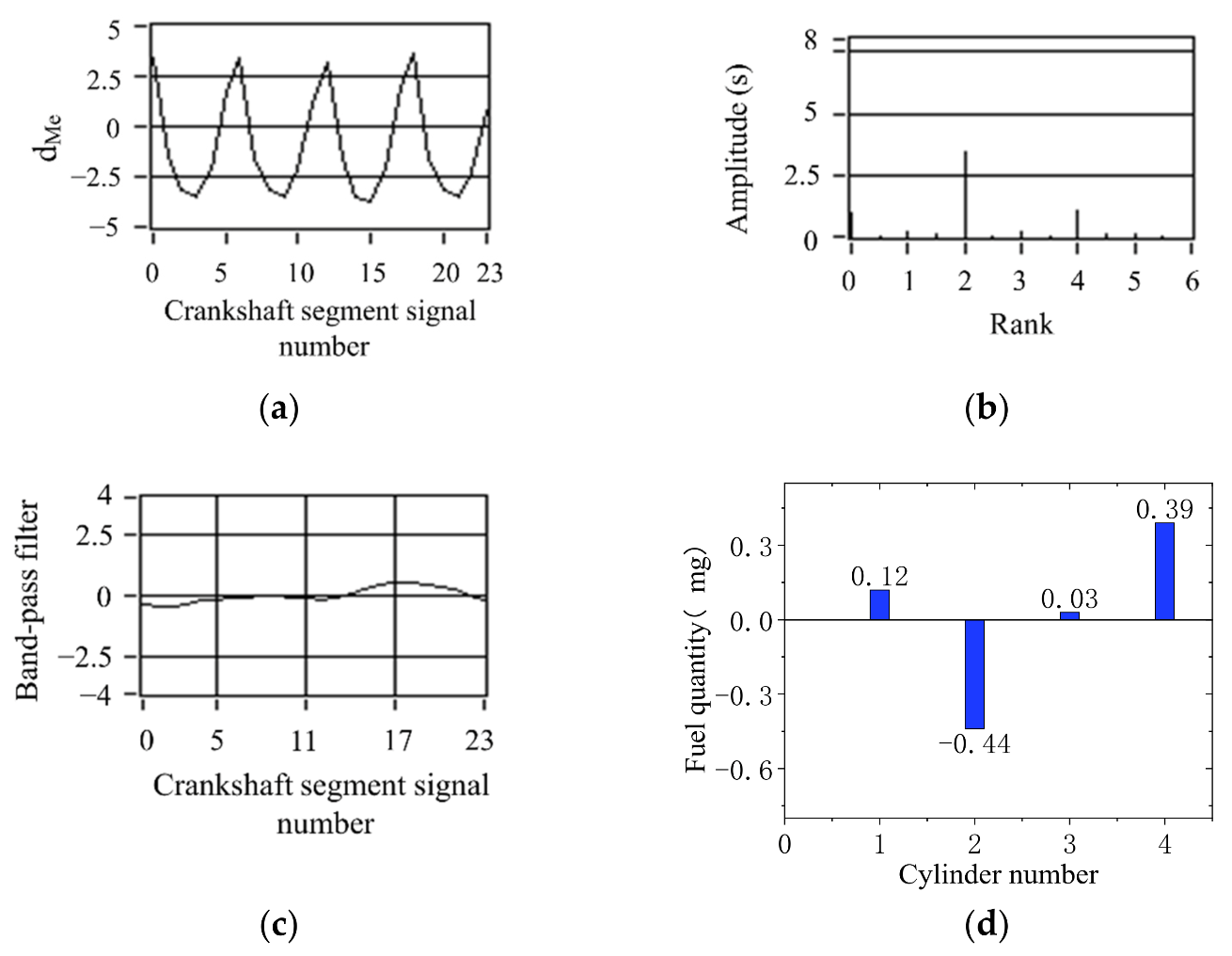

3.1. Signal Waveform Analysis and Information Extraction of Nonuniform Engine Operation

3.2. FOC Control Calculation Based on PI Control Principle

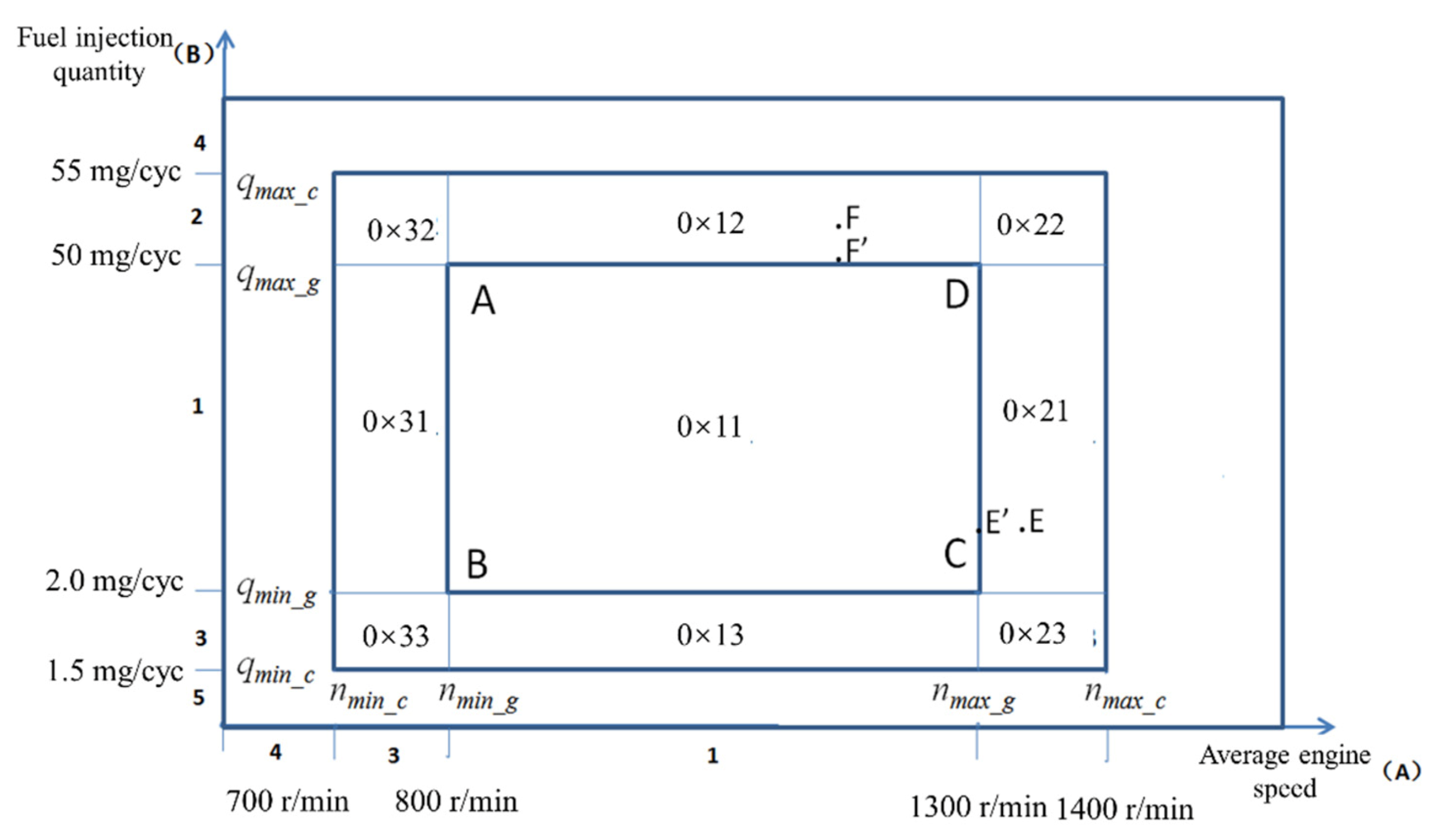

4. Control Strategy of Subcylinder Fuel

Offset Based on the Operating Condition

5. Control Strategy Simulation Experiment Verification

6. Conclusions and Future Directions

- (1)

- Based on the band-pass filtering method, the signal reflecting the nonuniformity of engine operation is extracted from the crankshaft segment signal, which is more resistant to interference than the traditional method of quantifying the nonuniformity parameter constructed based on the crest difference of instantaneous speed fluctuation, and the obtained parameter can accurately reflect the nonuniformity.

- (2)

- For a Z-cylinder engine, the lowest order Z/2 harmonic components lower than the firing frequency can fully reflect the nonuniformity state of the engine. According to the amplitude of the lowest Z/2 order, synthetic waveform is 0. A proportional-integral (PI) algorithm is proposed to quantify the working nonuniformity of each cylinder. The quantitative parameters of the working nonuniformity of each cylinder are obtained.

- (3)

- Based on the quantization parameters of the crankshaft segment signal, a reasonable working condition was proposed to detect the engine operating nonuniformity, and the open-loop and closed-loop cylinder fuel offset control algorithm was established.

- (4)

- The simulation results show that the offset fuel quantity calculated by FOC is consistent with the fuel supply state of each cylinder set by experiment. FOC algorithm based on crankshaft segment signal is an effective fuel offset control method for engine operating nonuniformity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Wang, X.; Guo, S.L.J.; Wang, Y.; Kong, M.; Shuai, S. Review and outlook of aftertreatment technologies to satisfy ultra-low emission regulations for heavy-duty diesel engines. Environ. Eng. 2002, 38, 159–167. [Google Scholar]

- Imtenan, S.; Varman, M.; Masjuki, H.H.; Kalam, M.A.; Sajjad, H.; Arbab, M.I.; Rizwanul Fattah, I.M. Impact of low temperature combustion attaining strategies on diesel engine emissions for diesel and biodiesels. A review. Energy Convers. Manag. 2014, 80, 329–356. [Google Scholar] [CrossRef]

- Song, M.L.; Zheng, W.P.; Wang, Z.Y. Environmental efficiency and energy consumption of highway transportation systems in China. Int. J. Prod. Econ. 2016, 181, 441–449. [Google Scholar] [CrossRef]

- Tan, P.; Wang, D.; Lou, D.; Wang, D.; Lou, D.; Hu, Z. Progress of control technologies on exhaust emissions for agricultural machinery. Trans. Chin. Soc. Agric. Eng. 2018, 34, 20183188027. [Google Scholar]

- Venu, H.; Subramani, L.; Raju, V.D. Emission reduction in a DI diesel engine using exhaust gas recirculation (EGR) of palm biodiesel blended with TiO2 nano additives. Renew. Energy 2019, 140, 245–263. [Google Scholar] [CrossRef]

- Hazar, H.; Tekdogan, R.; Sevinc, H. Investigating the effects of oxygen enrichment with modified zeolites on the performance and emissions of a diesel engine through experimental and ANN approach. Fuel 2021, 303, 121318. [Google Scholar] [CrossRef]

- Ning, W.; Zhao, L.; Bei, Z. Analysis of the Impact of China’s Energy Consumption Structure on Energy Security. In Proceedings of the International Conference on Advances in Energy, Environment and Chemical Science (AEECS 2021), Shanghai, China, 26–28 February 2022. [Google Scholar]

- Nikzadfar, K.; Shamekhi, A.H. More than one decade with development of common-rail diesel engine management systems: A literature review on modelling, control, estimation and calibration. Proc. Inst. Mech. Eng. 2015, 229, 1110–1142. [Google Scholar] [CrossRef]

- Huang, J.; Xu, H.; Sun, S.; Wang, D. Influence of fuel injection system’s optimization on performance of diesel engine and its injection parameter re-optimization. J. Dalian Marit. Univ. 2017, 43, 103–108. [Google Scholar]

- Karthic, S.V.; Senthil Kumar, M.; Nataraj, G.; Pradeep, P. An assessment on injection pressure and timing to reduce emissions on diesel engine powered by renewable fuel. J. Clean. Prod. 2020, 255, 120186. [Google Scholar] [CrossRef]

- Niklawy, W.; Shahin, M.; Amin, M.I.; Elmaihy, A. Modelling and experimental investigation of high—Pressure common rail diesel injection system. IOP Conf. Ser. Mater. Sci. Eng. 2020, 973, 12013–12037. [Google Scholar] [CrossRef]

- Liu, D.; Li, X.; Shang, H.; Xie, L.; Chen, Y.; Chang, J. Combustion performance and fuel injection timing adaptability of a lateral swirl combustion system for direct injection diesel engines. Fuel 2021, 296, 120663. [Google Scholar] [CrossRef]

- Bai, Y.; Lan, Q.; Fan, L.Y.; Ma, X.Z.; Liu, H. Investigation on the fuel injection stability of high pressure common rail system for diesel engines. Int. J. Engine Res. 2021, 22, 616–631. [Google Scholar] [CrossRef]

- Yan, F.; Wang, J. Common rail injection system iterative learning control based parameter calibration for accurate fuel injection quantity control. Int. J. automot. Technol.-Korea 2011, 12, 149–157. [Google Scholar] [CrossRef]

- Han, X.; Lin, X.; Li, D. A study on the control strategy for the transient fuel injection quantity in starting process of a light diesel engine. Automot. Eng. 2017, 46, 1103–1108. [Google Scholar] [CrossRef]

- Sun, H.; Li, S. Sliding mode control method for diesel engine fuel quantity actuator with disturbance estimation. Control Theory Appl. 2018, 35, 1568–1576. [Google Scholar]

- Liu, F.S.; Hu, R.; Li, Y.K.; Yang, Z.M.; Xu, H.M. Effects of fuel temperature on injection performance of an EUP system. Proc. Inst. Mech. Eng. Part D 2019, 233, 671–686. [Google Scholar] [CrossRef]

- Szpica, D. Research on the influence of LPG\/CNG injector outlet nozzle diameter on uneven fuel dosage. Transp.-Vilnius 2016, 33, 186–196. [Google Scholar] [CrossRef] [Green Version]

- Hoang, A.T. Applicability of Fuel Injection Techniques for Modern Diesel Engines. In Proceedings of the 2019 1st International Conference on Sustainable Manufacturing, Materials and Technologies (ICSMMT), Coimbatore, India, 25–26 October 2019; Haldorai, A., Onn, C.C., Ramu, A., Eds.; AIP Publishing: Melville, NY, USA, 2019. [Google Scholar]

- Du, C.; Jiang, F.; Ding, K.; Li, F.; Yu, F. Feature Extraction Method of Engine Misfire Fault Based on Signal Sparse Decomposition. Shock Vib. 2021, 2021, 6650932. [Google Scholar] [CrossRef]

- Chen, J.; Randall, R.B. Improved automated diagnosis of misfire in internal combustion engines based on simulation models. Mech. Syst. Signal Process. 2015, 64, 58–83. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Zhang, N.; Yan, Y.; Qin, L. Intelligent Diagnosis Method of Diesel Engine based on Fast Online Support Tensor Machine. J. Mech. 2018, 054, 30–37. [Google Scholar] [CrossRef]

- Zhang, K.; Tao, J.; Qin, C. Diesel Engine Misfire Diagnosis with Deep Convolutional Neural Network Using Dropout and Batch Normalization. J. Xi’an Jiaotong Univ. 2019, 53, 8. [Google Scholar]

- Liu, J.; Gao, Z.; Zhang, P.; Song, Q. Diagnosis of Misfire Fault of Diesel Engines Based on Segment Angular Acceleration and Neural Network. Chin. Intern. Combust. Engine Eng. 2019, 40, 79–85. [Google Scholar]

- Jia, J.; Jia, X.; Mei, J.; Zeng, R.; Zhang, S. Misfire Fault Diagnosis of Diesel Engine Based on Wavelet and Deep Belief Network. Automot. Eng. 2018, 40, 838–843. [Google Scholar]

- Liu, J.; Ma, B.; Jiang, Z. Probabilistic Diagnosis of Diesel Engine Misfire Based on the Noisy-Max Model and Vibration Signal from Adjacent and Opposite Cylinders. Trans. Csice 2020, 38, 84–92. [Google Scholar]

- Wang, Z.; Fu, X.; Wang, D.; Xu, Y.; Du, G.; You, J. A multilevel study on the influence of natural gas substitution rate on combustion mode and cyclic variation in a diesel/natural gas dual fuel engine. Fuel 2021, 294, 120499. [Google Scholar] [CrossRef]

- Wolff, S.; Schapel, J.S.; King, R. Application of Artificial Neural Networks for Misfiring Detection in an Annular Pulsed Detonation Combustor Mockup. J. Eng. Gas Turbines Power 2017, 139. [Google Scholar] [CrossRef]

- Song, Q.X.; Gao, W.Z.; Zhang, P.; Liu, J.K.; Wei, Z.Q. Detection of engine misfire using characteristic harmonics of angular acceleration. Proc. Inst. Mech. Eng. Part D 2019, 233, 3816–3823. [Google Scholar] [CrossRef]

- Hmida, A.; Hammami, A.; Chaari, F.; Ben Amar, M.; Haddar, M. Effects of misfire on the dynamic behavior of gasoline Engine Crankshafts. Eng. Fail. Anal. 2021, 121, 105149. [Google Scholar] [CrossRef]

- Liu, Z.W.; Wu, K.; Ding, Q.; Gu, J.X. Engine Misfire Diagnosis Based on the Torsional Vibration of the Flexible Coupling in a Diesel Generator Set: Simulation and Experiment. J. Vib. Eng. Technol. 2020, 8, 163–178. [Google Scholar] [CrossRef]

- Syta, A.; Czarnigowski, J.; Jaklinski, P. Detection of cylinder misfire in an aircraft engine using linear and non-linear signal analysis. Measurement 2021, 174, 108982. [Google Scholar] [CrossRef]

- Macian, V.; Lujan, J.M.; Guardiola, C.; Perles, A. A comparison of different methods for fuel delivery unevenness detection in Diesel engines. Mech. Syst. Signal Process. 2006, 20, 2219–2231. [Google Scholar] [CrossRef]

- Hu, Y.; Zhou, R.P.; Yang, J.G. Research on the Fault Diagnosis Technology of Diesel Engine Based on the Instantaneous Speed. In Proceedings of the 8th International Conference on Damage Assessment of Structures (DAMAS 2009), Beijing, China, 3–5 August 2009; pp. 547–552. [Google Scholar]

- Popovic, S.J.; Tomic, M.V. Possibilities to identify engine combustion model parameters by analysis of the instantaneous crankshaft angular speed. Therm. Sci. 2014, 18, 97–112. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Guo, Z.; Hu, C.; Li, A. On-line indicated torque estimation for internal combustion engines using discrete observer. Comput. Electr. Eng. 2017, 60, 100–115. [Google Scholar]

- Daniel, P.G.; Jiménez-Espadafor, F.J. Torsional system dynamics of low speed diesel engines based on instantaneous torque: Application to engine diagnosis. Mech. Syst. Signal Process. 2019, 116, 858–878. [Google Scholar]

- Yu, Y.; Chen, Y. Evaluation of the Health of Marine Diesel Engines Based on Instantaneous Angular Speed and Machine Learning. Chin. Intern. Combust. Engine Eng. 2020, 41, 107–112. [Google Scholar]

- Gu, L.C.; Tian, Q.Q.; Ma, Z.W. Extraction of the instantaneous speed fluctuation based on normal time-frequency transform for hydraulic system. Proc. Inst. Mech. Eng. Part C 2020, 234, 1196–1211. [Google Scholar] [CrossRef]

- Ali, S.A.; Saraswati, S. Reconstruction of cylinder pressure using crankshaft speed fluctuations. In Proceedings of the 2015 International Conference on Industrial Instrumentation & Control, Pune, India, 28–30 May 2015. [Google Scholar]

- Ostman, F.; Toivonen, H.T. Adaptive Cylinder Balancing of Internal Combustion Engines. IEEE Trans. Control Syst. Technol. 2011, 19, 782–791. [Google Scholar] [CrossRef]

- Jiang, S.; Luo, Y. An Analysis Method for Engine Ignition Waveform Based on Wavelet Threshold Denoising and Secondary Empirical Mode Decomposition. Automot. Eng. 2015, 37, 380–386. [Google Scholar]

- Liu, S.; Du, R.; Yang, S. Misfire Detection for Internal Combustion Engines by Speed Fluctuation Signals(3)—Method of Multiple Feature Integration. Trans. Csice 2000, 395–398. [Google Scholar] [CrossRef]

- Pei, S.C.; Yeh, M.H.; Luo, T.L. Fractional Fourier series expansion for finite signals and dual extension to discrete-time fractional Fourier transform. IEEE Trans. Signal Process. 1999, 47, 2883–2888. [Google Scholar]

- Yin, J.H.; de Pierro, A.R.; Wei, M.S. Reconstruction of a compactly supported function from the discrete sampling of its Fourier transform. IEEE Trans. Signal Process. 1999, 47, 3356–3364. [Google Scholar] [CrossRef]

- Macian, V.; Lujan, J.M.; Guardiola, C.; Yuste, P. DFT-based controller for fuel injection unevenness correction in turbocharged diesel engines. IEEE Trans. Control Syst. Technol. 2006, 14, 819–827. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, G. Interval observer-based fault detection in finite frequency domain for discrete-time fuzzy systems. Neurocomputing 2018, 310, 38–45. [Google Scholar] [CrossRef]

- Charchalis, A.; Dereszewski, M. Monitoring of instantaneous angular speed of the crankshaft for control of the ship engine performance changes. Diagnostyka 2011, 4, 53–58. [Google Scholar]

- Wang, Y.W.; Dong, D.W.; Yan, B. Influence Mechanism and Law of Sensor Working Clearance on Instantaneous Engine Speed Measurements. Trans. Csice 2014, 32, 466–473. [Google Scholar]

- Wen, C.; Meng, X.; Xie, Y.; Liu, R.; Fang, C. Online measurement of piston-assembly friction with wireless IMEP method under fired conditions and comparison with numerical analysis. Measurement 2021, 174, 109009. [Google Scholar] [CrossRef]

- Niu, Q.Y.; Fan, C.; Wang, X.C.; Zhao, Y.W.; Dong, Y.C. Research on the Parameter Calibration of the Internal-combustion Engine Work Process Simulation Model. In Advanced Design Technology, PTS 1–3, Proceedings of the International Conference on Advanced Design and Manufacturing Engineering (ADME 2011), Guangzhou, China, 16–18 September 2011; Gao, J., Ed.; Trans Tech Publications: Stafa-Zurich, Switzerland, 2011; p. 953. [Google Scholar]

- Getman, A.L.; Zhou, H.; Jammalamadaka, S.D. An Automated Network for Detecting Diesel Engine Misfire. In Proceedings of the 2007 International Joint Conference on Neural Networks IEEE, Orlando, FL, USA, 12–17 August 2007. [Google Scholar]

- Apazhev, A.K.; Shekikhachev, Y.A.; Batyrov, V.I.; Shekikhacheva, L.Z. Influence of non-uniformity of fuel supply parameters on diesel engine performance. J. Phys. Conf. Ser. 2020, 1679, 042063. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Wang, L.; Xue, J.; Jin, J.; Yu, D. A CEEMD Method for Diesel Engine Misfire Fault Diagnosis based on Vibration Signals. In Proceedings of the 2020 39th Chinese Control Conference (CCC), Shenyang, China, 27–30 July 2020. [Google Scholar]

- Ding, X.; Zhang, Y.; Wang, J. Injection Characteristics of Injector for High Pressure Common Rail Diesel Engine. Trans. Beijing Inst. Technol. 2008, 28, 970–974. [Google Scholar]

- Wang, Y.; Wang, G.; Yao, G.; Shen, L. Research on the Characteristics of Operating Non-Uniformity of a High-Pressure Common-Rail Diesel Engine Based on Crankshaft Segment Signals. IEEE Access 2021, 9, 64906–64917. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wang, G.; Yao, G.; Shen, L. Research on Fuel Offset Control of High-Pressure Common-Rail Diesel Engine Based on Crankshaft Segment Signals. Sensors 2022, 22, 3355. https://doi.org/10.3390/s22093355

Wang Y, Wang G, Yao G, Shen L. Research on Fuel Offset Control of High-Pressure Common-Rail Diesel Engine Based on Crankshaft Segment Signals. Sensors. 2022; 22(9):3355. https://doi.org/10.3390/s22093355

Chicago/Turabian StyleWang, Yuhua, Guiyong Wang, Guozhong Yao, and Lizhong Shen. 2022. "Research on Fuel Offset Control of High-Pressure Common-Rail Diesel Engine Based on Crankshaft Segment Signals" Sensors 22, no. 9: 3355. https://doi.org/10.3390/s22093355

APA StyleWang, Y., Wang, G., Yao, G., & Shen, L. (2022). Research on Fuel Offset Control of High-Pressure Common-Rail Diesel Engine Based on Crankshaft Segment Signals. Sensors, 22(9), 3355. https://doi.org/10.3390/s22093355