A Fabrication of Multichannel Graphite Electrode Using Low-Cost Stencil-Printing Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Instrumentation and Measurements

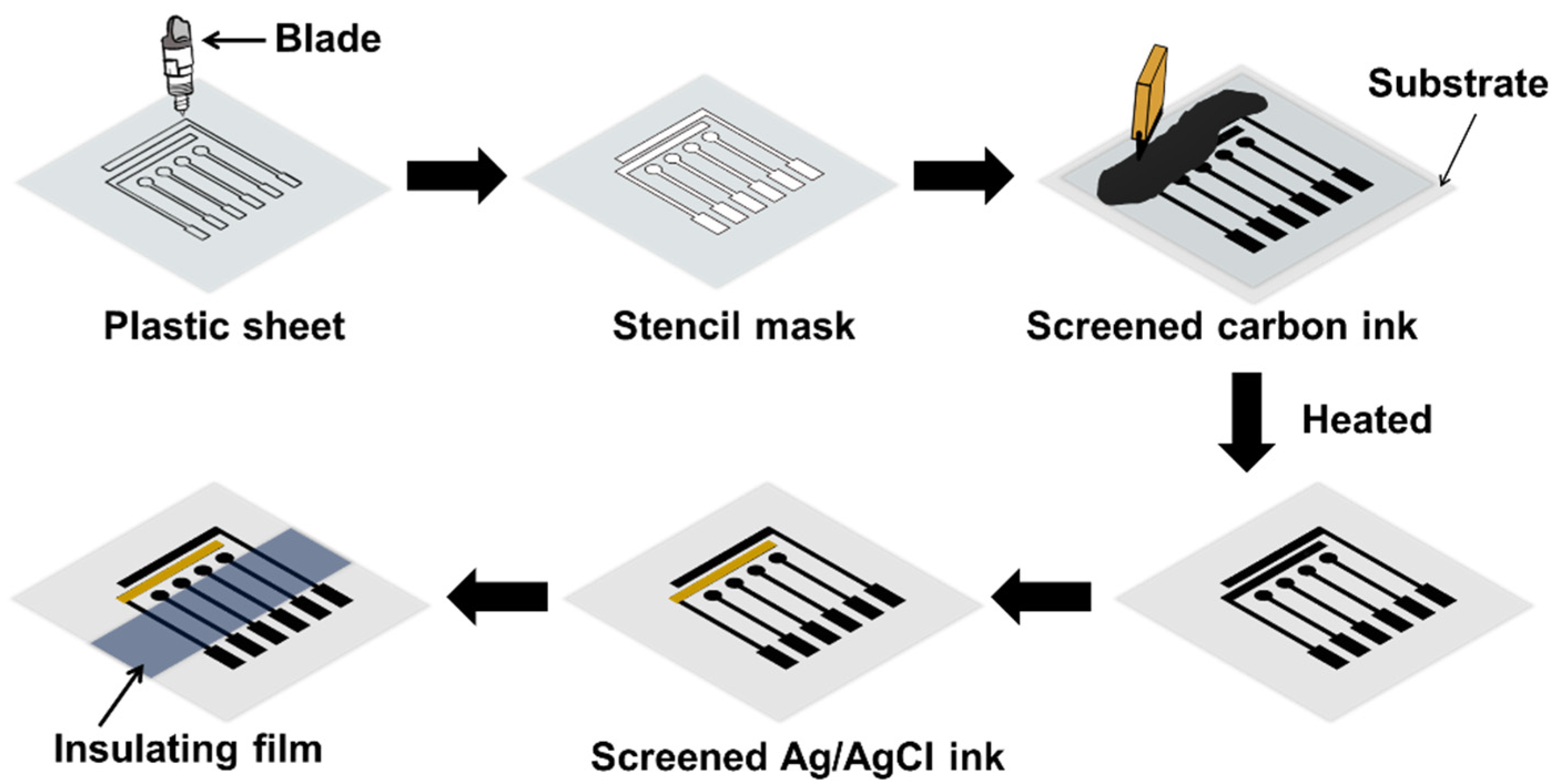

2.3. Electrode Construction

3. Results and Discussion

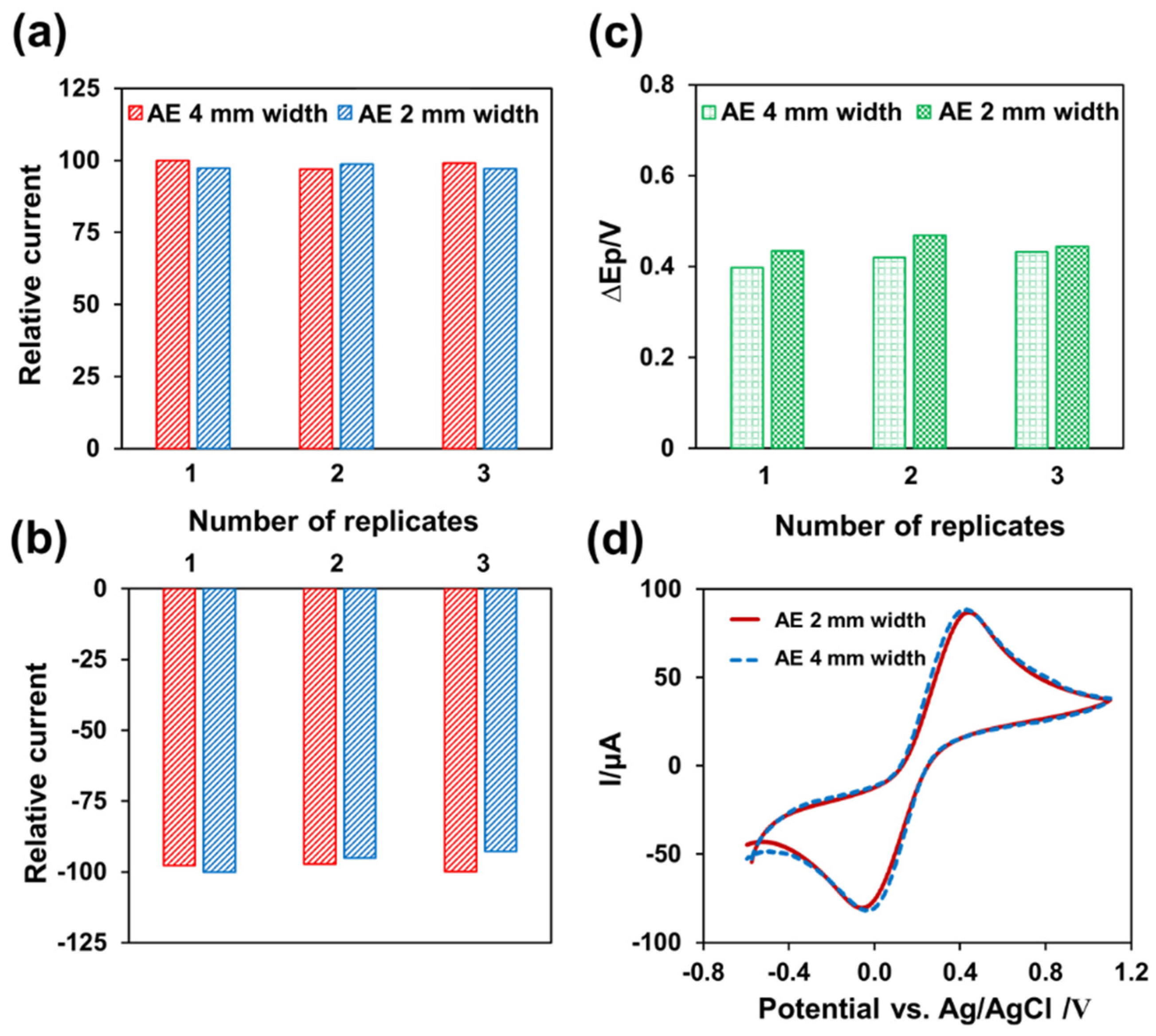

3.1. Studied the Fabrication of MGrEs Platform

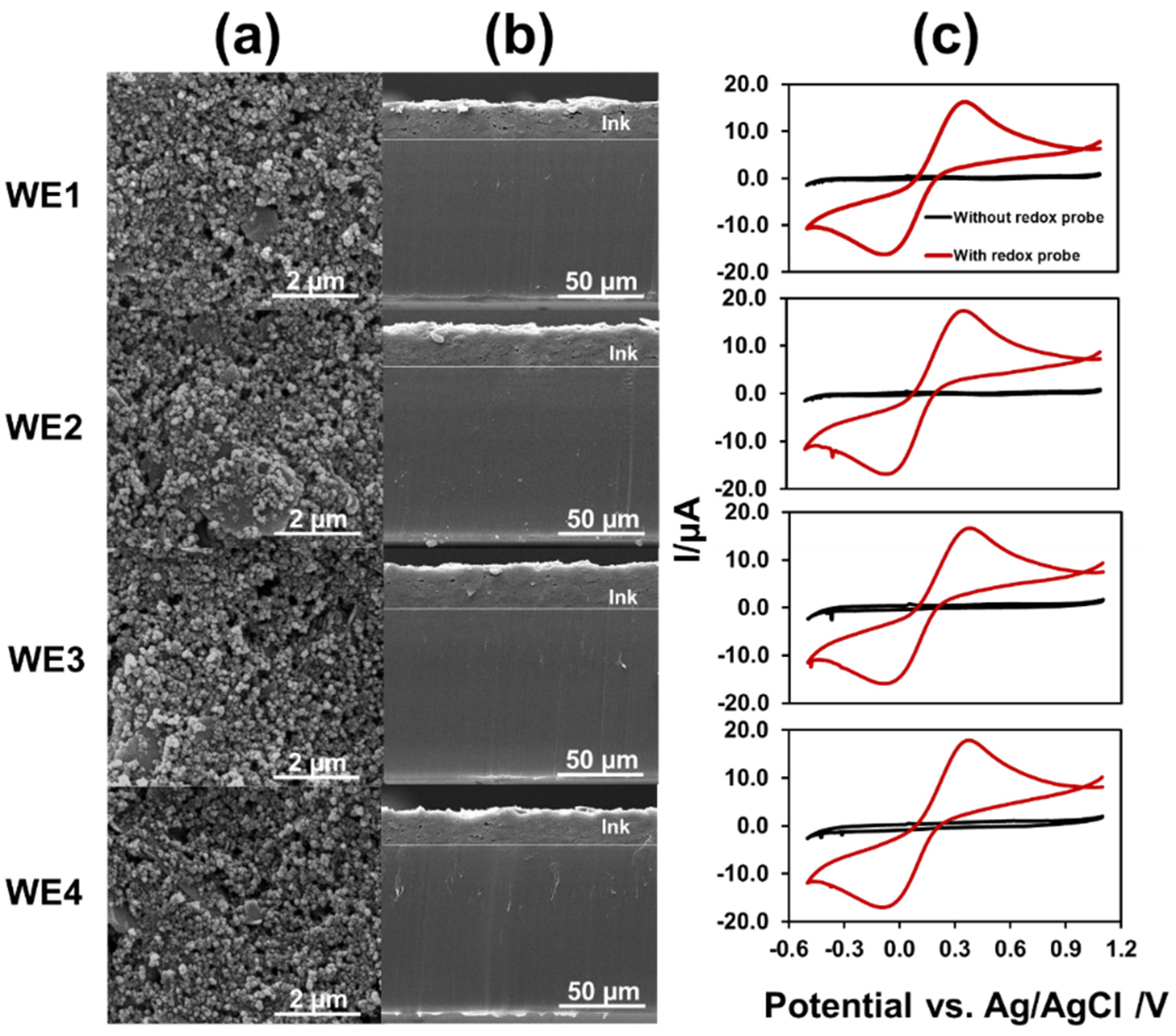

3.2. Characterization of MGrEs

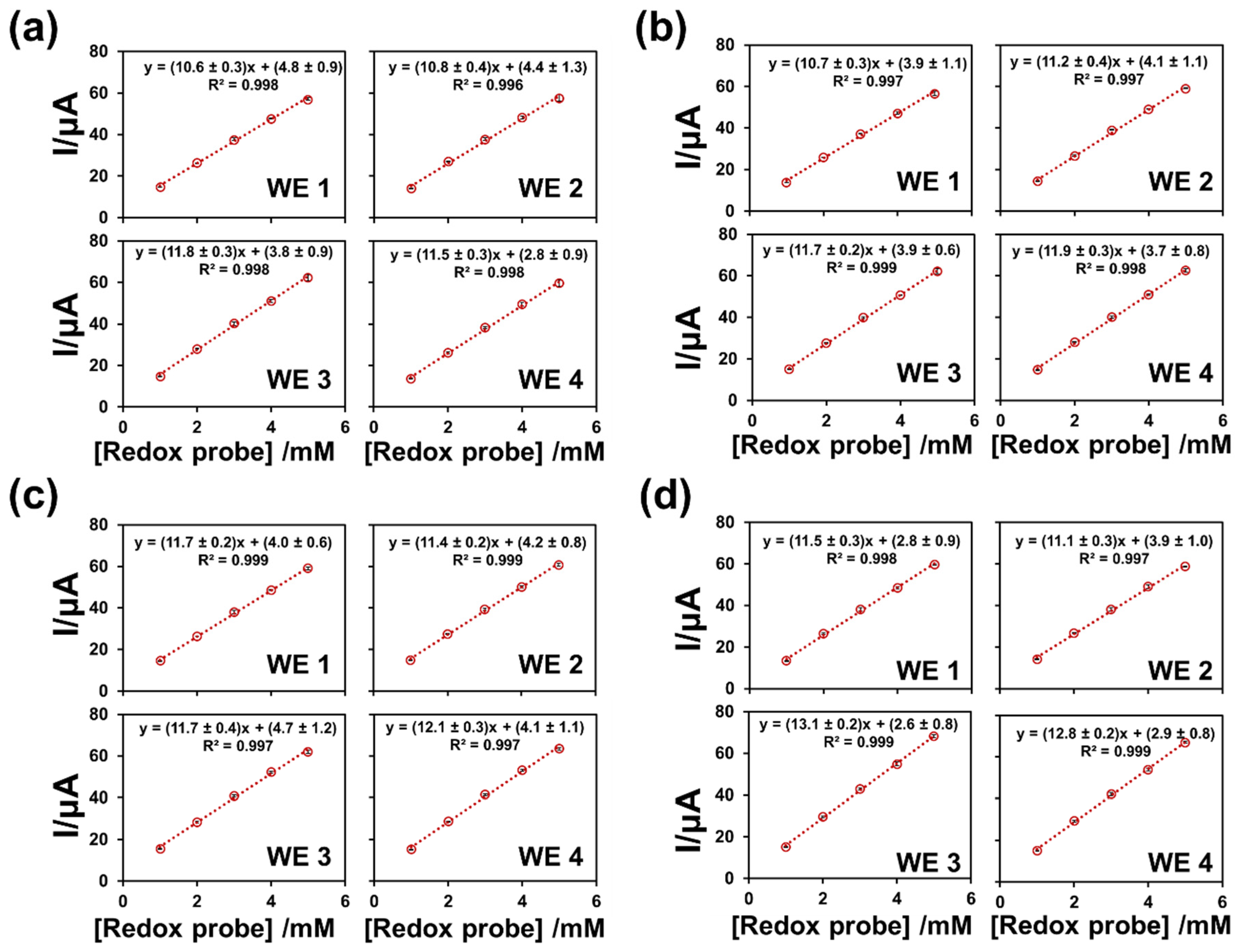

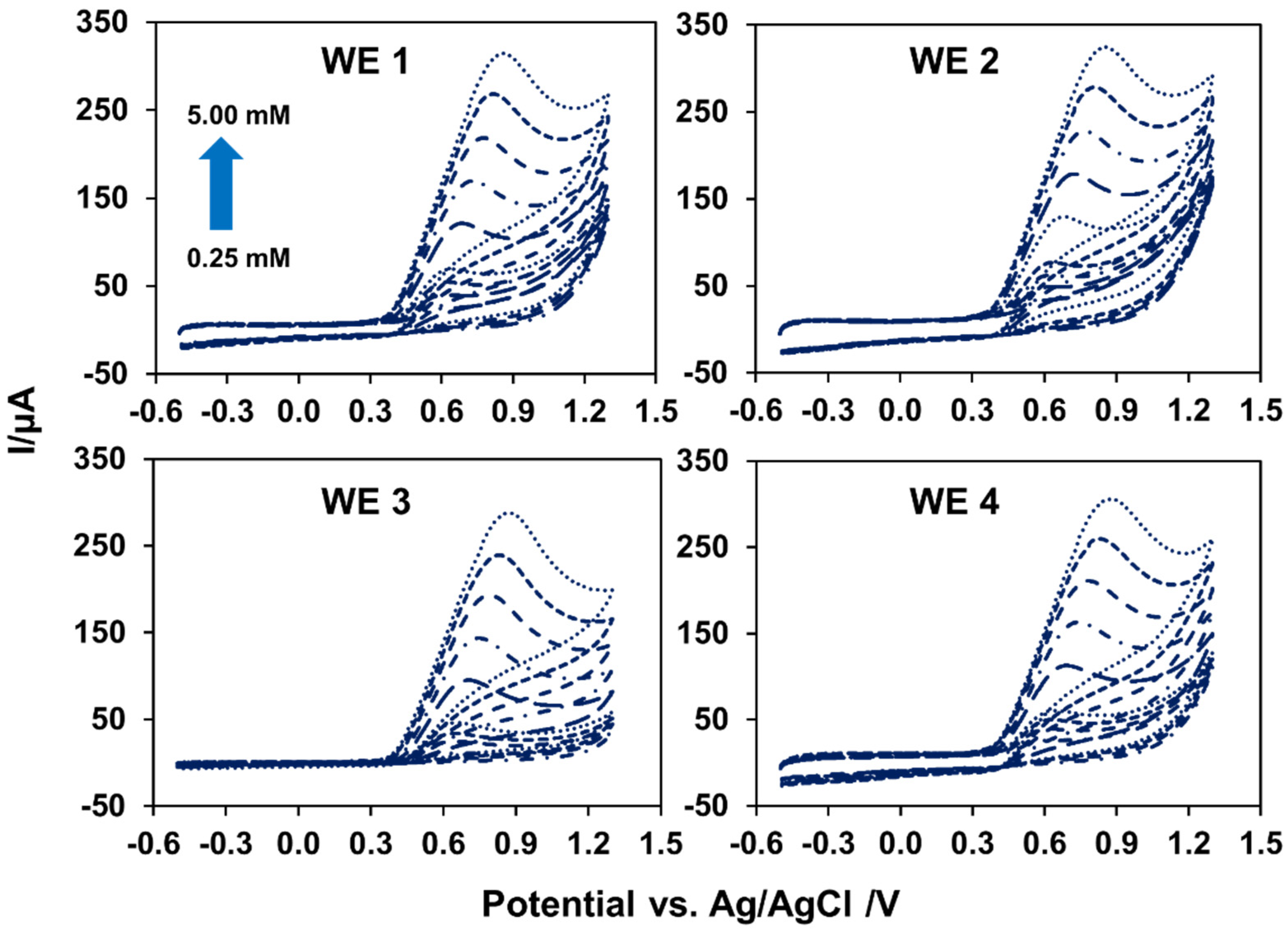

3.3. Electrochemical Performance of MGrEs

3.4. The Application of the MGrEs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- An, Q.; Gan, S.; Xu, J.; Bao, Y.; Wu, T.; Kong, H.; Zhong, L.; Ma, Y.; Song, Z.; Niu, L. A multichannel electrochemical all-solid-state wearable potentiometric sensor for real-time sweat ion monitoring. Electrochem. Commun. 2019, 107, 106553. [Google Scholar] [CrossRef]

- Gao, J.; Huang, W.; Chen, Z.; Yi, C.; Jiang, L. Simultaneous detection of glucose, uric acid and cholesterol using flexible microneedle electrode array-based biosensor and multi-channel portable electrochemical analyzer. Sens. Actuators B Chem. 2019, 287, 102–110. [Google Scholar] [CrossRef]

- Soleh, A.; Kanatharana, P.; Thavarungkul, P.; Limbut, W. Novel electrochemical sensor using a dual-working electrode system for the simultaneous determination of glucose, uric acid and dopamine. Microchem. J. 2020, 153, 104379. [Google Scholar] [CrossRef]

- Cotchim, S.; Thavarungkul, P.; Kanatharana, P.; Limbut, W. Multiplexed label-free electrochemical immunosensor for breast cancer precision medicine. Anal. Chim. Acta 2020, 1130, 60–71. [Google Scholar] [CrossRef] [PubMed]

- Teeparuksapun, K.; Kanatharana, P.; Limbut, W.; Thammakhet, C.; Asawatreratanakul, P.; Mattiasson, B.; Wongkittisuksa, B.; Limsakul, C.; Thavarungkul, P. Disposable electrodes for capacitive immunosensor. Electroanalysis 2009, 21, 1066–1074. [Google Scholar] [CrossRef]

- Ezquerra, A.; Vidal, J.C.; Bonel, L.; Castillo, J.R. A validated multi-channel electrochemical immunoassay for rapid fumonisin B1 determination in cereal samples. Anal. Methods 2015, 7, 3742–3749. [Google Scholar] [CrossRef]

- Koudelka-Hep, M.; van der Wal, P.D. Microelectrode sensors for biomedical and environmental applications. Electrochim. Acta 2000, 45, 2437–2441. [Google Scholar] [CrossRef]

- Silva, L.R.G.; Rodrigues, J.G.A.; Franco, J.P.; Santos, L.P.; D’Elia, E.; Romão, W.; Ferreira, R.d.Q. Development of a portable electroanalytical method using nickel modified screen-printed carbon electrode for ethinylestradiol determination in organic fertilizers. Ecotoxicol. Environ. Saf. 2021, 208, 111430. [Google Scholar] [CrossRef]

- Li, Q.; Wu, J.-T.; Liu, Y.; Qi, X.-M.; Jin, H.-G.; Yang, C.; Liu, J.; Li, G.-L.; He, Q.-G. Recent advances in black phosphorus-based electrochemical sensors: A review. Anal. Chim. Acta 2021, 1170, 338480. [Google Scholar] [CrossRef]

- Dungchai, W.; Chailapakul, O.; Henry, C.S. Electrochemical Detection for Paper-Based Microfluidics. Anal. Chem. 2009, 81, 5821–5826. [Google Scholar] [CrossRef]

- Rama, E.C.; Costa-García, A.; Fernández-Abedul, M.T. Pin-based electrochemical glucose sensor with multiplexing possibilities. Biosens. Bioelectron. 2017, 88, 34–40. [Google Scholar] [CrossRef] [PubMed]

- Ghoreishizadeh, S.S.; Taurino, I.; Carrara, S.; Micheli, G.D. A current-mode potentiostat for multi-target detection tested with different lactate biosensors. In Proceedings of the 2012 IEEE Biomedical Circuits and Systems Conference (BioCAS), Hsinchu, Taiwan, 28–30 November 2012; pp. 128–131. [Google Scholar]

- An, B.W.; Heo, S.; Ji, S.; Bien, F.; Park, J.-U. Transparent and flexible fingerprint sensor array with multiplexed detection of tactile pressure and skin temperature. Nat. Commun. 2018, 9, 2458. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Pan, L.; Ma, Z.; Yan, K.; Cheng, W.; Shi, Y.; Yu, G. All Inkjet-Printed Amperometric Multiplexed Biosensors Based on Nanostructured Conductive Hydrogel Electrodes. Nano Lett. 2018, 18, 3322–3327. [Google Scholar] [CrossRef] [PubMed]

- Erdem, A.; Congur, G.; Eksin, E. Multi channel screen printed array of electrodes for enzyme-linked voltammetric detection of MicroRNAs. Sens. Actuators B Chem. 2013, 188, 1089–1095. [Google Scholar] [CrossRef]

- Tolosa, V.M.; Wassum, K.M.; Maidment, N.T.; Monbouquette, H.G. Electrochemically deposited iridium oxide reference electrode integrated with an electroenzymatic glutamate sensor on a multi-electrode arraymicroprobe. Biosens. Bioelectron. 2013, 42, 256–260. [Google Scholar] [CrossRef]

- O’Mahony, C.; Haq, E.; Sillien, C.; Tofail, S. Rheological Issues in Carbon-Based Inks for Additive Manufacturing. Micromachines 2019, 10, 99. [Google Scholar] [CrossRef] [Green Version]

- Xie, Y.; Zhou, Y. Enhanced capacitive performance of activated carbon paper electrode material. J. Mater. Res. 2019, 34, 2472–2481. [Google Scholar] [CrossRef]

- Petroni, J.M.; Lucca, B.G.; Ferreira, V.S. Simple and Inexpensive Electrochemical Platform Based on Novel Homemade Carbon Ink and its Analytical Application for Determination of Nitrite. Electroanalysis 2017, 29, 1762–1771. [Google Scholar] [CrossRef]

- Couto, R.; Lima, J.L.F.C.; Quinaz, M.B. Screen-printed electrode based electrochemical sensor for the detection of isoniazid in pharmaceutical formulations and biological fluids. Int. J. Electrochem. Sci. 2015, 10, 8738–8749. [Google Scholar]

- Mohan, J.M.; Amreen, K.; Javed, A.; Dubey, S.K.; Goel, S. Modified Graphite Paper Based Miniaturized Electrochemically Optimized Hydrazine Sensing Platform. ECS J. Solid State Sci. Technol. 2020, 9, 115001. [Google Scholar] [CrossRef]

- Camargo, J.R.; Orzari, L.O.; Araújo, D.A.G.; de Oliveira, P.R.; Kalinke, C.; Rocha, D.P.; Luiz dos Santos, A.; Takeuchi, R.M.; Munoz, R.A.A.; Bonacin, J.A.; et al. Development of conductive inks for electrochemical sensors and biosensors. Microchem. J. 2021, 164, 105998. [Google Scholar] [CrossRef]

- Silva, L.A.J.; Stefano, J.S.; Cardoso, R.M.; Prado, N.S.; Soares, P.H.T.; Nossol, E.; Munoz, R.A.A.; Angnes, L.; Richter, E.M. Evaluation of graphite sheets for production of high-quality disposable sensors. J. Electroanal. Chem. 2019, 833, 560–567. [Google Scholar] [CrossRef]

- Li, G.; Ren, M.; Zhou, H. Observably boosted electrochemical performances of roughened graphite sheet/polyaniline electrodes for use in flexible supercapacitors. Surf. Interfaces 2022, 30, 101874. [Google Scholar] [CrossRef]

- Chen, X.; Wei, S.; Yadav, A.; Patil, R.; Zhu, J.; Ximenes, R.; Sun, L.; Guo, Z. Poly(Propylene)/Carbon Nanofiber Nanocomposites: Ex Situ Solvent-Assisted Preparation and Analysis of Electrical and Electronic Properties; Wiley: Hoboken, NJ, USA, 2011; Volume 296, pp. 434–443. [Google Scholar]

- Yoshino, K.; Demura, T.; Kawahigashi, M.; Miyashita, Y.; Kurahashi, K.; Matsuda, Y. The Application of Novel Polypropylene to the Insulation of Electric Power Cable. IEEE/PES Transm. Distrib. Conf. Exhib. 2002, 122, 872–879. [Google Scholar] [CrossRef]

- Adloo, A.; Sadeghi, M.; Masoomi, M.; Pazhooh, H.N. High performance polymeric bipolar plate based on polypropylene/graphite/graphene/nano-carbon black composites for PEM fuel cells. Renew. Energy 2016, 99, 867–874. [Google Scholar] [CrossRef]

- Shubhra, Q.T.; Alam, A.K.M.M.; Quaiyyum, M.A. Mechanical properties of polypropylene composites: A review. Thermoplast. Compos. Mater. 2011, 26, 362–391. [Google Scholar] [CrossRef]

- Liu, W.; Cheng, L.; Li, S. Review of electrical properties for polypropylene based nanocomposite. Compos. Commun. 2018, 10, 221–225. [Google Scholar] [CrossRef]

- Kongkaew, S.; Kanatharana, P.; Thavarungkul, P.; Limbut, W. Studying the preparation, electrochemical performance testing, comparison and application of a cost-effective flexible graphene working electrode. J. Colloid Interface Sci. 2021, 583, 487–498. [Google Scholar] [CrossRef]

- Galán-Vidal, C.A.; Muñoz, J.; Domínguez, C.; Alegret, S. Chemical sensors, biosensors and thick-film technology. TrAC Trends Anal. Chem. 1995, 14, 225–231. [Google Scholar] [CrossRef]

- Wang, J.; Pamidi, P.V.A. Disposable screen-printed electrodes for monitoring hydrazines. Talanta 1995, 42, 463–467. [Google Scholar] [CrossRef]

- Hyun, W.; Secor, E.; Hersam, M.; Frisbie, C.; Francis, L. High-Resolution Patterning of Graphene by Screen Printing with a Silicon Stencil for Highly Flexible Printed Electronics. Adv. Mater. 2015, 27, 109–115. [Google Scholar] [CrossRef]

- Liu, C.C. Applications of Thick Film Screen Printing and Ink Jet Printing for the Manufacturing of Single Use, Disposable Biosensors. ECS Trans. 2008, 16, 3–13. [Google Scholar] [CrossRef]

- Kava, A.A.; Henry, C.S. Exploring carbon particle type and plasma treatment to improve electrochemical properties of stencil-printed carbon electrodes. Talanta 2021, 221, 121553. [Google Scholar] [CrossRef]

- Rocha, D.S.; Silva-Neto, H.A.; de Oliveira, L.C.; Souza, S.G.; Santana, M.H.; Tomazelli, W.K. Disposable Stencil-Printed Carbon Electrodes for Electrochemical Analysis of Sildenafil Citrate in Commercial and Adulterated Tablets. Braz. J. Anal. Chem. 2022, 9, 210–228. [Google Scholar] [CrossRef]

- Sá, A.C.d.; Barbosa, S.C.; Raymundo-Pereira, P.A.; Wilson, D.; Shimizu, F.M.; Raposo, M.; Oliveira, O.N. Flexible Carbon Electrodes for Electrochemical Detection of Bisphenol-A, Hydroquinone and Catechol in Water Samples. Chemosensors 2020, 8, 103. [Google Scholar] [CrossRef]

- Dong, X.; Qi, X.; Liu, N.; Yang, Y.; Piao, Y. Direct Electrochemical Detection of Bisphenol A Using a Highly Conductive Graphite Nanoparticle Film Electrode. Sensors 2017, 17, 836. [Google Scholar] [CrossRef] [Green Version]

- Redivo, L.; Stredanský, M.; De Angelis, E.; Navarini, L.; Resmini, M.; Švorc, Ĺ. Bare carbon electrodes as simple and efficient sensors for the quantification of caffeine in commercial beverages. R. Soc. Open Sci. 2018, 5, 172146. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Zhang, Y.; Zhou, J.; Wang, L. Construction of a highly sensitive non-enzymatic nitrite sensor using electrochemically reduced holey graphene. Anal. Chim. Acta 2018, 1043, 28–34. [Google Scholar] [CrossRef]

- Genualdi, S.; Matos, M.P.V.; Mangrum, J.B.; DeJager, L. Investigation into the Concentrations and Sources of Nitrates and Nitrites in Milk and Plant-Based Powders. J. Agric. Food Chem. 2020, 68, 1725–1730. [Google Scholar] [CrossRef]

- Ruiz-Capillas, C.; Jimenez-Colmenero, F. Determination of preservatives in meat products by flow injection analysis (FIA). Food Addit. Contam. Part A 2008, 25, 1167–1178. [Google Scholar] [CrossRef]

- World Health Organization. Guidelines for Drinking-Water Quality (Fourth Edition Incorporating the First Addendum); World Health Organization: Geneva, Switzerland, 2017. [Google Scholar]

- Li, G.; Xia, Y.; Tian, Y.; Wu, Y.; Liu, J.; He, Q.; Chen, D. Review—Recent Developments on Graphene-Based Electrochemical Sensors toward Nitrite. J. Electrochem. Soc. 2019, 166, B881–B895. [Google Scholar] [CrossRef]

- Li, D.; Wang, T.; Li, Z.; Xu, X.; Wang, C.; Duan, Y. Application of Graphene-Based Materials for Detection of Nitrate and Nitrite in Water—A Review. Sensors 2020, 20, 54. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Zhou, X.; Yin, Y.; Fang, W. Determination of Nitrite by Noble Metal Nanomaterial-Based Electrochemical Sensors: A Minireview. Anal. Lett. 2021, 54, 2826–2850. [Google Scholar] [CrossRef]

- Liu, Z.; Manikandan, V.S.; Chen, A. Recent advances in nanomaterial-based electrochemical sensing of nitric oxide and nitrite for biomedical and food research. Curr. Opin. Electrochem. 2019, 16, 127–133. [Google Scholar] [CrossRef]

- Promsuwan, K.; Kanatharana, P.; Thavarungkul, P.; Limbut, W. Nitrite amperometric sensor for gunshot residue screening. Electrochim. Acta 2020, 331, 135309. [Google Scholar] [CrossRef]

- Esteban, M.; Ariño-Blasco, M.C.; Díaz-Cruz, J.M. 4.01—Chemometrics in Electrochemistry☆. In Comprehensive Chemometrics, 2nd ed.; Brown, S., Tauler, R., Walczak, B., Eds.; Elsevier: Oxford, UK, 2020; pp. 1–31. [Google Scholar] [CrossRef]

- Britz, D. iR elimination in electrochemical cells. J. Electroanal. Chem. Interfacial Electrochem. 1978, 88, 309–352. [Google Scholar] [CrossRef]

- AOAC International. Guidelines for Standard Method Performance Requirements; AOAC International: Rockville, MD, USA, 2016; pp. 1–18. [Google Scholar]

- Kim, H.-Y. Analysis of variance (ANOVA) comparing means of more than two groups. Restor. Dent. Endod. 2014, 39, 74–77. [Google Scholar] [CrossRef] [Green Version]

- Food and Drug Administration. Methods, Method Verification and Validation. In Food and Drug Administration Office of Regulatory Affairs Ora Laboratory Manual Volume II; Food and Drug Administration: Silver Spring, MD, USA, 2020; pp. 1–32. [Google Scholar]

- Xiao, Q.; Feng, M.; Liu, Y.; Lu, S.; He, Y.; Huang, S. The graphene/polypyrrole/chitosan-modified glassy carbon electrode for electrochemical nitrite detection. Ionics 2018, 24, 845–859. [Google Scholar] [CrossRef]

- Zheng, D.; Hu, C.; Peng, Y.; Hu, S. A carbon nanotube/polyvanillin composite film as an electrocatalyst for the electrochemical oxidation of nitrite and its application as a nitrite sensor. Electrochim. Acta 2009, 54, 4910–4915. [Google Scholar] [CrossRef]

- Zhang, D.; Fang, Y.; Miao, Z.; Ma, M.; Du, X.; Takahashi, S.; Anzai, J.-I.; Chen, Q. Direct electrodeposion of reduced graphene oxide and dendritic copper nanoclusters on glassy carbon electrode for electrochemical detection of nitrite. Electrochim. Acta 2013, 107, 656–663. [Google Scholar] [CrossRef]

| Electrodes | Linear Regression (Ipa) | R2 |

|---|---|---|

| Single MGrEs (consisted of 4WEs) | y = (29.7 ± 0.6)x + (1.1 ± 0.7) | 0.9986 |

| y = (30.3 ± 0.5)x + (0.7 ± 0.6) | 0.9991 | |

| y = (31.6 ± 0.6)x + (1.0 ± 0.6) | 0.9990 | |

| y = (31.9 ± 0.3)x + (0.1 ± 0.4) | 0.9997 | |

| Single WE | y = (30.8 ± 0.7)x − (0.4 ± 0.8) | 0.9985 |

| y = (33.4 ± 0.7)x − (1.2 ± 0.8) | 0.9987 | |

| y = (32.6 ± 0.6)x − (1.6 ± 0.7) | 0.9988 | |

| y = (34.5 ± 0.6)x − (2.4 ± 0.7) | 0.9990 |

| Samples | Added (mM) | Found (mM) | Recovery (%) | RSD (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| WE1 | WE2 | WE3 | WE4 | WE1 | WE2 | WE3 | WE4 | |||

| Tap water | - | - | - | - | - | - | - | - | - | - |

| 0.50 | 0.52 ± 0.01 | 0.488 ± 0.002 | 0.517 ± 0.007 | 0.512 ± 0.006 | 105 ± 3 | 97.6 ± 0.4 | 103 ± 1 | 102 ± 1 | 3.1 | |

| 0.75 | 0.794 ± 0.03 | 0.759 ± 0.005 | 0.82 ± 0.02 | 0.79 ± 0.03 | 106 ± 3 | 101.2 ± 0.7 | 109.4 ± 0.5 | 106 ± 4 | 3.8 | |

| Milk product | - | - | - | - | - | - | - | - | - | - |

| 0.75 | 0.79 ± 0.02 | 0.81 ± 0.004 | 0.79 ± 0.03 | 0.83 ± 0.02 | 106 ± 2 | 108 ± 2 | 106 ± 4 | 110 ± 2 | 3.0 | |

| 1.00 | 1.01 ± 0.02 | 1.04 ± 0.01 | 1.04 ± 0.01 | 1.07 ± 0.02 | 101 ± 2 | 103.6 ± 0.8 | 104 ± 1 | 107 ± 3 | 2.8 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kongkaew, S.; Tubtimtong, S.; Thavarungkul, P.; Kanatharana, P.; Chang, K.H.; Abdullah, A.F.L.; Limbut, W. A Fabrication of Multichannel Graphite Electrode Using Low-Cost Stencil-Printing Technique. Sensors 2022, 22, 3034. https://doi.org/10.3390/s22083034

Kongkaew S, Tubtimtong S, Thavarungkul P, Kanatharana P, Chang KH, Abdullah AFL, Limbut W. A Fabrication of Multichannel Graphite Electrode Using Low-Cost Stencil-Printing Technique. Sensors. 2022; 22(8):3034. https://doi.org/10.3390/s22083034

Chicago/Turabian StyleKongkaew, Supatinee, Suowarot Tubtimtong, Panote Thavarungkul, Proespichaya Kanatharana, Kah Haw Chang, Ahmad Fahmi Lim Abdullah, and Warakorn Limbut. 2022. "A Fabrication of Multichannel Graphite Electrode Using Low-Cost Stencil-Printing Technique" Sensors 22, no. 8: 3034. https://doi.org/10.3390/s22083034

APA StyleKongkaew, S., Tubtimtong, S., Thavarungkul, P., Kanatharana, P., Chang, K. H., Abdullah, A. F. L., & Limbut, W. (2022). A Fabrication of Multichannel Graphite Electrode Using Low-Cost Stencil-Printing Technique. Sensors, 22(8), 3034. https://doi.org/10.3390/s22083034