Heterogeneous Autonomous Robotic System in Viticulture and Mariculture: Vehicles Development and Systems Integration †

Abstract

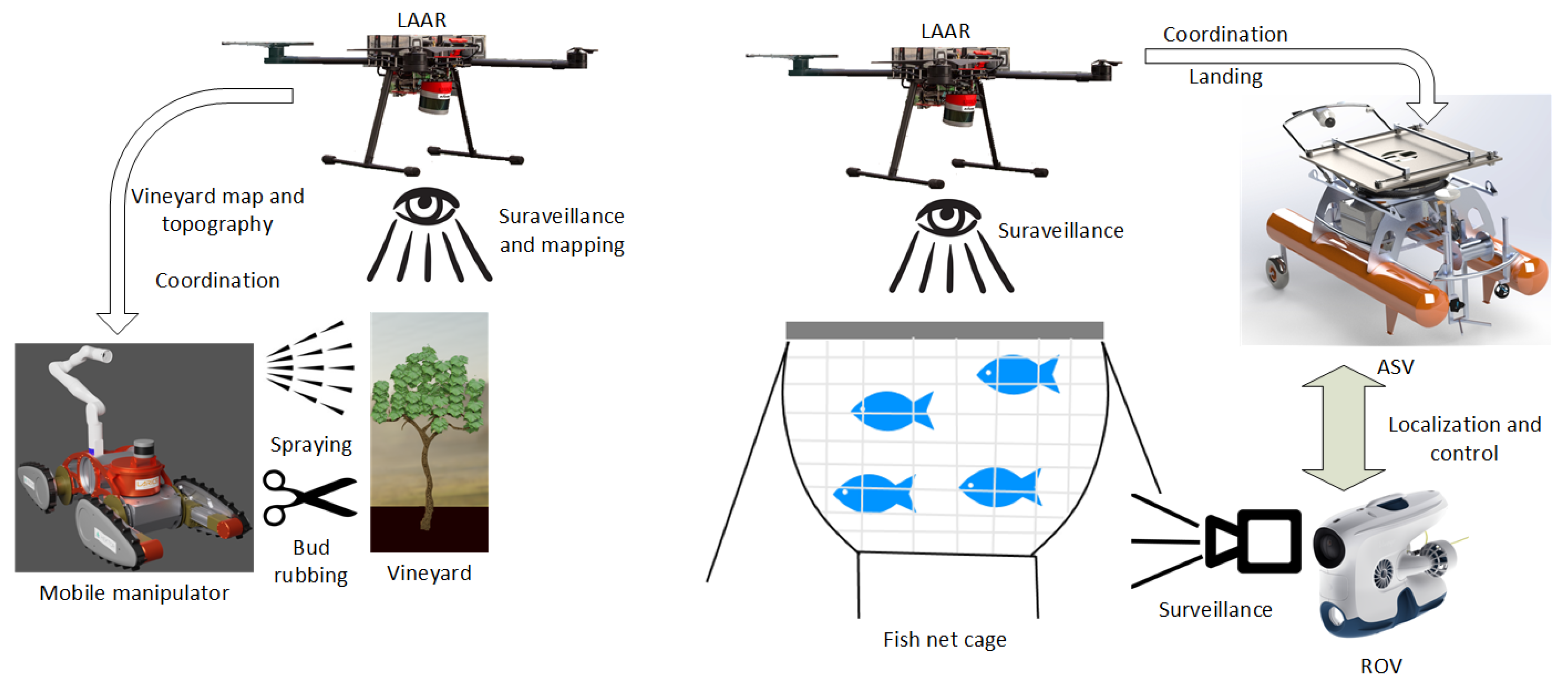

:1. Introduction

Organization of the Paper

2. Viticulture Scenarios

2.1. Vineyard Surveillance

2.2. Vineyard Spraying

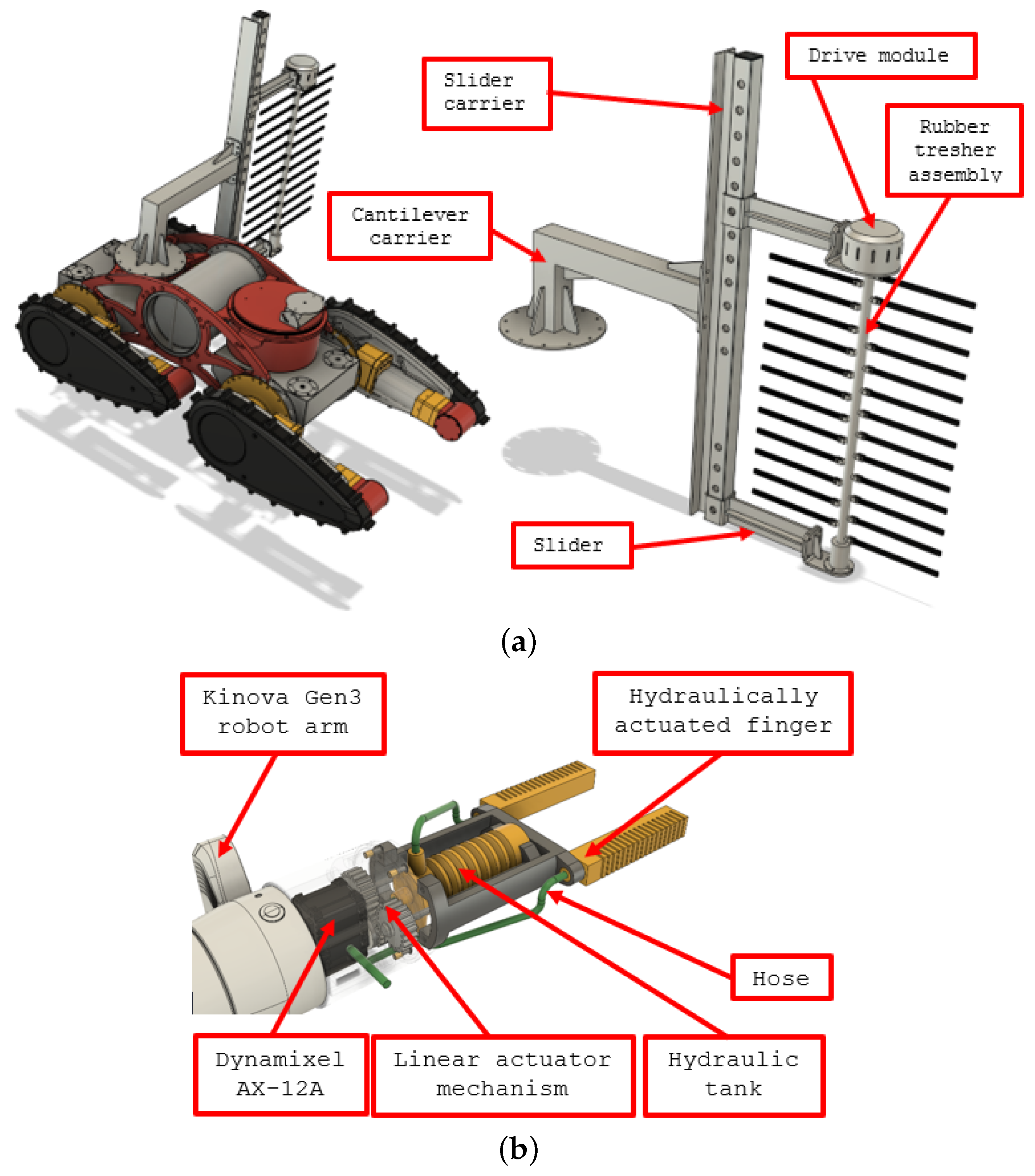

2.3. Suckering

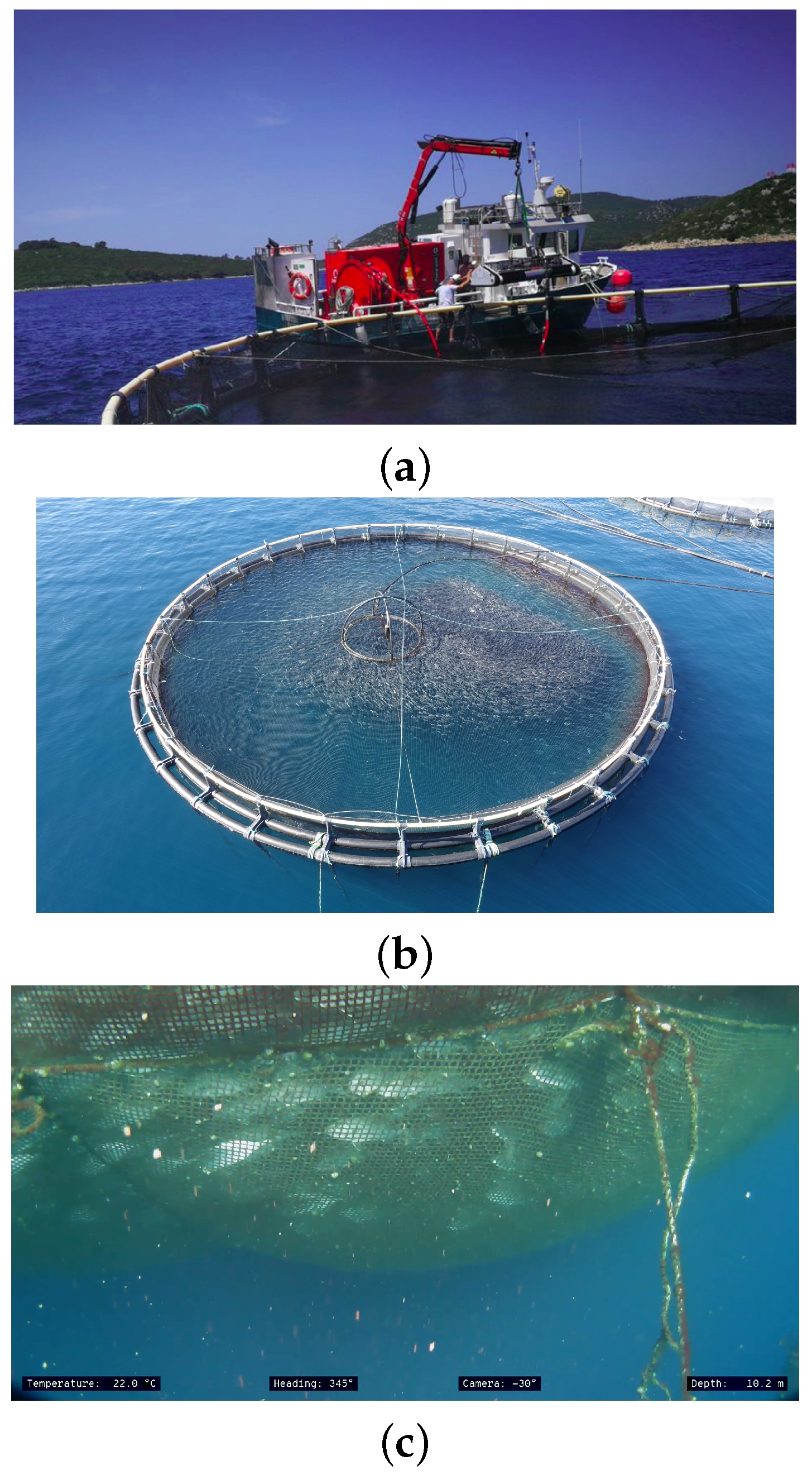

3. Mariculture Scenarios

3.1. Net Pen Inspection

3.2. Fish Population Modeling

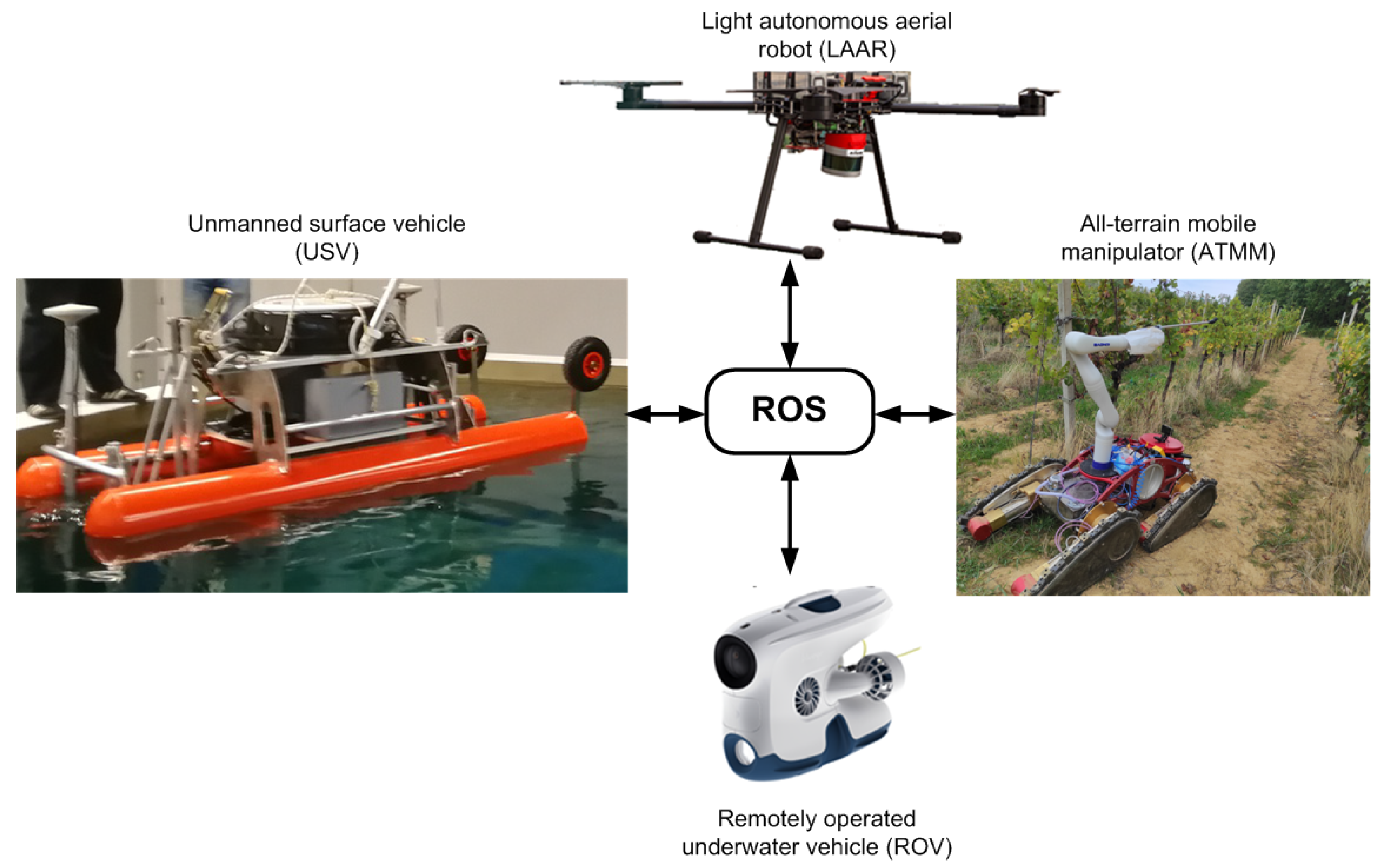

4. Robots of the HEKTOR System

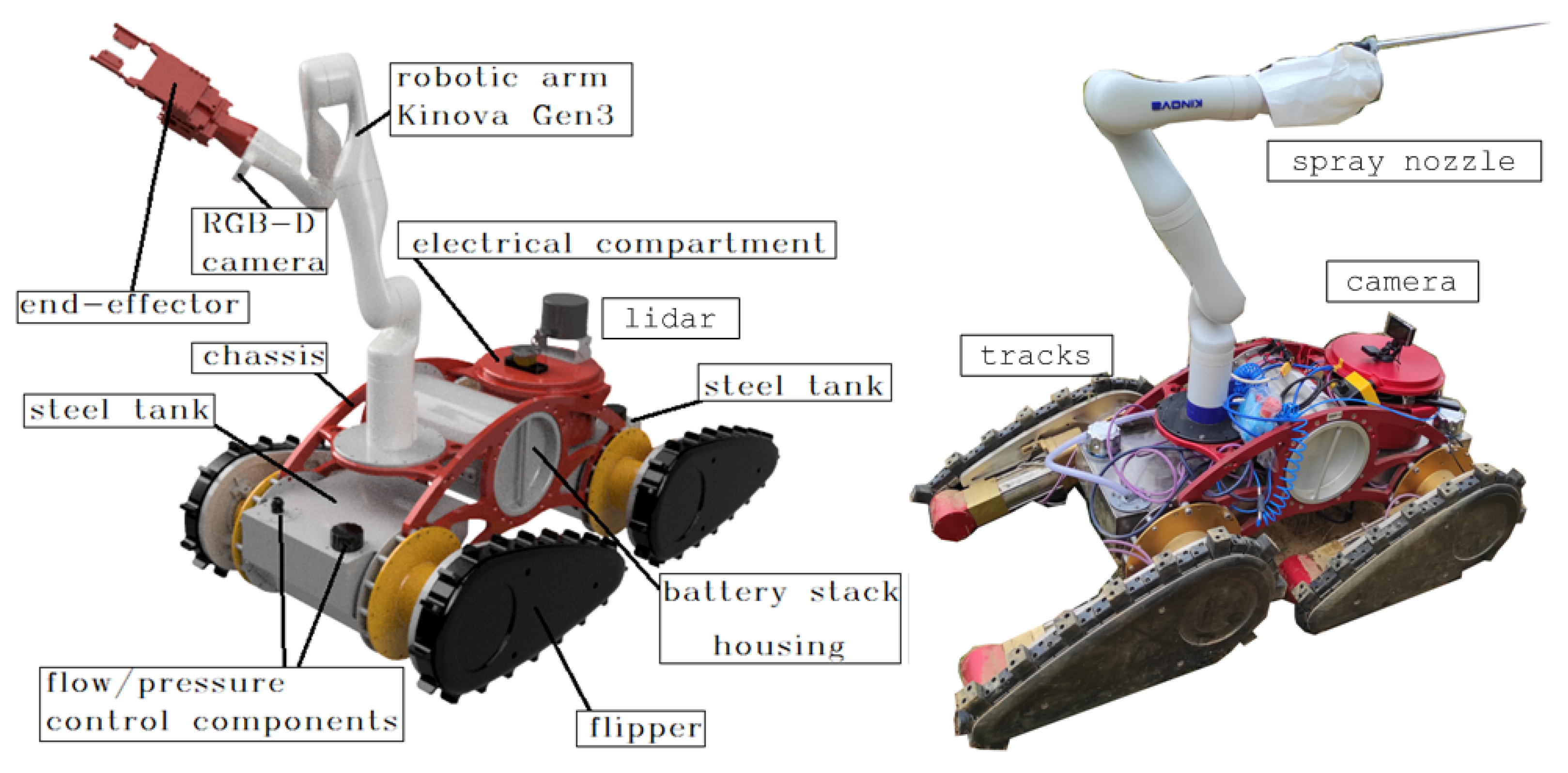

4.1. All-Terrain Mobile Manipulator (ATMM)

- i

- a chassis with four flippers/tracks,

- ii

- an electrical compartment and

- iii

- a robot arm carrying various robot tools (e.g., spray nozzle, soft gripper).

- -

- Easier control of the robot center of mass (CoM), since the flippers are relatively large compared to the robot body (each flipper contains its servo drive and control electronics);

- -

- More efficient overcoming of obstacles due to better distribution of the force to the flipper tracks, which contribute more than others to the robot’s movement upon contact with the ground;

- -

- Easier maintenance of the robot as each flipper is an independent module that can directly replace any other flipper module;

- -

- The raised center section of the robot skeleton prevents the robot from frequently colliding with or getting caught on the outer (top) edges of obstacles.

- continuous step-by-step passing over a vine canopy surface (in case of spraying);

- coordinated control of the movement of the mobile base and the robot arm;

- navigation that is always georeferenced and accurate with respect to the vine undergoing a particular treatment;

- force-controlled movement of a soft gripper on the vine (in case of suckering).

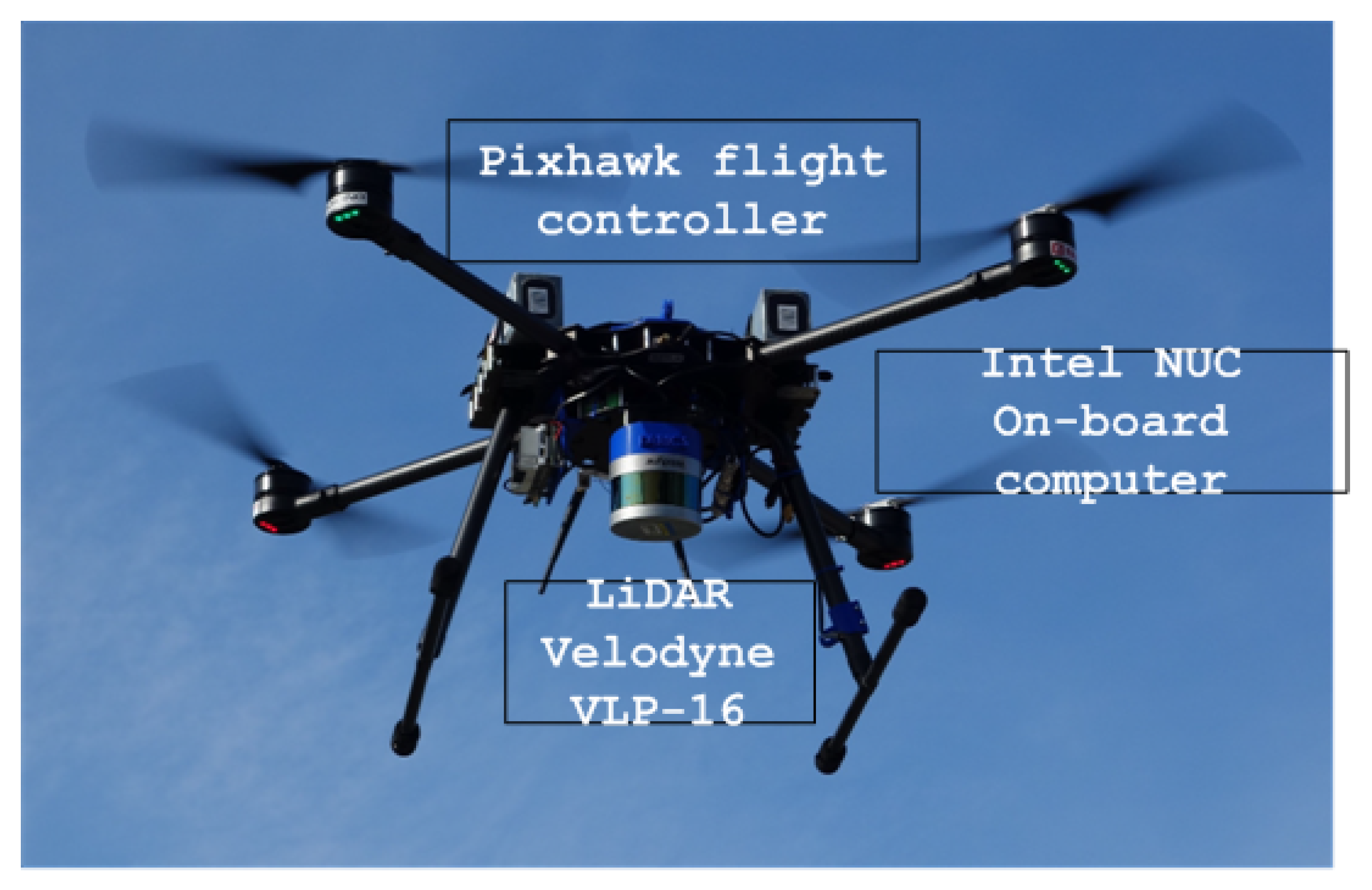

4.2. Light Autonomous Aerial Robot (LAAR)

- Velodyne Puck LiDAR is a 3D localization sensor with 16 channels, 360° horizontal and 30° vertical field of view. It can be used to create point cloud maps of the terrain or to localize LAAR in a GNSS denied environment.

- Sony RX100 high-resolution RGB camera with 1𠄳 type CMOS sensor, optical zoom and the ability to record 4K video at 25 or 50 fps.

- Flir Duo Pro R camera that combines high-resolution radiometric thermal imaging and 4K visual sensors. During vineyard survey flights, the thermal imaging camera can be used to detect areas of elevated plant temperature that may indicate disease or drought.

- Micasense RedEdge-MX is a multispectral sensor that can pick up 10 narrow bands in the visible and near-infrared light spectrum. It can be used to calculate various indices, such as the Normalized Difference Vegetation Index (NDVI), in surveyed areas.

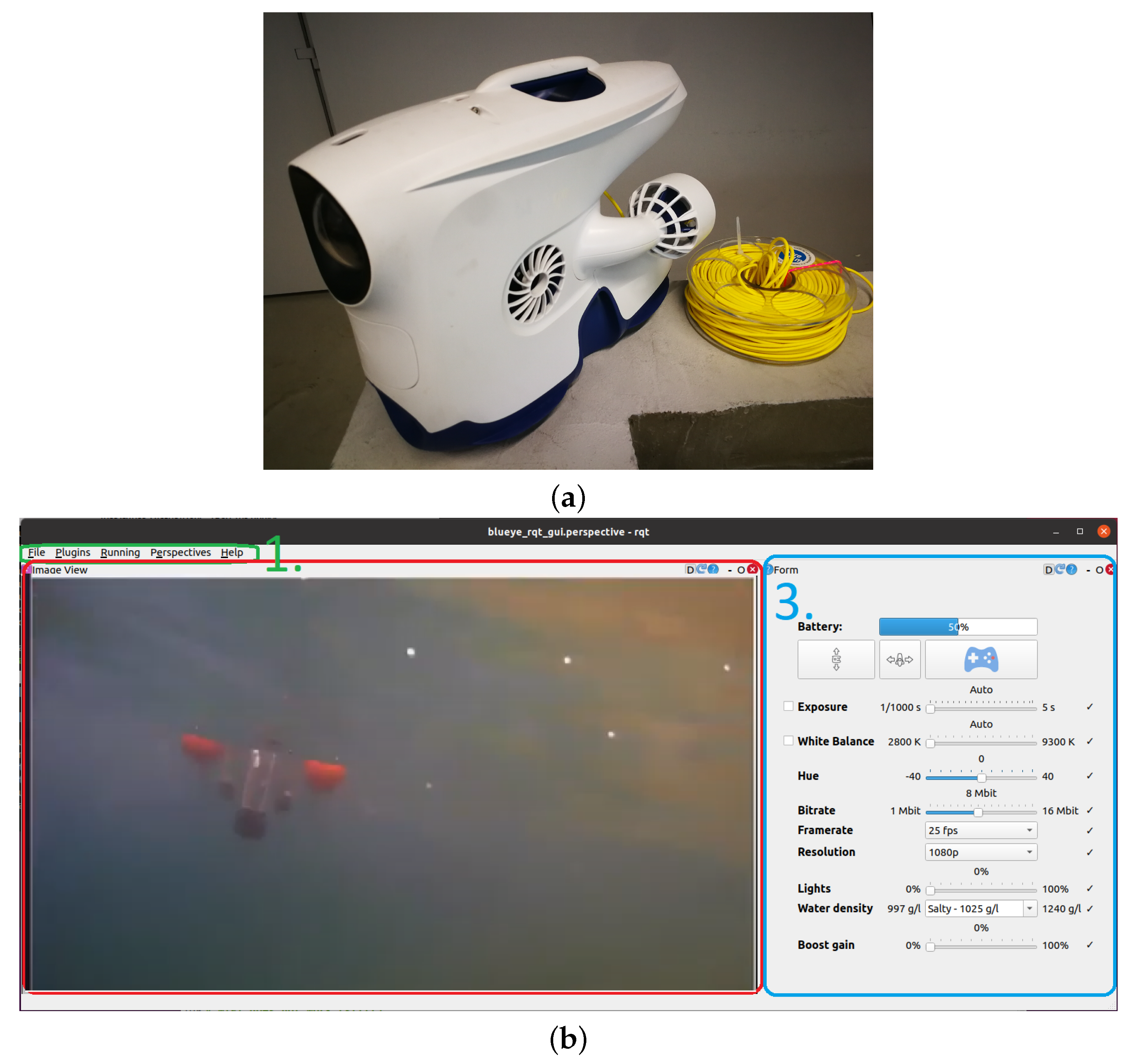

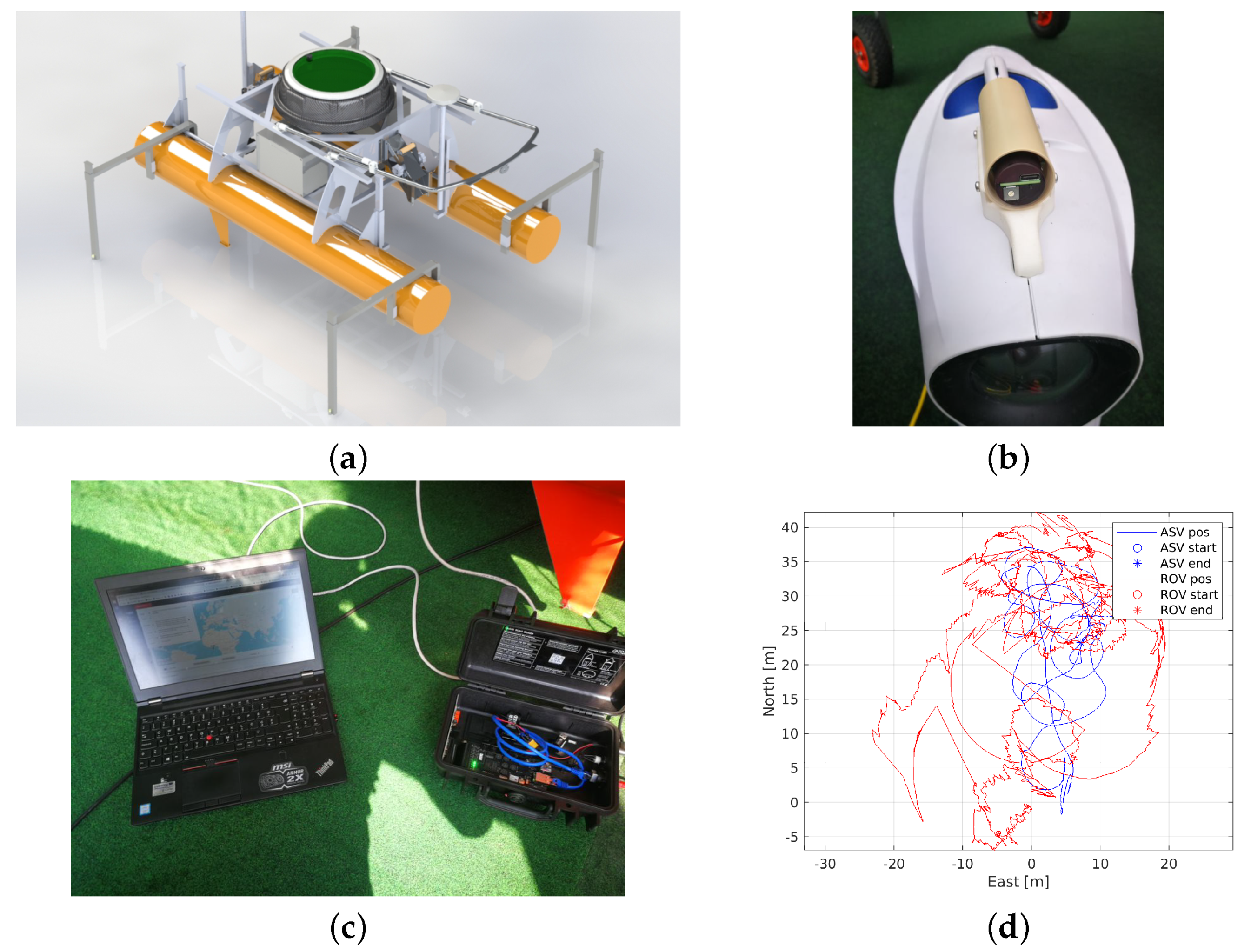

4.3. Remotely Operated Underwater Vehicle (ROV)

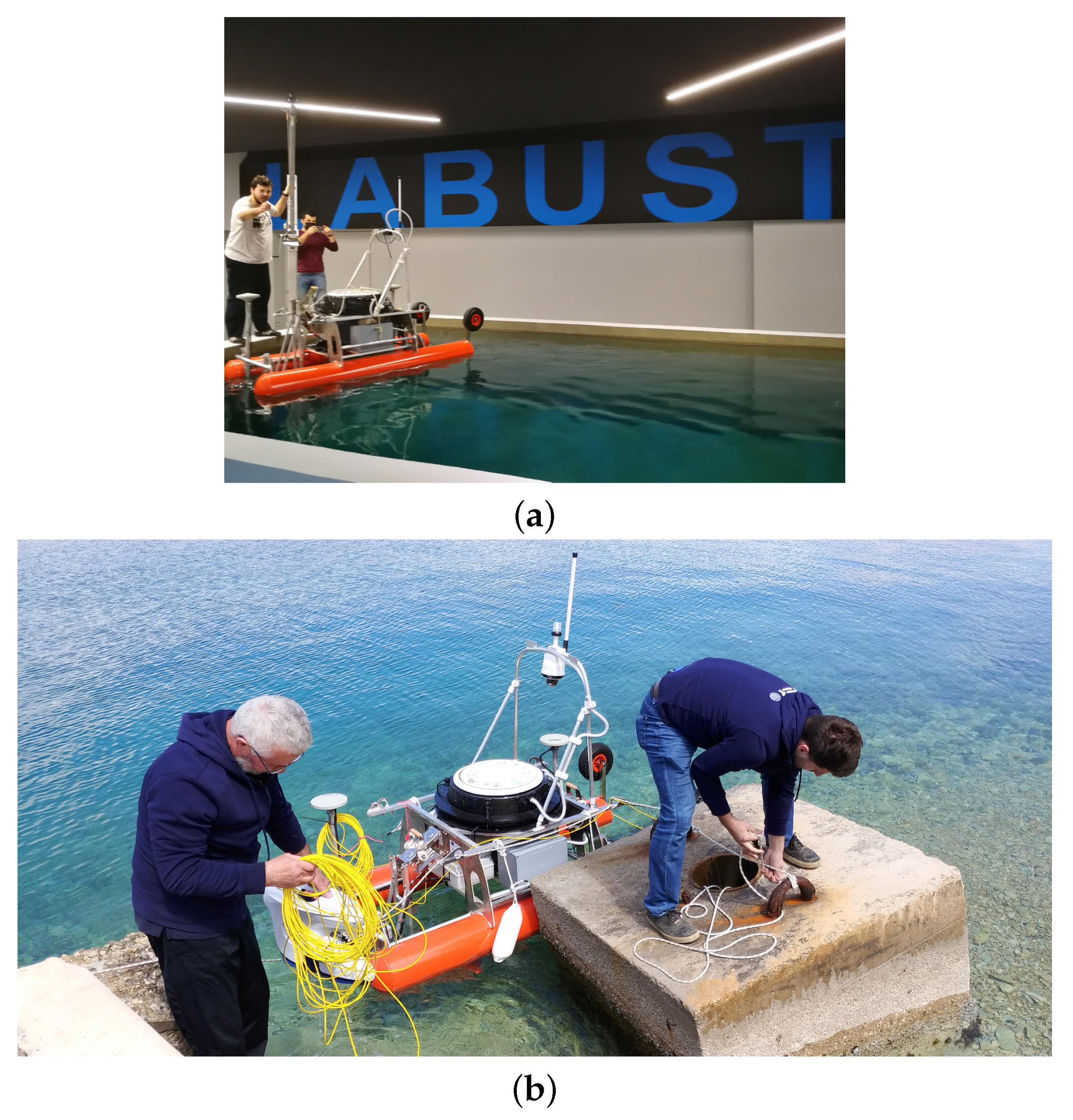

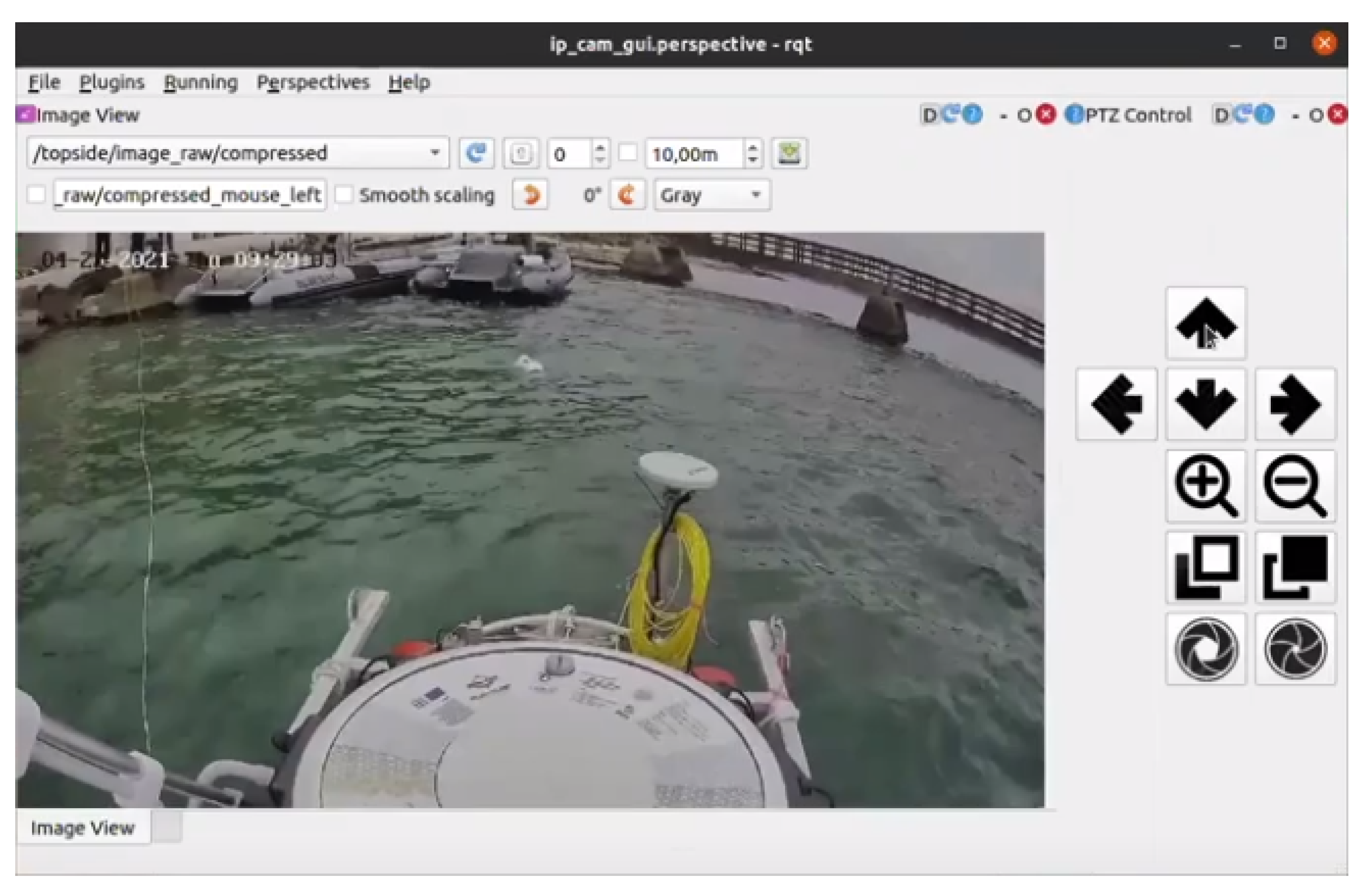

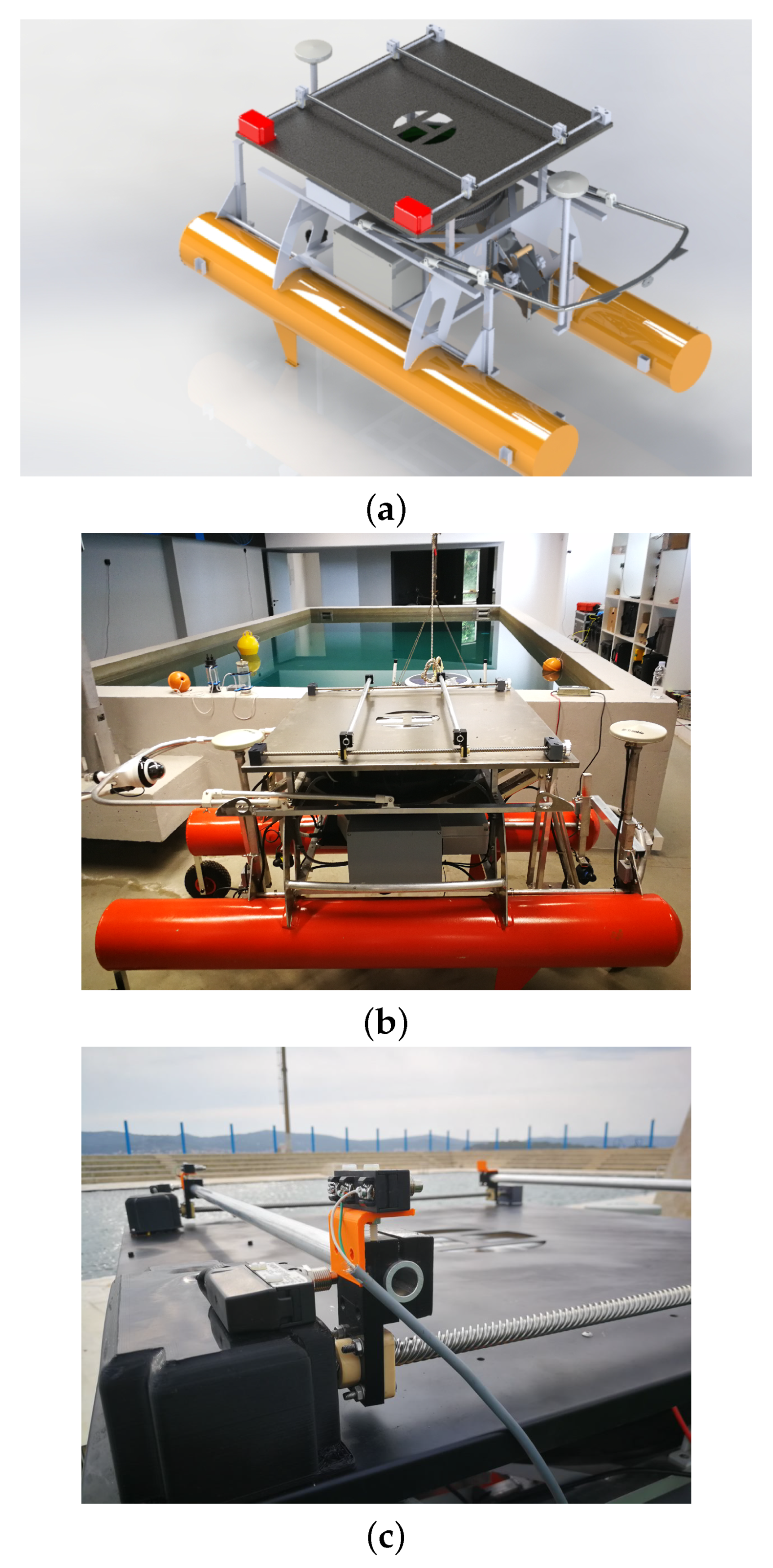

4.4. Autonomous Surface Vehicle (ASV)

5. HEKTOR Subsystems for Robot Collaboration

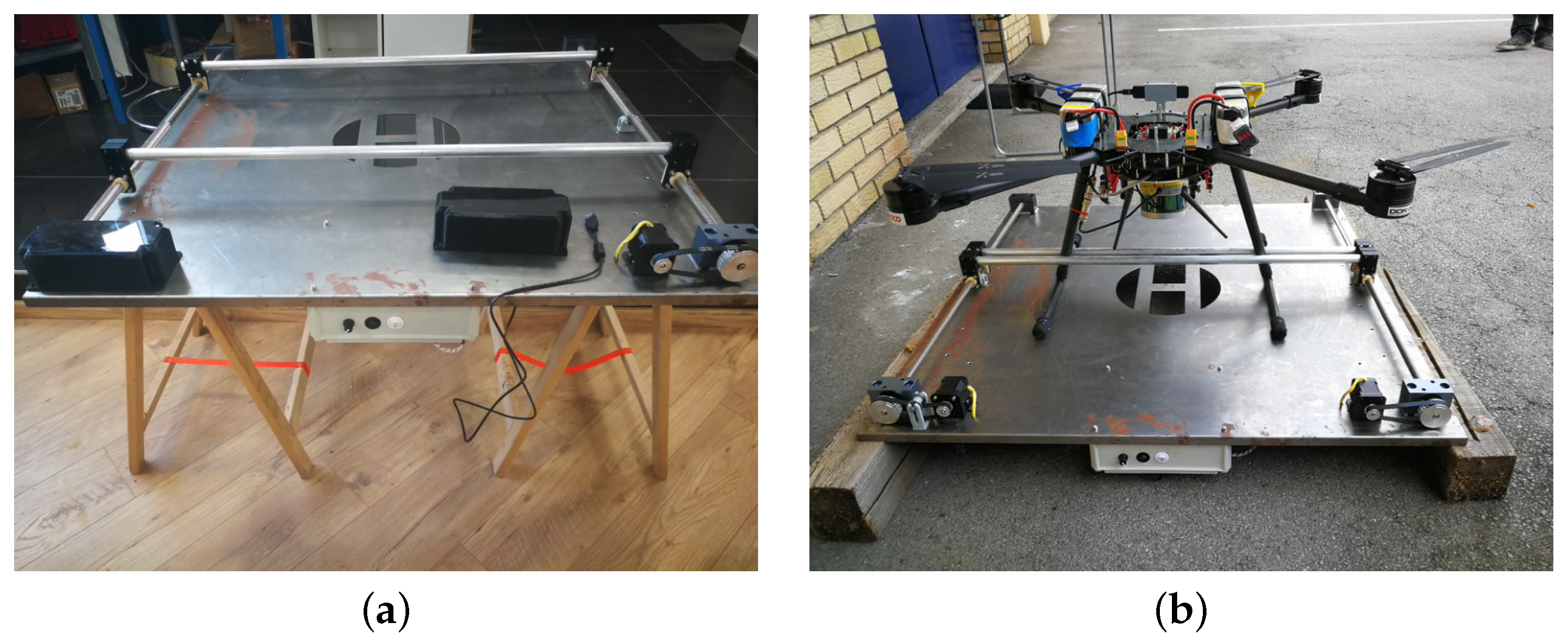

5.1. Landing Platform

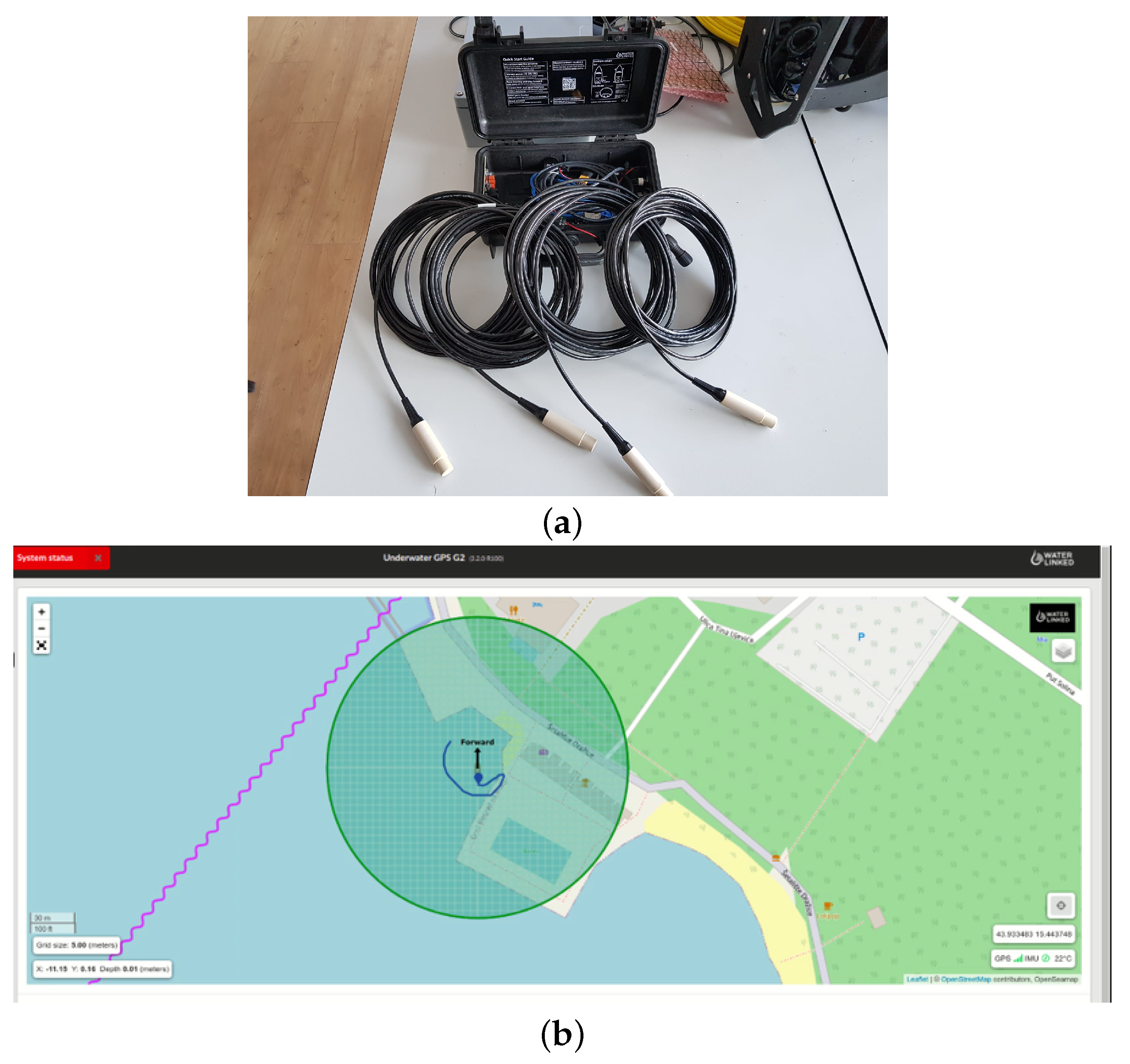

5.2. Underwater Acoustic Localization System

5.3. Tether Management System and ROV Docking Mechanism

5.4. ROS Autonomy and Collaboration Framework

6. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Fussel, G.E.; Nair, K.; Rasmussen, W.D.; Ordish, G.; Crawford, G.W.; Gray, A.W.; Mellanby, K. Origins of Agriculture. Available online: https://www.britannica.com/topic/agriculture (accessed on 28 February 2022).

- White, K.; O’Niell, B.; Tzankova, Z. At a Crossroads: Will Aquaculture Fulfill the Promise of the Blue Revolution? In A SeaWeb Aquaculture Clearinghouse Report; Aquaculture Clearinghouse: Providence, RI, USA, 2004; p. 17. [Google Scholar]

- Heterogeneous Autonomous Robotic System in Viticulture and Mariculture (HEKTOR Project)—2020–2023. Available online: http://hektor.fer.hr/en/homepage/ (accessed on 9 April 2020).

- Goričanec, J.; Kapetanović, N.; Vatavuk, I.; Hrabar, I.; Kurtela, A.; Anić, M.; Vasilijević, G.; Bolotin, J.; Kožul, V.; Stuhne, D.; et al. Heterogeneous autonomous robotic system in viticulture and mariculture—Project overview. In Proceedings of the 16th International Conference on Telecommunications—ConTEL, Zagreb, Croatia, 30 June–2 July 2021; pp. 1–8. [Google Scholar]

- Nuske, S.; Achar, S.; Bates, T.; Narasimhan, S.; Singh, S. Yield estimation in vineyards by visual grape detection. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; pp. 2352–2358. [Google Scholar]

- Lopes, C.; Graça, J.; Sastre, J.; Reyes, M.; Guzmán, R.; Braga, R.; Monteiro, A.; Pinto, P. Vineyard yield estimation by VINBOT robot—Preliminary results with the white variety Viosinho. In Proceedings 11th International Terroir Congres; Jones, G., Doran, N., Eds.; Southern Oregon University: Ashland, OR, USA, 2016; pp. 458–463. [Google Scholar]

- dos Santos, F.N.; Sobreira, H.; Campos, D.; Morais, R.; Paulo Moreira, A.; Contente, O. Towards a Reliable Robot for Steep Slope Vineyards Monitoring. J. Intell. Robot. Syst. Theory Appl. 2016, 83, 429–444. [Google Scholar] [CrossRef]

- Tanda, G.; Chiarabini, V. Use of multispectral and thermal imagery in precision viticulture. J. Phys. Conf. Ser. 2019, 1224, 012034. [Google Scholar] [CrossRef]

- Baluja, J.; Diago, M.P.; Balda, P.; Zorer, R.; Meggio, F.; Morales, F.; Tardaguila, J. Assessment of vineyard water status variability by thermal and multispectral imagery using an unmanned aerial vehicle (UAV). Irrig. Sci. 2012, 30, 511–522. [Google Scholar] [CrossRef]

- López-Granados, F.; Torres-Sánchez, J.; Jiménez-Brenes, F.M.; Oneka, O.; Marín, D.; Loidi, M.; Castro, A.I.; Santesteban, L.G. Monitoring vineyard canopy management operations using UAV-acquired photogrammetric point clouds. Remote Sens. 2020, 12, 2331. [Google Scholar] [CrossRef]

- Pádua, L.; Marques, P.; Hruška, J.; Adão, T.; Peres, E.; Morais, R.; Sousa, J.J. Multi-temporal vineyard monitoring through UAV-based RGB imagery. Remote Sens. 2018, 10, 1907. [Google Scholar] [CrossRef] [Green Version]

- Di Gennaro, S.F.; Matese, A.; Gioli, B.; Toscano, P.; Zaldei, A.; Palliotti, A.; Genesio, L. Multisensor approach to assess vineyard thermal dynamics combining high-resolution unmanned aerial vehicle (UAV) remote sensing and wireless sensor network (WSN) proximal sensing. Sci. Hortic. 2017, 221, 83–87. [Google Scholar] [CrossRef]

- Turner, D.; Lucieer, A.; Watson, C. Development of an unmanned aerial vehicle (UAV) for hyper resolution vineyard mapping based on visible, multispectral, and thermal imagery. In Proceedings of the 34th International Symposium on Remote Sensing of Environment—The GEOSS Era: Towards Operational Environmental Monitoring, Sydney, Australia, 10–15 April 2011. [Google Scholar]

- Berenstein, R.; Shahar, O.B.; Shapiro, A.; Edan, Y. Grape clusters and foliage detection algorithms for autonomous selective vineyard sprayer. Intell. Serv. Robot. 2010, 3, 233–243. [Google Scholar] [CrossRef]

- Berenstein, R. The use of agricultural robots in crop spraying/fertilizer applications. In Robotics and Automation for Improving Agriculture; Burleigh Dodds Science Publishing: Cambridge, UK, 2019; pp. 109–136. [Google Scholar]

- Oberti, R.; Marchi, M.; Tirelli, P.; Calcante, A.; Iriti, M.; Hočevar, M.; Baur, J.; Pfaff, J.; Schütz, C.; Ulbrich, H. Selective spraying of grapevine’s diseases by a modular agricultural robot. J. Agric. Eng. 2013, 44, 149–153. [Google Scholar] [CrossRef]

- Oberti, R.; Marchi, M.; Tirelli, P.; Calcante, A.; Iriti, M.; Tona, E.; Hočevar, M.; Baur, J.; Pfaff, J.; Schütz, C.; et al. Selective spraying of grapevines for disease control using a modular agricultural robot. Biosyst. Eng. 2016, 146, 203–215. [Google Scholar] [CrossRef]

- Kang, F.; Wang, H.; Pierce, F.J.; Zhang, Q.; Wang, S. Sucker Detection of Grapevines for Targeted Spray Using Optical Sensors. Trans. ASABE 2012, 55, 2007–2014. [Google Scholar] [CrossRef]

- Martelloni, L.; Raffaelli, M.; Frasconi, C.; Fontanelli, M.; Peruzzi, A.; D’Onofrio, C. Using flaming as an alternative method to vine suckering. Agronomy 2019, 9, 147. [Google Scholar] [CrossRef] [Green Version]

- Hrabar, I.; Vasiljević, G.; Kovačić, Z. Estimation of the Energy Consumption of an All-Terrain Mobile Manipulator for Operations in Steep Vineyards. Electronics 2022, 11, 217. [Google Scholar] [CrossRef]

- Miller, G.T.; Spoolman, S. Modern Synthetic Pesticides Have Several Disadvantages. In Sustaining the Earth; Cengage Learning: Belmont, CA, USA, 2011. [Google Scholar]

- Gil, Y.; Sinfort, C.; Brunet, Y.; Polveche, V.; Bonicelli, B. Atmospheric loss of pesticides above an artificial vineyard during air-assisted spraying. Atmos. Environ. 2007, 41, 2945–2957. [Google Scholar] [CrossRef]

- McCauley, L.A.; Anger, W.K.; Keifer, M.; Langley, R.; Robson, M.G.; Rohlman, D. Studying Health Outcomes in Farmworker Populations Exposed to Pesticides. Environ. Health Perspect. 2006, 114, 953–960. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vatavuk, I.; Vasiljević, G.; Kovačić, Z. Task Space Model Predictive Control for Vineyard Spraying with a Mobile Manipulator. Agriculture 2022, 12, 381. [Google Scholar] [CrossRef]

- Meyers, J.M.; Miles, J.A.; Tejeda, D.G.; Faucett, J.; Janowitz, I.; Weber, E.; Smith, R.; Garcia, L. Priority Risk Factors for Back Injury in Agricultural Field Work: Vineyard Ergonomics. J. Agromed. 2002, 8, 39–54. [Google Scholar] [CrossRef]

- AGRISHIELD Vineyard Sucker Remover. Available online: https://agrishieldllc.com/vineyard/vineyard-sucker-remover/ (accessed on 9 April 2021).

- Skøien, K.R.; Alver, M.O.; Zolich, A.P.; Alfredsen, J.A. Feed spreaders in sea cage aquaculture—Motion characterization and measurement of spatial pellet distribution using an unmanned aerial vehicle. Comput. Electron. Agric. 2016, 129, 27–36. [Google Scholar] [CrossRef] [Green Version]

- Lien, A.M.; Schellewald, C.; Stahl, A.; Frank, K.; Skøien, K.R.; Tjølsen, J.I. Determining spatial feed distribution in sea cage aquaculture using an aerial camera platform. Aquac. Eng. 2019, 87, 102018. [Google Scholar] [CrossRef]

- Chen, C.X.; Juang, J.G. Vision based target recognition for cage aquaculture detection. J. Mar. Sci. Technol. (Taiwan) 2020, 28, 480–490. [Google Scholar]

- Belarmino, M.D.B.; Libatique, N.J.C. Implementation of image processing and machine learning in high resolution aerial image datasets for lake resource usage, aquaculture, and coastal community. In Proceedings of the IEEE Region 10 Annual International Conference, Proceedings/TENCON, Osaka, Japan, 16–19 November 2020; pp. 940–945. [Google Scholar]

- Reshma, B.; Kumar, S.S. Precision aquaculture drone algorithm for delivery in sea cages. In Proceedings of the 2nd IEEE International Conference on Engineering and Technology, ICETECH 2016, Coimbatore, India, 17–18 March 2016; pp. 1264–1270. [Google Scholar]

- Bjerkeng, M.; Kirkhus, T.; Caharija, W.; Thielemann, J.T.; Amundsen, H.B.; Ohrem, S.J.; Grøtli, E.I. ROV navigation in a fish cage with laser-camera triangulation. J. Mar. Sci. Eng. 2021, 9, 79. [Google Scholar] [CrossRef]

- Livanos, G.; Zervakis, M.; Chalkiadakis, V.; Moirogiorgou, K.; Papandroulakis, N. Intelligent Navigation and Control of a Prototype Autonomous Underwater Vehicle for Automated Inspection of Aquaculture net pen cages. In Proceedings of the IEEE International Conference on Imaging Systems and Techniques, Kraków, Poland, 16–18 October 2018; pp. 1–6. [Google Scholar]

- Betancourt, J.; Coral, W.; Colorado, J. An integrated ROV solution for underwater net-cage inspection in fish farms using computer vision. SN Appl. Sci. 2020, 2, 1946. [Google Scholar] [CrossRef]

- Osen, O.L.; Leinan, P.M.; Blom, M.; Bakken, C.; Heggen, M.; Zhang, H. A Novel Sea Farm Inspection Platform for Norwegian Aquaculture Application. In Proceedings of the OCEANS 2018 MTS/IEEE Charleston, Charleston, SC, USA, 22–25 October 2018. [Google Scholar]

- Shortis, M.R.; Ravanbakhsh, M.; Shafait, F.; Mian, A. Progress in the Automated Identification, Measurement, and Counting of Fish in Underwater Image Sequences. Mar. Technol. Soc. J. 2016, 50, 4–16. [Google Scholar] [CrossRef]

- Saberioon, M.; Císař, P. Automated within tank fish mass estimation using infrared reflection system. Comput. Electron. Agric. 2018, 150, 484–492. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, X.; Wang, Y.; Zhao, Z.; Liu, J.; Liu, Y.; Sun, C.; Zhou, C. Automatic fish population counting by machine vision and a hybrid deep neural network model. Animals 2020, 10, 364. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Lu, H.; Cao, Z.; Xiao, Y. Counting Fish in Sonar Images. In Proceedings of the 2018 25th IEEE International Conference on Image Processing (ICIP), Athens, Greece, 7–10 October 2018; pp. 3189–3193. [Google Scholar]

- Almansa, C.; Reig, L.; Oca, J. The laser scanner is a reliable method to estimate the biomass of a Senegalese sole (Solea senegalensis) population in a tank. Aquac. Eng. 2015, 69, 78–83. [Google Scholar] [CrossRef] [Green Version]

- Konovalov, D.A.; Saleh, A.; Efremova, D.B.; Domingos, J.A.; Jerry, D.R. Automatic weight estimation of harvested fish from images. arXiv 2019, arXiv:1909.02710. [Google Scholar]

- Muñoz-Benavent, P.; Puig-Pons, V.; Andreu-García, G.; Espinosa, V.; Atienza-Vanacloig, V.; Pérez-Arjona, I. Automatic bluefin tuna sizing with a combined acoustic and optical sensor. Sensors 2020, 20, 5294. [Google Scholar] [CrossRef]

- Abinaya, N.S.; Susan, D.; Rakesh Kumar, S. Naive Bayesian fusion based deep learning networks for multisegmented classification of fishes in aquaculture industries. Ecol. Inform. 2021, 61, 101248. [Google Scholar]

- Rezo, M.; Čagalj, K.M.; Ušljebrka, I.; Kovačić, Z. Collecting Information for Biomass Estimation in Mariculture with a Heterogeneous Robotic System. In Proceedings of the 44th International ICT Convention MIPRO, Opatija, Croatia, 27 September–1 October 2021; pp. 1295–1300. [Google Scholar]

- Hrabar, I.; Goričanec, J.; Kovačić, Z. Towards Autonomous Navigation of a Mobile Robot in a Steep Slope Vineyard. In Proceedings of the 44th International ICT Convention MIPRO, Opatija, Croatia, 27 September–1 October 2021; pp. 1289–1294. [Google Scholar]

- Kapetanović, N.; Vuković, J. Blueye SDK-ROS2 Interface. 2021. Available online: https://github.com/labust/blueye-ros2-pkg.git (accessed on 22 July 2021).

- Kapetanović, N.; Nad, D.; Mišković, N. Towards a Heterogeneous Robotic System for Autonomous Inspection in Mariculture. In Proceedings of the OCEANS 2021 Conference and Exposition, San Diego—Porto (Hybrid), San Diego, CA, USA, 20–23 September 2021; pp. 1–6. [Google Scholar]

- Farkas, A.; Parunov, J.; Katalinić, M. Wave Statistics for the Middle Adriatic Sea. Pomor. Zb. 2016, 52, 33–47. [Google Scholar] [CrossRef]

- Katalinić, M.; Parunov, J. Comprehensive Wind and Wave Statistics and Extreme Values for Design and Analysis of Marine Structures in the Adriatic Sea. J. Mar. Sci. Eng. 2021, 9, 522. [Google Scholar] [CrossRef]

- Đula, N.; Mišković, N.; Mandić, F. Navigation, guidance and control of an overactuated marine surface vehicle. Annu. Rev. Control 2015, 40, 172–181. [Google Scholar]

- Lončar, I.; Babić, A.; Arbanas, B.; Vasiljević, G.; Petrović, T.; Bogdan, S.; Mišković, N. A Heterogeneous Robotic Swarm for Long-Term Monitoring of Marine Environments. Appl. Sci. 2019, 9, 1388. [Google Scholar] [CrossRef] [Green Version]

- Kapetanović, N. WaterLinked Underwater GPS G2 Python API-ROS2 Interface. 2021. Available online: https://github.com/labust/waterlinked-uwgpsg2-ros2-pkg (accessed on 5 November 2021).

| Ref. | Tasks in Viticulture | Vehicles | Unstruct. Env. | |||

|---|---|---|---|---|---|---|

| Surveillance | Spraying | Suckering | LAAR | ATMM | ||

| [5] | X | X | ||||

| [6] | X | X | X | |||

| [7] | X | X | X | |||

| [8] | X | X | X | |||

| [9] | X | X | X | |||

| [10] | X | X | X | |||

| [11] | X | X | X | |||

| [12] | X | X | X | |||

| [13] | X | X | X | |||

| [14,15] | X | X | ||||

| [16,17] | X | X | ||||

| [18] | X | X | X | |||

| [19] | X | X | ||||

| HEKTOR | X | X | X | X | X | X |

| Ref | Tasks in Mariculture | Vehicles | Unstruct. Env. | ||||

|---|---|---|---|---|---|---|---|

| Net Pen Inspection | Biomass Estimation | Feeding | LAAR | ASV | ROV | ||

| [27] | X | X | X | ||||

| [28] | X | X | X | ||||

| [29] | X | X | X | ||||

| [30] | X | X | |||||

| [31] | X | X | |||||

| [32] | X | X | X | ||||

| [33] | X | X | X | ||||

| [34] | X | X | X | ||||

| [35] | X | X | X | X | |||

| [36] | X | ||||||

| [37] | X | ||||||

| [38] | X | ||||||

| [39] | X | ||||||

| [40] | X | ||||||

| [41] | X | ||||||

| [42] | X | ||||||

| [43] | X | ||||||

| [44] | X | X | (X) | X | X | ||

| HEKTOR | X | X | X | X | X | X | |

| HEKTOR System Requirements for Viticulture Scenarios | |

| Terrain characteristics | ATMM should function on slopes from 0% to 60%, on rocky, earthy or seismic terrain. |

| Vineyard size | The estimated vineyard size for application of HEKTOR system without human intervention is 1 ha, with an average planting height of 1.5 m and row spacing of 1.2–2 m. |

| Permissible flying height | Aerial survey of vineyards should be carried out at a height of at least 10 m above the height of the plantation. When mapping vineyards, the maximum height depends on the area of the vineyard (≤30 m). |

| Permissible wind state | UAV should be able to fly and execute its tasks at wind speeds up to 15 m/s. |

| 3D map of vineyards | The HEKTOR system should produce a 3D map of vineyards with an accuracy of 10 cm. |

| Reliable communication | The operator’s system should communicate reliably with the HEKTOR system at a distance of 150 m. |

| Localization ATMM | ATMM should know its position in space with an accuracy of 10 cm. |

| Spraying efficiency | ATMM should treat plantations with a travel speed of at least 0.7 m/s at a slope of up to 30%. |

| Suckering efficiency | ATMM shall achieve a suckering rate of at least 20 vines per hour. |

| HEKTOR System Requirements for Mariculture Scenarios | |

| Operating depth ROV | ROV should work at depths up to 300 m. |

| Weather conditions | ROV should work in fish farms at currents up to 2 knots. |

| ROV maneuverability | ROV should be able to move in 4 degrees of freedom, namely: yaw (rotation around the z-axis, i.e., rotation left–right), sinking (movement along the z-axis, i.e., movement up and down), heading (movement along the x-axis, i.e., forward–backward movement), and drift (movement along the y-axis, i.e., lateral left–right movement). |

| Localization ROV | ROV should know its position in space with an accuracy better than 1 m. |

| Weather conditions LAAR | The LAAR must be able to fly safely with the wind speed up to 15 m/s. |

| Weather conditions ASV | The ASV must be able to successfully complete missions at sea state 2. |

| ASV maneuverability | ASV should be able to move in 3 degrees of freedom, namely: yaw (rotation around the z-axis, i.e., rotation left–right), heading (movement along the x-axis, i.e., movement back and forth), and drift (movement along the y-axis, i.e., lateral movement left–right). |

| Reliable communication | The operator’s system should communicate reliably with ASV at a distance of 150 m. |

| Localization ASV | ASV should know its position in space with an accuracy better than 1 m. |

| Robot | ATMM | LAAR | ROV | ASV |

|---|---|---|---|---|

| Type | Terrestrial | Aerial | Underwater | Water surface |

| Dimensions | 709 × 565 × 1327 | 1200 × 1200 × 450 | 485 × 257 × 354 | 2000 × 1000 × 1400 |

| W × L × H [mm] | ||||

| Weight [kg] | 90 + 10 | 8 | 9 | 100 |

| Payload [kg] | >200 | 2 | n/a | 100 |

| Battery [Wh] | 1248 | 2 × 266 | 96 | 3730 |

| Autonomy [min] | 300 | 30 | 120 | 600 |

| Actuators | 4 × 250 W + | 4 × 1600 W | 4 × 350 W | 4 × 390 W + |

| 7DoF arm 36 W | 1 × 720 W | |||

| Speed | 0.7 m/s | >10 m/s | 3 kt | 4 kt |

| Basic | Camera | Camera | Camera | Camera |

| sensors | LiDAR | LiDAR | IMU | IMU |

| IMU | IMU | Pressure | GNSS | |

| GNSS | GNSS | Temperature | ||

| Optional | Flow | Thermal camera | Multibeam sonar | |

| sensors | Pressure | Multispectral camera | LiDAR | |

| Communication | WiFi + Radio | WiFi + Radio | Ethernet + WiFi | WiFi + Radio + LTE |

| Control unit | NUC 10 | NUC 11 | N/A | NUC 7 + |

| + Pixhawk | + Pixhawk | NUC 10 | ||

| CubeOrange | CubeBlack |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapetanović, N.; Goričanec, J.; Vatavuk, I.; Hrabar, I.; Stuhne, D.; Vasiljević, G.; Kovačić, Z.; Mišković, N.; Antolović, N.; Anić, M.; et al. Heterogeneous Autonomous Robotic System in Viticulture and Mariculture: Vehicles Development and Systems Integration. Sensors 2022, 22, 2961. https://doi.org/10.3390/s22082961

Kapetanović N, Goričanec J, Vatavuk I, Hrabar I, Stuhne D, Vasiljević G, Kovačić Z, Mišković N, Antolović N, Anić M, et al. Heterogeneous Autonomous Robotic System in Viticulture and Mariculture: Vehicles Development and Systems Integration. Sensors. 2022; 22(8):2961. https://doi.org/10.3390/s22082961

Chicago/Turabian StyleKapetanović, Nadir, Jurica Goričanec, Ivo Vatavuk, Ivan Hrabar, Dario Stuhne, Goran Vasiljević, Zdenko Kovačić, Nikola Mišković, Nenad Antolović, Marina Anić, and et al. 2022. "Heterogeneous Autonomous Robotic System in Viticulture and Mariculture: Vehicles Development and Systems Integration" Sensors 22, no. 8: 2961. https://doi.org/10.3390/s22082961

APA StyleKapetanović, N., Goričanec, J., Vatavuk, I., Hrabar, I., Stuhne, D., Vasiljević, G., Kovačić, Z., Mišković, N., Antolović, N., Anić, M., & Kozina, B. (2022). Heterogeneous Autonomous Robotic System in Viticulture and Mariculture: Vehicles Development and Systems Integration. Sensors, 22(8), 2961. https://doi.org/10.3390/s22082961