Adaptive Thin Film Temperature Sensor for Bearing’s Rolling Elements Temperature Measurement

Abstract

:1. Introduction

2. Working Principle and Structural Design

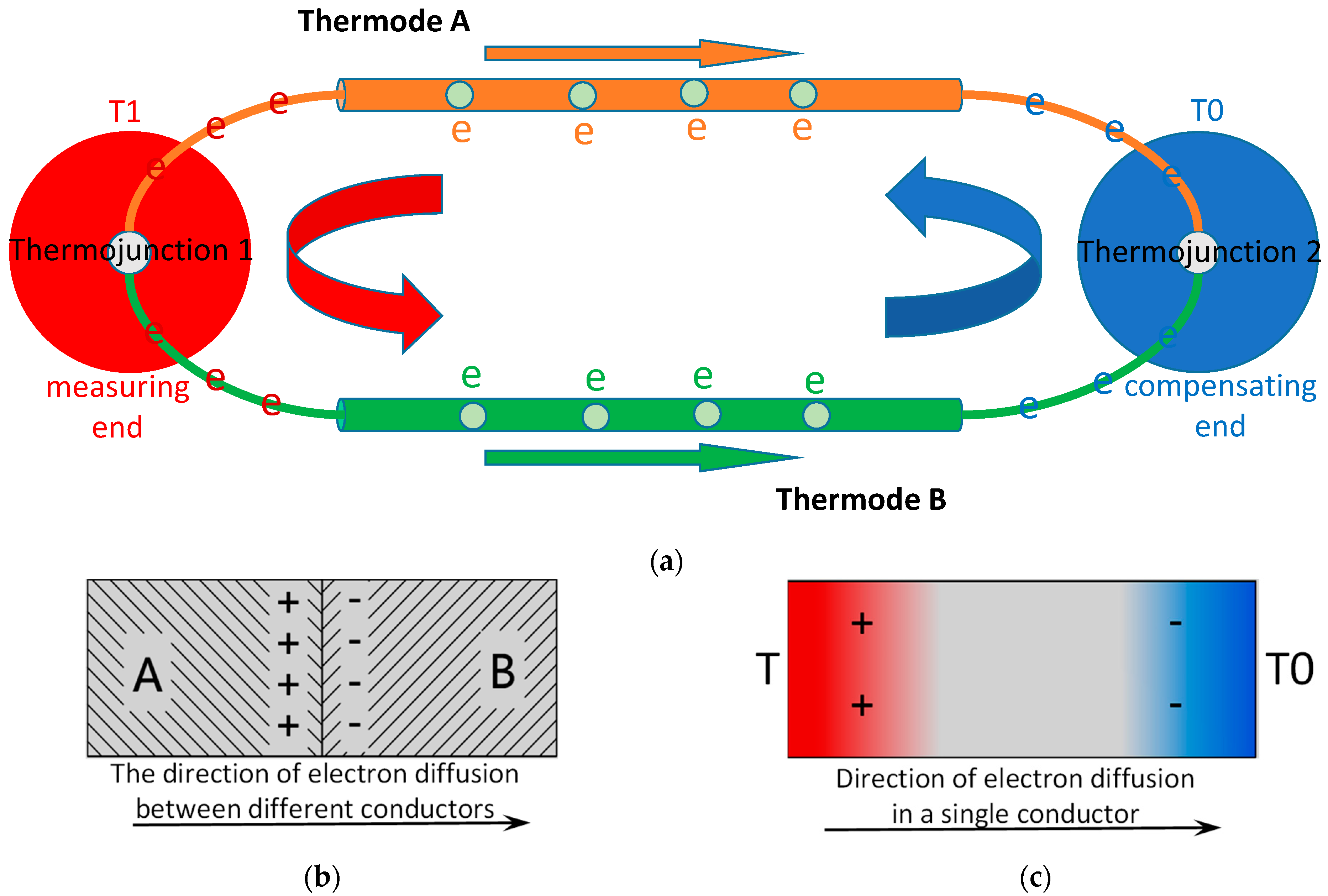

2.1. Working Principle

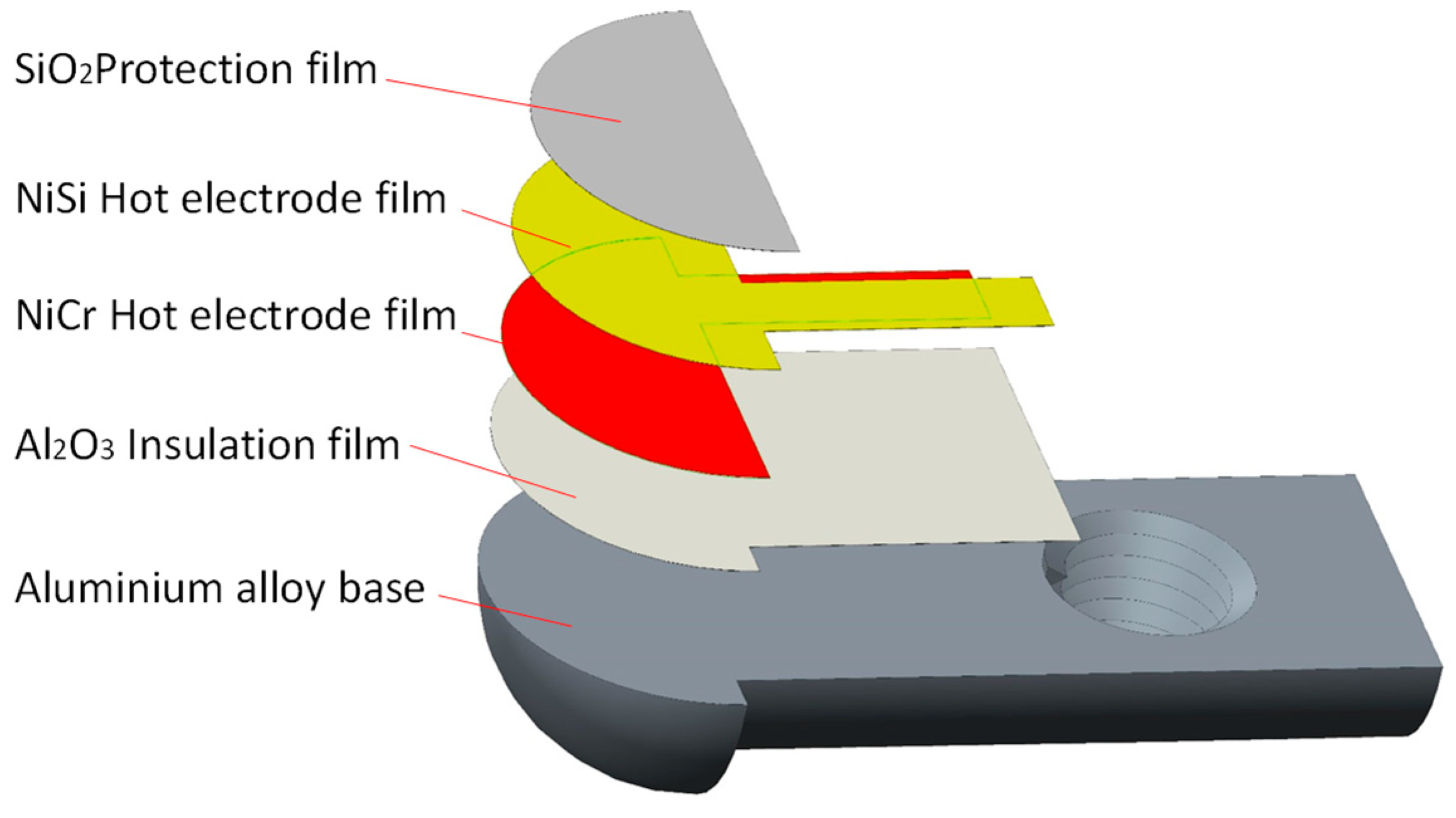

2.2. Structural Design

3. Development of Adaptive Thin-Film Thermocouple Temperature Sensor

3.1. Thin Film Temperature Sensor Function Film Preparation

3.1.1. Preparation of Al2O3 Insulating Film

3.1.2. Preparation of NiCr/ NiSi Functional Thin Films

3.1.3. Preparation of SiO2 Protective Film

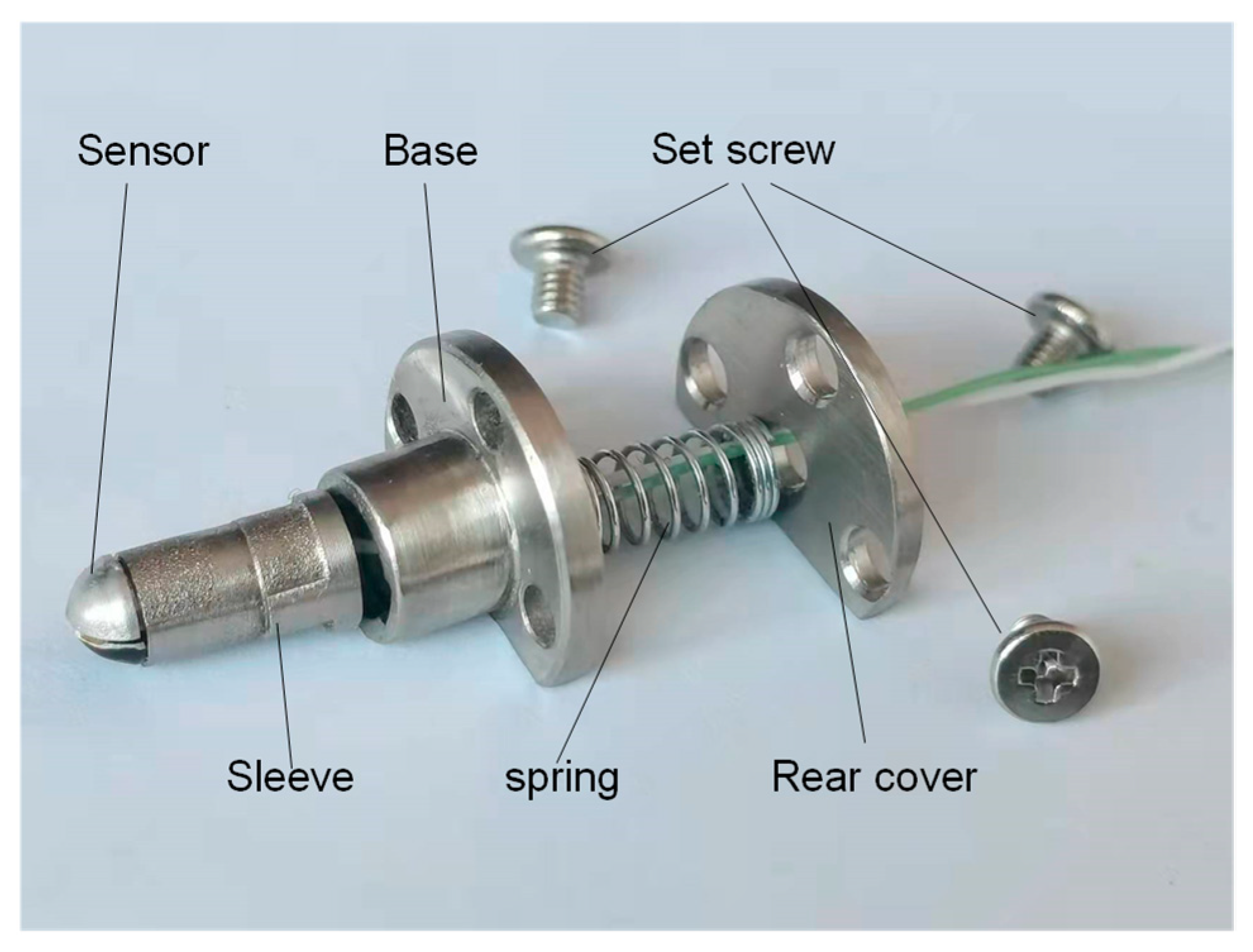

3.2. Lead-Film Mechanical Clamping Construction

3.3. Design of Sensor Adaptive Function

4. Results and Discussion

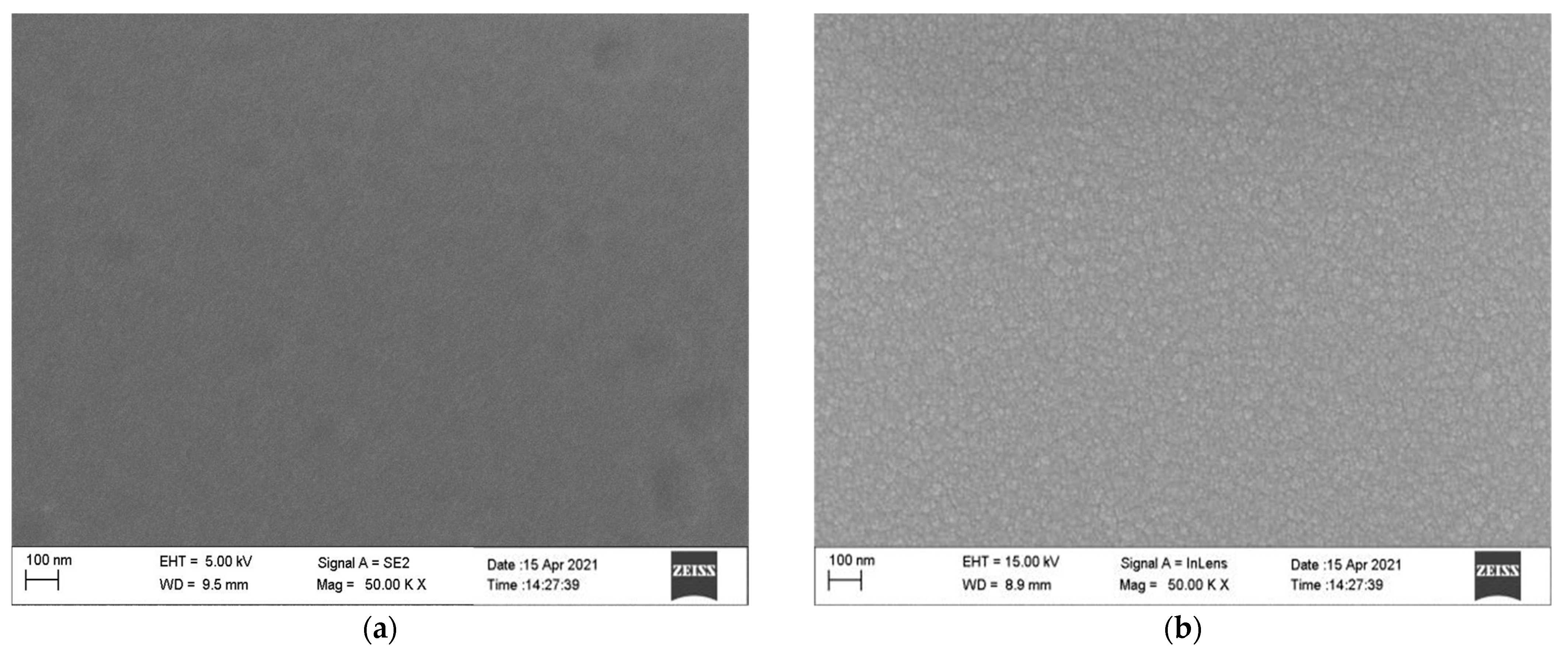

4.1. Surface Morphology Analysis of Thin Films

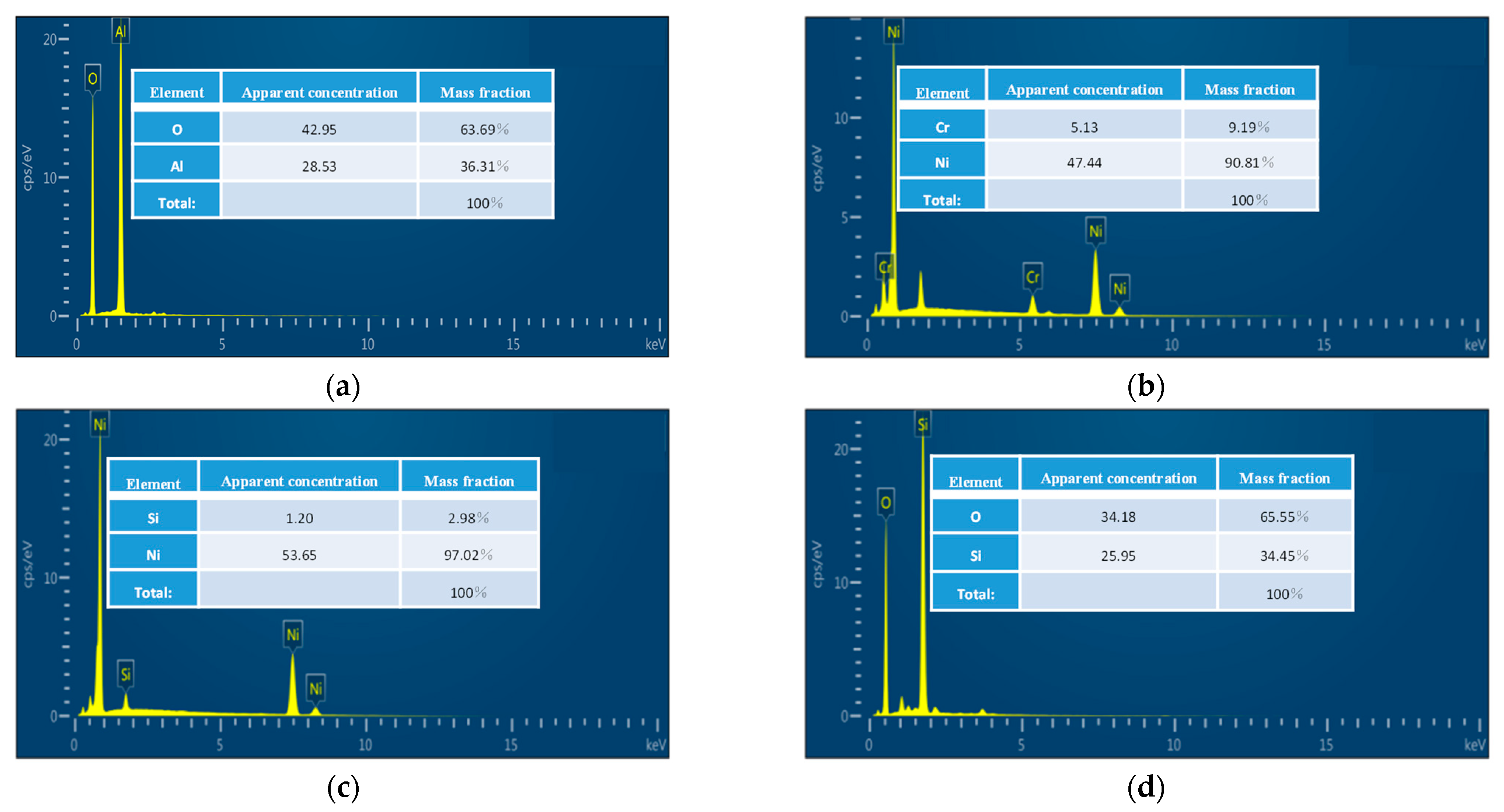

4.2. Composition Analysis of Thin Films

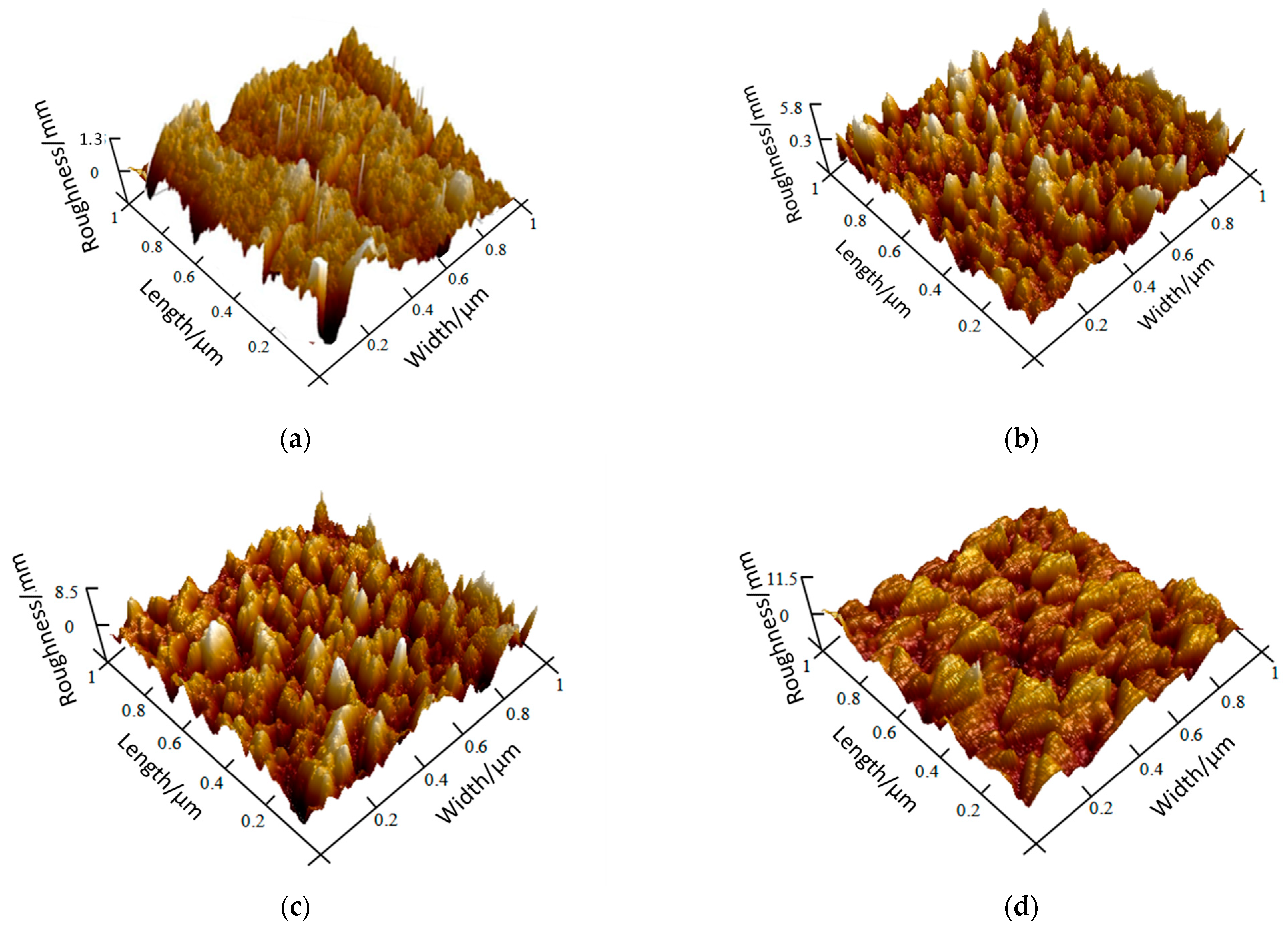

4.3. Surface Morphology and Roughness Analysis

4.4. Static Characteristic of Thin Film Thermocouple Temperature Sensor

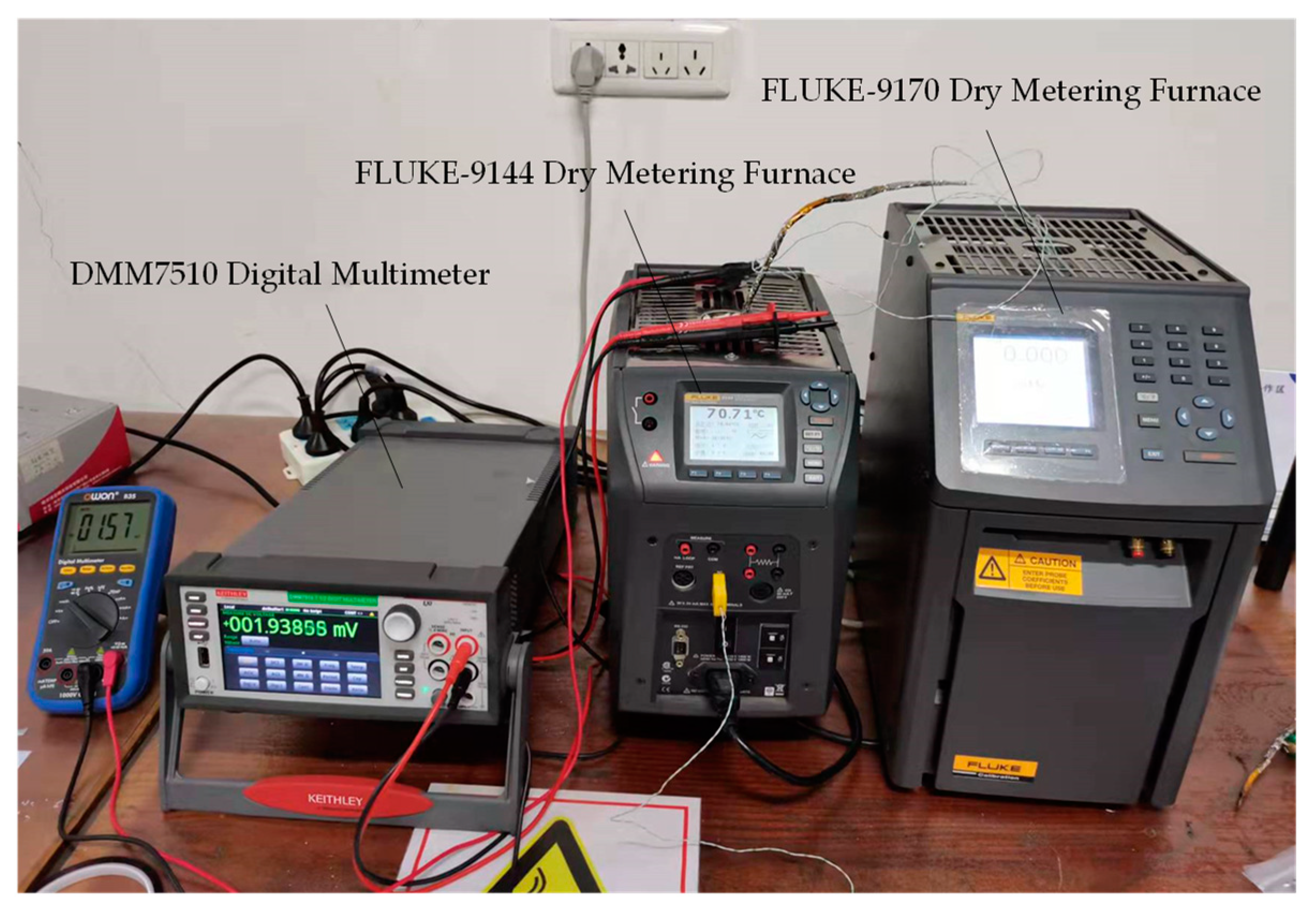

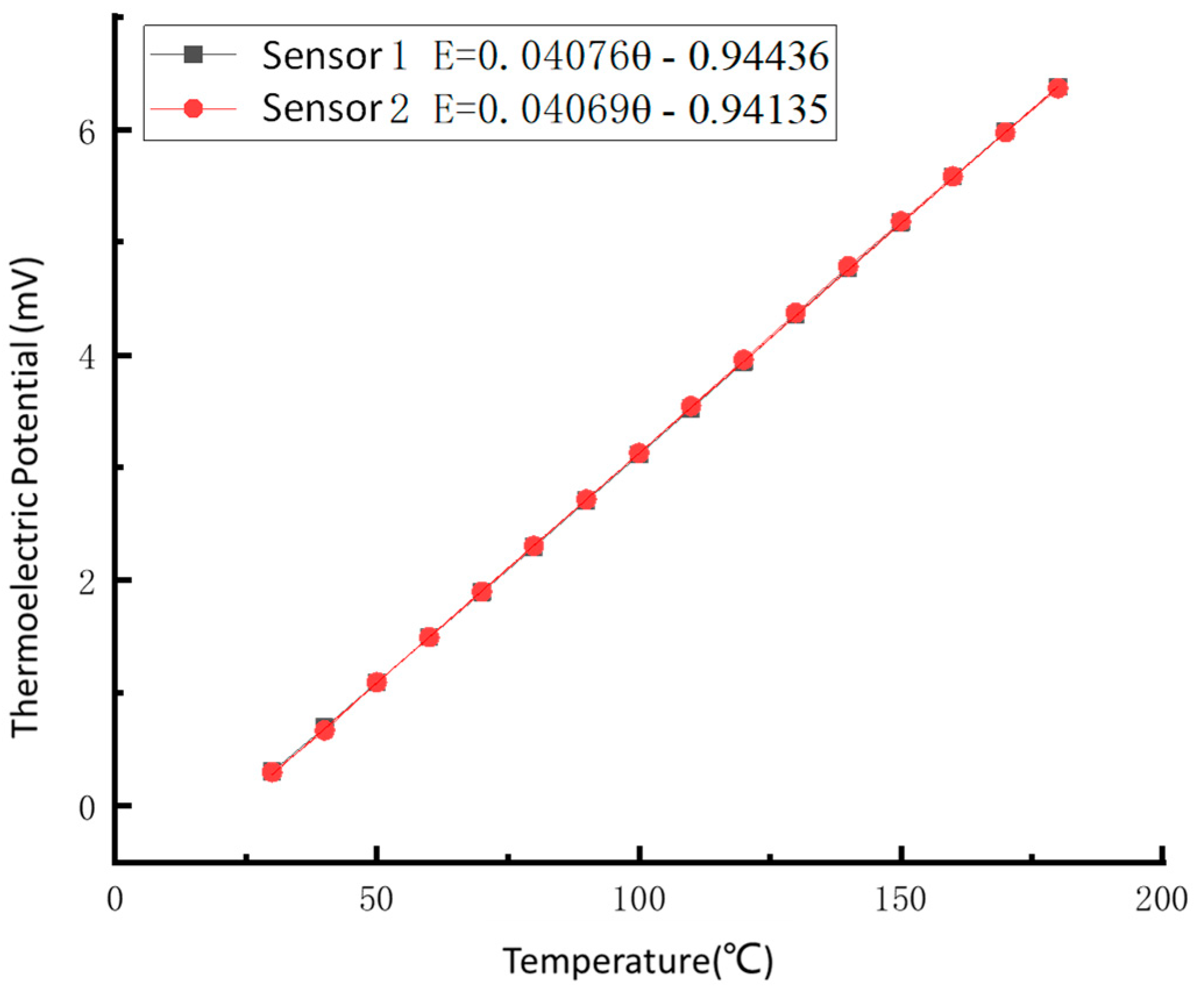

4.4.1. Static Calibration

4.4.2. Repetitive Experiment

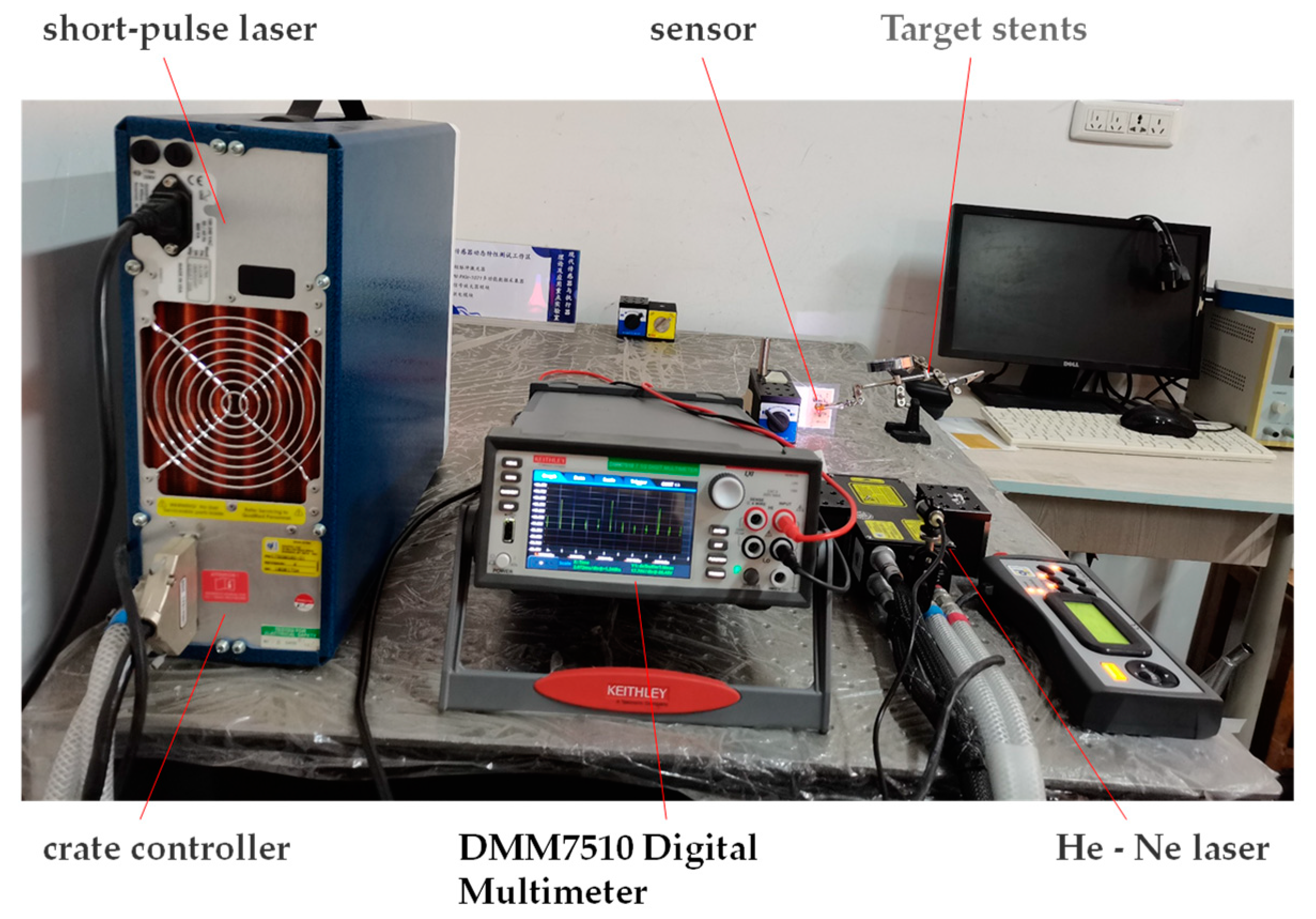

4.5. Dynamic Performance Test of Thin Film Thermocouple Temperature Sensor

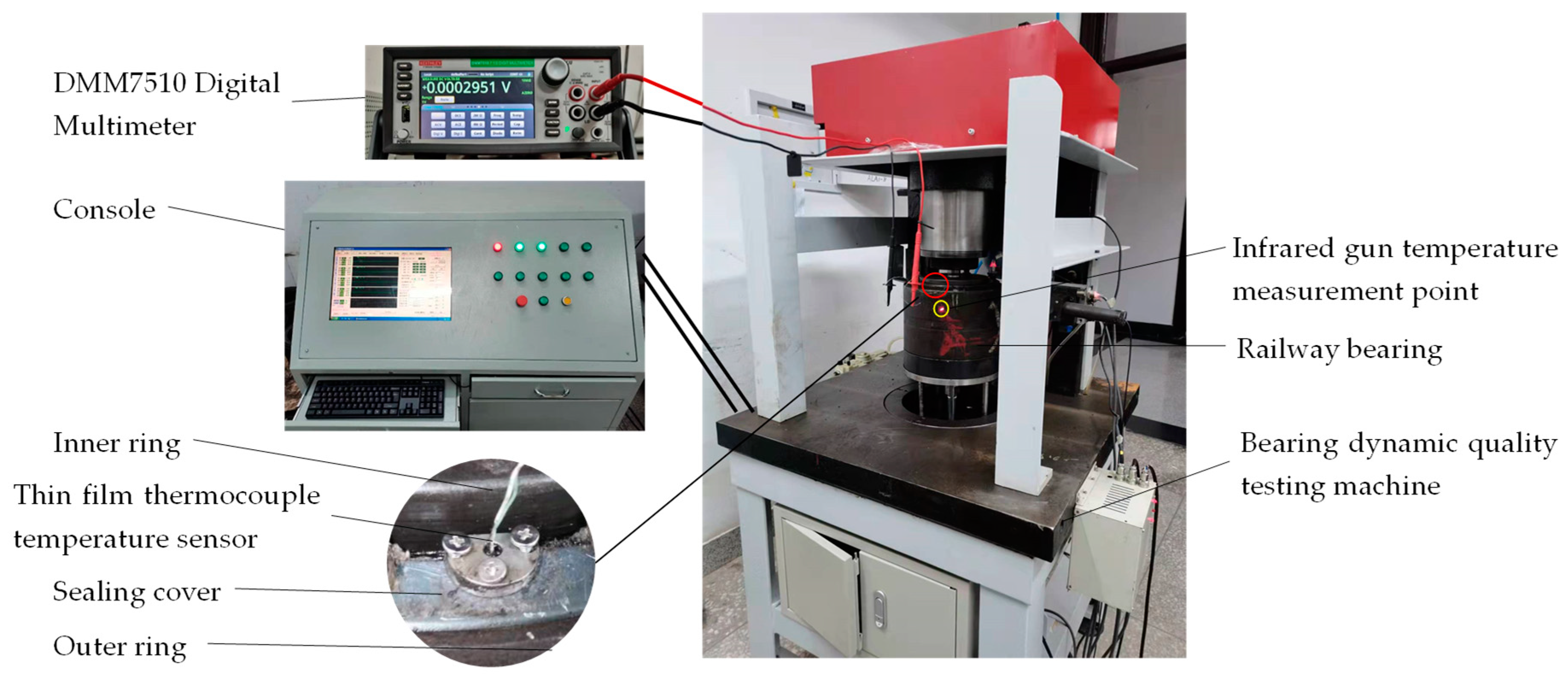

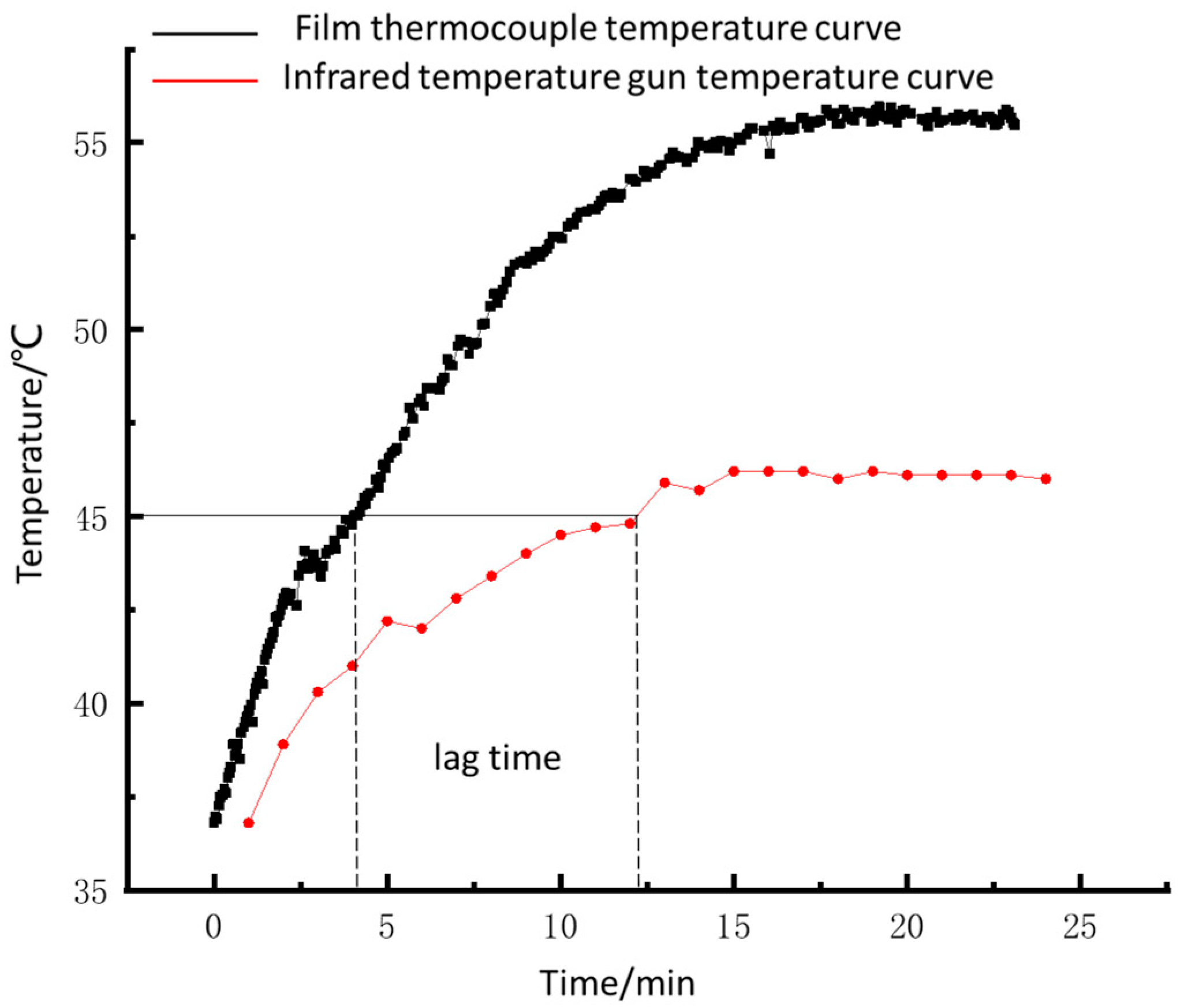

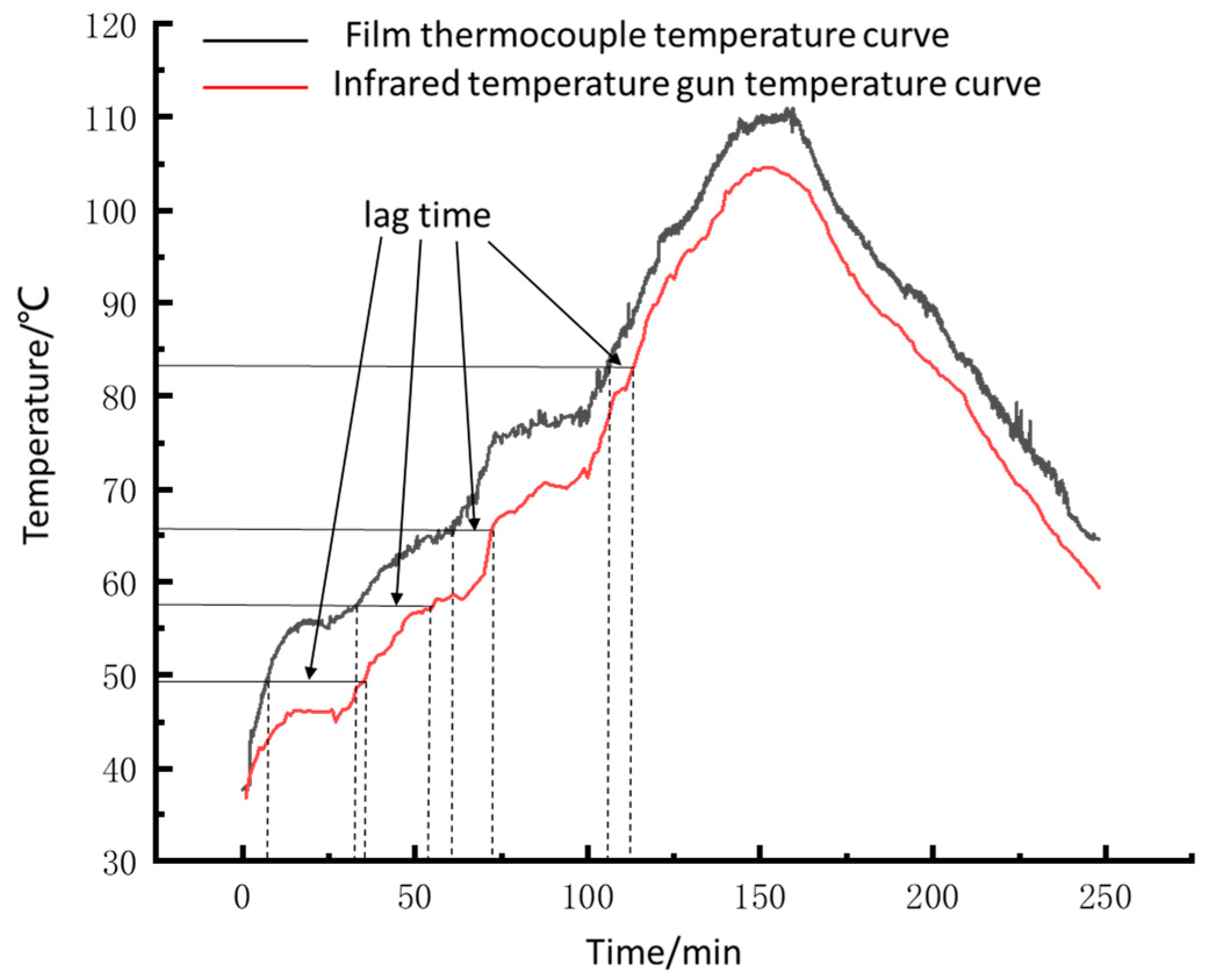

4.6. Temperature Measurement Experiment of Thin Film Thermocouple Temperature Sensor Bearing

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, H.; Jing, B. A Review of Fault Detection and Diagnosis for the Traction System in High-Speed Trains. IEEE Trans. Intell. Transp. Syst. 2019, 21, 450–465. [Google Scholar] [CrossRef]

- Li, Y.J. Research on Intelligent Fault Diagnosis Technique of Axle Box Bearing of High Speed Train; Southwest Jiaotong University: Chengdu, China, 2017. [Google Scholar]

- Yang, G.; Wu, N. Study on Safety and Reliability of CRH3 High-speed EMU Axle Temperature Monitoring System. Railw. Locomot. Car 2011, 31, 91–94. [Google Scholar] [CrossRef]

- Gao, R.X.; Holm-Hansen, B.T.; Wang, C. Design of a mechatronic bearing through sensor integration. Int. Soc. Opt. Eng. Proceeding 1998, 3518, 244–250. [Google Scholar] [CrossRef]

- Gao, R.X.; Jin, Y.; Warrington, R.O. Microcomputer-based real-time bearing monitor. IEEE Trans. Instrum. Meas. 1994, 43, 216–219. [Google Scholar] [CrossRef]

- Shao, Y.M.; Tu, W.B.; Zhou, X.J.; Ge, L. Intelligent Bearing Based on Embedded Multi-Parameter Sensor. China Mech. Eng. 2010, 21, 2527–2531. [Google Scholar]

- Shao, Y.M.; Tu, W.B.; Ye, J. Structure and Monitoring Capability Analysis of New Intelligent Bearing. Bearing 2012, 34, 27–31. [Google Scholar] [CrossRef]

- SKF. A New Bearing Condition Monitoring Technology—SKF Insight [EB/OL]. Available online: https://wenku.baidu.com/View/9c40a86387c24028905fc31a.html (accessed on 2 November 2013).

- Schaeffler. Schaeffler Puts Forward The Concept of Machine Tools—Moving Forward along the Digital Strategy [EB/OL]. Available online: http://www.cq361.com/question/1740 (accessed on 5 October 2015).

- Andreas, S. Bearings with Airborne Sensors [EB/OL]. Available online: https://mma.vogel.com.cn/c/2017-08-23/876615.shtml (accessed on 23 August 2017).

- Wang, F.Z.; Zhu, Y.Z.; Yan, K.; Hong, J. Wireless Monitoring Technology of Rolling Bearing Inner Ring Temperature. J. Mech. Eng. 2018, 54, 22–28. [Google Scholar] [CrossRef]

- Yan, K.; Gao, C.; Zhu, Y.S.; Hong, J. Research Technology the Temperature Measurement Principle and Realization Rolling Bearing Inner Ring Based on CdTe Quantum Dots. J. Mech. Eng. 2017, 53, 134–140. [Google Scholar] [CrossRef]

- Zhang, P.; Yan, K.; Pan, A.; Zhu, Y.; Hong, J.; Liang, P. Use of CdTe Quantum Dots as Heat Resistant Temperature Sensor for Bearing Rotating Elements Monitoring. IEEE J. Sel. Areas Commun. 2020, 38, 463–470. [Google Scholar] [CrossRef]

- Yan, K.; Yan, B.; Li, B.Q.; Hong, J. Investigation of bearing inner ring-cage thermal characteristics based on CdTe quantum dots fluorescence thermometry. Appl. Therm. Eng. 2017, 114, 279–286. [Google Scholar] [CrossRef]

- Yan, K.; Wang, N.; Zhai, Q.; Zhu, Y.; Zhang, J.; Niu, Q. Theoretical and experimental investigation on the thermal characteristics of double-row tapered roller bearings of high speed locomotive. Int. J. Heat Mass Transf. 2015, 84, 1119–1130. [Google Scholar] [CrossRef]

- Cui, Y.X. Research on NiCr/NiSi Thin Film Thermocouple Temperature Measuring Tool for Transient Cutting; Dalian University of Technology: Dalian, China, 2011; pp. 33–37. [Google Scholar]

- Ren, L.; Huang, F.L. Analysis and Prospect of Research Methods for Dynamic Characteristics of Temperature Sensor. Instrum. Technol. 2007, 2, 50–52. [Google Scholar] [CrossRef]

- Xi, Y.Y.; Sun, Y.F.; Hu, T.C.; Zhao, G.Y. Thermal and Vibration Mechanical Reliability of Multicoat Compound Thin-Film Thermocouple. Key Eng. Mater. 2021, 6138, 57–63. [Google Scholar] [CrossRef]

- Liu, Y.; Mitsutake, Y.; Monde, M. Development of fast response heat transfer measurement technique with thin-film thermocouples. Int. J. Heat Mass Transf. 2020, 162, 120331. [Google Scholar] [CrossRef]

- Yu, H.B.; Liu, F.M.; Wang, B.; Chen, C. China Standardization EMU Shaft Temperature Detection System. In Proceedings of the 10th China Intelligent Transportation Annual Conference, Wuxi, China, 4 November 2015. [Google Scholar]

| Feature Film | Background Vacuum (Pa) | Working Pressure (Pa) | Ar Flow (sccm) | O2 Flow (sccm) | Power (W) | Sputtering Time (H) |

|---|---|---|---|---|---|---|

| Al2O3 | 6.0 × 10−3 | 0.6 | 20 | 4 | 1000 | 3 |

| Feature Film | Background Vacuum (Pa) | Working Pressure (Pa) | Ar Flow (sccm) | Power (W) | Sputtering Time (min) |

|---|---|---|---|---|---|

| NiCr | 7.0 × 10−3 | 0.7 | 20 | 350 | 40 |

| NiSi | 7.0 × 10−3 | 0.7 | 20 | 350 | 39 |

| Feature Film | Background Vacuum (Pa) | Working Pressure (Pa) | Ar Flow (sccm) | O2 Flow (sccm) | Power (W) | Sputtering Time (min) |

|---|---|---|---|---|---|---|

| SiO2 | 6.0 × 10−3 | 0.6 | 20 | 10 | 600 | 120 |

| Temperature Value (℃) | Sensor 1 Thermoelectric Force(mV) | Sensor 2 Thermoelectric Force(mV) |

|---|---|---|

| 30 | 0.297 | 0.305 |

| 40 | 0.669 | 0.696 |

| 50 | 1.098 | 1.095 |

| 60 | 1.493 | 1.495 |

| 70 | 1.897 | 1.894 |

| 80 | 2.306 | 2.299 |

| 90 | 2.719 | 2.710 |

| 100 | 3.129 | 3.115 |

| 110 | 3.544 | 3.525 |

| 120 | 3.958 | 3.935 |

| 130 | 4.372 | 4.354 |

| 140 | 4.785 | 4.766 |

| 150 | 5.183 | 5.176 |

| 160 | 5.583 | 5.583 |

| 170 | 5.973 | 5.980 |

| 180 | 6.364 | 6.376 |

| Spindle Speed (r/min) | 400 | 600 | 800 | 1000 |

|---|---|---|---|---|

| temperature stabilization time (min) | 20 | 40 | 20 | 65 |

| sensor stabilization temperature (℃) | 55.8 | 66.8 | 77.6 | 110.3 |

| Infrared stabilization temperature (℃) | 46.4 | 58.2 | 70.5 | 103.8 |

| Temperature difference (℃) | 9.4 | 8.6 | 7.1 | 6.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Gao, P.; Tang, W.; Mo, G.; Yin, J. Adaptive Thin Film Temperature Sensor for Bearing’s Rolling Elements Temperature Measurement. Sensors 2022, 22, 2838. https://doi.org/10.3390/s22082838

Cui Y, Gao P, Tang W, Mo G, Yin J. Adaptive Thin Film Temperature Sensor for Bearing’s Rolling Elements Temperature Measurement. Sensors. 2022; 22(8):2838. https://doi.org/10.3390/s22082838

Chicago/Turabian StyleCui, Yunxian, Pengfei Gao, Wuchu Tang, Guowei Mo, and Junwei Yin. 2022. "Adaptive Thin Film Temperature Sensor for Bearing’s Rolling Elements Temperature Measurement" Sensors 22, no. 8: 2838. https://doi.org/10.3390/s22082838

APA StyleCui, Y., Gao, P., Tang, W., Mo, G., & Yin, J. (2022). Adaptive Thin Film Temperature Sensor for Bearing’s Rolling Elements Temperature Measurement. Sensors, 22(8), 2838. https://doi.org/10.3390/s22082838