Voltage and Current Sensor Fault Diagnosis Method for Traction Converter with Two Stator Current Sensors

Abstract

:1. Introduction

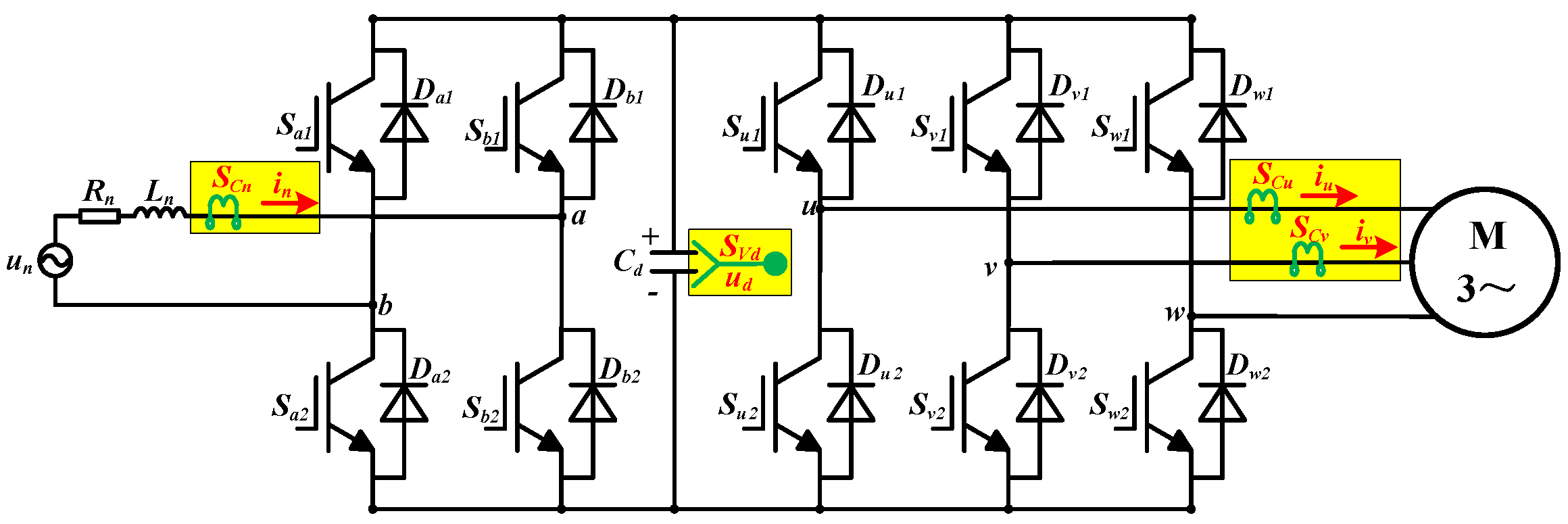

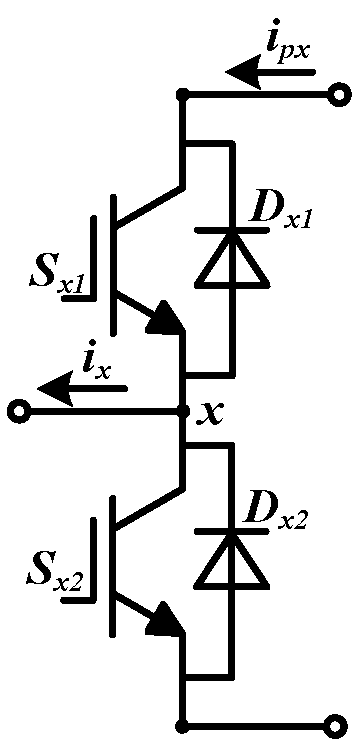

2. Converter Topology and DC-link Model

2.1. Converter Topology

2.2. DC-Link Model

3. Fault Analysis and Diagnosis

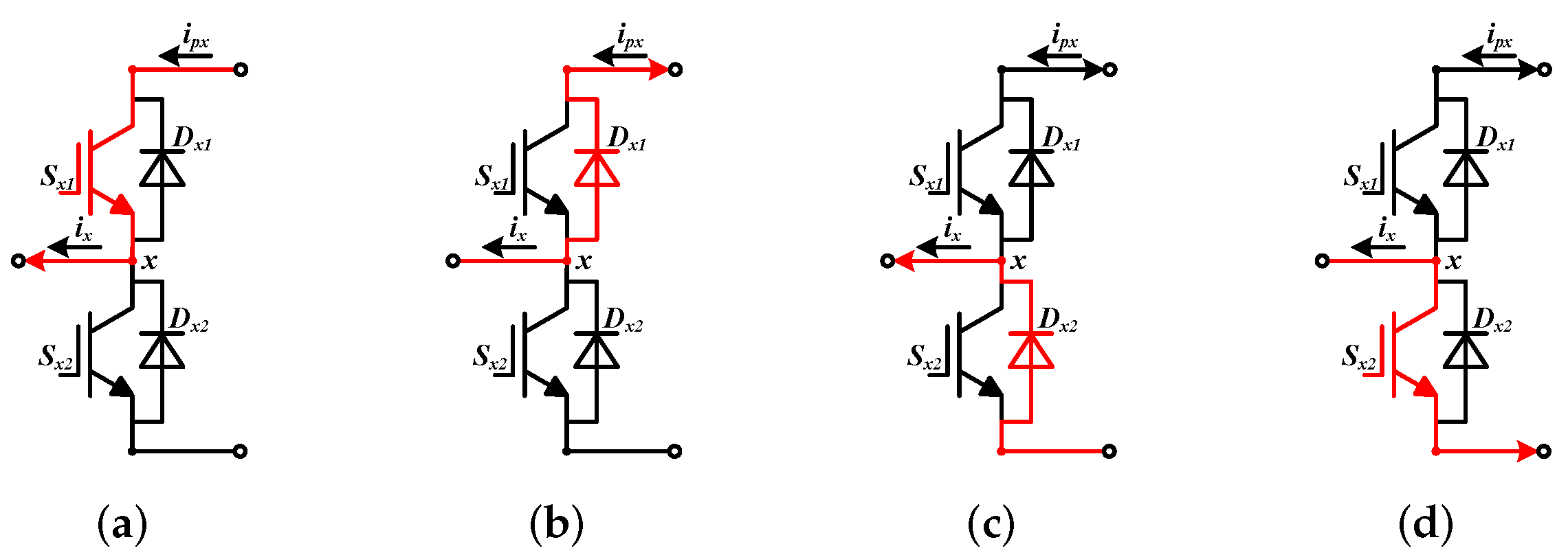

3.1. Sensor Fault Analysis

3.2. Fault Detection

3.3. Fault Diagnosis

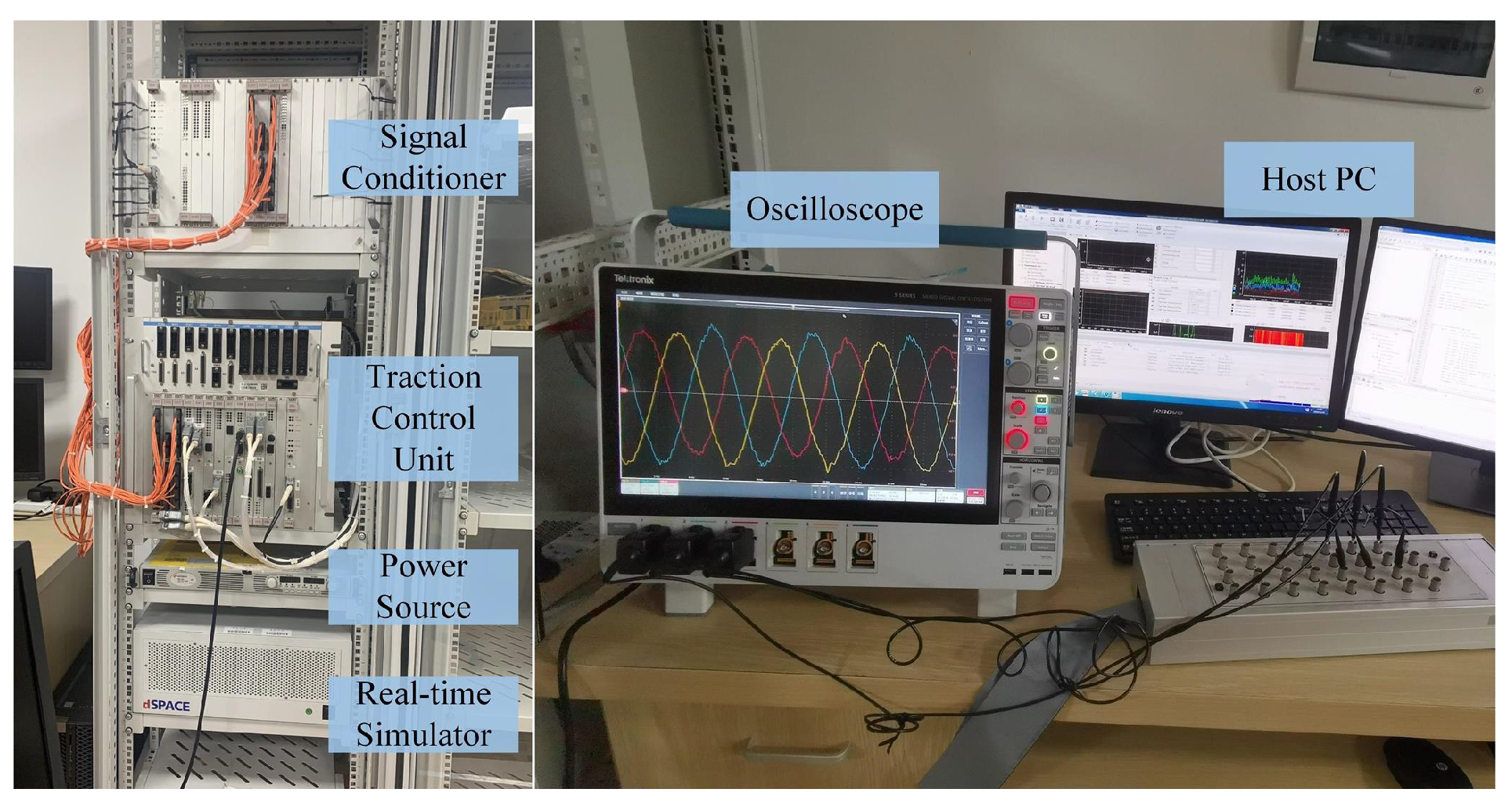

4. HIL Results

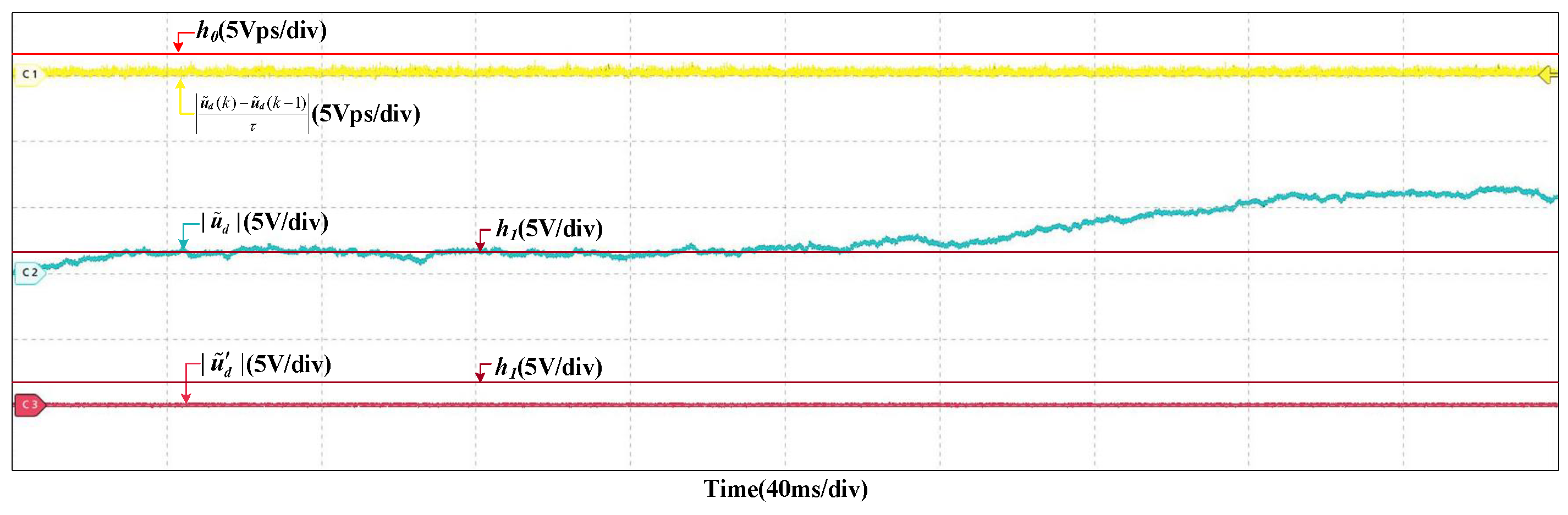

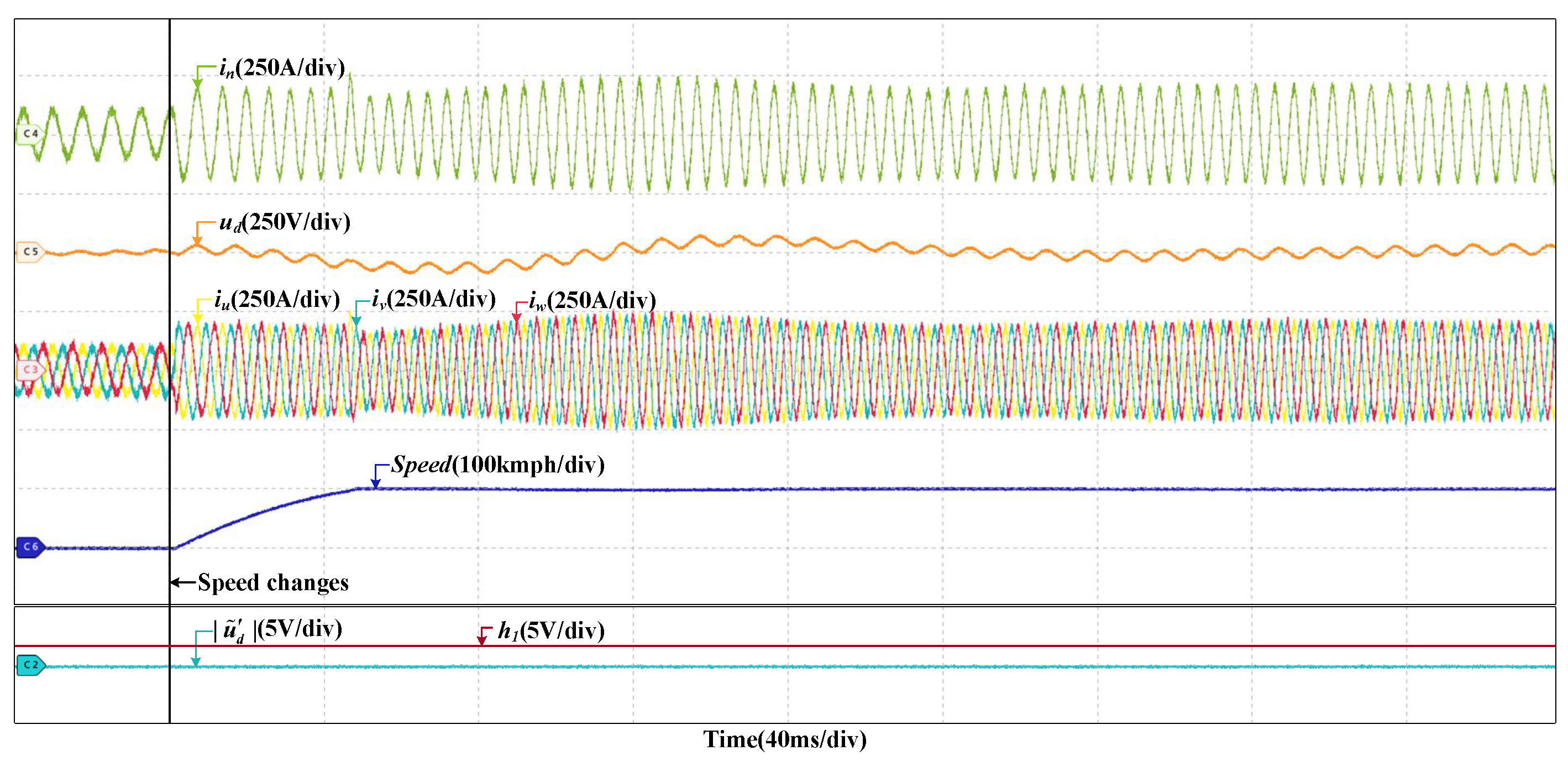

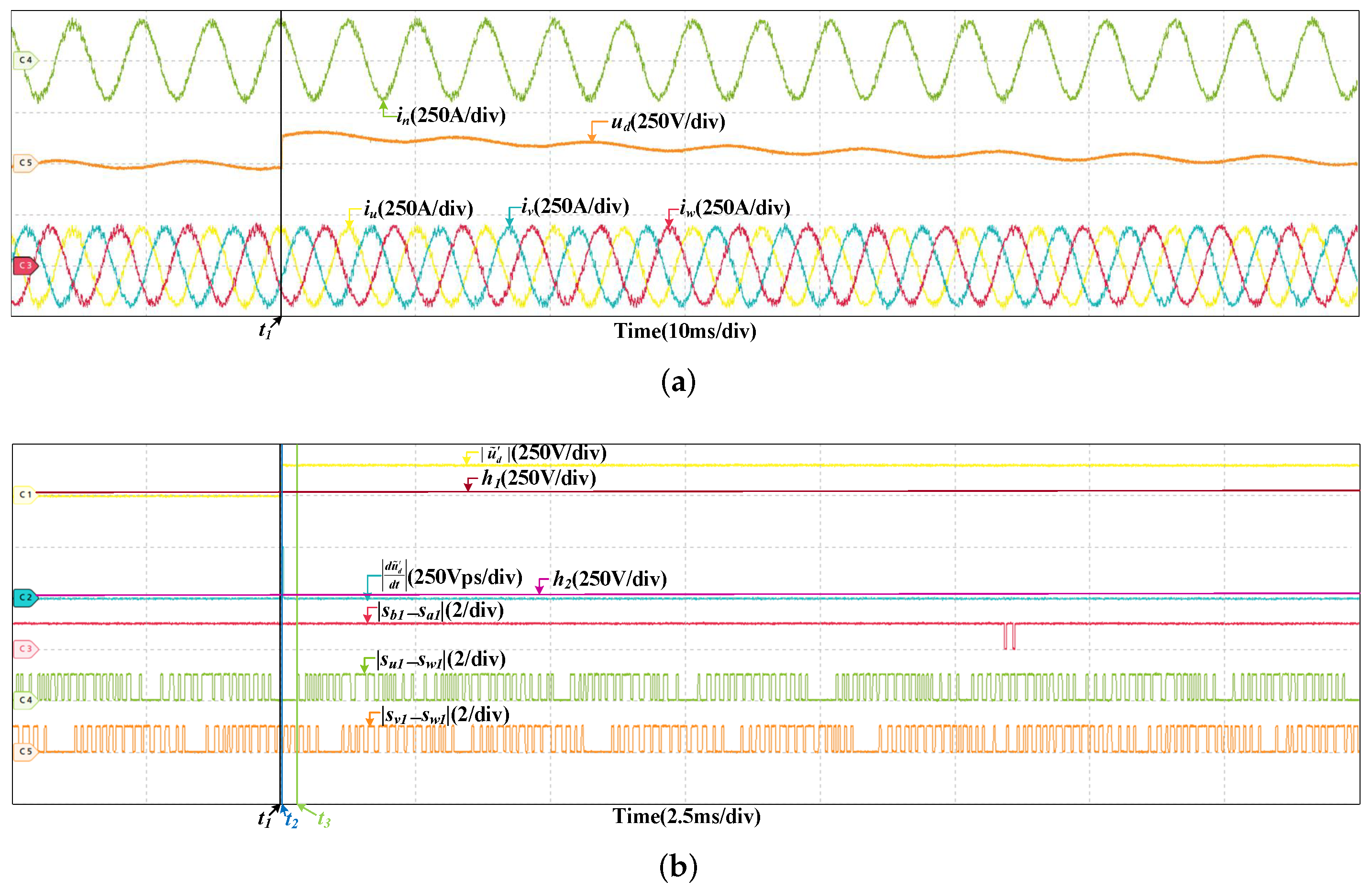

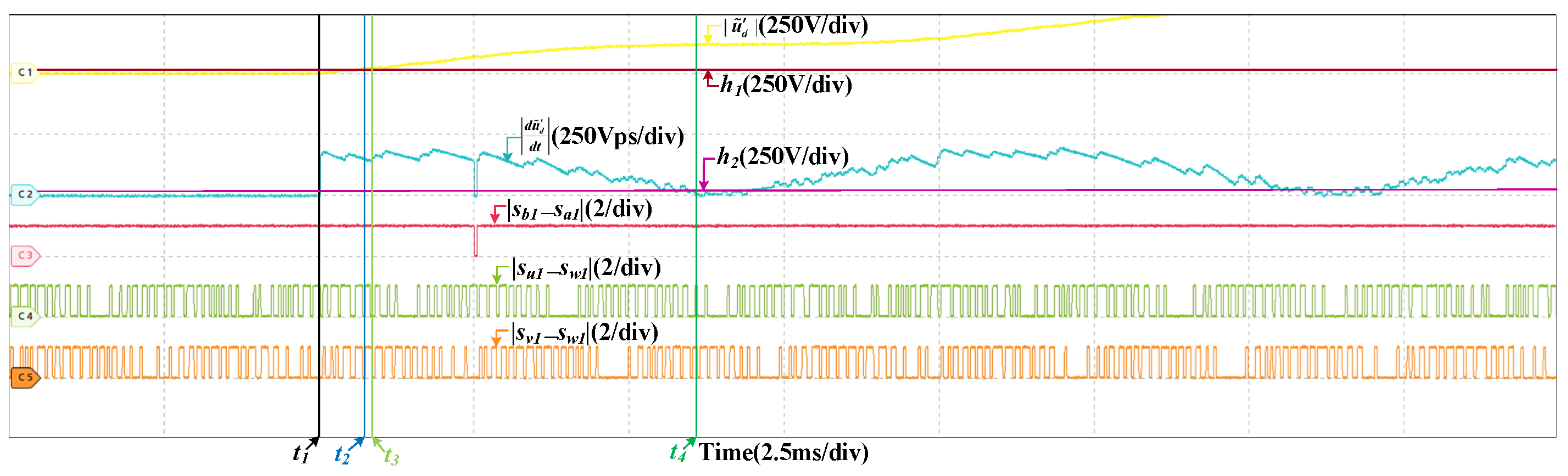

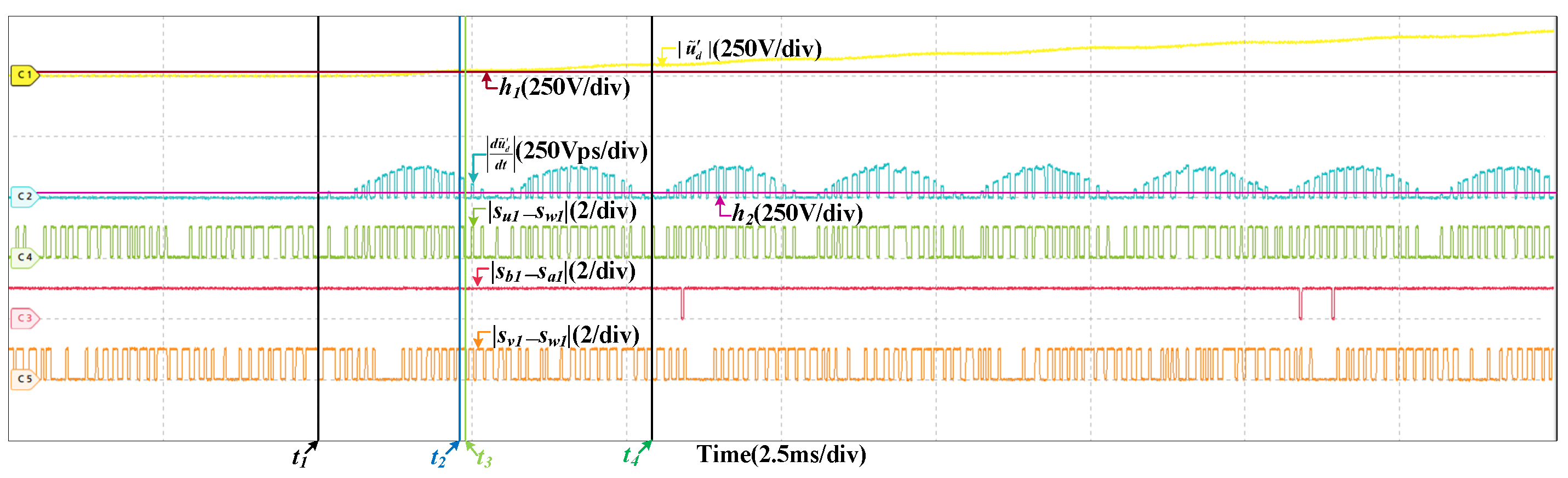

4.1. Fault in DC-Link Voltage Sensor

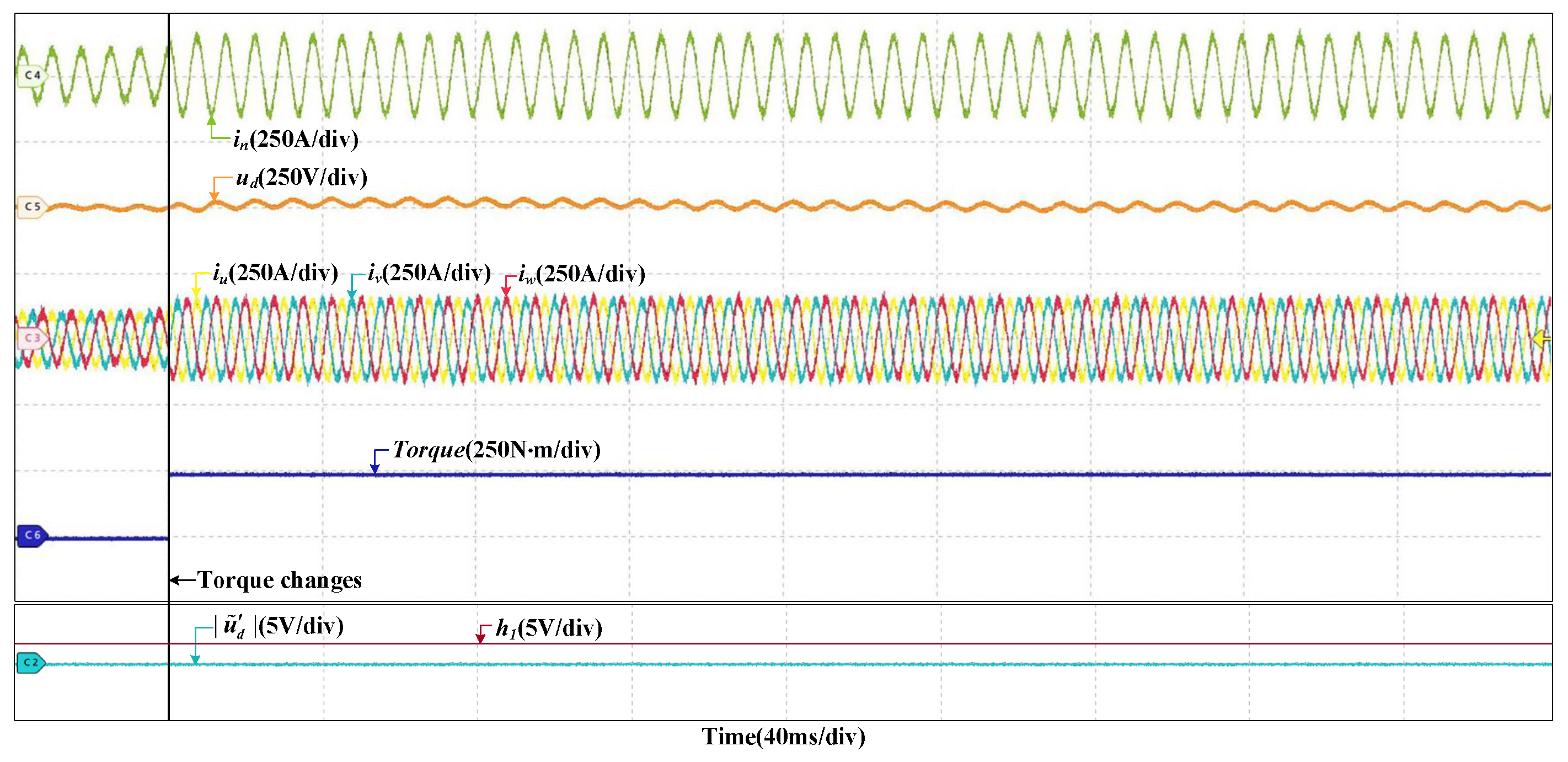

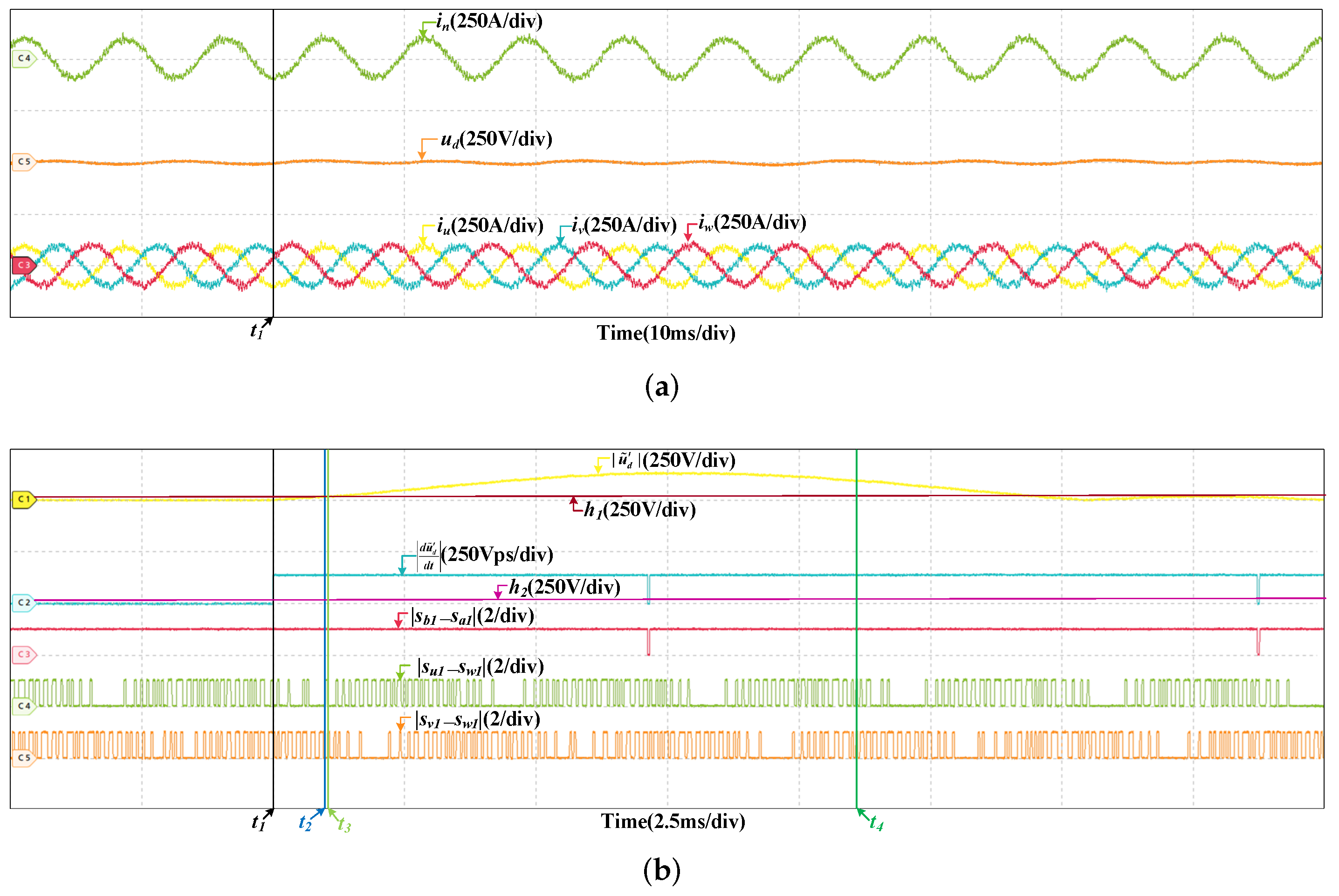

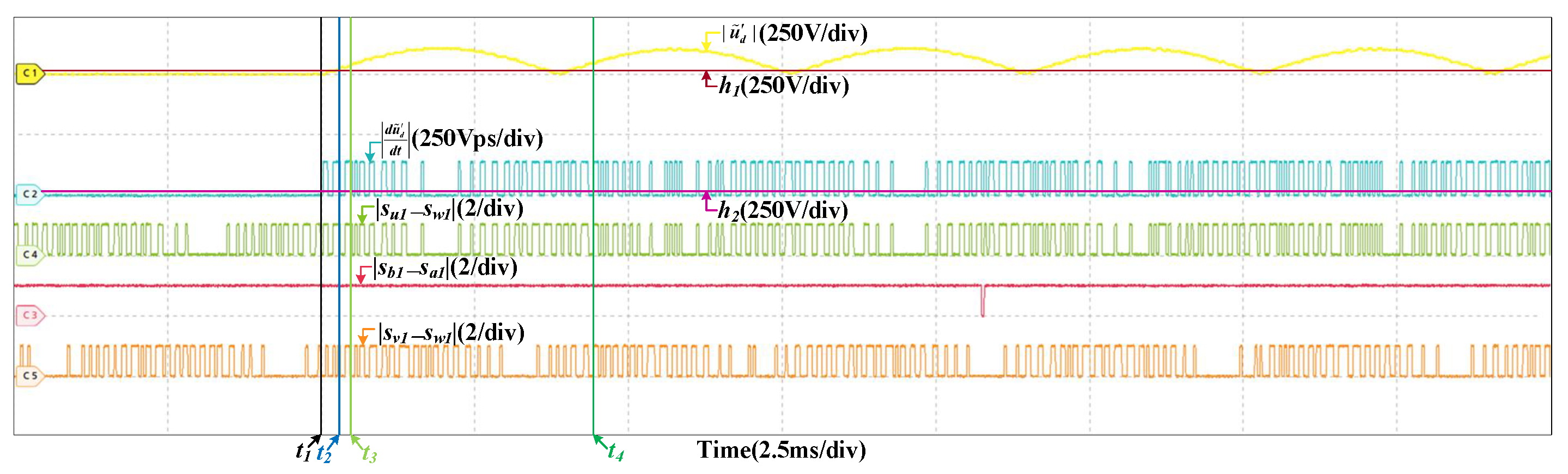

4.2. Fault in Grid Current Sensor

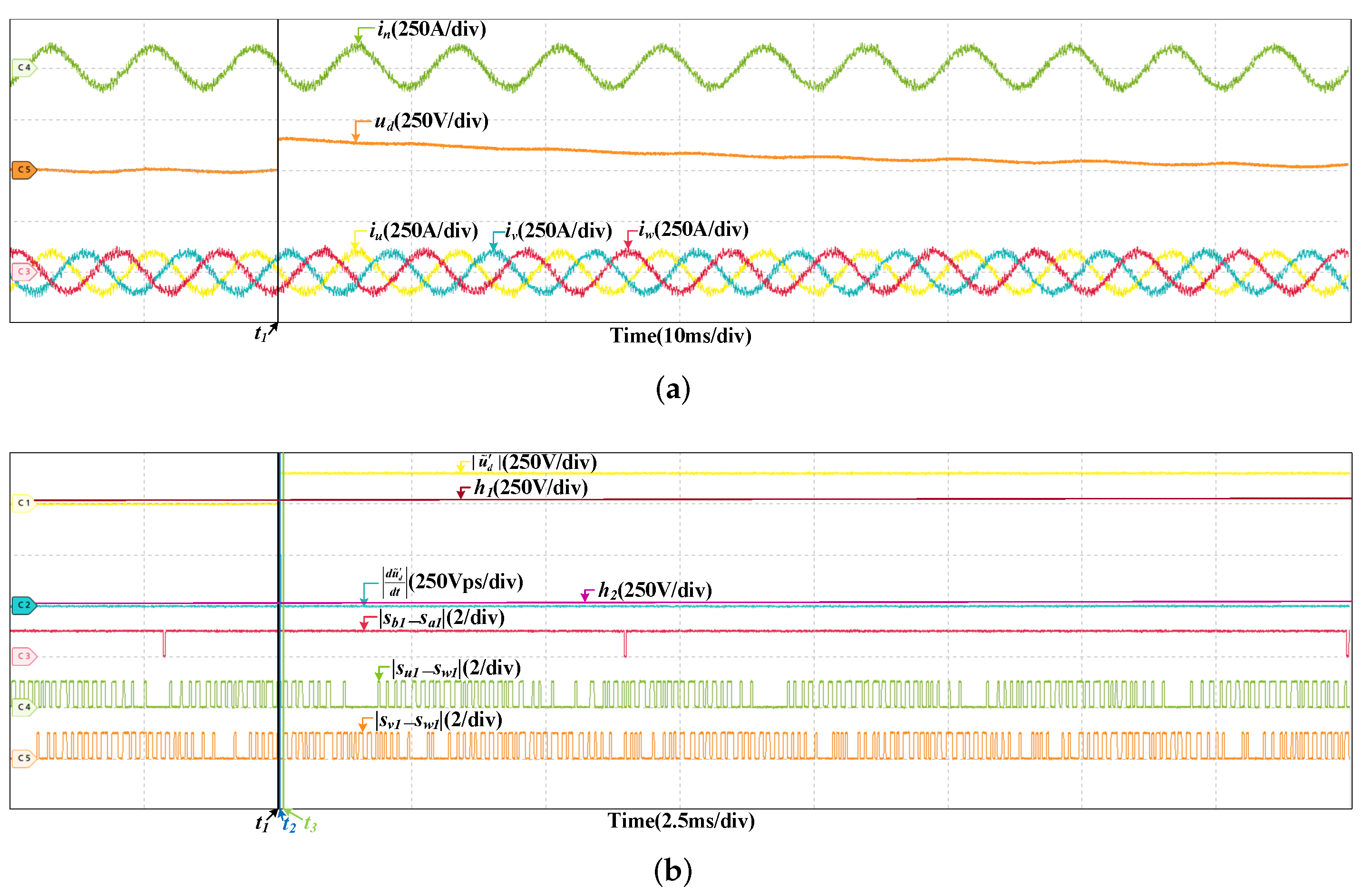

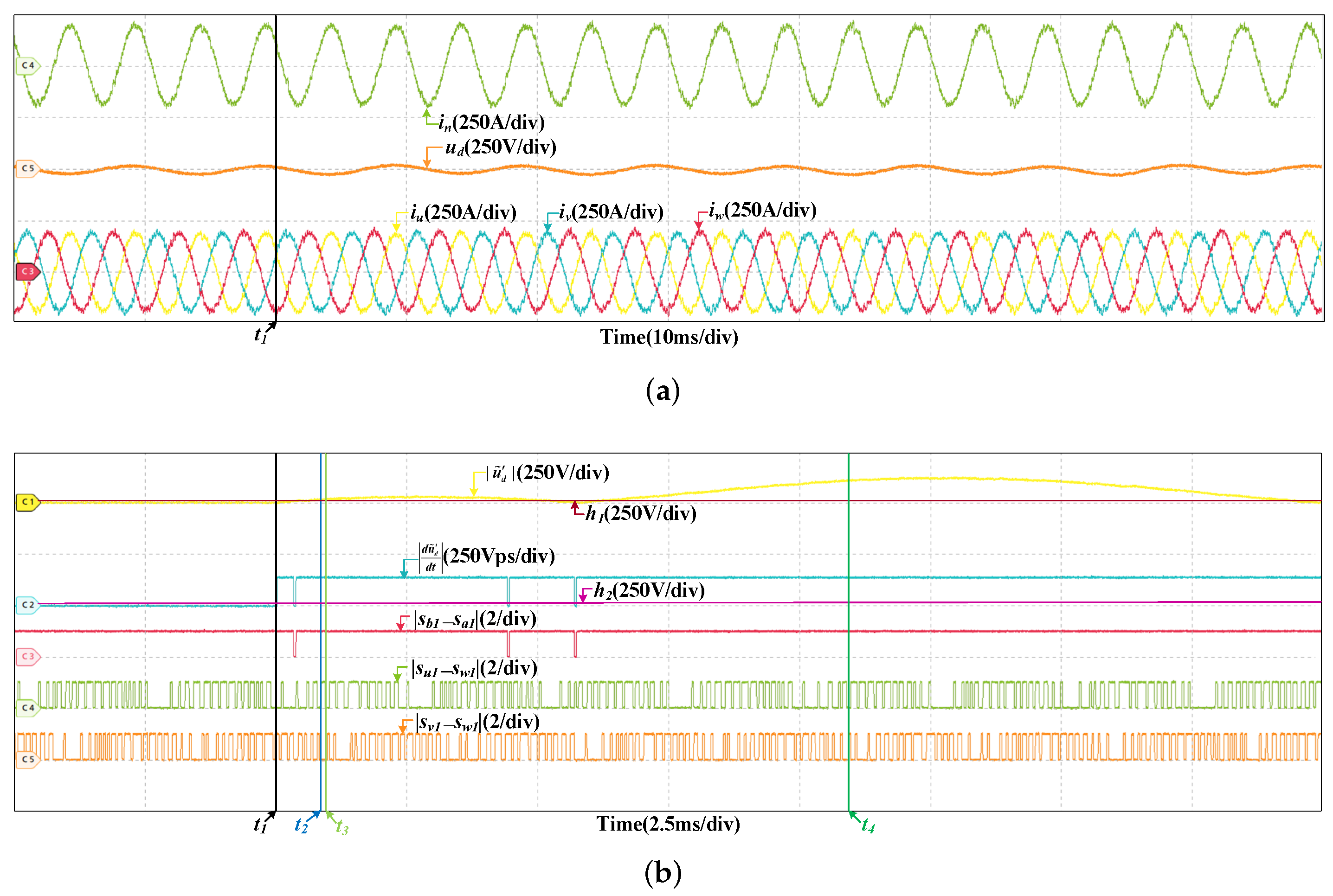

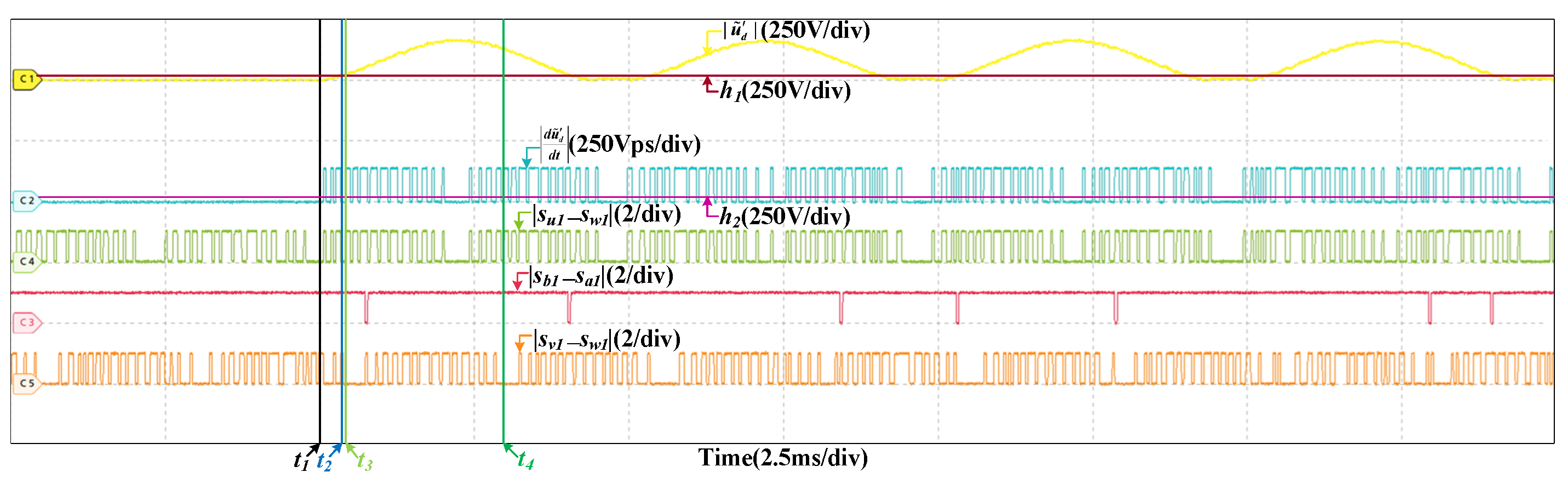

4.3. Fault in Stator Current Sensors

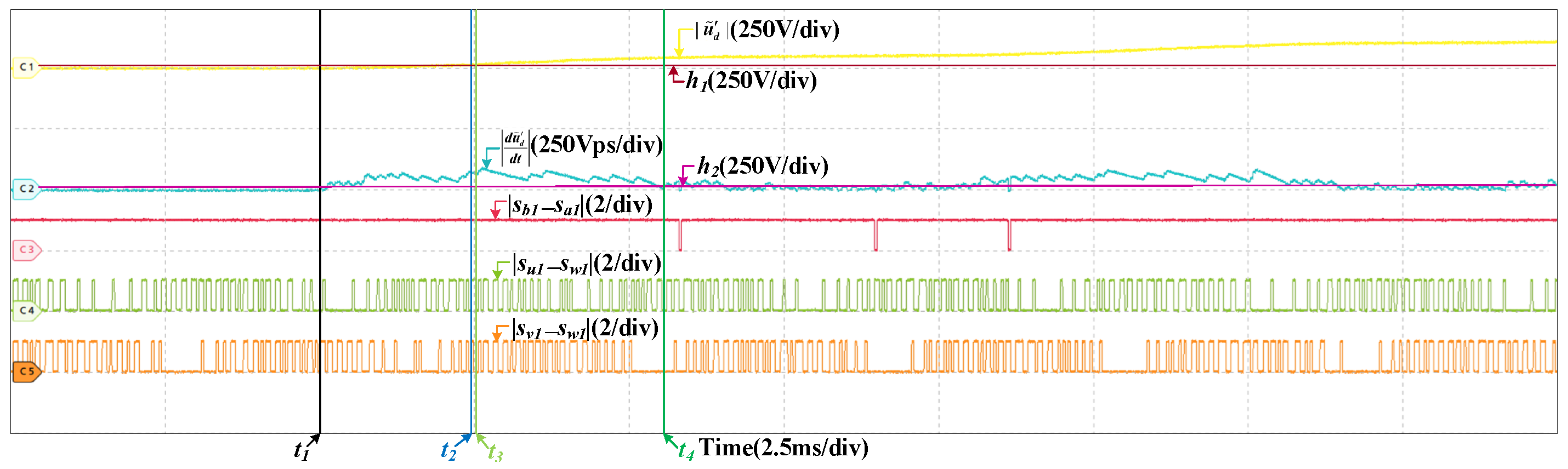

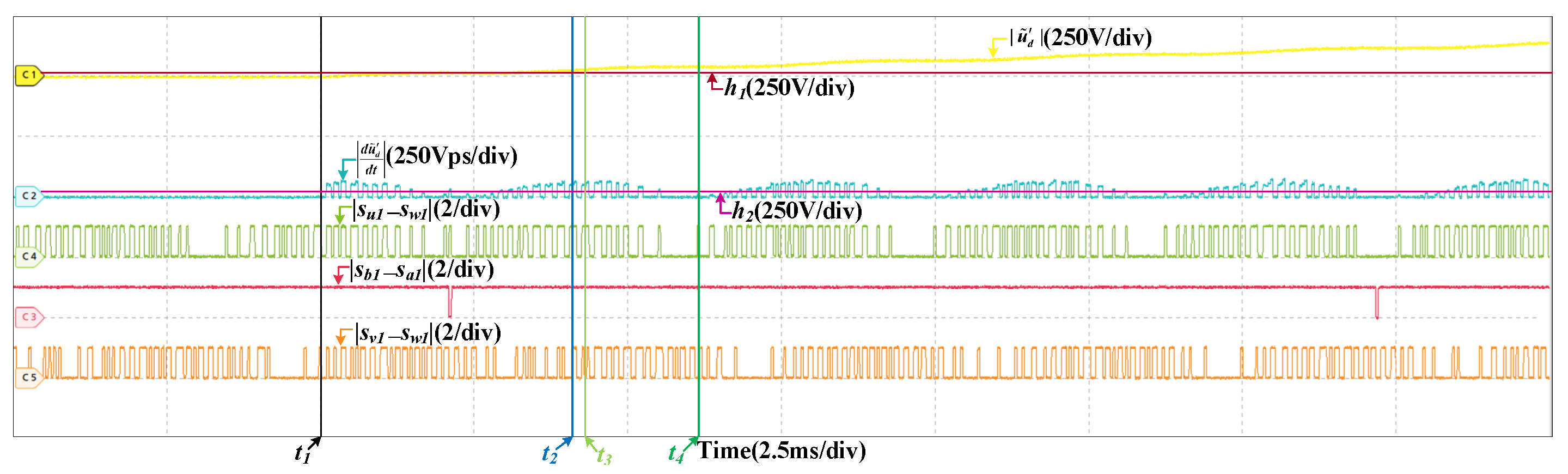

4.4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, D.; Ji, H.; He, X.; Shang, J. Fault detection and isolation of the brake cylinder system for electric multiple units. IEEE Trans. Control Syst. Technol. 2018, 26, 1744–1757. [Google Scholar] [CrossRef]

- Peng, T.; Tao, H.; Yang, C.; Chen, Z.; Yang, C.; Gui, W.; Karimi, H.R. A uniform modeling method based on open-circuit faults analysis for NPC-three-level converter. IEEE Trans. Circuits Syst. II-Express Briefs 2019, 66, 457–461. [Google Scholar] [CrossRef]

- Yang, X.; Qiao, X.; Cheng, C.; Zhong, K.; Chen, H. A tutorial on hHardware-implemented fault injection and online fault diagnosis for high-speed trains. Sensors 2021, 27, 5957. [Google Scholar] [CrossRef] [PubMed]

- Tao, H.; Peng, T.; Yang, C.; Chen, Z.; Yang, C.; Gui, W. Open-circuit fault analysis and mModeling for power converter based on single arm model. Electronics 2019, 8, 633. [Google Scholar] [CrossRef] [Green Version]

- Foo, G.H.B.; Zhang, X.; Vilathgamuwa, D.M. A sensor fault detection and isolation method in interior permanent-magnet synchronous motor drives based on an extended Kalman filter. IEEE Trans. Ind. Electron. 2013, 60, 3485–3495. [Google Scholar] [CrossRef]

- Jan, S.U.; Lee, Y.; Shin, J.; Koo, I. Sensor fault classification based on support vector machine and statistical time-domain features. IEEE Trans. Ind. Electron. 2013, 60, 3485–3495. [Google Scholar] [CrossRef]

- Wu, F.; Zhao, J. A real-time multiple open-circuit fault diagnosis method in voltage-source-inverter fed vector controlled drives. IEEE Trans. Power Electron. 2016, 31, 1425–1437. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, B. A review of fault detection and diagnosis for the traction system in high-speed trains. IEEE Trans. Intell. Transp. Syst. 2020, 21, 45–465. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, B.; Ding, S.X.; Huang, B. Data-driven fault diagnosis for traction systems in high-speed trains: A survey, challenges, and perspectives. IEEE Trans. Intell. Transp. Syst. 2022, 23, 1700–1716. [Google Scholar] [CrossRef]

- Xia, Y.; Xu, Y.; Gou, B. Current sensor fault diagnosis and faulttolerant control for single-phase PWM rectifier based on a hybrid model-based and datadriven method. IET Power Electron. 2020, 13, 4150–4157. [Google Scholar] [CrossRef]

- Li, X.; Xu, J.; Chen, Z.; Xu, S.; Liu, K. Real-time fault diagnosis of pulse rectifier in traction system based on structural model. IEEE Trans. Intell. Transp. Syst. 2022, 23, 2130–2143. [Google Scholar] [CrossRef]

- Youssef, A.B.; Khil, S.K.E.; Slama-Belkhodja, I. State observer-based sensor fault detection and isolation, and fault tolerant control of a single-phase PWM rectifier for electric railway traction. IEEE Trans. Power Electron. 2013, 28, 5842–5853. [Google Scholar] [CrossRef]

- Xia, J.; Guo, Y.; Dai, B.; Zhang, X. Sensor fault diagnosis and system reconfiguration approach for an electric traction PWM rectifier based on sliding mode observer. IEEE Trans. Ind. Appl. 2017, 53, 4768–4778. [Google Scholar] [CrossRef]

- Zhao, K.; Li, P.; Zhang, C.; Li, X.; He, J.; Lin, Y. Sliding mode observer-based current sensor fault reconstruction and unknown load disturbance estimation for PMSM driven system. Sensor 2017, 17, 2833. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Zhao, Y.; Wang, B.; Huang, X.; Xu, D. Current sensor fault diagnosis and tolerant control for VSI-based induction motor drives. IEEE Trans. Power Electron. 2018, 33, 4238–4248. [Google Scholar] [CrossRef]

- Huang, G.; Luo, Y.; Zhang, C.; He, J.; Huang, Y. Current sensor fault reconstruction for PMSM drives. Sensor 2016, 16, 178. [Google Scholar] [CrossRef]

- Manohar, M.; Das, S. Current sensor fault-tolerant control for direct torque control of induction motor drive using flux-linkage observer. IEEE Trans. Ind. Informat. 2017, 13, 2824–2833. [Google Scholar] [CrossRef]

- Berriri, H.; Naouar, M.W.; Slama-Belkhodja, I. Easy and fast sensor fault detection and isolation algorithm for electrical drives. IEEE Trans. Power Electron. 2012, 27, 490–499. [Google Scholar] [CrossRef]

- Salmasi, F.R. A self-healing induction motor drive with model free sensor tampering and sensor fault detection, isolation, and compensation. IEEE Trans. Ind. Electron. 2017, 64, 6105–6115. [Google Scholar] [CrossRef]

- Jlassi, I.; Estima, J.O.; Khil, S.K.E.; Bellaaj, N.M.; Cardoso, A.J.M. A robust observer-based method for IGBTs and current sensors fault diagnosis in voltage-source inverters of PMSM drives. IEEE Trans. Ind. Appl. 2017, 53, 2894–2905. [Google Scholar] [CrossRef]

- Dybkowski, M.; Klimkowski, K. Artificial neural network application for current sensors fault detection in the vector controlled induction motor drive. Sensors 2019, 19, 571. [Google Scholar] [CrossRef] [Green Version]

- Gou, B.; Xu, Y.; Xia, Y.; Deng, Q.; Ge, X. An online data-driven method for simultaneous diagnosis of IGBT and current sensor fault of three-phase PWM inverter in induction motor drives. IEEE Trans. Power Electron. 2020, 35, 13281–13294. [Google Scholar] [CrossRef]

- Li, Z.; Wheeler, P.; Watson, A.; Costabeber, A.; Wang, B.; Ren, Y.; Bai, Z.; Ma, H. A fast diagnosis method for both IGBT faults and current sensor faults in grid-tied three-phase inverters with two current sensors. IEEE Trans. Power Electron. 2020, 35, 5267–5278. [Google Scholar] [CrossRef]

- Dan, H.; Yue, W.; Xiong, W.; Liu, Y.; Su, M.; Sun, Y. Open-switch and current sensor fault diagnosis strategy for matrix converter based PMSM drive system. IEEE Trans. Transp. Electrif. 2021. [Google Scholar] [CrossRef]

- Trinh, Q.N.; Wang, P.; Tang, Y.; Koh, L.H.; Choo, F.H. Compensation of DC offset and scaling errors in voltage and current measurements of three-phase AC/DC converters. IEEE Trans. Power Electron. 2018, 33, 5401–5414. [Google Scholar] [CrossRef]

- Kim, M.; Peng, T.; Sul, S.; Chen, Z.; Lee, J. Compensation of current measurement error for current-controlled PMSM drives. IEEE Trans. Ind. Appl. 2014, 50, 3365–3373. [Google Scholar] [CrossRef]

| Fault Diagnosis Rules | Fault Location | Fault Type |

|---|---|---|

| None | None | |

| ; ; | Offset fault | |

| ; ; | Offset fault | |

| ; ; | Scaling fault | |

| ; ; | Offset fault | |

| ; ; | Scaling fault | |

| ; ; | Offset fault | |

| ; ; | Scaling fault |

| Parameter | Symbol | Value |

|---|---|---|

| RMS grid voltage | 1770 V | |

| Traction winding leakage inductor | 2.3 mH | |

| Traction winding leakage resistor | 0.068 | |

| DC-link voltage | 3000 V | |

| Support Capacitor | 3 mF | |

| Stator resistance | 0.1065 | |

| Stator inductance | 1.318 mH | |

| Rotor resistance | 0.0663 | |

| Rotor inductance | 1.93 mH | |

| Mutual inductance | 53.6 mH | |

| Rated voltage | 2750 V | |

| Rated speed | 4100 r/min | |

| Rated frequency | 138 Hz | |

| Rated output power | 562 kW | |

| Rated slip frequency | 0.04 | |

| Number of the pole pairs | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, H.; Peng, T.; Yang, C.; Gao, J.; Yang, C.; Gui, W. Voltage and Current Sensor Fault Diagnosis Method for Traction Converter with Two Stator Current Sensors. Sensors 2022, 22, 2355. https://doi.org/10.3390/s22062355

Tao H, Peng T, Yang C, Gao J, Yang C, Gui W. Voltage and Current Sensor Fault Diagnosis Method for Traction Converter with Two Stator Current Sensors. Sensors. 2022; 22(6):2355. https://doi.org/10.3390/s22062355

Chicago/Turabian StyleTao, Hongwei, Tao Peng, Chao Yang, Jinqiu Gao, Chunhua Yang, and Weihua Gui. 2022. "Voltage and Current Sensor Fault Diagnosis Method for Traction Converter with Two Stator Current Sensors" Sensors 22, no. 6: 2355. https://doi.org/10.3390/s22062355

APA StyleTao, H., Peng, T., Yang, C., Gao, J., Yang, C., & Gui, W. (2022). Voltage and Current Sensor Fault Diagnosis Method for Traction Converter with Two Stator Current Sensors. Sensors, 22(6), 2355. https://doi.org/10.3390/s22062355