1. Introduction

Internet of Things (IoT) technologies are blooming and are expected to reach a 1567 billion USD market value by 2025 [

1]. Currently, there are a little over 7 billion sensor nodes worldwide [

1]. These sensors represent the backbone of IoT systems since they are responsible for detecting essential information about the surrounding environment and monitoring the health conditions of structures such as compressors, pumps, bridges, tunnels, railroads, and other dynamic structures [

2]. Monitoring the health conditions of structures using these sensors helps in preventing catastrophic failures and loss of lives [

2].

Presently, the majority of these sensors are powered using traditional batteries [

3]. The use of these traditional batteries limits the scope and value of these IoT sensors [

4,

5]. This is due to the fact that the use of conventional batteries as a power source for IoT sensors results in several challenges. Not only do these batteries require continuous and frequent replacement and maintenance [

6], but also they have a limited lifespan and pose an environmental threat [

7]. Given the projected worldwide spread of these IoT sensors, this environmental concern has become a pressing issue to deal with [

8]. Moreover, in harsh environments and remote locations, including wildlife, gas and oil fields, and drilling in mining fields, a self-powered solution becomes the only viable option for deploying long-lasting, stand-alone, eco-friendly, and sustainable sensors [

9].

Consequently, there has been a growing interest in developing autonomous, self-powered, environment-friendly sensor technologies as a necessary and integral part of the flourishing IoT systems and technologies [

10]. Tremendous recent studies have investigated the issue of developing autonomous sensors powered by free sources of energies surrounding these sensors including solar and vibration energies. Vibration-powered sensors are an attractive option since they are not constrained by the availability of sunlight and can operate indoors and underground [

3]. Moreover, vibration energy consists of a broadband vibration spectrum rich in low frequencies with a power density as high as 500 µW/cm

3 [

11]. Vibration energy also represents a wealthy form of freely-available energy in transportation [

12] and industry sectors [

13].

To this end, Xin Li et al. developed a vibration-powered sensor node [

3]. The system used a piezoelectric transducer to harvest ambient vibrations. The fully integrated self-powered sensing and transmitting system consisted of a few units including energy generation, energy transduction, energy-boosting, energy management and circuitry, and demonstration unit (mobile interface). The system was successfully demonstrated under various vibrations conditions. In another effort, two wireless sensor nodes were powered using an electromagnetic vibration energy harvesting system [

1]. A custom-built power conditioning system was integrated into the energy harvesting system and then used to power a sensor node with a duty cycle of 30 s. The self-powered system was shown to produce enough power to receive and transmit information at intervals of less than 60 s. Moreover, in Ref [

14] a piezoelectric energy harvester was used to power a wireless platform which consisted of a vibration sensor, a microcontroller, a power management circuitry, and a custom-built low power radio transmitter. The fully integrated system was operated at acceleration level and frequency of 0.25 g [m/s

2] and 100 Hz, respectively. The system was able to transmit the sensor data every 10 s for a duty cycle of 0.2%. Moreover, in their study, Lu Wang et al. [

15] built a wireless temperature sensor node powered by a piezoelectric bimorph cantilever vibration energy harvesting system. A big proof mass was attached to the harvester to lower its resonant frequency to approximately 22 Hz. A power management circuitry was built for rectifying the output from the harvester which was then used to power the temperature sensor. In Ref [

16], the authors utilized a commercial piezoelectric cantilever as an energy harvester for powering a wireless temperature sensor node. The study focused on investigating the design methodology for the power management circuitry used in their work. A demonstration of the self-powered temperature sensor was performed. Additionally, Lu Wang et al. [

17] built a hybrid piezoelectric-triboelectric unit and used it to construct an autonomous wireless sensor node where the piezoelectric generator served as the energy source and the triboelectric worked as an accelerometer (i.e., sensing unit). The piezoelectric harvester produced approximately 6.5 [mW] at 1 g [m/s

2] and 25 [Hz] and the triboelectric accelerometer showed a sensitivity of 15 V/g for acceleration range 0–1.5 g [m/s

2]. In another effort, a piezoelectric energy harvesting-sensor unit was developed and implemented in monitoring airflow from an HVAC outlet [

18]. To avoid signal distortion from the sensor the proposed system used two separate piezoelectric devices (i.e., one for energy harvesting and one for sensing purposes).

One of the major constraints in wireless sensor technologies is associated with the limitations in the supplied energy to the wireless sensor nodes [

19,

20,

21]. Overcoming this challenge can only be achieved through minimizing energy consumption by means of ultra-low-power techniques. Several techniques to reduce energy consumption have emerged in recent years, such as duty cycling [

22]. Other techniques include topology control [

23], which deals with the distribution of the wireless sensor nodes in order to reduce energy consumption while eliminating interference at the lowest cost possible. Additionally, data transmission network protocol selection is based on application, where different protocols have variable bandwidths with varying energy consumptions [

24]. Cyber security of those networks is also amongst the necessary features that when added would require more processing power from the sensor node [

25].

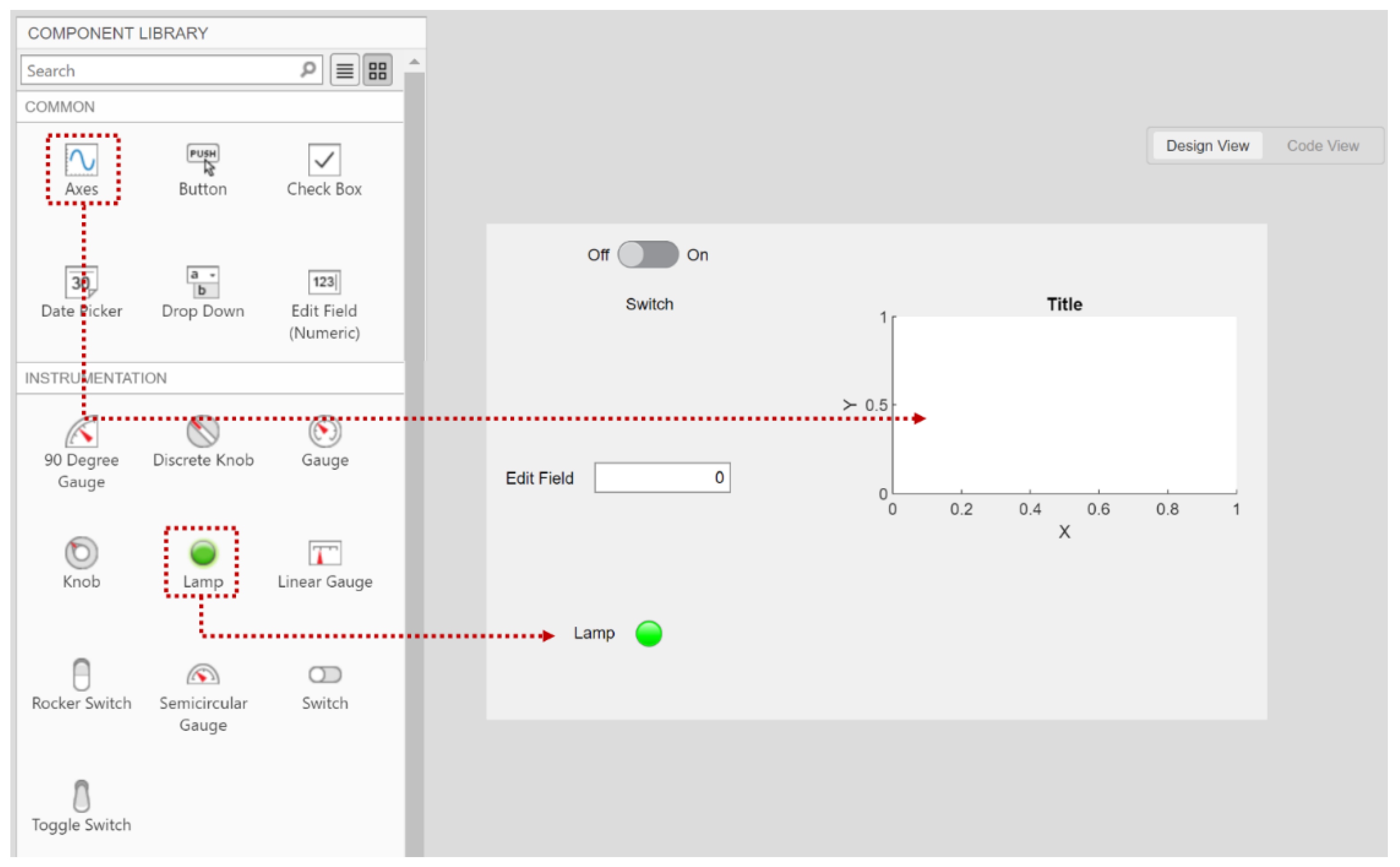

The work presented in this article is focused on developing a novel, self-powered, self-contained, environment-friendly, and wireless vibration sensor. One of the major issues that the vibration-powered wireless sensor node designers are faced with is the unstable power source causing much noise to the transmitted data [

14]. This causes a need for stringent supply regulation using linear or switching regulators that amounts to power losses due to heat as a result of the regulation. In this work, power is conserved from not using any regulators, and instead, the noise corrupted data is retrieved from post-processing through a custom-developed dynamic fast Fourier transform (FFT) app. A given dynamic structure has a vibration signature where a frequency shift can be detected by implementing an FFT algorithm to the time series data [

26]. Furthermore, there is an ample amount of noise introduced into the signal due to interference from the use of radiofrequency modules [

14] and the use of FFT in post-processing of the data lessens the impact of noise on the signal [

27]. The custom developed app in this work can fetch the sensor bit-stream, buffer the data, and use it to plot the vibration signal amplitude and its frequency in real-time.

Moreover, unlike in the relatively high voltages produced in piezoelectric transducers that would set a need for voltage regulation [

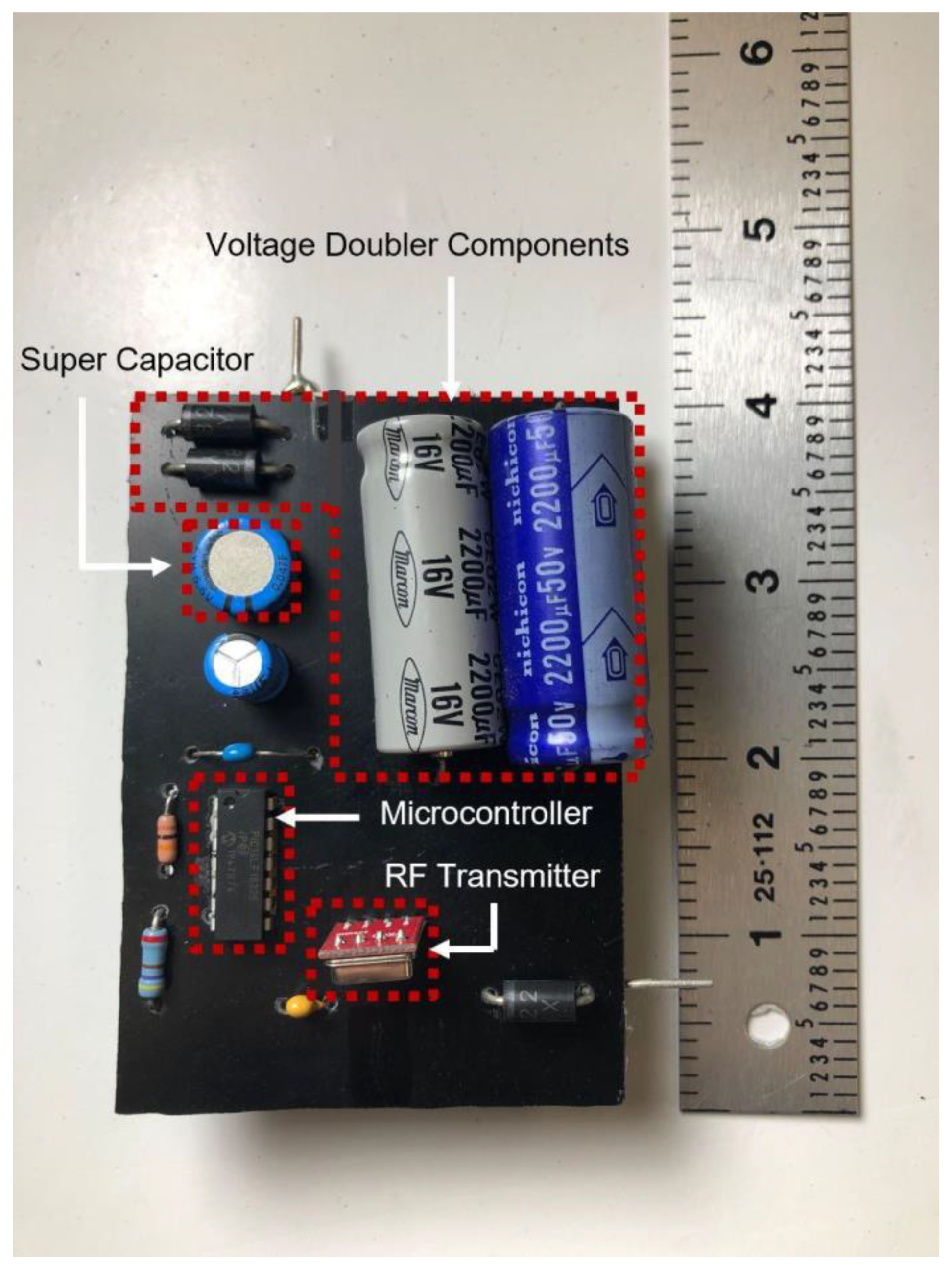

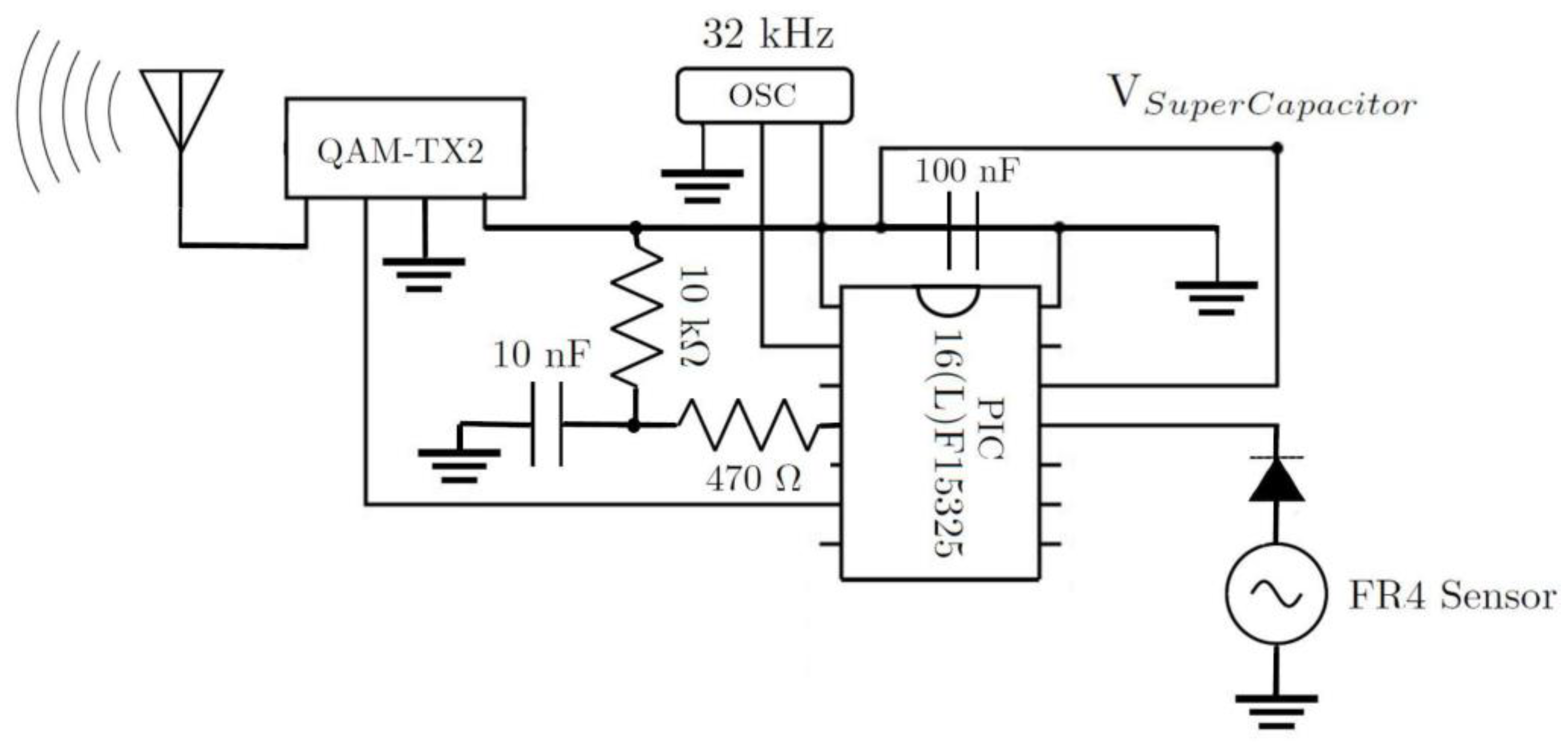

3], in this work, electromagnetic transduction is used and the output voltages are within the electronics acceptable supplied voltage range. Also, unlike the aforementioned studies and state-of-the-art developments, in this work, the self-powered sensor uses vibrations to synchronously perform two functions. First, these free vibrations are converted into useful electric power through the presented energy harvester system. Second, these vibrations are detected as electric signals (voltage) by the presented vibration sensor, and are then transmitted wirelessly to the workstation (laptop). Thus, the harvester-sensor hardware is self-contained and self-powered. That is, the mechanical power required to operate the sensor is obtained from the energy harvester. A charge pump circuit, also known as a voltage multiplier, is used to rectify the AC output of the energy harvester. The output DC is then stored in a supercapacitor that provides the energy to the microcontroller and sensor transmitter circuit. The voltage multiplier circuit allows immediate circuit startup due to the transmitter circuit having sufficient voltage and electric current to operate. The signal from the sensor is sampled using a 10-bit analog to digital converter (ADC) and is transmitted over an RF amplitude modulated (AM) carrier. When monitoring the health conditions of a structure, a shift in its vibrations signature may indicate a malfunction in the structure which could lead to impending failure [

2,

28]. In this article, collected sensor data are analyzed through a custom-developed dynamic displacement monitoring software which helps in mitigating damage to vibrating structures.

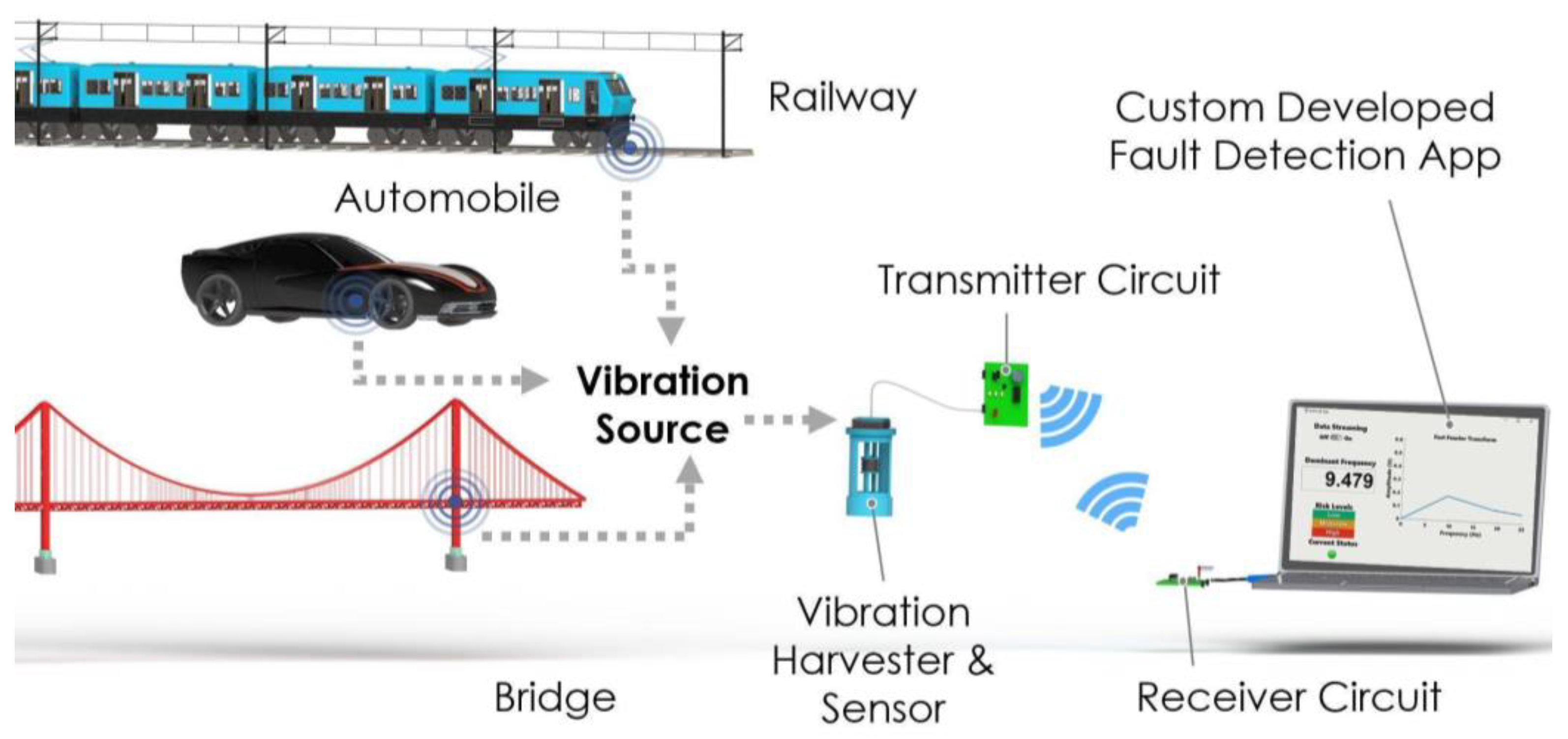

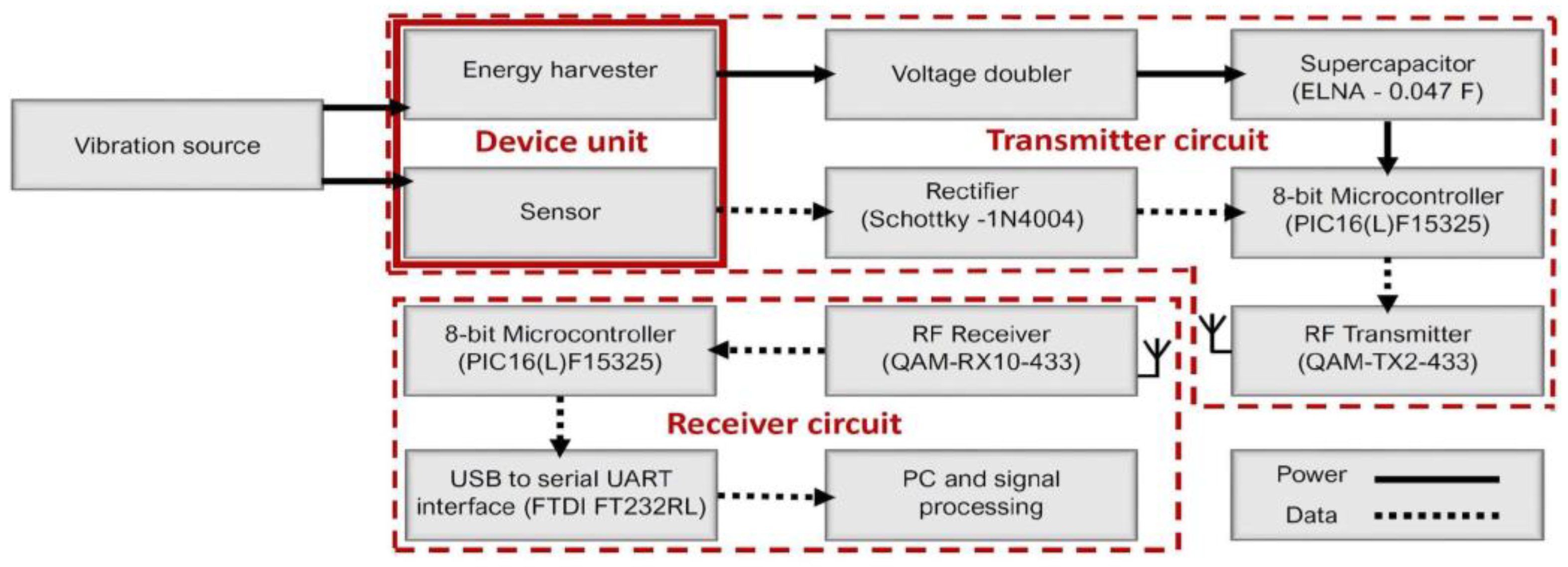

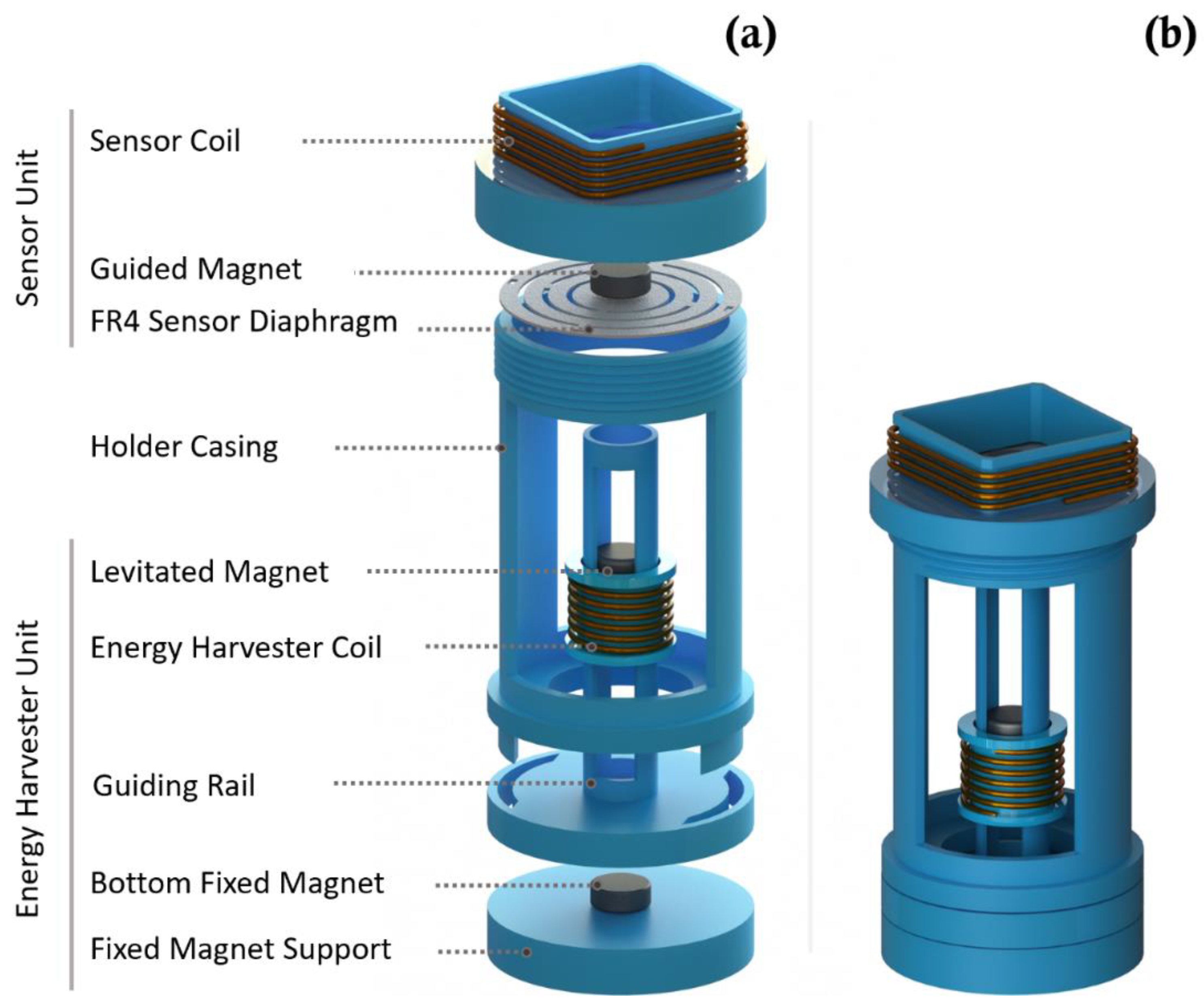

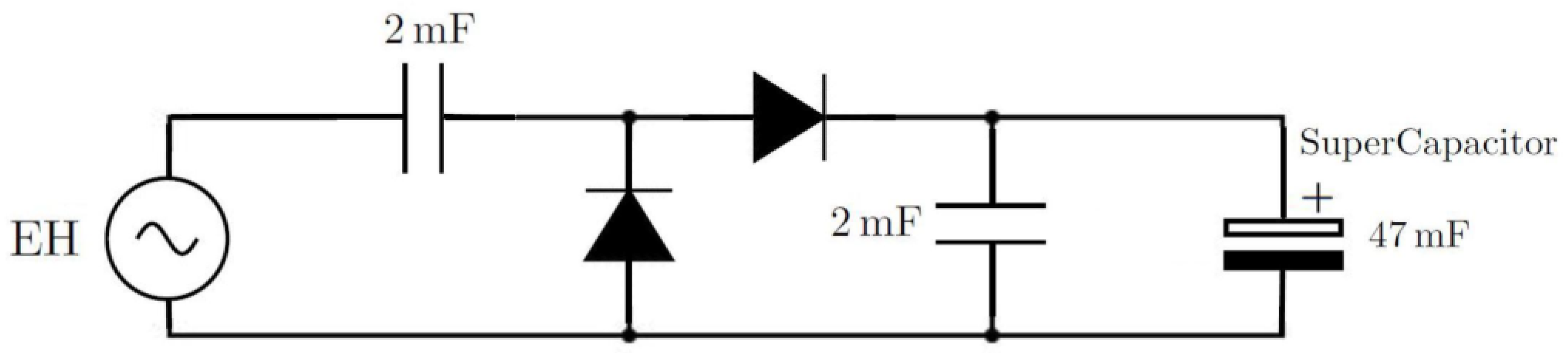

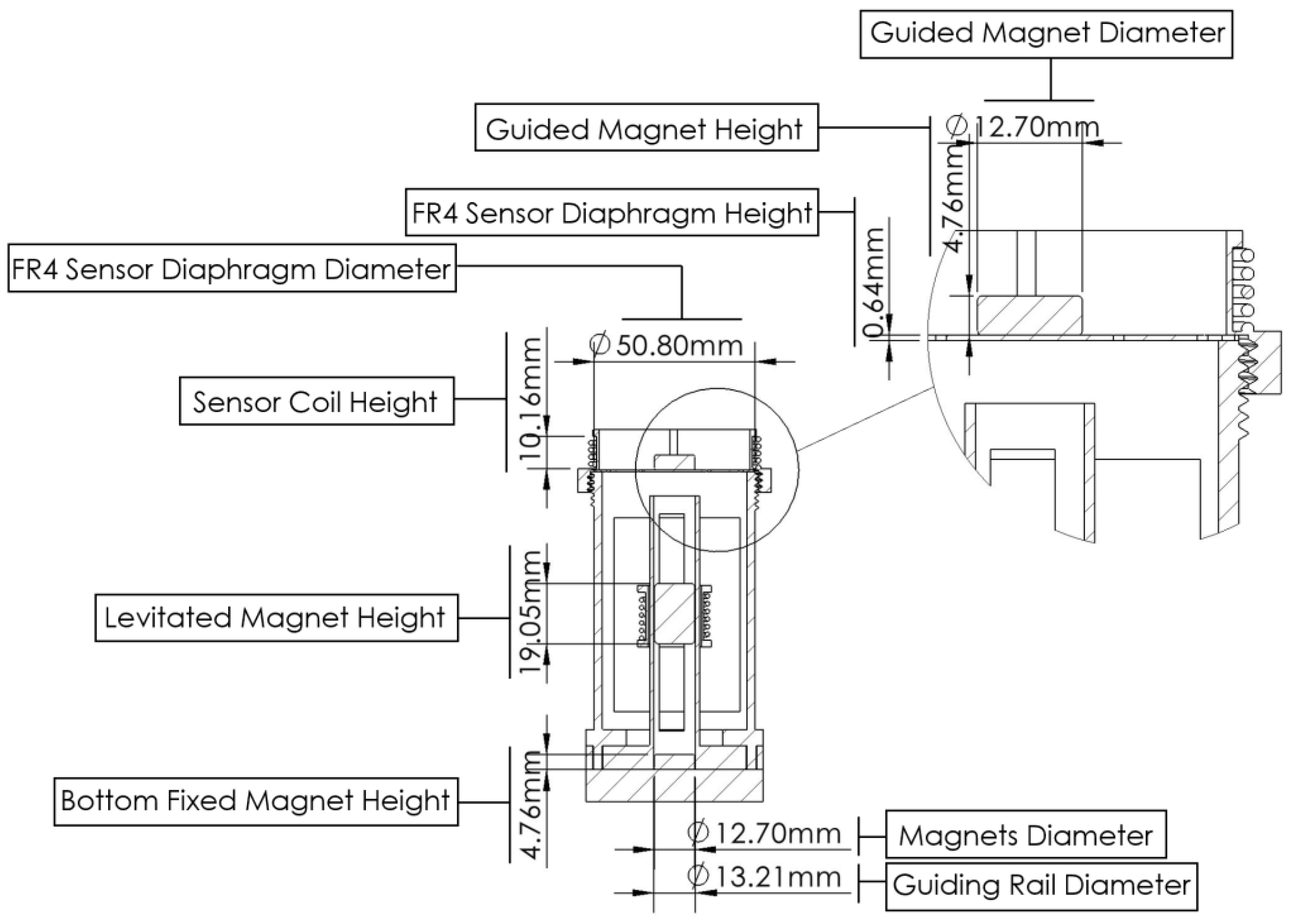

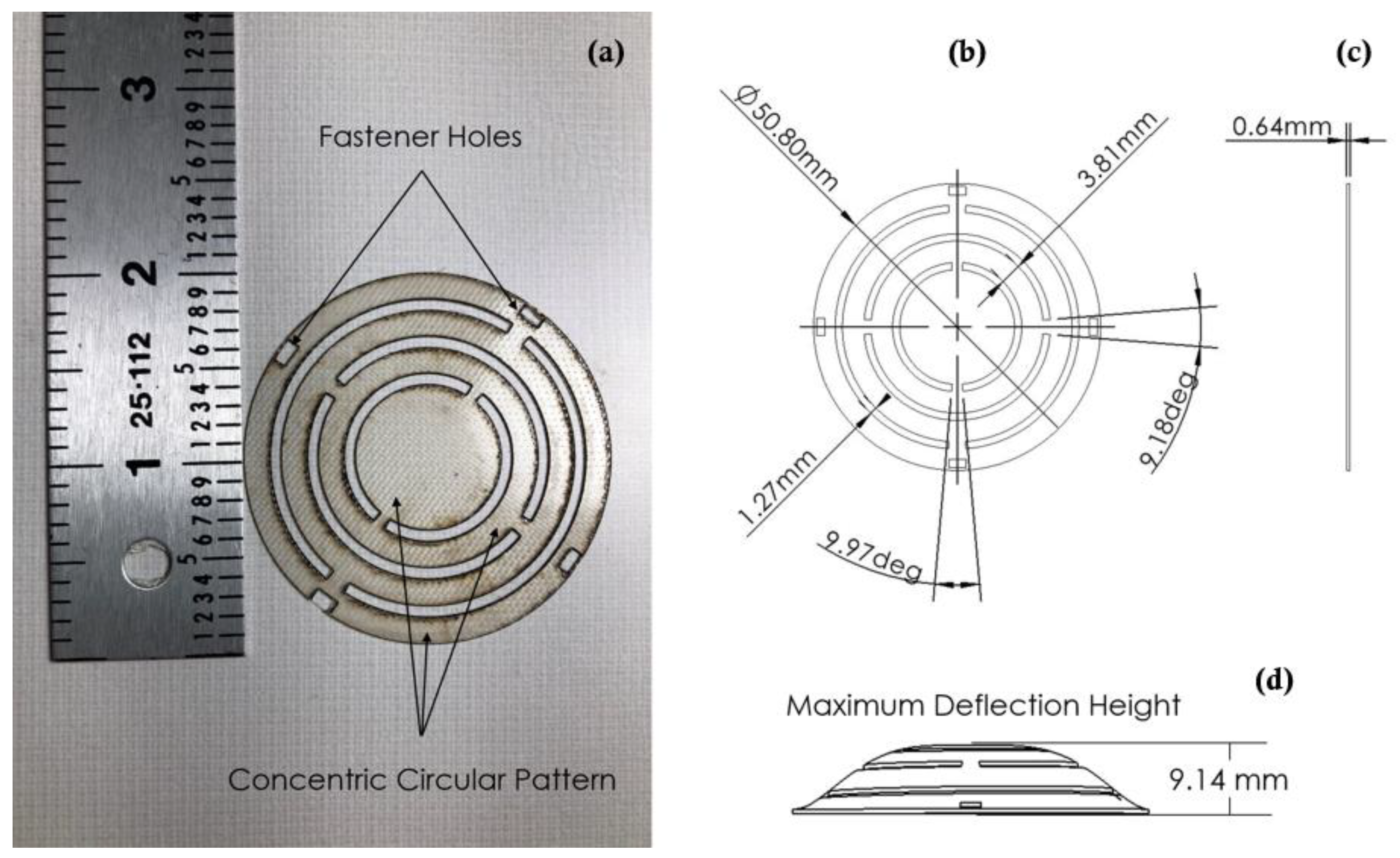

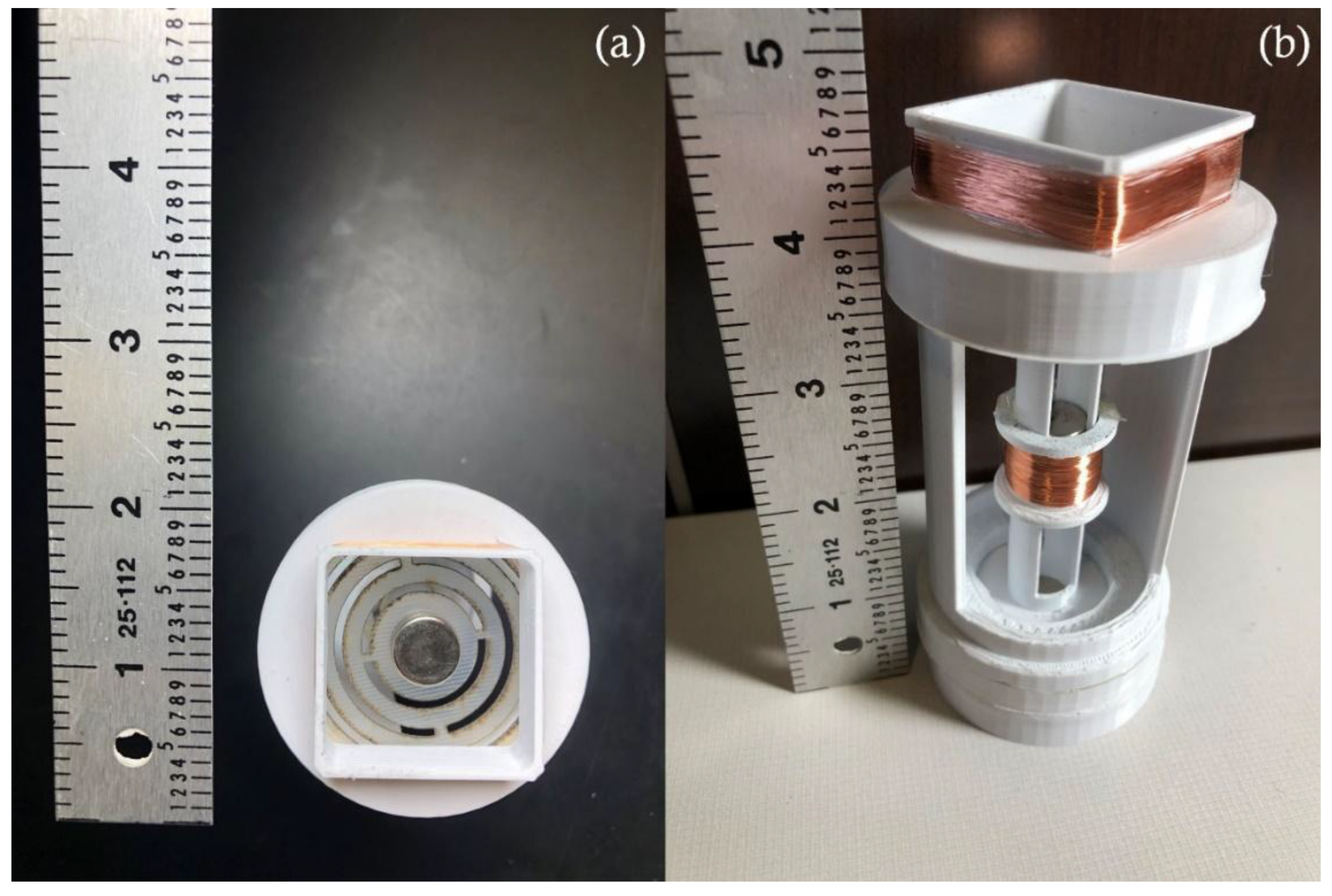

The structure and organization of the article are outlined next. The design and structure of the self-powered self-contained wireless sensor are presented in

Section 2. The manufacturing and fabrication of the system components are detailed in

Section 3. Experimental methods and testing techniques are detailed in

Section 4. Results and findings from this work and system operation and demonstration are discussed in

Section 5. Finally,

Section 6 presents the major conclusions and summarizes the results from this work.

5. Results and Discussion

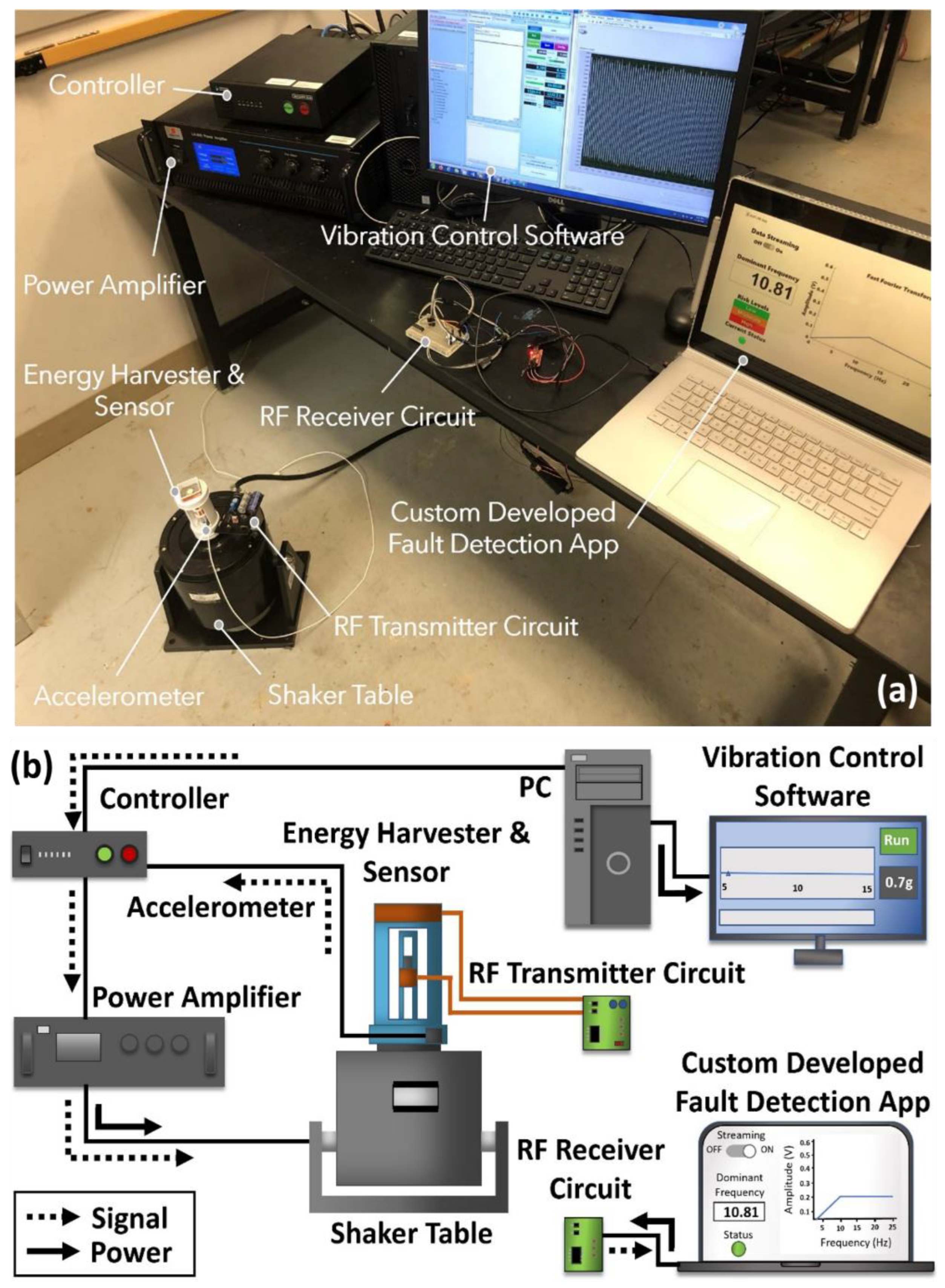

Using the experimental apparatus shown in

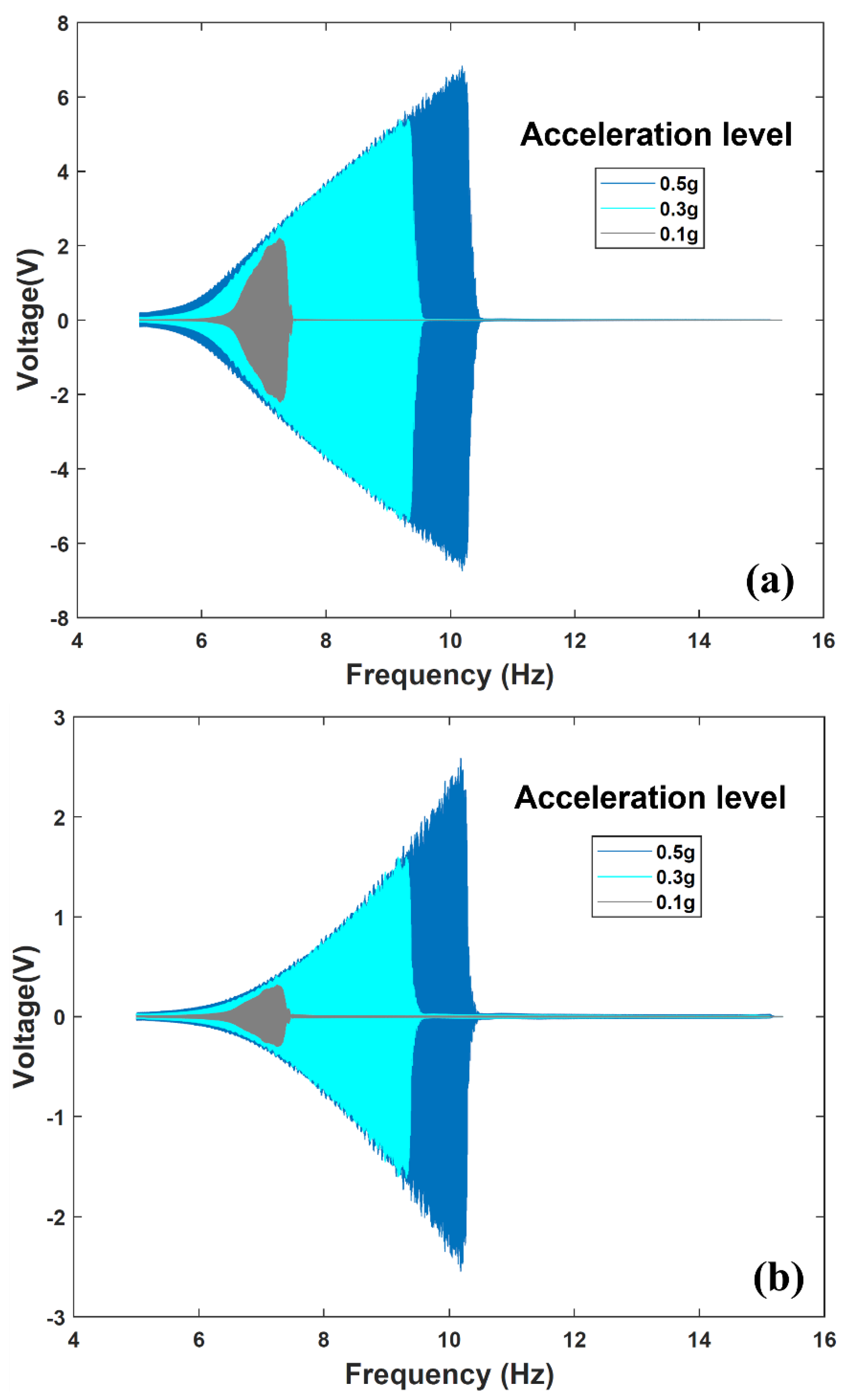

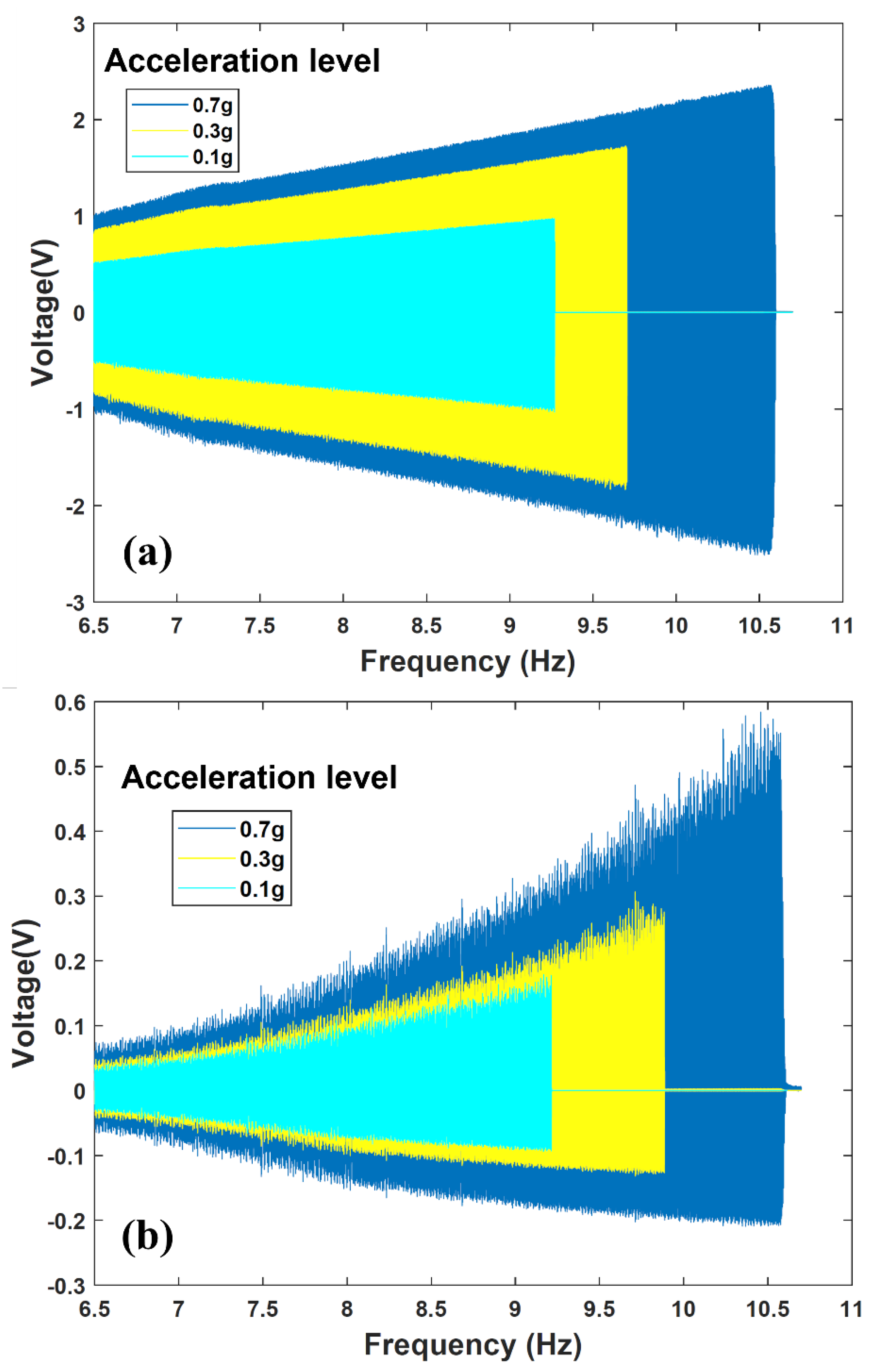

Figure 12, dynamic characterization of the fabricated energy harvester-sensor unit was performed. The resulting voltage frequency responses of both the energy harvester and sensor are shown in

Figure 13 and

Figure 14. The energy harvester-sensor unit was subject to fixed input acceleration values ranging from 0.1 g up to 0.7 g [m/s

2] while the frequency was swept at a rate of 0.0833 Hz/s.

The nonlinear magnetic spring stiffness nature of the energy harvester is evident in the voltage frequency response as shown in both

Figure 13 and

Figure 14. That is, the repulsive magnetic forces experienced by the levitated magnet can be described as a nonlinear spring force [

7,

8]. This results in a hardening effect that is evident when comparing the trend in output voltage peaks shown in

Figure 13 and

Figure 14. One can notice that these peaks are shifting to higher frequencies as the input acceleration is increased. The nonlinear behavior of magnetic levitation-based energy harvesting system was studied extensively in our prior work [

5,

7,

8,

29]. Furthermore, during the frequency sweep, an abrupt sharp decline of the energy harvester’s frequency response is evident. This drop, known as the frequency jump phenomenon [

7,

8], is attributed to the coexistence of multiple energy states at the frequency branch. The discontinuity in the response is a characteristic of magnetic levitation-based energy harvesting systems [

5,

29].

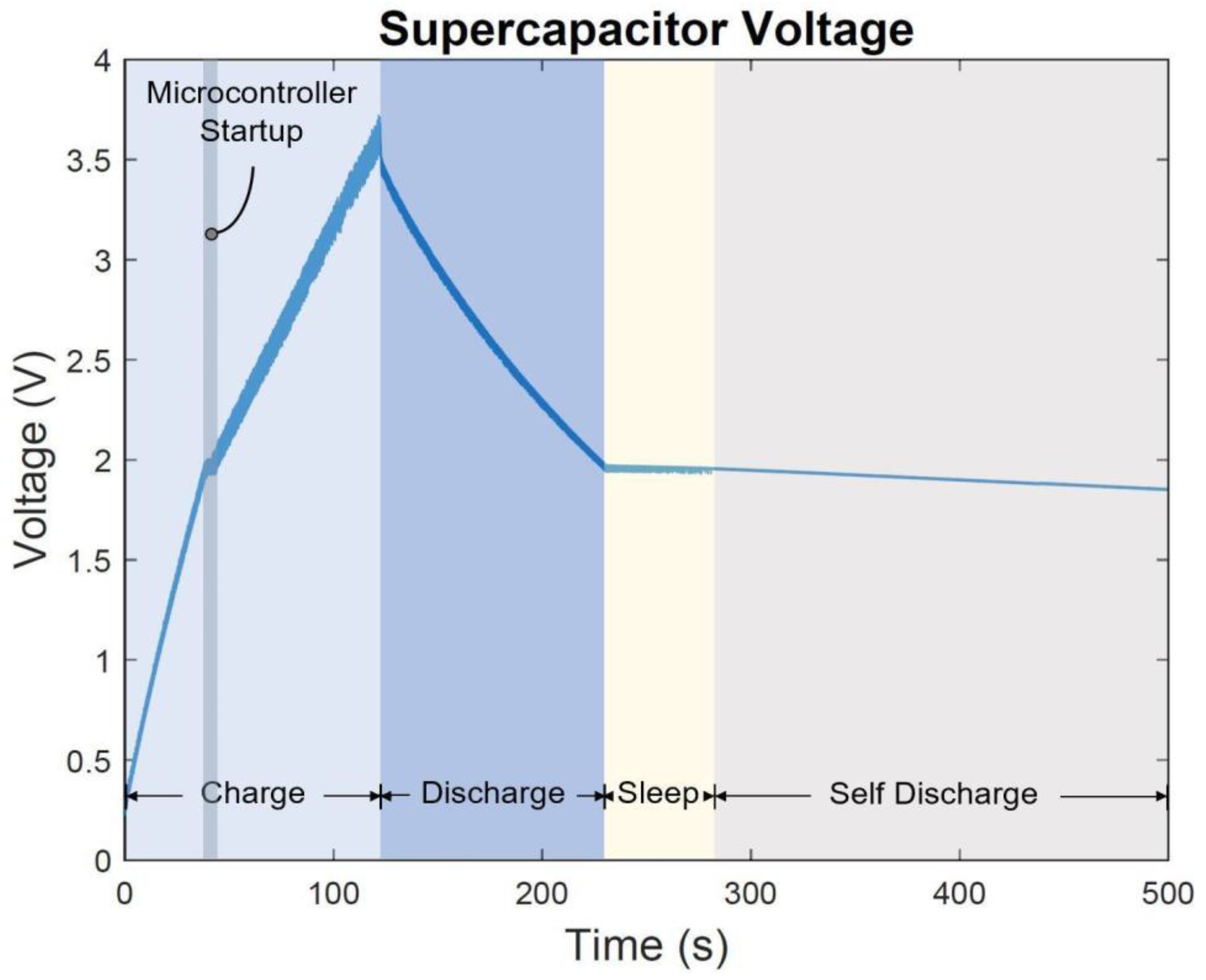

The supercapacitor charging and discharging cycles were measured using a data acquisition device (NI myDAQ) and the graphical programming environment LabVIEW software. The supercapacitor charging history is shown in

Figure 15 where the maximum charge is held at 3.7 V after 122 s. During the charging cycle and after approximately 39 s, a slight shift in voltage level that lasts for 4 s occurs during the microcontroller waking up and voltage rails stabilization stage. The rate of the voltage held by the supercapacitor is seen to decrease from 44 mV/s to 22 mV/s after the microcontroller startup period. This is likely due to the fact that during this stage the system is draining the supercapacitor in order to operate. After approximately 122 s of charging, while simultaneously the energy harvester -sensor unit crosses the resonant frequency point during the frequency sweep, the supercapacitor discharging cycle starts to take effect at a voltage decline rate of 15 mV/s. The supercapacitor charging period after the microcontroller startup takes 79 s while it takes 108 s to discharge before the microcontroller enters the sleep mode as shown in

Figure 15. At 230 s and 2 V, the microcontroller enters the sleep mode for a period that lasts approximately 50 s before the supercapacitor voltage level drops below 1.8 V which is no longer a sufficient amount of power for the microcontroller to operate. Consequently, the supercapacitor starts a self-discharge process as shown in

Figure 15.

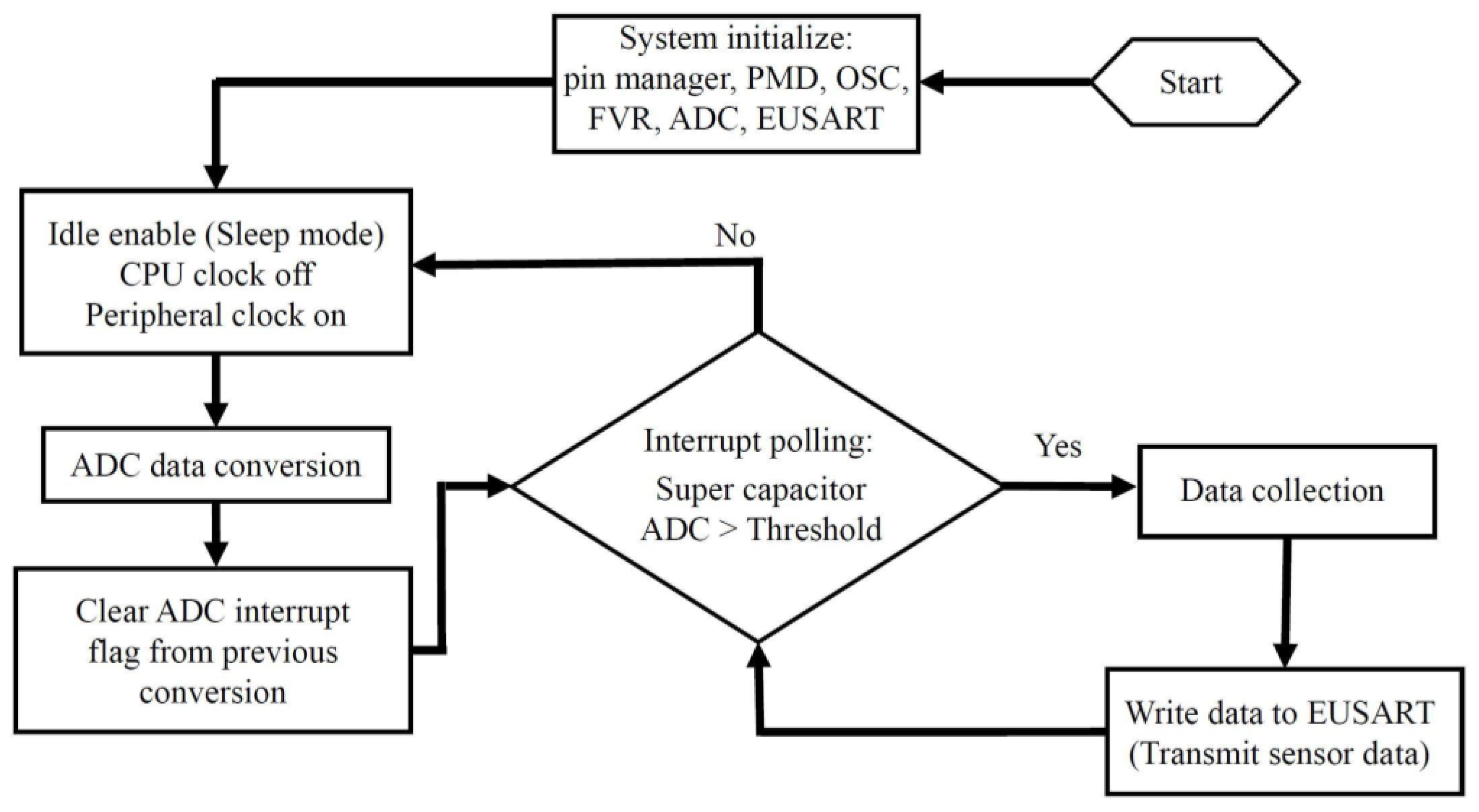

Next, the fully integrated, self-powered, self-contained sensor system was subject to harmonic oscillations and was tested under lab-controlled settings using the experimental apparatus shown in

Figure 12. The resulting energy consumptions at different system states are shown in

Table 2. The microcontroller internal oscillator was set to the lowest clock frequency of 32 kHz to minimize energy consumption. The ADC peripheral was configured to use the internal system clock oscillator. The microcontroller takes 10 measurements from the sensor signal during analog to digital bit conversion at a sampling rate of 51 kHz. After the measurements conversion is completed in 19.55 µs, the data are stored in the 16-bit ADC results register. The data are then retrieved by the EUSART serial communication peripheral, and the 10-bit data frame is transmitted asynchronously with 1 start bit and 1 stop bit added to each 8-bit sensor data packet and no parity bit.

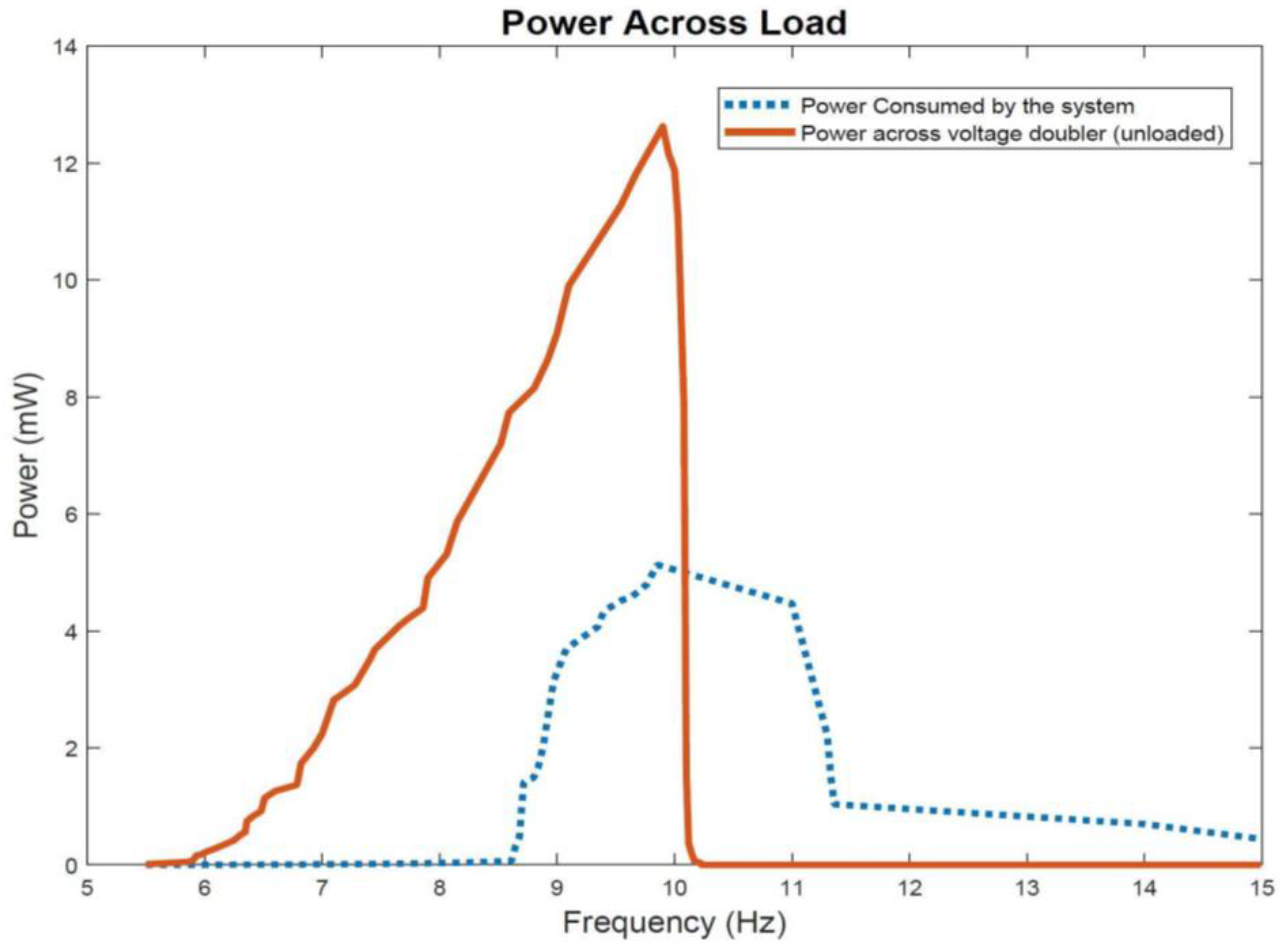

Figure 16 shows the power consumed by the transmitter subsystem as well as the power generated at an unloaded voltage doubler circuit. The power generated from the unloaded voltage doubler at resonant frequency is 12.6 mW and it exceeds the power consumed by the transmitter subsystem load of 5.1 mW. In the power consumed curve, the decline in power is more gradual compared to the abrupt decline seen in the power generated curve due to having the supercapacitor in the transmitter subsystem circuitry. In both power curves, the profiles show maximum power generation and consumption at resonant frequency of 9.9 Hz.

The operation and realization of the fully integrated self-powered fault detection system are examined next. A video recording of the self-powered, self-contained, environment-friendly, and wireless vibration sensor during data acquisition and transmission process is included in the

Supplementary Materials. The video recording includes segments from the custom developed fault detection app along with the EDM shaker table vibration control software and the energy harvester and sensor voltage waveforms as well as the experimental setup showing the fabricated energy harvester-sensor unit mounted on the shaker table.

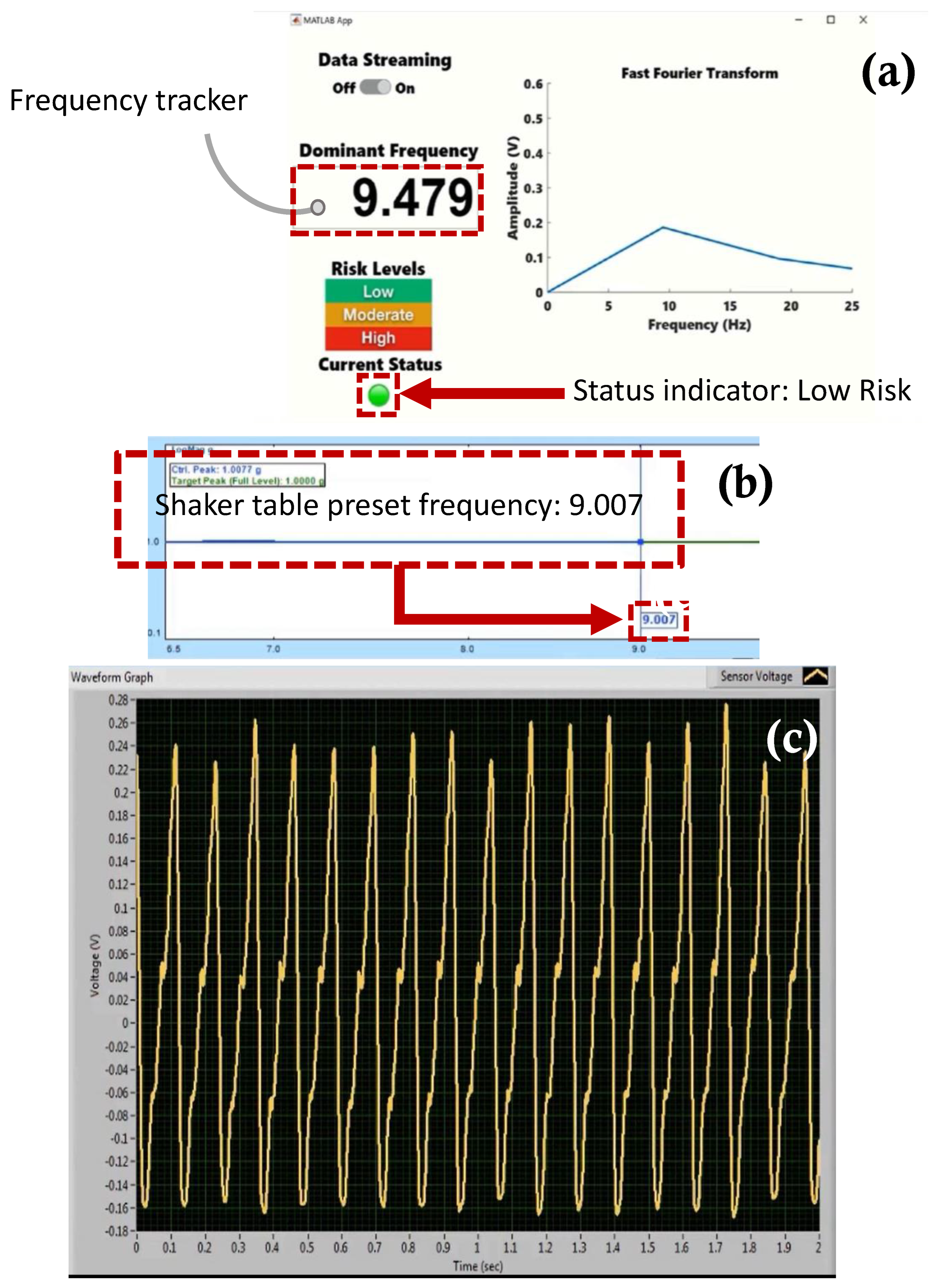

Figure 17,

Figure 18,

Figure 19 and

Figure 20 show selected timeframes showing the operation of the fully integrated self-powered wireless fault detection system at different stages during the system’s operation.

Figure 17,

Figure 18,

Figure 19 and

Figure 20 demonstrate the ability to self-power the sensor and the ability of the frequency tracker in the custom developed app to detect the vibration frequency from the self-powered sensor. For example,

Figure 17a shows the vibration frequency from the sensor, detected by the frequency tracker in the custom developed app, at 9.479 Hz. The sensor vibration frequency value can be confirmed by the EDM software shaker table preset frequency, as shown in

Figure 17b. Here, the preset frequency was approximately 9.007 Hz. Thus, there is a very slight discrepancy between the frequency detected by the frequency tracker in the custom developed app and the preset frequency from the shaker table. The error is estimated at approximately 5%. This discrepancy may be attributed to a few factors including the high noise in the AM transmitter/receiver module that is not filtered out during the FFT filtering process. Other factors include the use of the internal microcontroller oscillator in this work as opposed to using an external oscillator which would have resulted in a more accurate frequency stability. A bitrate estimated error of approximately 1.24% in the transmitted data is also a contributing factor to the overall error in the received and filtered data. Moreover,

Figure 17c demonstrates the output signal from the fabricated self-powered, self-contained senor as the top magnet moves inside the top coil in response to the detected vibrations. That is, the dynamic displacement induced in the sensor causes induced voltage in the top coil surrounding the top guided magnet as shown in

Figure 17c. Here, the power generated by the energy harvester is used to operate the RF transmitter circuit. The output voltage from the sensor is then sampled by the microcontroller on the transmitter circuit. The app, shown in

Figure 17a, also demonstrates successful status indicator monitoring capabilities where it shows a green light, indicating a low level of acceleration experienced by the sensor (i.e., low risk operation). Similarly,

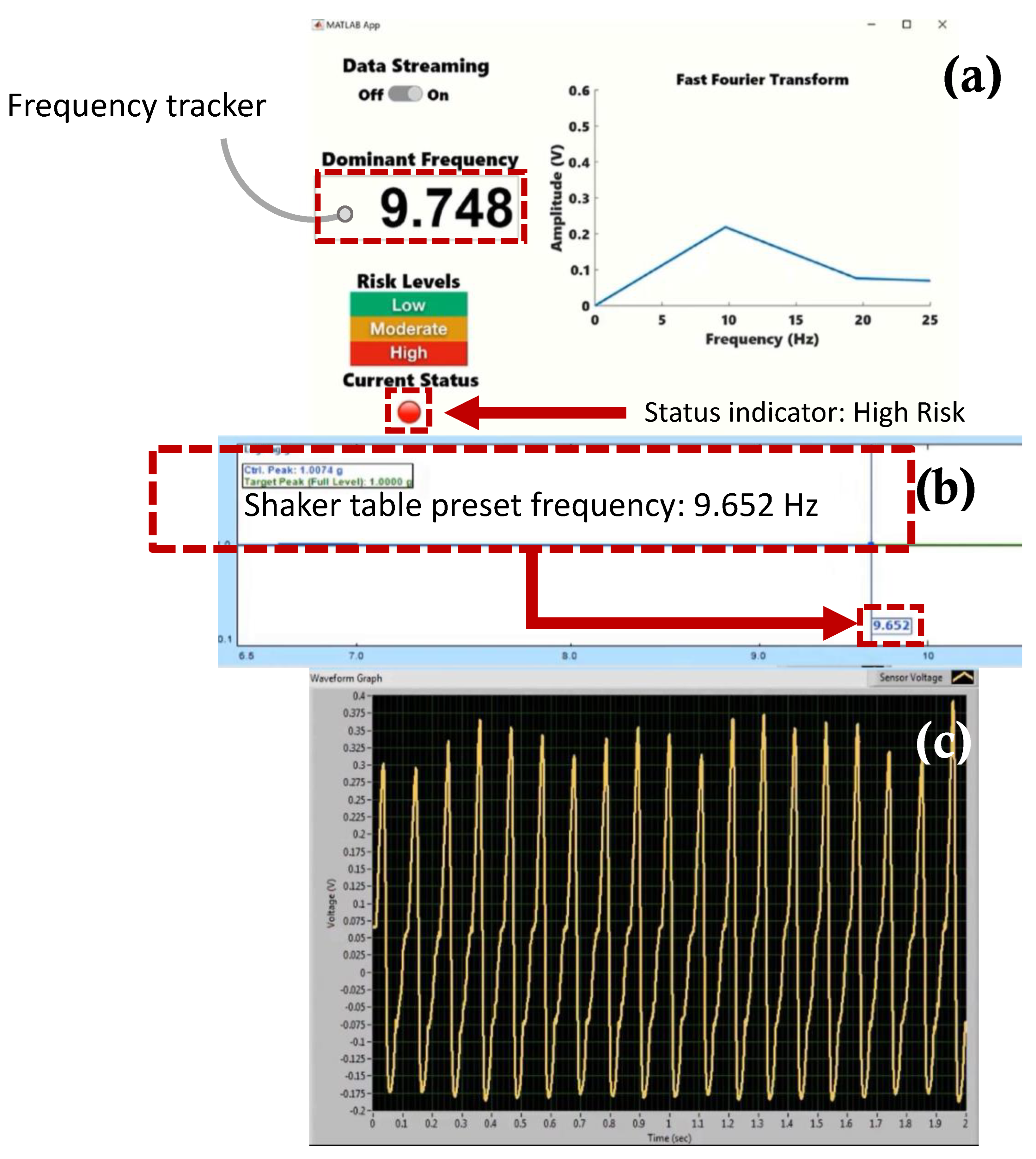

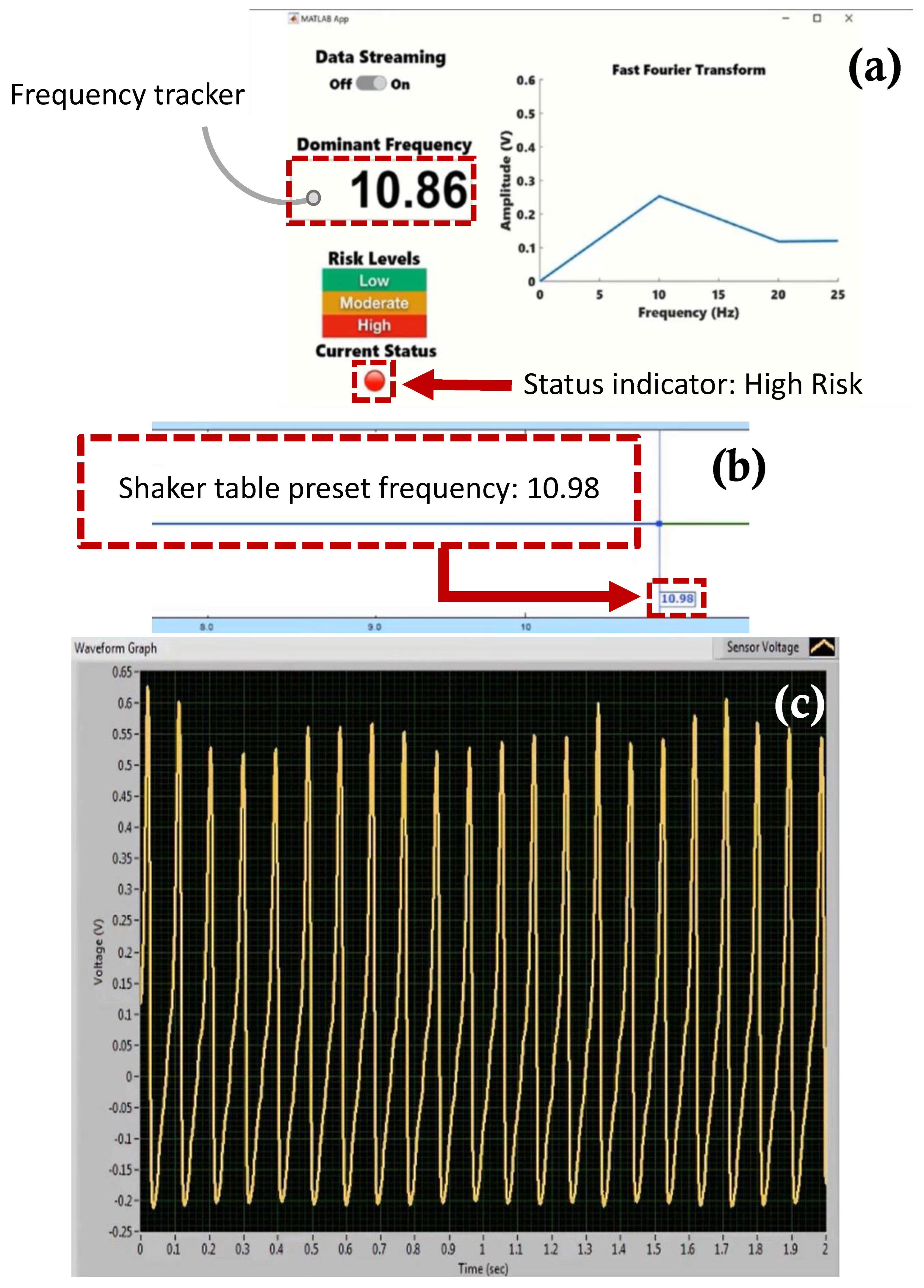

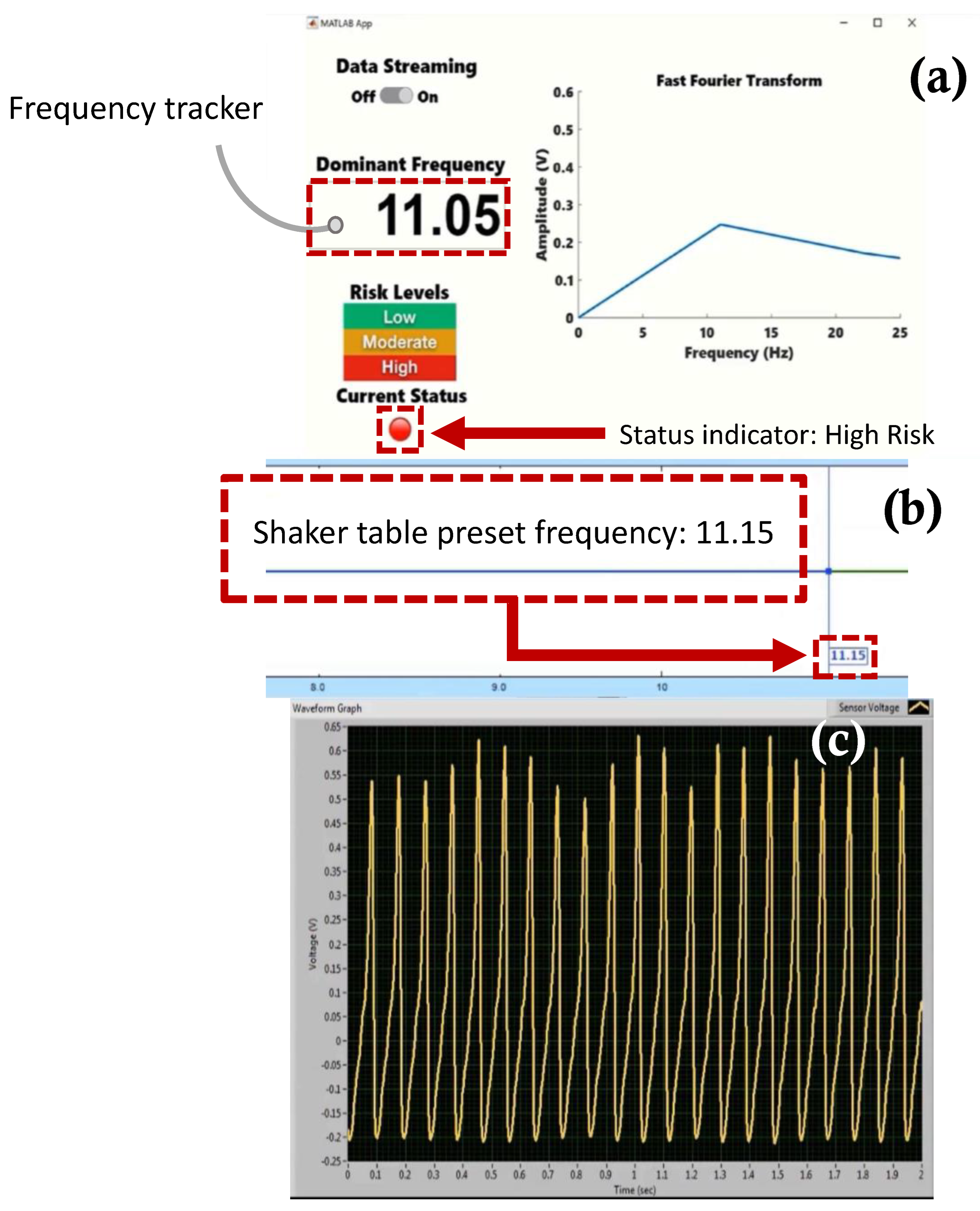

Figure 18,

Figure 19 and

Figure 20 show subsequent timeframes from the demonstration experiment. In those timeframes, the sensor is self-powered, and the app detects a transition from a lower risk operation to a higher risk operation as seen signaled by the status indicator turning red in

Figure 18. In

Figure 18, the preset frequency from the vibration source (i.e., the shaker table) was approximately 9.652 Hz whereas the app detected tracker frequency was at 9.748 Hz. This results in a small error of approximately 1%. Likewise, the next timeframe in

Figure 19 shows the preset frequency was at 10.98 Hz with the app detecting a 10.86 Hz also corresponding to a 1% error in the detected frequency value. The last presented timeframe from the demonstration experiment is shown in

Figure 20 with the app detecting a frequency of 11.05 Hz compared to the preset frequency of 11.15 Hz resulting in only a 0.9% error. The mean absolute error value for all frequencies under investigation is found to be 0.8 while the mean percent error value is 2.6%.