An Overview on Bipolar Junction Transistor as a Sensor for X-ray Beams Used in Medical Diagnosis

Abstract

1. Introduction

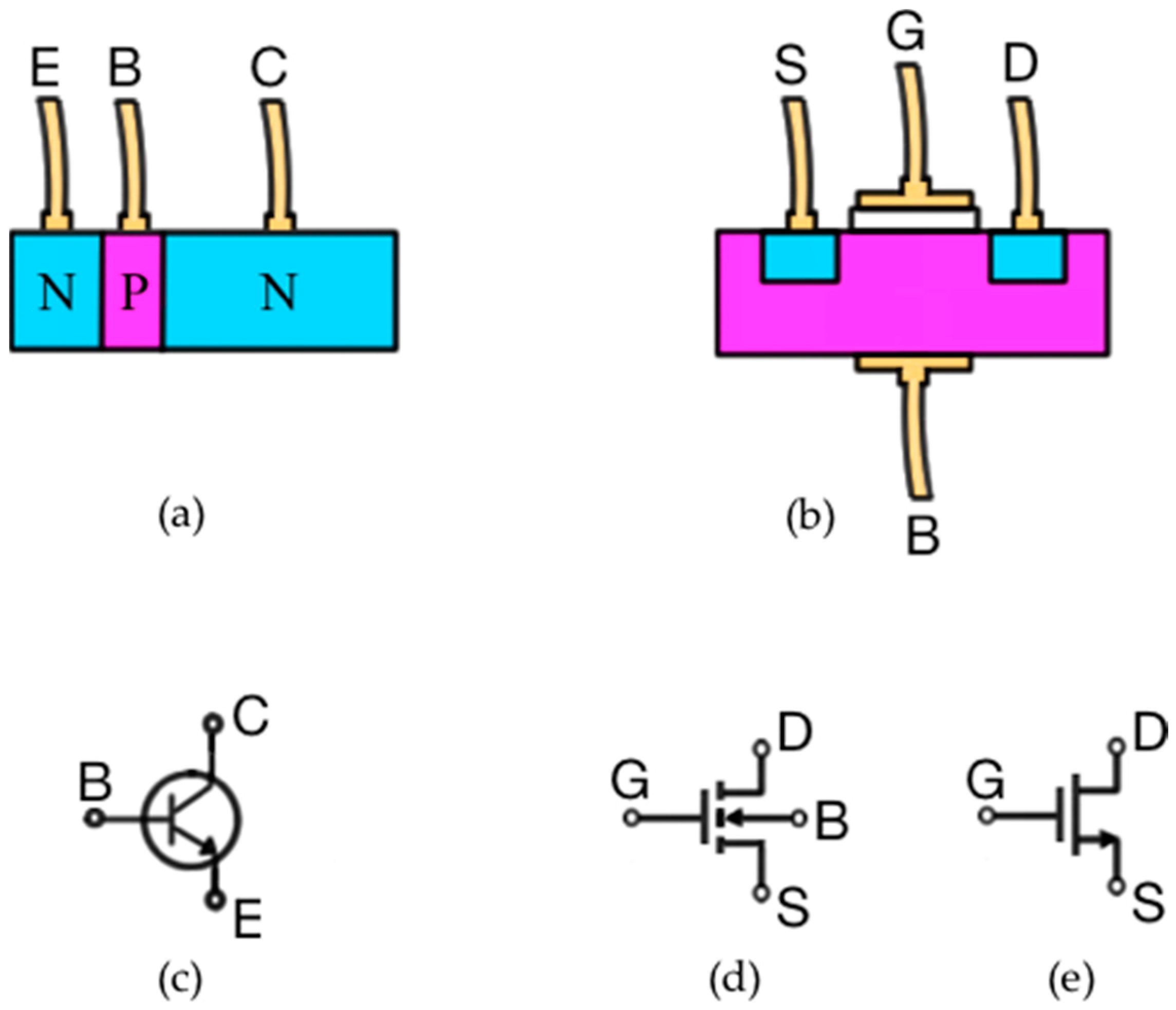

1.1. A Brief Background on Bipolar Junction Transistor

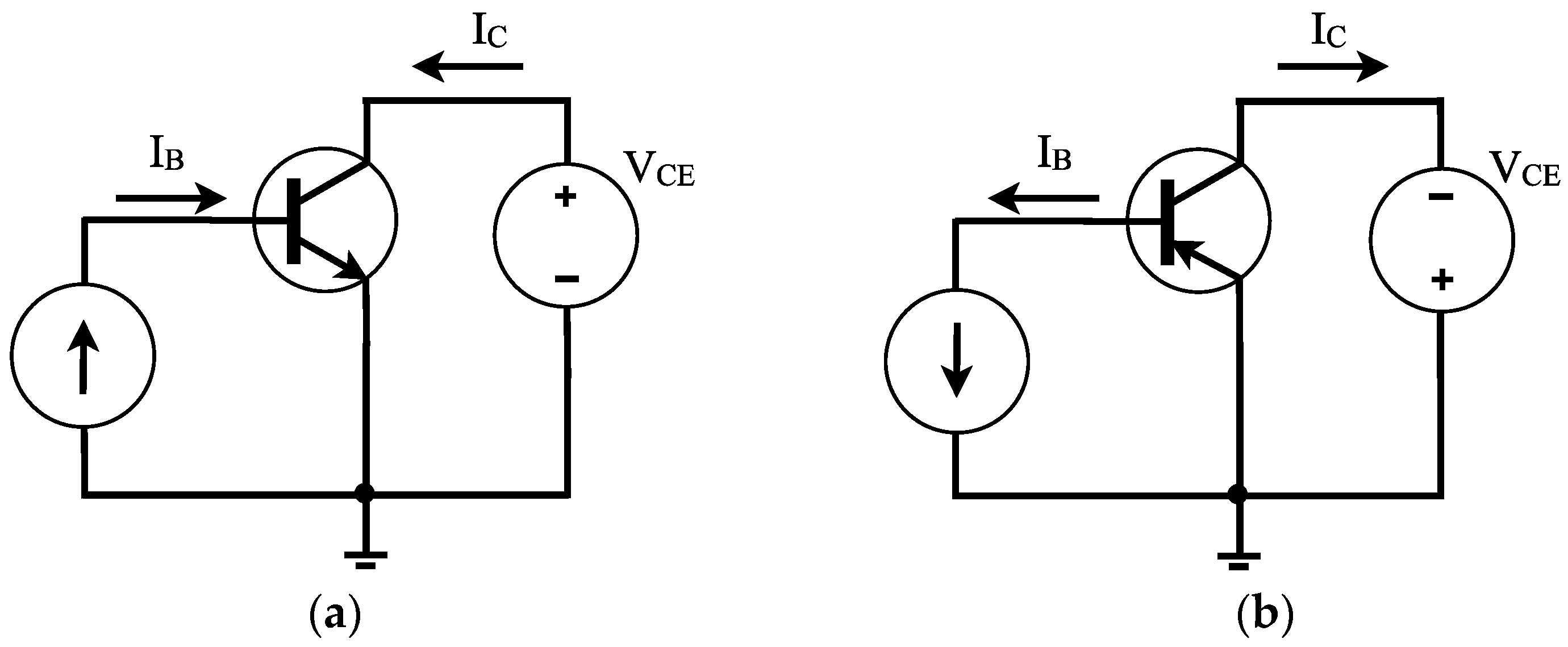

1.2. Principle of Operation of the BJT

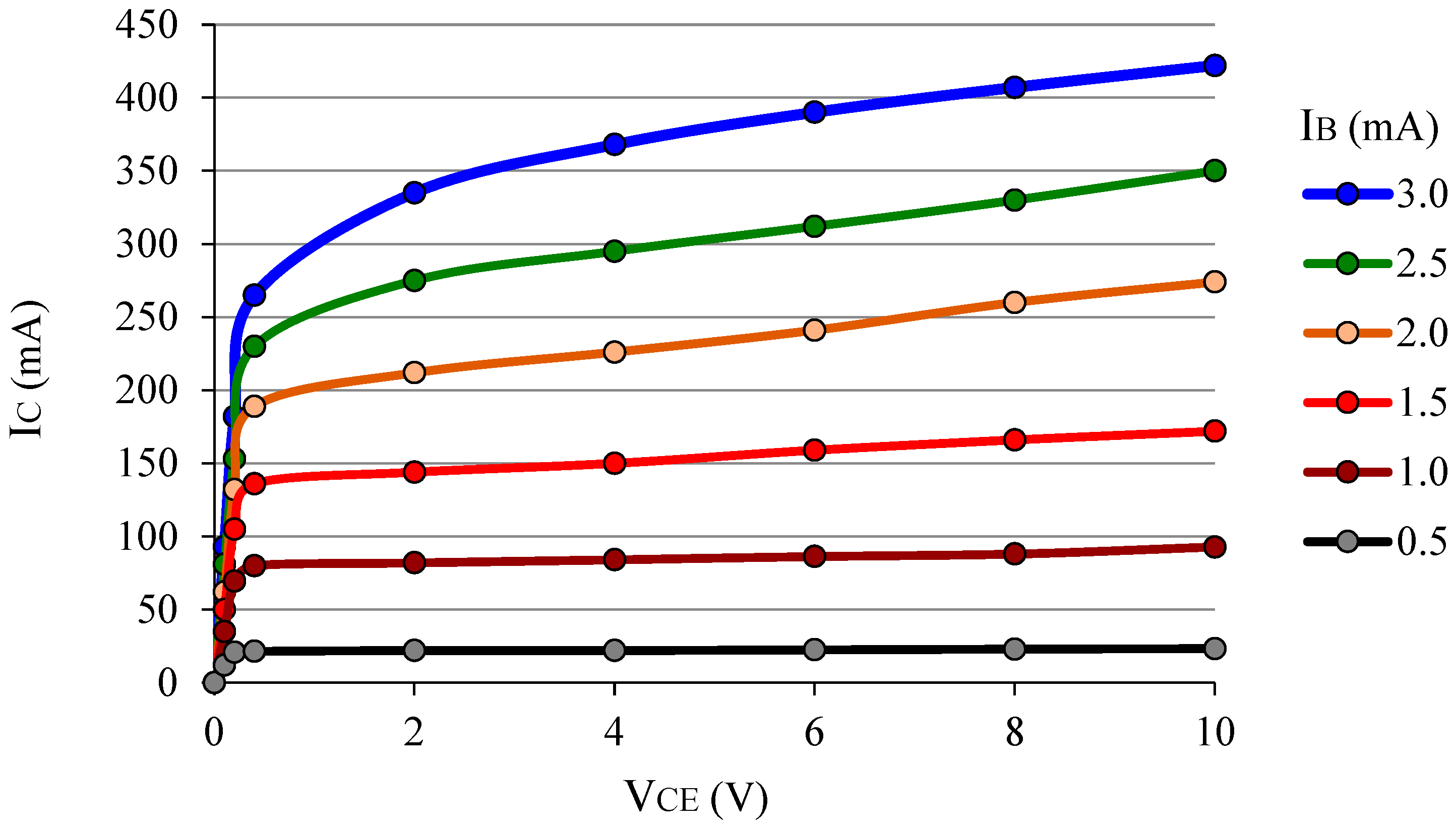

1.3. Main Modes of Operation of the BJT

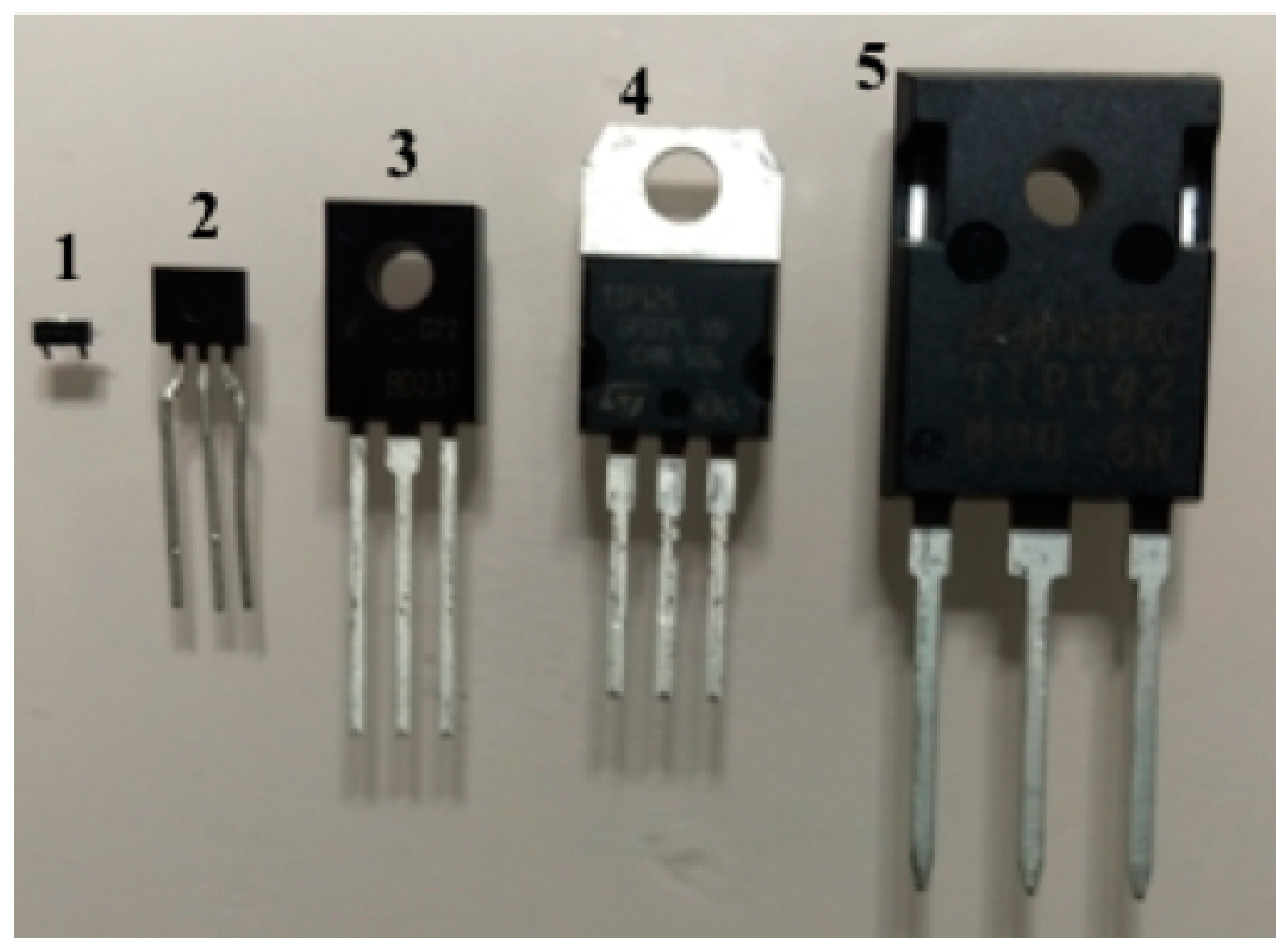

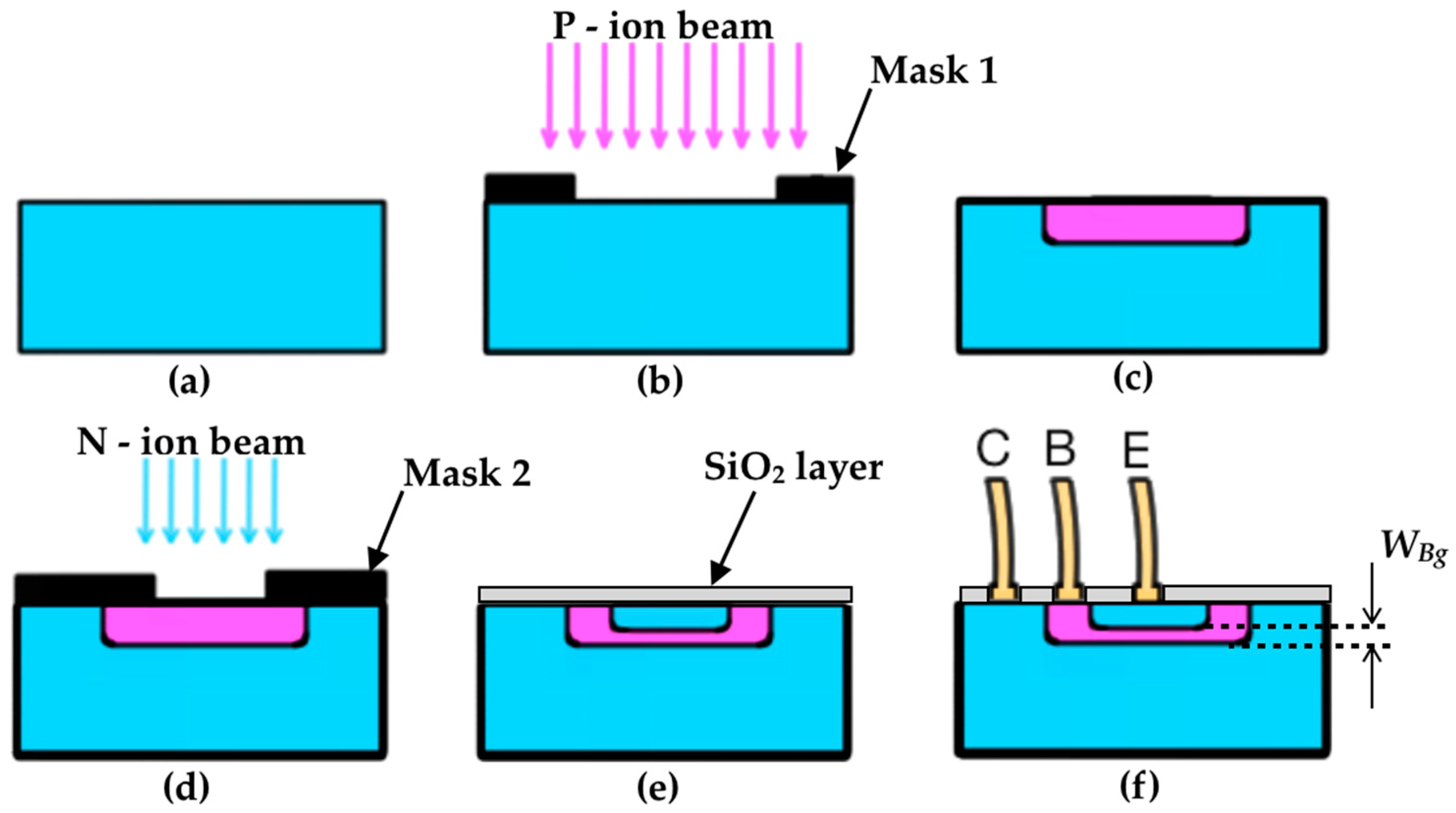

1.4. A Brief Overview on Manufacturing of BJTs

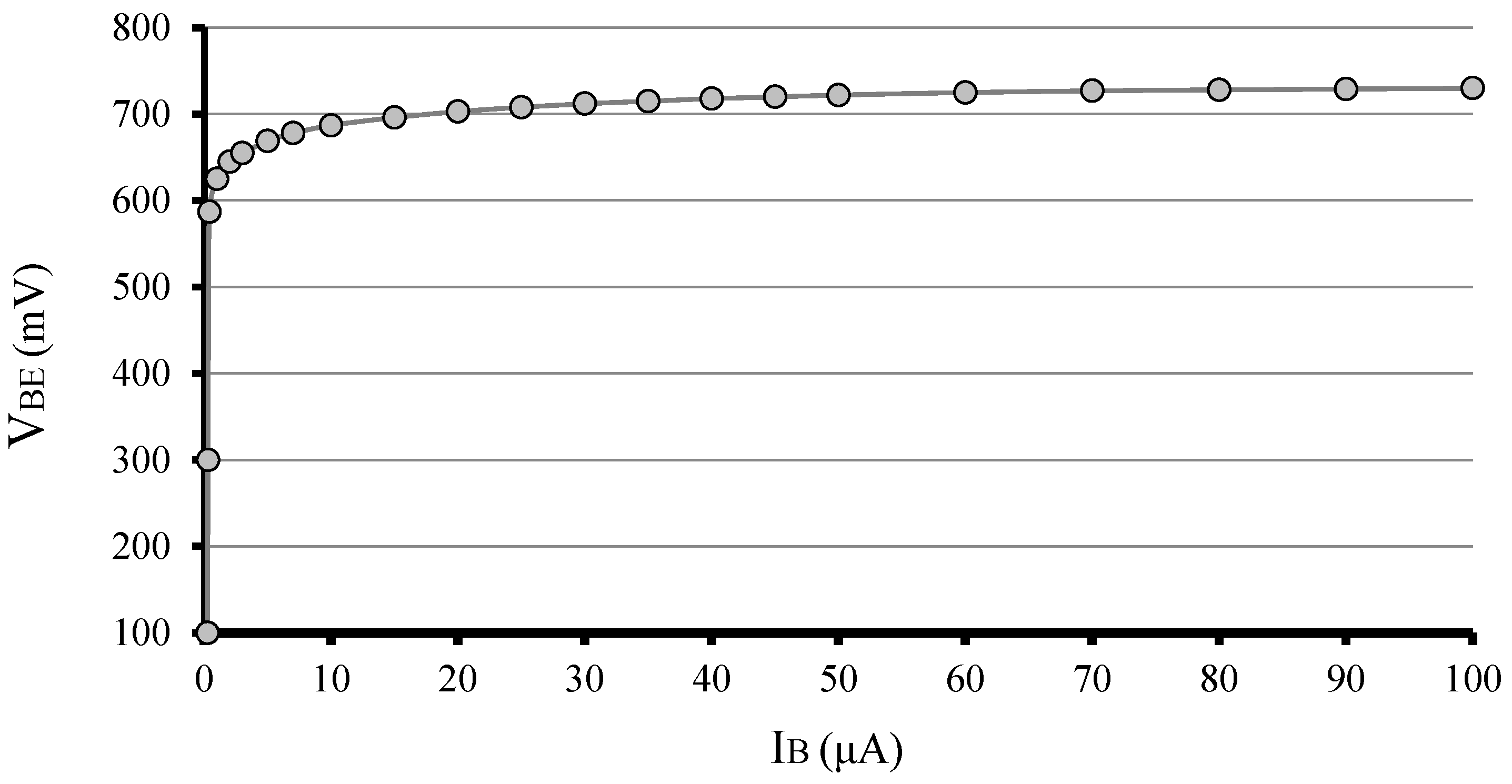

1.5. Variables That Can Change the Output Signal of the BJTs

1.5.1. Temperature

1.5.2. Incidence of Light

1.5.3. The Operation Point

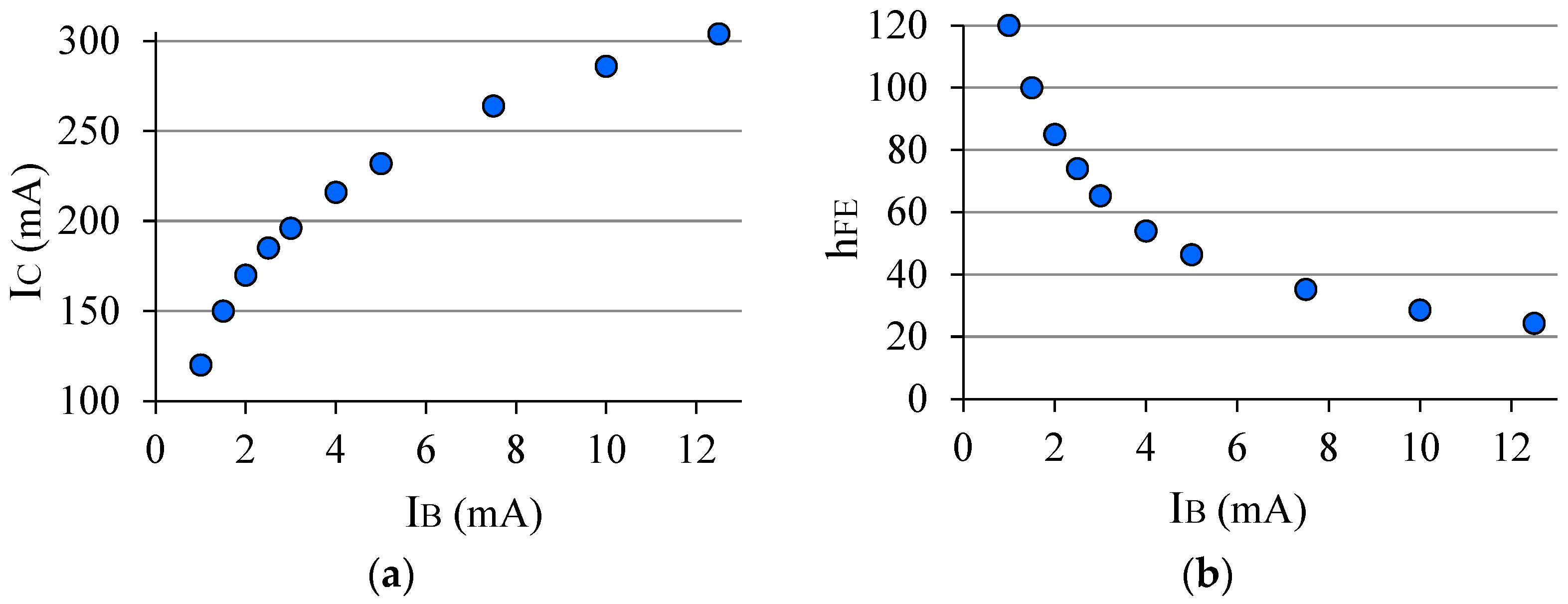

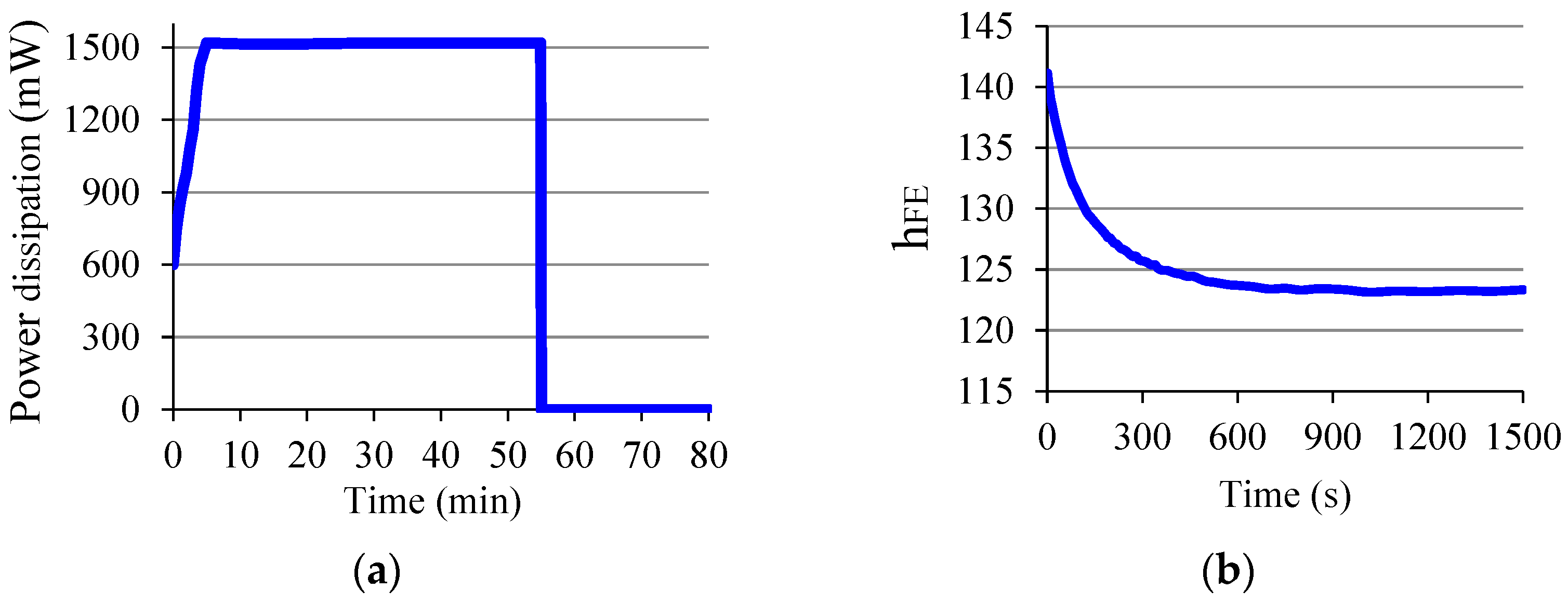

1.6. Electrical Stress in a BJT

2. Materials and Methods

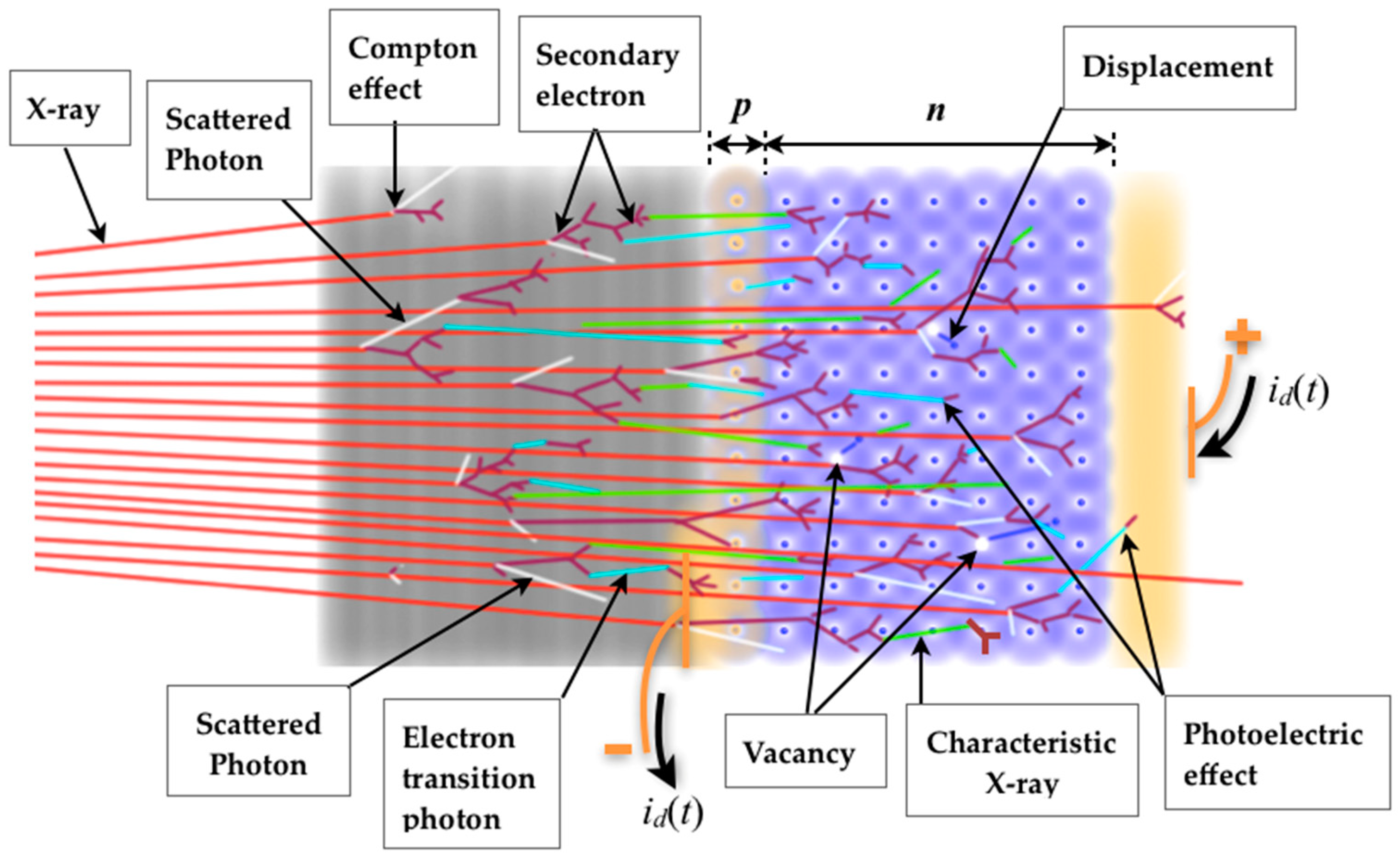

2.1. BJT Typical Operation as an X-ray Sensor

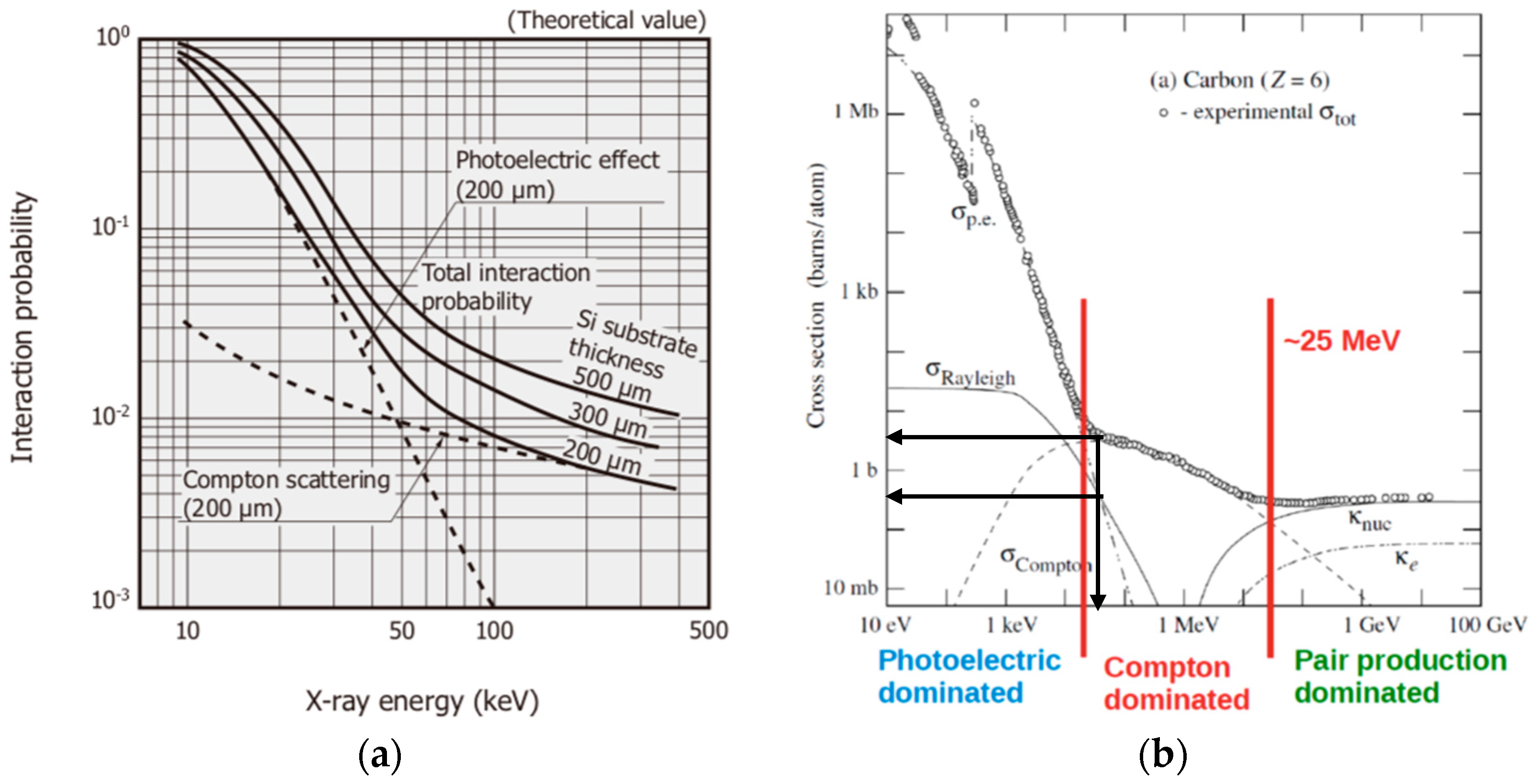

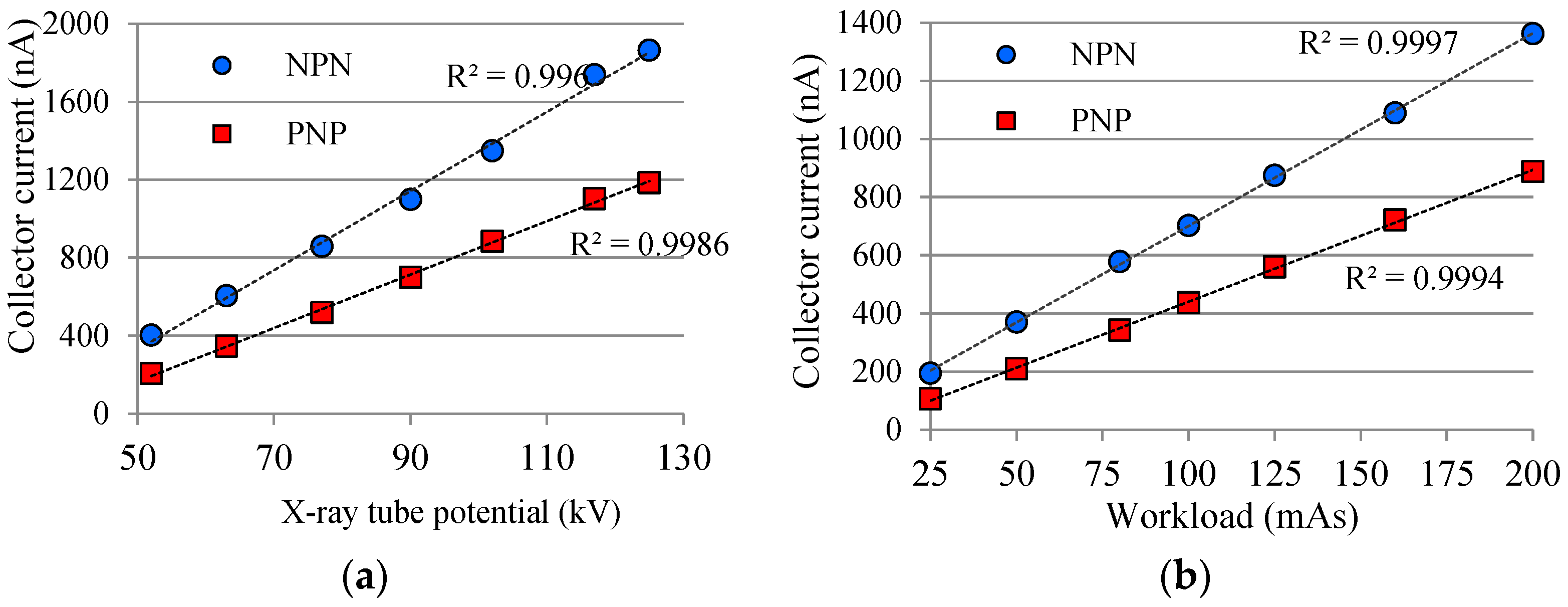

2.1.1. X-ray Photon Energy

2.1.2. Device Package

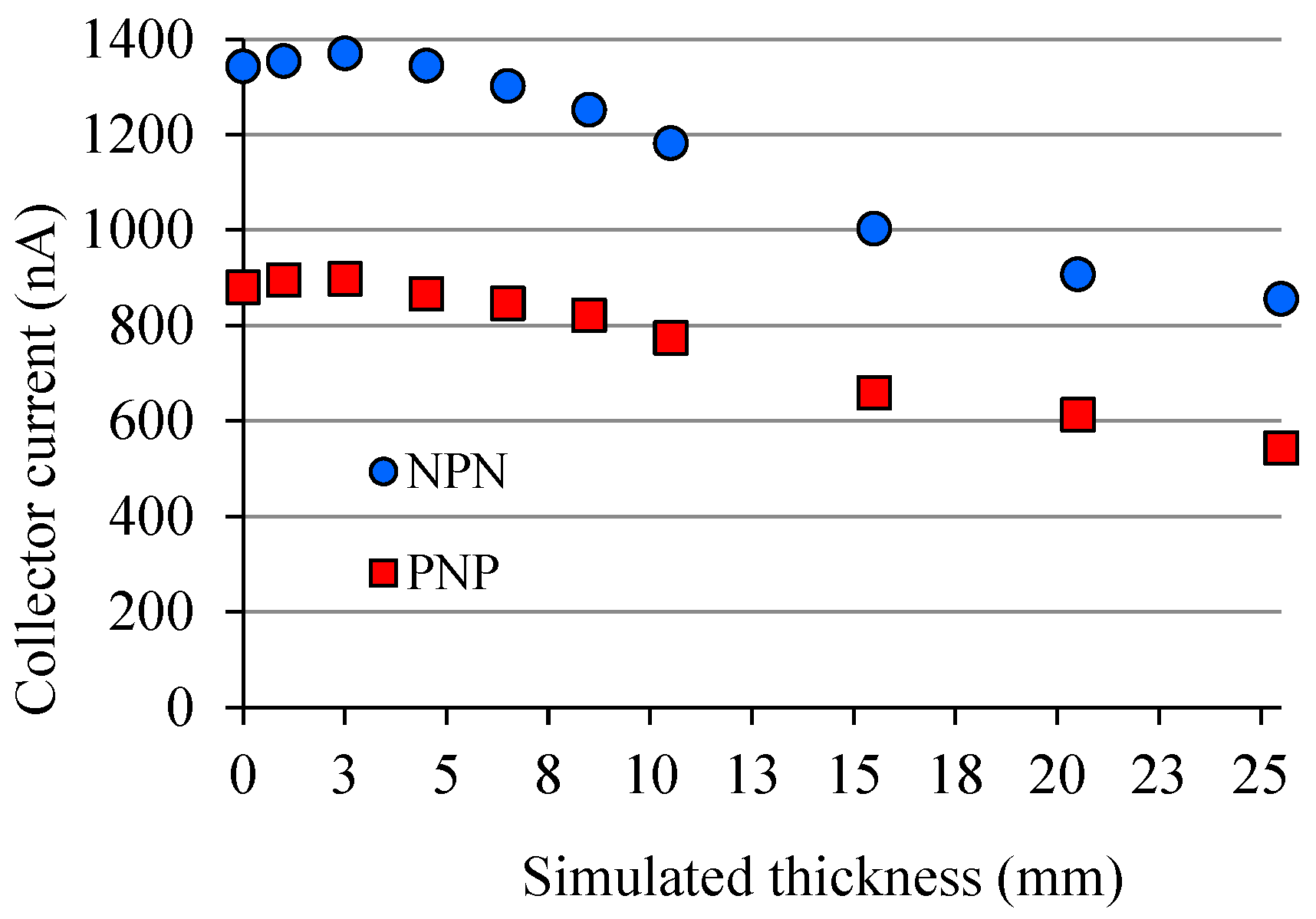

2.1.3. Scattered Radiation

2.1.4. Angular Dependence

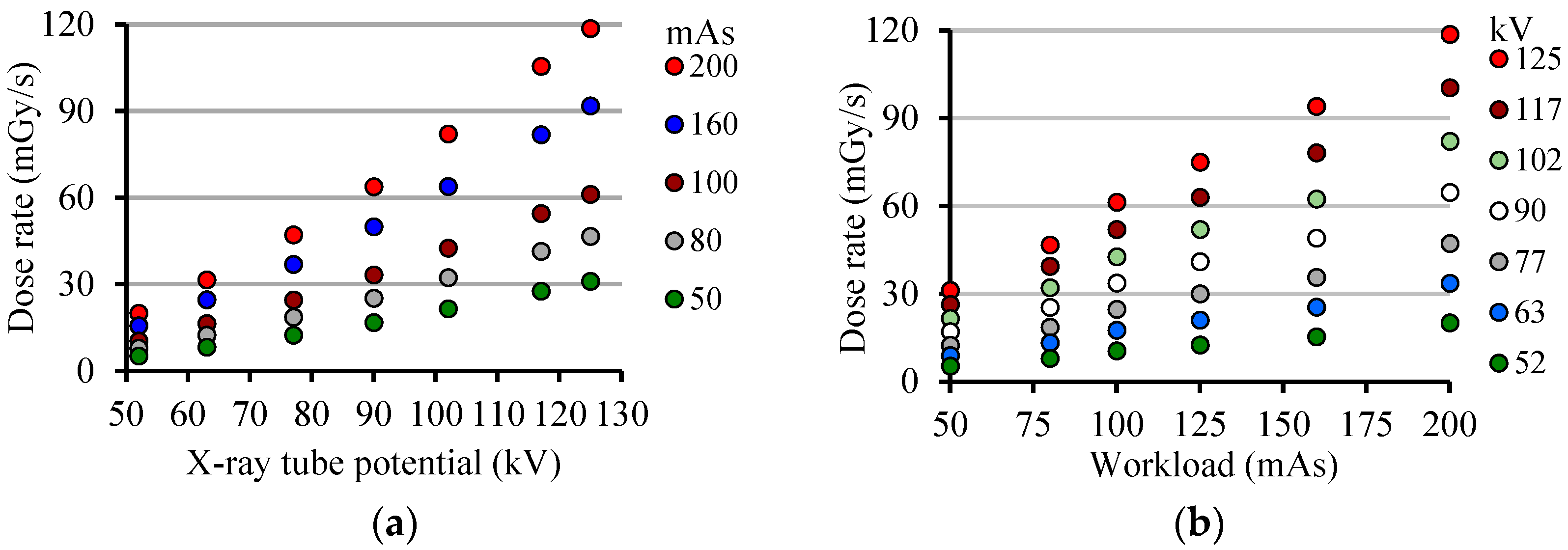

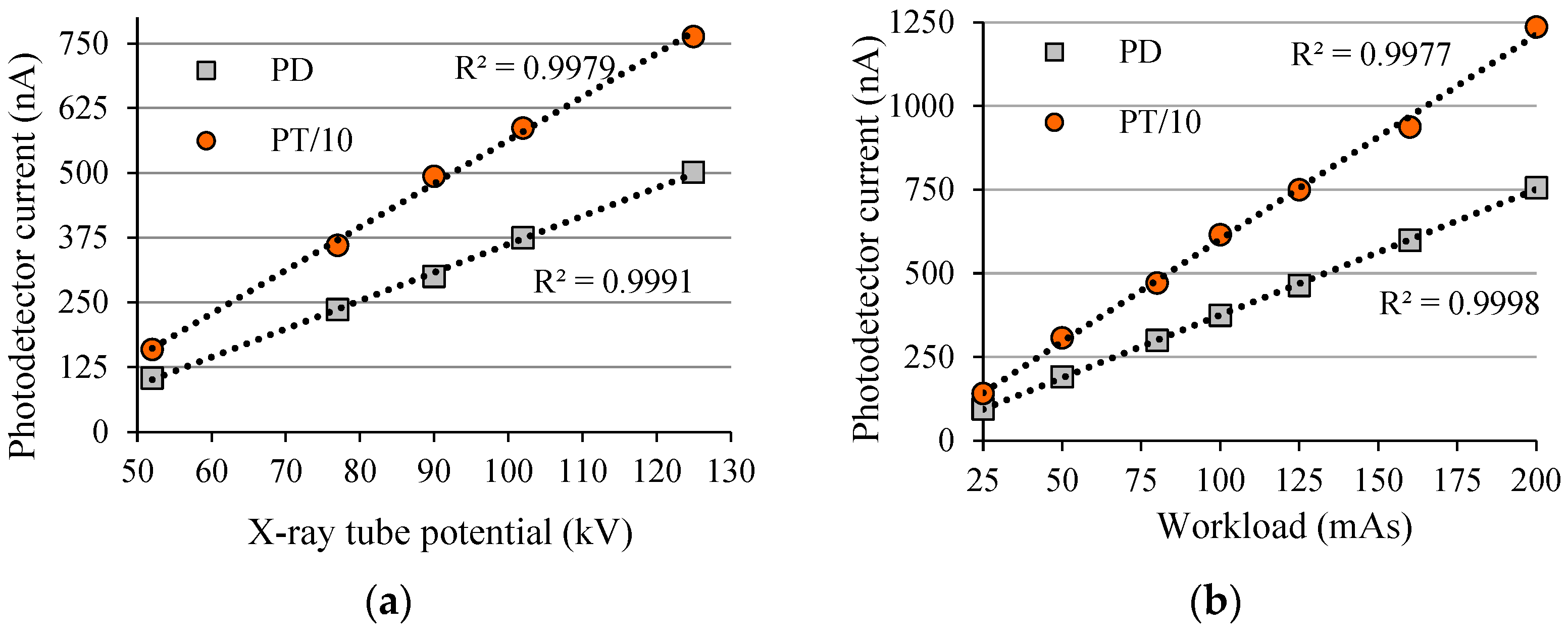

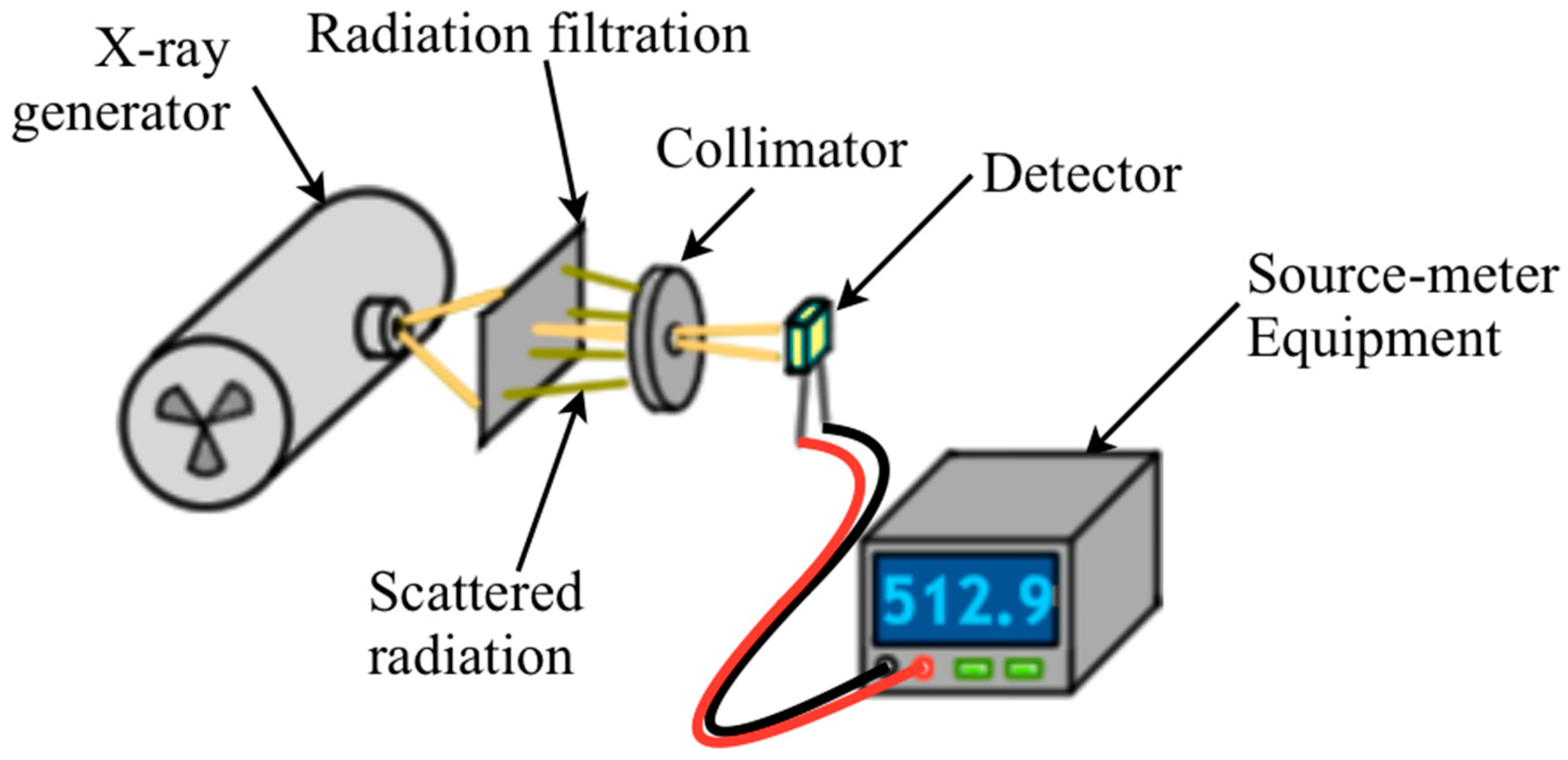

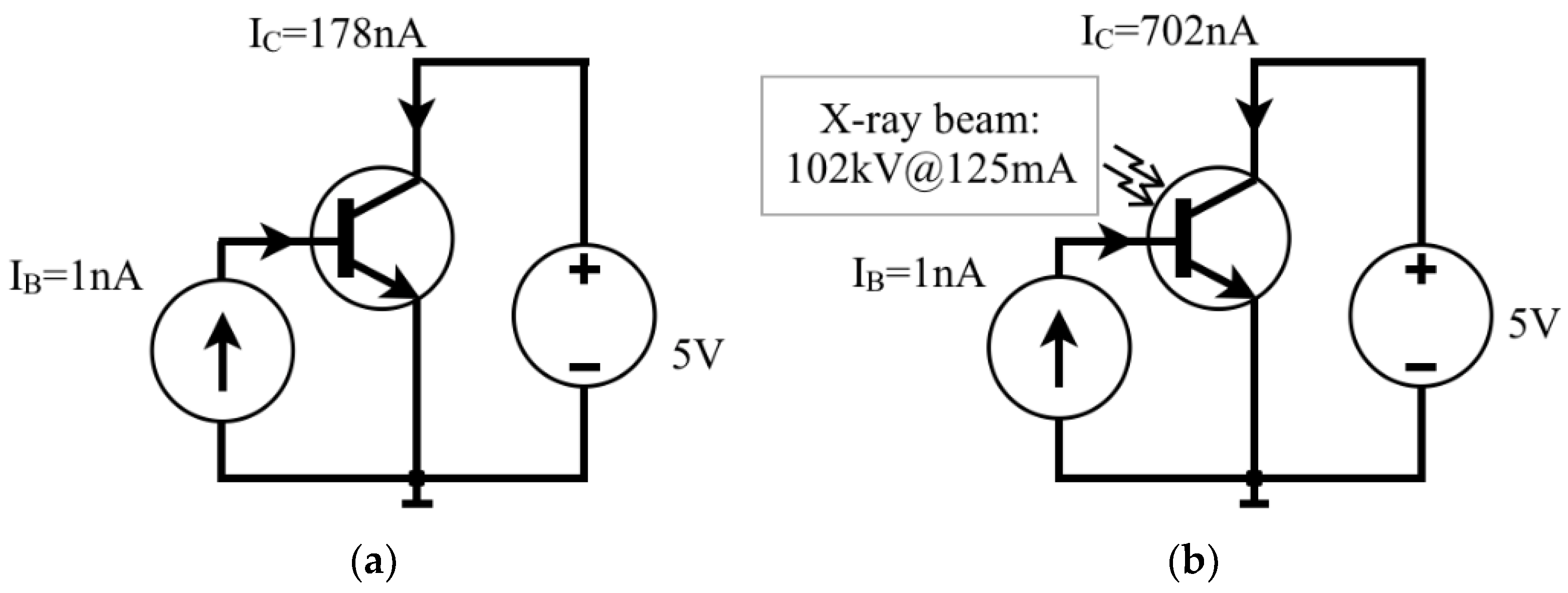

2.2. Method for Measuring ICX in a BJT

3. Results

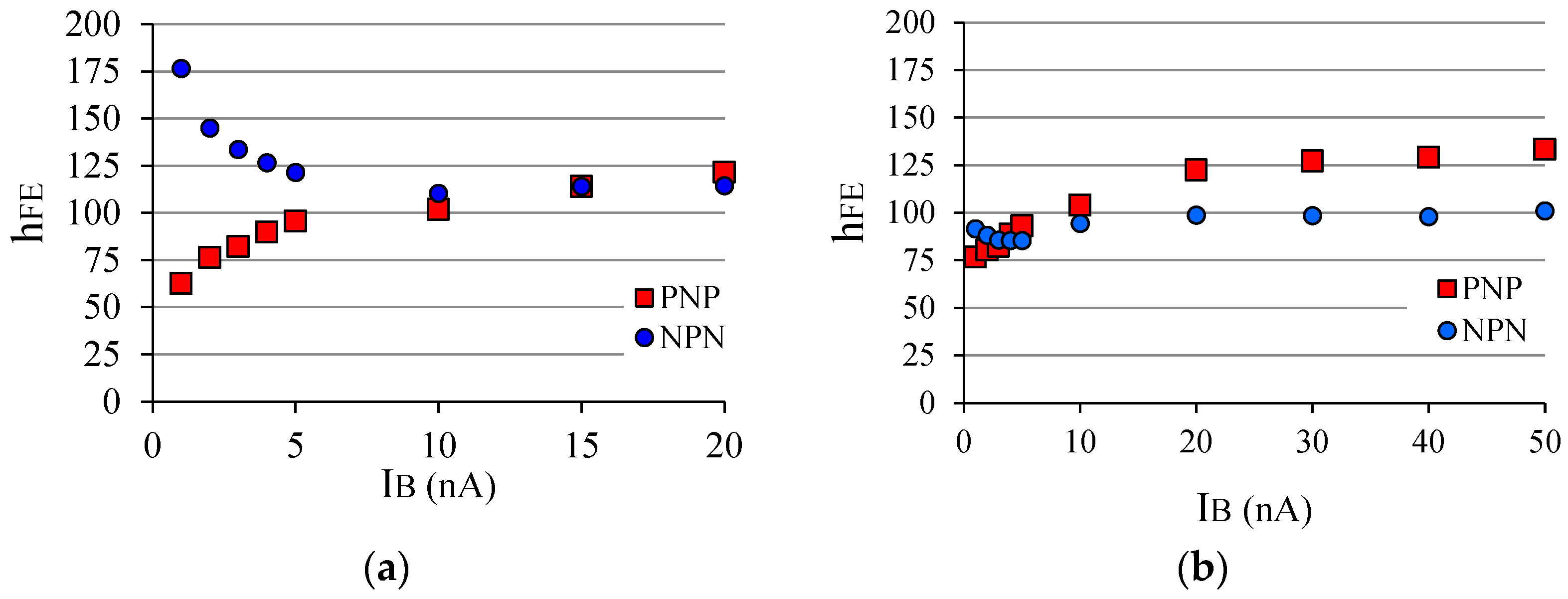

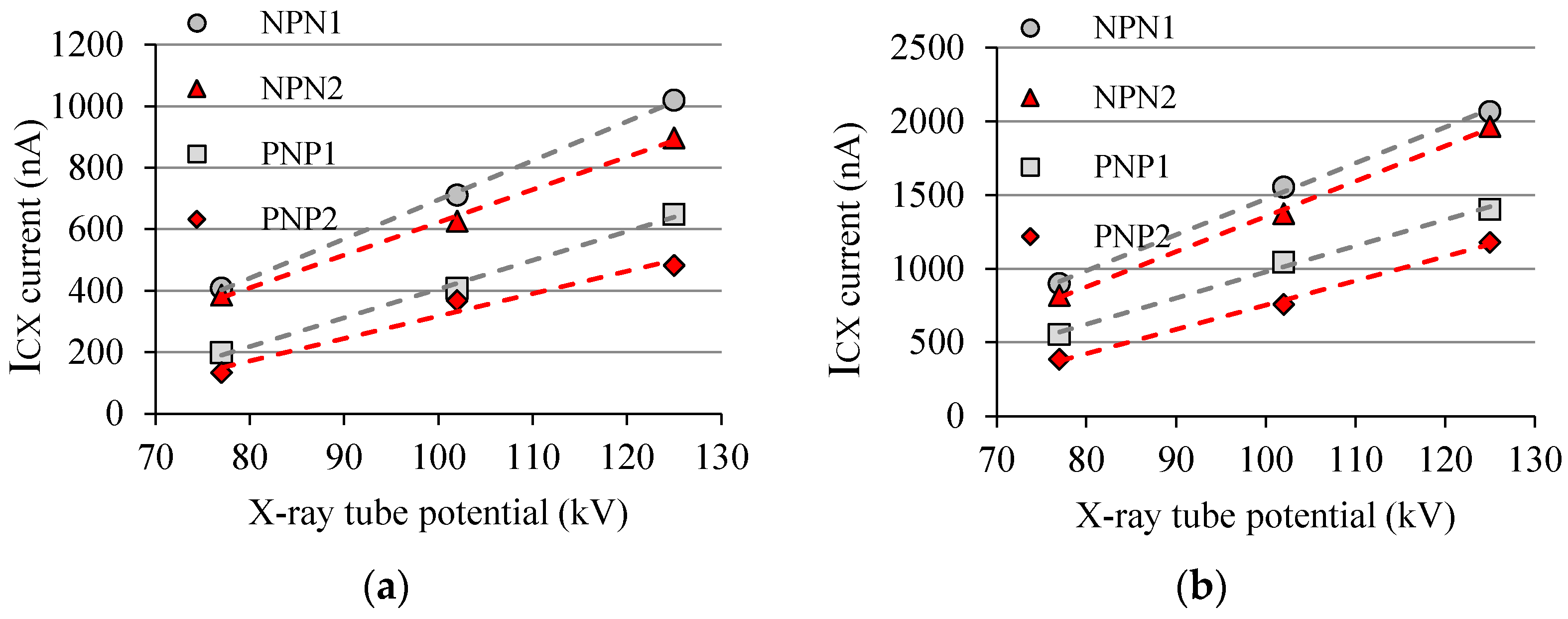

3.1. Influence of IB for a BJT Operating as an X-ray Sensor

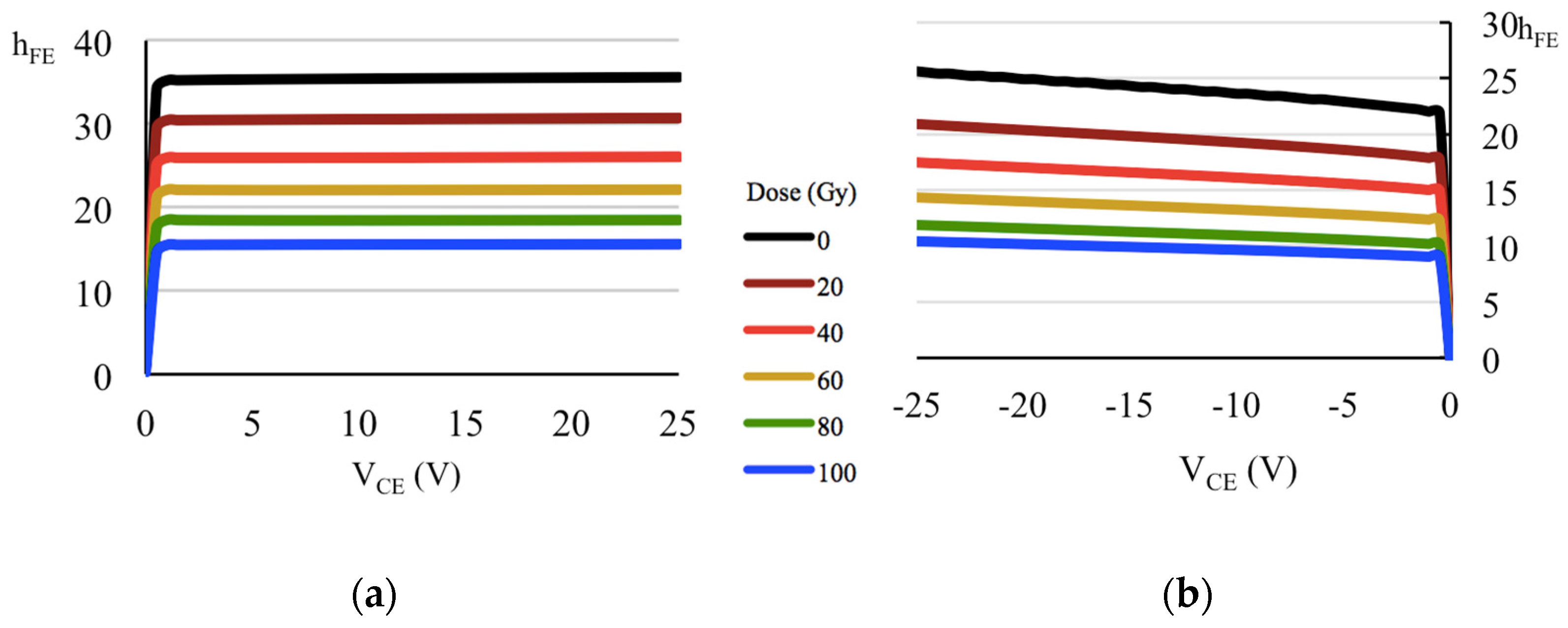

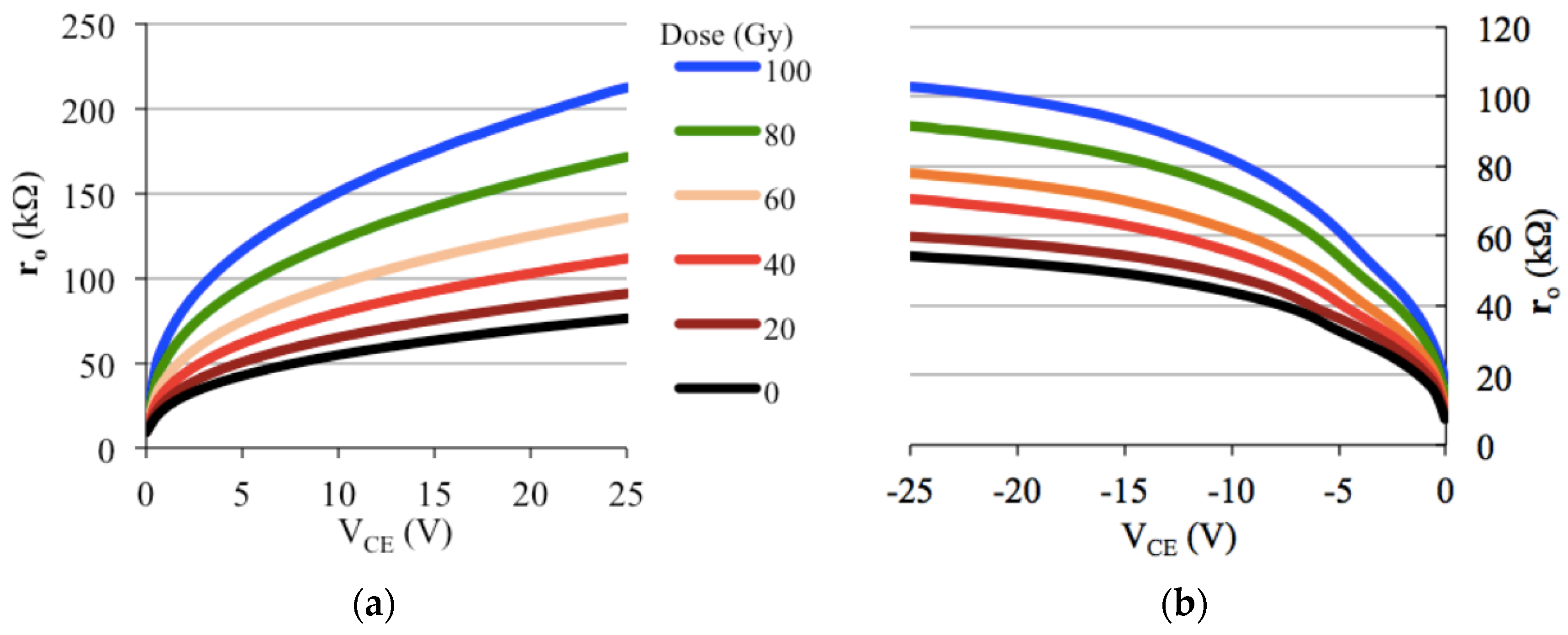

3.2. Radiation Damage in BJT as an X-ray Sensor

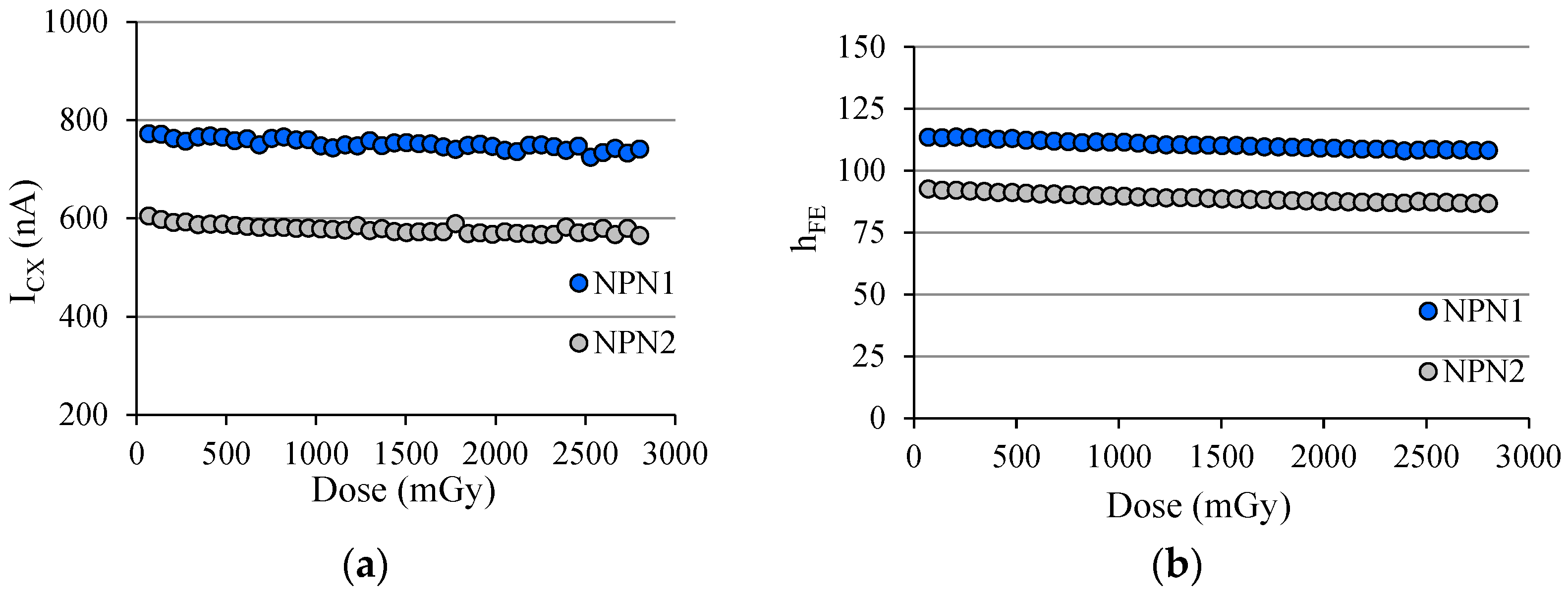

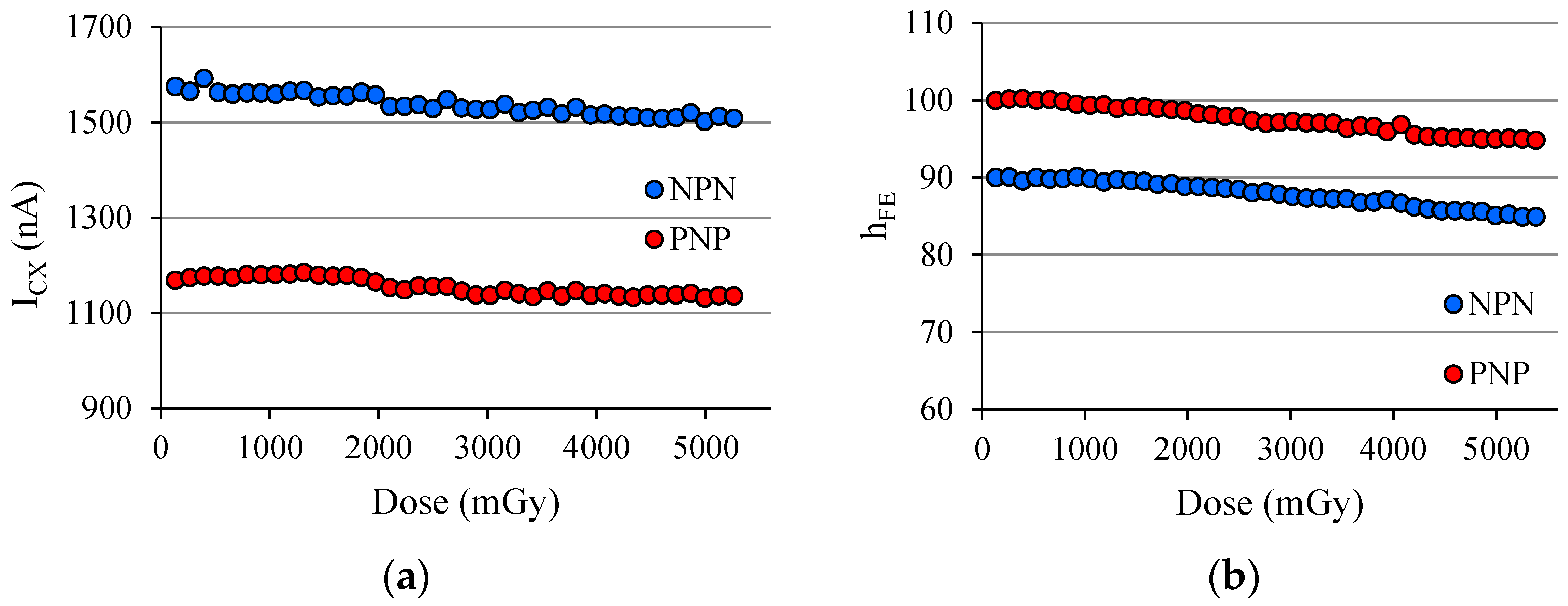

3.3. Repeatability in Measurements Made with BJT as an X-ray Sensor

4. Discussion

5. Conclusions

6. Patents

- Multimeter Electronic System for Measuring parameters of Diagnostic X-ray Equipment—“Sistema Eletrônico Multimedidor de Parâmetros de Equipamentos de Raios-X Diagnósticos”, Brazil Patent BR102015008361-0.

- Electronic Memory System Using X-rays—“Sistema de Memória Eletrônica Usando Raios-X”, WIPO Patent PCT/BR2020/050387.

Funding

Acknowledgments

Conflicts of Interest

References

- Duncan, T. Electronics for Today and Tomorrow; John Murray: London, UK, 1998. [Google Scholar]

- Harrison, P. The Cassell Dictionary of Physics; Cassell Wellington House: London, UK, 1998. [Google Scholar]

- Landshoff, P.; Metherell, A.; Rees, G. Transistors. In Essential Quantum Physics; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Sze, S.M. Modern Semiconductor Device Physics; John Willey & Sons: New York, NY, USA, 1998. [Google Scholar]

- Sah, C.T. Fundamentals of Solid State Electronics; World Scientific: Singapore, 2006. [Google Scholar]

- Gray, P.R.; Hurst, P.J.; Lewis, S.H.; Meyer, R.G. Analysis and Design of Analog Integrated Circuits, 4th ed.; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Reisch, M. High-Frequency Bipolar Transistors; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Sedra, A.S.; Smith, K.C. Microrelectronic Circuits; Oxford University Press: New York, NY, USA, 2004. [Google Scholar]

- Schroder, D.K. Semiconductor Material and Device Characterization, 3rd ed.; John Willey & Sons: New Jersey, NJ, USA, 2005. [Google Scholar]

- Tietze, U.; Schenk, C.; Gamm, E. Electronic Circuits, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Ross, I.M. The invention of the transistor. Proc. IEEE 1998, 86, 7–28. [Google Scholar] [CrossRef]

- Rimini, E. Ion Implantation: Basics to Device Fabrication; Springer Science + Business Media LLC: New York, NY, USA, 1995. [Google Scholar]

- Bower, R.W.; Shifrin, G.A. Method of Making Bipolar Transistor Devices. U.S. Patent 3523042A, 4 August 1970. [Google Scholar]

- Sullivan, P.A.; Collins, G.J. Process for Fabricating a Bipolar Transistor with a Thin Base and an Abrupt Base-Collector Junction. U.S. Patent 4,523,370, 18 June 1985. [Google Scholar]

- Fair, R.B. History of some early developments in ion-implantation technology leading to silicon transistor manufacturing. Proc. IEEE 1998, 86, 111–137. [Google Scholar] [CrossRef]

- Costa, A.M. BJT Inside. Available online: https://pt.wikipedia.org/wiki/Ficheiro:Transistor_Bipolar_por_dentro_211016.jpeg (accessed on 29 December 2021).

- ONSEMI. 2N3904 Datasheet. Available online: https://www.onsemi.com/pdf/datasheet/2n3904-d.pdf (accessed on 11 February 2022).

- Morris, A.S.; Langari, R. Measument and Instrumentation: Theory and Application; Academic Press: Whaltham, MA, USA, 2012. [Google Scholar]

- Sze, S.M.; Lee, M.K. Semiconductor Devices: Physics and Technology; John Willey & Sons: New York, NY, USA, 2012. [Google Scholar]

- Costa, A.M. Photo-BJT. Available online: https://commons.wikimedia.org/wiki/File:Fototransistor_base_flutuante_220212.jpg (accessed on 11 February 2022).

- Early, J.M. Effects of space-charge layer widening in junction transistors. Proc. IRE 1952, 40, 1401–1406. [Google Scholar] [CrossRef]

- Messenger, G.C.; Ash, M.S. The Effects of Radiation on Electronic System; Springer: New York, NY, USA, 1986. [Google Scholar]

- Creemer, J.F. The Effect of Mechanical Stress on Bipolar Transistor Characteristics. Ph.D. Thesis, Technical University of Delft, Delft, The Netherlands, 2002. [Google Scholar]

- Toufik, N.; Mialhe, P. Degradation of junction parameters of an electrically stressed bipolar transistor. Act. Passiv. Electron. Compon. 2001, 24, 053209. [Google Scholar] [CrossRef]

- Central Semiconductor. 2N3903 datasheet. Available online: https://my.centralsemi.com/datasheets/2N3903.PDF (accessed on 2 December 2021).

- Hamamatsu Photonics. X-ray Detectors/Technical Note. Available online: https://www.hamamatsu.com/resources/pdf/ssd/X-ray_kmpd9016e.pdf (accessed on 20 January 2022).

- Magalhães, C.M.S.; Sobrinho, M.L.; Souza, D.N.; Antonio Filho, J.; Silva, E.F., Jr.; Santos, L.A.P. A novel dosimetry system for computed tomography using phototransistor. Radiat. Meas. 2012, 47, 30–33. [Google Scholar] [CrossRef][Green Version]

- Alves, A.N. Caracterização de Transistor Bipolar de Junção para Avaliação da dose em Profundidade em Feixes de Raios-X Diagnosticos. Master’s Thesis, Universidade Federal de Pernambuco, Recife, Brazil, 2014. [Google Scholar]

- Santos, L.A.P.; Cavalcanti, F.A.; Monte, D.S.; Araujo, G.G.; Alves, A.N.; Nobrega, G.S.; Santos, M.A.P. Techniques for measuring some characteristics of ionizing radiation beams using bipolar junction transistor as a detector. In Proceedings of the 2013 3rd International Conference on Advancements in Nuclear Instrumentation, Measurement Methods and Their Applications (ANIMMA), Marseille, France, 23–27 June 2013. [Google Scholar]

- Santos, L.A.P.; Araujo, G.G.; Oliveira, F.L.; Silva, E.F., Jr.; Santos, M.A.P. An alternative method for using bipolar junction transistors as a radiation dosimetry detector in breast cancer treatment. Radiat. Meas. 2014, 71, 407–411. [Google Scholar] [CrossRef]

- Haba, T.; Koyama, S.; Aoyama, T.; Kinomura, Y.; Ida, Y.; Kobayashi, M.; Kameyama, H.; Tsutsumi, Y. Pin-photodiode array for the measurement of fan-beam energy and air kerma distribution of X-ray CT scanners. Phys. Med. 2016, 32, 905–913. [Google Scholar] [CrossRef] [PubMed]

- IAEA. Diagnostic Radiology Physics: A Handbook for Teachers and Students; IAEA: Vienna, Austria, 2014. [Google Scholar]

- McLean, D. X-ray spectra and beam qualities. In Proceedings of the Joint ICTP-IAEA Advanced School on Dosimetry in Diagnostic Radiology, Trieste, Italy, 11–15 May 2009. [Google Scholar]

- Lechner, A. Proceedings of the CAS-CERN Accelerator School: Beam Injection, Extraction and Transfer, Erice, Italy, 10–19 March 2017; CERN Yellow Reports: Geneve, Switzerland, 2018. [Google Scholar]

- Lutz, G. Semiconductor Radiation Detector; Springer: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

- Valença, C.P.V.; Gonçalves Filho, L.C.; Macedo, M.A.; Aguiar, J.A.; Santos, L.A.P. Comparison between Photodetectors, Transistors and a ZnO Nanodevice under Standard Diagnostic X-ray Beams. In Proceedings of the ANIMMA 2019, Portoroz, Slovenia, 17–21 June 2019; Available online: http://www.animma.com/wp-content/uploads/xyz987/09-1352.pdf (accessed on 16 November 2021).

- Diodes Incorporated. ZTX851 Datasheet. Available online: https://www.diodes.com/assets/Datasheets/ZTX851.pdf (accessed on 16 November 2021).

- Diodes Incorporated. ZTX948 Datasheet. Available online: https://www.diodes.com/assets/Datasheets/ZTX948.pdf (accessed on 16 November 2021).

- Turner, J.E. Atoms, Radiation, and Radiation Protection, 3rd ed.; Willey-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2007. [Google Scholar]

- Monte, D.S.; Cavalcanti, F.A.; Santos, L.A.P. Sistema Eletrônico Multimedidor de Parâmetros de Equipamentos de Raios-X Diagnósticos. Brazil Patent No. 102015008361-0, 2018. [Google Scholar]

- Claeys, C.; Simoen, E. Radiation Effects in Advanced Semiconductors Materials and Devices; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Leroy, C.; Rancoita, P.G. Particle interaction and displacement damage in silicon devices operated in radiation environments. Rep. Prog. Phys. 2007, 70, 493. [Google Scholar] [CrossRef]

- Srour, J.R.; Marshall, C.J.; Marshall, P.W. Review of displacement damage effects in silicon devices. IEEE Trans. Nucl. Sci. 2003, 50, 653–670. [Google Scholar] [CrossRef]

- Oldham, T.R.; McLean, F.B. Total ionizing dose effects in MOS oxide and devices. IEEE Trans. Nucl. Sci. 2003, 50, 483–499. [Google Scholar] [CrossRef]

- Schwank, J.R.; Shaneyfelt, M.R.; Fleetwood, D.M.; Felix, J.A.; Dodd, P.E.; Paillet, P.; Ferlet-Cravois, V. Radiation Effects in MOS Oxides. IEEE Trans. Nucl. Sci. 2008, 55, 1833–1853. [Google Scholar] [CrossRef]

- Monte, D.S.; Santos, L.A.P. A method for measuring ionizing radiation dose by analyzing hybrid-π parameters of transistors. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference, Dubrovnik, Croatia, 25–28 May 2020. [Google Scholar] [CrossRef]

- Monte, D.S. Efeito da Radiação X, Nível Radiodiagnóstico, Sobre os Parâmetros Pi-Híbridos de Transistors. Ph.D. Thesis, Universidade Federal de Pernambuco, Recife, Brazil, 2020. [Google Scholar]

- Central Semiconductor. TIP41 Datasheet. Available online: https://my.centralsemi.com/datasheets/TIP41.PDF (accessed on 15 November 2021).

- Central Semiconductor. TIP42 Datasheet. Available online: https://my.centralsemi.com/datasheets/TIP42.PDF (accessed on 15 November 2021).

- Schmidt, D.M.; Fleetwood, D.M.; Schrimpf, R.D.; Pease, R.L.; Graves, R.J.; Johnson, G.H.; Galloway, K.F.; Combs, W.E. Comparison of ionizing radiation-induced gain degradation in lateral, substrate, and vertical PNP BJTs. IEEE Trans. Nucl. Sci. 1995, 42, 1541–1549. [Google Scholar] [CrossRef]

- Wu, A.; Schrimpf, R.D.; Barnaby, H.J.; Fleetwood, D.M.; Pease, R.L.; Kosier, S.L. Radiation-induced gain degradation in lateral PNP BJTs with lightly and heavily doped emitters. IEEE Trans. Nucl. Sci. 1997, 44, 1914–1921. [Google Scholar] [CrossRef]

- Chen, X.J.; Barnaby, H.J.; Schrimpf, R.D.; Fleetwood, D.M.; Pease, R.L.; Platteter, D.G.; Dunham, G.W. Nature of interface defect buildup in gated bipolar devices under low dose rate irradiation. IEEE Trans. Nucl. Sci. 2006, 53, 3649–3654. [Google Scholar] [CrossRef]

- Barnaby, H.J.; Schrimpf, R.D.; Galloway, K.F.; Li, X.; Yang, J.; Liu, C. Displacement damage in bipolar junction transistor: Beyond Messenger-Spratt. IEEE Trans. Nucl. Sci. 2017, 64, 149–155. [Google Scholar] [CrossRef]

- IAEA. Applying Radiation Safety Standards in Diagnostic Radiology and Interventional Procedures Using X rays; Safety Report Series No. 39; IAEA: Vienna, Austria, 2006. [Google Scholar]

- Santos, L.A.P.; Monte, D.S.; Prazeres, P.J.N.B.; Santos, L.R.R.P.; Santos, J.A.P. Sistema de Memória Eletrônica Usando Raios-X. WIPO Patent No. PCT/BR/2020/050387, 2020. [Google Scholar]

- Scients. Available online: http://www.scients.com.br/blog/?p=6 (accessed on 21 December 2021).

| Parameter | IB (μA) | hFE | IC (mA) | Temperature (°C) |

|---|---|---|---|---|

| Before ES | 100 | 120 | 12.0 | 21.5 |

| During ES | 12,500 | 24.3 | 303.8 | 115.4 |

| After ES | 100 | 123 | 12.3 | 21.4 |

| Instrument | Model | Manufacturer | Lab. |

|---|---|---|---|

| Semiconductor analyzer | 4200A-SCS | Keithley | 1 |

| Source-meter 1 | 6430 | Keithley | 1 |

| Source-meter 2 | 6430 | Keithley | 1 |

| Source-meter 3 | 2450 | Keithley | 2 |

| Source-meter 4 | EFF1705 | Scients | 2 |

| Collimator Area (cm2) | ~200 | 100 | 64 | 36 | 16 | 4 | 1 | ~0.2 |

|---|---|---|---|---|---|---|---|---|

| ICX (nA) | 1021.9 | 1009.4 | 1003.9 | 995.4 | 997.0 | 970.4 | 936.3 | 901.6 |

| Rotation | Counterclockwise | Clockwise | |||||

|---|---|---|---|---|---|---|---|

| Angle | 60° | 45° | 30° | 0° | 30° | 45° | 60° |

| ICX (nA) | 951.8 | 988.4 | 1047.2 | 1020.5 | 1000.6 | 946.9 | 929.6 |

| BJT | NPN | PNP | ||||||

|---|---|---|---|---|---|---|---|---|

| IB (nA) | hFE | IC (nA) | ICX (nA) | IBX (nA) | hFE | IC (nA) | ICX (nA) | IBX (nA) |

| 5 | 100.0 | 500.2 | 704.0 | 7.0 | 101.9 | 509.4 | 483.7 | 4.7 |

| 10 | 100.6 | 1006.3 | 872.4 | 8.7 | 100.7 | 1007.4 | 650.6 | 6.5 |

| 20 | 100.7 | 2014.0 | 836.7 | 8.4 | 125.1 | 2501.8 | 601.1 | 4.8 |

| 30 | 100.0 | 3001.5 | 795.8 | 8.0 | 130.0 | 3899.1 | 555.4 | 4.3 |

| 40 | 100.2 | 4008.1 | 974.8 | 9.7 | 132.5 | 5301.9 | 646.0 | 4.9 |

| 50 | 103.3 | 5163.4 | 942.1 | 9.1 | 135.5 | 6774.1 | 705.3 | 5.2 |

| BJT | X-ray Tube Potential (kV) | 77 | 102 | 125 |

|---|---|---|---|---|

| npn β ≈ 100 | Measured IBX(JBC) (nA) | 5.2 | 8.3 | 11.0 |

| Measured ICX (nA) | 569.5 | 922.3 | 1229.1 | |

| Estimated IBX(JBE) (nA) | 0.5 | 0.9 | 1.3 | |

| pnp β ≈ 100 | Measured IBX(JBC) (nA) | 2.9 | 4.9 | 6.3 |

| Measured ICX (nA) | 396.7 | 652.3 | 874.5 | |

| Estimated IBX(JBE) (nA) | 1.1 | 1.6 | 2.4 |

| BJT | X-ray Tube Potential (kV) | 77 | 102 | 125 |

|---|---|---|---|---|

| npn β ≈ 100 | Measured IBX(JBC) (nA) | 9.9 | 16.2 | 21.9 |

| Measured ICX (nA) | 1099.9 | 1770.8 | 2356.1 | |

| Estimated IBX(JBE) (nA) | 1.1 | 1.5 | 1.7 | |

| pnp β ≈ 100 | Measured IBX(JBC) (nA) | 5.6 | 9.3 | 12.4 |

| Measured ICX (nA) | 799.3 | 1282.1 | 1722.7 | |

| Estimated IBX(JBE) (nA) | 2.4 | 3.5 | 4.8 |

| BJT Type | TIP41 (npn) | TIP42 (pnp) | ||

|---|---|---|---|---|

| Dose (Gy) | hFE | ro (kΩ) | hFE | ro (kΩ) |

| 0 | 35.6 | 76.2 | 25.6 | 54.2 |

| 20 | 30.7 | 90.8 | 20.9 | 59.7 |

| 40 | 26.1 | 111.5 | 17.5 | 70.5 |

| 60 | 22.1 | 135.5 | 14.3 | 77.9 |

| 80 | 18.5 | 171.3 | 11.9 | 91.4 |

| 100 | 15.6 | 212.0 | 10.4 | 102.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, L.A.P. An Overview on Bipolar Junction Transistor as a Sensor for X-ray Beams Used in Medical Diagnosis. Sensors 2022, 22, 1923. https://doi.org/10.3390/s22051923

Santos LAP. An Overview on Bipolar Junction Transistor as a Sensor for X-ray Beams Used in Medical Diagnosis. Sensors. 2022; 22(5):1923. https://doi.org/10.3390/s22051923

Chicago/Turabian StyleSantos, Luiz A. P. 2022. "An Overview on Bipolar Junction Transistor as a Sensor for X-ray Beams Used in Medical Diagnosis" Sensors 22, no. 5: 1923. https://doi.org/10.3390/s22051923

APA StyleSantos, L. A. P. (2022). An Overview on Bipolar Junction Transistor as a Sensor for X-ray Beams Used in Medical Diagnosis. Sensors, 22(5), 1923. https://doi.org/10.3390/s22051923