Remote IoT Education Laboratory for Microcontrollers Based on the STM32 Chips

Abstract

:1. Introduction

2. Background and Motivation

- Question: “Is it difficult to study microprocessor technology online?” 40% (n = 8) of students answered this question with “yes” and 60% (n = 12) answered “no”, which means almost half of the students had problems with online learning.

- Question: “Would you rather study the Microprocessor technology subject in full-time than online form?” For this question, up to 80% (n = 16) answered “yes” and only 20% (n = 4) of students responded with “no”.

- Question: “Where is the biggest problem of online learning?” Students could select more than one answer, where 50% (n = 10) of them responded with: “I have trouble asking the teacher for help over the internet” and 25% (n = 5) answered, “If the teacher does not ask me how I am working, I will not say that the program does not work.” As another problem, 30% (n = 6) of the students commented: “I am stuck with the program in one place and I cannot continue.”

- Question: “If the study was full-time, would you ask the teacher for help with programming rather than through online study?” For the question, up to 85% (n = 17) of students responded with “yes” and only 15% (n = 3) of them selected “no” (see in Figure 1a).

- Question: “If you have a choice, would you rather learn with a simulator or real microcontroller?” This question was important and 90% (n = 18) of students selected “microcontroller”. Only 10% (n = 2) selected “simulator”.

- Question: “Would an additional IoT module to Nucleo-64 help you, with which the teacher would monitor the status of your microcontroller, so that he could identify possible problems in solving tasks?” This was the most important question. Up to 60% (n = 12) of students would welcome additional hardware for microprocessor technology learning. A total of 15% (n = 3) of students answered “no” and 25% (n = 5) responded with “I do not know” (see in Figure 1b).

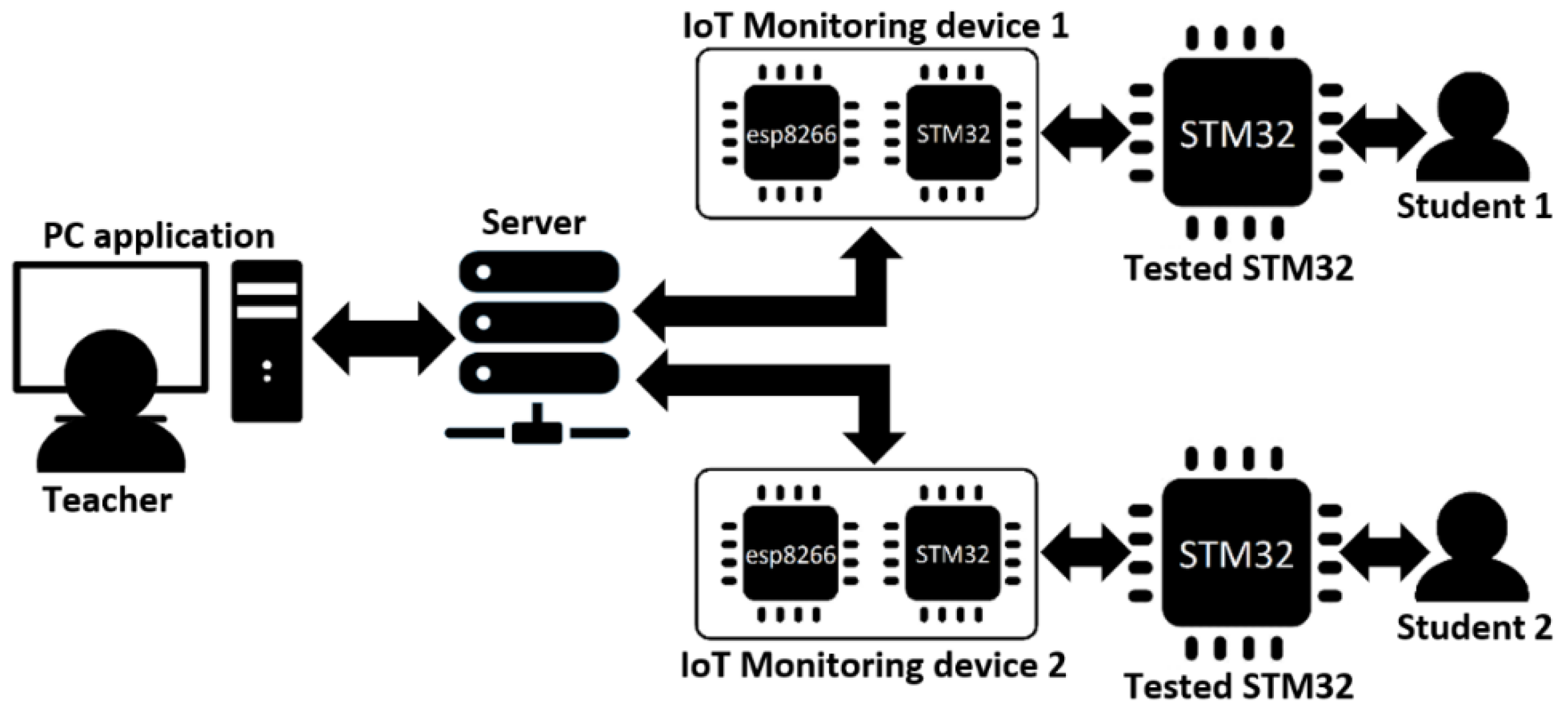

3. Materials and Methods

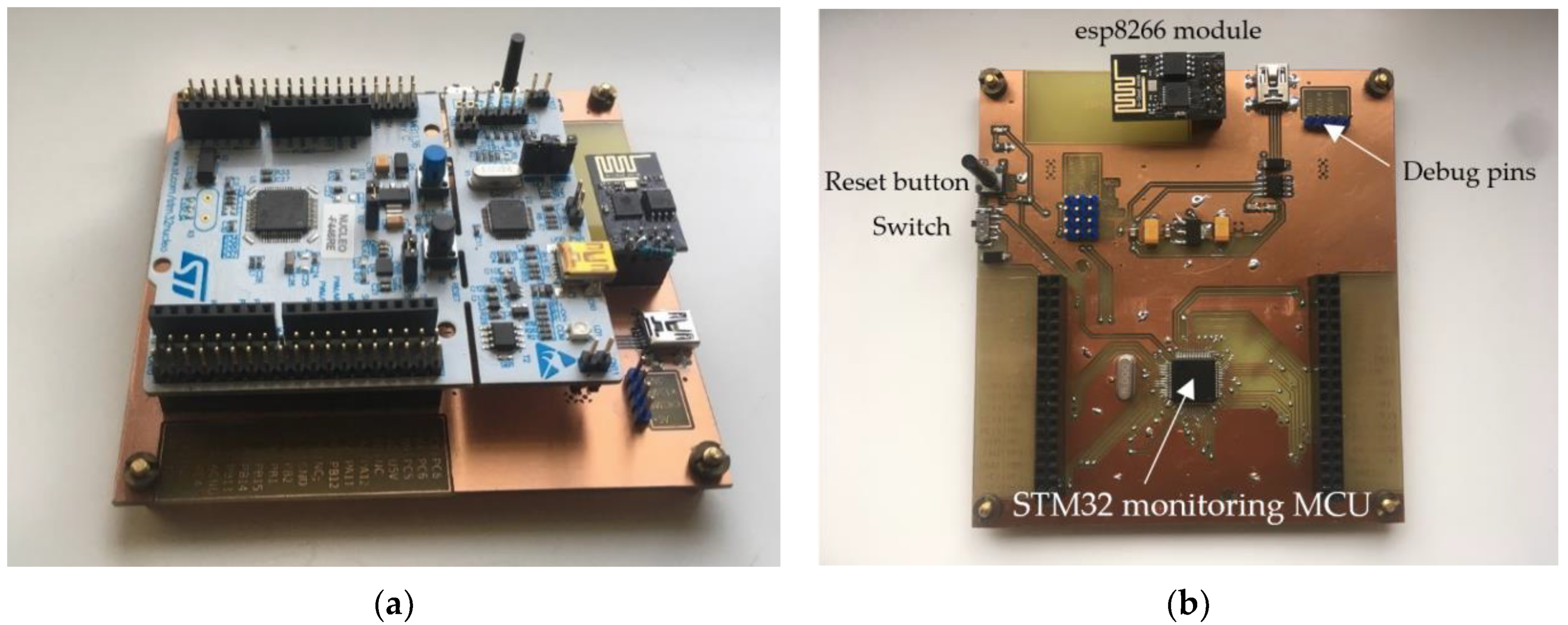

3.1. Hardware Parts

3.2. Software Parts

3.2.1. Server Program

- Starts the server;

- Connects the teacher application (control application);

- Connects the student IoT monitoring device;

- Collects stored information about student connections during the lesson;

- Control application to student IoT monitoring device: “sx-y”, where “s” represents addressing a student with an IoT monitoring device number corresponding to “x”. The “y” character represents other data which are transmitted.

- Student IoT monitoring device to control application: “tx-y”, where the recipient is a teacher by the first “t” character. The “x” indicates the IoT monitoring device number from which the response comes from.

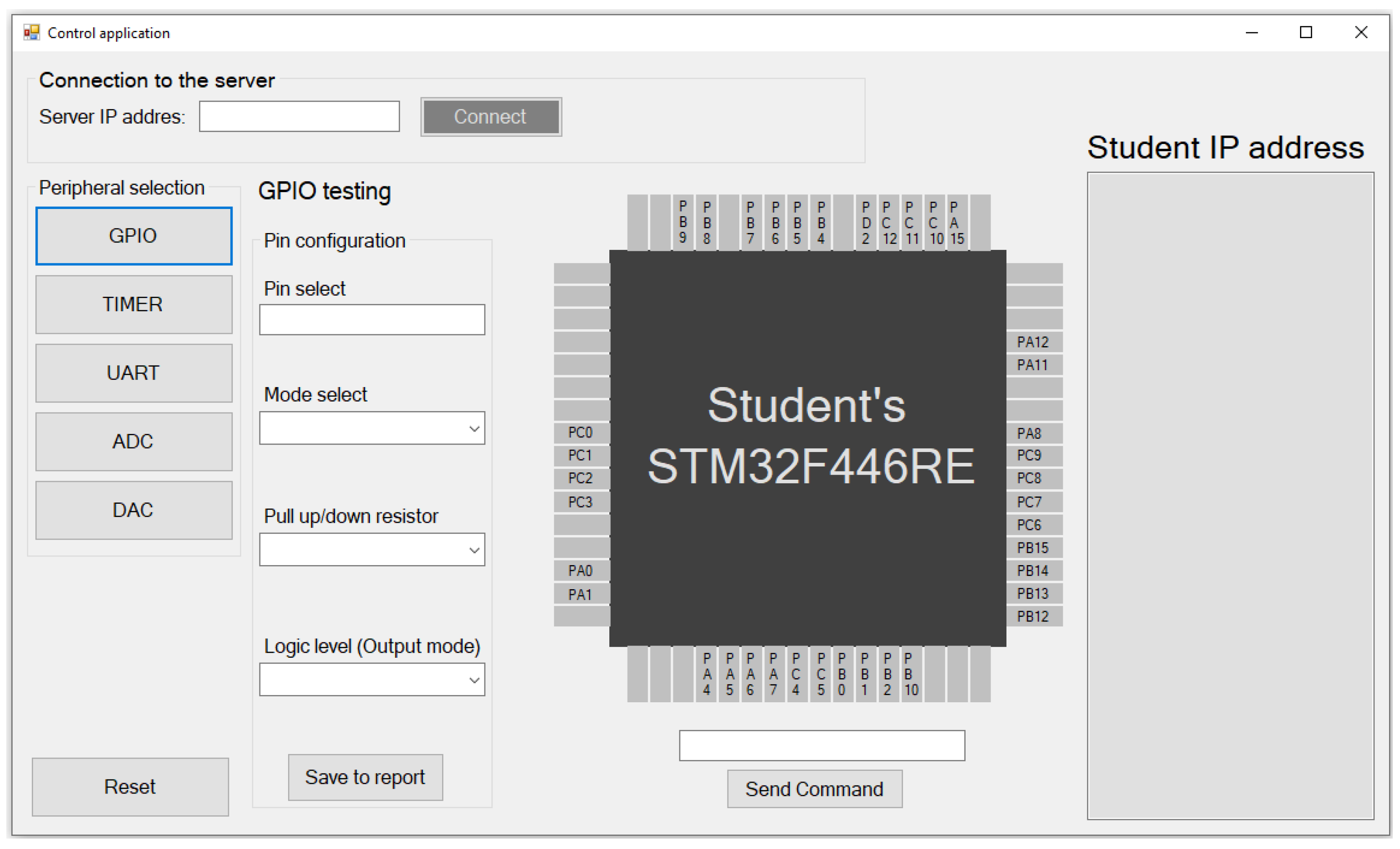

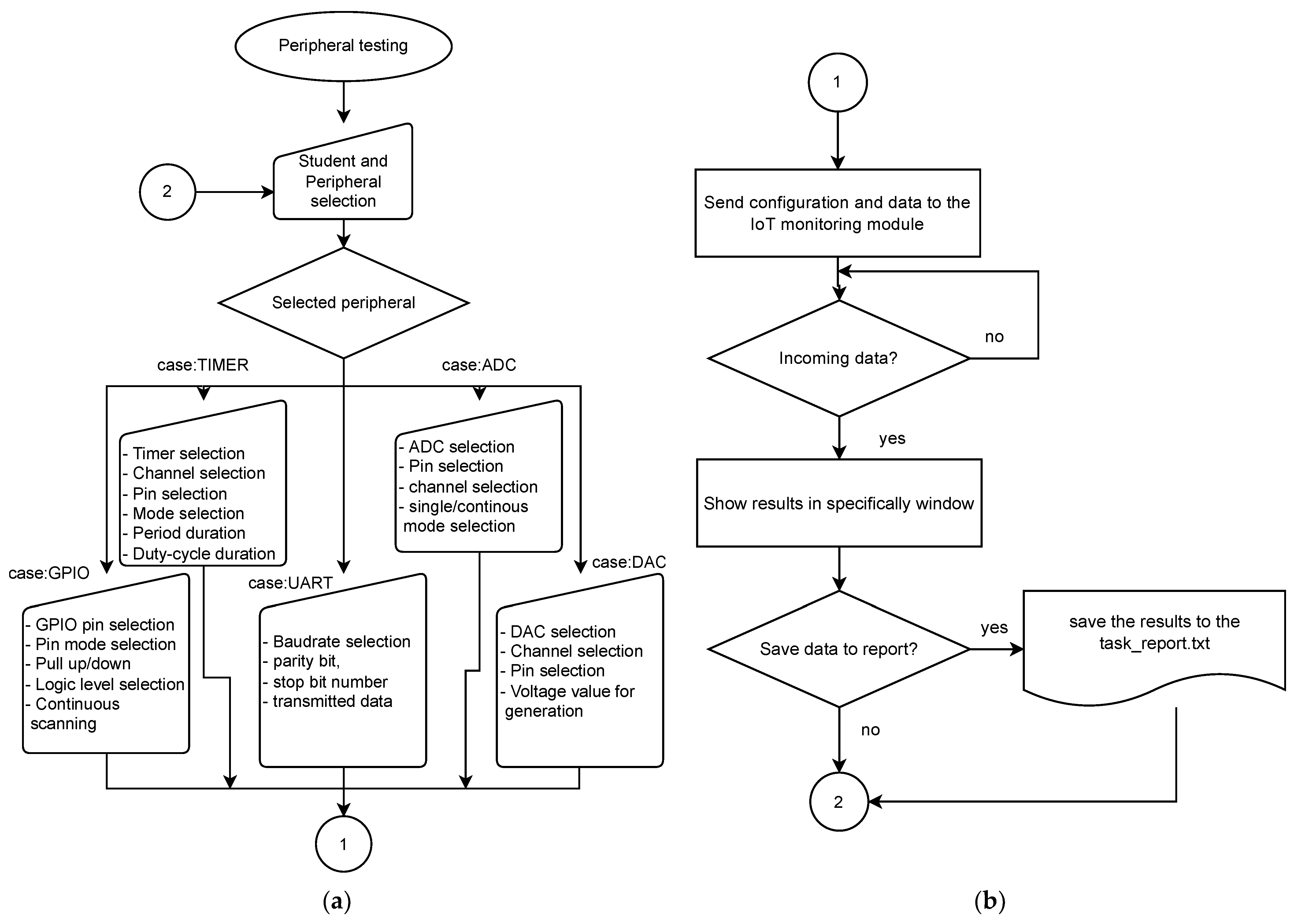

3.2.2. Control Application

- Connection to the server, shown in the left upper corner, where the user (teacher) enters the server IP address. In this case, two parameters are required—server IP address and port. Both parameters are static. Therefore, it will not be changed (unless the application is on another server with a different IP address). After the connection, the program informs the user about a successful connection;

- Student IP address is used for the students’ IP address and module number display connected to the virtual laboratory. This list is refreshed each time a new student joins. The teacher sees the number of the IoT monitoring device and the corresponding IP address of this module. By clicking on a specific module number, the teacher selects the module with which he wants to communicate;

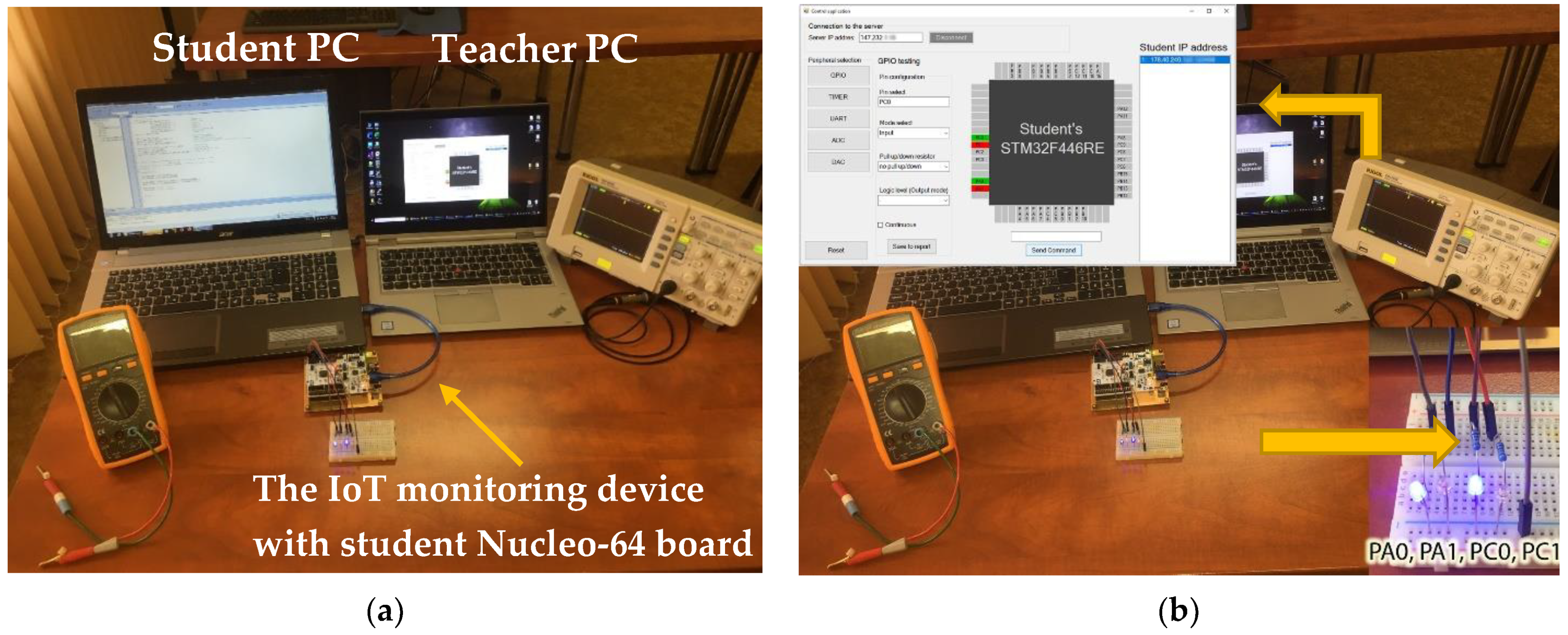

- Peripheral selection is used for peripheral selection, where the teacher can choose GPIO, TIMER, USART, ADC, or DAC peripheral. By clicking on a button, specific peripheral testing is shown. In this case, it is GPIO testing;

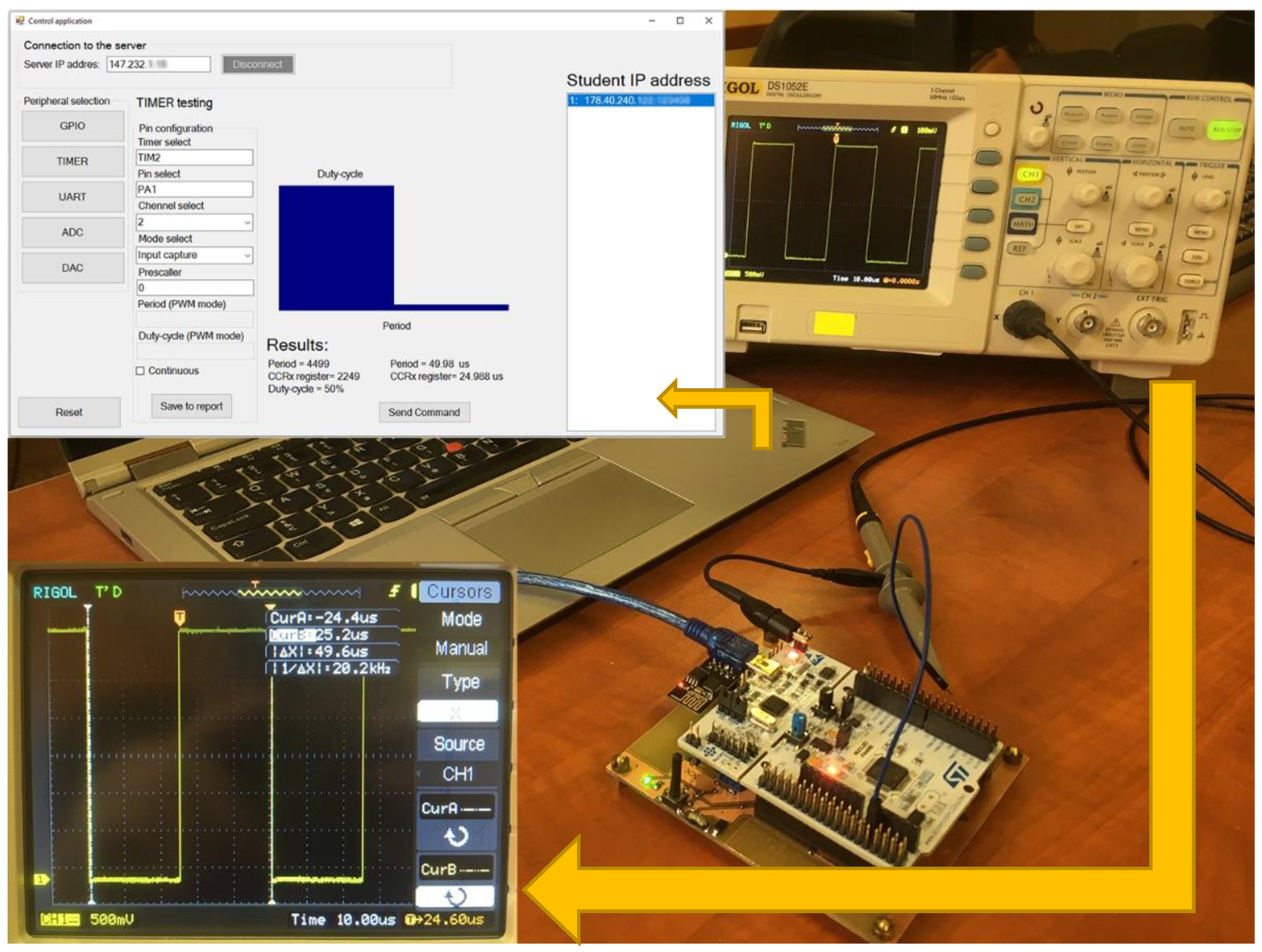

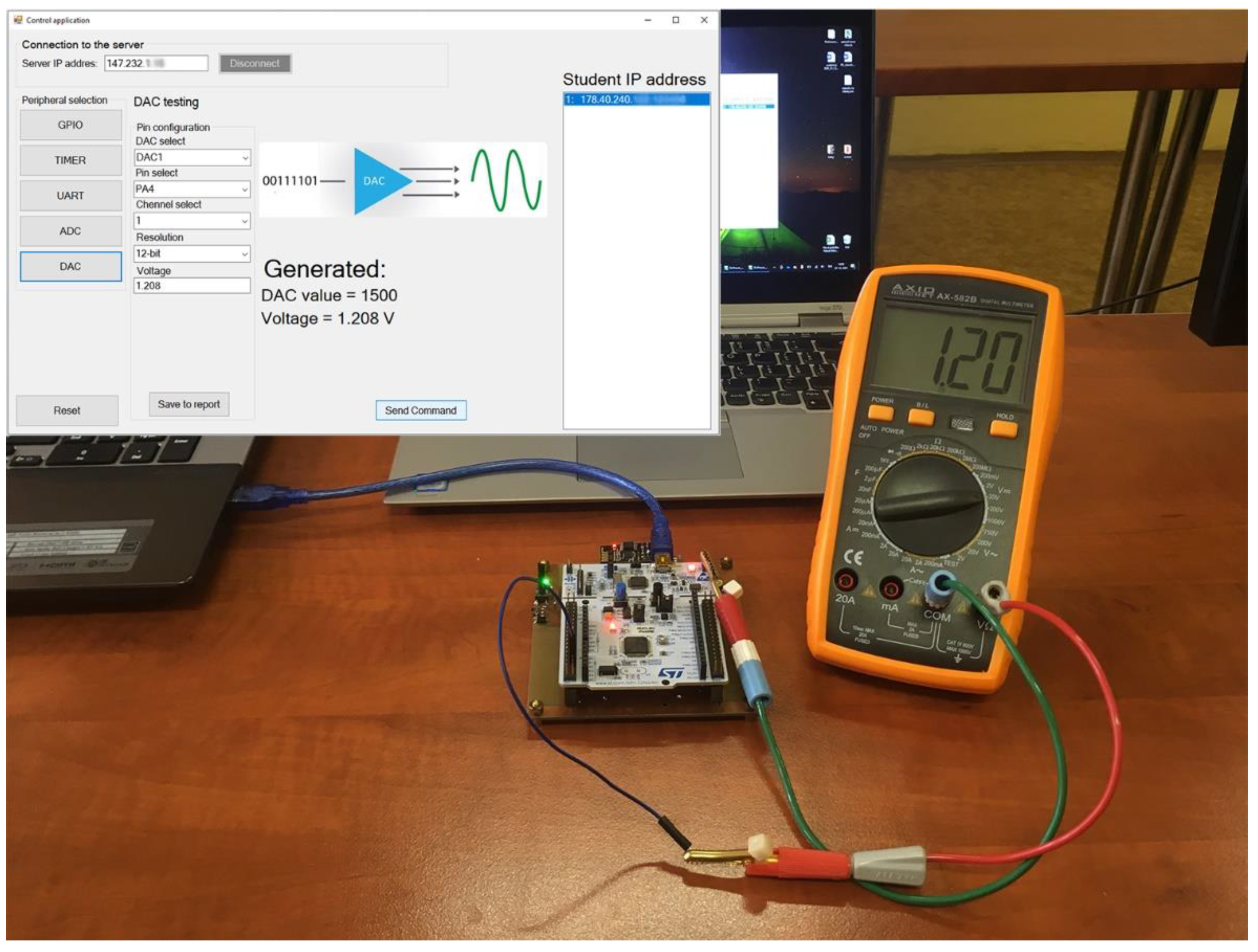

- The peripheral testing shown in the middle of the application has specific parameters. While the GPIO shows all the usable pins of the microcontroller with pin configuration such as pin mode, pull up/down resistor activation, etc., TIMER peripheral window includes period configuration, duty-cycle, timer mode which means Input capture or Output Compare (PWM). Using a timer, of course, requires a timer number and channel selection. The UART testing includes a text box for data receiving in string form and a transmit text box for characters or strings that the teacher wants to send to the student microcontroller. Of course, ADC and DAC testing include parts with measured voltage blocks or voltage values that the teacher wants to generate by IoT monitoring device for students. All peripherals can work together. The other peripheral testing windows will be shown in the Results and Discussion chapter.

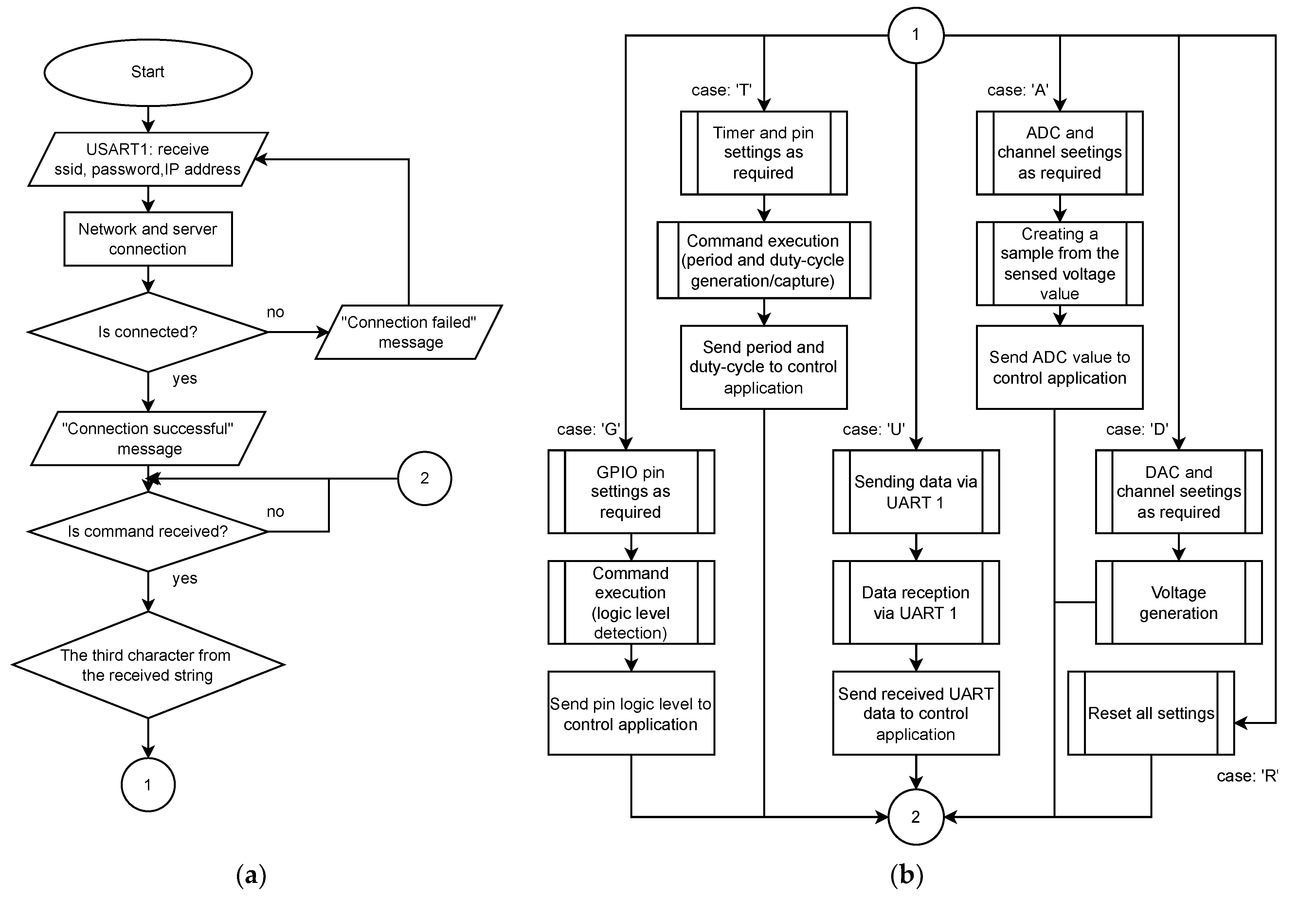

3.2.3. IoT Monitoring Device Program

3.3. IoT Remote Laboratory Applaing to the Education

4. Results and Discussion

4.1. Functionality Results

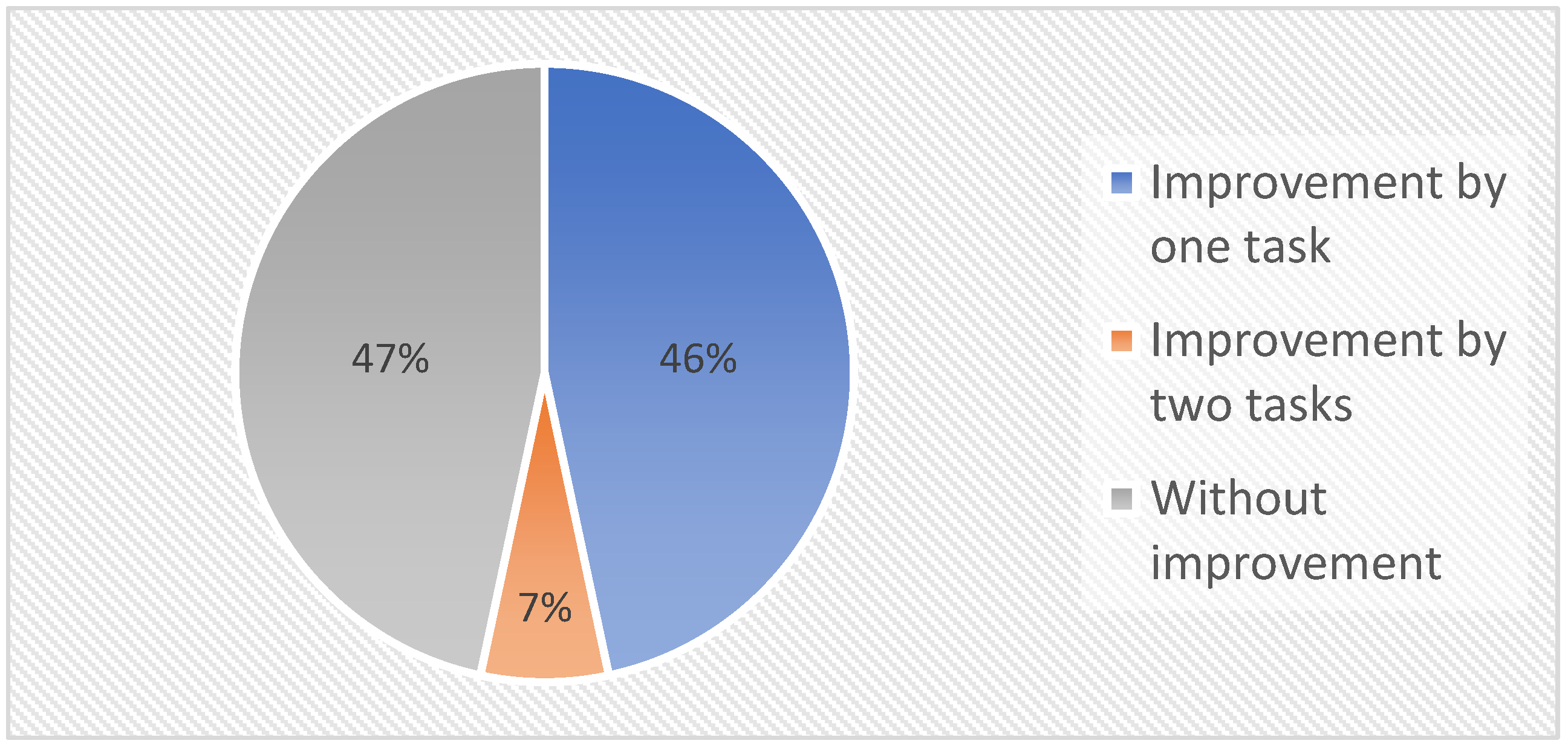

4.2. Educational Results

4.3. Discussion

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zamora-Antuñano, M.A.; Rodríguez-Reséndiz, J.; Rodriguez Segura, L.; Cruz Pérez, M.Á.; Altamirano Corro, J.A.; Paredes-Garcia, W.J.; Rodríguez-Reséndiz, H. Analysis of Emergency Remote Education in COVID-19 Crisis Focused on the Perception of the Teachers. Sustainability 2021, 13, 3820. [Google Scholar] [CrossRef]

- Rodriguez-Segura, L.; Zamora-Antuñano, M.A.; Rodriguez-Resendiz, J.; Paredes-García, W.J.; Altamirano-Corro, J.A.; Cruz-Pérez, M.Á. Teaching Challenges in COVID-19 Scenery: Teams Platform-Based Student Satisfaction Approach. Sustainability 2020, 12, 7514. [Google Scholar] [CrossRef]

- Zamora-Antuñano, M.A.; Rodríguez-Reséndiz, J.; Cruz-Pérez, M.A.; Rodríguez Reséndíz, H.; Paredes-García, W.J.; Díaz, J.A.G. Teachers’ Perception in Selecting Virtual Learning Platforms: A Case of Mexican Higher Education during the COVID-19 Crisis. Sustainability 2022, 14, 195. [Google Scholar] [CrossRef]

- Farid, F.; Simin, Z.M.; Farzaneh, F.; Mohammad, R.K. Impact of COVID-19 on dental education a scoping review. BMC Med. Educ. 2021, 21, 587. [Google Scholar] [CrossRef]

- Chavarría, D.; Gómez, A.; Dittel, C.; Montero, M. E-Learning in Dental Schools in the Times of COVID-19: A Review and Analysis of an Educational Resource in Times of the COVID-19 Pandemic. Odovtos Int. J. Dent. Sci. 2020, 22, 69–86. [Google Scholar]

- Galibourg, A.; Maret, D.; Monsarrat, P.; Nasr, K. Impact of COVID-19 on dental education: How couldpre-clinical training be done at home? J. Dent. Educ. 2020, 84, 949. [Google Scholar] [CrossRef]

- Coughlan, J.; Timus, D.; Crnic, T. Impact of COVID-19 on dental education in Europe: The students’ perspective. Eur. J. Dent. Educ. 2021. [Google Scholar] [CrossRef]

- Ferrel, M.N.; Ryan, J.J. The Impact of COVID-19 on Medical Education. Cureus 2020, 12, e7492. [Google Scholar] [CrossRef] [Green Version]

- Aziz, A.; Aamer, S.; Khan, A.M. A Bumpy Road to Online Teaching: Impact of COVID-19 on Medical Education. Ann. King Edw. Med. Univ. Lahore Pak. 2020, 26, 181–186. [Google Scholar]

- Guadix, S.W.; Sha, C.; Sandrone, S.; Safdieh, J.E.; Sarva, H. The Impact of COVID-19 on Neurology Education: A Medical Student Perspective. Front. Educ. 2020, 5, 567421. [Google Scholar] [CrossRef]

- Rassudov, L.; Korunets, A. COVID-19 Pandemic Challenges for Engineering Education. In Proceedings of the 2020 XI International Conference on Electrical Power Drive Systems (ICEPDS), St. Petersburg, Russia, 4–7 October 2020; pp. 1–3. [Google Scholar] [CrossRef]

- Crick, T.; Knight, C.; Watermeyer, R.; Goodall, J. The International Impact of COVID-19 and “Emergency Remote Teaching” on Computer Science Education Practitioners. In Proceedings of the 2021 IEEE Global Engineering Education Conference (Educon), Vienna, Austria, 21–23 April 2021. [Google Scholar] [CrossRef]

- Opris, I.; Ionescu, C.S.; Costinas, S.; Nistoran, D.E.G. Challenges and Opportunities to Overcome The Impact Of COVID-19 Pandemic on Power Engineering Education. TEM J.-Technol. Educ. Manag. Inform. 2020, 9, 1687–1691. [Google Scholar] [CrossRef]

- Martin, J. A Neuroscience Approach Regarding Student Engagement in The Classes Of Microcontrollers During The COVID-19 Pandemic. In Proceedings of the 14th International Conference of Education, Research and Innovation (ICERI2021), Online, 8–9 November 2021. [Google Scholar] [CrossRef]

- Praselia, D.; Handayani, A.N.; Wibawanto, S.; Mustika, S.N.; Kurniawan, W.C.; Asmara, R.A. Design and Development of Online Media Learning on Analog Electronics Course under COVID-19. In Proceedings of the 2021 International Conference on Electrical and Information Technology (IEIT), Malang, Indonesia, 14–15 September 2021; pp. 45–49. [Google Scholar] [CrossRef]

- Ortiz, F.M.; de Almeida, T.T. Experimental vs. simulation analysis of LoRa for vehicular communications. Comput. Commun. 2020, 160, 299–310. [Google Scholar] [CrossRef]

- Matlashov, A.N.; Schultz, L.J.; Espy, M.A.; Kraus, R.H.; Savukov, I.M.; Volegov, P.L.; Wurden, C.J. SQUIDs vs. Induction Coils for Ultra-Low Field Nuclear Magnetic Resonance: Experimental and Simulation Comparison. IEEE Trans. Appl. Supercond. 2011, 21, 465–468. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bokeloh, J.; Wilde, G. Nucleation barriers for the liquid-to-crystal transition in simple metals: Experiment vs. simulation. Eur. Phys. J.-Spec. Top. 2014, 223, 511–526. [Google Scholar] [CrossRef]

- Garduño-Aparicio, M.; Rodríguez-Reséndiz, J.; Macias-Bobadilla, G.; Thenozhi, S. A Multidisciplinary Industrial Robot Approach for Teaching Mechatronics-Related Courses. IEEE Trans. Educ. 2018, 61, 55–62. [Google Scholar] [CrossRef]

- Kapilan, N.; Vidhya, P.; Gao, X.-Z. Virtual Laboratory: A Boon to the Mechanical Engineering Education During COVID-19 Pandemic. High. Educ. Future 2021, 8, 31–46. [Google Scholar] [CrossRef]

- Ramya, M.V.; Purushothama, G.K.; Prakash, K.R. Design and Implementation of IoT Based Remote Laboratory for Sensor Experiments. iJIM 2020, 14, 227–238. [Google Scholar]

- Zapata-Rivera, L.F.; Larrondo-Petrie, M.M.; Da Silva, L.R. Implementation of Cloud-Based Smart Adaptive Remote Laboratories for Education. In Proceedings of the 2017 IEEE Frontiers in Education Conference (FIE), Indianapolis, IN, USA, 18–21 October 2017. [Google Scholar]

- Chamunorwa, T.; Modran, H.A.; Ursuțiu, D.; Samoilă, C.; Hedeșiu, H. Reconfigurable Wireless Sensor Node Remote Laboratory Platform with Cloud Connectivity. Sensors 2021, 21, 6405. [Google Scholar] [CrossRef]

- Saliah, H.H.; Nurse, E.; Abecassis, A. Design of a Generic, Interactive, Virtual and Remote Electrical Engineering Laboratory. In Proceedings of the 29th ASEE/IEEE Frontiers in Education Conference, San Juan, Puerto Rico, 10–13 November 1999. [Google Scholar]

- Cheong, K.H.; Koh, J.M. Integrated Virtual Laboratory in Engineering Mathematics Education: Fourier Theory. IEEE Access 2018, 6, 58231–58243. [Google Scholar] [CrossRef]

- Altalbe, A.A. Performance Impact of Simulation-Based Virtual Laboratory on Engineering Students: A Case Study of Australia Virtual System. IEEE Access 2019, 7, 177387–177396. [Google Scholar] [CrossRef]

- Svatos, J.; Holub, J.; Sobotka, J. Online teaching at CTU in Prague aka university under COVID restrictions. Meas. Sens. 2021, 18, 10012. [Google Scholar] [CrossRef]

- Veligorsky, O.; Nesterov, I.; Khomenko, M.; Khomenko, M. Remote Debugging Of Embedded Systems in STM32CubeMonitor. Ph.D. Thesis, II International Scientific and Practical Conference Theoretical and Applied Aspects of Device Development on Microcontrollers and FPGAs (MC&FPGA), Kharkiv, Ukraine, 2020; pp. 22–25. [Google Scholar] [CrossRef]

- Kaewmanee, W.; Yodwong, B.; Sikkabut, S.; Phattanasak, M.; Guilbert, D. A New Low-cost Hardware-in-the-Loop Simulator for Control of Power Electronics Systems Laboratory. In Proceedings of the 2021 Research, Invention, and Innovation Congress: Innovation Electricals and Electronics (RI2C), Bangkok, Thailand, 1–3 September 2021; pp. 233–237. [Google Scholar] [CrossRef]

- Vince, T.; Bereš, M.; Kováčová, I.; Molnár, J.; Fecko, B.; Dziak, J.; Tomčiková, I.; Guzan, M. IoT Implementation in Remote Measuring Laboratory VMLab Analyses. JUCS J. Univers. Comput. Sci. 2020, 26, 1402–1421. [Google Scholar] [CrossRef]

- Jacko, P.; Guzan, M.; Kalinov, A. Remote Microcontroller Scanner Design for STM32 Microcontrollers Used to Distance Education Form. In Proceedings of the 2021 IEEE International Conference on Modern Electrical and Energy Systems (MEES), Kremenchuk, Ukraine, 21–24 September 2021; pp. 1–6. [Google Scholar] [CrossRef]

- R. Alves, G.; Marques, A.; da Silva, J.B. Lab-based Education. In Proceedings of the Ninth International Conference on Technological Ecosystems for Enhancing Multiculturality (TEEM’21), Barcelona Spain, 26–29 October 2021. [Google Scholar]

- Molnár, J.; Kirešová, S.; Vince, T.; Kováč, D.; Jacko, P.; Bereš, M.; Hrabovský, P. Weather Station IoT Educational Model Using Cloud Services. JUCS J. Univers. Comput. Sci. 2020, 26, 1495–1512. [Google Scholar] [CrossRef]

- STM32F446xC/E Datasheet. Available online: https://www.st.com/resource/en/datasheet/stm32f446re.pdf (accessed on 15 November 2021).

- ESP8266EX Datasheet. 2020. Available online: https://www.espressif.com/sites/default/files/documentation/0a-ESP8266ex_datasheet_en.pdf (accessed on 20 November 2021).

| Step | Action |

|---|---|

| 1 | Start the program |

| 2 | Enter the IP address of the server |

| 3 | Click the “Connect” button and wait for the connection |

| 4 | Select the IoT monitoring module number from the “Student IP address” block |

| 5 | Select the peripheral, pin, and all required configurations |

| 6 | Press the “Send command” button |

| 7 | Wait for received data from the IoT monitoring device |

| 8 | If it is required, save data to the report or reset all current configurations via a particular button |

| Step | Action |

|---|---|

| 1 | Connect student Nucleo-64 to the IoT monitoring device |

| 2 | Connect Nucleo-64 board to the PC |

| 3 | Turn on the IoT monitoring device using the switch |

| 4 | Send a command to connect the module to the network |

| 5 | If the connection is successful, the student can work on their tasks |

| Number of Completed Tasks | Student Number before IoT Remote Laboratory Applying | Student Number after IoT Remote Laboratory Applying |

|---|---|---|

| 2x | 5 | 10 |

| 1x | 9 | 8 |

| 0x | 6 | 2 |

| Task Completion | PWM and Duty-Cycle Detection | Voltage Detection |

|---|---|---|

| Without help | 8 | 8 |

| Resolved via IoT remote laboratory | 9 | 11 |

| Unresolved | 3 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jacko, P.; Bereš, M.; Kováčová, I.; Molnár, J.; Vince, T.; Dziak, J.; Fecko, B.; Gans, Š.; Kováč, D. Remote IoT Education Laboratory for Microcontrollers Based on the STM32 Chips. Sensors 2022, 22, 1440. https://doi.org/10.3390/s22041440

Jacko P, Bereš M, Kováčová I, Molnár J, Vince T, Dziak J, Fecko B, Gans Š, Kováč D. Remote IoT Education Laboratory for Microcontrollers Based on the STM32 Chips. Sensors. 2022; 22(4):1440. https://doi.org/10.3390/s22041440

Chicago/Turabian StyleJacko, Patrik, Matej Bereš, Irena Kováčová, Ján Molnár, Tibor Vince, Jozef Dziak, Branislav Fecko, Šimon Gans, and Dobroslav Kováč. 2022. "Remote IoT Education Laboratory for Microcontrollers Based on the STM32 Chips" Sensors 22, no. 4: 1440. https://doi.org/10.3390/s22041440

APA StyleJacko, P., Bereš, M., Kováčová, I., Molnár, J., Vince, T., Dziak, J., Fecko, B., Gans, Š., & Kováč, D. (2022). Remote IoT Education Laboratory for Microcontrollers Based on the STM32 Chips. Sensors, 22(4), 1440. https://doi.org/10.3390/s22041440