Comparative Performance Analysis of the DC-AC Converter Control System Based on Linear Robust or Nonlinear PCH Controllers and Reinforcement Learning Agent

Abstract

1. Introduction

- Presentation, synthesis, and implementation of the robust control algorithm for DC-AC converter control;

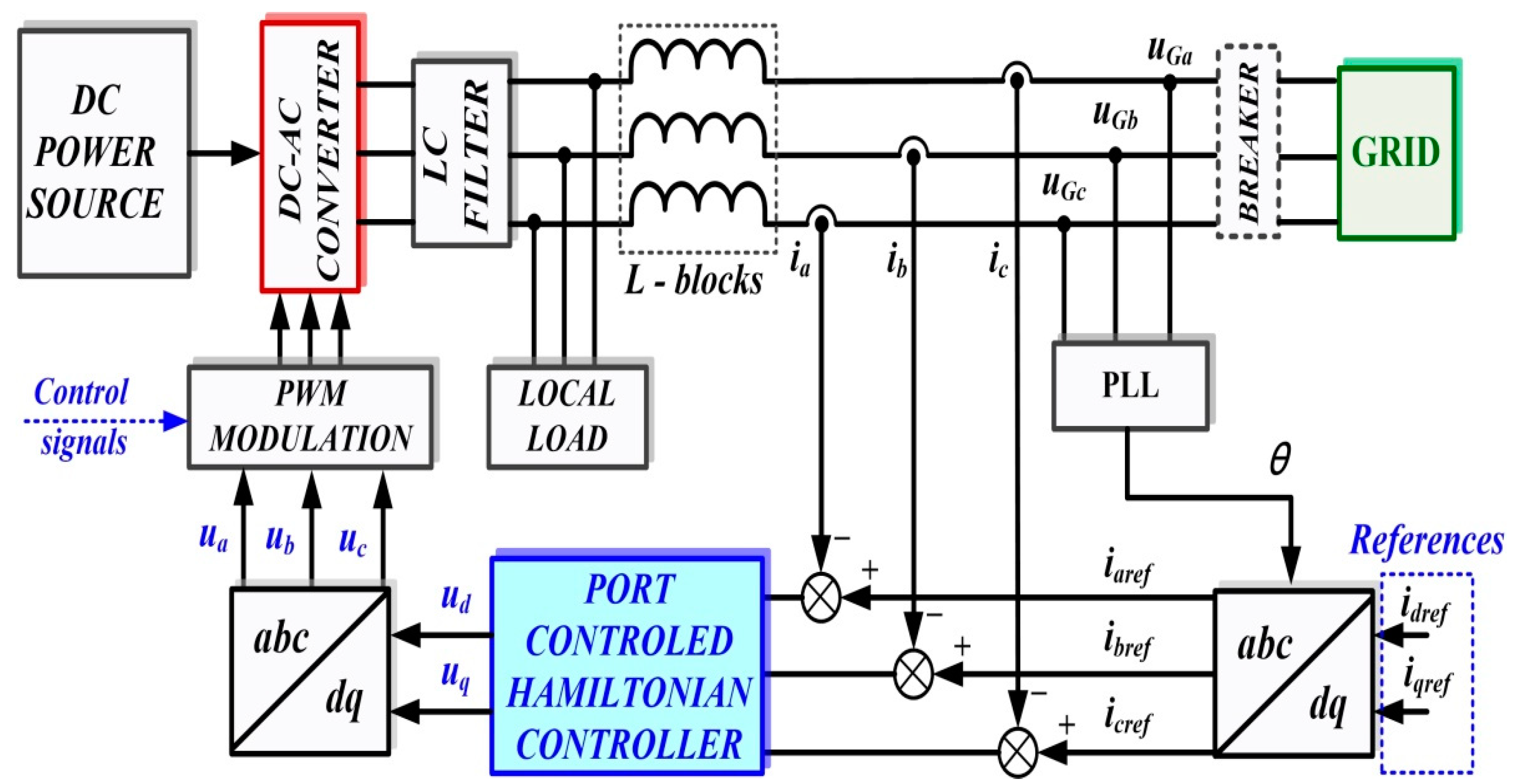

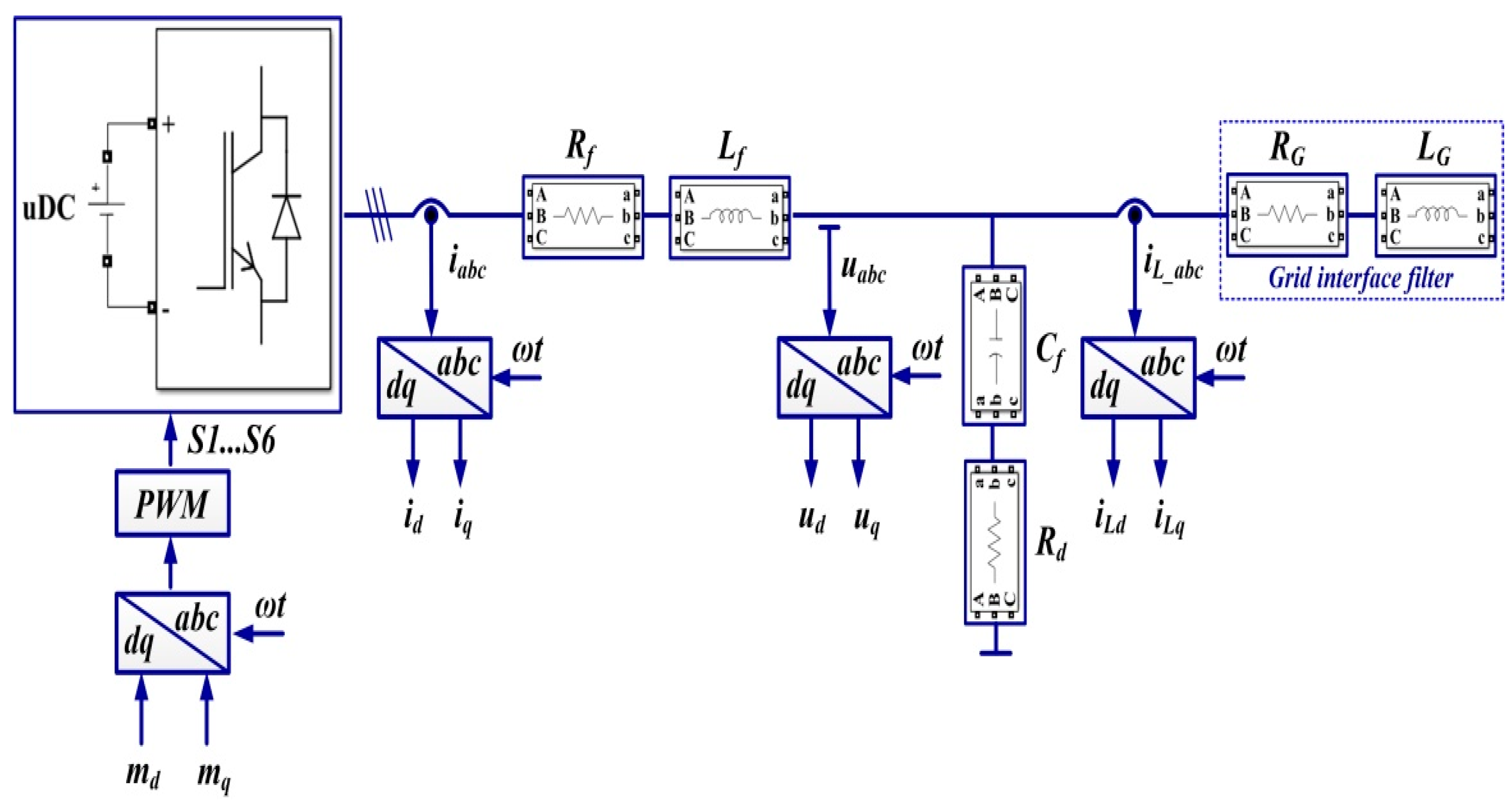

- Presentation, synthesis, and implementation of the PCH control algorithm based on the passivity theory for the DC-AC converter control;

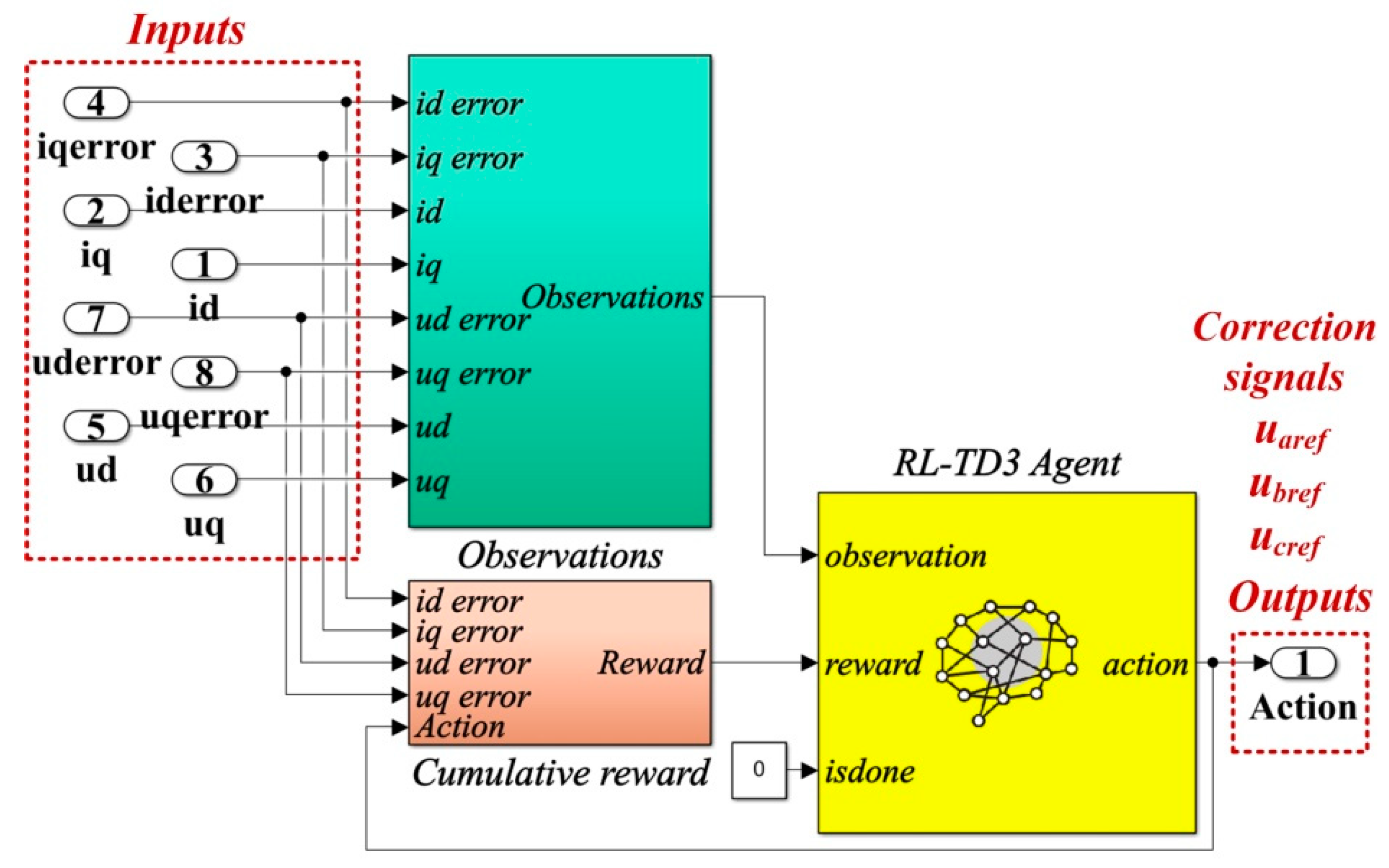

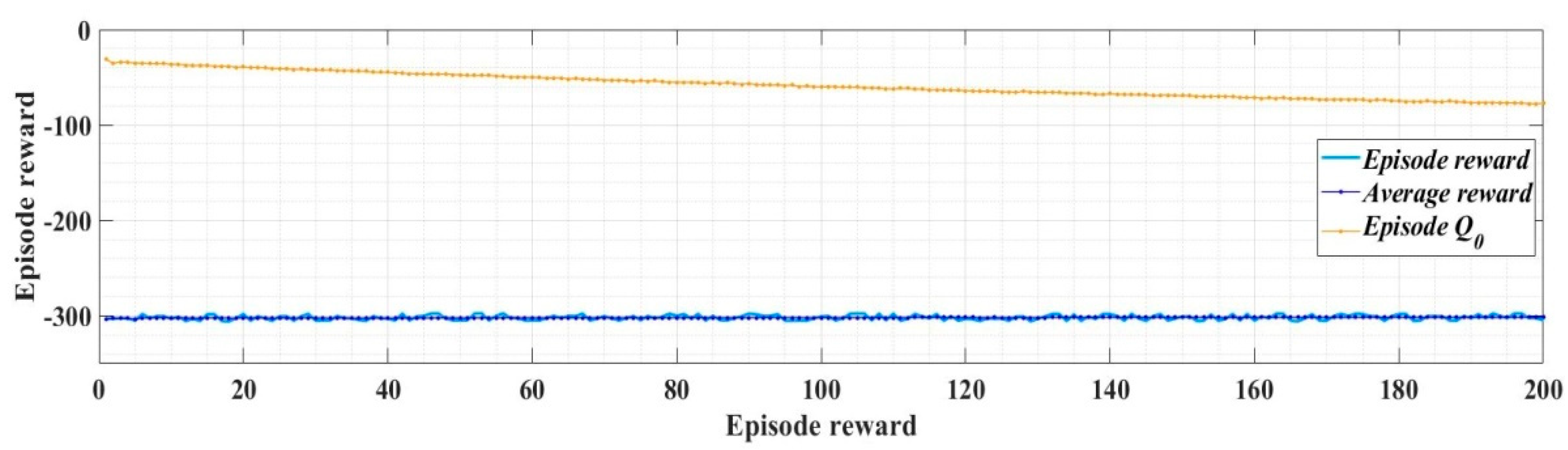

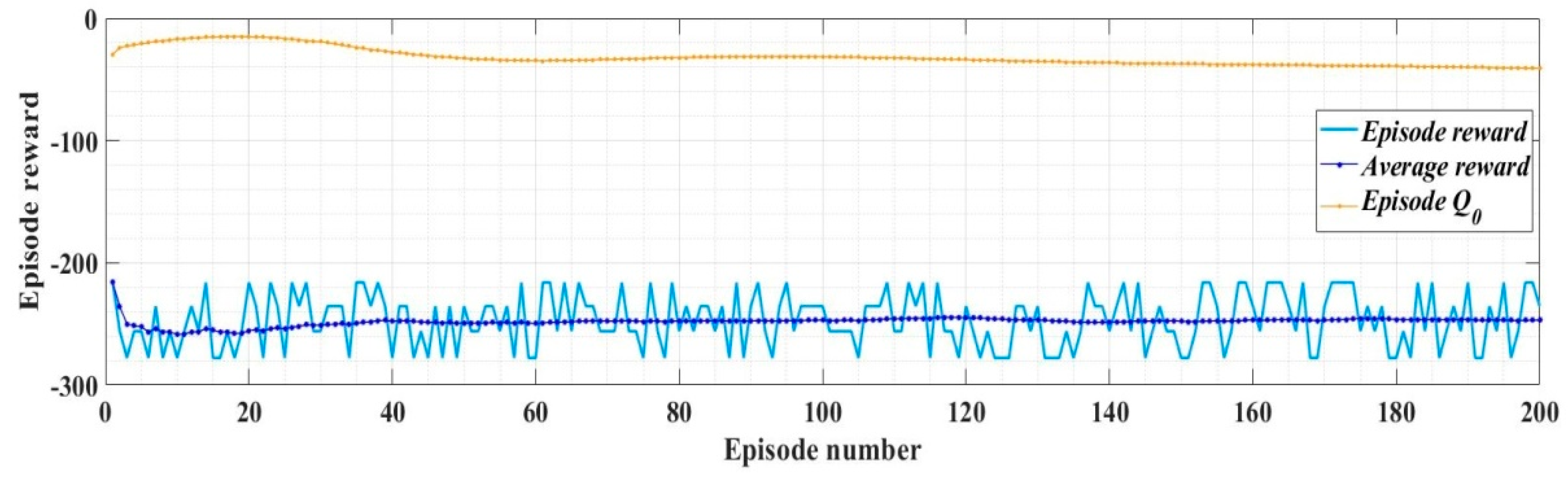

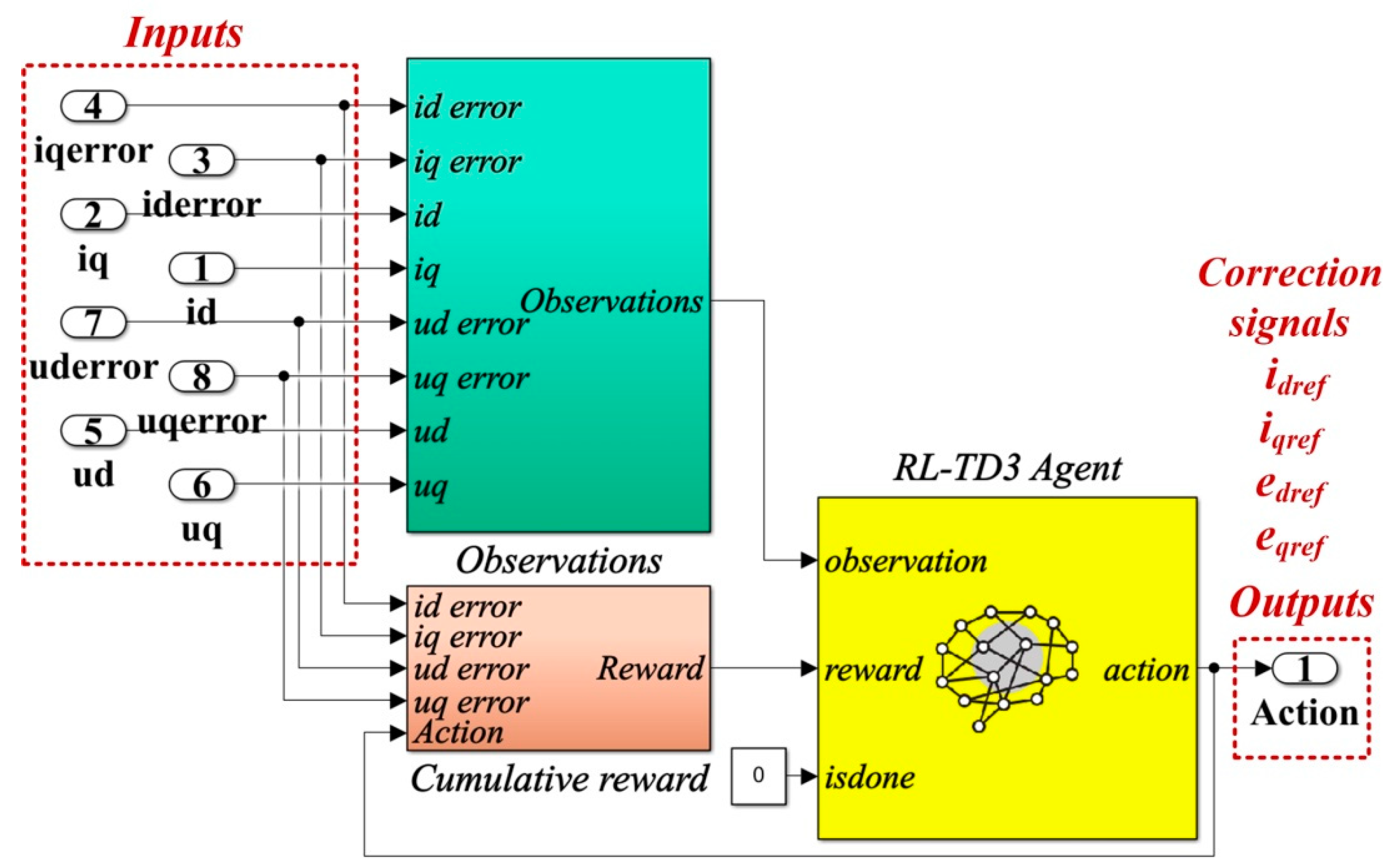

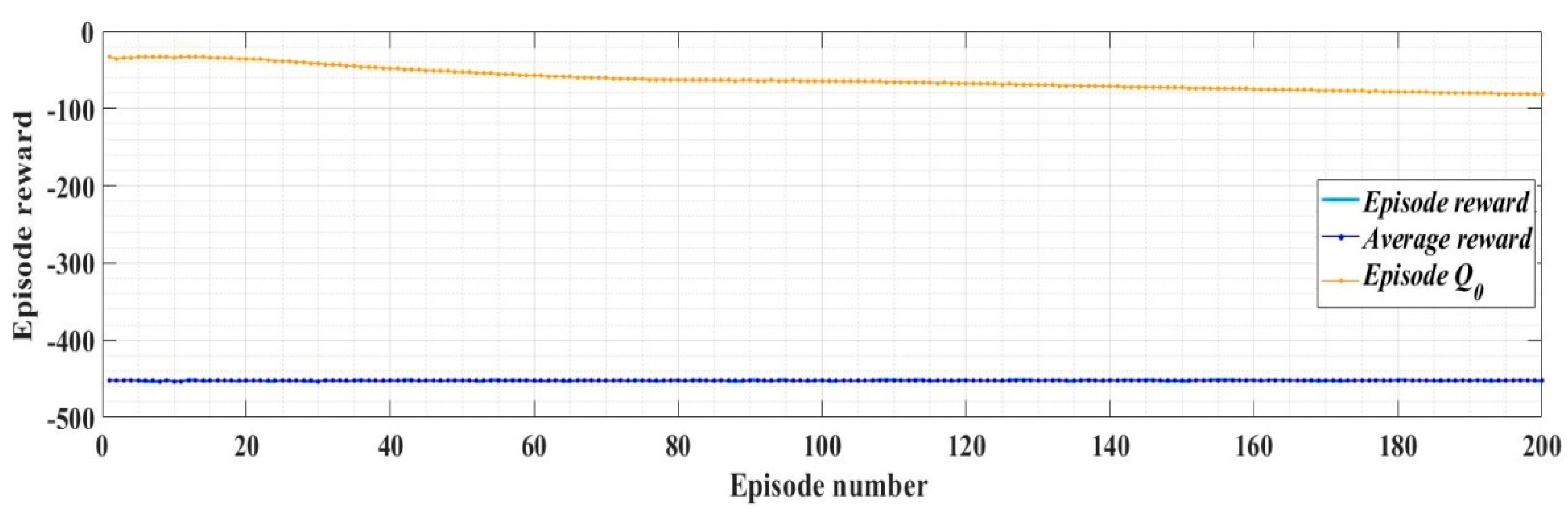

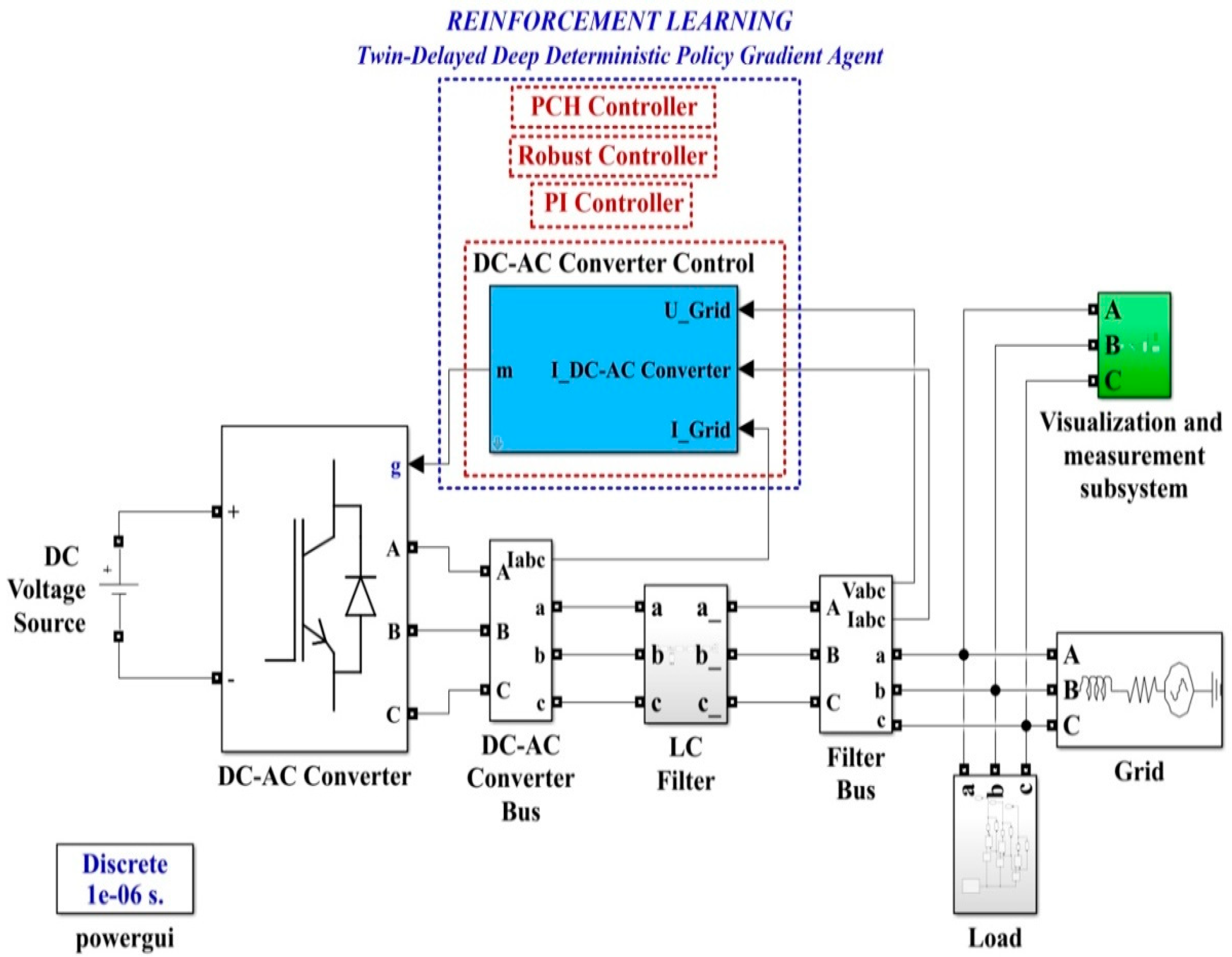

- Presentation, synthesis, and implementation of an RL-TD3 agent, by covering the stages of creation, training, testing and validation for each of the PI, robust and PCH controllers;

- Implementation in Matlab/Simulink of the software applications for the calculation of the steady-state error performance indicators and the error ripple of the ud voltage and THD current phase a of the microgrid-to-the-main-grid connection system using a DC-AC converter for the comparative analysis of PI, robust and PCH control systems with or without the RL-TD3 agent.

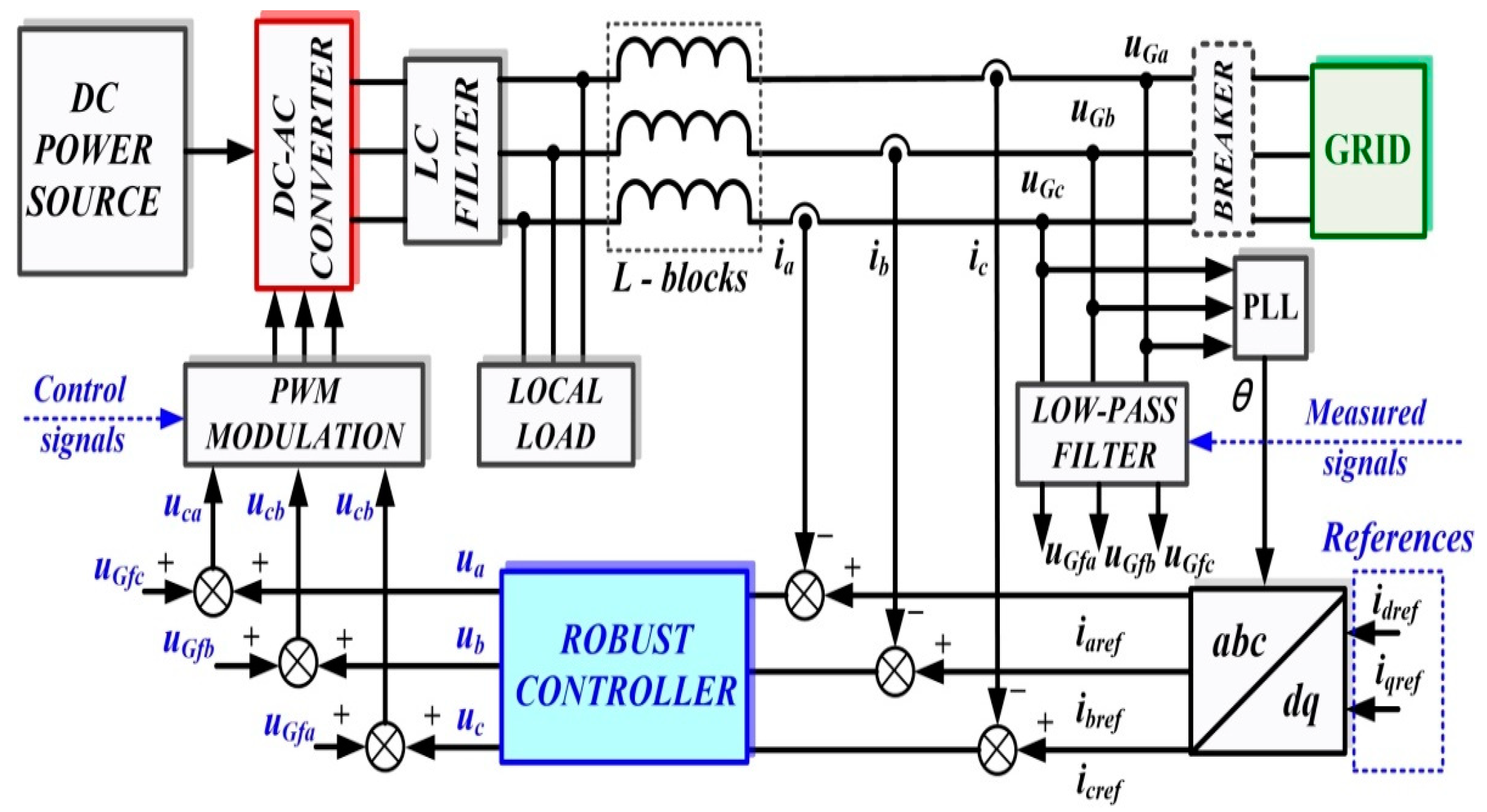

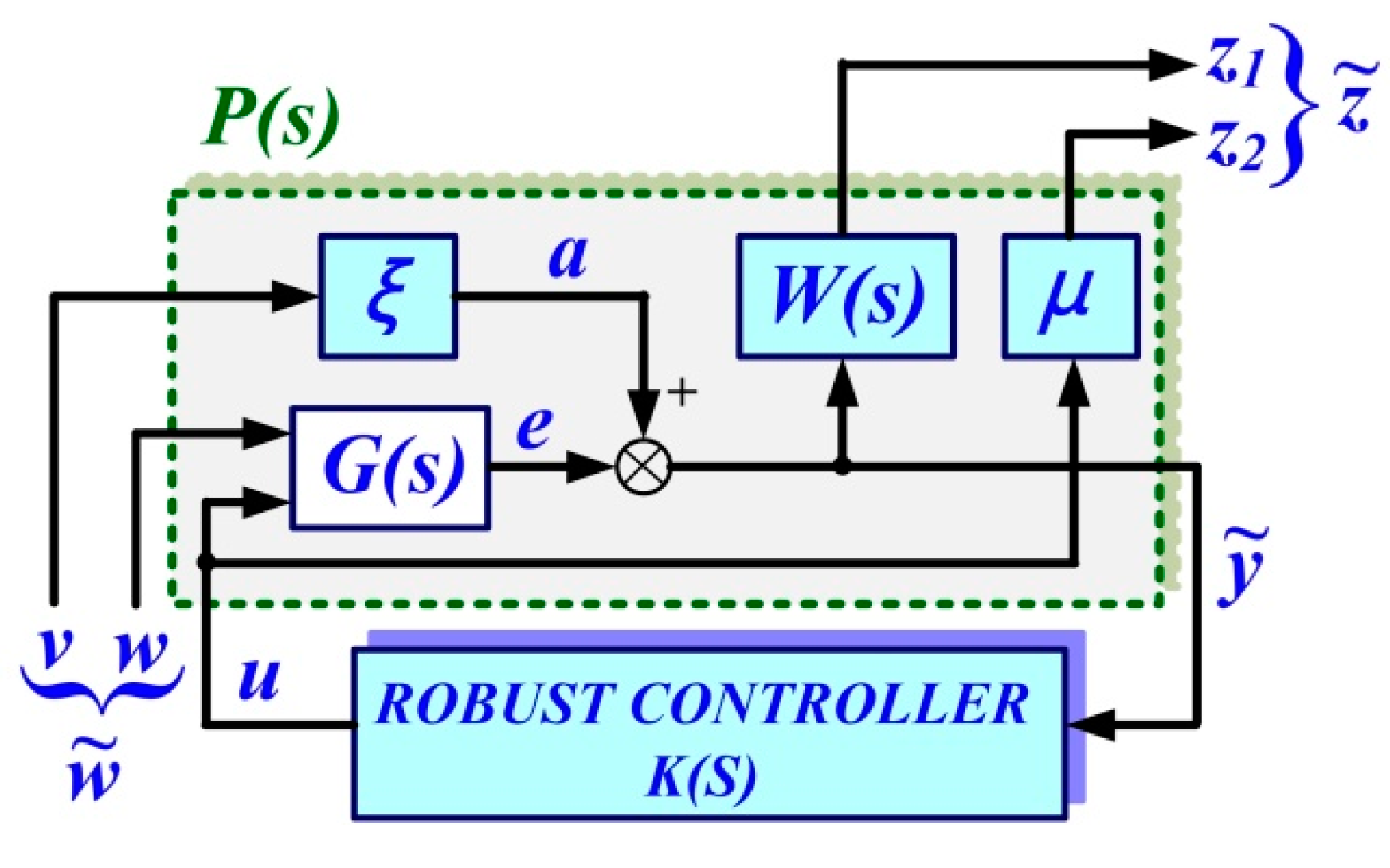

2. Robust Control of the DC-AC Converter

2.1. Mathematical Description of the Robust Control for DC-AC Converter

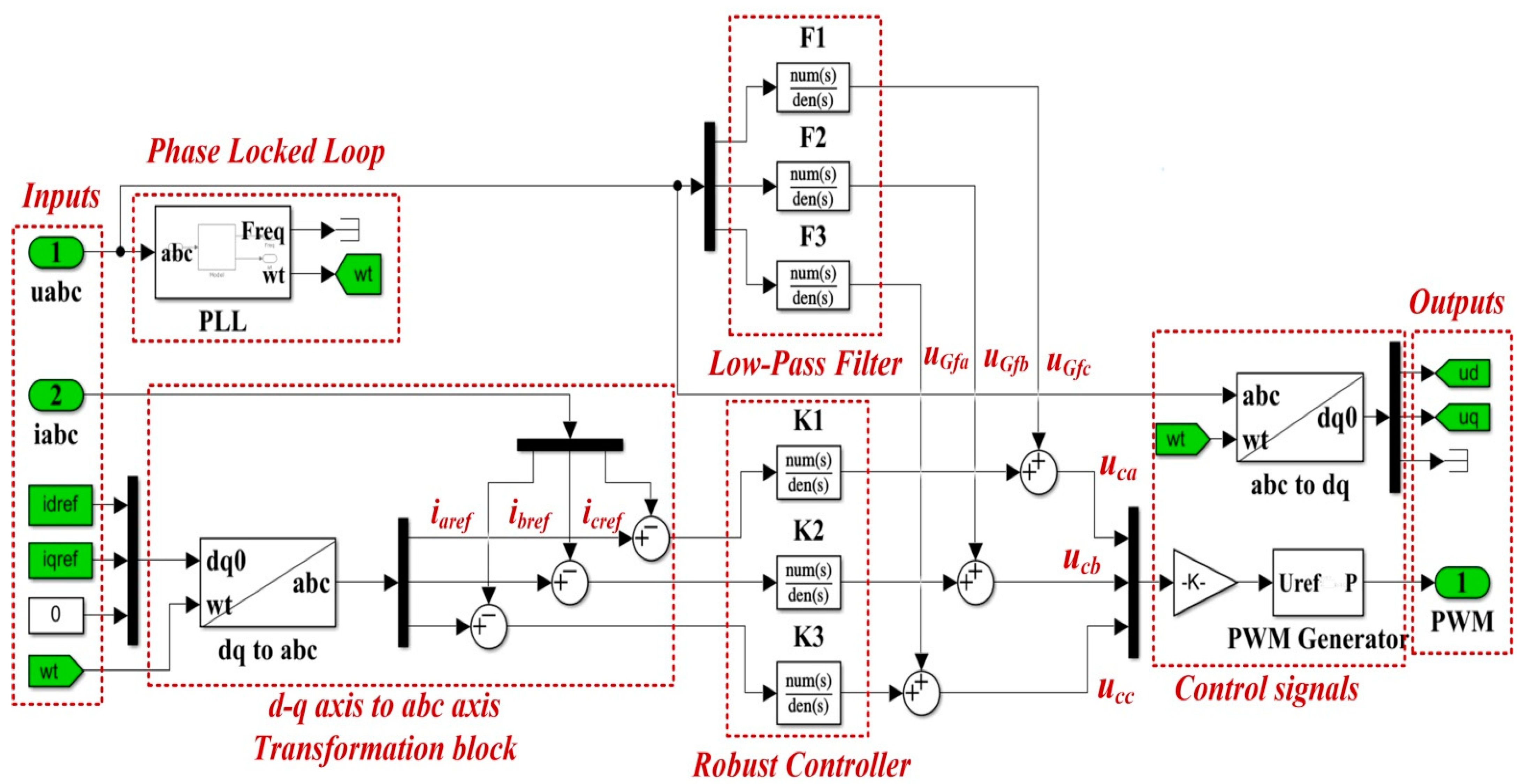

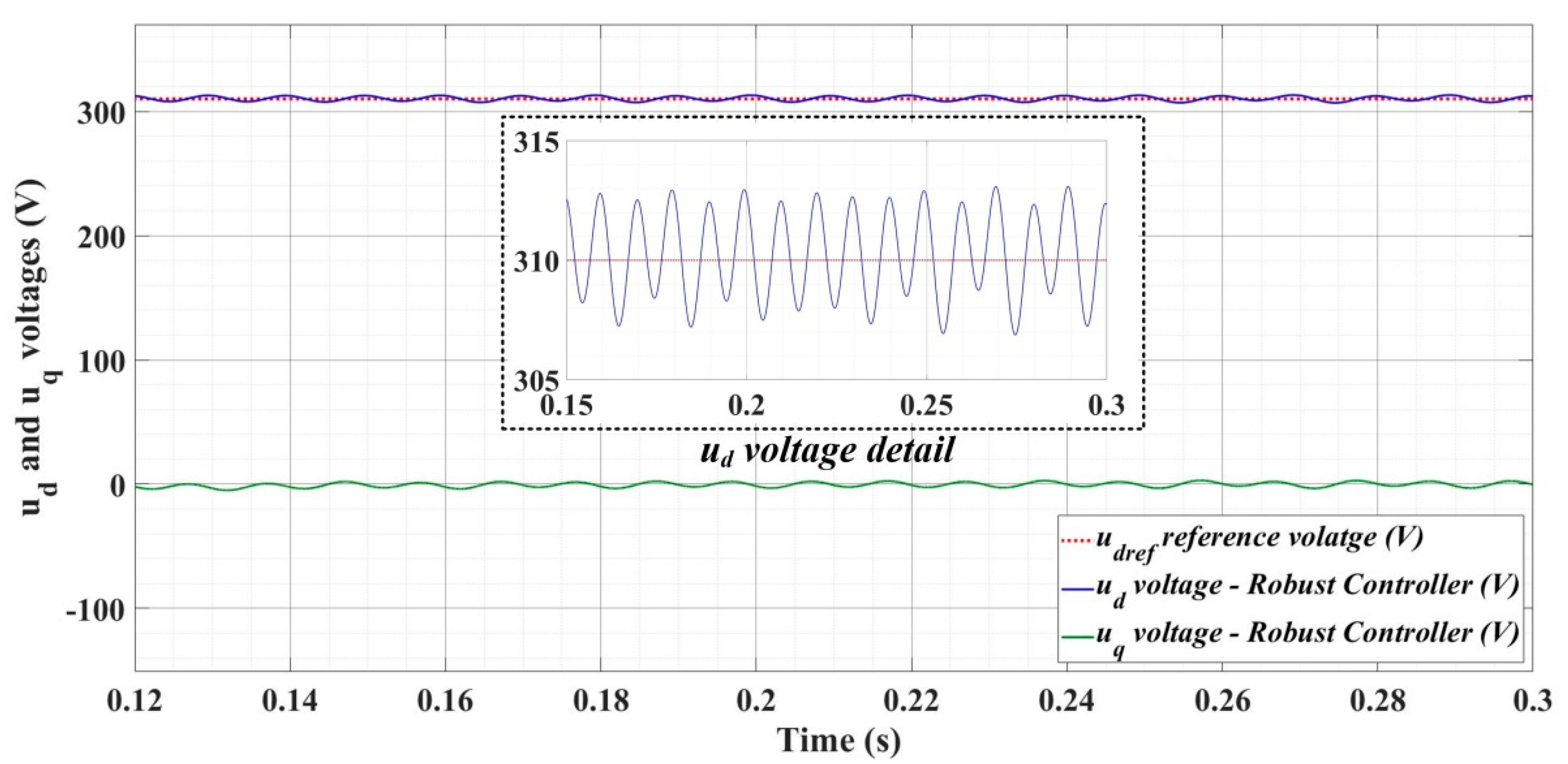

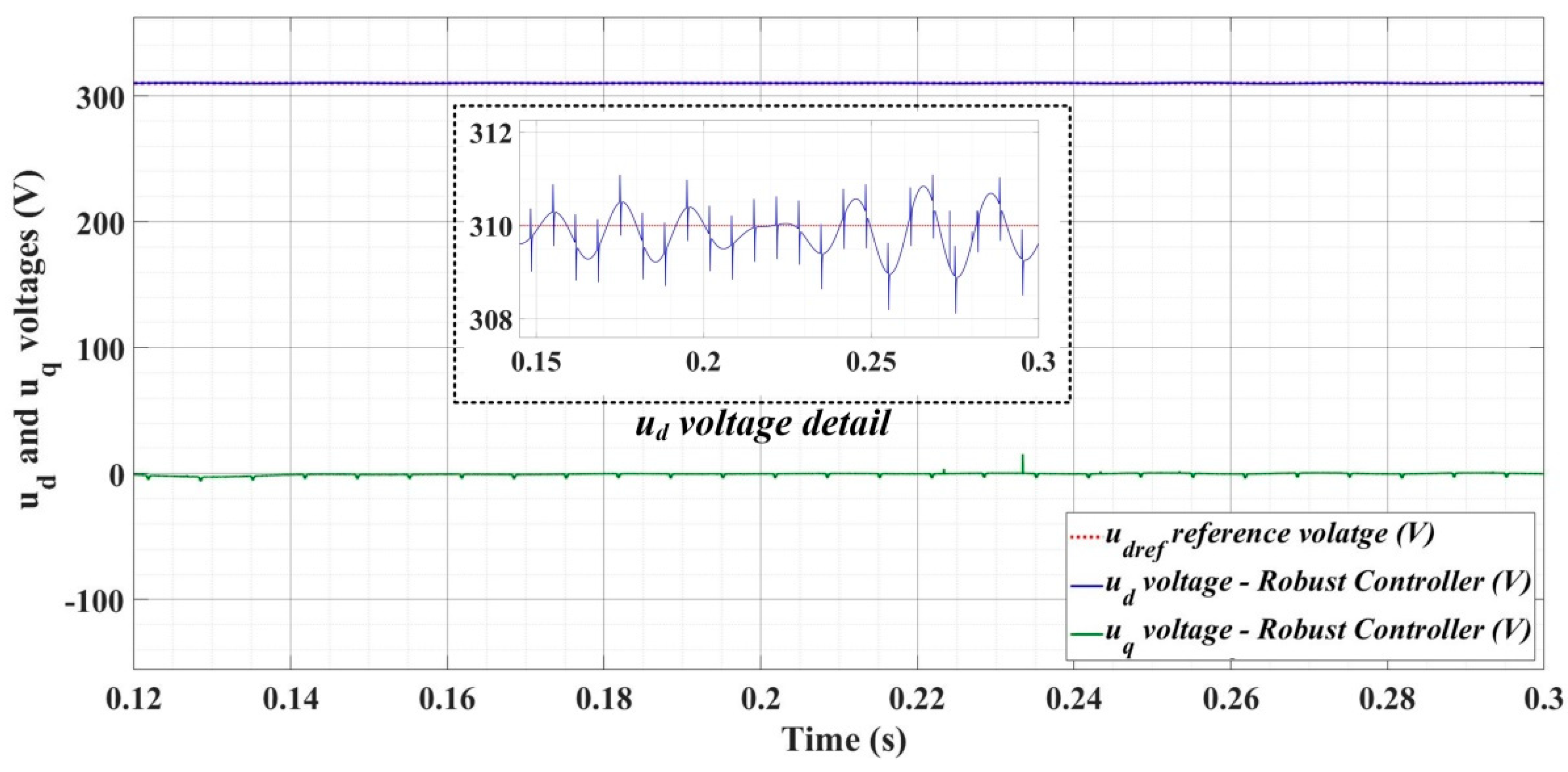

2.2. Matlab/Simulink Implementation of the Robust Control for DC-AC Converter

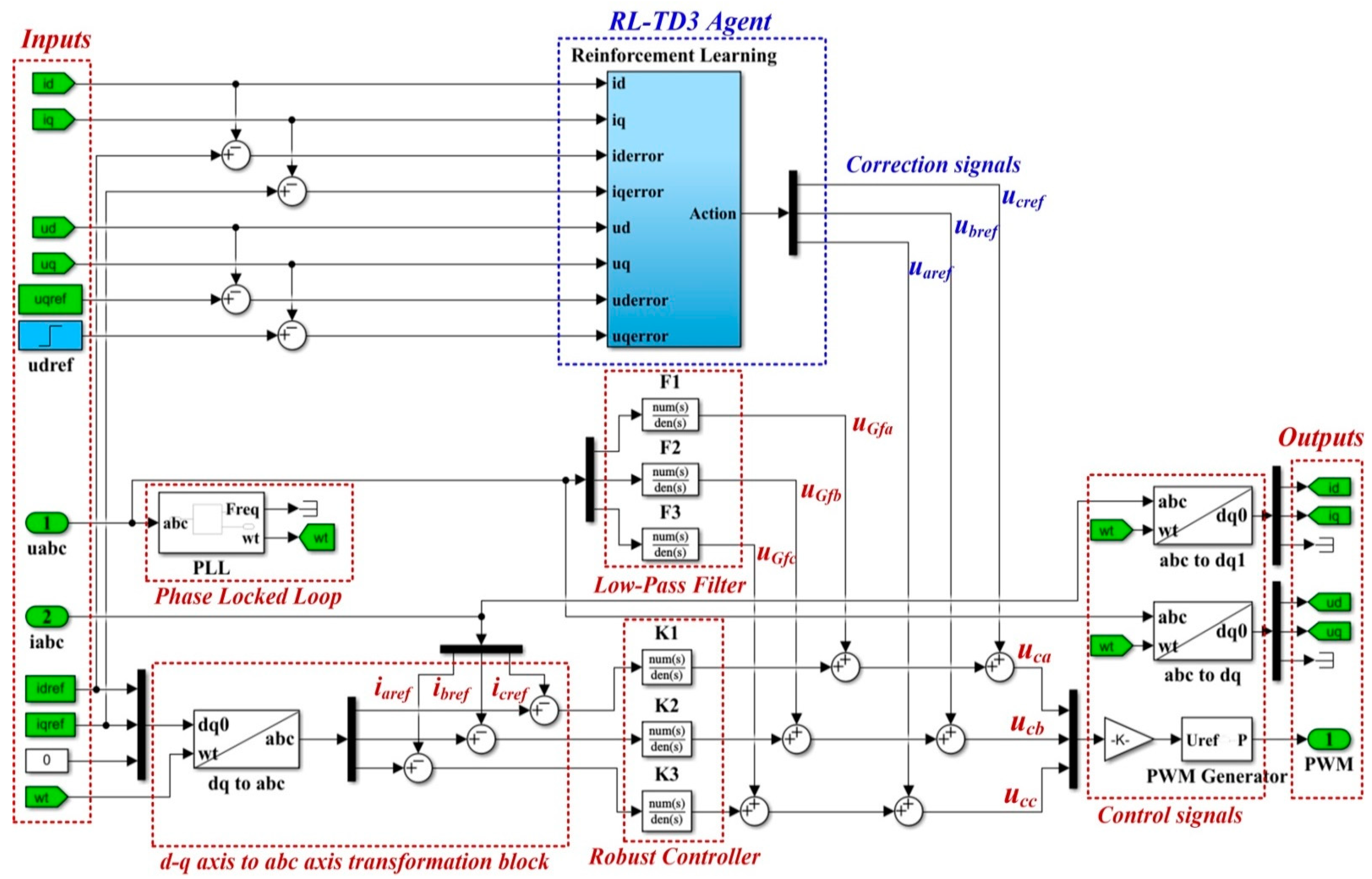

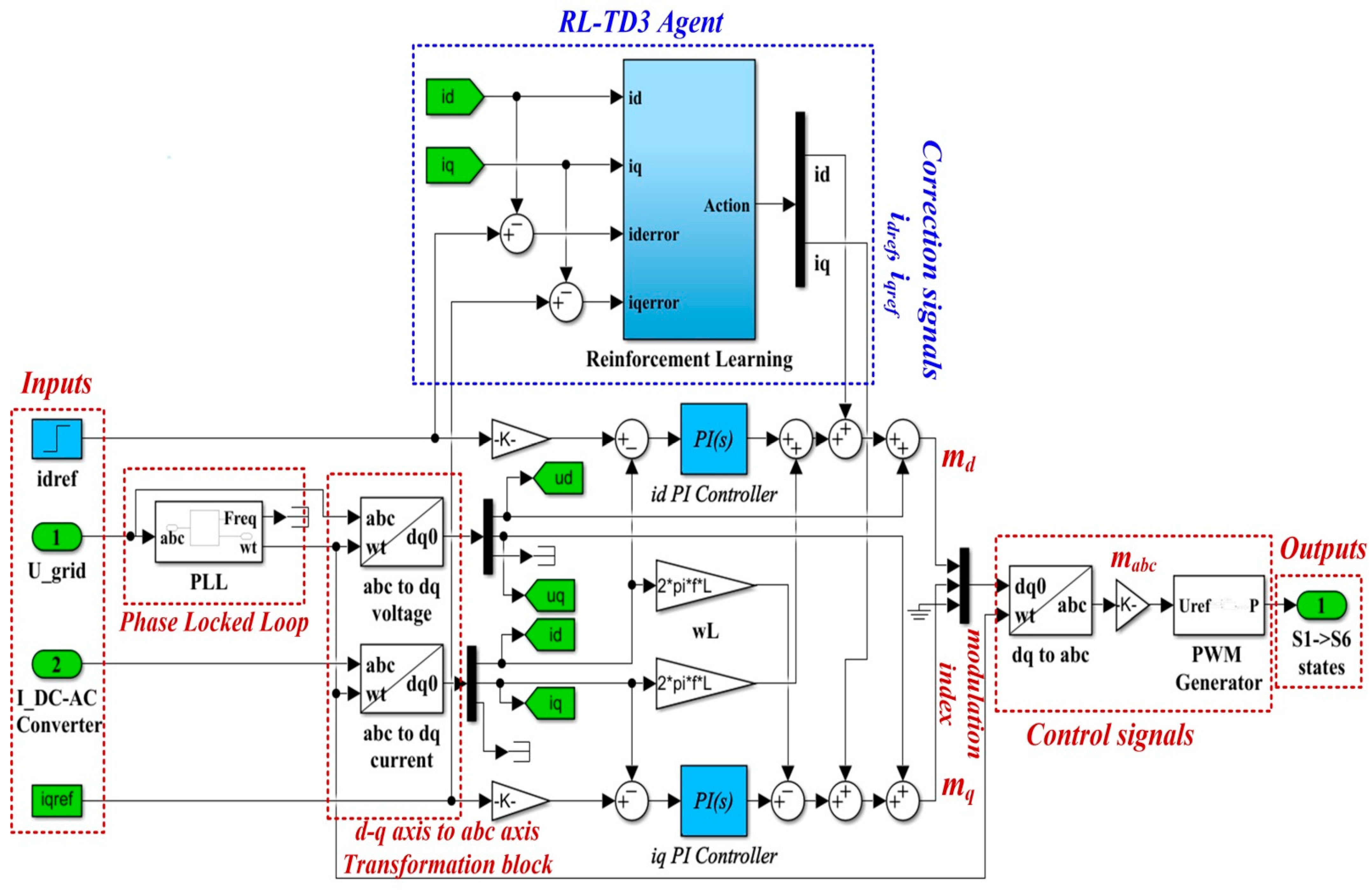

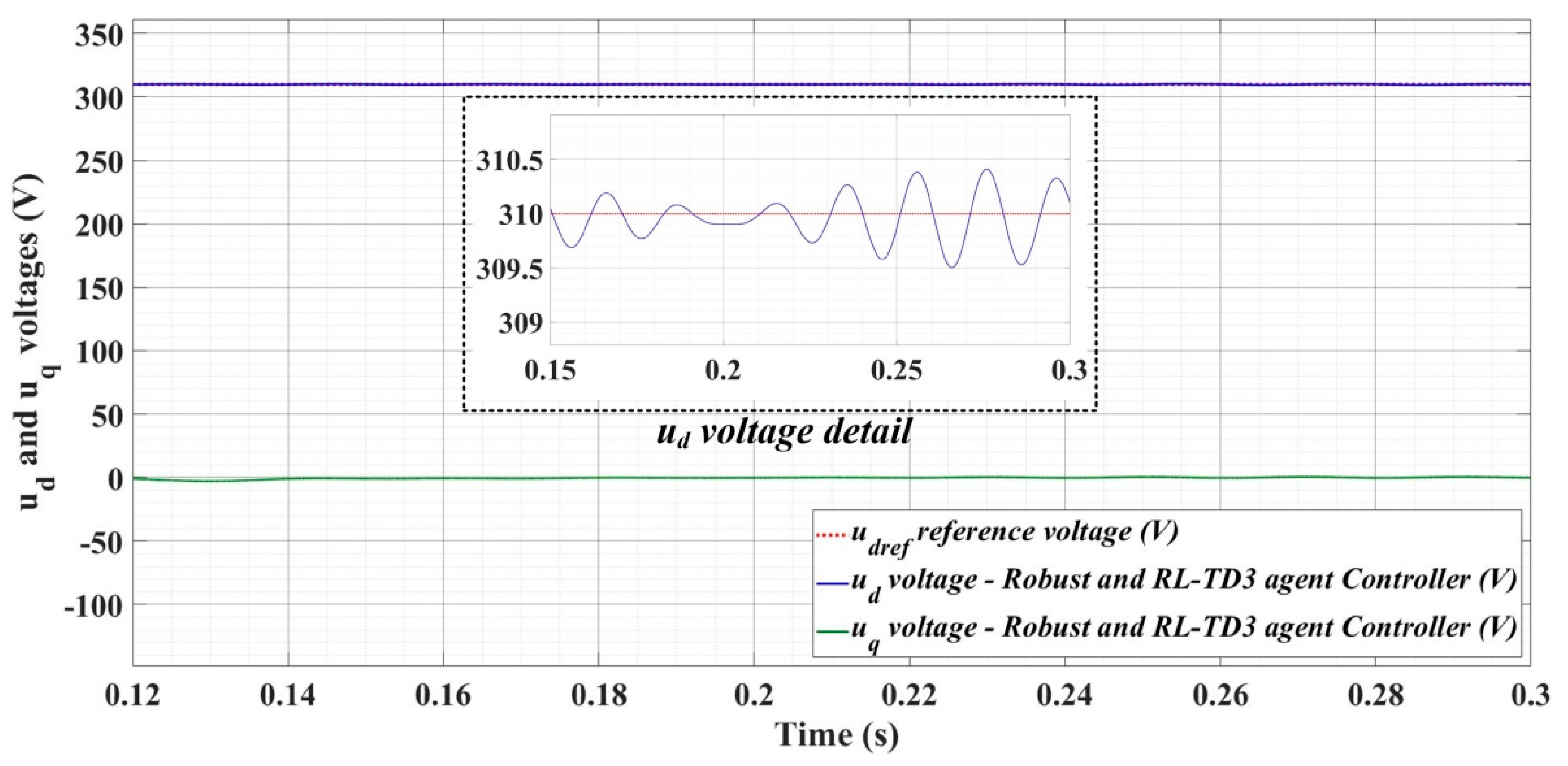

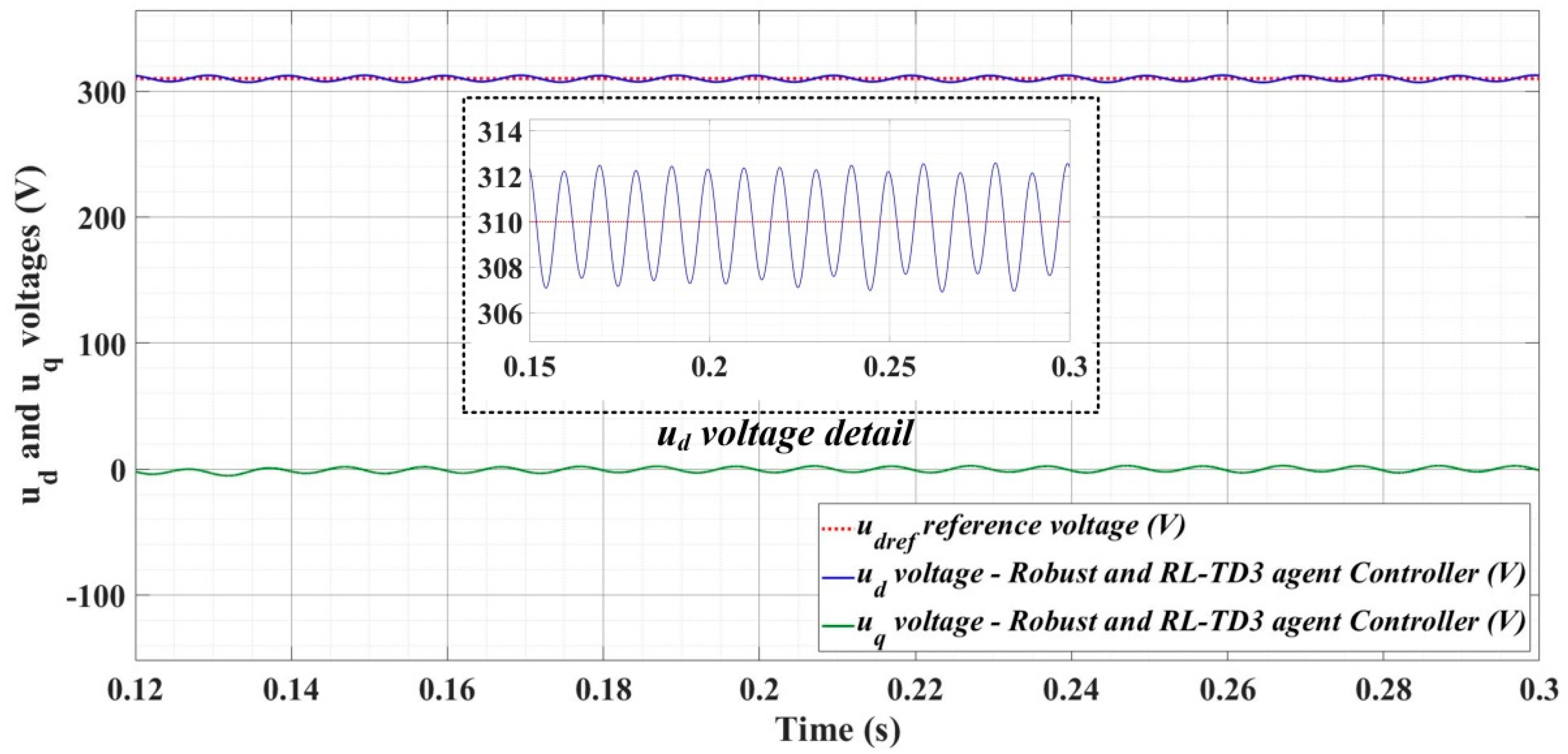

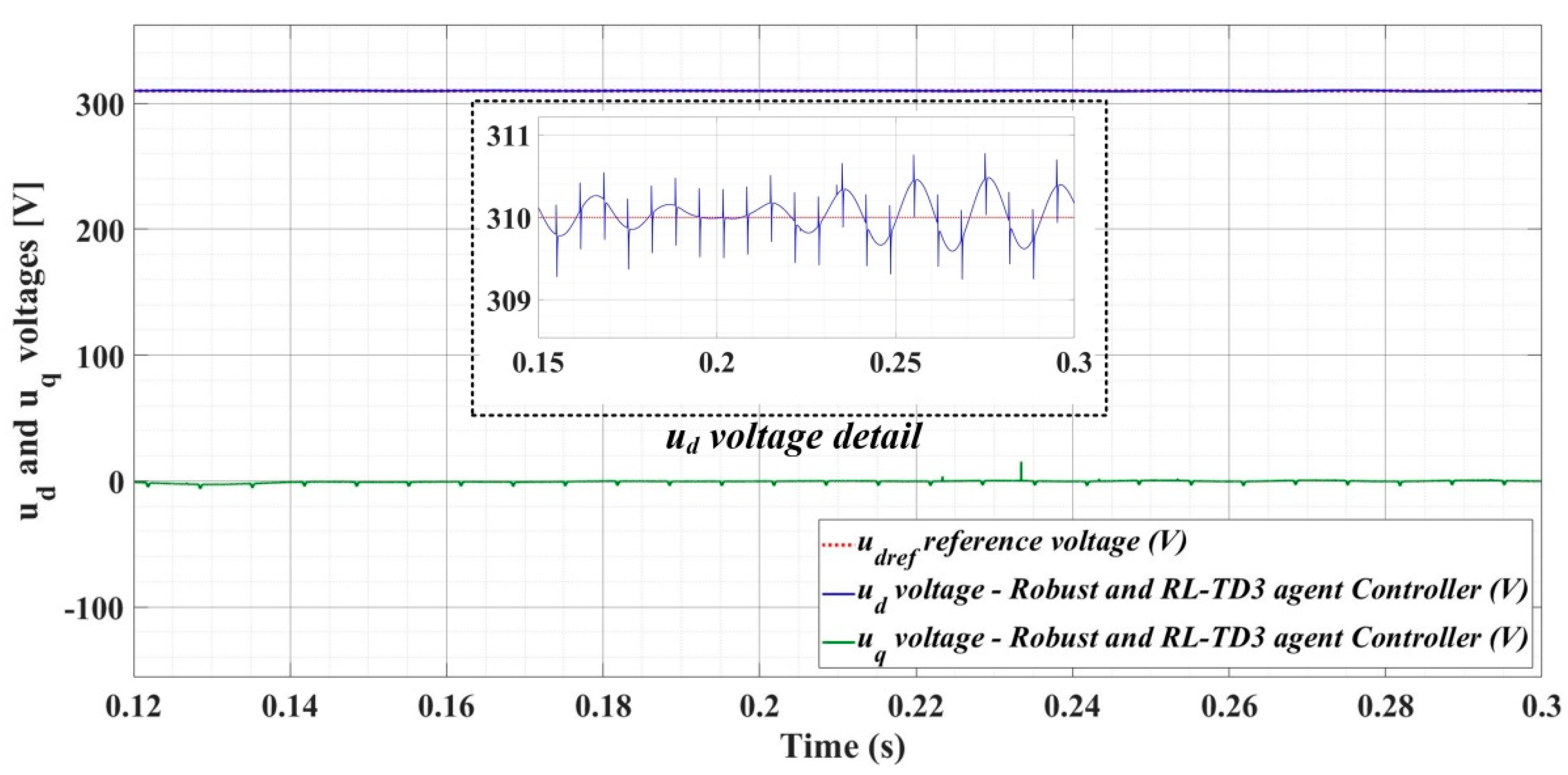

2.3. Improvement of the Robust Control for DC-AC Converter Using RL-TD3 Agent

3. PCH Control of the DC-AC Converter

3.1. Mathematical Description of the PCH Control

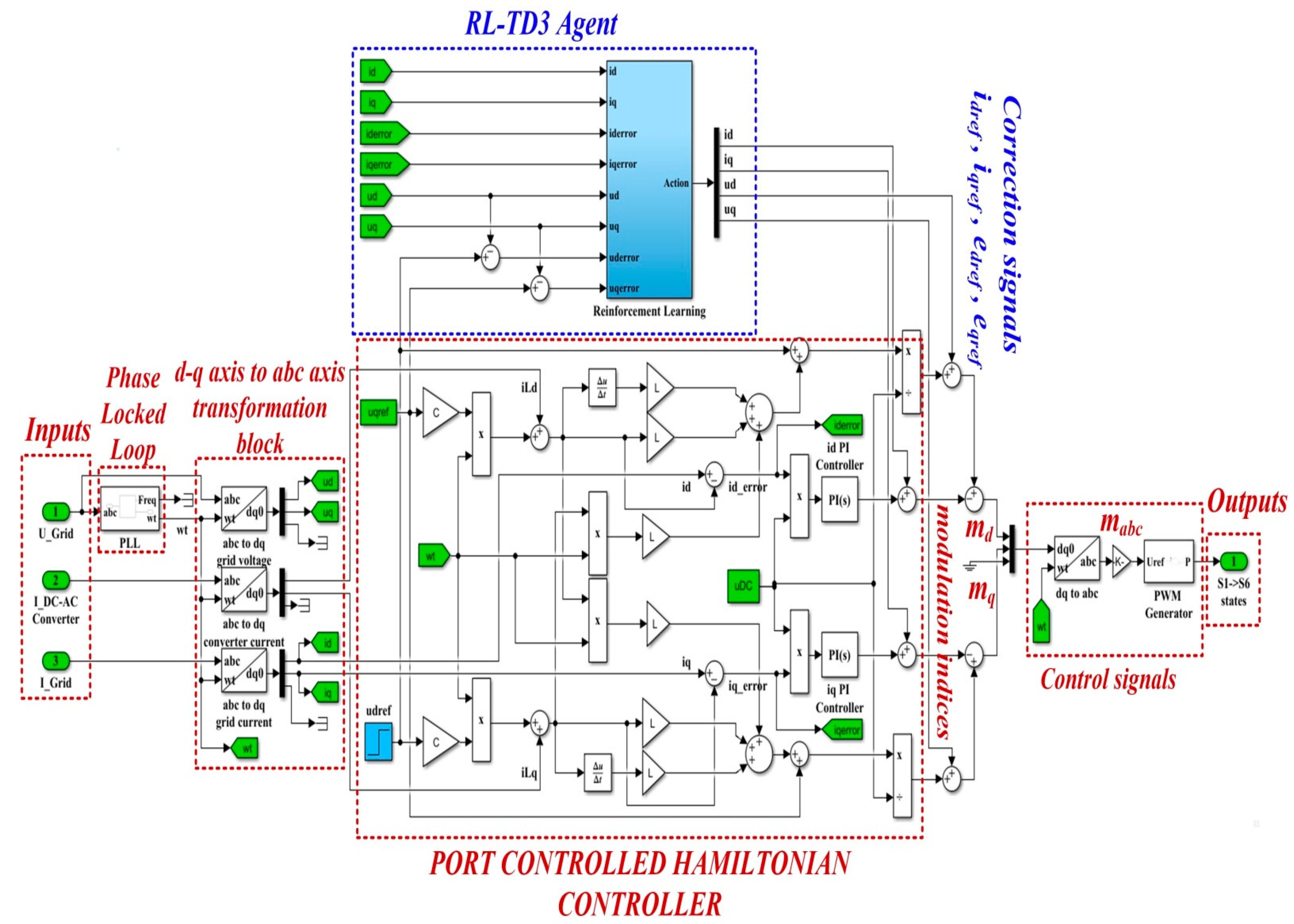

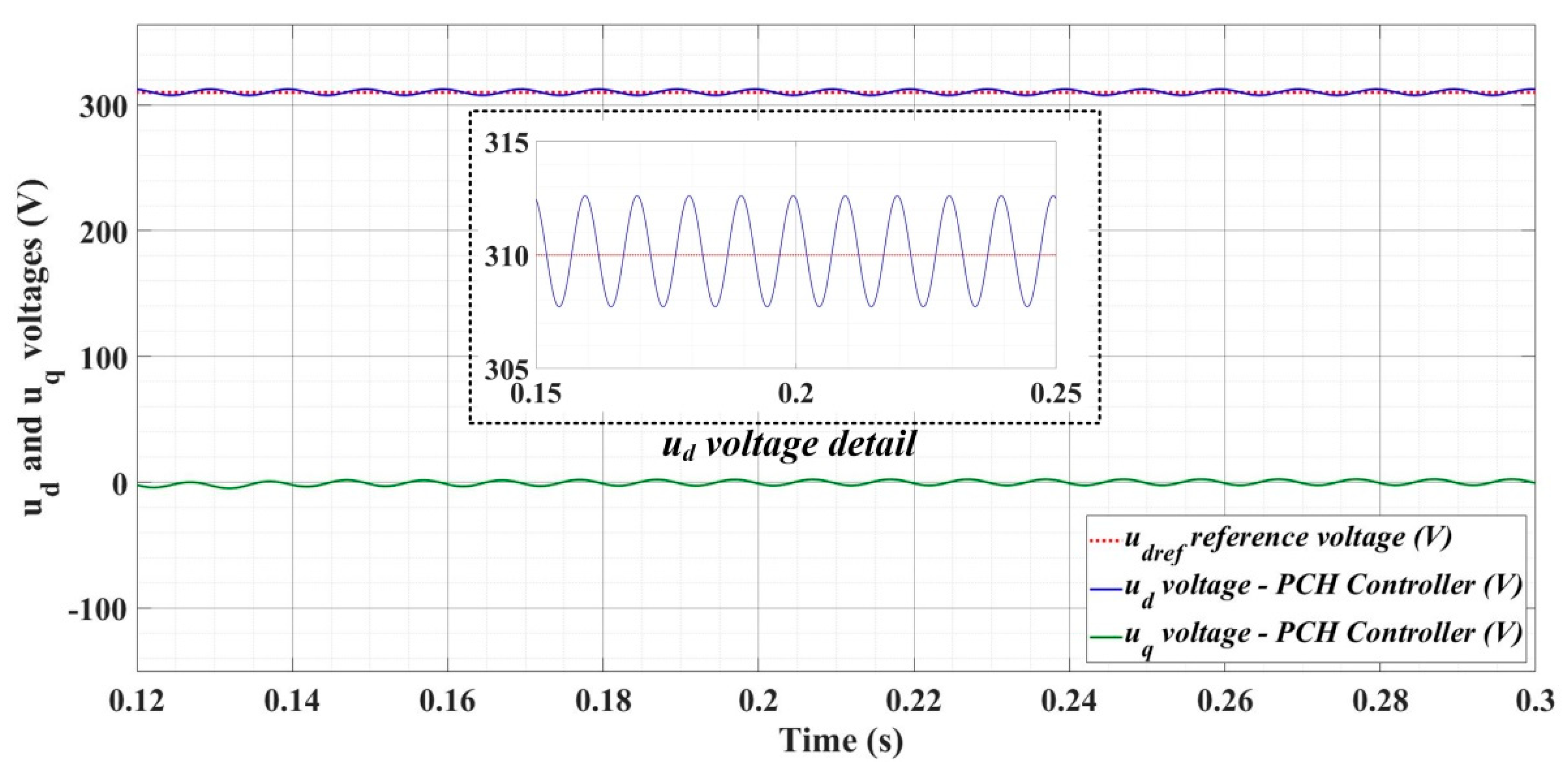

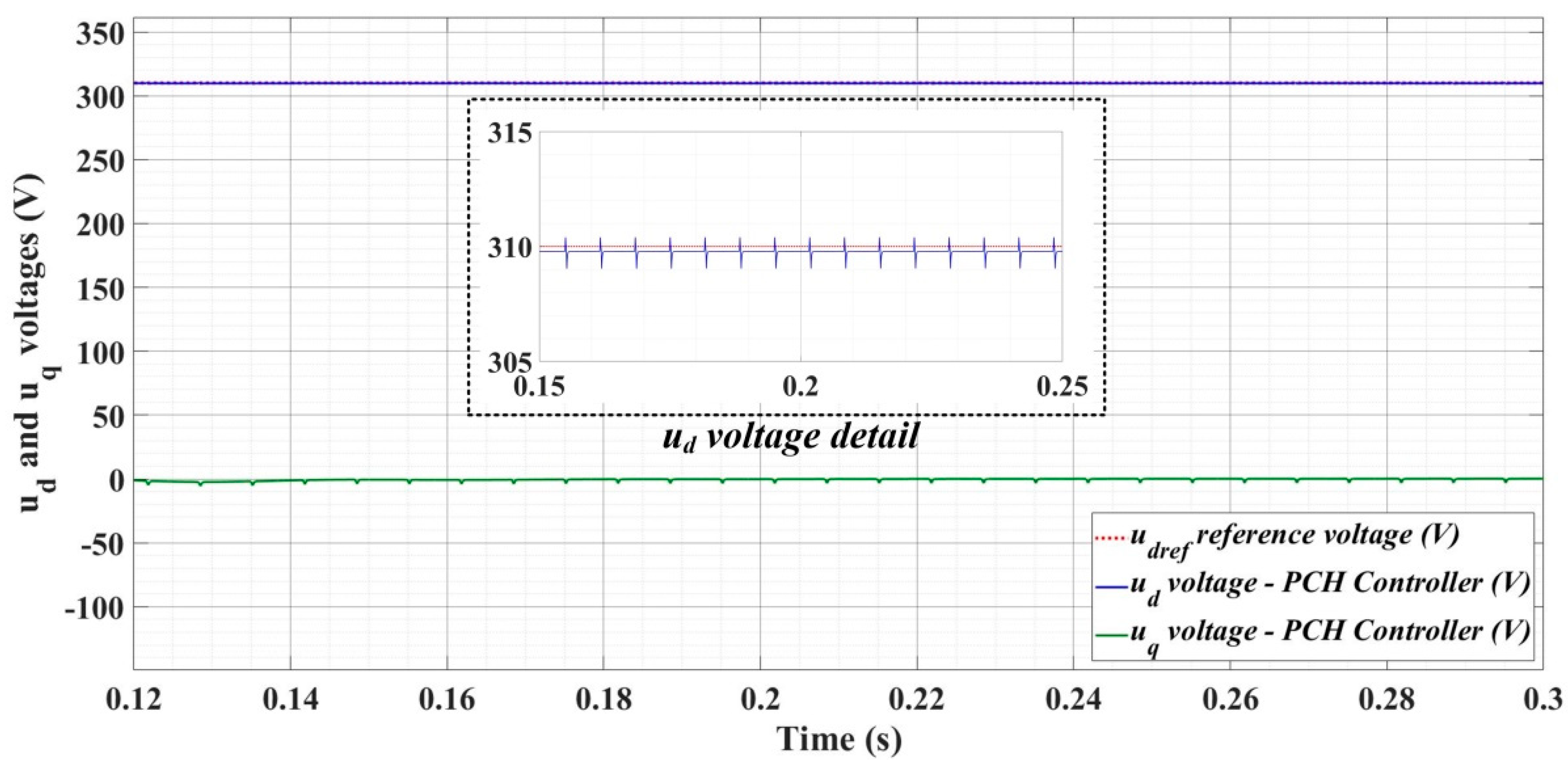

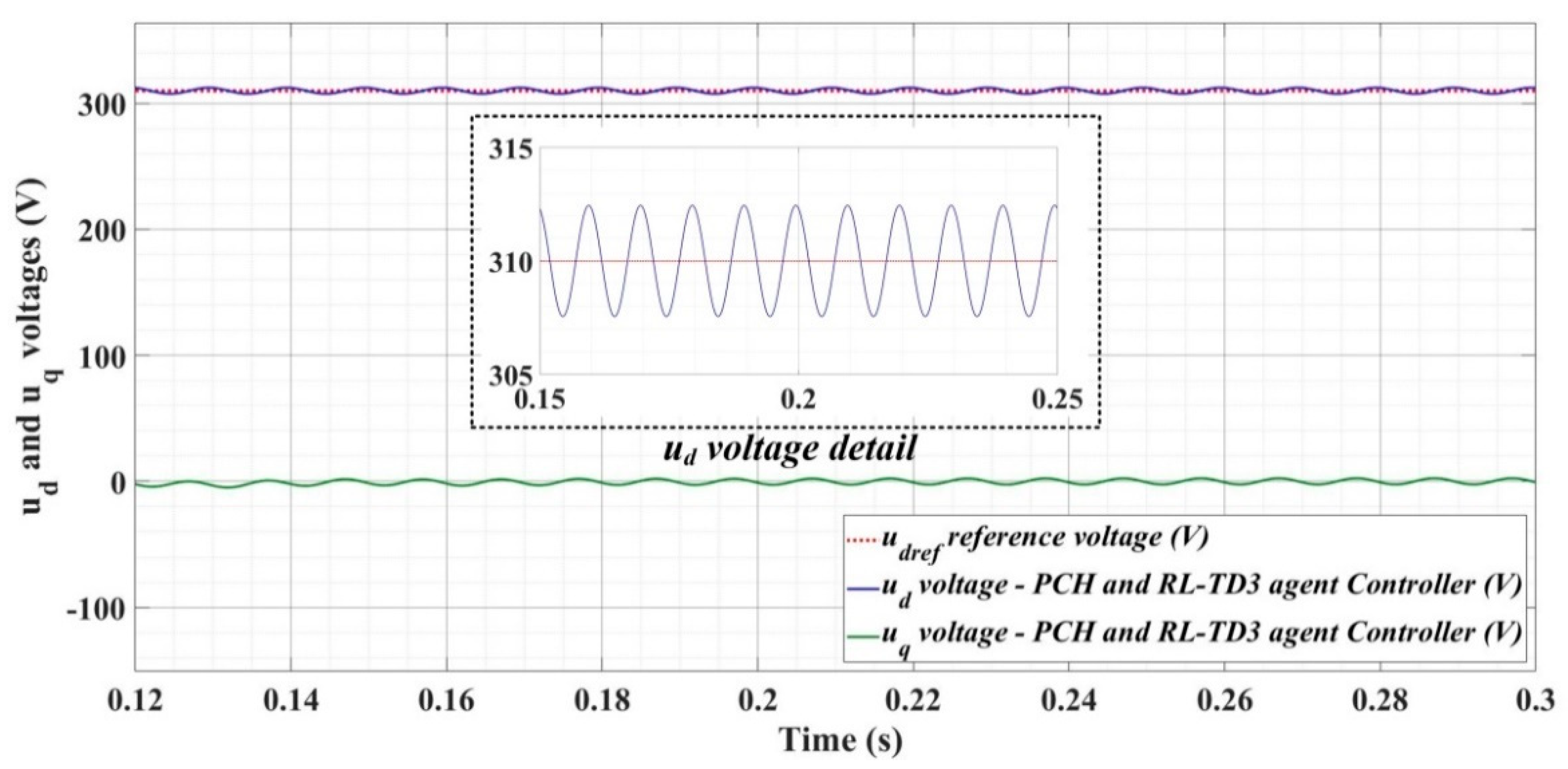

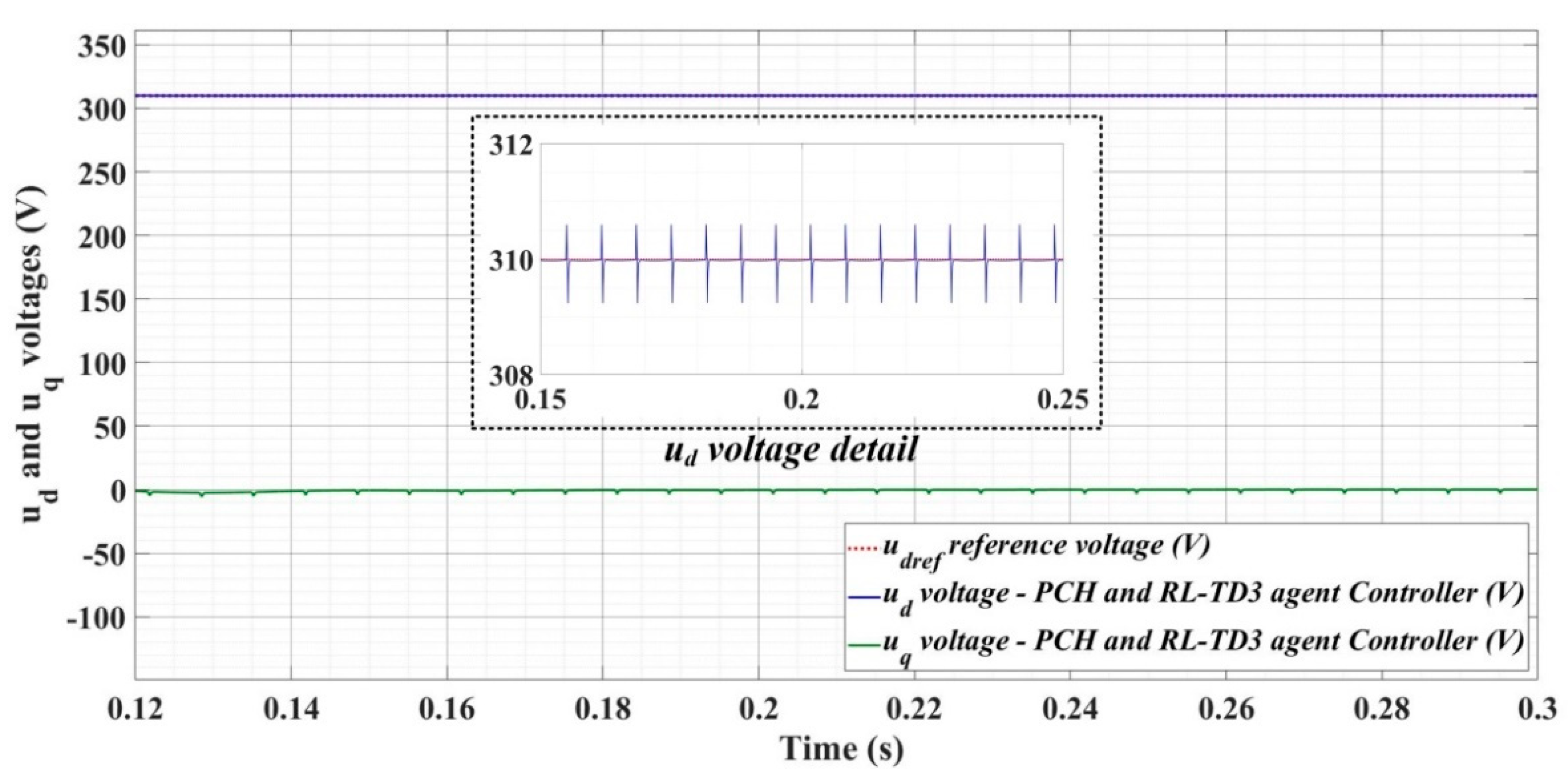

3.2. Matlab/Simulink Implementation of the PCH Control Combined with RL-TD3 Agent for Command Signals Correction

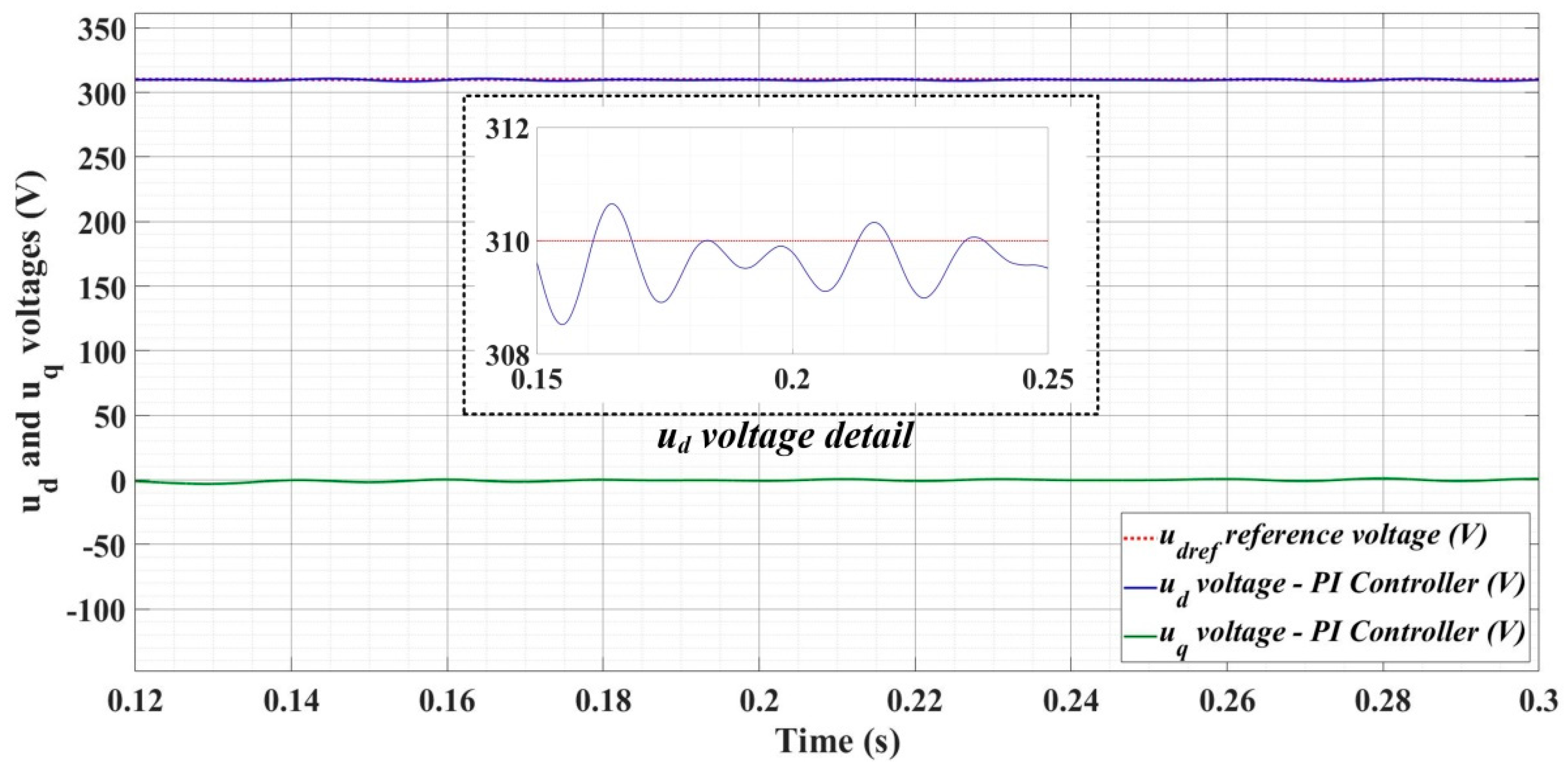

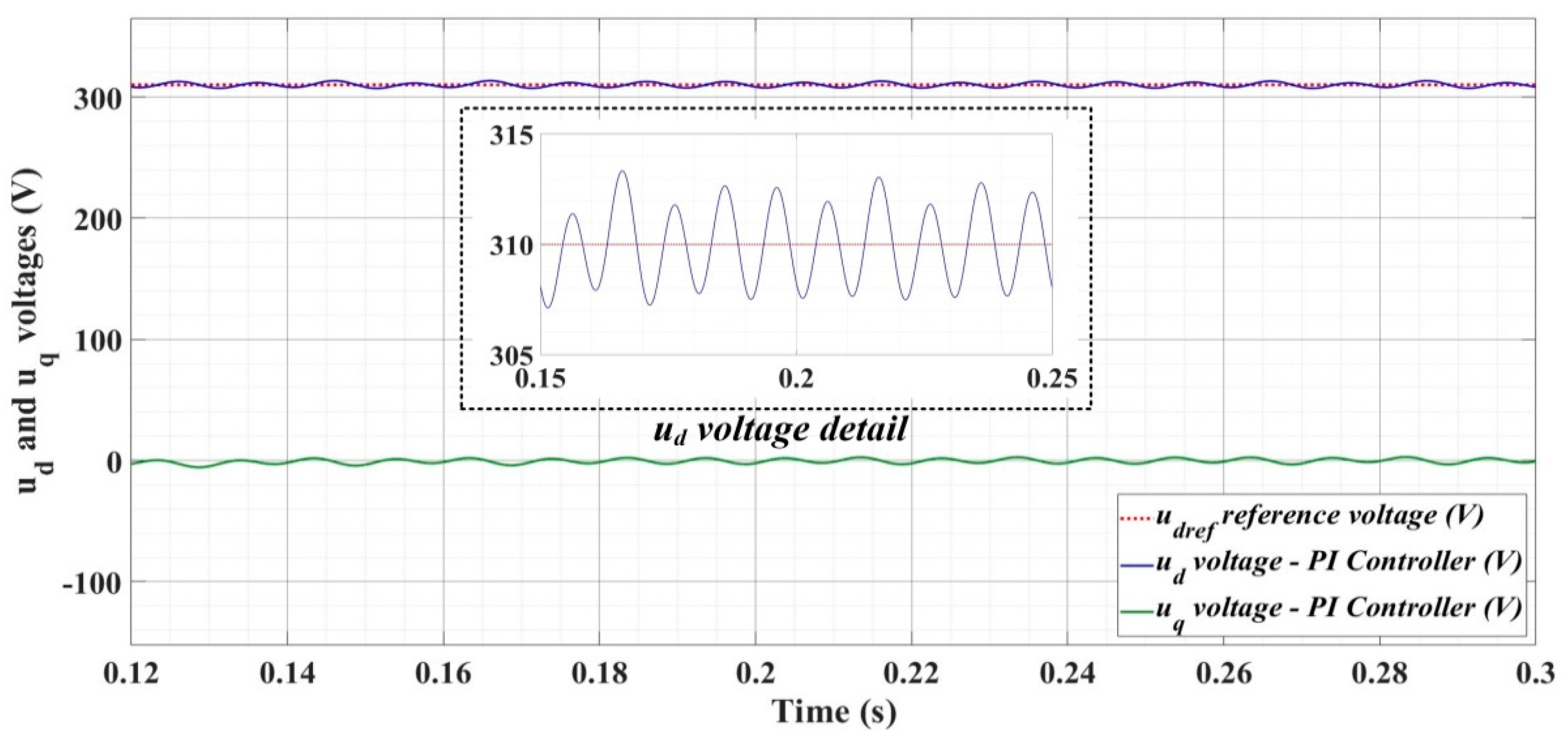

4. Numerical Simulations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Azeem, A.; Ismail, I.; Jameel, S.M.; Romlie, F.; Danyaro, K.U.; Shukla, S. Deterioration of Electrical Load Forecasting Models in a Smart Grid Environment. Sensors 2022, 22, 4363. [Google Scholar] [CrossRef] [PubMed]

- Fotopoulou, M.; Rakopoulos, D.; Blanas, O. Day Ahead Optimal Dispatch Schedule in a Smart Grid Containing Distributed Energy Resources and Electric Vehicles. Sensors 2021, 21, 7295. [Google Scholar] [CrossRef] [PubMed]

- Das, P.P.; Chatterjee, D.; Kadavelugu, A.K. Control Technique for Transformerless Regenerative Testing of Grid-Connected Power Converters. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Houston, TX, USA, 20−24 March 2022; pp. 1430–1436. [Google Scholar]

- Tricarico, T.; Gontijo, G.; Neves, M.; Soares, M.; Aredes, M.; Guerrero, J.M. Control Design, Stability Analysis and Experimental Validation of New Application of an Interleaved Converter Operating as a Power Interface in Hybrid Microgrids. Energies 2019, 12, 437. [Google Scholar] [CrossRef]

- Reich, D.; Oriti, G. Rightsizing the Design of a Hybrid Microgrid. Energies 2021, 14, 4273. [Google Scholar] [CrossRef]

- Nayak, P.; Rajashekara, K. An Asymmetrical Space Vector PWM Scheme for a Three Phase Single-stage DC-AC Converter. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 635–639. [Google Scholar]

- Aouichak, I.; Jacques, S.; Bissey, S.; Reymond, C.; Besson, T.; Le Bunetel, J.-C. A Bidirectional Grid-Connected DC–AC Converter for Autonomous and Intelligent Electricity Storage in the Residential Sector. Energies 2022, 15, 1194. [Google Scholar] [CrossRef]

- Wu, C.; Liu, Y.; Zhou, T.; Cao, S. A Multistage Current Charging Method for Energy Storage Device of Microgrid Considering Energy Consumption and Capacity of Lithium Battery. Energies 2022, 15, 4526. [Google Scholar] [CrossRef]

- Bui, V.-H.; Nguyen, X.Q.; Hussain, A.; Su, W. Optimal Sizing of Energy Storage System for Operation of Wind Farms Considering Grid-Code Constraints. Energies 2021, 14, 5478. [Google Scholar] [CrossRef]

- Sayed, K.; Almutairi, A.; Albagami, N.; Alrumayh, O.; Abo-Khalil, A.G.; Saleeb, H. A Review of DC-AC Converters for Electric Vehicle Applications. Energies 2022, 15, 1241. [Google Scholar] [CrossRef]

- MATLAB Central File Exchange—Three Phase Grid Connected Inverter. Available online: https://www.mathworks.com/matlabcentral/fileexchange/102054-three-phase-grid-connected-inverter (accessed on 10 January 2022).

- Huu, D.N. A Novel Adaptive Control Approach Based on Available Headroom of the VSC-HVDC for Enhancement of the AC Voltage Stability. Energies 2021, 14, 3222. [Google Scholar] [CrossRef]

- Rasool, M.A.U.; Khan, M.M.; Ahmed, Z.; Saeed, M.A. Analysis of an H∞ Robust Control for a Three-Phase Voltage Source Inverter. Inventions 2019, 4, 18. [Google Scholar] [CrossRef]

- Mahmud, M.R.; Pota, H.R. Robust Nonlinear Controller Design for DC-AC Converter in Grid-Connected Fuel Cell System. IEEE J. Emerg. Sel. Top. Ind. Electron. 2022, 3, 342–351. [Google Scholar] [CrossRef]

- Dyga, L.; Alhasheem, M.; Davari, P.; Rymarski, Z. Robustness of Model-Predictive and Passivity-Based Control in the Three-Phase DC/AC Converter Application. Appl. Sci. 2022, 12, 4329. [Google Scholar] [CrossRef]

- Hornik, T.; Zhong, Q. A Current-Control Strategy for Voltage-Source Inverters in Microgrids Based on H∞ and Repetitive Control. IEEE Trans. Power Electron. 2011, 26, 943–952. [Google Scholar] [CrossRef]

- Nicola, M.; Nicola, C.-I. Improved Performance for the DC-AC Converters Control System Based on Robust Controller and Reinforcement Learning Agent. In Proceedings of the International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Nevsehir, Turkey, 14–17 June 2022. accepted. [Google Scholar]

- Kamal, T.; Karabacak, M.; Perić, V.S.; Hassan, S.Z.; Fernández-Ramírez, L.M. Novel Improved Adaptive Neuro-Fuzzy Control of Inverter and Supervisory Energy Management System of a Microgrid. Energies 2020, 13, 4721. [Google Scholar] [CrossRef]

- Gil-González, W.; Montoya, O.D.; Restrepo, C.; Hernández, J.C. Sensorless Adaptive Voltage Control for Classical DC-DC Converters Feeding Unknown Loads: A Generalized PI Passivity-Based Approach. Sensors 2021, 21, 6367. [Google Scholar] [CrossRef] [PubMed]

- Magaldi, G.L.; Serra, F.M.; de Angelo, C.H.; Montoya, O.D.; Giral-Ramírez, D.A. Voltage Regulation of an Isolated DC Microgrid with a Constant Power Load: A Passivity-based Control Design. Electronics 2021, 10, 2085. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, H.; Wang, S. Development of Optimized Cooperative Control Based on Feedback Linearization and Error Port-Controlled Hamiltonian for Permanent Magnet Synchronous Motor. IEEE Access 2021, 9, 41036–141047. [Google Scholar] [CrossRef]

- Serra, F.M.; Fernández, L.M.; Montoya, O.D.; Gil-González, W.; Hernández, J.C. Nonlinear Voltage Control for Three-Phase DC-AC Converters in Hybrid Systems: An Application of the PI-PBC Method. Electronics 2020, 9, 847. [Google Scholar] [CrossRef]

- Nicola, M.; Nicola, C.-I. Improved Performance for the DC-AC Converters Control System Based on PCH Controller and Reinforcement Learning Agent. In Proceedings of the 4th Global Power, Energy and Communication Conference (GPECOM), Nevsehir, Turkey, 14−17 June 2022; pp. 26–31. [Google Scholar]

- MathWorks—Reinforcement Learning Toolbox™ User’s Guide. Available online: https://www.mathworks.com/help/reinforcement-learning/getting-started-with-reinforcement-learning-toolbox.html?s_tid=CRUX_lftnav (accessed on 10 December 2021).

- Brandimarte, P. Approximate Dynamic Programming and Reinforcement Learning for Continuous States. In From Shortest Paths to Reinforcement Learning: A MATLAB-Based Tutorial on Dynamic Programming; Springer Nature: Cham, Switzerland, 2021; pp. 185–204. [Google Scholar]

- Beale, M.; Hagan, M.; Demuth, H. Deep Learning Toolbox™ Getting Started Guide, 14th ed.; MathWorks, Inc.: Natick, MA, USA, 2020. [Google Scholar]

- Nicola, M.; Nicola, C.-I.; Selișteanu, D. Improvement of the Control of a Grid Connected Photovoltaic System Based on Synergetic and Sliding Mode Controllers Using a Reinforcement Learning Deep Deterministic Policy Gradient Agent. Energies 2022, 15, 2392. [Google Scholar] [CrossRef]

- IEEE Std 1159-2019; IEEE Recommended Practice for Monitoring Electric Power Quality. Institute of Electrical and Electronics Engineers: New York, NY, USA, 2019.

| Parameter | Value | Unit |

|---|---|---|

| Filter inductance Lf | 150·10−6 | H |

| Filter resistance Rf | 0.045 | Ω |

| Coupling capacitor Cf | 22·10−6 | F |

| Grid resistance filter RG | 0.135 | Ω |

| Grid inductance filter LG | 450·10−6 | H |

| Resistance of coupling capacitor Rd | 1 | Ω |

| Switching frequency of IGBTs | 20·103 | Hz |

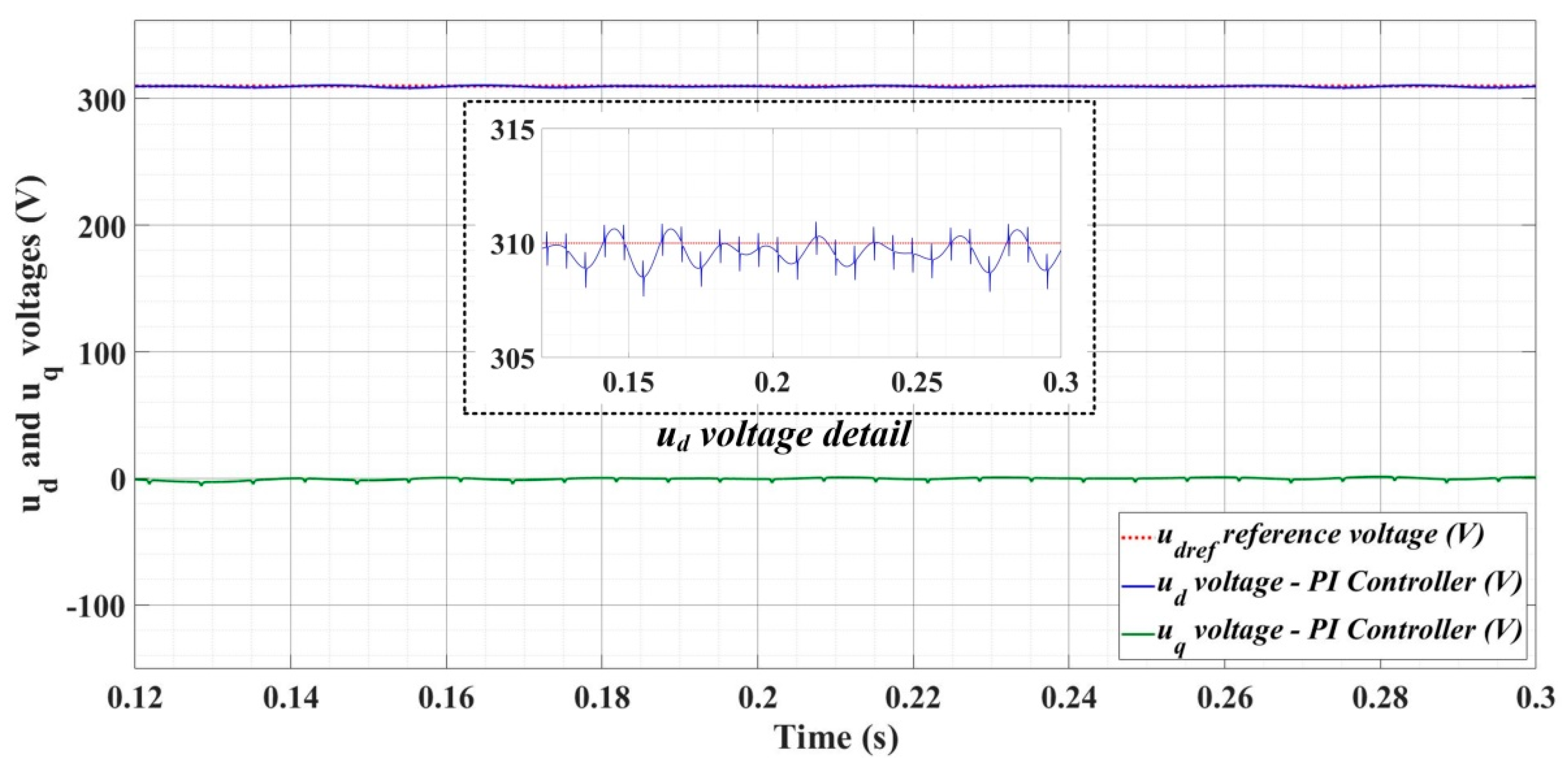

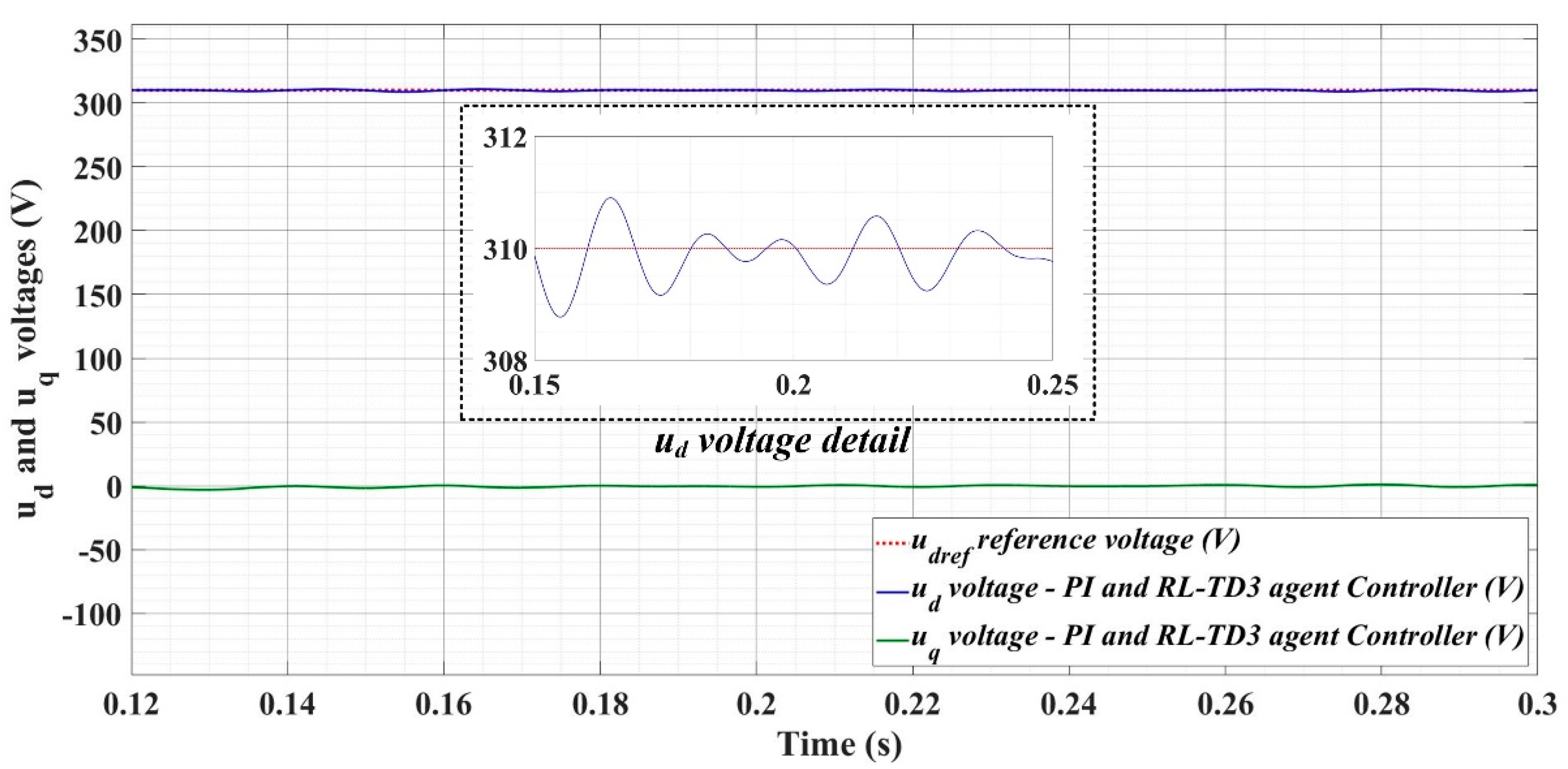

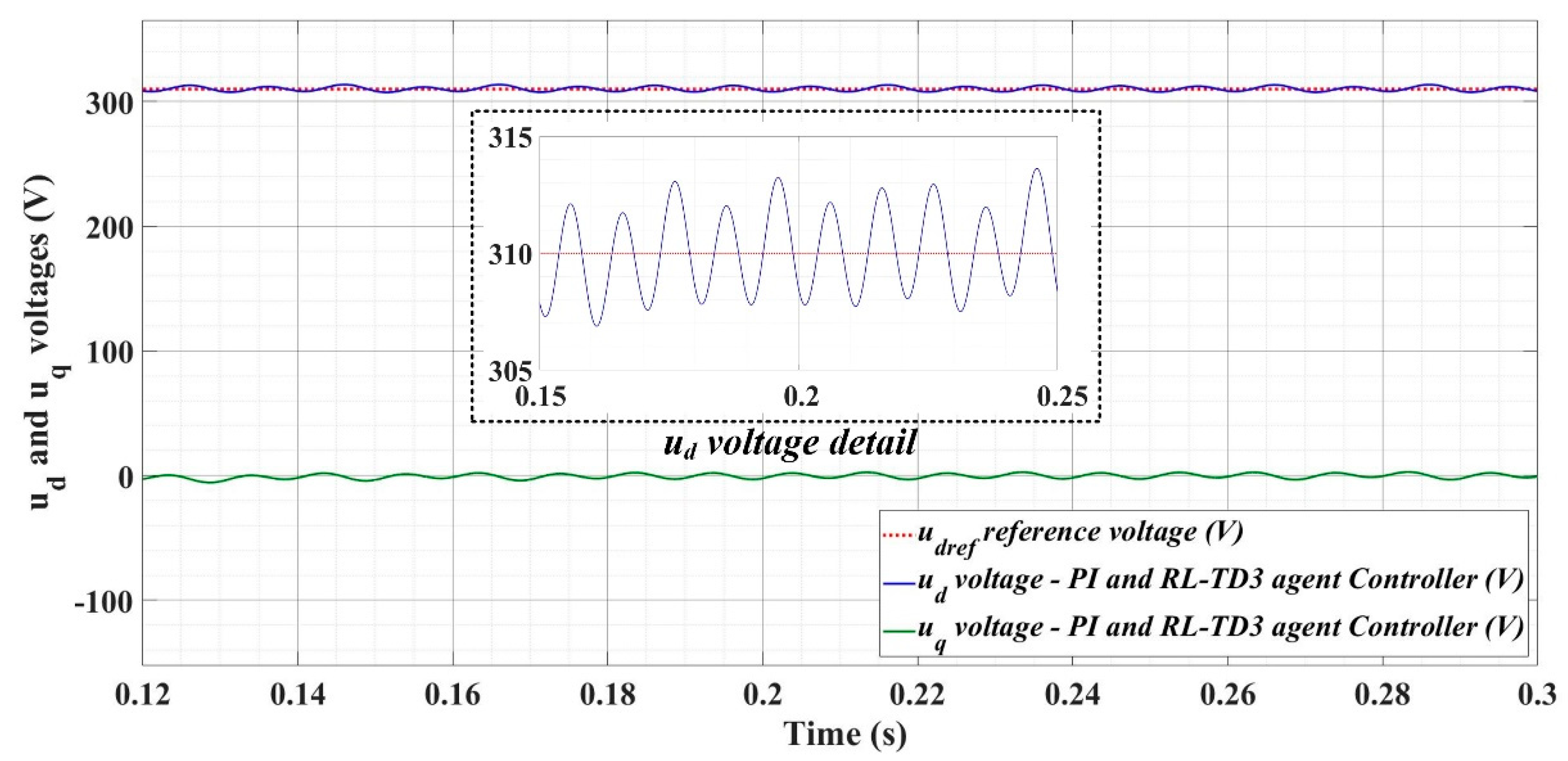

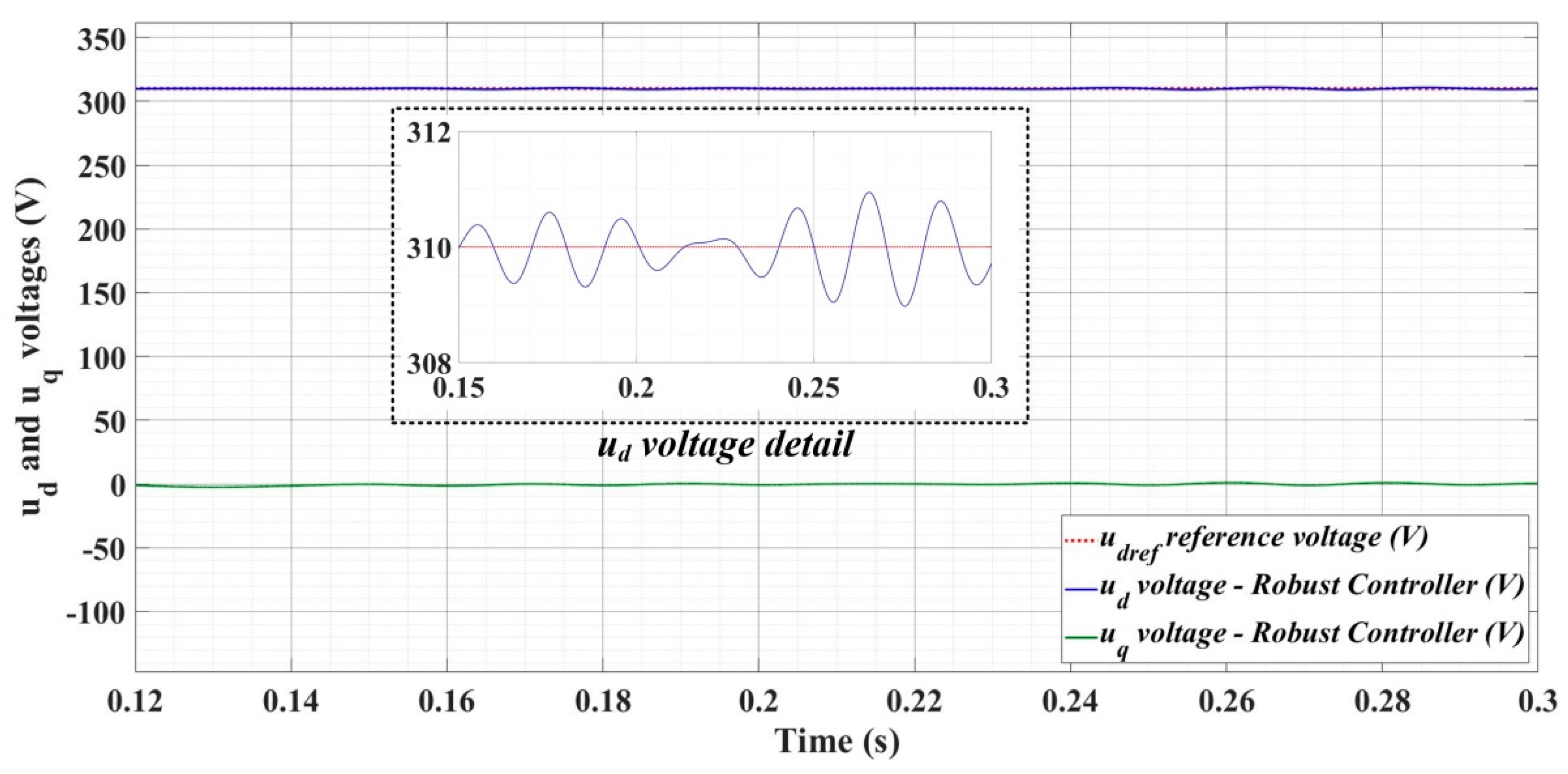

| Performance Indices of the DC-AC Converter Control System | PI Controller | PI-RLTD3 Controller | ROBUST Controller | ROBUST-RL-TD3 Controller | PCH Controller | PCH-RL-TD3 Controller | |

|---|---|---|---|---|---|---|---|

| Stationary error [V] | Balanced load | 1.64 | 0.82 | 0.71 | 0.41 | 0.51 | 0.33 |

| Unbalanced load | 4.19 | 3.92 | 3.05 | 2.43 | 2.61 | 2.14 | |

| Nonlinear load | 2.29 | 1.68 | 1.02 | 0.84 | 0.93 | 0.52 | |

| Voltage Ripple [V] | Balanced load | 0.622 | 0.522 | 0.514 | 0.332 | 0.433 | 0.217 |

| Unbalanced load | 1.774 | 1.792 | 1.801 | 1.738 | 1.799 | 1.729 | |

| Nonlinear load | 0.645 | 0.531 | 0.523 | 0.359 | 0.441 | 0.319 | |

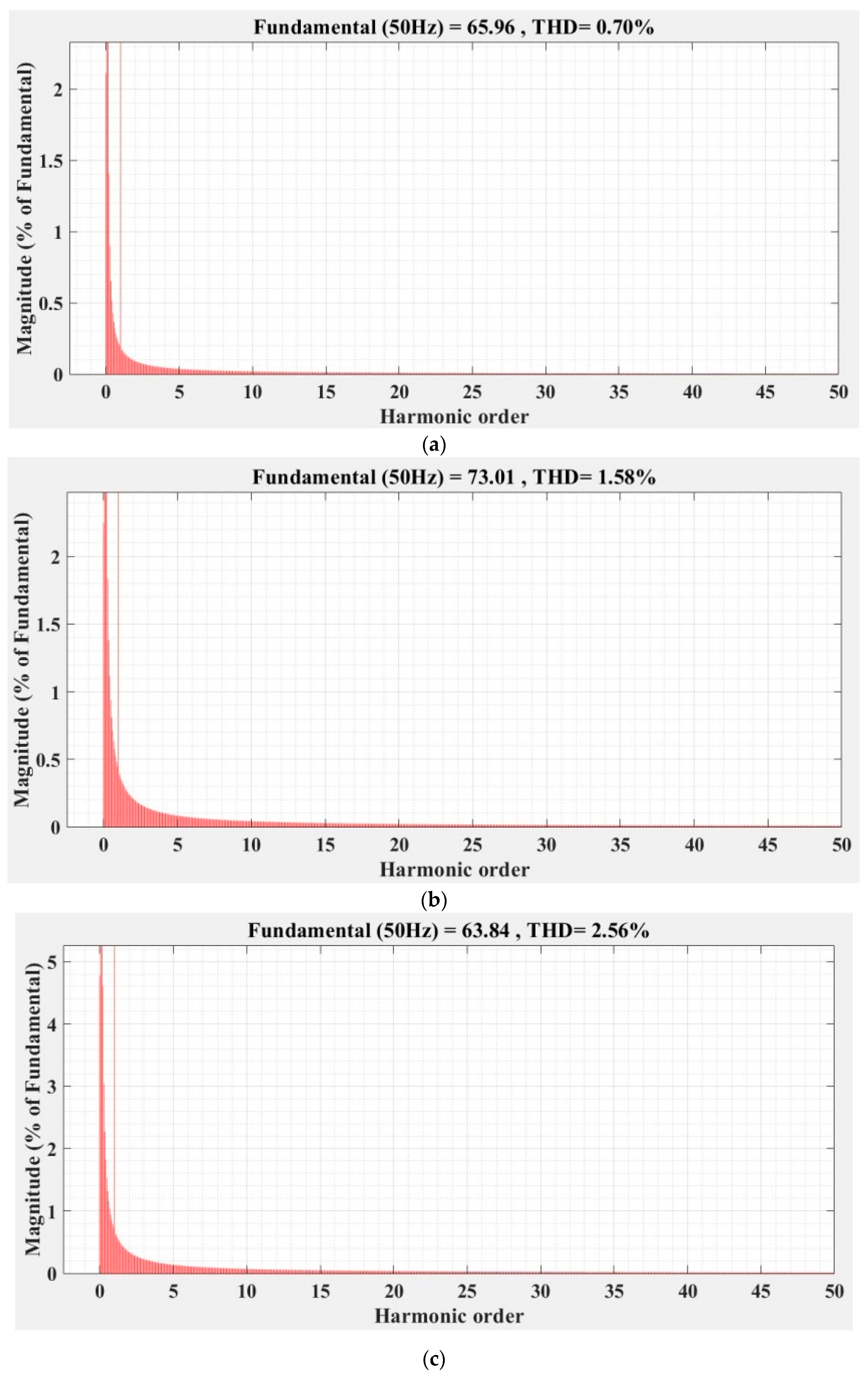

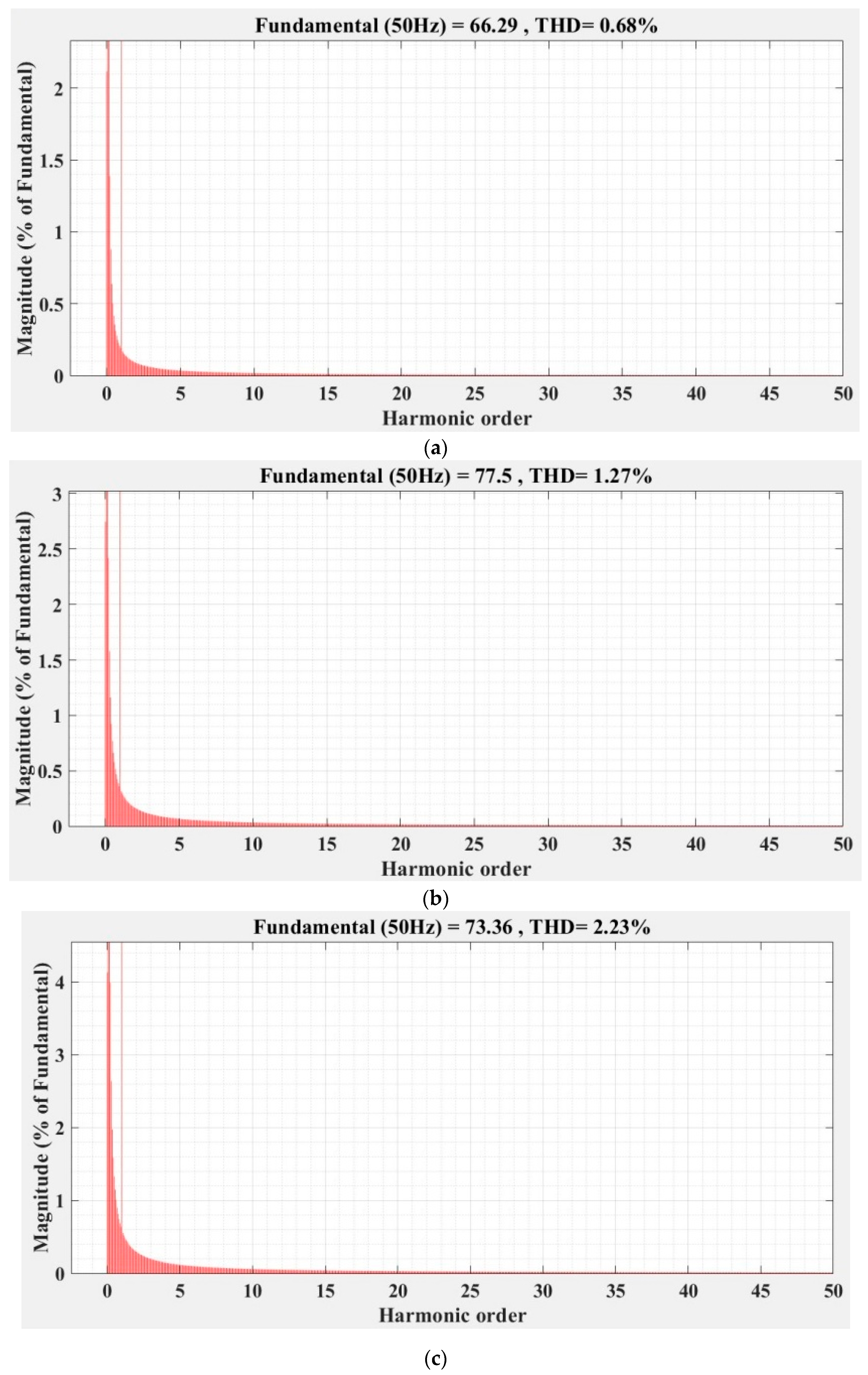

| Current phase a THD [%] | Balanced load | 1.44 | 1.23 | 0.75 | 0.72 | 0.70 | 0.68 |

| Unbalanced load | 2.14 | 2.08 | 1.86 | 1.41 | 1.58 | 1.37 | |

| Nonlinear load | 2.93 | 2.86 | 2.60 | 2.53 | 2.56 | 2.23 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nicola, M.; Nicola, C.-I. Comparative Performance Analysis of the DC-AC Converter Control System Based on Linear Robust or Nonlinear PCH Controllers and Reinforcement Learning Agent. Sensors 2022, 22, 9535. https://doi.org/10.3390/s22239535

Nicola M, Nicola C-I. Comparative Performance Analysis of the DC-AC Converter Control System Based on Linear Robust or Nonlinear PCH Controllers and Reinforcement Learning Agent. Sensors. 2022; 22(23):9535. https://doi.org/10.3390/s22239535

Chicago/Turabian StyleNicola, Marcel, and Claudiu-Ionel Nicola. 2022. "Comparative Performance Analysis of the DC-AC Converter Control System Based on Linear Robust or Nonlinear PCH Controllers and Reinforcement Learning Agent" Sensors 22, no. 23: 9535. https://doi.org/10.3390/s22239535

APA StyleNicola, M., & Nicola, C.-I. (2022). Comparative Performance Analysis of the DC-AC Converter Control System Based on Linear Robust or Nonlinear PCH Controllers and Reinforcement Learning Agent. Sensors, 22(23), 9535. https://doi.org/10.3390/s22239535