2.1. Experimental Setup

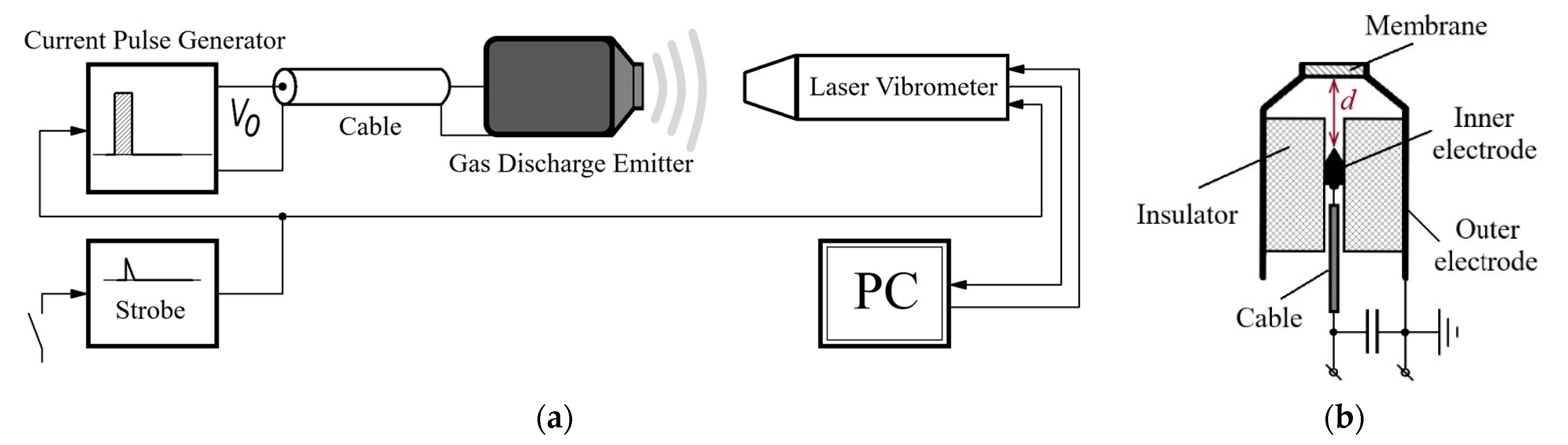

Air-coupled gas discharge emitters represent a novel type of non-contact devices, which are able to generate acoustic waves in a pulsed mode. Their operation principle is based on using the gas pressure rise in a gas discharge gap, which appears under the warming up and expanding of the discharge plasma area due to current pulse flow. The pressure jump, which forms in the inter-electrode space, unbalances the emitter membrane, thus, leading to the generation of acoustic waves in the ambient air. The technical performance of a gas discharge emitter was investigated by using the SLDV setup, as shown in

Figure 1.

The experimental setup includes a gas discharge emitter of acoustic waves, communication line and current pulse generator, as well as a scanning laser Doppler vibrometer PSV-500-3D-HV (Polytec, Germany), as shown in

Figure 1. The discharge was excited by using a home-made current pulse generator with an output voltage of V

0 < 12 kV and short-circuit current up to1 kA. In the experiments, the pulse repetition rate varied up to 3 Hz in order to avoid possible overheating of the electrodes during multiple measurements and the necessity to ventilate the discharge chamber. It is worth noting that the chamber design allowed us to reach a pulse repetition rate of 60 Hz and higher. The upper repetition rate limit was 500 Hz, which corresponded to the continuous operation mode of the emitter. However, this was beyond the scope of this research. The inter-electrode gap (specified as

d in the

Figure 1b) was 5 mm. The Fast Fourier Transform (FFT) spectrometer option with a resolution of 30 Hz was used to analyze the amplitude–frequency spectrum of generated vibrations.

2.2. Modeling

The resonance frequencies of the emitter depend on the size and properties of the membrane; however, the discharge itself appears broadband [

14,

15,

16,

17]. Therefore, the development of a membrane model simulating the vibrational characteristics of objects seems to be appropriate in order to minimize the size of experiments and correct some object properties, such as the mass/size ratio and rigidity and/or damping. The analysis of the dynamic characteristics of objects, such as the vibration parameters (mode shape and frequency), is useful for altering object resonance frequencies.

The FEM modeling of vibrations in the emitter membrane was based on Basic Modal Analysis by using Autodesk Inventor software. The model included solid-type volume elements with properties similar to a tested material, in particular, aluminum, see [

21] for details.

In general, the calculation of membrane natural frequencies requires the knowledge of its physical properties, which are united under the term of bending stiffness (

D) [

22]:

where

h is the membrane thickness,

E and

v are the Young modulus and Poisson ratio of the material, respectively.

The natural frequencies depend on the sample geometry and on the support conditions on the edges. In this study, a disk-like aluminum membrane with a clamped edge support was considered. In the classical approach, the fundamental resonance frequency of a circular membrane with a clamped edge was recently suggested in [

22]:

where

m is the mass of the membrane and

r is the radius.

For instance, by substituting Equation (1) into Equation (2) with

ω = 2

πf, one obtains [

22]:

where

is the material density.

The resonance frequency of the emitter membrane was calculated for the following experimental parameters:

r = 19 mm and

h = 1 mm. The aluminum mechanical properties were:

E = 70 × 10

9 Pa,

v = 0.34 and

= 2700 kg/m

3.

Figure 2 shows the used finite element model (

Figure 2a) and the respective numerical mesh (

Figure 2b) with a mean element size of 0.3 mm; the computation time was 10 s.

The results of the calculation were of the membrane resonance frequency fm and distributions of mechanical vibrations by z coordinates. In the model, the boundary condition involved the clamped edge support, thus, well correlating the real experiment. Additionally, Basic Modal Analysis assumed that the model was dynamically tested in ideal conditions, i.e., without taking into account additional internal and external factors. The experimental values of the resonance frequency fr determined by SLDV, given below, are to be used for validating the mathematical model.

2.3. Analyzing Membrane Natural Frequencies: Experimental and Modeling Results

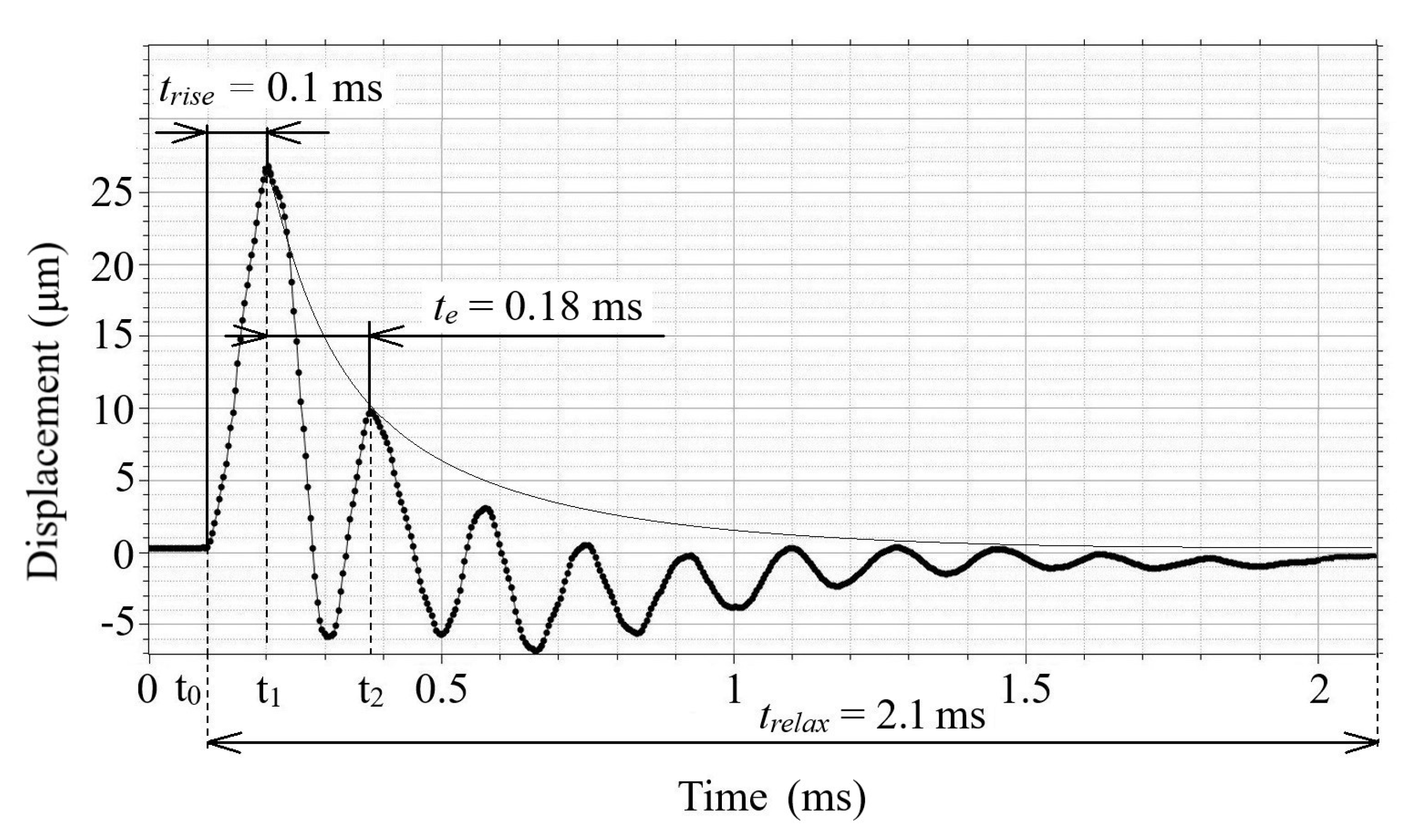

The gas discharge process in the electrode system of the emitter led to the appearance of acoustic vibrations on the emitter surface and, correspondingly, in the ambient air. By using the SLDV technique in time mode, the damped vibrations of the emitter membrane were measured during discharge current pulse flow. A typical graph of damped vibrations in the center of the 1 mm thick aluminum membrane is shown in

Figure 2.

We considered the oscillations of the gas discharge emitter membrane excited by an electric current pulse. It follows from the graph in

Figure 3, wherein the amplitude of the first maximum of membrane oscillations

reached 26.7 μm at 0.1 ms. The second maximum

of the damped oscillations (at 9.9 μm) appeared at the time

= 0.18 ms when the oscillation amplitude decayed by

e times in respect to the maximum value. In turn, the time of full signal relaxation was 2.1 ms. In general, the results above show that when the grade of damping of the oscillating system is low, it can be corrected by changing damping characteristics in particular applications.

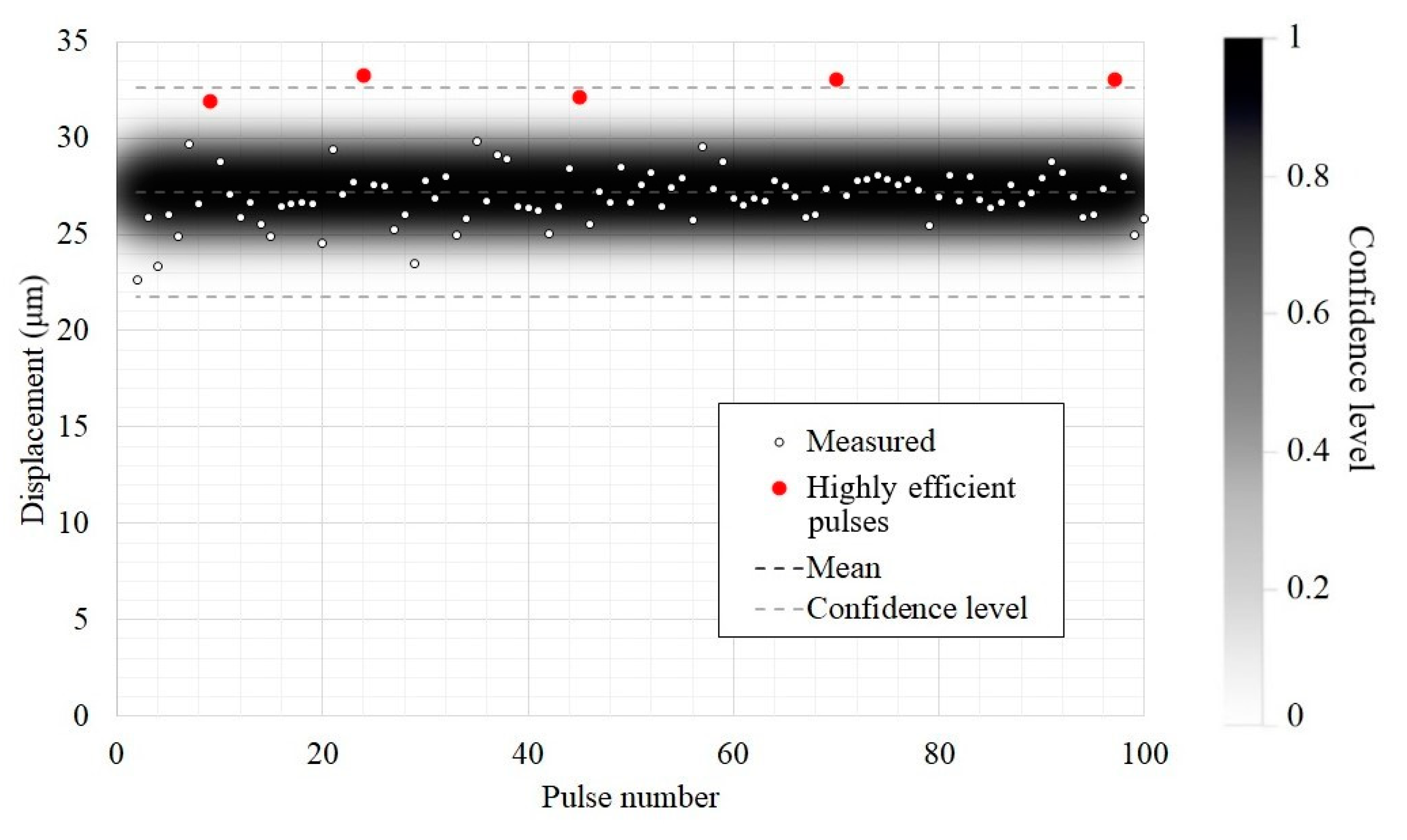

The magnitude of displacements during the flow of the electric current was evaluated in 100 pulses. All measurements were conducted at a pulse repetition rate of 2.5 Hz.

Figure 4 shows these displacements in the center of the membrane.

The analysis of obtained results shows that the amplitude of vibration displacements at the end of the emitter varied from 22.7 to 33 μm. It can be seen that only 3 measurements out of a total of 100 fell out of the confidence level interval, thus, corresponding to 95% confidence. In those three measurements, the signal amplitudes exceeded 33 μm, and, in two other measurements, they reached 32 μm, thus, still being within the confidence level interval. Such five signal peaks appeared once every 20 measurements, and this corresponded to the most efficient regime of acoustic wave generation under the conditions described. It was probably related to both variations in the discharge parameters and physical processes in the gas discharge gap. The mean displacement amplitude was 27.2 μm, thus, matching well with the corresponding characteristic of classical piezoelectric and magnetostrictive transducers [

23].

A recent study demonstrated that an air-coupled magnetostrictive transducer (resonance frequency 22 ± 1.65 kHz), in combination with high-power ultrasonic generator (electrical power 0.63 ± 10% kW), provides a vibration displacement at the horn end of up to 30 μm by optimizing the horn design [

13]. Commercial piezoelectric transducers, for example, Ultran ACU (resonance frequency 110 kHz), have revealed a vibration displacement of about 10 μm at the emitter end (generator voltage 70 V and alternating current frequency 113 kHz) [

13]. In the same study [

13], it was shown that continuous ultrasonic excitation using both piezoelectric and magnetostrictive transducers is accompanied by distortions in the amplitude of the resulting signal because of interference between incident and reflected waves. The distortion magnitude depends on the distance between the emitter and a test object. Therefore, in order to achieve optimal matching of the entire acoustic system, the air gap thickness should be multiple to the half-length of the acoustic wave propagating in the air. This operational problem of non-contact acoustic devices can be solved by applying broadband pulsed stimulation implemented in gas discharge devices.

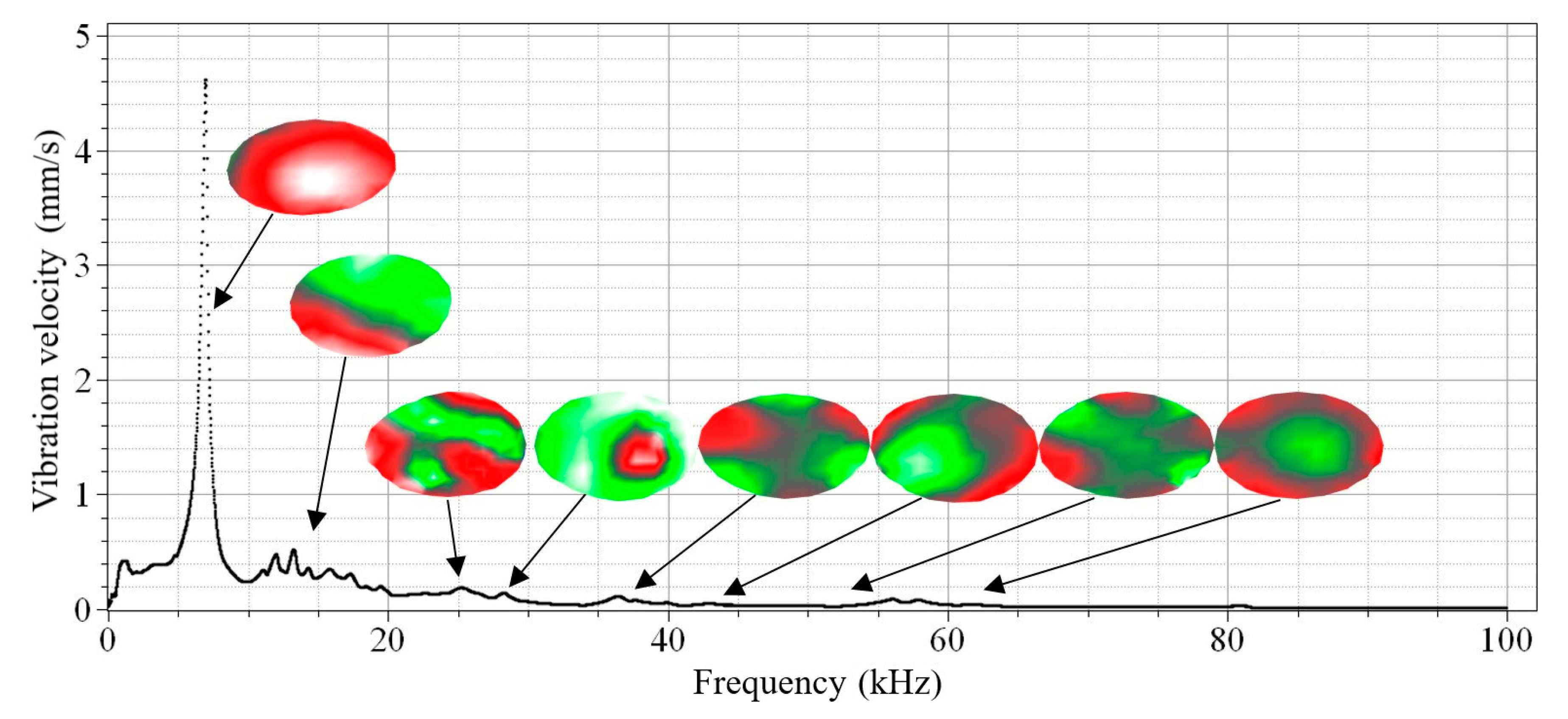

To continue the testing of the oscillations of the gas discharge emitter membrane, the vibration signal was converted into amplitude spectrum in order to demonstrate characteristic frequency domains (

Figure 5).

As follows from

Figure 5, the amplitude of vibration velocity is smooth through the entire frequency spectrum with a central resonance peak appearing at 7 kHz that corresponds to the membrane eigenfrequency. There is no contact between the plasma and the ambient air in this configuration, and this might be important in practical applications. However, in this case, the amplitude–frequency characteristic of the system will be determined by the membrane rather than the discharge parameters. In particular, the velocity amplitude reaches 4.62 mm/s with a high quality factor (

Q ≈ 15), and this may further be used for compensation purposes by introducing damping elements. Generally, an atmospheric pressure gas discharge can be used to generate acoustic waves in the range from 50 Hz to 100 kHz and, thus, perform the acoustic stimulation of composite materials.

Both analytical and numerical modeling can also be helpful for explaining some spectral resonances. The Autodesk Inventor software was used to visualize the eigenmodes of vibrations and compare the experimental and theoretical results of the membrane by applying finite element analysis. In the model, the membrane was fixed by the perimeter to simulate real conditions where the sample was fixed by a clamping flange. The modeling allowed us to determine 20 resonance modes in the range from 0 to 100 kHz and compare them with the experimental values of the electric pulse emitter resonances (

) obtained at frequencies from 10 Hz to 100 kHz (

Table 1). In addition, these data were used to explain the origin of the resonance peaks in the amplitude–frequency spectrum of the gas discharge emitter.

Table 1 and

Figure 5 present the results of vibration modeling in the aluminum membrane with clamped edges, along with the estimates of relative measurement errors

, where

and

are the modeled and experimental resonance frequencies (the experimental data were obtained by using the laser vibrometry technique).

The results above (

Table 1 and

Figure 5) demonstrate that, with increasing frequencies, one observes the decrease in both vibration velocity amplitudes on the emitter surface, as well as the decrease in their root-mean-square values. In the frequency range analyzed, the maximum amplitude of vibration velocity was 4.62 mm/s at a frequency of 6.69 kHz. The minimum velocity amplitude of 0.006 mm/s appeared at 84 kHz, while the mean value was 0.132 mm/s. This proves that the main energy of emitter surface vibrations is concentrated in a frequency range of up to 10 kHz, even if some peaks were observed at frequencies higher than 80 kHz.

It is worth noting that the discrepancy between the theoretical and experimental values of resonance frequencies did not exceed 5%. The spatial distribution of vibrations, which was evaluated by means of laser vibrometry, matched well with the results of modal analysis, and some disturbances were caused by non-stationary phenomena in the plasma, as well as, probably, by uneven clamping of the membrane. In addition, the resonance frequency of the discharge emitter electrode significantly influences the work frequencies of the emitter, which was confirmed by the analysis of amplitude–frequency spectrum. Hence, the use of different types of electrodes may help to produce the required resonance frequencies of electrodes and, thus, define the acoustic spectrum of gas discharge systems.

2.4. Spectral Characteristics of Metal Membranes

In order to analyze the peculiarities of the operation of gas discharge emitters and optimize their configuration, some membranes made of different metals were investigated. In particular, these metals were: aluminum (D16T), brass (LS59), titanium (BT6-1) and steel (St3). Each sample series included five membranes with a size of 38 × 2, 38 × 2.3 and 38 × 2.6 mm.

Figure 6 shows the amplitude–frequency spectrum of vibrations in a frequency range from 1.5 kHz to 30 kHz for four types of metals.

As shown in

Figure 6, different membranes reveal different amplitude–frequency spectra even in the case of membranes of the same size and thickness. In the case of Al, the resonance frequency was 5.81 kHz, the resonance frequency of titanium was 4.32 kHz and the resonance frequency of steel was 7.68 kHz. The resonance peaks in the brass membrane were less obvious compared to other materials, i.e., in this case, the amplitude–frequency spectrum was smoothed with a maximum at 2.57 kHz. Oppositely, the aluminum and titanium membranes were characterized by pronounced resonance peaks. In these cases, the vibration amplitudes (aluminum 20.3 μm and titanium 20.1 μm) were higher than for other metals. In steel membranes, one may also observe a characteristic resonance maximum with an amplitude of vibration velocity similar to that in a brass membrane but 2.5 times lower compared to aluminum and titanium. The vibration peculiarities above can be explained by different physical properties of the metals that affect the work frequencies of membranes. It is also worth noting that the presence of high-frequency peaks in the spectra investigated takes place because of the activation of membrane higher resonance harmonics during their relaxation.

Notably, the vibration energy is mainly emitted in the 1.5–11 kHz frequency range, where spectral maximums for all investigated metals are located. However, brass membranes should be recommended for NDT purposes due to their smoother amplitude–frequency spectrum in regard to other metals.

The data above prompts that the desired frequency range of emitters can be defined by optimizing the material, size and geometry of membranes according to practical requirements.

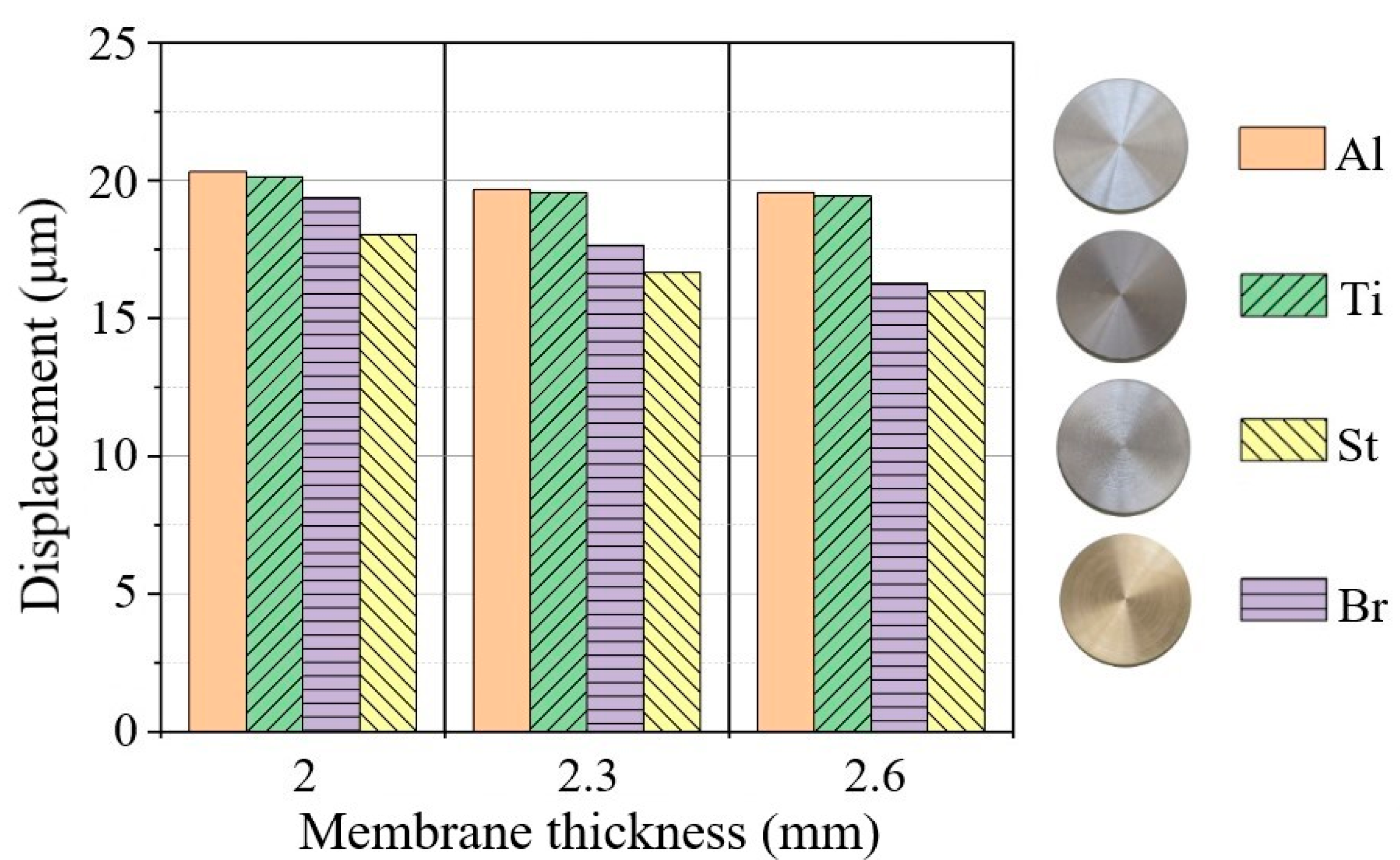

Figure 7 shows histograms of vibration displacements for metallic membranes of varying thickness. It can be seen that displacement amplitudes are different for different metals and slightly decrease for thicker membranes, provided the electrical power of the generator is constant. In the center of aluminum and titanium membranes, the maximum displacement amplitude reached 20 μm. In these membranes, both the frequency and amplitude of vibrations are related to the lower density of the metals when compared to steel and brass.

The influence of the inter-electrode distance on displacement amplitude was investigated on the aluminum membrane (diameter

D = 38 mm and thickness

h = 1 mm). The inter-electrode distance was varied by changing the position of the potential electrode with respect to the membrane. The minimal gap thickness was 5 mm, the channel diameter was 3 mm, and the gas discharge volume varied approximately from 15 to 35 mm

3. In all cases, the pulse repetition rate was 2 Hz, and the variation of the vibration displacement in time was measured by means of laser vibrometer. The corresponding graph is presented in

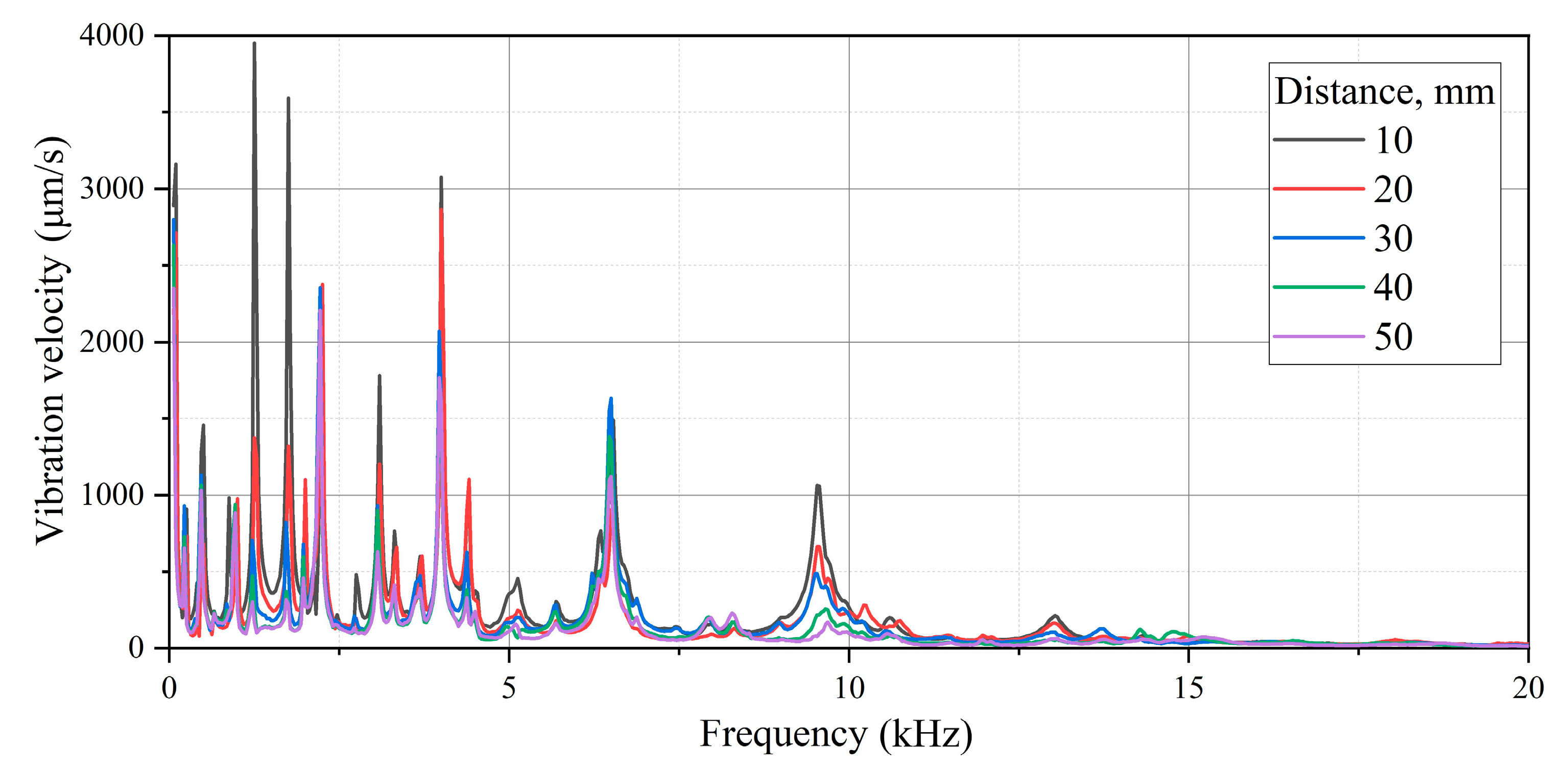

Figure 8 for the aluminum membrane and different inter-electrode gap thicknesses.

The electric field strength, which is necessary for breakdown, was practically constant. With thicker gaps, the breakdown voltage increases, while the energy stored in the capacitor is proportional to the square of the voltage. On the other hand, by assuming the membrane rigidity constant, the energy at the point of maximum displacement will be proportional the square of the displacement. This would lead to the direct proportion between the displacement and gap thickness d. However, one more factor is the gap volume, which acts as a kind of a muffler. Moreover, discharge resistance may increase with longer discharge gaps, thus, decreasing the current in the discharge contour. Therefore, the increase in d by 50% leads to an increase in the displacement amplitude by only 40%.