Study of the Influence of the Backplate Position on EMAT Thickness-Measurement Signals

Abstract

:1. Introduction

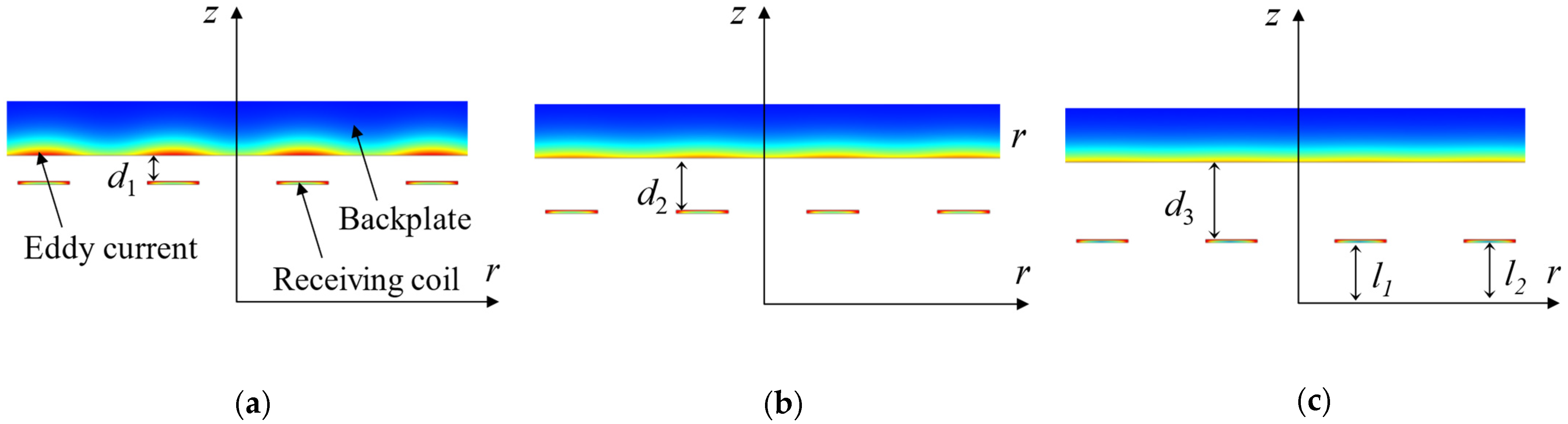

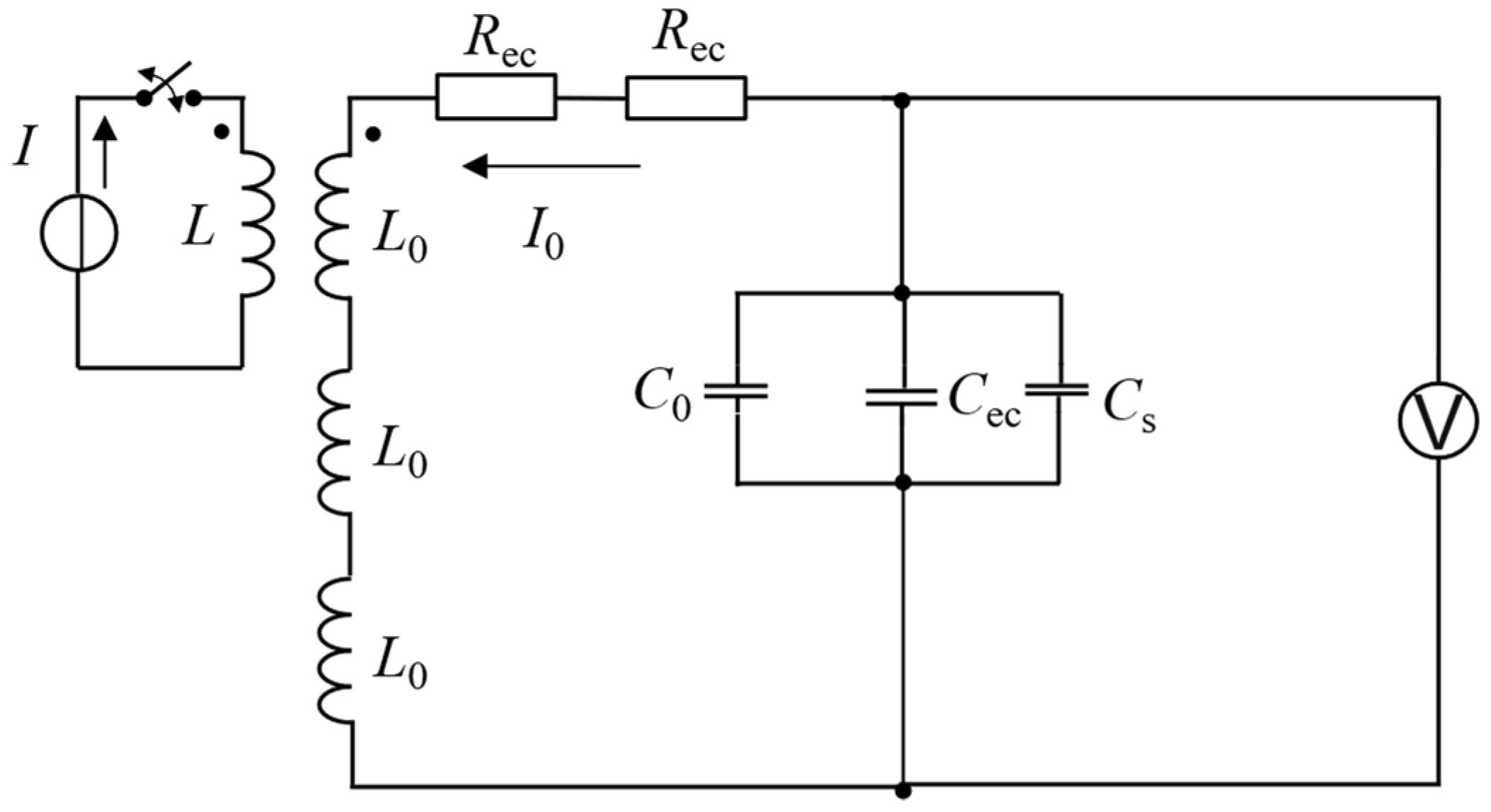

2. Modeling of Receiving Process

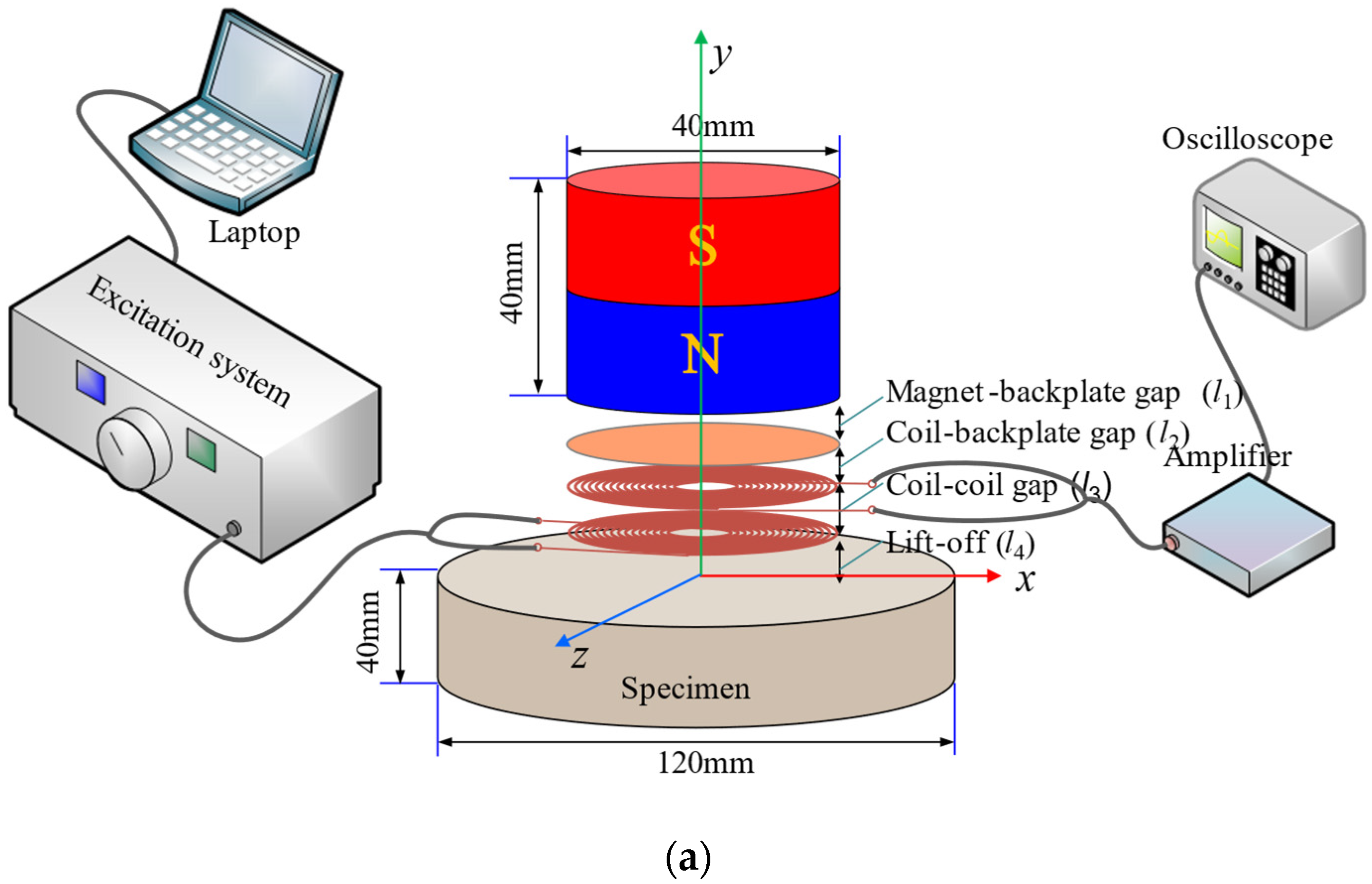

2.1. Configuration of EMATs and Equivalent Model of Receiving Process

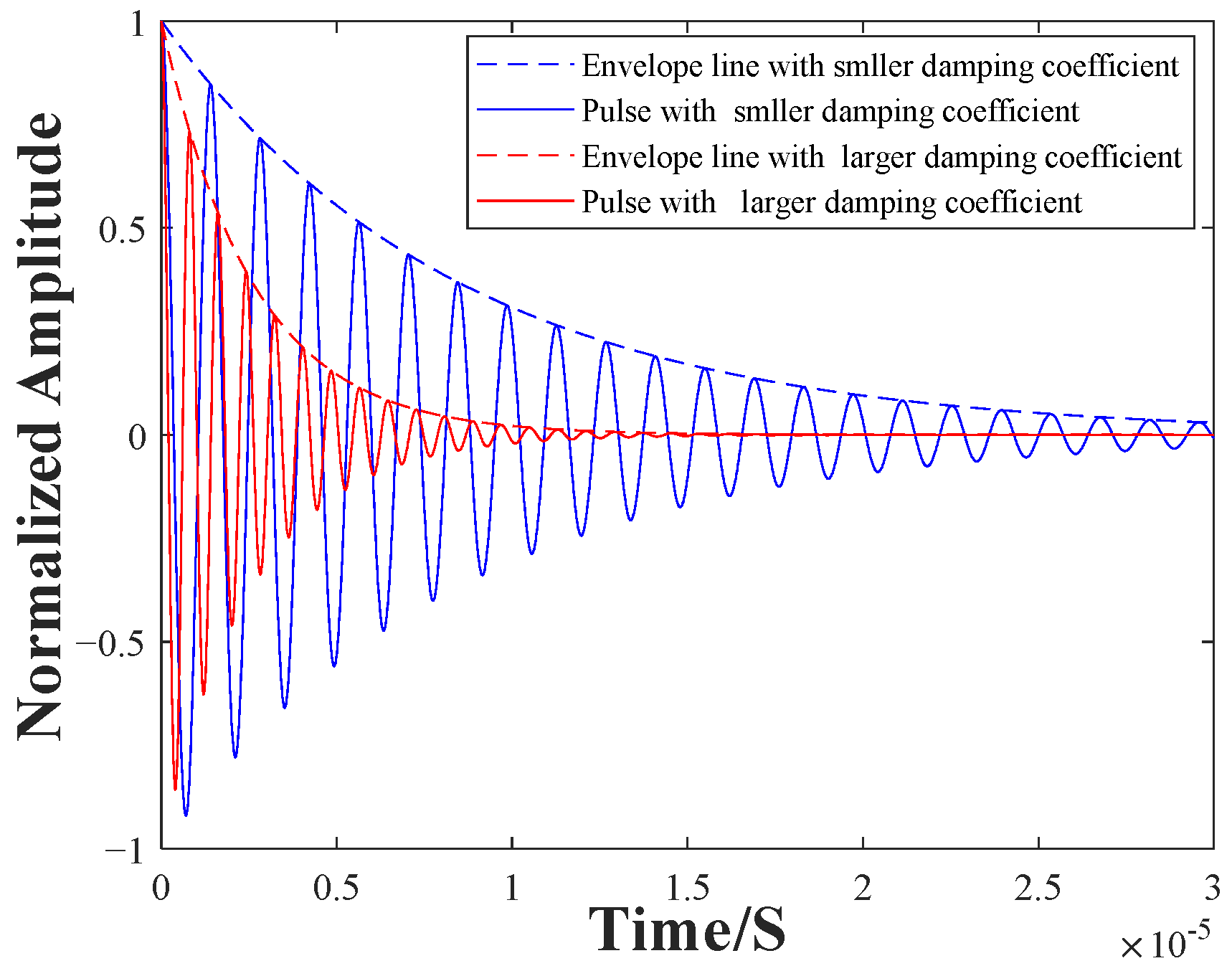

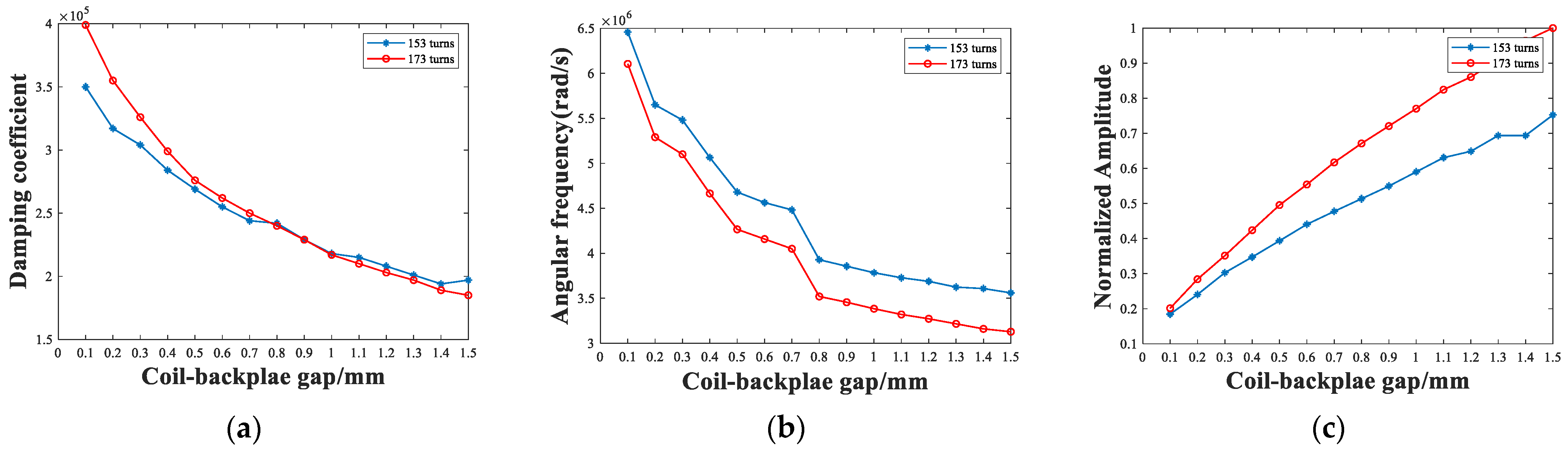

2.2. Effects of the Backplate Position on Output Voltage Signal of EMAT

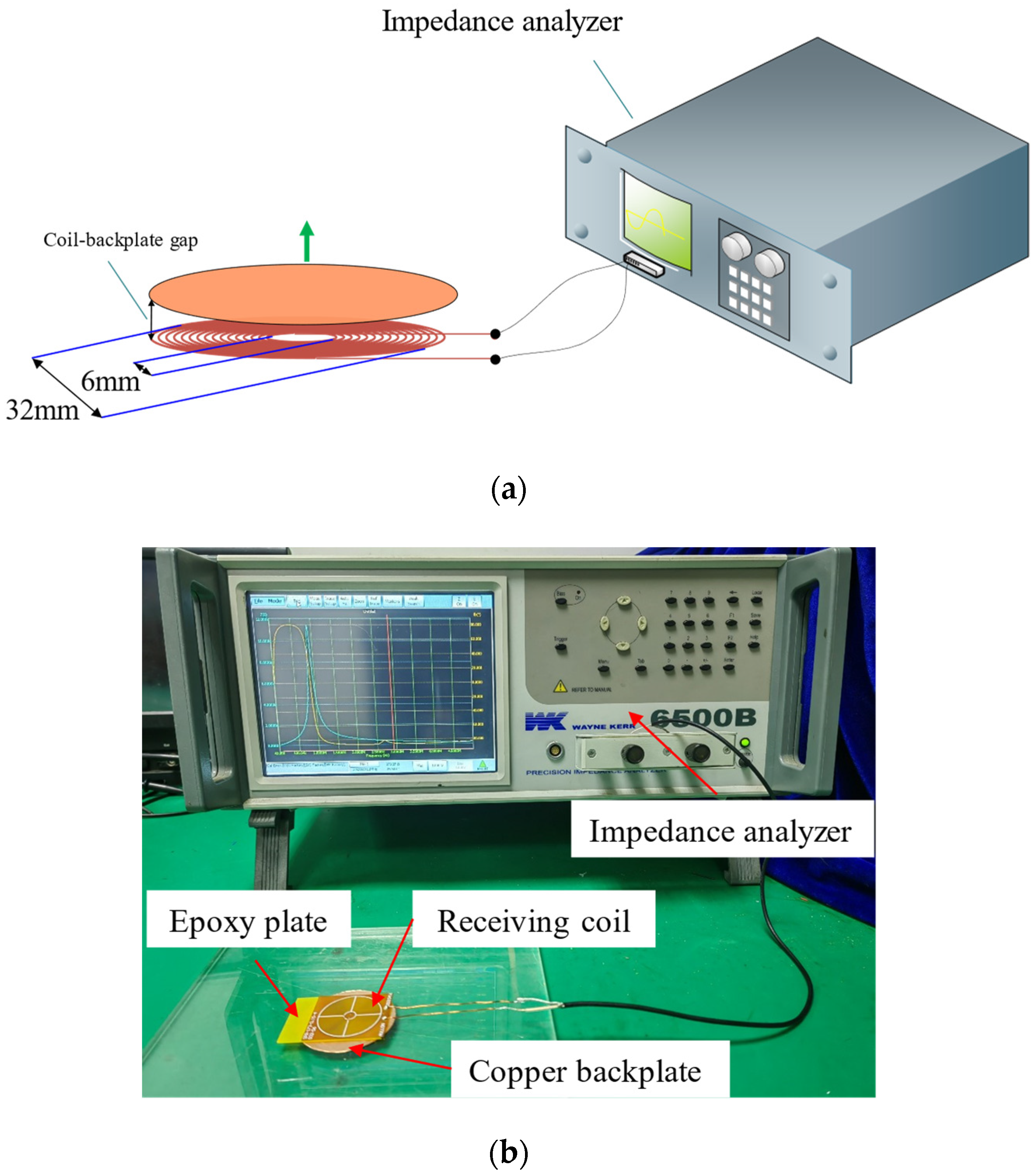

3. Experiments and Results

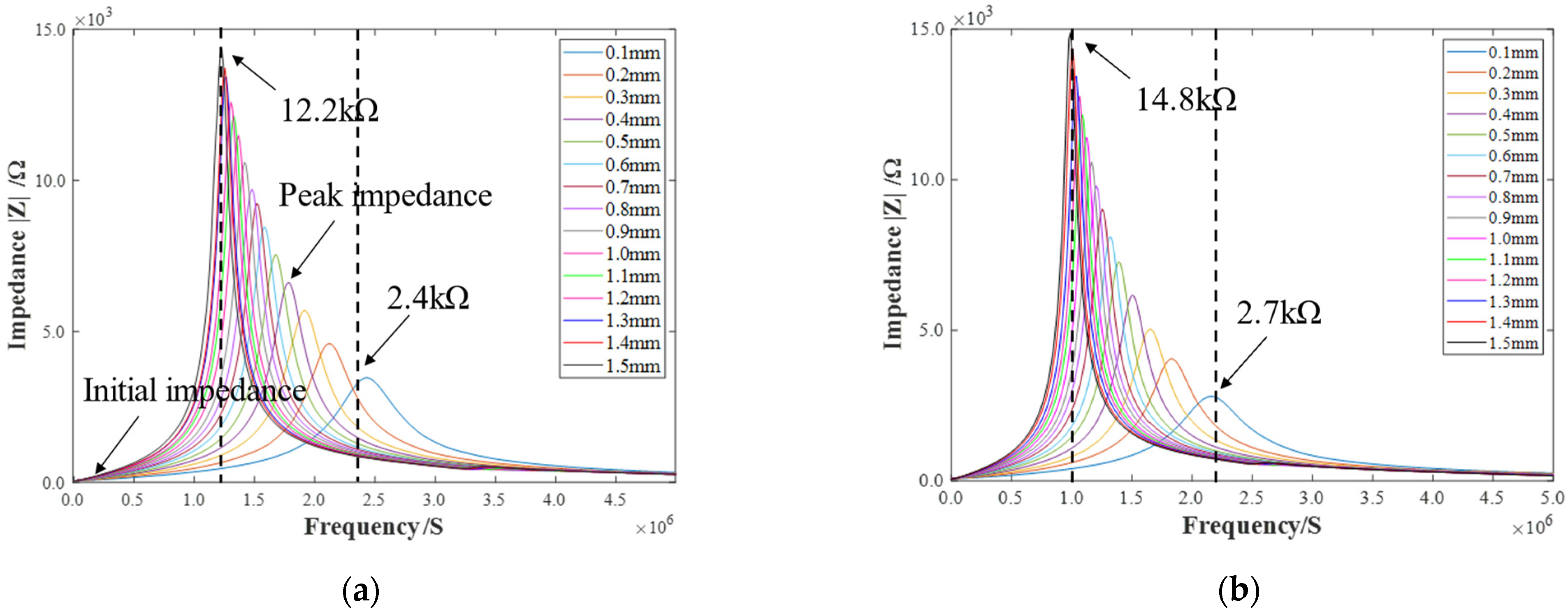

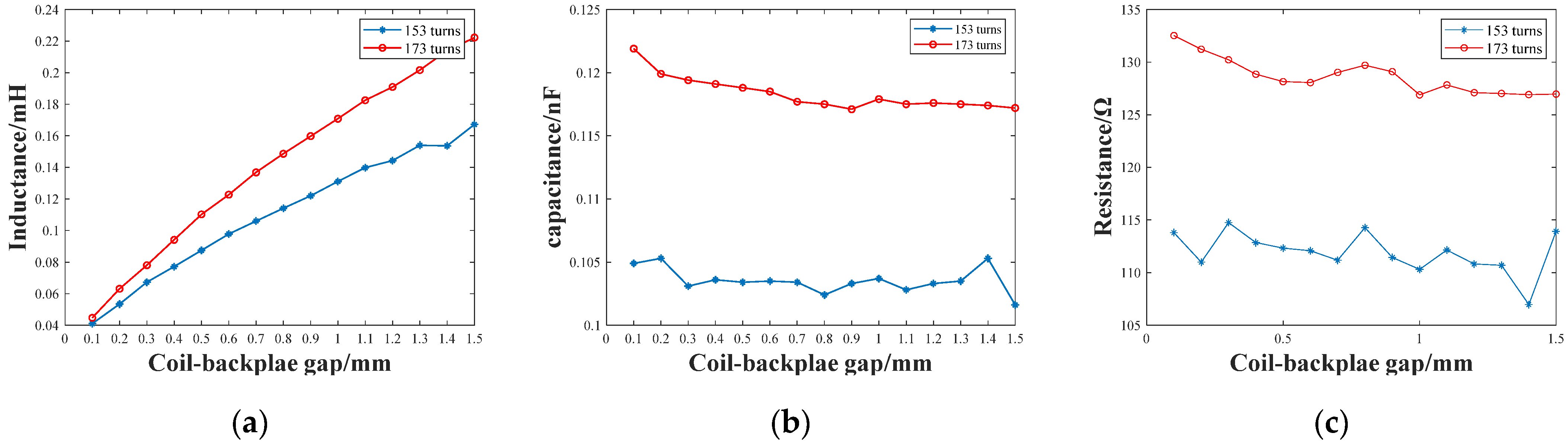

3.1. Experiment for Impedance Measurement of Models

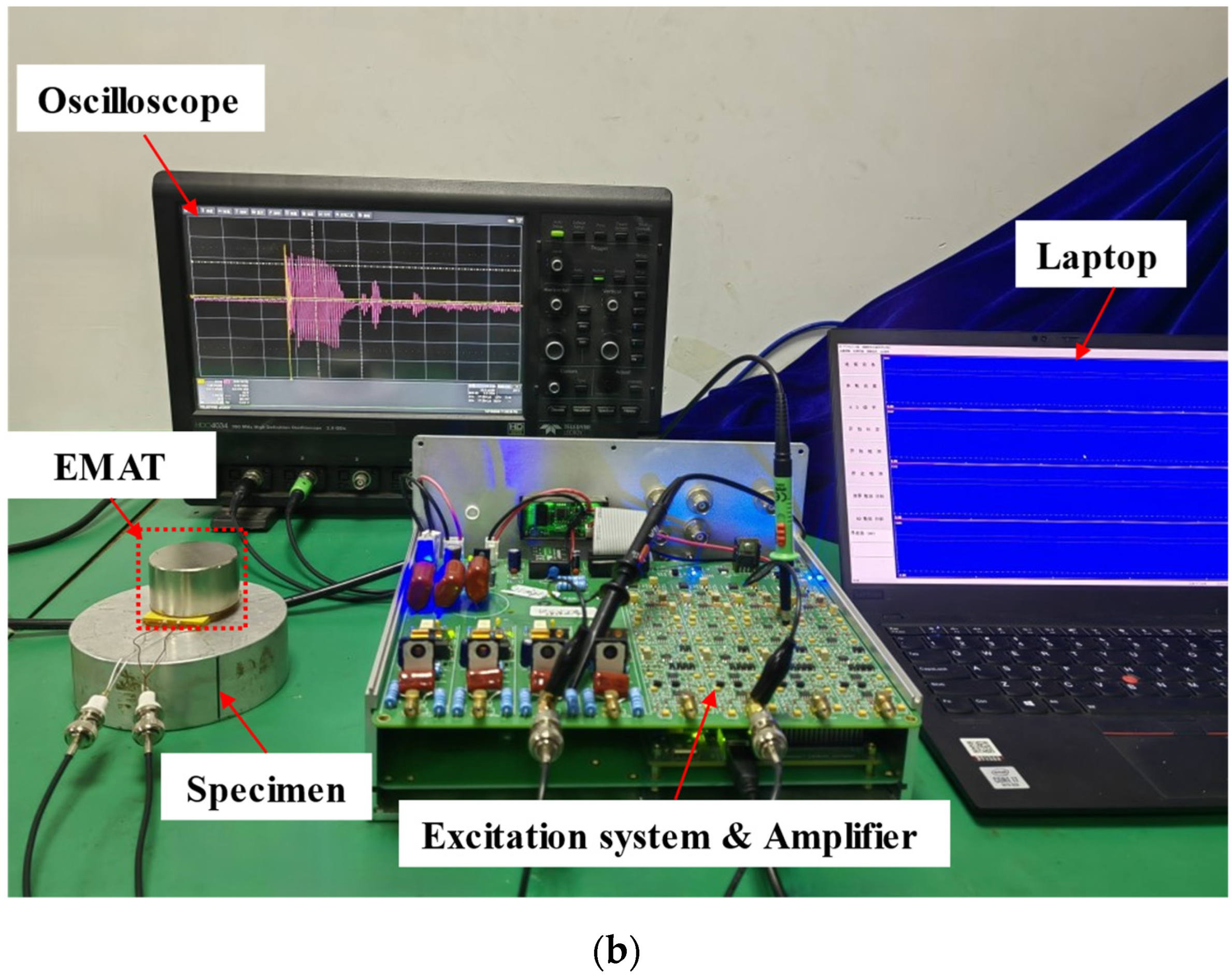

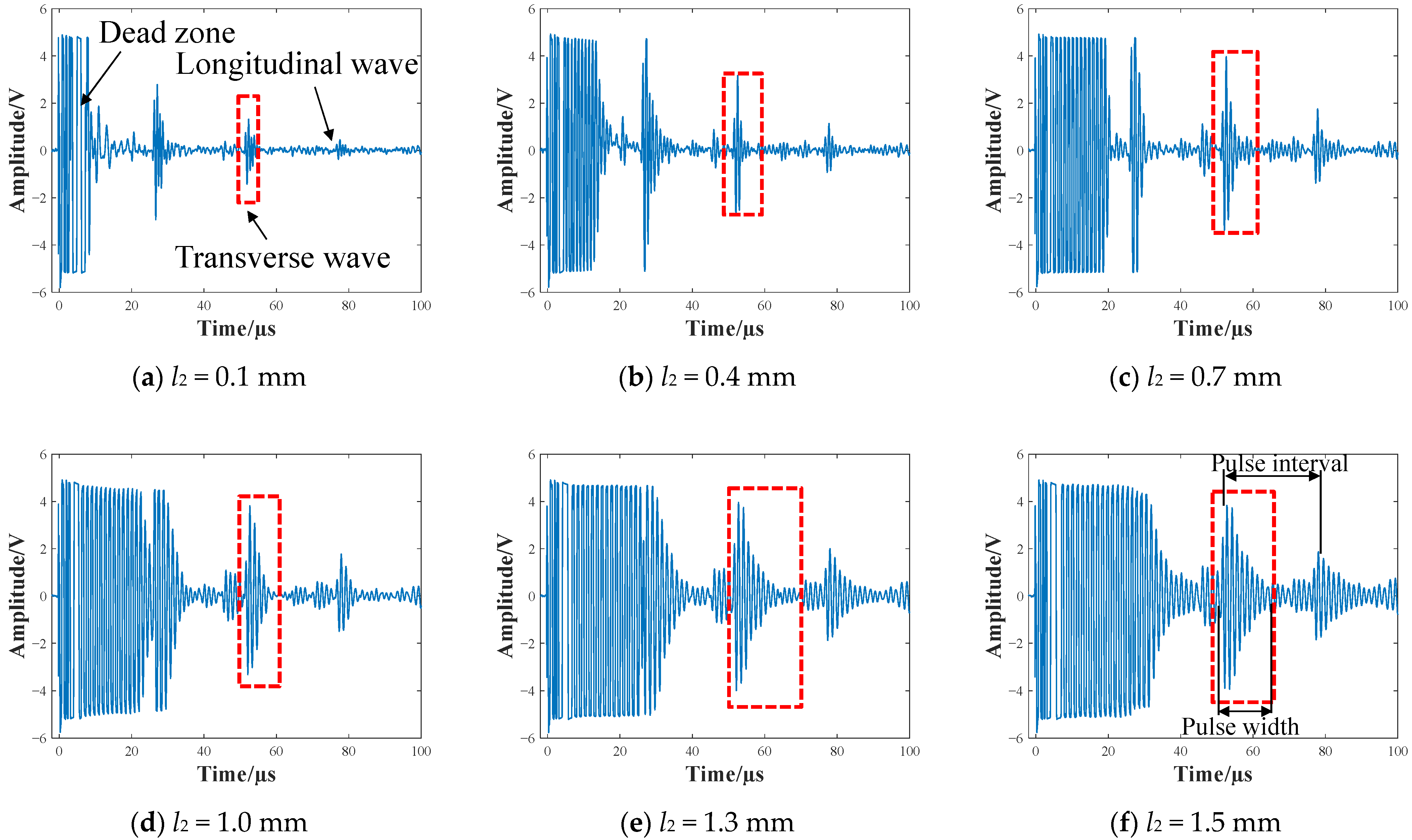

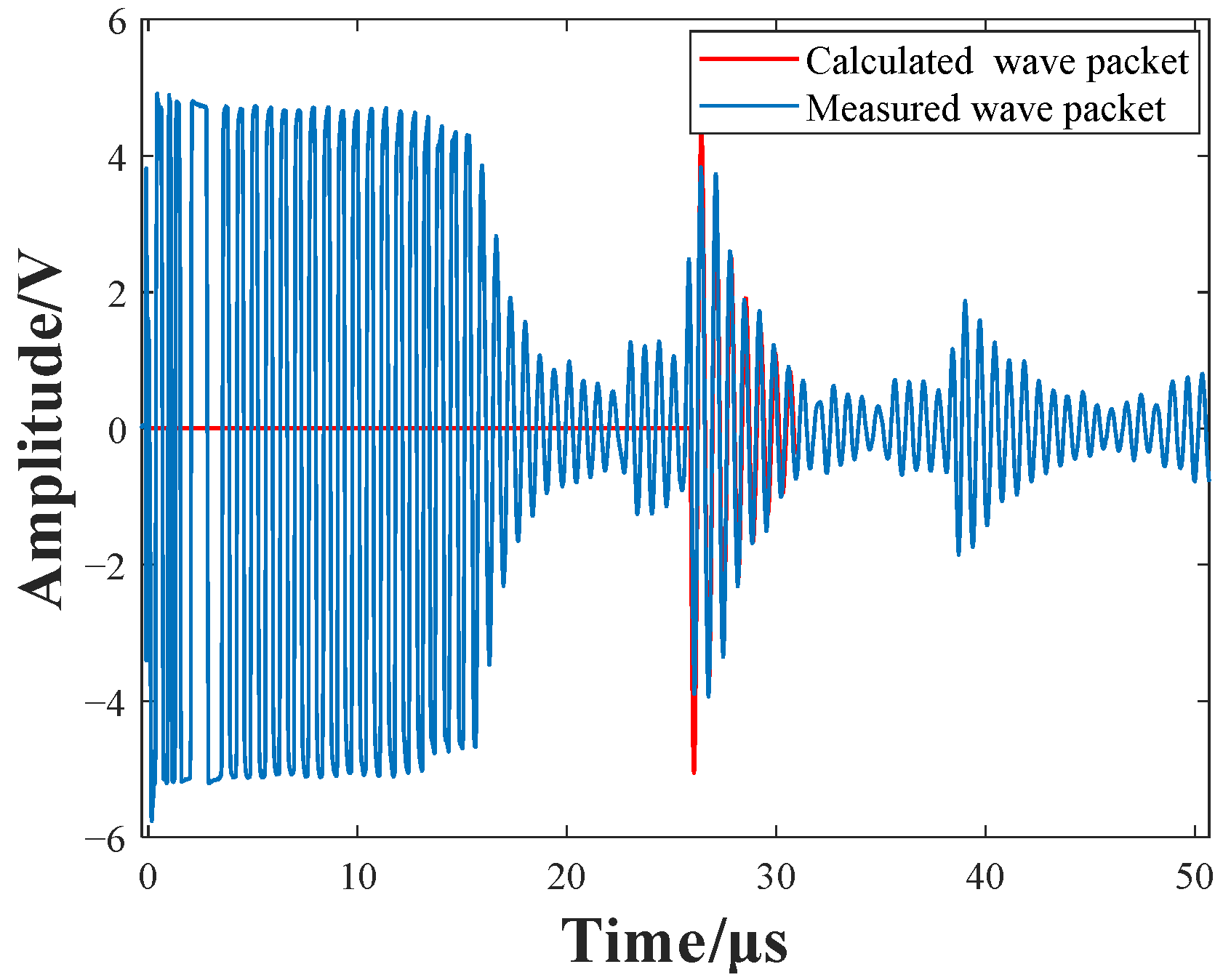

3.2. Experiments for Output Signal Measurement

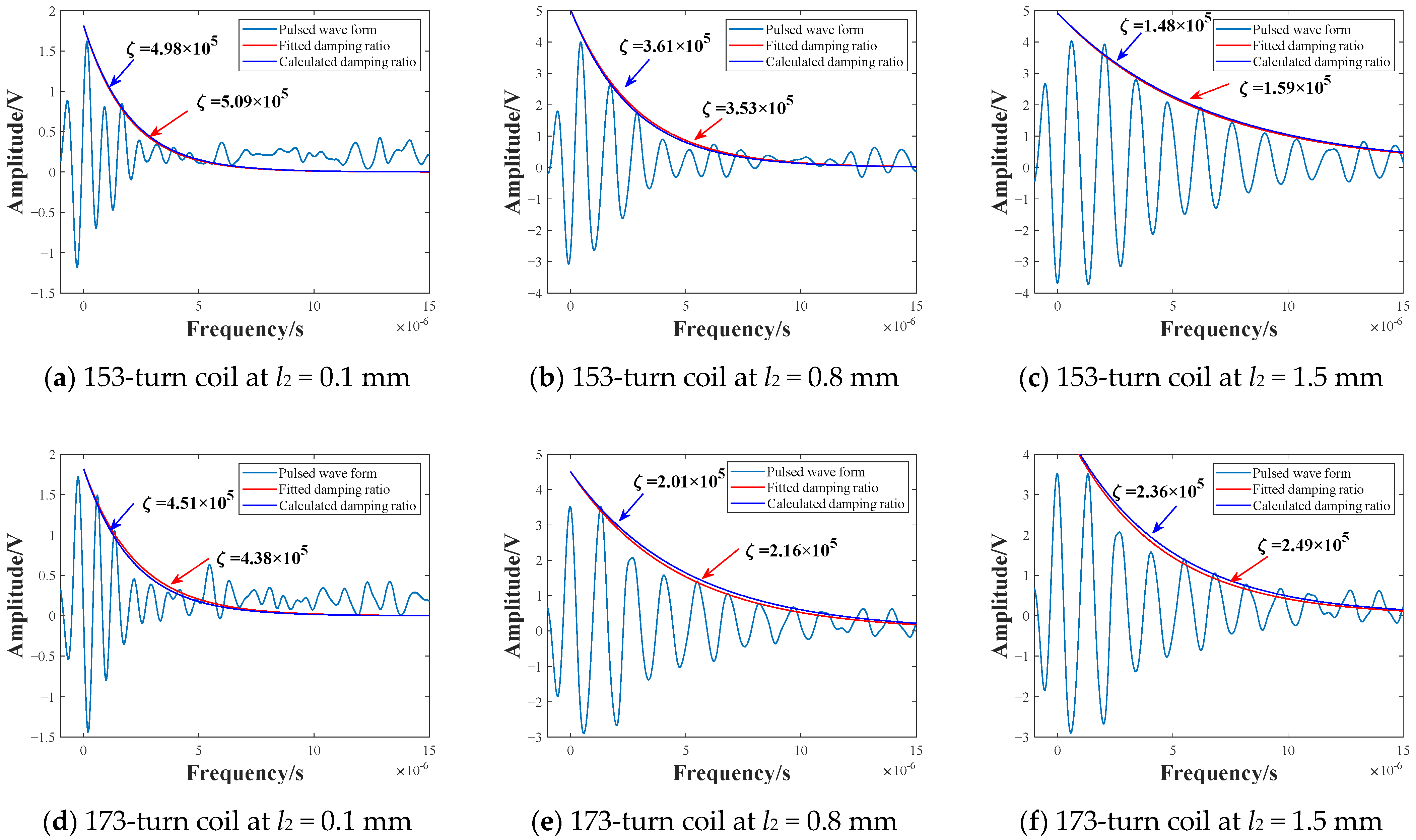

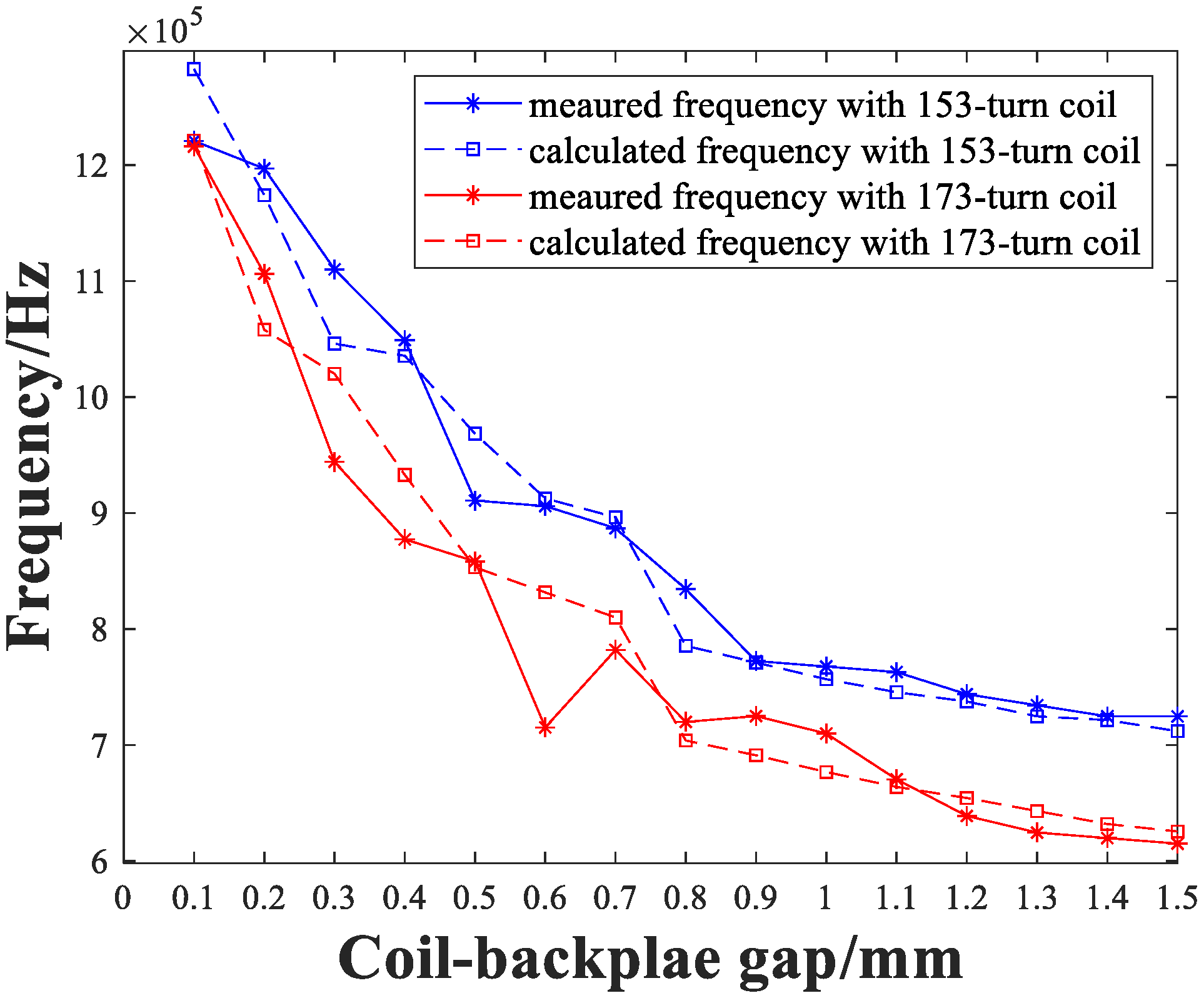

4. Results and Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.; Zhao, X.; Pei, N.; Huo, Z.; Chen, Z.; He, C.; Wu, B. Numerical Decoupling Study of EMAT Testing Signal for Ferromagnetic Materials. IEEE Sens. J. 2019, 20, 3476–3486. [Google Scholar] [CrossRef]

- Xin, J.; Chen, J.; Li, C.; Lu, R.-K.; Li, X.; Wang, C.; Zhu, H.; He, R. Deformation characterization of oil and gas pipeline by ACM technique based on SSA-BP neural network model. Measurement 2022, 189, 110654. [Google Scholar] [CrossRef]

- Gao, B.; Woo, W.L.; Tian, G. Sensors, Signal, and Artificial Intelligent Processing. J. Sens. 2022, 2022, 9793204. [Google Scholar] [CrossRef]

- Jian, X.; Dixon, S. Enhancement of EMAT and eddy current using a ferrite back-plate. Sens. Actuators A Phys. 2007, 136, 132–136. [Google Scholar] [CrossRef]

- Ren, W.; He, J.; Dixon, S.; Xu, K. Enhancement of EMAT’s efficiency by using silicon steel laminations back-plate. Sens. Actuators A Phys. 2018, 274, 189–198. [Google Scholar] [CrossRef] [Green Version]

- Grewe, M.; Gururaja, T.; Shrout, T.; Newnham, R. Acoustic properties of particle/polymer composites for ultrasonic transducer backing applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1990, 37, 506–514. [Google Scholar] [CrossRef] [PubMed]

- Qu, M.; Chen, X.; Zhu, K.; Guo, X.; Xie, J. Beam-Membrane Coupled Piezoelectric Micromachined Ultrasonic Transducers with Enhanced Transmitting Sensitivity. Micromachines 2022, 13, 423. [Google Scholar] [CrossRef] [PubMed]

- Sayers, C.; Tait, C. Ultrasonic properties of transducer backings. Ultrasonics 1984, 22, 57–60. [Google Scholar] [CrossRef]

- State, M.; Brands, P.J.; van de Vosse, F.N. Improving the thermal dimensional stability of flexible polymer composite backing materials for ultrasound transducers. Ultrasonics 2010, 50, 458–466. [Google Scholar] [CrossRef] [PubMed]

- Suits, L.D.; Sheahan, T.; Lee, J.-S.; Santamarina, J.C. P-Wave Reflection Imaging. Geotech. Test. J. 2005, 28, 12595. [Google Scholar] [CrossRef]

- McKeighen, R.E. Design guidelines for medical ultrasonic arrays. In Medical Imaging 1998: Ultrasonic Transducer Engineering; SPIE: Bellingham, DC, USA, 1998; pp. 2–18. [Google Scholar]

- Kossoff, G. The effects of backing and matching on the performance of piezoelectric ceramic transducers. IEEE Trans. Sonics Ultrason. 1966, 4, 20. [Google Scholar] [CrossRef]

- Jian, X.; Dixon, S.; Edwards, R.S.; Reed, J. Coupling mechanism of electromagnetic acoustical transducers for ultrasonic generation. J. Acoust. Soc. Am. 2006, 119, 2693–2701. [Google Scholar] [CrossRef]

- Hirao, M.; Ogi, H. Electromagnetic Acoustic Transducers: Noncontacting Ultrasonic Measurements Using EMATs; Springer: Tokyo, Japan, 2017. [Google Scholar]

- Shi, W.; Wu, Y.; Gong, H.; Zhang, T.; Tan, L.; Han, L.; Yang, J.; Li, W. Optimal design of spiral coil electromagnetic acoustic transducers considering lift-off sensitivity operating on non-ferromagnetic media. Nondestruct. Test. Eval. 2018, 33, 56–74. [Google Scholar] [CrossRef]

- Fan, Y.; Dixon, S.; Jian, X.; Thompson, D.O.; Chimenti, D.E. Lift-off performance of ferrite enhanced generation emats. AIP Conf. Proc. 2008, 975, 835–840. [Google Scholar]

- Jian, X.; Dixon, S.; Edwards, R. Optimising ultrasonic wideband Rayleigh wave generation by pulsed electromagnetic coils. Nondestruct. Test. Eval. 2005, 20, 43–62. [Google Scholar] [CrossRef]

- Harrison, D.J.; Jones, L.D.; Burke, S.K. Benchmark problems for defect size and shape determination in eddy-current nondestructive evaluation. J. Nondestruct. Eval. 1996, 15, 21–34. [Google Scholar] [CrossRef]

- Li, X.; Tian, G.; Li, K.; Wang, H.; Zhang, Q. Differential ECT Probe Design and Investigation for Detection of Rolling Contact Fatigue Cracks With Different Orientations. IEEE Sens. J. 2022, 22, 11615–11625. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Ren, L.; Lin, Z.; Wang, Q.; Xu, Y.; Zou, J. Analysis and Restraining of Eddy Current Damping Effects in Rotary Voice Coil Actuators. IEEE Trans. Energy Convers. 2017, 32, 309–317. [Google Scholar] [CrossRef]

- Dodd, C.V.; Deeds, W.E. Analytical Solutions to Eddy-Current Probe-Coil Problems. J. Appl. Phys. 1968, 39, 2829–2838. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wu, X.; Song, Y.; Sun, L. Study of the Influence of the Backplate Position on EMAT Thickness-Measurement Signals. Sensors 2022, 22, 8741. https://doi.org/10.3390/s22228741

Wang J, Wu X, Song Y, Sun L. Study of the Influence of the Backplate Position on EMAT Thickness-Measurement Signals. Sensors. 2022; 22(22):8741. https://doi.org/10.3390/s22228741

Chicago/Turabian StyleWang, Junjie, Xinjun Wu, Yun Song, and Lingsi Sun. 2022. "Study of the Influence of the Backplate Position on EMAT Thickness-Measurement Signals" Sensors 22, no. 22: 8741. https://doi.org/10.3390/s22228741

APA StyleWang, J., Wu, X., Song, Y., & Sun, L. (2022). Study of the Influence of the Backplate Position on EMAT Thickness-Measurement Signals. Sensors, 22(22), 8741. https://doi.org/10.3390/s22228741