Fault Detection in Induction Motor Using Time Domain and Spectral Imaging-Based Transfer Learning Approach on Vibration Data

Abstract

1. Introduction

- Magnetic stresses resulting from electromagnetic pressures, magnetic asymmetry forces, sounds, and electromagnetic vibrations;

- Thermal stresses resulting from over-load, uneven heat distribution, hot spot, and arc;

- Remaining stress from the manufacturing process;

- Dynamic stress brought on by the axial torque and centrifugal forces of the rotor;

- Circumferential stress brought on by the rotor material’s deterioration and contamination by chemical substances and humidity;

- Mechanical stress brought on by mechanical fatigue of various parts, bearing damage, loosened laminations, etc.

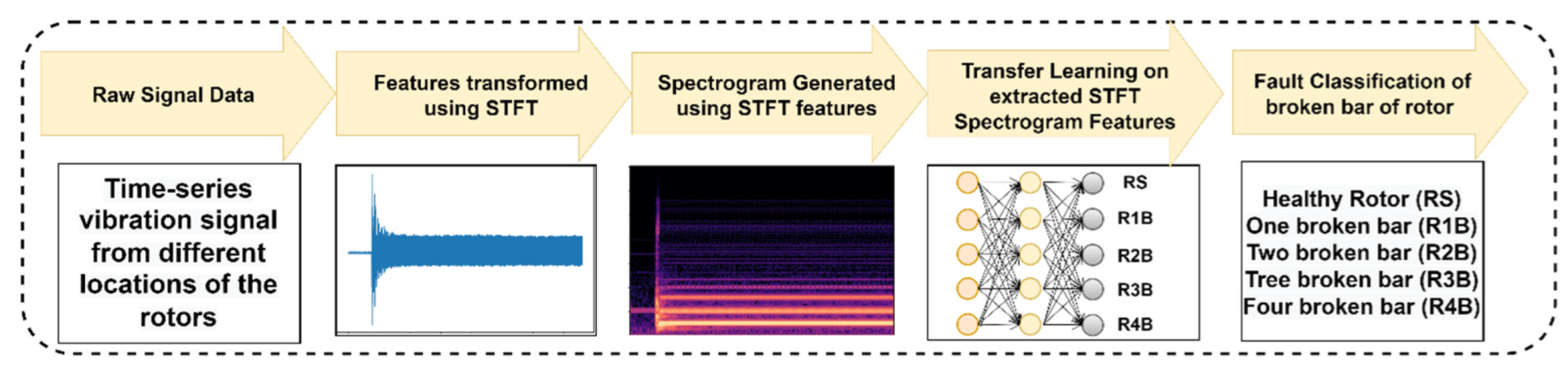

- The open-source dataset of the rotor with the broken bars in a three-phase induction motor is available on the IEEE data port and is used to extract the data’s time, frequency, and time-frequency domain features.

- The extracted time-domain and frequency-domain features are provided to ML models for the rotor fault classification.

- This study also provides a viable method of applying time-frequency-based feature extraction (STFT) on signals from multiple sensors to convert the one-dimensional time-series signal into a two-dimensional image to learn better information using fine-tuned transfer learning models.

2. Related Work

3. Database Description

4. Proposed Work

4.1. Feature Extraction

4.1.1. Time Domain Analysis

4.1.2. Frequency Domain Analysis

Fast Fourier Transform

4.1.3. Time-Frequency Domain Analysis

Short Time Fourier Transform

4.2. Classification

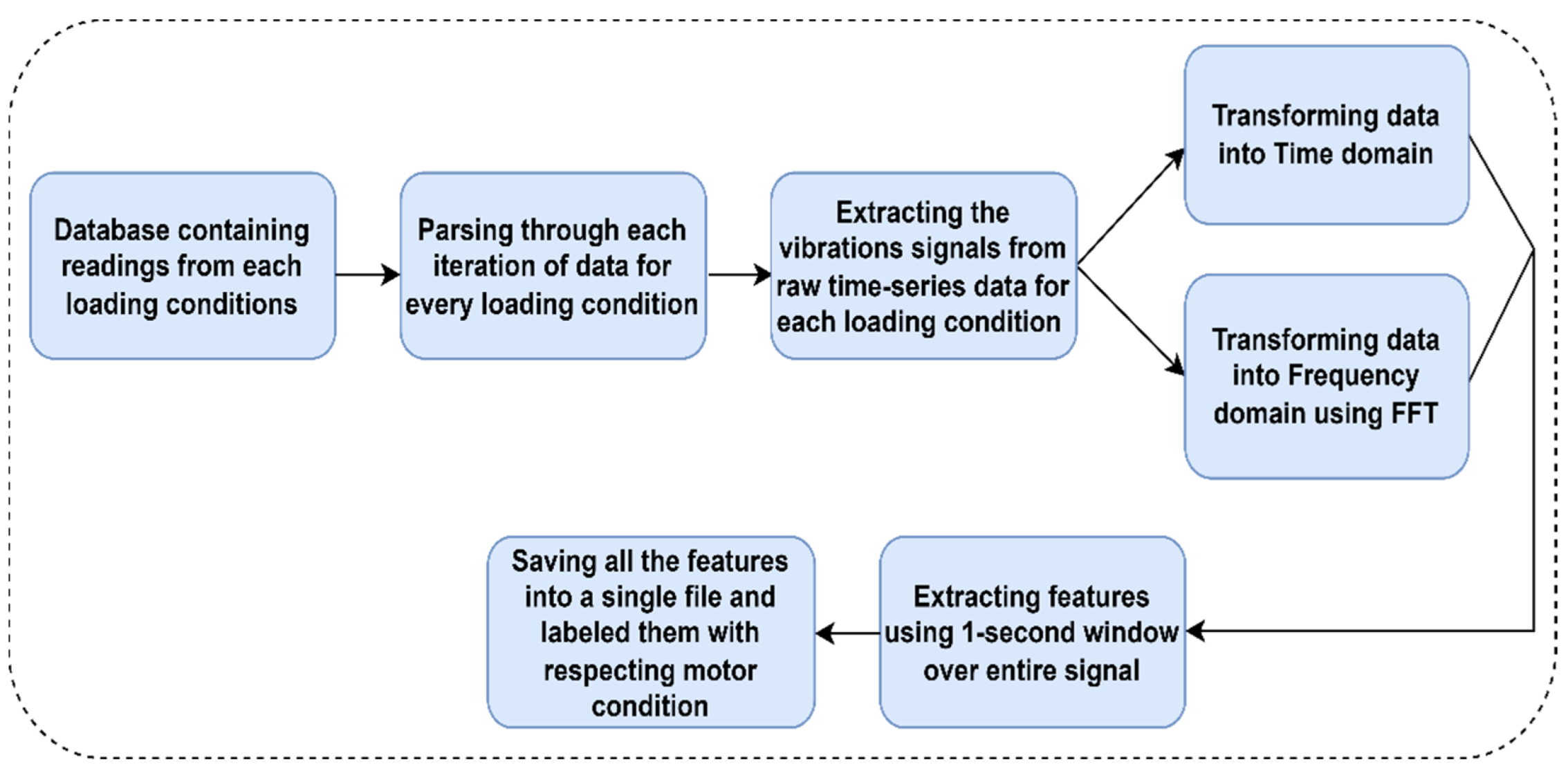

- The database in .mat (MATLAB structural array format) was parsed using a python program which goes through each loading condition containing time-series data and all the vibration data in the files are saved in separate .csv files format.

- A Python program extracts the features from the vibration data from multiple sensors into the time domain and frequency domain (after applying FFT on raw data) by using a window size of 1-s.

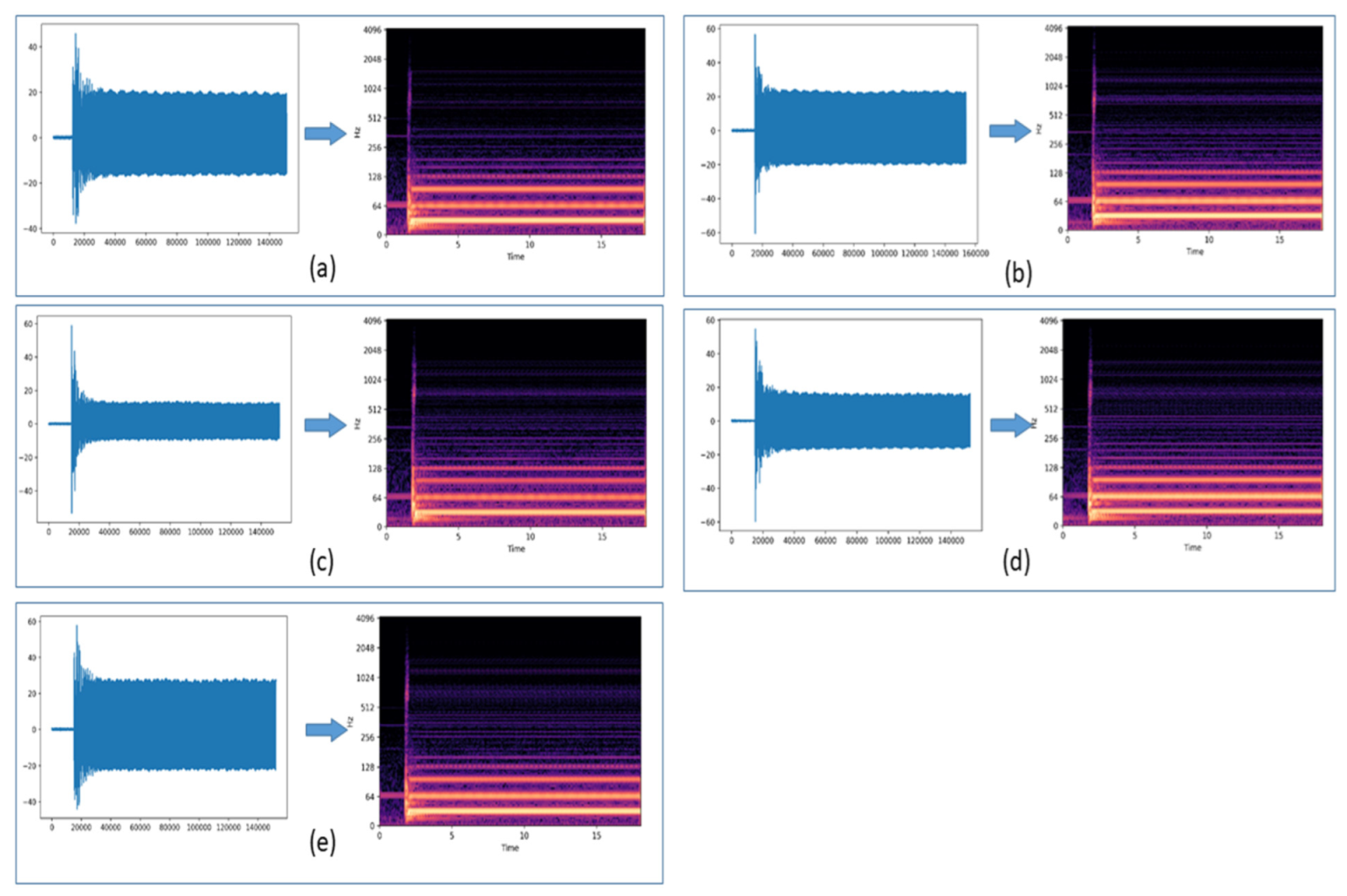

- Another Python program extracts the features from raw data into the time-frequency domain with the help of STFT, and then respective features are converted into spectrograms.

- The generated spectrograms are then saved in image format and used by the neural networks for fault diagnosis.

- All the data in multiple domains are then labeled as “rs”, “r1b”, “r2b”, “r3b”, and “r4b” i.e., specific motor conditions.

- The time domain and frequency domain features are then used to train the ML model for classification. KNN, Decision tree classifier, and Random Forest Classifiers are used for the classification of the broken bar diagnosis.

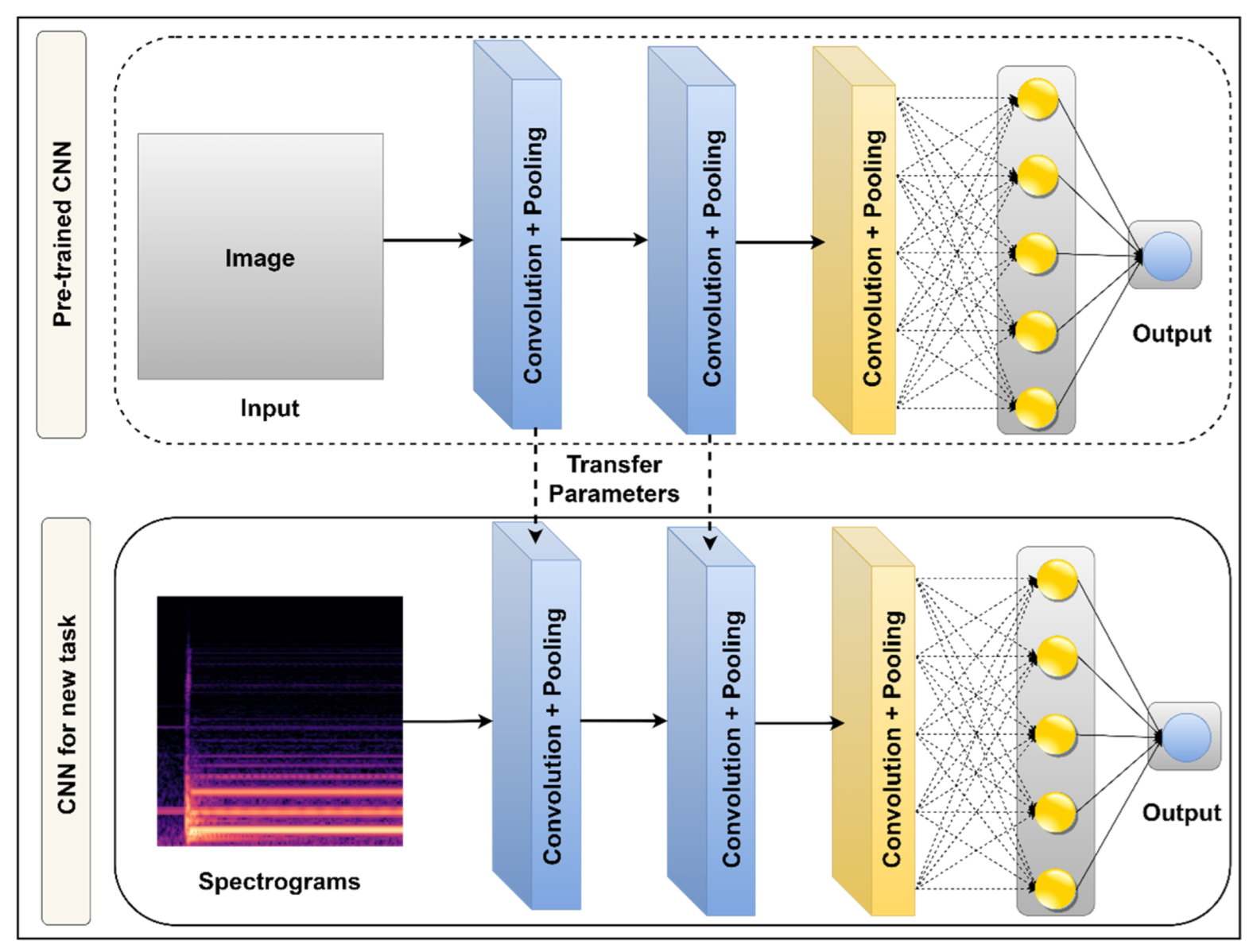

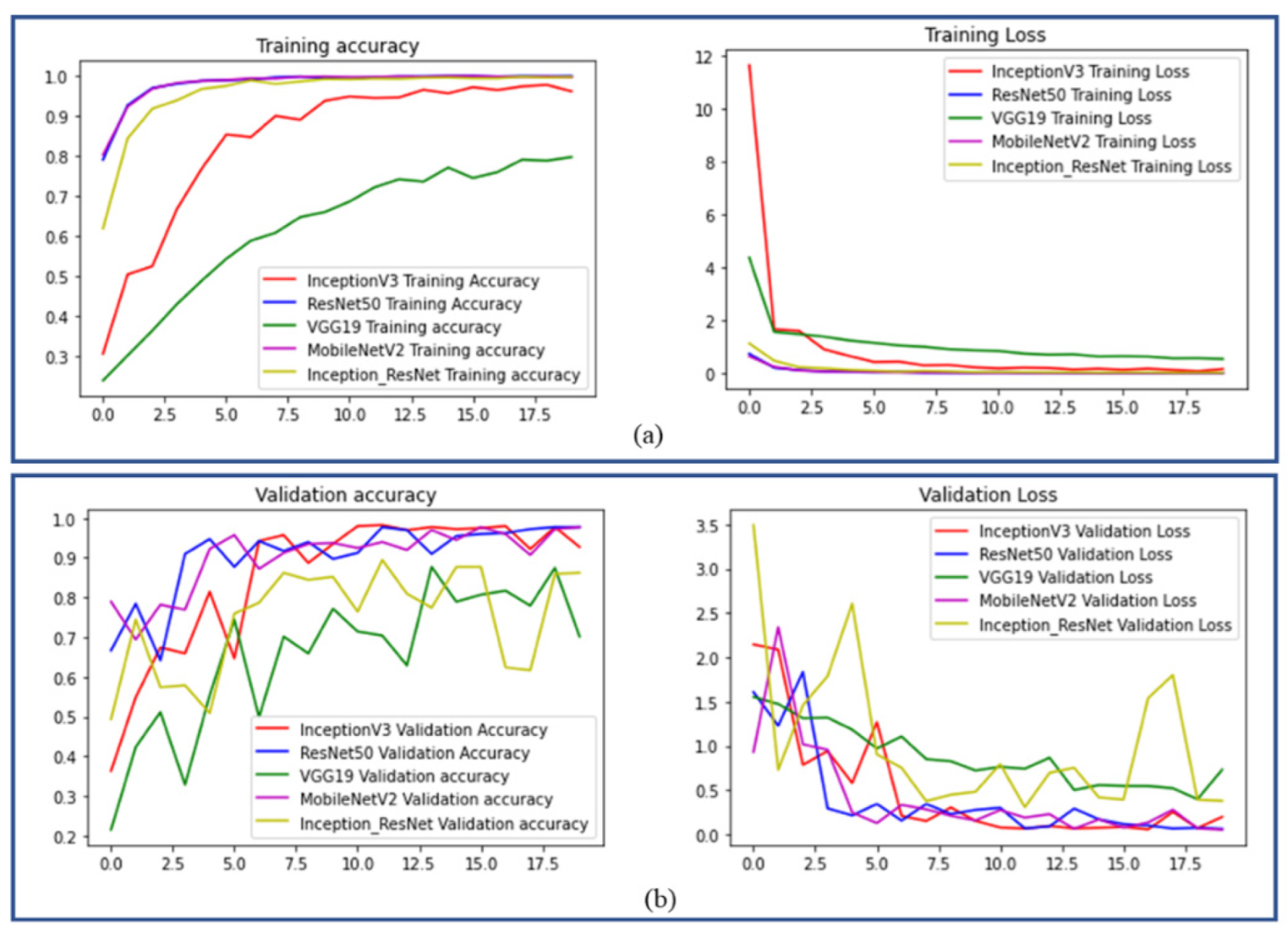

- The images of spectrograms are fed into different fine-tuned Convolutional neural networks (CNN) transfer learning models such as VGG16, InceptionV3, MobileNetV2, and Inception_ResNetV2 for feature learning and to build a system that could easily detect the failure in an induction motor due to broken rotor bars with its respective fault labels.

5. Results

6. Conclusions

- The suggested strategy utilizes the optimal capacity of STFT to process the non-stationary vibration signals by transforming the STFT features into a spectrogram. The fault diagnosis test accuracy obtained are around 95.33%, 94%, 92.33%, and 97.67% for VGG19, InceptionV3, Inception_ResNetV2, and MobileNetV2 models respectively.

- The use of fine-tuned CNN-based transfer learning models helped to achieve accurate results with having less training data of spectrograms generated under different loading conditions

- The empirical results show that the suggested approach can altogether work in diagnosing the damaged rotor bars fault in a three-phase induction motor with promising results for fault classification in induction motors under different loading conditions

- The method can be used to classify the fault severity by observing the vibration signal from the induction motor and transforming those signals into the time-frequency domain to feed into the model for the classification task.

- Further improvement can be made by generating and oversampling the database using Generative Adversarial Networks (GANs) and combining that with the transfer learning approach. Furthermore, signal processing techniques like noise filtering or others can be employed to the raw signal to extract more refined features.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Glowacz, A.; Glowacz, W.; Glowacz, Z.; Kozik, J. Early fault diagnosis of bearing and stator faults of the single-phase induction motor using acoustic signals. Measurement 2018, 113, 1–9. [Google Scholar] [CrossRef]

- Berredjem, T.; Benidir, M. Bearing faults diagnosis using fuzzy expert system relying on an improved range overlaps and similarity method. Expert Syst. Appl. 2018, 108, 132–142. [Google Scholar] [CrossRef]

- Sayyad, S.; Kumar, S.; Bongale, A.; Kamat, P.; Patil, S.; Kotecha, K. Data-driven remaining useful life estimation for milling process: Sensors, algorithms, datasets, and future directions. IEEE Access 2021, 9, 110255–110286. [Google Scholar] [CrossRef]

- El Hachemi Benbouzid, M. A review of induction motors signature analysis as a medium for faults detection. IEEE Transact. Ind. Electron. 2000, 47, 984–993. [Google Scholar] [CrossRef]

- Hassan, O.E.; Amer, M.; Abdelsalam, A.K.; Williams, B.W. Induction motor broken rotor bar fault detection techniques based on fault signature analysis—A review. IET Electr. Power Appl. 2018, 12, 895–907. [Google Scholar] [CrossRef]

- Karami, F.; Poshtan, J.; Poshtan, M. Broken bar fault detection in induction motors based on modified winding function. In Proceedings of the 2010 IEEE International Conference on Control Applications, Yokohama, Japan, 8–10 September 2010; pp. 1951–1956. [Google Scholar] [CrossRef]

- Mehrjou, M.R.; Mariun, N.; Hamiruce Marhaban, M.; Misron, N. Rotor fault condition monitoring techniques for squirrel-cage induction machine—A review. Mech. Syst. Signal Process. 2011, 25, 2827–2848. [Google Scholar] [CrossRef]

- Culbert, I.; Rhodes, W. Using current signature analysis technology to reliably detect cage winding defects in squirrel cage induction motors. In Proceedings of the Record of Conference Papers Industry Applications Society 52nd Annual Petroleum and Chemical Industry Conference, IEEE 2005, Denver, CO, USA, 12–14 September 2005; pp. 95–101. [Google Scholar] [CrossRef]

- Finley, W.R.; Hodowanec, M.M.; Holter, W.G. An analytical approach to solving motor vibration problems. IEEE Transact. Ind. Appl. 2000, 36, 1467–1480. [Google Scholar] [CrossRef]

- Kliman, G.B.; Koegl, R.A.; Stein, J.; Endicott, R.D.; Madden, M.W. Noninvasive detection of broken rotor bars in operating induction motors. IEEE Transact. Energy Convers. 1988, 3, 873–879. [Google Scholar] [CrossRef]

- Bellini, A.; Filippetti, F.; Tassoni, C.; Capolino, G.-A. Advances in diagnostic techniques for induction machines. IEEE Transact. Ind. Electron. 2008, 55, 4109–4126. [Google Scholar] [CrossRef]

- Ilonen, J.; Kamarainen, J.-K.; Lindh, T.; Ahola, J.; Kalviainen, H.; Partanen, J. Diagnosis tool for motor condition monitoring. IEEE Transact. Ind. Appl. 2005, 41, 963–971. [Google Scholar] [CrossRef]

- Filippetti, F.; Franceschini, G.; Tassoni, C. Neural networks aided on-line diagnostics of induction motor rotor faults. IEEE Trans. Ind. Appl. 1995, 31, 892–899. [Google Scholar] [CrossRef]

- Zhang, R.; Tao, H.; Wu, L.; Guan, Y. Transfer learning with neural networks for bearing fault diagnosis in changing working conditions. IEEE Access 2017, 5, 14347–14357. [Google Scholar] [CrossRef]

- Shi, P.; Chen, Z.; Vagapov, Y.; Zouaoui, Z. A new diagnosis of broken rotor bar fault extent in three phase squirrel cage induction motor. Mech. Syst. Signal Process. 2014, 42, 388–403. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, N.; Shen, C. A new deep transfer learning method for bearing fault diagnosis under different working conditions. IEEE Sens. J. 2020, 20, 8394–8402. [Google Scholar] [CrossRef]

- Du, Y.; Wang, A.; Wang, S.; He, B.; Meng, G. Fault diagnosis under variable working conditions based on STFT and transfer deep residual network. Shock Vib. 2020, 2020, 1274380. [Google Scholar] [CrossRef]

- Hur, J.W.; Shifat, T.A. Motor vibration analysis for the fault diagnosis in non-stationary operating conditions. Int. J. Integr. Eng. 2020, 12, 151–160. [Google Scholar] [CrossRef]

- Supangat, R.; Ertugrul, N.; Soong, W.L.; Gray, D.A.; Hansen, C.; Grieger, J. Broken rotor bar fault detection in induction motors using starting current analysis. In Proceedings of the European Conference on Power Electronics and Applications, Dresden, Germany, 11–14 September 2005. [Google Scholar] [CrossRef]

- Ferrucho-Alvarez, E.R.; Martinez-Herrera, A.L.; Cabal-Yepez, E.; Rodriguez-Donate, C.; Lopez-Ramirez, M.; Mata-Chavez, R.I. Broken rotor bar detection in induction motors through contrast estimation. Sensors 2021, 21, 7446. [Google Scholar] [CrossRef]

- Mohanty, S.; Mohanty, D.S.K. Broken rotor bar fault detection using wavlet. Int. J. Innov. Eng. Technol. 2014, 4, 72–79. [Google Scholar]

- Mehala, N.; Dahiya, R. Condition monitoring methods, failure identification and analysis for induction machines. Int. J. Circuits Syst. Signal Process. 2009, 3, 10–17. [Google Scholar]

- Almounajjed, A.; Sahoo, A.K. Wavelet-based multi-class support vector machine for stator fault diagnosis in induction motor. Transact. Inst. Meas. Control 2022, 01423312221109725. [Google Scholar] [CrossRef]

- Mian, T.; Choudhary, A.; Fatima, S. Vibration and infrared thermography based multiple fault diagnosis of bearing using deep learning. Nondestruct. Test. Eval. 2022, 1–22. [Google Scholar] [CrossRef]

- Choudhary, A.; Fatima, S.; Panigrahi, B.K. State of the art technologies in fault diagnosis of electric vehicles: A component-based review. IEEE Transact. Transp. Electr. 2022. [Google Scholar] [CrossRef]

- Chang, H.-C.; Wang, Y.-C.; Shih, Y.-Y.; Kuo, C.-C. Fault diagnosis of induction motors with imbalanced data using deep convolutional generative adversarial network. Appl. Sci. 2022, 12, 4080. [Google Scholar] [CrossRef]

- Treml, A.; Flauzino, R.; Suetake, M.; Maciejewski, R.; Afonso, N. Experimental Database for Detecting and Diagnosing Rotor Broken Bar in a Three-Phase Induction Motor. IEEE Dataport 2020. Available online: https://ieee-dataport.org/open-access/experimental-database-detecting-and-diagnosing-rotor-broken-bar-three-phase-induction (accessed on 22 February 2022).

- Sayyad, S.; Kumar, S.; Bongale, A.; Kotecha, K.; Selvachandran, G.; Suganthan, P.N. Tool wear prediction using long short-term memory variants and hybrid feature selection techniques. Int. J. Adv. Manuf. Technol. 2022, 121, 6611–6633. [Google Scholar] [CrossRef]

- Brandt, A. Frequency Analysis Theory. In Noise and Vibration Analysis; Wiley: Hoboken, NJ, USA, 2011; pp. 167–176. [Google Scholar] [CrossRef]

- Cohen, L. Time-Frequency Analysis; Prentice Hall: Englewood Cliffs, NJ, USA, 1995. [Google Scholar]

- Do, S.; Song, K.D.; Chung, J.W. Basics of deep learning: A radiologist’s guide to understanding published radiology articles on deep learning. Korean J. Radiol. 2020, 21, 33–41. [Google Scholar] [CrossRef]

- Sayyad, S.; Kumar, S.; Bongale, A.; Bongale, A.M.; Patil, S. Estimating remaining useful life in machines using artificial intelligence: A scoping review. Libr. Philos. Pract. 2021, 2021, 1–26. [Google Scholar]

- Al-kubaisi, A.; Khamiss, N.N. A transfer learning approach for lumbar spine disc state classification. Electronics 2022, 11, 85. [Google Scholar] [CrossRef]

| Condition of Rotor | Class Label | Number of Spectrograms Generated |

|---|---|---|

| Healthy rotor bar (rs) | 0 | 400 |

| 1 broken bar (r1b) | 1 | 395 |

| 2 broken bars (r2b) | 2 | 400 |

| 3 broken bars (r3b) | 3 | 400 |

| 4 broken bars (r4b) | 4 | 400 |

| Classification Models | Test Accuracy (%) | |

|---|---|---|

| Using Time-Domain Features | Using Frequency-Domain Features | |

| K-Nearest neighbors | 77.37 | 80.53 |

| Decision Tree | 83.80 | 81.71 |

| Random Forest | 86.80 | 85.92 |

| Networks | Training Accuracy (%) | Validation Accuracy (%) | Test Accuracy (%) |

|---|---|---|---|

| CNN | 98.83 | 91.30 | 89.99 |

| VGG16 | 95.89 | 93.98 | 95.33 |

| InceptionV3 | 99.93 | 94.31 | 94.00 |

| Inception_ResNetV2 | 99.93 | 91.30 | 92.33 |

| MobileNetV2 | 99.93 | 95.32 | 97.67 |

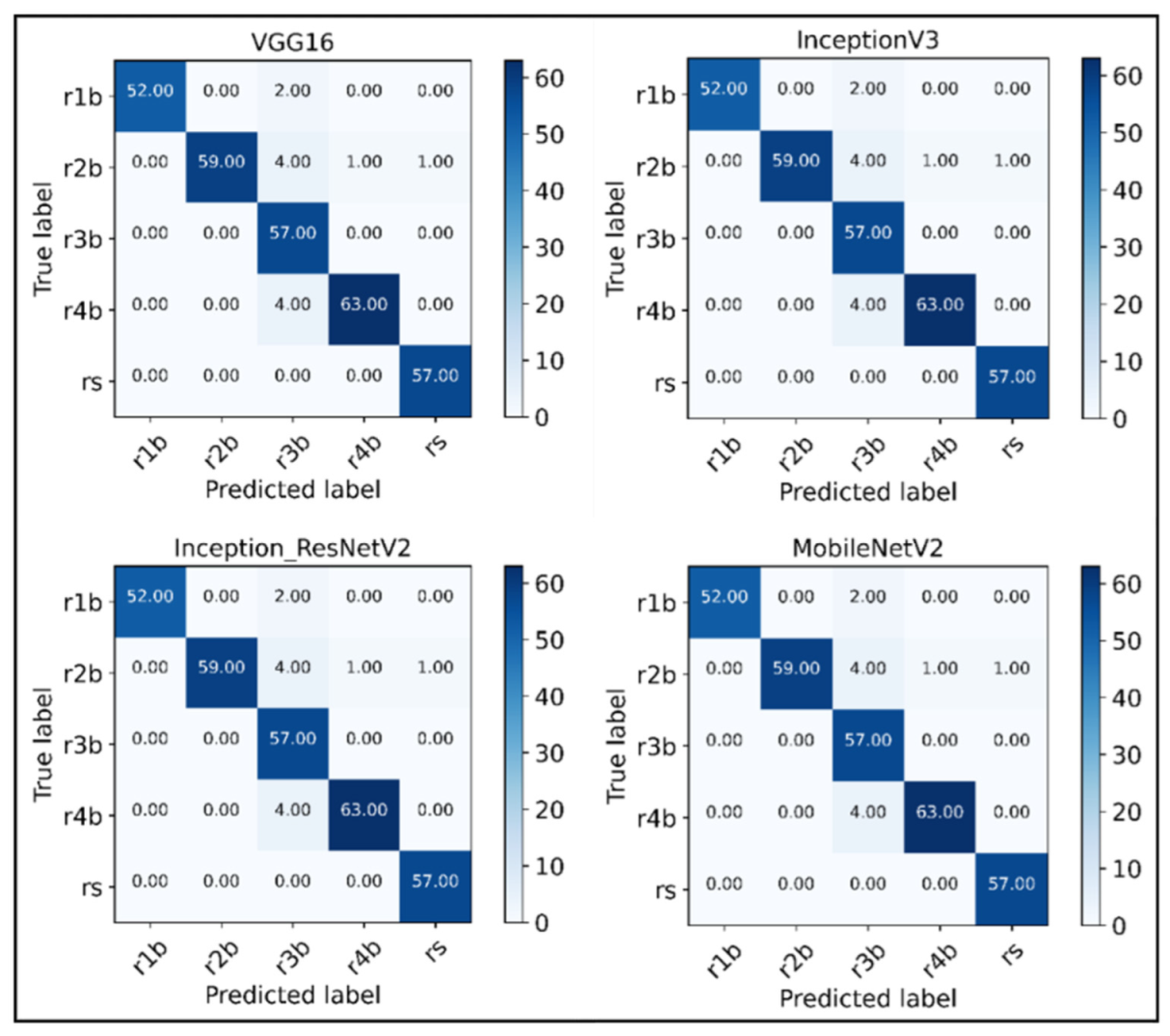

| Classification report of VGG16 model | Condition | Precision | Recall | F1-score | Support |

| 1 broken bar (r1b) | 0.99 | 0.91 | 0.95 | 54 | |

| 2 broken bar (r2b) | 0.99 | 0.92 | 0.96 | 65 | |

| 3 broken bar (r3b) | 0.85 | 1.00 | 0.92 | 57 | |

| 4 broken bar (r4b) | 0.98 | 0.94 | 0.96 | 67 | |

| Healthy rotor (rs) | 0.95 | 0.98 | 0.97 | 57 | |

| Avg. Accuracy | 0.95 | ||||

| Classification report of InceptionV3 model | 1 broken bar (r1b) | 0.91 | 0.91 | 0.91 | 54 |

| 2 broken bar (r2b) | 0.97 | 0.94 | 0.95 | 65 | |

| 3 broken bar (r3b) | 0.96 | 0.96 | 0.96 | 57 | |

| 4 broken bar (r4b) | 0.93 | 0.93 | 0.93 | 67 | |

| Healthy rotor (rs) | 0.93 | 0.96 | 0.95 | 57 | |

| Avg. Accuracy | 0.94 | ||||

| Classification report of Inception_ResNetV2 model | 1 broken bar (r1b) | 0.85 | 0.93 | 0.88 | 54 |

| 2 broken bar (r2b) | 0.97 | 0.91 | 0.94 | 65 | |

| 3 broken bar (r3b) | 0.86 | 0.99 | 0.93 | 57 | |

| 4 broken bar (r4b) | 0.97 | 0.84 | 0.90 | 67 | |

| Healthy rotor (rs) | 0.98 | 0.96 | 0.97 | 57 | |

| Avg. Accuracy | 0.92 | ||||

| Classification report of MobileNetV2 model | 1 broken bar (r1b) | 0.95 | 0.98 | 0.96 | 54 |

| 2 broken bar (r2b) | 0.95 | 0.95 | 0.95 | 65 | |

| 3 broken bar (r3b) | 0.99 | 0.96 | 0.98 | 57 | |

| 4 broken bar (r4b) | 0.99 | 0.99 | 0.99 | 67 | |

| Healthy rotor (rs) | 0.99 | 0.99 | 0.99 | 57 | |

| Avg. Accuracy | 0.98 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Misra, S.; Kumar, S.; Sayyad, S.; Bongale, A.; Jadhav, P.; Kotecha, K.; Abraham, A.; Gabralla, L.A. Fault Detection in Induction Motor Using Time Domain and Spectral Imaging-Based Transfer Learning Approach on Vibration Data. Sensors 2022, 22, 8210. https://doi.org/10.3390/s22218210

Misra S, Kumar S, Sayyad S, Bongale A, Jadhav P, Kotecha K, Abraham A, Gabralla LA. Fault Detection in Induction Motor Using Time Domain and Spectral Imaging-Based Transfer Learning Approach on Vibration Data. Sensors. 2022; 22(21):8210. https://doi.org/10.3390/s22218210

Chicago/Turabian StyleMisra, Sajal, Satish Kumar, Sameer Sayyad, Arunkumar Bongale, Priya Jadhav, Ketan Kotecha, Ajith Abraham, and Lubna Abdelkareim Gabralla. 2022. "Fault Detection in Induction Motor Using Time Domain and Spectral Imaging-Based Transfer Learning Approach on Vibration Data" Sensors 22, no. 21: 8210. https://doi.org/10.3390/s22218210

APA StyleMisra, S., Kumar, S., Sayyad, S., Bongale, A., Jadhav, P., Kotecha, K., Abraham, A., & Gabralla, L. A. (2022). Fault Detection in Induction Motor Using Time Domain and Spectral Imaging-Based Transfer Learning Approach on Vibration Data. Sensors, 22(21), 8210. https://doi.org/10.3390/s22218210