Intelligent Manufacturing Technology in the Steel Industry of China: A Review

Abstract

1. Introduction

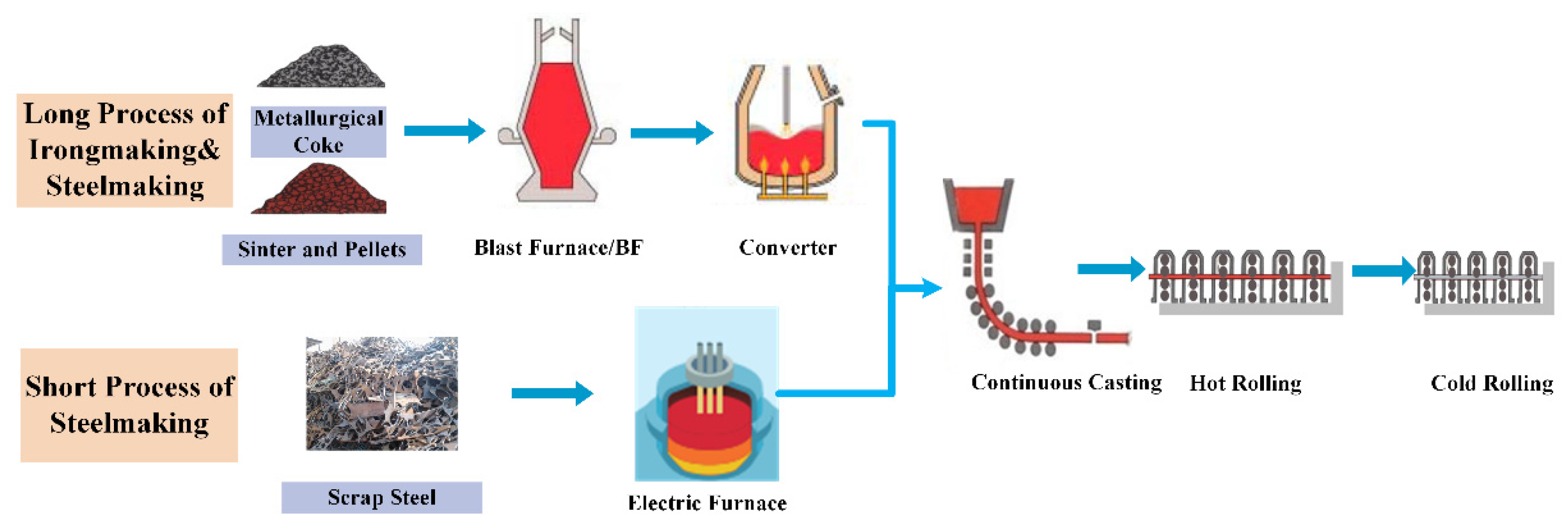

2. Analysis of Intelligent Development of Steel Industry of China

2.1. General Briefing on Intelligent Manufacturing in the Steel Industry of China

2.2. Aims for Intelligent Manufacturing

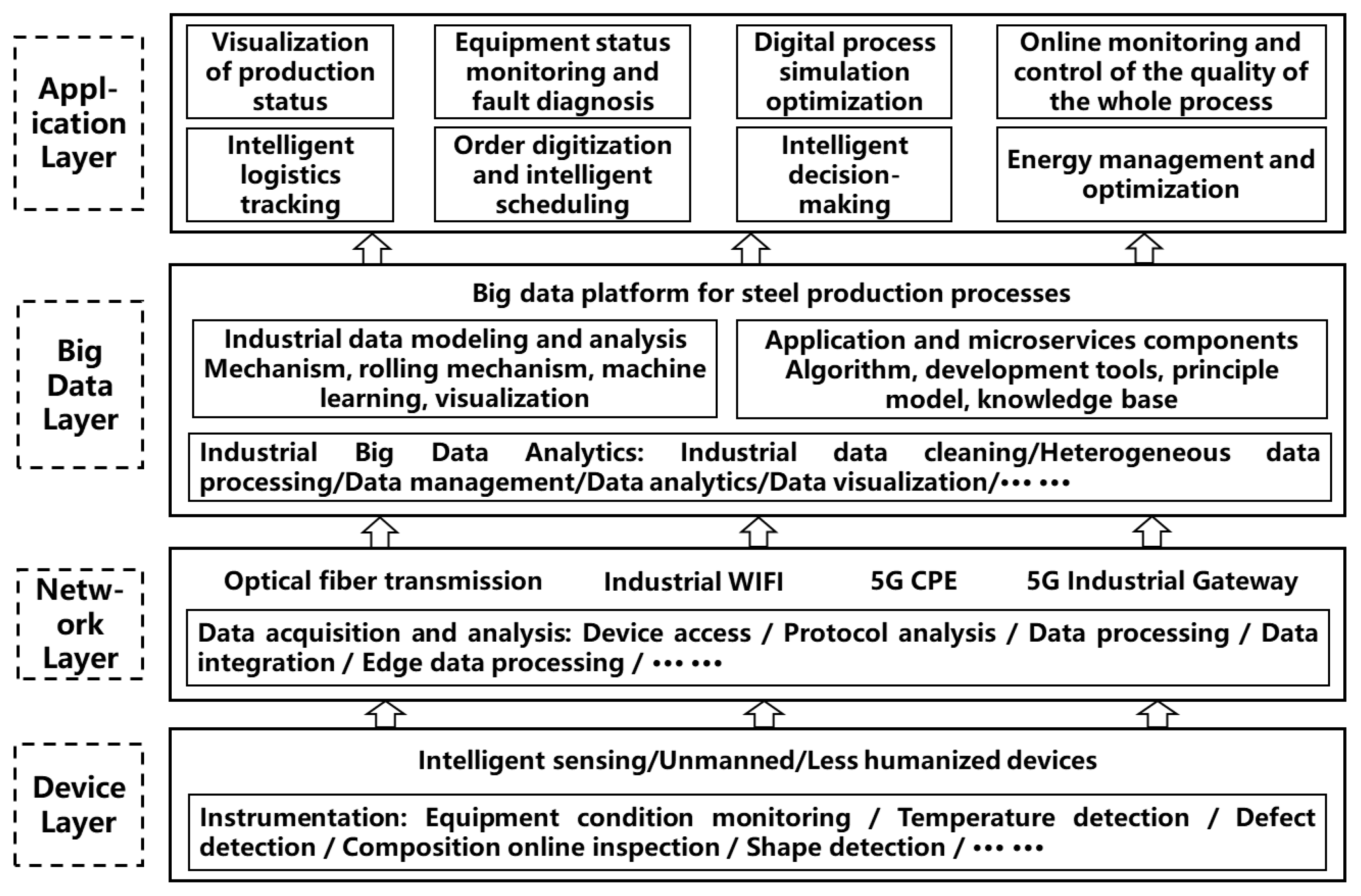

2.3. Framework for Intelligent Manufacturing

2.4. Sensors and Hardware for Intelligent Manufacturing

3. Typical Models for Intelligent Manufacturing of Steel Industry

3.1. Rolling Process Intelligent Manufacturing Model

3.2. Steelmaking and Rolling Process Intelligent Manufacturing Model

- Intelligent sensing system. The monitoring of important process parameters such as steelmaking converters, refining furnaces, continuous casting ladles, and continuous casting machines is critical to optimizing the control model and increasing the degree of intelligence. Sensors, intelligent cameras, radio-frequency identification, and gateways are commonly used; and key technologies such as high-temperature heat pipes, image recognition, and voice recognition are integrated to create a comprehensive collection of production data that includes equipment data, product identification data, and factory environmental data to settle the demand for real-time awareness of the manufacturing process, operating data, and the status of important equipment. Simultaneously, in order to improve real-time sensor data transmission, it should be outfitted with high-performance network equipment with high system capacity, high transmission rate, multiple fault-tolerant mechanisms, and low latency, as well as using distributed industrial control networks, building software-defined agile networks, and realizing network optimized resource allocation.

- Centralized monitoring and controlling system. Integrate the control systems of major steelmaking and continuous casting processes, such as the converter area, refining area, continuous casting area, heating furnace area, and rolling area, and set up a production line monitoring system based on data collection. This system provides real-time monitoring of the manufacturing process, remote centralized control of equipment, and abnormal alert reminders, minimizing on-site operators and inspection staff, lowering labor intensity, and maintaining product safety.

- Production management and intelligent scheduling system. To realize real-time monitoring, balance coordination, and decision-making functions, it should build a production organization and intelligent scheduling system based on raw and fuel conditions, equipment status, and field-of-view requirements with plan execution, resource utilization, statistical analysis of output and quality, optimal scheduling of stable operating conditions, dynamic scheduling of abnormal operating conditions, as well as auxiliary production scheduling and decision-making functions.

- Intelligent device administration system. It should begin with equipment life-cycle state monitoring, tracking, and information maintenance throughout the whole equipment planning, design, production, procurement, installation, operation, maintenance, upgrading and transformation, and scrapping process. Then, create a full equipment status database by using big data analysis, artificial intelligence, virtual reality, and other technologies and use the main core equipment to produce a simulation model to achieve equipment failure early warning, alarm, and prediagnosis. Finally, create a standardized information collecting and control system, automatic diagnosis system, fault prediction model based on an expert system, and knowledge base of fault indexes. This should realize remote unmanned control, early warning of a hazardous working environment, monitoring of operational state, fault diagnostics, and self-repair.

- Quality controlling system. The quality management idea relates to information management, and a quality management system with quality standard maintenance, quality monitoring, inspection and laboratory testing, statistical analysis, and quality optimization should be built. Then, the product quality and operation parameters of the entire product manufacturing process are integrated by using big data analysis and machine-learning methods, which could accomplish the online judgment of product quality and the quality traceability analysis of the entire process. Finally, the important quality characteristics in the steelmaking and rolling processes are investigated, and the completed product quality could be obtained through online statistics, diagnosis, prediction, analysis, and optimization to improve the stability of product quality.

- Process simulation and prediction system. When combined with the actual status of the steelmaking procedure, it is difficult to coordinate this process because of the considerable production fluctuation and difficult precise control. First and foremost, the value of the production database is deeply excavated when combined with expert knowledge of the smelting process and on-site operation experiences. While the empirical model of the metallurgical process is established by using statistical analysis, machine learning, big data analysis, and other technical means, the model generalization ability is continuously improved through model training, the smelting production experience is mathematically expressed, and the decision optimization system related artificial intelligence ingredients are built to achieve the operation guidance and prediction of the actual production process. Then, comprehensive simulation calculations of fluid mechanics, chemical reaction, heat and mass transfer, and other simulation calculations on the equipment of the steelmaking converter procedure are performed by using the combination of a mechanism model and a data model. Similarly, the simulation model of the melting processes, continuous casting process, and rolling process should also be constructed. Finally, the actual steel procedure and virtual system interact in real time, which could optimize the manufacturing operation parameters during steelmaking and rolling procedures.

- An early warning system for employee safety. The entire process of tracking and managing employees visiting the manufacturing areas should be implemented by using satellite location, Wi-Fi, 5G, and other communication technologies, as well as intelligent wearable gadgets. Then a personnel management system should be created that can automatically perceive and obtain basic personnel information, personnel location, safety status, surrounding environment operation process information, statistical analysis of operation process data, and real-time grasp of personnel location trajectory and personnel position status. The system can automatically pop up alarm information and corresponding monitoring screens, as well as push the relevant reminder information to the relevant posts or personnel when entering the dangerous zone; or when key equipment abnormalities, major hazard source abnormalities, or other situations occur, achieving the aim of online monitoring, intelligent analysis, and linkage alarm to maintain employees’ safety.

4. Key Technologies for Intelligent Manufacturing in Steel Industry

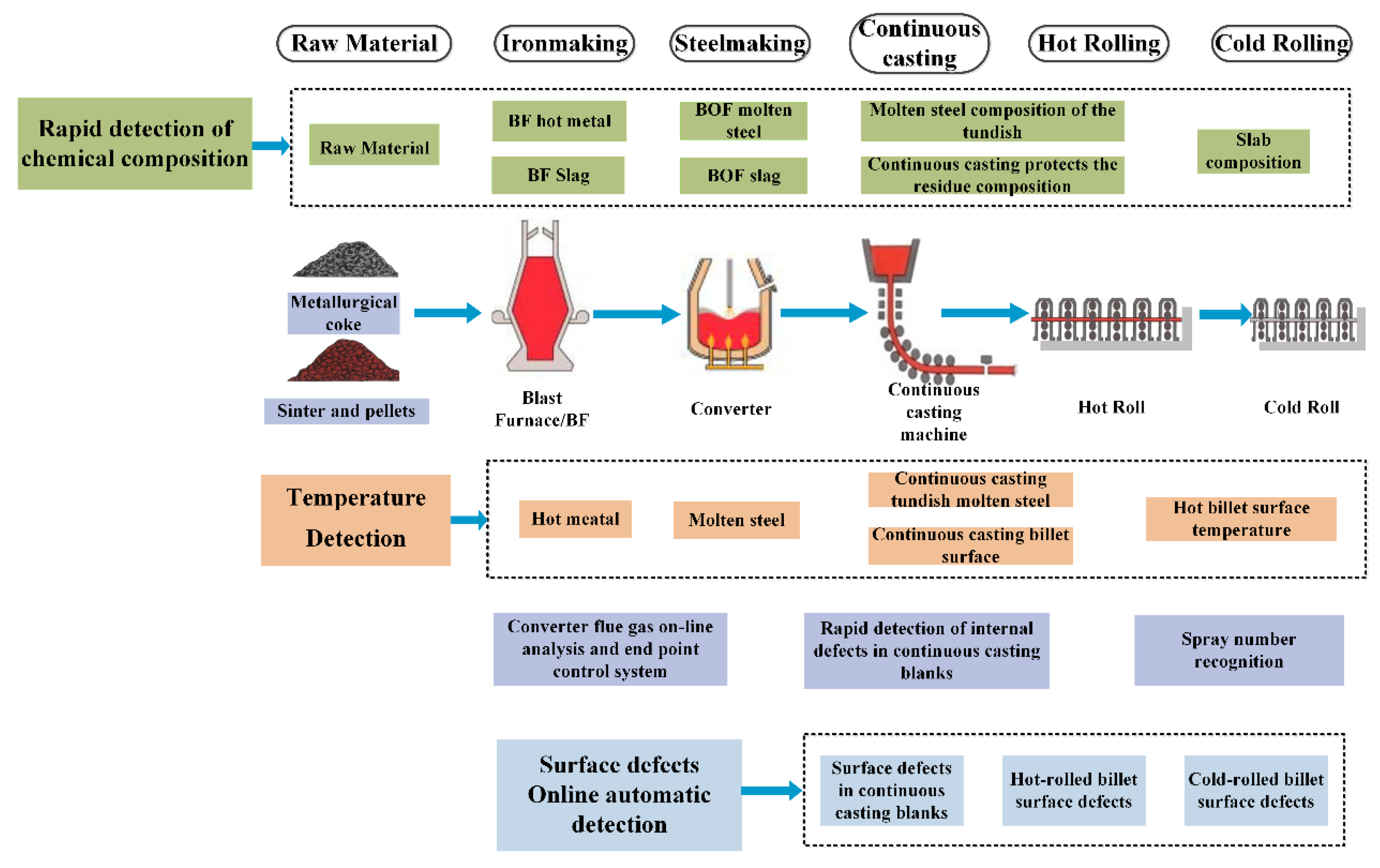

4.1. Online Detection Technologies

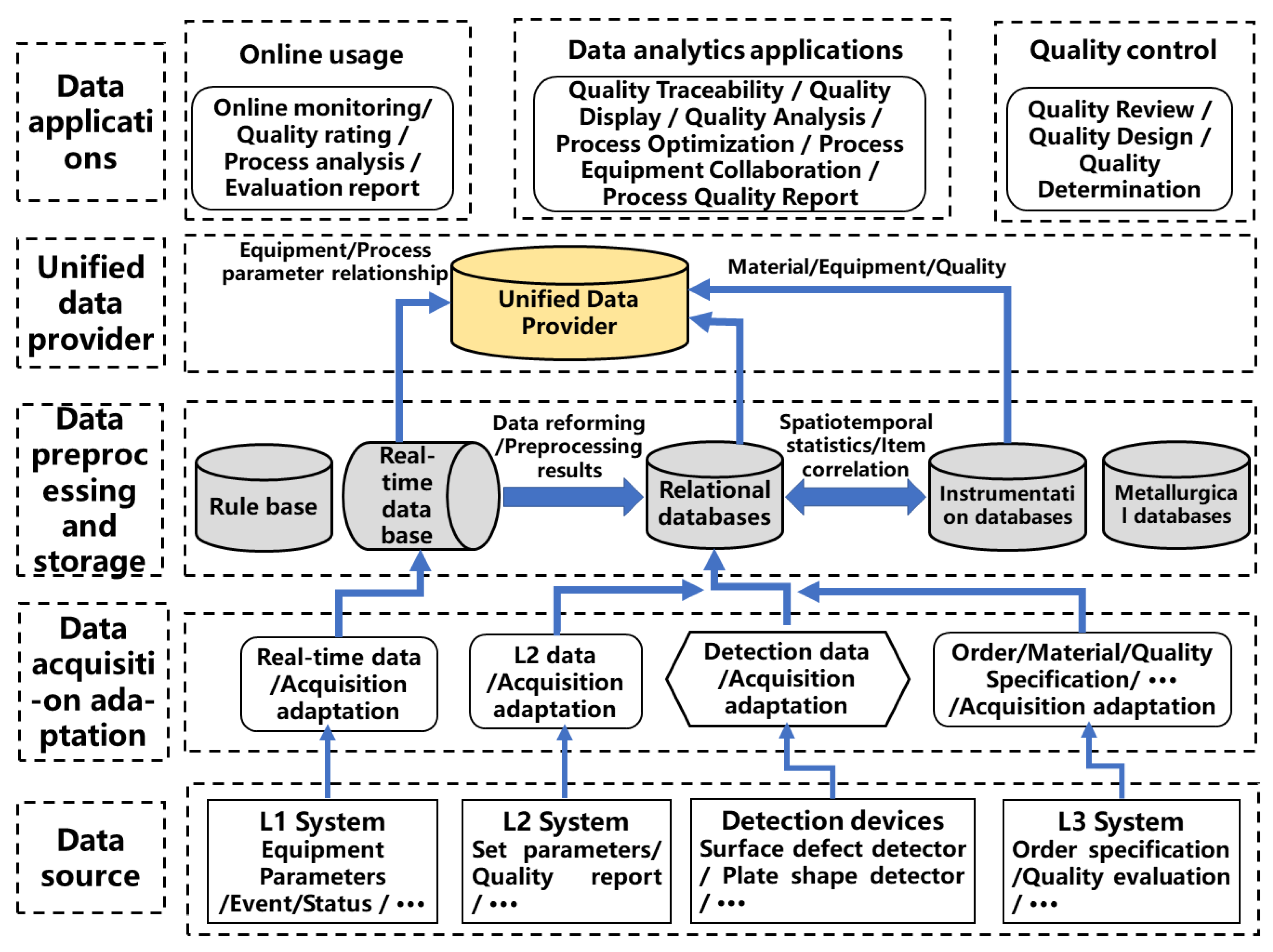

4.2. Quality Controlling Technology for the Entire Procedure of Steel Industry

4.3. Equipment Troubleshooting Technology

4.4. Intelligent Machinery

- Intelligent logistics equipment, such as an AGV (automated guided transport vehicle), unmanned elevators, intelligent roller rooms, intelligent three-dimensional factories, and flat storage facilities;

- Industrial robots including automatic slag fishing robots, automatic slag cleaning robots, intelligent temperature measurement robots, intelligent inspection robots, automatic baling robots, automatic coding robots, automatic alignment devices, automatic loading and unloading devices, and automatic welding devices;

- Intelligent detection equipment, which includes, in addition to the previously mentioned key component detection technology, intelligent monitoring of personnel safety, intelligent monitoring of safety facilities, and intelligent monitoring of equipment operational status; eddy current flaw detector; particle detector; thickness gauge; convexity meter; plate roller; and product contour detection device;

- Advanced control technology, one-key intelligent control technology of steelmaking, converter automatic steel production technology, refining process automatic control system, plate-type intelligent control technology, and other process intelligence and refined control technology.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Guo, Z.; Wang, C.; Yang, G.; Huang, Z.; Li, G. MSFT-YOLO: Improved YOLOv5 Based on Transformer for Detecting Defects of Steel Surface. Sensors 2022, 22, 3467. [Google Scholar] [CrossRef]

- Word Steel Association. The White Book of Steel. Available online: https://worldsteel.org/publications/bookshop/the-white-book-of-steel/ (accessed on 10 March 2022).

- Shi, M.; Yang, L.; Gao, S.; Wang, G. Metal Surface Defect Detection Method Based on TE01 Mode Microwave. Sensors 2022, 22, 4848. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.D.; Xu, K.; Zhou, P.; Jiang, X. The production of large blast furnaces of China in 2018 and thoughts of intelligent manufacturing in the ironmaking process. Ironmak. Steelmak. 2020, 47, 650–654. [Google Scholar] [CrossRef]

- Mele, M.; Magazzino, C. A Machine Learning analysis of the relationship among iron and steel industries, air pollution, and economic growth in China. J. Clean. Prod. 2020, 277, 123293. [Google Scholar] [CrossRef]

- Shi, Z.; Xie, Y.; Xue, W.; Chen, Y.; Fu, L.; Xu, X. Smart factory in Industry 4.0. Syst. Res. Behav. Sci. 2020, 37, 607–617. [Google Scholar] [CrossRef]

- Xiao, Y.; Zeng, Z. A Construction Method of Intelligent Manufacturing System under Industry 4.0 Model. Sci. Program. 2021, 2021, 4775237. [Google Scholar] [CrossRef]

- Veiga, J.T.; Pessoa, M.A.O.; Junqueira, F.; Miyagi, P.E.; Dos Santos Filho, D.J. Intelligent Manufacturing Systems: Self-organization in the I4.0 context. In Proceedings of the 2021 14th IEEE International Conference on Industry Applications (INDUSCON), São Paulo, Brazil, 15–18 August 2021; pp. 153–160. [Google Scholar]

- Hou, T.; Cheng, B.; Wang, R.; Xue, W.; Chaudhry, P.E. Developing Industry 4.0 with systems perspectives. Syst. Res. Behav. Sci. 2020, 37, 741–748. [Google Scholar] [CrossRef]

- Shan, S.; Wen, X.; Wei, Y.; Wang, Z.; Chen, Y. Intelligent manufacturing in industry 4.0: A case study of Sany heavy industry. Syst. Res. Behav. Sci. 2020, 37, 679–690. [Google Scholar] [CrossRef]

- Xie, Y.; Yin, Y.; Xue, W.; Shi, H.; Chong, D. Intelligent supply chain performance measurement in Industry 4.0. Syst. Res. Behav. Sci. 2020, 37, 711–718. [Google Scholar] [CrossRef]

- Guo, D.; Li, M.; Zhong, R.; Huang, G.Q. Graduation Intelligent Manufacturing System (GiMS): An Industry 4.0 paradigm for production and operations management. Ind. Manag. Data Syst. 2021, 121, 86–98. [Google Scholar] [CrossRef]

- Chen, Y.; Han, Z.; Cao, K.; Zheng, X.; Xu, X. Manufacturing upgrading in industry 4.0 era. Syst. Res. Behav. Sci. 2020, 37, 766–771. [Google Scholar] [CrossRef]

- Stojadinovic, S.M.; Majstorovic, V.D.; Durakbasa, N.M. Toward a cyber-physical manufacturing metrology model for industry 4.0. Ai Edam 2021, 35, 20–36. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2020, 58, 1319–1337. [Google Scholar] [CrossRef]

- Osterrieder, P.; Budde, L.; Friedli, T. The intelligent factory as a key construct of industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Ching, N.T.; Ghobakhloo, M.; Iranmanesh, M.; Maroufkhani, P.; Asadi, S. Industry 4.0 applications for sustainable manufacturing: A systematic liter-ature review and a roadmap to sustainable development. J. Clean. Prod. 2022, 334, 130133. [Google Scholar] [CrossRef]

- Leng, J.; Ye, S.; Zhou, M.; Zhao, J.L.; Liu, Q.; Guo, W.; Cao, W.; Fu, L. Blockchain-Secured Intelligent Manufacturing in Industry 4.0: A Survey. IEEE Trans. Syst. Man Cybern. Syst. 2021, 51, 237–252. [Google Scholar] [CrossRef]

- Chauhan, A.; Jakhar, S.K.; Chauhan, C. The interplay of circular economy with industry 4.0 enabled intelligent city drivers of healthcare waste disposal. J. Clean. Prod. 2021, 279, 123854. [Google Scholar] [CrossRef]

- He, B.; Bai, K. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2021, 9, 1–21. [Google Scholar] [CrossRef]

- Hung, M.; Lin, Y.; Hsiao, H.; Chen, C.; Lai, K.; Hsieh, Y.; Tieng, H.; Tsai, T.; Huang, H.; Yang, H.; et al. A Novel Implementation Framework of Digital Twins for Intelligent Manufacturing Based on Container Technology and Cloud Manufacturing Services. IEEE Trans. Autom. Sci. Eng. 2022, 19, 1614–1630. [Google Scholar] [CrossRef]

- Moeller, D.P.F.; Vakilzadian, H.; Hou, W. Intelligent Manufacturing with Digital Twin. In Proceedings of the 2021 IEEE International Conference ON Electro Information Technology (EIT), Mt. Pleasant, MI, USA, 14–15 May 2021; pp. 413–418. [Google Scholar]

- Tan, F. Financial performance of intelligent manufacturing enterprises based on fuzzy neural network and data twinning. J. Intell. Fuzzy Syst. 2021, 40, 6641–6653. [Google Scholar]

- Wu, Q.; Mao, Y.; Chen, J.; Wang, C. Application Research of Digital Twin-Driven Ship Intelligent Manufacturing System: Pipe Machining Production Line. J. Mar. Sci. Eng. 2021, 9, 338. [Google Scholar] [CrossRef]

- Li, L.; Mao, C.; Sun, H.; Yuan, Y.; Lei, B. Digital Twin Driven Green Performance Evaluation Methodology of Intelligent Manufacturing: Hybrid Model Based on Fuzzy Rough-Sets AHP, Multistage Weight Synthesis, and PROMETHEE II. Complexity 2020, 2020, 3853925. [Google Scholar] [CrossRef]

- Zhang, L.; Feng, L.; Wang, J.; Lin, K. Integration of Design, Manufacturing, and Service Based on Digital Twin to Realize Intelligent Manufacturing. Machines 2022, 10, 275. [Google Scholar] [CrossRef]

- Li, H.; Yang, C. Digital Transformation of Manufacturing Enterprises. In Proceedings of the 2020 International Conference on Identification, Information and Knowledge in the Internet of Things (IIKI2020), Online, 1–5 November 2021; Volume 187, pp. 24–29. [Google Scholar]

- Wang, J.; Xu, C.; Zhang, J.; Zhong, R. Big data analytics for intelligent manufacturing systems: A review. J. Manuf. Syst. 2022, 62, 738–752. [Google Scholar] [CrossRef]

- Deng, K. Research on Evaluation of Intelligent Manufacturing Capability and Layout Superiority of Supply Chains by Big Data Analysis. J. Glob. Inf. Manag. 2022, 30, 1–20. [Google Scholar] [CrossRef]

- Ge, J.; Wang, F.; Sun, H.; Fu, L.; Sun, M. Research on the maturity of big data management capability of intelligent manufacturing enterprise. Syst. Res. Behav. Sci. 2020, 37, 646–662. [Google Scholar] [CrossRef]

- Li, C.; Chen, Y.; Shang, Y. A review of industrial big data for decision making in intelligent manufacturing. Eng. Sci. Technol.-Int. J. 2022, 29, 101021. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, N.; Xu, Z.; Wu, K. The internet of things-based decision support system for information processing in intelligent manufacturing using data mining technology. Mech. Syst. Signal Process. 2020, 142, 106630. [Google Scholar] [CrossRef]

- Yan, L.; Zhang, N.; Wang, A.; He, H. Data driven and Running simulation system for intelligent workshop. In Proceedings of the 2020 3rd World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM 2020), Shanghai, China, 4–6 December 2020; pp. 260–264. [Google Scholar]

- Hu, C.; Cao, Y.; Feng, Z. Research and Application of Key Technology of Data-Driven Intelligent Manufacturing of Electronic Components. In Proceedings of the 2020 8th Asia Conference on Mechanical and Materials Engineering (ACMME 2020), Singapore, 11–14 June 2020; Volume 319. [Google Scholar]

- Ghahramani, M.; Qiao, Y.; Zhou, M.; O’Hagan, A.; Sweeney, J. AI-based modeling and data-driven evaluation for smart manufacturing processes. IEEE-CAA J. Autom. Sin. 2020, 7, 1026–1037. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Liu, Y.; Yang, H.; Lv, J.; Ren, S. Data-driven sustainable intelligent manufacturing based on demand response for energy-intensive industries. J. Clean. Prod. 2020, 274, 123155. [Google Scholar] [CrossRef]

- Majeed, A.; Zhang, Y.; Ren, S.; Lv, J.; Peng, T.; Waqar, S.; Yin, E. A big data-driven framework for sustainable and intelligent additive manufacturing. Robot. Comput. Integr. Manuf. 2021, 67, 102026. [Google Scholar] [CrossRef]

- Zhang, X.; Ming, X.; Yin, D. Application of industrial big data for intelligent manufacturing in product service system based on system engineering using fuzzy DEMATEL. J. Clean. Prod. 2020, 265, 121863. [Google Scholar] [CrossRef]

- Ben, K. Research on Intelligent Manufacturing System Architecture and Key Technology of Radar Complete Machine Assembly. In Proceedings of the Seventh Asia International Symposium on Mechatronics: Volume 1; Springer: Singapore, 2020; Volume 589, pp. 30–41. [Google Scholar]

- Wang, L.; Wu, M.; Xu, X.; Fan, W. The diffusion of intelligent manufacturing applications based SIR model. J. Intell. Fuzzy Syst. 2020, 38, 7725–7732. [Google Scholar] [CrossRef]

- Lan, X.; Chen, H. Research on Modeling and Scheduling Methods of an Intelligent Manufacturing System Based on Deep Learning. Wirel. Commun. Mob. Comput. 2021, 2021, 4586518. [Google Scholar] [CrossRef]

- Kong, L.; Ma, B. Intelligent manufacturing model of construction industry based on Internet of Things technology. Int. J. Adv. Manuf. Technol. 2020, 107, 1025–1037. [Google Scholar] [CrossRef]

- Tang, H.; Li, D.; Wan, J.; Imran, M.; Shoaib, M. A Reconfigurable Method for Intelligent Manufacturing Based on Industrial Cloud and Edge Intelligence. IEEE Internet Things 2020, 7, 4248–4259. [Google Scholar] [CrossRef]

- Xie, Q. Machine learning in human resource system of intelligent manufacturing industry. Enterp. Inf. Syst. 2022, 16, 264–284. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, J. Research on a Compound Dual Innovation Capability Model of Intelligent Manufacturing Enterprises. Sustainability 2021, 13, 12521. [Google Scholar] [CrossRef]

- Wang, W.; Wang, J.; Chen, C.; Su, S.; Chu, C.; Chen, G. A Capability Maturity Model for Intelligent Manufacturing in Chair Industry Enterprises. Processes 2022, 10, 1180. [Google Scholar] [CrossRef]

- Han, Y.; Hu, Y.; Wang, Y.; Jia, G.; Ge, C.; Zhang, C.; Huang, X. Research and Application of Information Model of a Lithium Ion Battery Intelligent Manufacturing Workshop Based on OPC UA. Batteries 2020, 6, 52. [Google Scholar] [CrossRef]

- Jung, K.J.; Kim, D.H.; Kim, H.; Jang, G.W.; HYUN, H.S. A Study on an Intelligent Control of Manufacturing with Dual Arm Robot Based on Neural Network for Smart Factory Implementation. J. Korean Soc. Ind. Converg. 2021, 24, 351–361. [Google Scholar]

- Liu, C.; Tang, D.; Zhu, H.; Nie, Q. A Novel Predictive Maintenance Method Based on Deep Adversarial Learning in the Intelligent Manufacturing System. IEEE Access 2021, 9, 49557–49575. [Google Scholar] [CrossRef]

- Geng, T.; Du, Y. The business model of intelligent manufacturing with Internet of Things and machine learning. Enterp. Inf. Syst. 2022, 16, 307–325. [Google Scholar] [CrossRef]

- Li, S.; Xiao, H.; Qiao, J. Multi-chain and data-chains partitioning algorithm in intelligent manufacturing CPS. J. Cloud Comput.-Adv. Syst. Appl. 2021, 10, 9. [Google Scholar] [CrossRef]

- Geng, T.; Du, Y. Applying the blockchain-based deep reinforcement consensus algorithm to the intelligent manufacturing model under internet of things. J. Supercomput. 2022, 78, 15882–15904. [Google Scholar] [CrossRef]

- Kim, J.; Seo, D.; Moon, J.; Kim, J.; Kim, H.; Jeong, J. Design and Implementation of an HCPS-Based PCB Smart Factory System for Next-Generation Intelligent Manufacturing. Appl. Sci. 2022, 12, 7645. [Google Scholar] [CrossRef]

- Yan, C.; Li, Y.; Xia, Y. Analysis and Design for Intelligent Manufacturing Cloud Control Systems. In Proceedings of the 2020 Chinese Automation Congress (CAC 2020), Shanghai, China, 6–8 November 2020; pp. 7174–7179. [Google Scholar]

- Chen, X.; Ren, G. Key technologies and development trends of intelligent manufacturing and robot application. In Proceedings of the 2019 5th International Conference on Energy Equipment Science and Engineering (ICEESE), Zhuhai, China, 19–21 November 2020; Volume 461. [Google Scholar]

- Xing, G. Motion control method of multi degree of freedom industrial robot for intelligent manufacturing. In Proceedings of the 2021 2nd International Conference on Intelligent Design (ICID 2021), Xi’an, China, 19 October 2021; pp. 6–9. [Google Scholar]

- Zhou, L.; Wang, F. Edge computing and machinery automation application for intelligent manufacturing equipment. Microprocess. Microsyst. 2021, 87, 104389. [Google Scholar] [CrossRef]

- Lievano-Martinez, F.A.; Fernandez-Ledesma, J.D.; Burgos, D.; Branch-Bedoya, J.W.; Jimenez-Builes, J.A. Intelligent Process Automation: An Application in Manufacturing Industry. Sustainability 2022, 14, 8804. [Google Scholar] [CrossRef]

- Yang, J.; Ying, L.; Gao, M. The influence of intelligent manufacturing on financial performance and innovation performance: The case of China. Enterp. Inf. Syst. 2020, 14, 812–832. [Google Scholar] [CrossRef]

- Liu, J.; Yang, Y.; Cao, Y.; Forrest, J.Y. Stimulating effects of intelligent policy on the performance of listed manufacturing companies in China. J. Policy Model. 2021, 43, 558–573. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Z.; Li, K.; Zhang, Z.; Sheng, Y.; Liu, S. Research on key technologies of fault diagnosis and early warning for high-end equipment based on intelligent manufacturing and Internet of Things. Int. J. Adv. Manuf. Technol. 2020, 107, 1039–1048. [Google Scholar] [CrossRef]

- Yang, T.; Yi, X.; Lu, S.; Johansson, K.H.; Chai, T. Intelligent Manufacturing for the Process Industry Driven by Industrial Artificial Intelligence. Engineering 2021, 7, 1224–1230. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Y.; Li, K.; Yu, S.; Li, S. Design and Application Research of a Digitized Intelligent Factory in a Discrete Manufacturing Industry. Intell. Autom. Soft Comput. 2020, 26, 1081–1096. [Google Scholar] [CrossRef]

- Huang, X. Quality of service optimization in wireless transmission of industrial Internet of Things for intelligent manufacturing. Int. J. Adv. Manuf. Technol. 2020, 107, 1007–1016. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Intelligent Manufacturing: Past Research, Present Findings, and Future Directions. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. Intelligent manufacturing: Characteristics, technologies and enabling factors. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2019, 233, 1342–1361. [Google Scholar] [CrossRef]

- Ren, S.; Zhang, Y.; Liu, Y.; Sakao, T.; Huisingh, D.; Almeida, C.M. A comprehensive review of big data analytics throughout product lifecycle to support sustainable intelligent manufacturing: A framework, challenges and future research directions. J. Clean. Prod. 2019, 210, 1343–1365. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, Y.; Zhao, X.; Song, X. CPS-Based Self-Adaptive Collaborative Control for Intelligent Production-Logistics Systems. IEEE Trans. Cybern. 2021, 51, 188–198. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y. Digital Twins and Cyber-Physical Systems toward Intelligent Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Xia, K.; Sacco, C.; Kirkpatrick, M.; Saidy, C.; Nguyen, L.; Kircaliali, A.; Harik, R. A digital twin to train deep reinforcement learning agent for intelligent manufacturing plants: Environment, interfaces and intelligence. J. Manuf. Syst. 2021, 58, 210–230. [Google Scholar] [CrossRef]

- Yin, R.Y. A discussion on intelligent steel plant-view from physical system side. Iron Steel 2017, 52, 1–12. [Google Scholar]

- Yao, L.; Wang, J.S. Goal and realization of intelligent manufacturing in steel industry. China Metall. 2020, 30, 1–4. [Google Scholar]

- Liu, W.Z. Current situation and thinking of intelligent manufacturing in China’s iron and steel industry. China Metall. 2020, 30, 1. [Google Scholar]

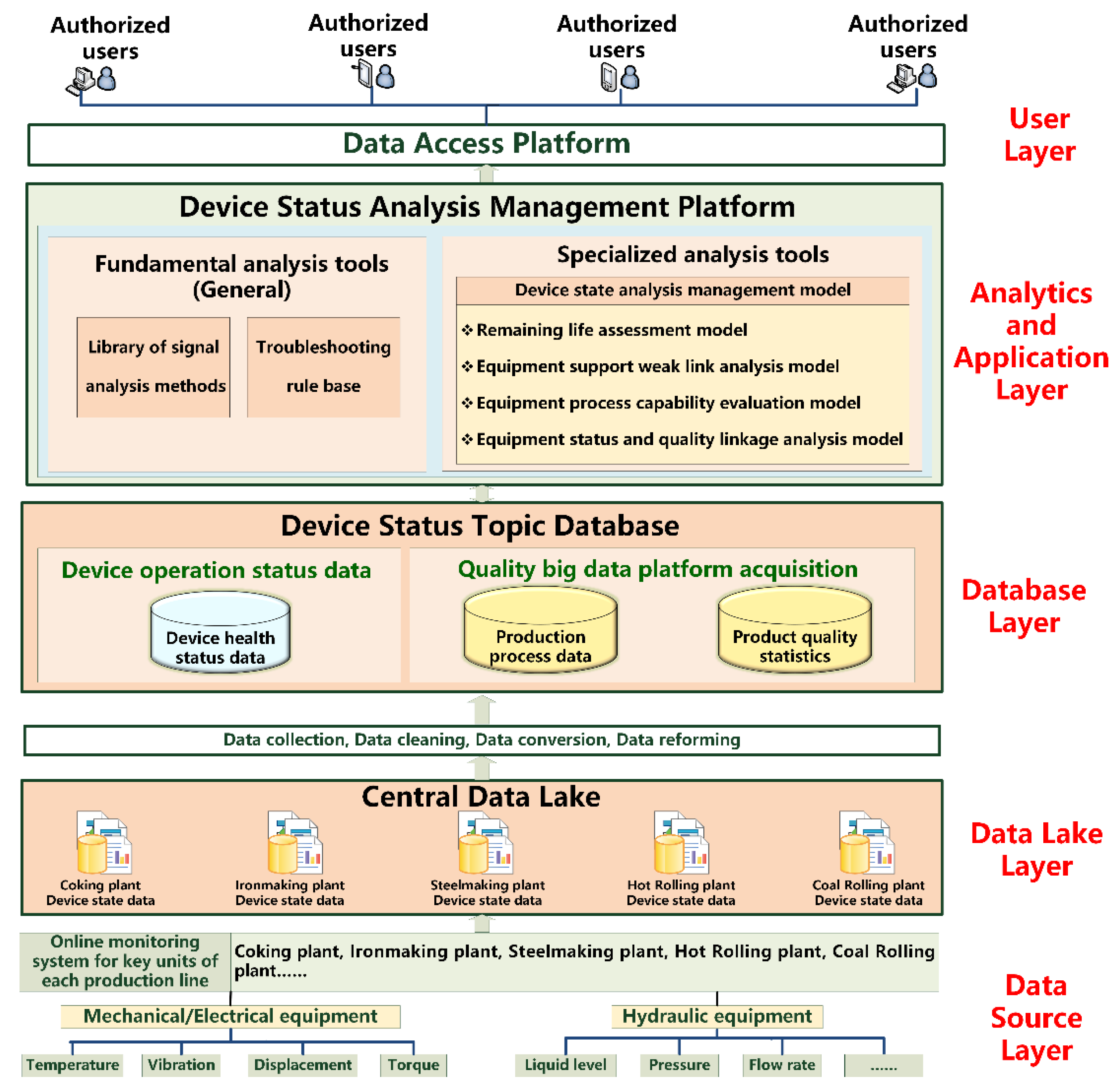

- Li, Y.R.; Li, T.K. Architecture based on big data for iron and steel intelligent manufacturing systems. Metall. Ind. Autom. 2021, 45, 1–8. [Google Scholar]

- Yuan, Q.T.; Yin, R.Y.; Liu, P.C. Strategic research on the goals, characteristics, and paths of intelligentization of process manufacturing industry for 2035. Strateg. Study CAE 2020, 22, 148–156. [Google Scholar] [CrossRef]

- Iannino, V.; Colla, V.; Denker, J.; Göttsche, M. A CPS-Based Simulation Platform for Long Production Factories. Metals 2019, 9, 1025. [Google Scholar] [CrossRef]

- Iannino, V.; Mocci, C.; Colla, V. A Hybrid Peer-to-Peer Architecture for Agent-Based Steel Manufacturing Processes: IFAC PAPERSONLINE. In Proceedings of the 17th IFAC Symposium on Information Control Problems in Manufacturing (INCOM), Budapest, Hungary, 7–9 June 2021; Volume 54, pp. 528–533. [Google Scholar]

- Govender, E.; Telukdarie, A.; Sishi, M.N. Approach for Implementing Industry 4.0 Framework in the Steel Industry. In Proceedings of the 2019 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macao, China, 15–18 December 2019; pp. 1314–1318. [Google Scholar]

- Shin, K.; Park, H. Intelligent Manufacturing Systems Engineering for Designing Intelligent Product-Quality Monitoring System in the Industry 4.0. In Proceedings of the 2019 19th International Conference on Control, Automation and Systems (ICCAS 2019), Hokkaido, Japan, 6–9 July 2019; pp. 1693–1698. [Google Scholar]

- Zheng, Z.; Zhang, K.; Gao, X. Human-cyber-physical system for production and operation decision optimization in intelligent steel plants. Sci. China Technol. Sci. 2022, 65, 247–260. [Google Scholar] [CrossRef]

- Kartashov, O.O.; Chernov, A.V.; Alexandrov, A.A.; Polyanichenko, D.S.; Ierusalimov, V.S.; Petrov, S.A.; Butakova, M.A. Machine Learning and 3D Reconstruction of Materials Surface for Nondestructive Inspection. Sensors 2022, 22, 6201. [Google Scholar] [CrossRef]

- Chen, X.; Lv, J.; Fang, Y.; Du, S. Online Detection of Surface Defects Based on Improved YOLOV3. Sensors 2022, 22, 817. [Google Scholar] [CrossRef]

- Farag, H.E.; Toyserkani, E.; Khamesee, M.B. Non-Destructive Testing Using Eddy Current Sensors for Defect Detection in Additively Manufactured Titanium and Stainless-Steel Parts. Sensors 2022, 22, 5440. [Google Scholar] [CrossRef] [PubMed]

- Mostafa, A.; Lee, S.J.; Peker, Y.K. Physical Unclonable Function and Hashing Are All You Need to Mutually Authenticate IoT Devices. Sensors 2020, 20, 4361. [Google Scholar] [CrossRef]

- Liang, Y.; Xu, K.; Zhou, P. Mask Gradient Response-Based Threshold Segmentation for Surface Defect Detection of Milled Aluminum Ingot. Sensors 2020, 20, 4519. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Gao, F.; Wang, J.; Xu, K. Study of Surface Temperature Distribution for High-Temperature U75V Rail Steel Plates in Rolling Process by Colorimetry Thermometry. Metals 2022, 12, 860. [Google Scholar] [CrossRef]

- Liang, Y.; Xu, K.; Zhou, P.; Zhou, D.D. Automatic defect detection of texture surface with an efficient texture removal network. Adv. Eng. Inform. 2022, 53, 101672. [Google Scholar] [CrossRef]

- Zhou, D.D.; Xu, K.; Bai, J.Y.; He, D. On-line detecting the tuyere coke size and temperature distribution of raceway zone in a working blast furnace. Fuel 2022, 316, 123349. [Google Scholar] [CrossRef]

- Liu, X.M.; Xu, K.; Zhou, D.D.; Zhou, P. Improved contourlet transform construction and its application to surface defect recognition of metals. Multidimens. Syst. Signal Process. 2022, 31, 951. [Google Scholar] [CrossRef]

- Liu, X.M.; Xu, K.; Zhou, P.; Zhou, D.D.; Zhou, Y.J. Surface defect identification of aluminium strips with non-subsampled shearlet transform. Opt. Lasers Eng. 2020, 127, 105986. [Google Scholar] [CrossRef]

- He, D.; Xu, K.; Zhou, P.; Zhou, D.D. Surface defect classification of steels with a new semi-supervised learning method. Opt. Lasers Eng. 2019, 117, 40. [Google Scholar]

- Zhou, D.D.; Cheng, S.S. Measurement Study of the PCI Process on the Temperature Distribution in Raceway Zone of Blast Furnace by Using Digital Imaging Techniques. Energy 2019, 174, 814. [Google Scholar] [CrossRef]

- Su, P.; Liu, S.; Min, H.; An, Y.; Yan, C.; Li, C. Accuracy improvement on quantitative analysis of the total iron content in branded iron ores by laser-induced breakdown spectroscopy combined with the double back propagation artificial neural network. Anal. Methods 2022, 14, 427–437. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Yang, J.; Huang, Y.; Lin, X. A study of the temperature variation effect in a steel sample for rapid analysis using LIBS. Opt. Laser Technol. 2022, 147, 107707. [Google Scholar] [CrossRef]

- Zehra, S.S.; Varvarezos, L.; Hayden, P.; Nicolosi, P.; Zupella, P.; Alli, M.B. Line plasma versus point plasma VUV LIBS for the detection of carbon in steel: A comparative study. J. Anal. At. Spectrom. 2022, 37, 883. [Google Scholar] [CrossRef]

- Khater, M.A.; Mostafa, A.M.; Al-Ashkar, E.A. Role of laser fluence on ionic emission characteristics from steel plasmas induced in atmospheric air. Radiat. Phys. Chem. 2021, 185, 109515. [Google Scholar] [CrossRef]

- Gruenberger, S.; Eschlboeck-Fuchs, S.; Hofstadler, J.; Pissenberger, A.; Duchaczek, H.; Trautner, S. Analysis of minor elements in steel and chemical imaging of micro-patterned polymer by laser ablation-spark discharge-optical emission spectroscopy and laser-induced breakdown spectroscopy. Spectrochim. Acta Part B At. Spectrosc. 2020, 169, 105884. [Google Scholar] [CrossRef]

- Lin, L.; Zeng, J.Q. Consideration of green intelligent steel processes and narrow window stability control technology on steel quality. Int. J. Miner. Metall. Mater. 2021, 28, 1264. [Google Scholar] [CrossRef]

- Zhou, D.D.; Zhou, Y.J.; Zhang, X.M.; Xu, K. Surface Quality Evaluation of Heavy and Medium Plate Using an Analytic Hierarchy Process Based on Defects Online Detection. ISIJ Int. 2022, 62, 1461. [Google Scholar] [CrossRef]

- Li, H.B.; Zhao, Z.W.; Zhang, J.; Kong, N.; Bao, R.R.; Jia, S.H.; He, F. Analysis of flatness control capability based on the effect function and roll contour optimization for 6-h CVC cold rolling mill. Int. J. Adv. Manuf. Technol. 2019, 100, 2387. [Google Scholar] [CrossRef]

- Schlobohm, J. Controlling Equipment Failures Caused by Petroleum-Based Fluid Degradation. Iron Steel Technol. 2020, 17, 8. [Google Scholar]

- Wu, G.F.; Yu, M.; Shi, W.W.; Li, S.Q.; Bao, J.T. Image recognition in online monitoring of power equipment. Int. J. Adv. Robot. Syst. 2020, 17, 1729881419900836. [Google Scholar] [CrossRef]

- Jue, J.S.; Rastinehad, A.R. MRI Fusion Transperineal Prostate Biopsy Instructions and Troubleshooting. J. Endourol. 2021, 35, 2. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.C.; Jia, G.Z.; Zheng, K.; Wei, F.J.; Pan, X.; Chang, W.B.; Zhou, S.H. An Unmanned Aerial Vehicle Troubleshooting Mode Selection Method Based on SIF-SVM with Fault Phenomena Text Record. Aerospace 2021, 8, 347. [Google Scholar] [CrossRef]

- Ma, Y.; Wen, G.; Cheng, S.; He, X.; Mei, S. Multimodal Convolutional Neural Network Model with Information Fusion for Intelligent Fault Diagnosis in Rotating Machinery. Meas. Sci. Technol. 2022, 33, 125109. [Google Scholar] [CrossRef]

- Xia, M.; Shao, H.; Williams, D.; Lu, S.; Shu, L.; Silva, C. Intelligent Fault Diagnosis of Machinery Using Digital Twin-assisted Deep Transfer Learning. Reliab. Eng. Syst. Saf. 2021, 215, 107938. [Google Scholar] [CrossRef]

- Thomas, G.; Balocco, S.; Mann, D.; Simundsson, A.; Khorasani, N. Intelligent Agricultural Machinery Using Deep Learning. IEEE Instrum. Meas. Mag. 2021, 24, 2. [Google Scholar] [CrossRef]

- Cai, H. Building Construction Operation Simulation Based on BIM Technology and Intelligent Robots. J. Interconnect. Netw. 2022, 22, 2145005. [Google Scholar] [CrossRef]

| Project Name | Main Production Lines | Enterprise | Time/Year |

|---|---|---|---|

| Digital metallurgical mine | Mine | Angang Mining Company | 2015 |

| Intelligent workshop for hot rolling | Rolling | Baosteel | 2015 |

| Intelligent factory for iron and steel enterprise | Steelmaking and rolling | Hesteel | 2016 |

| Intelligent factory for silicon steel in the cold rolling process | Rolling | Shougang | 2016 |

| Intelligent manufacturing of high-precision special steel wire | Rolling | Shengtong Steel | 2017 |

| Digital workshop for cold rolling | Rolling | Baosteel | 2017 |

| Digital workshop for stainless steel in cold continuous rolling | Rolling | Taisteel | 2017 |

| Intelligent manufacturing in the whole process of high-end wire rod | Steelmaking and rolling | ShaSteel | 2017 |

| Intelligent factory for seamless steel pipe | Pipe Rolling | Hengyang Valin Steel Pipe | 2018 |

| Intelligent manufacturing for steel plate | Plate Rolling | Nangang | 2018 |

| Intelligent manufacturing for steel thick plate | Plate Rolling | Angang Steel | 2018 |

| Sensor Types | Sensor Names |

|---|---|

| General sensors | Material composition detector, flue gas composition detector, material particle size detector, temperature detector, flow meter, pressure gauge, gas alarm, spectrum analyzer, fluorescence analyzer, etc. |

| High-temperature application sensors | Furnace melt pool height detection, furnace hot field image recognition, solid material automatic sampling analysis, material surface height online detection, material pile morphology automatic monitoring, melt temperature online detection, furnace temperature online detection, melt composition online detection, flame morphology online detection, high-temperature flue gas online detection, etc. |

| Rolling testing sensors | Rolling pressure, rolling time, steel surface temperature, vibration signal, hydraulic signal, motor signal, etc. |

| Quality testing sensors | Surface defect detection, steel roughness, steel dimensions, steel thickness, internal defect detection, mechanical property testing, stress testing, welding performance testing, etc. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, D.; Xu, K.; Lv, Z.; Yang, J.; Li, M.; He, F.; Xu, G. Intelligent Manufacturing Technology in the Steel Industry of China: A Review. Sensors 2022, 22, 8194. https://doi.org/10.3390/s22218194

Zhou D, Xu K, Lv Z, Yang J, Li M, He F, Xu G. Intelligent Manufacturing Technology in the Steel Industry of China: A Review. Sensors. 2022; 22(21):8194. https://doi.org/10.3390/s22218194

Chicago/Turabian StyleZhou, Dongdong, Ke Xu, Zhimin Lv, Jianhong Yang, Min Li, Fei He, and Gang Xu. 2022. "Intelligent Manufacturing Technology in the Steel Industry of China: A Review" Sensors 22, no. 21: 8194. https://doi.org/10.3390/s22218194

APA StyleZhou, D., Xu, K., Lv, Z., Yang, J., Li, M., He, F., & Xu, G. (2022). Intelligent Manufacturing Technology in the Steel Industry of China: A Review. Sensors, 22(21), 8194. https://doi.org/10.3390/s22218194