K-Means Clustering and Bidirectional Long- and Short-Term Neural Networks for Predicting Performance Degradation Trends of Built-In Relays in Meters

Abstract

1. Introduction

2. Material and Methods

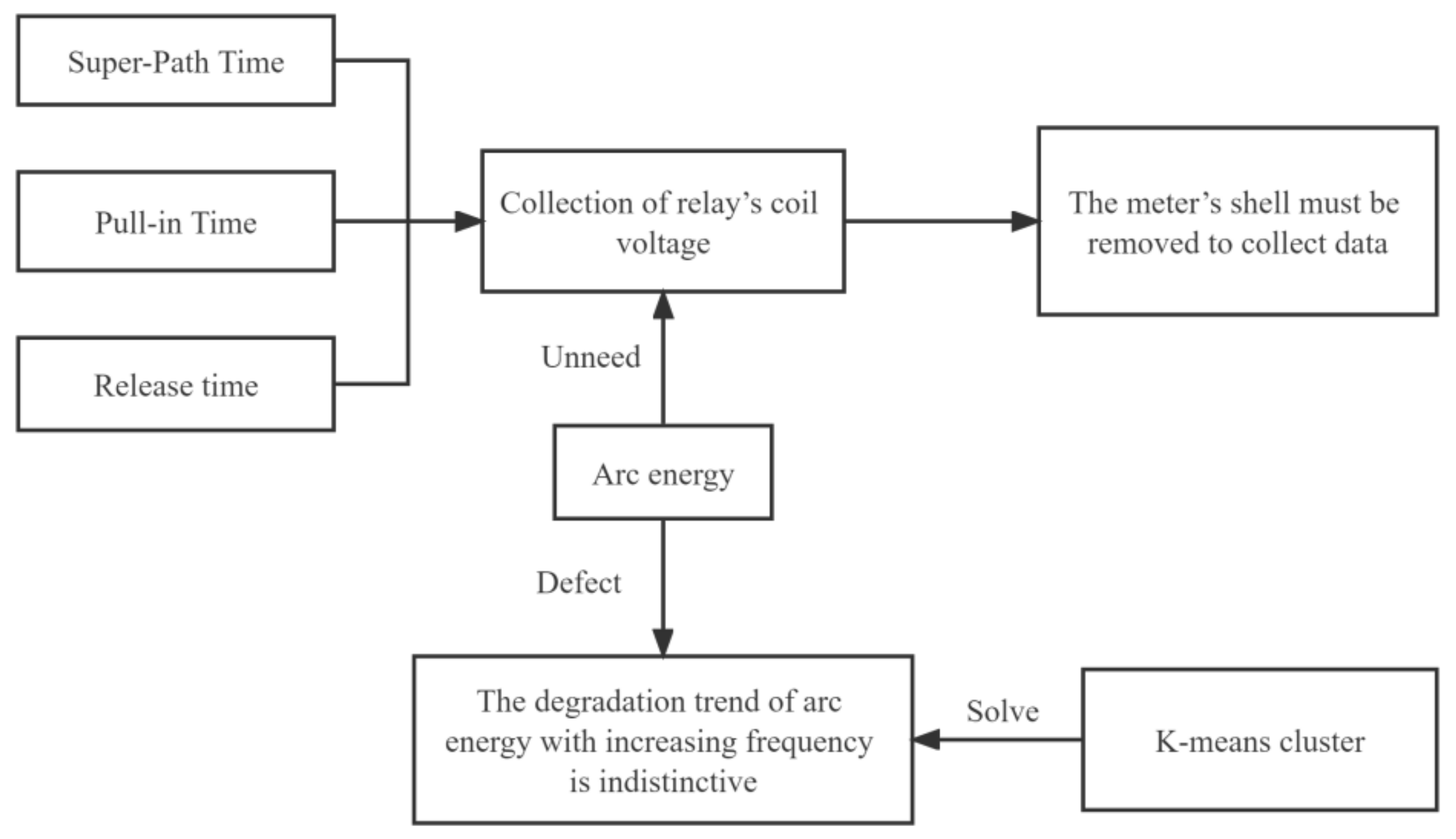

2.1. Characteristics of the Research Subjects

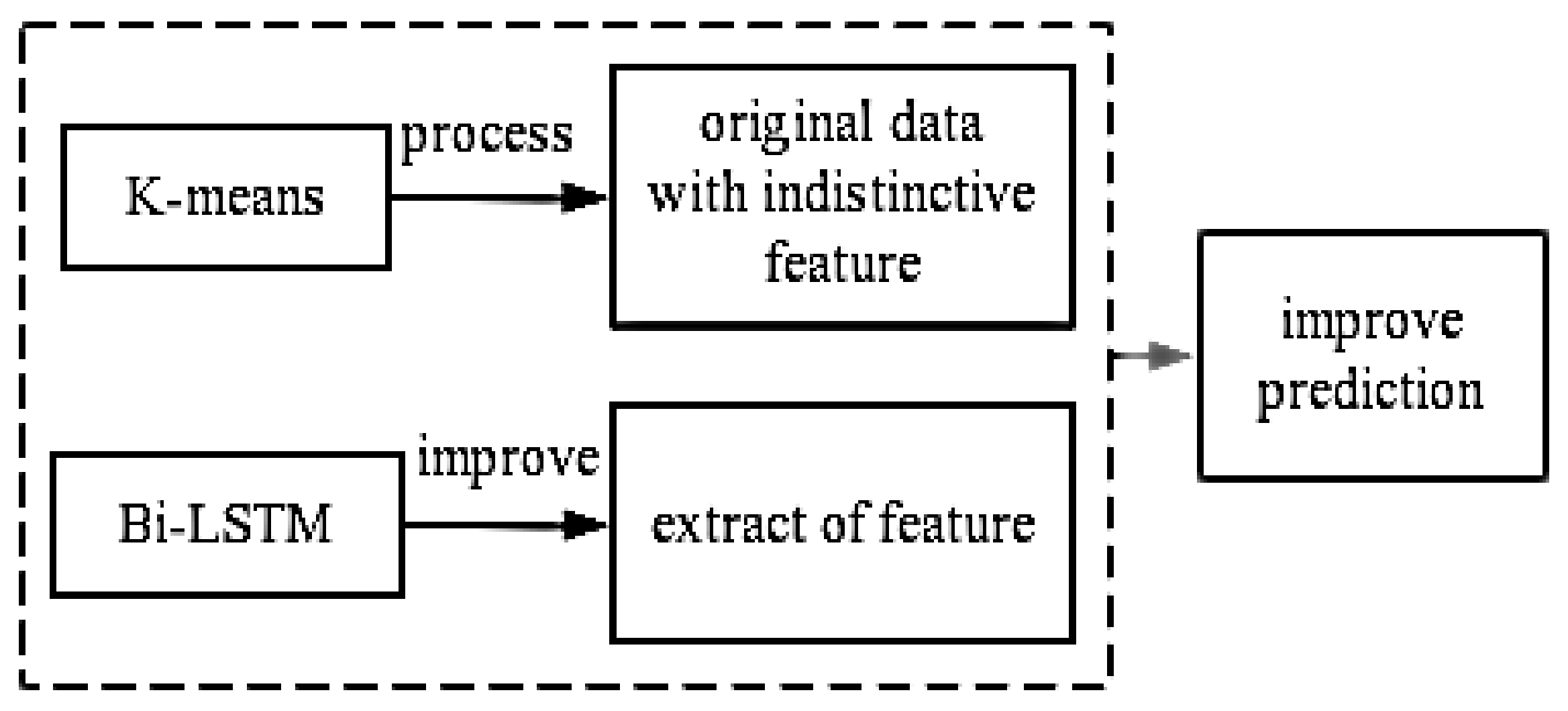

2.2. Model Building

K-Means

- Input the sample set S = { }, which is the number of m-dimensional samples.

- Calculate the maximum and minimum values in the sample set and record their occurrences as a and b, respectively. Calculate the results of rounding the mean of a and b, c, and then the initial clustering centre .

- Calculate the minimised mean error E between the sample x and the centre , as shown in Equation (1):In Equation (2), place the nearest to the corresponding cluster in the cluster, and repeat this process for the nearest in the cluster. Then, update = .

- Recalculate the new centre of mass

- If none the centres of mass have changed, the final cluster C = {., k}; otherwise, repeat steps 3 and 4 and iterate until the maximum number of iterations N is reached.

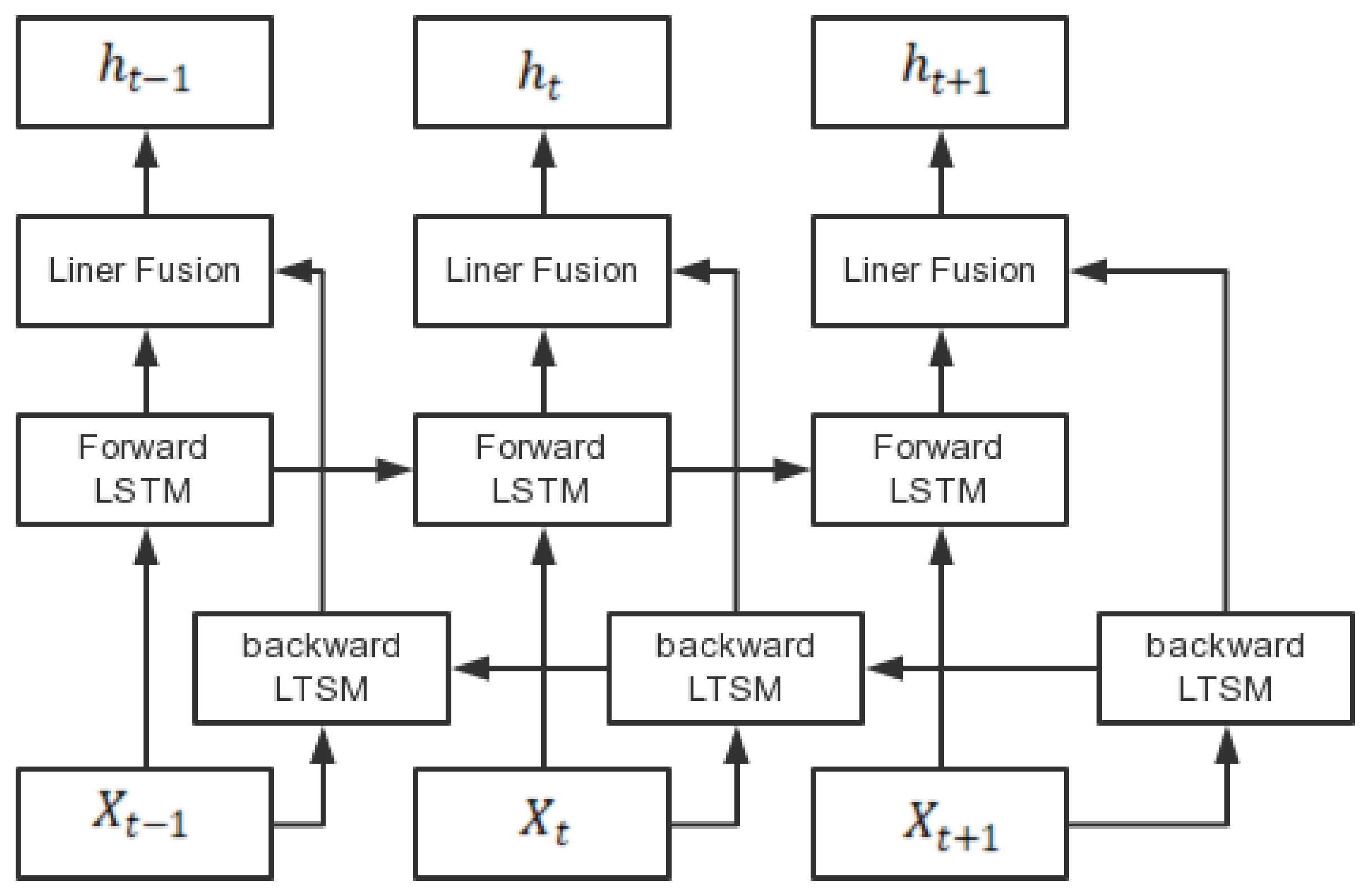

2.3. Bidirectional Long Short-Term Memory Networks

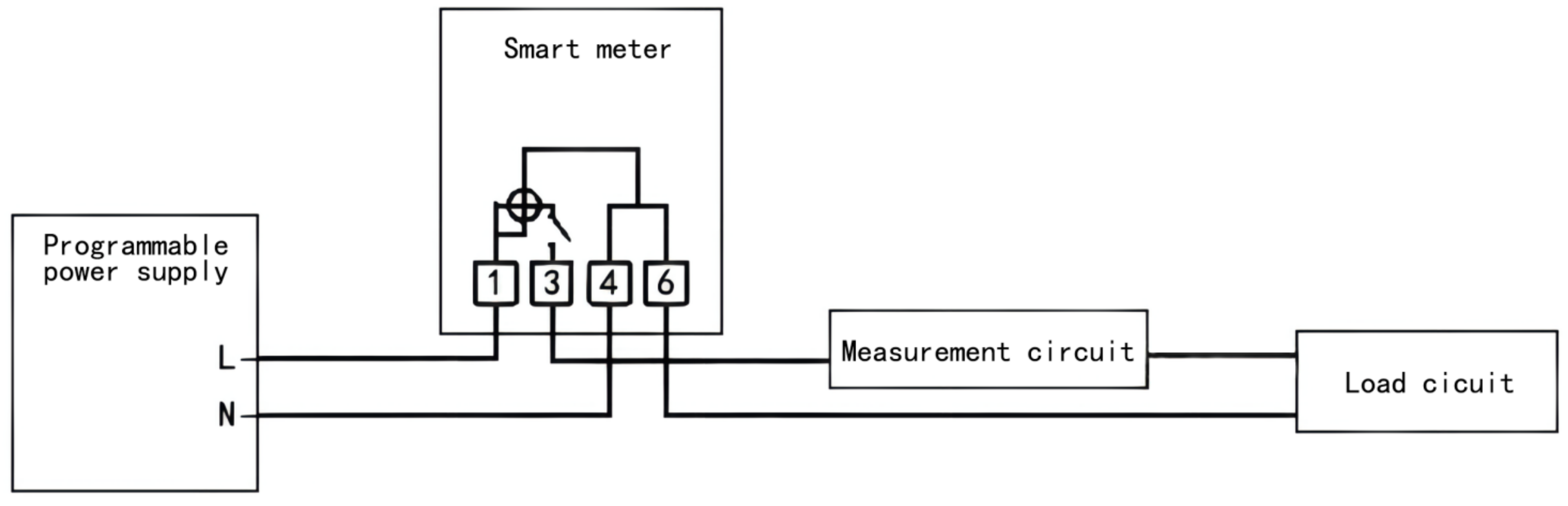

2.4. Construction of the Test Platform and Feature Extraction

Test Platform Construction

3. Results

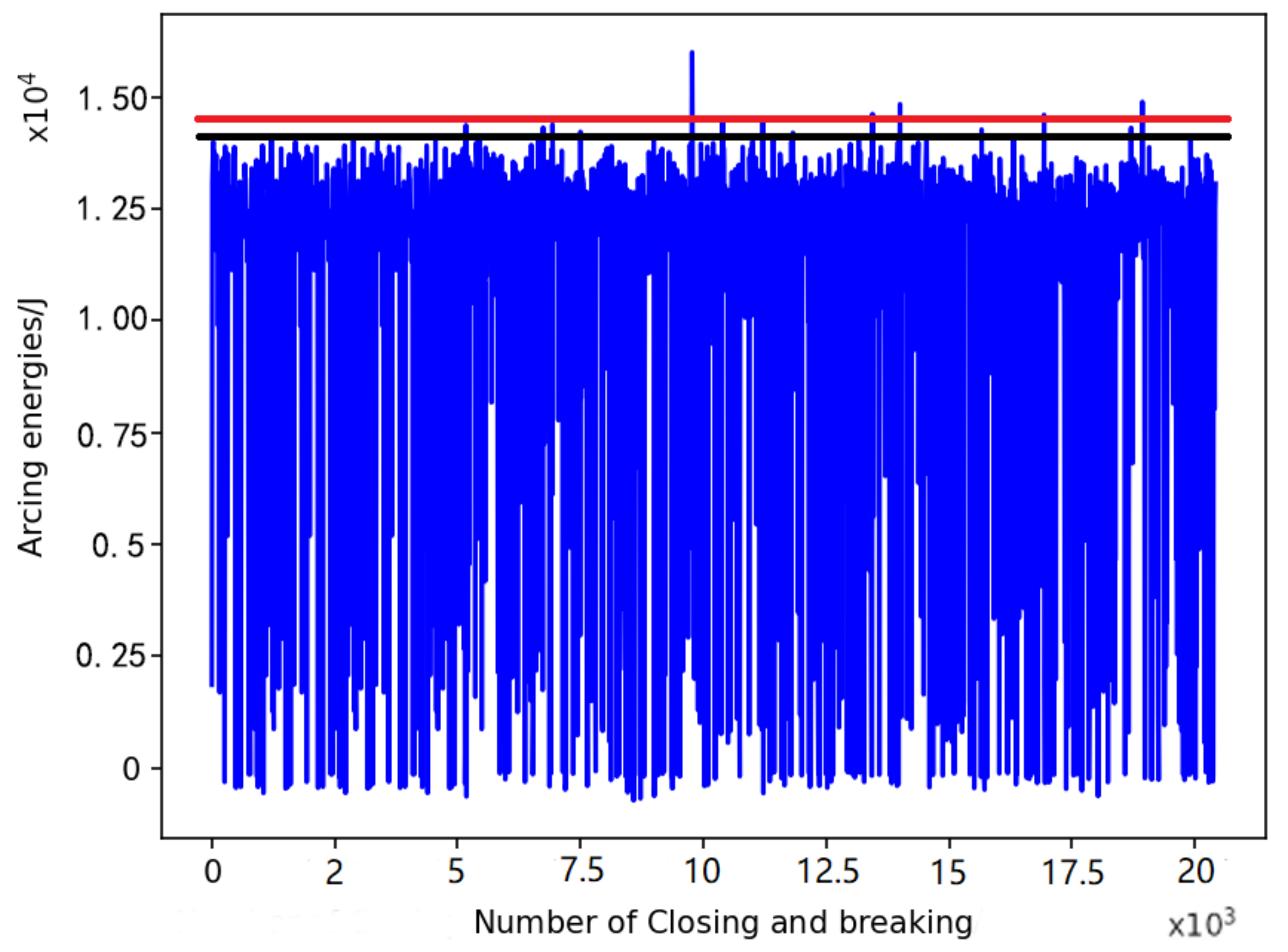

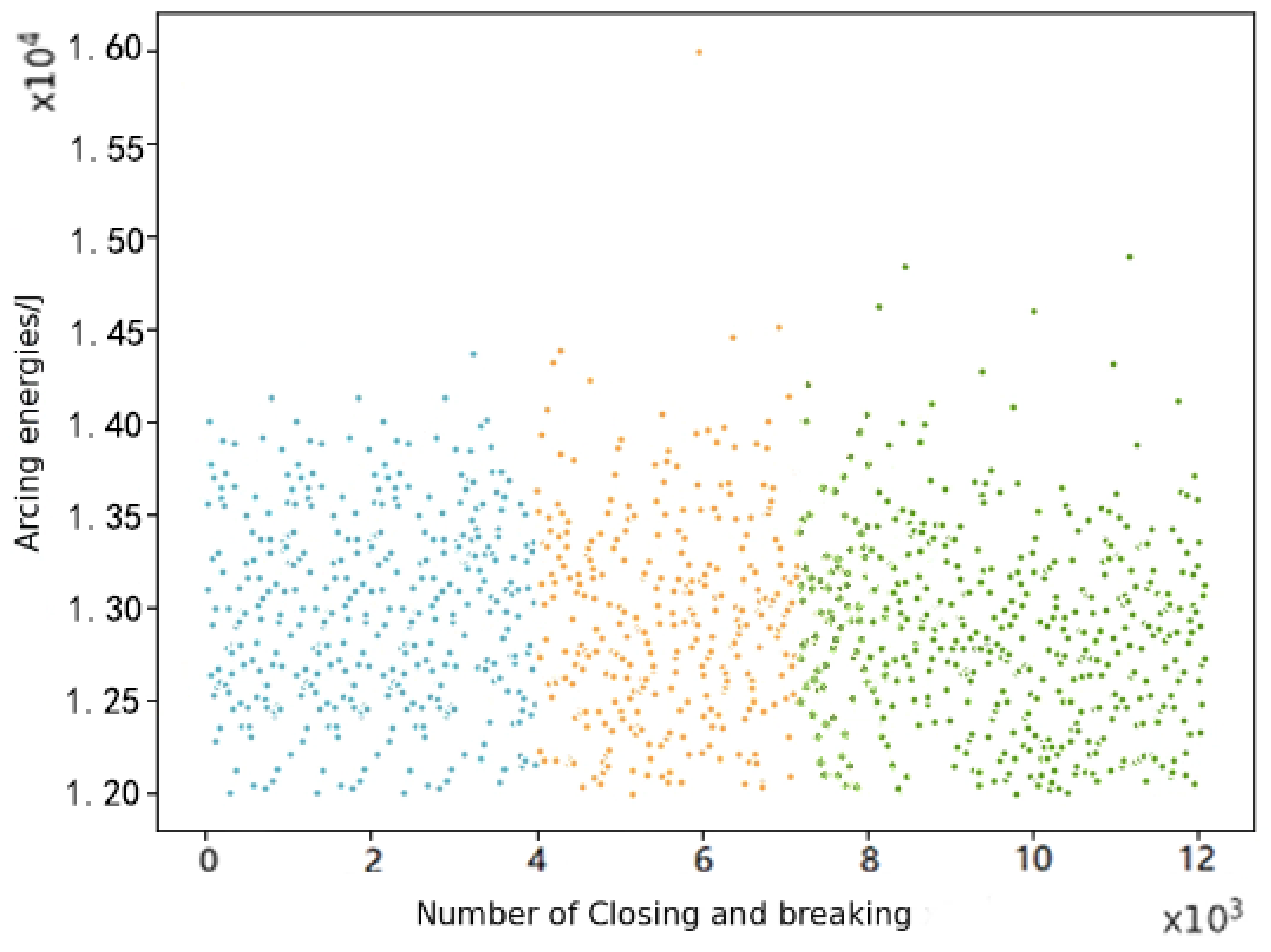

3.1. Feature Extraction

3.2. Model Building and Forecasting of Degradation Trends

Model Building

3.3. Comparison of the Predicted Results and Outcomes of Degradation Trends

4. Conclusions

- In this paper, a conversion of the form of arc-burning energy data is achieved by means of K-means cluster analysis. Arc-burning energy over time data are converted to a trend in the frequency of occurrence of high-energy level arc-burning energy over time. This enables the arc energy to be used to effectively describe the degradation trend of a relay without the need to disassemble the meter. The enhanced degradation characteristics of the arc energy greatly increase the accuracy of the subsequent neural network moaadel in predicting the degradation trend of the relay, and the effectiveness of using the arc energy to describe the degradation of the relay performance instead of the degradation parameters such as overtravel time and suction time is successfully verified.

- The Bi-LSTM neural network model is used to achieve a more accurate prediction of the reliable lifetime. Its prediction accuracy is improved by 12.31% compared with LSTM, and the MSE and are 0.0016 and 0.067 higher than those of LSTM, respectively, indicating that the prediction effect and fitting accuracy of Bi-LSTM are better than LSTM under the conditions presented this paper.

- The experimental results of this paper demonstrate that only the amount of data in the training set needs to be used, i.e., when performing reliability tests on meter relays, the number of openings and closings in the timed truncation test needs to be set to the same number as in the training set, and the predicted object is the same distribution of products under the condition that the degradation trend of the product can be better predicted to significantly reduce the test time. However, the disadvantage is that a larger number of relays need to be input into the first neural network construction to ensure that the products in the subsequent trials have approximately the same distribution as the input data in the first neural network construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rana, S.; Reynolds, J.D.; Ling, T.Y.; Shamsudin, M.S.; Pu, S.H.; Chong, H.M.H.; Pamunuwa, D. Nano-crystalline graphite for reliability improvement in MEM relay contacts. Carbon 2018, 133, 193–199. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, J.; Kong, X. A literature review on planning and analysis of multi-stress accelerated life test for reliability assessment. Recent Pat. Eng. 2021, 15, 12–21. [Google Scholar] [CrossRef]

- Li, Q.; Yan, C.; Chen, G.; Wang, H.; Li, H.; Wu, L. Remaining useful life prediction of rolling bearings based on risk assessment and degradation state coefficient. ISA Trans. 2022, 129, 413–428. [Google Scholar] [CrossRef] [PubMed]

- Al-Bossly, A. Bayesian statistics application on reliability prediction and analysis. J. Stat. Appl. Probab. 2020, 9, 19–34. [Google Scholar] [CrossRef]

- Sun, Y.; Cao, Y.; Zhang, Y.; Xu, C. A novel life prediction method for railway safety relays using degradation parameters. IEEE Intell. Transp. Syst. Mag. 2018, 10, 48–56. [Google Scholar] [CrossRef]

- Qiao, J.; Zhu, B.; Wang, X.; Luo, K. Application research of artificial intelligence technology in error diagnosis of electric energy meter. In Proceedings of the 2019 IEEE 4th International Conference on Cloud Computing and Big Data Analysis (ICCCBDA), Chengdu, China, 12–15 April 2019; pp. 155–159. [Google Scholar]

- Li, K.; Gao, Z.; Wu, Y.; Zheng, S.; Li, Z. Remaining lifetime prediction of AC contactor based on statistical regression and nonlinear Wiener process. Trans. China Electrotechn. Soc. 2019, 34, 4058–4070. [Google Scholar]

- Su, J. Research on Electrical Life Trace Prediction of Contact Based on SG-BP Algorithm. J. Phys. Conf. Ser. 2021, 1952, 032035. [Google Scholar] [CrossRef]

- Wenman, J.; Zhen, Z.; Jia, Q.; Dezhong, M. Life prediction of electromagnetic relay based on bayesian method. In Proceedings of the 2018 IEEE International Conference of Safety Produce Informatization (IICSPI), Chongqing, China, 10–12 December 2018; pp. 340–345. [Google Scholar]

- Li, B.; Bian, Z.; Wang, Z. Research on the electric life prediction of relay contact based on harris hawk optimized. IEEE Trans. Instrum. Meas. 2022, 71, 1–10. [Google Scholar] [CrossRef]

- Li, K.; Zhao, C.; Niu, F.; Zheng, S.; Duan, Y.; Huang, S.; Wu, Y. Electrical performance degradation model and residual electrical life prediction for AC contactor. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 400–417. [Google Scholar] [CrossRef]

- Sun, S.; Liu, J.; Wang, J.; Chen, F.; Wei, S.; Gao, H. Remaining useful life prediction for AC contactor based on MMPE and LSTM with dual attention mechanism. IEEE Trans. Instrum. Meas. 2022, 71, 1–13. [Google Scholar] [CrossRef]

- Le, T.; Vo, M.T.; Vo, B.; Hwang, E.; Rho, S.; Baik, S.W. Improving electric energy consumption prediction using CNN and Bi-LSTM. Appl. Sci. 2019, 9, 4237. [Google Scholar] [CrossRef]

- Zheng, S.; Niu, F.; Li, K.; Huang, S.; Liu, Z.; Wu, Y. Analysis of electrical life distribution characteristics of AC contactor based on performance degradation. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 1604–1613. [Google Scholar] [CrossRef]

- Fu, B.; Xie, Z.; Huang, H.; Du, L. Research on electrical life test method with double-circuit for AC contactor. Low Volt. Appar. 2021, 4, 52. [Google Scholar]

- Zheng, Z.; Ren, W.; Wang, T. Experimental investigation of the breaking arc behavior and interruption mechanisms for AC contactors. IEEE Trans. Plasma Sci. 2021, 49, 389–395. [Google Scholar] [CrossRef]

- Govender, P.; Sivakumar, V. Application of k-means and hierarchical clustering techniques for analysis of air pollution: A review (1980–2019). Atmos. Pollut. Res. 2020, 11, 40–56. [Google Scholar] [CrossRef]

- Sherstinsky, A. Fundamentals of Recurrent Neural Network (RNN) and Long Short-Term Memory (LSTM) network. Phys. D Nonlinear Phenom. 2020, 404, 132306. [Google Scholar] [CrossRef]

- Yu, Y.; Si, X.; Hu, C.; Zhang, J. A review of recurrent neural networks: LSTM cells and network architectures. Neural Comput. 2019, 31, 1235–1270. [Google Scholar] [CrossRef] [PubMed]

- Smagulova, K.; James, A.P. A survey on LSTM memristive neural network architectures and applications. Eur. Phys. J. Spec. Top. 2019, 228, 2313–2324. [Google Scholar] [CrossRef]

- Tang, Z.; Xu, Z. Breaking Arc Model of Intelligent AC Contactor and Arc Extinguishing Analysis of Metal Plates. In Proceedings of the 2021 IEEE 4th International Electrical and Energy Conference (CIEEC), Wuhan, China, 28–30 May 2021. [Google Scholar]

- Bo, Y.; Zhang, L.; Liu, S.; Zhang, Y.; Cao, Y. Application of improved EMD threshold algorithm in the study of the electric life state of the AC contactor. MATEC Web Conf. 2018, 232, 03040. [Google Scholar] [CrossRef]

| Characteristic Parameter | Equation | Remarks |

|---|---|---|

| Release time | is the moment of arc generation, and is the moment when the coil is deenergised | |

| Closing time | is the moment of contact of the relay, and is the moment when the coil is energised | |

| Overtravel time | is the moment of relay operation, i.e., the moment when the coil voltage rises, and is the point at which the coil current slopes to a positive value followed by a negative value | |

| Arc-burning energy | are the voltage and current of the contact, respectively, with a sampling range between the moment of suction and when the voltage change becomes smooth. is the point at 10–90% of the open circuit voltage. is the sampling rate. |

| Parameter | Value |

|---|---|

| Load voltage | 220 V |

| Type of load | Inductive |

| Load current | 65 A |

| Power factor | 0.5 L |

| Rated current of the meter | 60 A |

| Parameter | LSTM | Bi-LSTM |

|---|---|---|

| MSE | 0.0126 | 0.0110 |

| Average relative error | 0.8562 | 0.9793 |

| 0.8801 | 0.9471 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Zhong, C.; Chen, J.; Han, Y.; Zhou, J.; Wang, L. K-Means Clustering and Bidirectional Long- and Short-Term Neural Networks for Predicting Performance Degradation Trends of Built-In Relays in Meters. Sensors 2022, 22, 8149. https://doi.org/10.3390/s22218149

Chen J, Zhong C, Chen J, Han Y, Zhou J, Wang L. K-Means Clustering and Bidirectional Long- and Short-Term Neural Networks for Predicting Performance Degradation Trends of Built-In Relays in Meters. Sensors. 2022; 22(21):8149. https://doi.org/10.3390/s22218149

Chicago/Turabian StyleChen, Jiayan, Chaochun Zhong, Jing Chen, Yuanxun Han, Juan Zhou, and Limin Wang. 2022. "K-Means Clustering and Bidirectional Long- and Short-Term Neural Networks for Predicting Performance Degradation Trends of Built-In Relays in Meters" Sensors 22, no. 21: 8149. https://doi.org/10.3390/s22218149

APA StyleChen, J., Zhong, C., Chen, J., Han, Y., Zhou, J., & Wang, L. (2022). K-Means Clustering and Bidirectional Long- and Short-Term Neural Networks for Predicting Performance Degradation Trends of Built-In Relays in Meters. Sensors, 22(21), 8149. https://doi.org/10.3390/s22218149