Switchgear Digitalization—Research Path, Status, and Future Work

Abstract

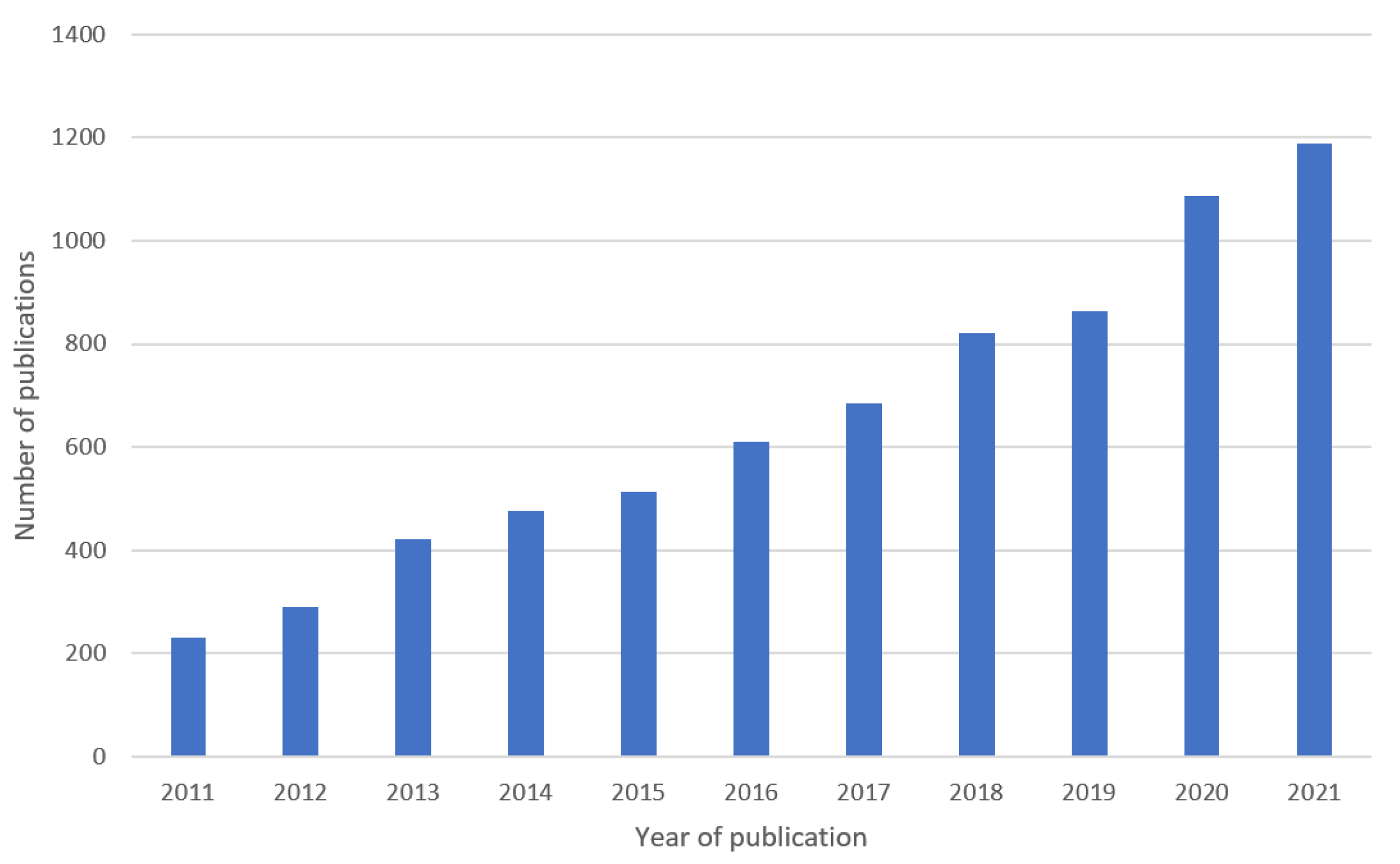

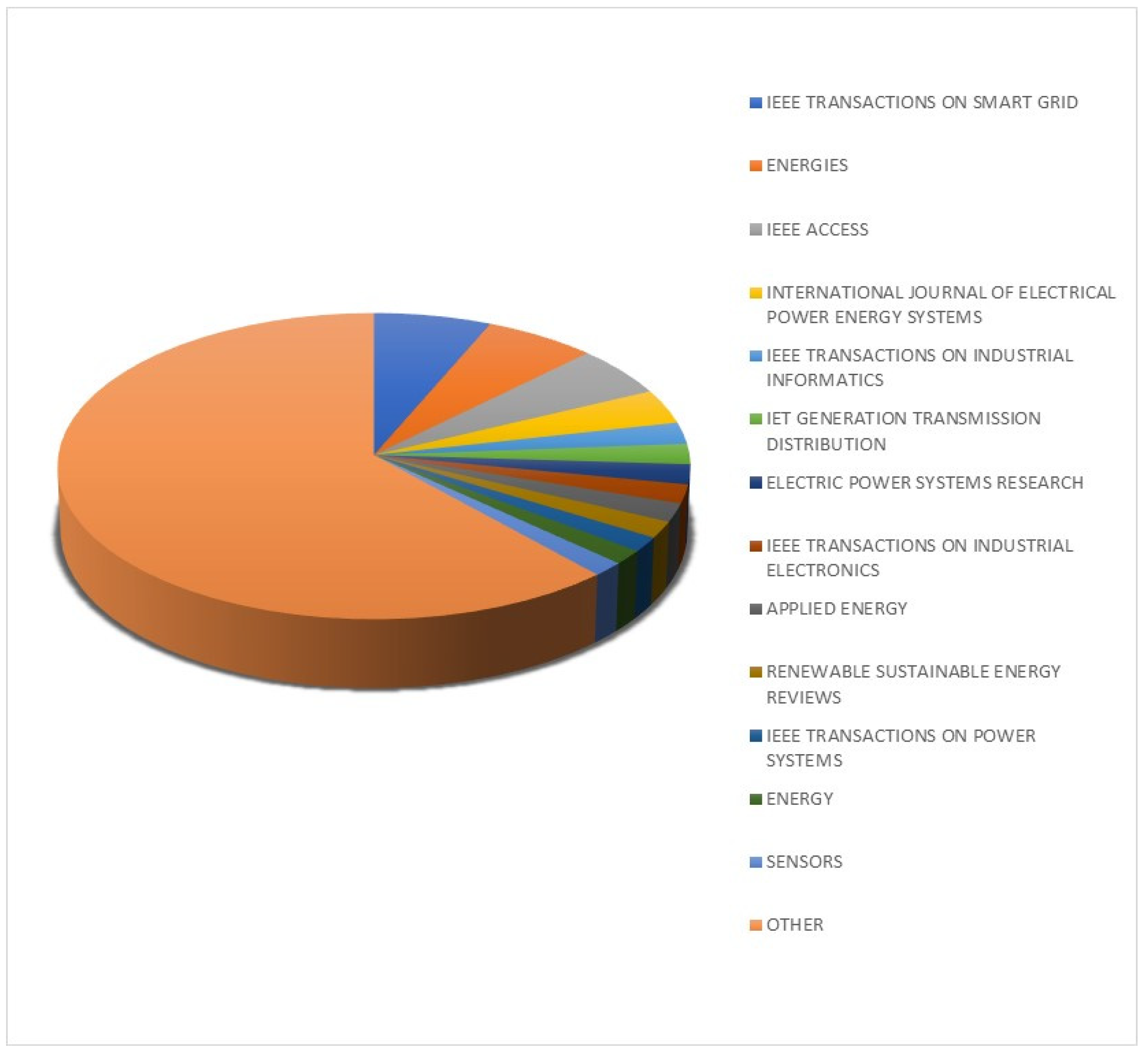

1. Introduction

- Section 2 describes previous optimization efforts in switchgear and explains the need to update metering equipment in switchgear.

- Section 2.1 describes the implementation of sensors and the resulting benefits.

- Section 3 describes the communication protocol that allows the switchgear to meet the above definition of a digital switchgear.

- Section 4 describes the different measurements and sensor types.

- Section 5 describes the use of the data manipulations collected by the sensors in terms of fault detection, condition monitoring, and predictive maintenance.

- Section 6 gives a discussion.

- Section 7 gives the conclusions from this research.

2. The Initial Situation

2.1. Replacement of Outdated Measurement Components

- resistive or capacitive voltage dividers as voltage sensors;

- Rogowski coil as current sensor;

- current sensor with non-saturable magnetic core.

- non-saturable, since no iron core is used;

- high degree of accuracy;

- increased personnel safety (low secondary voltages);

- small size and weight;

- wide dynamic range;

- environmental friendliness, as less raw material is used;

- no damage caused in case of overload.

- two incoming feeders;

- twelve outgoing feeders.

3. The Broadening of the Perspective

4. Expansion of the Types of Measurement Sensors

- temperature sensors;

- humidity sensors;

- partial discharge sensors.

4.1. Temperature Measurements

- surface acoustic wave (SAW) temperature sensors;

- infrared (IR) temperature sensors;

- IR window implementation;

- fiber optic sensors.

4.2. Humidity Measurements

4.3. Partial Discharge (Arc) Measurements

5. Applications of Measurement Data Manipulation

5.1. Condition Monitoring

- labor-free measurements;

- accurate data due to real time operational measurements;

- improved service decision due to failure start/progress information;

- unnecessary maintenance reduction due to decisions based on data from continuous measurements;

- prioritization of equipment repair order.

5.2. Fault Detection

5.3. Predictive Maintenance

6. Discussion

7. Conclusions

- Since the framework for conducting experimental studies varies, there is an obvious need to “standardize” the procedures, which are also categorized by the type of data used (temperature, partial discharge, voltage/current, etc.). “Standardization” would lead to a universal framework for data collection (creation of a freely accessible database) that could be used to accurately compare the developed algorithms, and adequately monitor improvements in the application of machine/deep learning algorithms in prediction maintenance.

- The developed dataset could also be used in digital twin simulations of both shore and marine power grids to increase the overall model accuracy, as real data would be implemented, and as the complex dynamics of switchgear are mostly ignored today. Overall, digital twin models offer great optimization opportunities, especially in the maritime domain, which are in line with IMO’s future goals.

- The development of digital switchgear will lead to an effective predictive maintenance plan that will be continuously optimized with the growing measurement database and machine/deep learning analysis. Repair procedures are optimized, as the source of PD is automatically located, reducing labor and replacement costs. In summary, digital switchgear provides a safer and more cost-effective distribution system compared to its “analog” counterparts. Safety and reliability are enhanced by the active monitoring of equipment to predict failures, and there is a reduction in manpower requirements for data interpretation and equipment monitoring/repair procedures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Energy Outlook—Topics. Available online: https://www.iea.org/topics/world-energy-outlook (accessed on 25 February 2022).

- Bortuzzo, V.; Bertagna, S.; Dodero, M.; Ferrari, J.; Marinò, A.; Bucci, V. Electrification of Vessels for Garbage Collection and Treatment in Venice Lagoon. In Proceedings of the 2021 Sixteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 5–7 May 2021; pp. 1–6. [Google Scholar]

- Campillo, J.; Domínguez-Jimenez, J.A.; Cabrera, J. Sustainable Boat Transportation Throughout Electrification of Propulsion Systems: Challenges and Opportunities. In Proceedings of the 2019 2nd Latin American Conference on Intelligent Transportation Systems (ITS LATAM), Bogota, Colombia, 19–20 March 2019; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- 6Anwar, S.; Zia, M.Y.I.; Rashid, M.; de Rubens, G.Z.; Enevoldsen, P. Towards Ferry Electrification in the Maritime Sector. Energies 2020, 13, 6506. [Google Scholar] [CrossRef]

- Fourth Greenhouse Gas Study. 2020. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Fourth-IMO-Greenhouse-Gas-Study-2020.aspx (accessed on 8 September 2022).

- Al-Falahi, M.; Tarasiuk, T.; Jayasinghe, S.; Jin, Z.; Enshaei, H.; Guerrero, J. AC Ship Microgrids: Control and Power Management Optimization. Energies 2018, 11, 1458. [Google Scholar] [CrossRef]

- Chennakeshava, R.; Niharika Rao, R.; Karthik, M.; Mohammed, S.; Prajath Mahabala, R. A Review on Switchgear Analysis and Common Challenges Observed in Switchgear. IJERT 2021, 10, 4. [Google Scholar] [CrossRef]

- Yoon, D.-H.; Yoon, J. Deep Learning-Based Method for the Robust and Efficient Fault Diagnosis in the Electric Power System. IEEE Access 2022, 10, 44660–44668. [Google Scholar] [CrossRef]

- Sirojan, T.; Lu, S.; Phung, B.T.; Zhang, D.; Ambikairajah, E. Sustainable Deep Learning at Grid Edge for Real-Time High Impedance Fault Detection. IEEE Trans. Sustain. Comput. 2022, 7, 346–357. [Google Scholar] [CrossRef]

- Gouda, O.E.; Darwish, M.M.F.; Mahmoud, K.; Lehtonen, M.; Elkhodragy, T.M. Pollution Severity Monitoring of High Voltage Transmission Line Insulators Using Wireless Device Based on Leakage Current Bursts. IEEE Access 2022, 10, 53713–53723. [Google Scholar] [CrossRef]

- Karandikar, H.; Neighbours, T.; Pate, R. The Next Phase in the Evolution of Safety by Design—Digital Switchgear. In Proceedings of the 2019 IEEE Petroleum and Chemical Industry Committee Conference (PCIC), Vancouver, BC, Canada, 9–12 September 2019; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2019; pp. 233–240. [Google Scholar]

- Neighbours, T.; Moser, D. Switchgear Moves into the Digital World. 8. Technical Paper, ABB. Available online: https://library.e.abb.com/public/36631a885cd247b3a968c41504b613fc/Technical%20paper_Digital%20switchgear.pdf (accessed on 21 May 2022).

- Deaconu, G.G.M.; Costinas, S.; Stoenescu, I.B.; Opris, I. The Testing of Digital Substation—An Important Issue in Power Engineering Education. In Proceedings of the 2021 12th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 25–27 March 2021; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2021; pp. 1–6. [Google Scholar]

- Almalaq, A.; Albadran, S.; Mohamed, M.A. Deep Machine Learning Model-Based Cyber-Attacks Detection in Smart Power Systems. Mathematics 2022, 10, 2574. [Google Scholar] [CrossRef]

- Starke, A.; Nagaraj, K.; Ruben, C.; Aljohani, N.; Zou, S.; Bretas, A.; McNair, J.; Zare, A. Cross-layered Distributed Data-driven Framework for Enhanced Smart Grid Cyber--physical Security. IET Smart Grid 2022, 5, 1–19. [Google Scholar] [CrossRef]

- Elsisi, M.; Tran, M.-Q.; Mahmoud, K.; Mansour, D.-E.A.; Lehtonen, M.; Darwish, M.M.F. Towards Secured Online Monitoring for Digitalized GIS Against Cyber-Attacks Based on IoT and Machine Learning. IEEE Access 2021, 9, 78415–78427. [Google Scholar] [CrossRef]

- Tuballa, M.L.; Abundo, M.L. A Review of the Development of Smart Grid Technologies. Renew. Sustain. Energy Rev. 2016, 59, 710–725. [Google Scholar] [CrossRef]

- Sroubova, L.; Kropik, P.; Hamar, R.; Dolezel, I. Minimization of Force and Thermal Effects in Bus Bars. In Proceedings of the 2016 ELEKTRO, Strbske Pleso, Slovakia, 16–18 May 2016; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2016; pp. 383–386. [Google Scholar]

- Yusop, F.M.; Jamil, M.K.M.; Ishak, D.; Masri, S. Study on the Electromagnetic Force Affected by Short-Circuit Current in Vertical and Horizontal Arrangement of Busbar System. In Proceedings of the International Conference on Electrical, Control and Computer Engineering 2011 (InECCE), Kuantan, Malaysia, 21–22 June 2011; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2011; pp. 196–200. [Google Scholar]

- Milovac, P.; Javora, R.; Skendzic, V. Sensor Technology in a Medium-Voltage Switchgear for the US Market Applications. CIRED—Open Access Proc. J. 2017, 2017, 432–435. [Google Scholar] [CrossRef][Green Version]

- Shepard, D.E.; Yauch, D.W. An Overview of Rogowski Coil Current Sensing Technology; LEM DynAmp Inc.: Grove City, OH, USA, 2000. [Google Scholar]

- Proca, V.; Paduraru, N. Methods for Non-Conventional Measuring Sensor Integration in the Medium Voltage Electrical Equipment. In Proceedings of the 2005 IEEE Russia Power Tech, St. Petersburg, Russia, 27–30 June 2005; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2005; pp. 1–6. [Google Scholar]

- Stefanka, M.; Prokop, V.; Salge, G. Application of IEC 61850-9-2 in MV Switchgear with Sensors Use. In Proceedings of the 22nd International Conference and Exhibition on Electricity Distribution (CIRED 2013), Stockholm, Sweden, 10–13 June 2013; Institution of Engineering and Technology: Piscataway, NJ, USA, 2013; p. 0103. [Google Scholar]

- Elgargouri, A.; Virrankoski, R.; Elmusrati, M. IEC 61850 Based Smart Grid Security. In Proceedings of the 2015 IEEE International Conference on Industrial Technology (ICIT), Seville, Spain, 17–19 March 2015; nstitute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2015; pp. 2461–2465. [Google Scholar]

- Huang, W. Learn IEC 61850 Configuration in 30 Minutes. In Proceedings of the 2018 71st Annual Conference for Protective Relay Engineers (CPRE), College Station, TX, USA, 26–29 March 2018; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2018; pp. 1–5. [Google Scholar]

- Kumar, S.; Abu-Siada, A.; Das, N.; Islam, S. Toward a Substation Automation System Based on IEC 61850. Electronics 2021, 10, 310. [Google Scholar] [CrossRef]

- Al-Tibbi, W. Energy Efficient Software and Hardware Configuration of the Digital Substation in Accordance with IEC 61850. E3S Web Conf. 2021, 279, 01024. [Google Scholar] [CrossRef]

- Subramaniam, A.; Sahoo, A.; Manohar, S.S.; Raman, S.J.; Panda, S.K. Switchgear Condition Assessment and Lifecycle Management: Standards, Failure Statistics, Condition Assessment, Partial Discharge Analysis, Maintenance Approaches, and Future Trends. IEEE Electr. Insul. Mag. 2021, 37, 27–41. [Google Scholar] [CrossRef]

- Slavtchev, Y.; Mateev, V.; Tzeneva, R. 3D Coupled Electric-Thermal-Fluid Analysis of Bolted Busbar Connection. In Proceedings of the 2019 16th Conference on Electrical Machines, Drives and Power Systems (ELMA), Varna, Bulgaria, 6–8 June 2019; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2019; pp. 1–4. [Google Scholar]

- Park, S.W.; Cho, H. A Practical Study on Electrical Contact Resistance and Temperature Rise at at the Connections of the Copper Busbars in Switchgears. In Proceedings of the 2014 IEEE 60th Holm Conference on Electrical Contacts (Holm), New Orleans, LA, USA, 12–15 October 2014; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2014; pp. 1–7. [Google Scholar]

- Budyn, M.; Karandikar, H.M.; Urmson, M.G. Switchgear Condition Monitoring. 9. CIGRÉ Canada. In Proceedings of the Conference on Power Systems, Vancouver, BC, Canada, 17–19 October 2010. [Google Scholar]

- Woelke, B.; Monedero, M.; Jebamony, D. Application of Novel Sensor Technology in an Environmental Friendly SF6 Free Medium Voltage Gas Insulated Switchgear Pilot Setup. In Proceedings of the VDE High Voltage Technology 2018, ETG-Symposium, Berlin, Germany, 12–14 November 2018; pp. 1–6. [Google Scholar]

- Wildermuth, S.; Szasz, P.; Gebhardt, J.; Kaul, H.; Koenig, K. Infrared Temperature Sensing in Electrical Equipment by Low-Cost IR Cameras. In Proceedings of the VDE High Voltage Technology 2018, ETG-Symposium, Berlin, Germany, 12–14 November 2018; pp. 1–5. [Google Scholar]

- Durocher, D.B.; Loucks, D. Infrared Windows Applied in Switchgear Assemblies: Taking Another Look. In Proceedings of the 2015 61st IEEE Pulp and Paper Industry Conference (PPIC), Milwaukee, WI, USA, 14–18 June 2015; pp. 1–6. [Google Scholar]

- Alam, S.; Islam, T.; Mittal, U. A Sensitive Surface Acoustic Wave Sensor for Monitoring Humidity for Substation Application. In Proceedings of the 2019 International Conference on Power Electronics, Control and Automation (ICPECA), New Delhi, India, 16–17 November 2019; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2019; pp. 1–4. [Google Scholar]

- Byrne, T. Humidity Effects in Substations. In Proceedings of the 2014 Petroleum and Chemical Industry Conference Europe, Amsterdam, The Netherlands, 3–5 June 2014; pp. 1–10. [Google Scholar]

- Meng, F.; Zhang, X.; Wu, X.; Xu, B. Experimental Studies on Air Humidity Affecting Partial Discharge in Switchgear. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Chenzhen, China, 20–23 October 2013; pp. 1237–1241. [Google Scholar]

- Kumpulainen, L.; Hussain, G.A.; Lehtonen, M.; Kay, J.A. Preemptive Arc Fault Detection Techniques in Switchgear and Controlgear. IEEE Trans. Ind. Appl. 2013, 49, 1911–1919. [Google Scholar] [CrossRef]

- Polužanski, V.; Kovacevic, U.; Bacanin, N.; Rashid, T.A.; Stojanovic, S.; Nikolic, B. Application of Machine Learning to Express Measurement Uncertainty. Appl. Sci. 2022, 12, 8581. [Google Scholar] [CrossRef]

- Levi, D.; Gispan, L.; Giladi, N.; Fetaya, E. Evaluating and Calibrating Uncertainty Prediction in Regression Tasks. Sensors 2022, 22, 5540. [Google Scholar] [CrossRef]

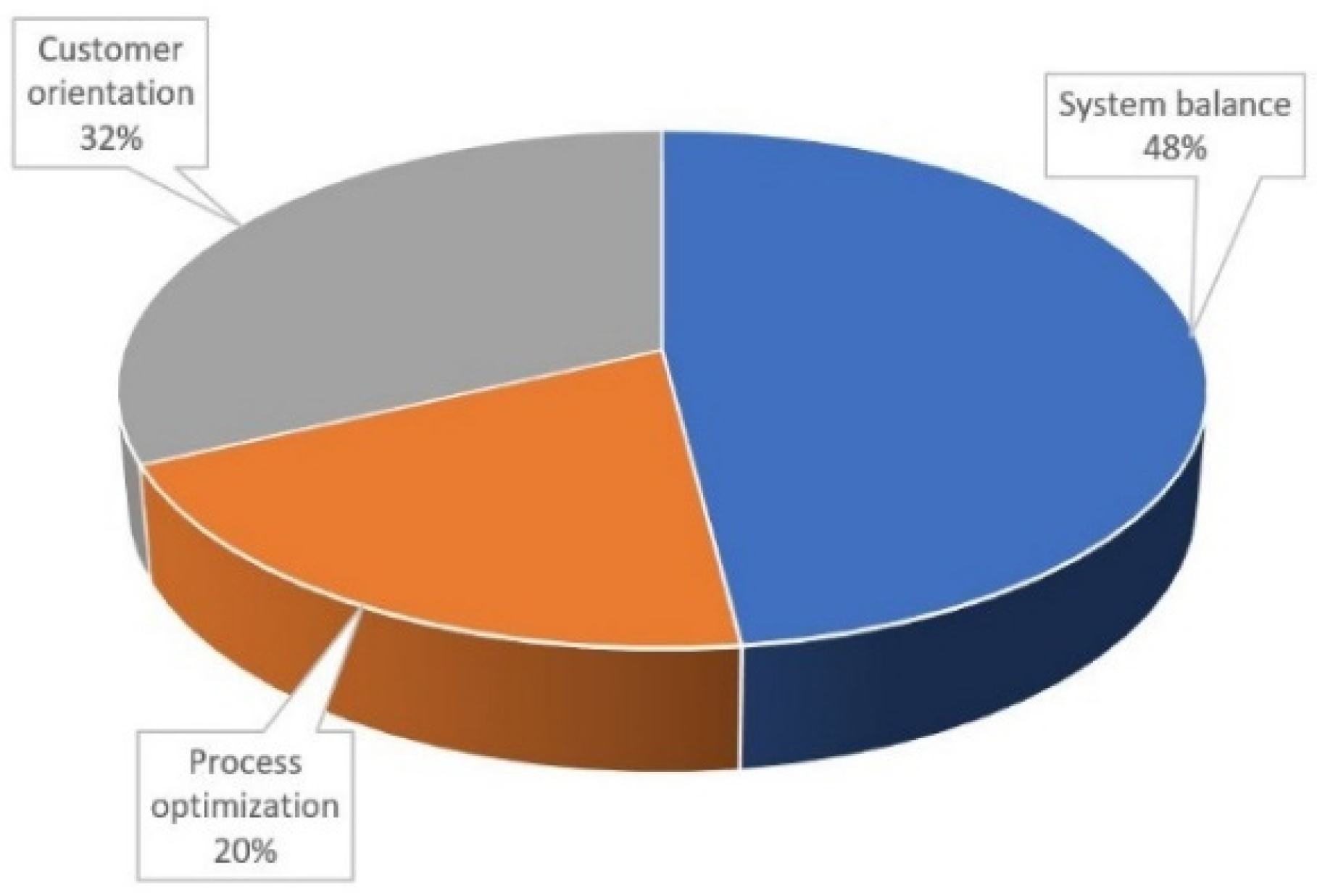

- Weigel, P.; Fischedick, M. Review and Categorization of Digital Applications in the Energy Sector. Appl. Sci. 2019, 9, 5350. [Google Scholar] [CrossRef]

- Esteban, A.; Zafra, A.; Ventura, S. Data Mining in Predictive Maintenance Systems: A Taxonomy and Systematic Review. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2022, 12, e1471. [Google Scholar] [CrossRef]

- Ayers, W.; Herinckx, T. Arc Flash in Marine Installations. Elliott Bay Design Group, Technical Paper. 2022. Available online: https://www.ebdg.com/wp-ebdg-content/uploads/2022/02/Arc-Flash-In-Marine-Installations-Technical-Paper-WNA-and-TMH.pdf (accessed on 21 May 2022).

- Kane, C.; Golubev, A. Advantages of Continuous Monitoring of Partial Discharges in Rotating Equipment and Switchgear. In Proceedings of the Conference Record of the 2003 Annual Pulp and Paper Industry Technical Conference, Charleston, SC, USA, 16–20 June 2003; pp. 117–122. [Google Scholar]

- Fechet, R.; Petrariu, A.I.; Graur, A. Partial Discharge and Internet of Things: A Switchgear Cell Maintenance Application Using Microclimate Sensors. Sensors 2021, 21, 8372. [Google Scholar] [CrossRef]

- Seatracker. Power Failures on Ships, Safety Study—Safety Investigation Authority; Marine Tracker; [2017, PDF]; Turvallisuustutkinta: Helsinki, Finland, 2017. [Google Scholar]

- Helbig, D.; Singh, P.; Gomez Hennig, E. Transmission Products and Systems for Utilities of the Future—IoT Connected, Digital Twin Based, Intelligent. In Proceedings of the 2020 CIGRE Canada Conference, Toronto, ON, Canada, 19–22 October 2020. [Google Scholar]

- Assani, N.; Matić, P.; Katalinić, M. Ship’s Digital Twin—A Review of Modelling Challenges and Applications. Appl. Sci. 2022, 12, 6039. [Google Scholar] [CrossRef]

- Perabo, F.; Park, D.; Zadeh, M.K.; Smogeli, O.; Jamt, L. Digital Twin Modelling of Ship Power and Propulsion Systems: Application of the Open Simulation Platform (OSP). In Proceedings of the 2020 IEEE 29th International Symposium on Industrial Electronics (ISIE), Delft, The Netherlands, 17–19 June 2020; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2020; pp. 1265–1270. [Google Scholar]

- Ewaida, R.F.; Wani, N.R.; Khan, Y.; Al-Arainy, A.A. Defect Localization Inside Simulated MV Switchgear Based on Cumulative Energy Curve Using Transient Earth Voltage Sensors. Energies 2021, 14, 320. [Google Scholar] [CrossRef]

- Portugues, I.E.; Moore, P.J.; Glover, I.A.; Johnstone, C.; McKosky, R.H.; Goff, M.B.; van der Zel, L. RF-Based Partial Discharge Early Warning System for Air-Insulated Substations. IEEE Trans. Power Deliv. 2009, 24, 20–29. [Google Scholar] [CrossRef]

- Yao, M. The Application of Temporary Earth Voltage (TEV) Measurement in the Online Monitoring of the Partial Discharge of HV Switch Cabinet. In Proceedings of the CICED 2010 Proceedings, Nanjing, China, 13–16 September 2010; pp. 1–6. [Google Scholar]

- Lu, S.; Chai, H.; Sahoo, A.; Phung, B.T. Condition Monitoring Based on Partial Discharge Diagnostics Using Machine Learning Methods: A Comprehensive State-of-the-Art Review. IEEE Trans. Dielect. Electr. Insul. 2020, 27, 1861–1888. [Google Scholar] [CrossRef]

- Long, J.; Wang, X.; Zhou, W.; Zhang, J.; Dai, D.; Zhu, G. A Comprehensive Review of Signal Processing and Machine Learning Technologies for UHF PD Detection and Diagnosis (I): Preprocessing and Localization Approaches. IEEE Access 2021, 9, 69876–69904. [Google Scholar] [CrossRef]

- State of Data Science and Machine Learning. 2021. Available online: https://www.kaggle.com/kaggle-survey-2021 (accessed on 5 September 2022).

- Rahmani, A.; Haddadnia, J.; Seryasat, O. Intelligent Fault Detection of Electrical Equipment in Ground Substations Using Thermo Vision Technique. In Proceedings of the 2010 2nd International Conference on Mechanical and Electronics Engineering, Kyoto, Japan, 1–3 August 2010; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2010; pp. 2–154. [Google Scholar]

- Bai, T.; Zhang, L.; Duan, L.; Wang, J. NSCT-Based Infrared Image Enhancement Method for Rotating Machinery Fault Diagnosis. IEEE Trans. Instrum. Meas. 2016, 65, 2293–2301. [Google Scholar] [CrossRef]

- Zhao, K.; Li, H.; Gao, S.; Li, Y.; Liu, Y.; Ma, J. Deep Learning Based Infrared Image Recognize and Internal Overheating Fault Diagnosis of Gas Insulated Switchgear. In Proceedings of the 2021 International Conference on Sensing, Measurement & Data Analytics in the era of Artificial Intelligence (ICSMD), Nanjing, China, 21–23 October 2021; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2021; pp. 1–5. [Google Scholar]

- Ding, R.; Zhao, K.; Teng, Y.; Zhuang, T.; Liu, J.; Yang, J. Detection and Analysis of GIS Discharge Defects Based on Deep Learninng Method. In Proceedings of the 2022 4th Asia Energy and Electrical Engineering Symposium (AEEES), Chengdu, China, 25–28 March 2022; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2022; pp. 706–711. [Google Scholar]

- Peng, X.; Zhou, C.; Hepburn, D.M.; Judd, M.D.; Siew, W.H. Application of K-Means Method to Pattern Recognition in on-Line Cable Partial Discharge Monitoring. IEEE Trans. Dielect. Electr. Insul. 2013, 20, 754–761. [Google Scholar] [CrossRef]

- Lin, Y.-H. Using K-Means Clustering and Parameter Weighting for Partial-Discharge Noise Suppression. IEEE Trans. Power Deliv. 2011, 26, 2380–2390. [Google Scholar] [CrossRef]

- Li, L.; Tang, J.; Liu, Y. Partial Discharge Recognition in Gas Insulated Switchgear Based on Multi-Information Fusion. IEEE Trans. Dielect. Electr. Insul. 2015, 22, 1080–1087. [Google Scholar] [CrossRef]

- Si, W.; Li, J.; Li, D.; Yang, J.; Li, Y. Investigation of a Comprehensive Identification Method Used in Acoustic Detection System for GIS. IEEE Trans. Dielect. Electr. Insul. 2010, 17, 721–732. [Google Scholar] [CrossRef]

- Chang, C.S.; Jin, J.; Chang, C.; Hoshino, T.; Hanai, M.; Kobayashi, N. Separation of Corona Using Wavelet Packet Transform and Neural Network for Detection of Partial Discharge in Gas-Insulated Substations. IEEE Trans. Power Deliv. 2005, 20, 1363–1369. [Google Scholar] [CrossRef]

- Nguyen, M.-T.; Nguyen, V.-H.; Yun, S.-J.; Kim, Y.-H. Recurrent Neural Network for Partial Discharge Diagnosis in Gas-Insulated Switchgear. Energies 2018, 11, 1202. [Google Scholar] [CrossRef]

- Song, H.; Dai, J.; Sheng, G.; Jiang, X. GIS Partial Discharge Pattern Recognition via Deep Convolutional Neural Network under Complex Data Source. IEEE Trans. Dielect. Electr. Insul. 2018, 25, 678–685. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016; ISBN 978-0-262-33737-3. [Google Scholar]

- Mantach, S.; Lutfi, A.; Moradi Tavasani, H.; Ashraf, A.; El-Hag, A.; Kordi, B. Deep Learning in High Voltage Engineering: A Literature Review. Energies 2022, 15, 5005. [Google Scholar] [CrossRef]

- Ardila-Rey, J.A.; Ortiz, J.E.; Creixell, W.; Muhammad-Sukki, F.; Bani, N.A. Artificial Generation of Partial Discharge Sources Through an Algorithm Based on Deep Convolutional Generative Adversarial Networks. IEEE Access 2020, 8, 24561–24575. [Google Scholar] [CrossRef]

- Hoffmann, M.W.; Wildermuth, S.; Gitzel, R.; Boyaci, A.; Gebhardt, J.; Kaul, H.; Amihai, I.; Forg, B.; Suriyah, M.; Leibfried, T.; et al. Integration of Novel Sensors and Machine Learning for Predictive Maintenance in Medium Voltage Switchgear to Enable the Energy and Mobility Revolutions. Sensors 2020, 20, 2099. [Google Scholar] [CrossRef]

- Gitzel, R.; Amihai, I.; Garcia Perez, M.S. Towards Robust ML-Algorithms for the Condition Monitoring of Switchgear. In Proceedings of the 2019 First International Conference on Societal Automation (SA), Krakow, Poland, 4–6 September 2019; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2019; pp. 1–4. [Google Scholar]

- IEEE SA—IEEE C37.111-1991. Available online: https://standards.ieee.org/ieee/C37.111/2644/ (accessed on 5 October 2022).

- Hong, J.; Kim, Y.-H.; Nhung-Nguyen, H.; Kwon, J.; Lee, H. Deep-Learning Based Fault Events Analysis in Power Systems. Energies 2022, 15, 5539. [Google Scholar] [CrossRef]

- Bhatt, A.; Karthikeyan, V. Digital Twin Framework and Its Application for Protection Functions Testing of Relays. In Proceedings of the 2022 3rd International Conference on Electronics and Sustainable Communication Systems (ICESC), Coimbatore, India, 17–19 August 2022; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2022; pp. 682–687. [Google Scholar]

- Miao, W.; Lingen, L.; Yong, Q.; Hui, S.; Gehao, S. Partial Discharge Inversion Localization Method for GIS Based on Twin Database. In Proceedings of the 2022 7th Asia Conference on Power and Electrical Engineering (ACPEE), Hangzhou, China, 15–17 April 2022; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2022; pp. 2183–2187. [Google Scholar]

- He, X.; Ai, Q.; Pan, B.; Tang, L.; Qiu, R. Spatial-Temporal Data Analysis of Digital Twin. Digit. Twin 2022, 2, 7. [Google Scholar] [CrossRef]

| Description | Reference |

|---|---|

| Support Vector Machine (SVM) trained with infrared imagery of substations for equipment monitoring | [56] |

| Enhancing IR images of rotating machinery and feeding features into SVM and Feed Forward Neural Networks (FFNN) to effectively improve fault diagnosis | [57] |

| Deep learning-based component recognition in a switchgear overheating fault diagnostic | [58] |

| PD type identification technology based on deep learning method with a comparison of recognition methods using Convolutional Neural Network (CNN) and Back Propagation Neural Network (BPNN) | [59] |

| K-Means method to detect partial discharges in equipment | [60,61] |

| NN and SVM to detect partial discharges in equipment | [62] |

| NN to detect partial discharge in equipment | [63,64] |

| Recurrent Neural Network (RNN) to diagnose PD in gas-insulated switchgear | [65] |

| Deep Convolutional Neural Network (DCNN) to detect PD patterns in gas-insulated switchgear | [66] |

| Reference | Proposed Method | Compared to | Result |

|---|---|---|---|

| [66] | Deep convolutional neural network (DCNN) for PD recognition | Back propagation neural network (BPNN) and support vector machine (SVM) | DCNN has outperformed both BPNN and SVM with 89.7% accuracy |

| [59] | Residual neural network (ResNet) for PD recognition | BPNN | ResNet outperformed BPNN with 95.83% accuracy (with increased network depth) |

| [65] | Long short-term memory (LSTM) recurrent neural network (RNN) for PD detection | SVM | LSTM RNN outperformed SVM with 96.74% accuracy |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaštelan, N.; Vujović, I.; Krčum, M.; Assani, N. Switchgear Digitalization—Research Path, Status, and Future Work. Sensors 2022, 22, 7922. https://doi.org/10.3390/s22207922

Kaštelan N, Vujović I, Krčum M, Assani N. Switchgear Digitalization—Research Path, Status, and Future Work. Sensors. 2022; 22(20):7922. https://doi.org/10.3390/s22207922

Chicago/Turabian StyleKaštelan, Nediljko, Igor Vujović, Maja Krčum, and Nur Assani. 2022. "Switchgear Digitalization—Research Path, Status, and Future Work" Sensors 22, no. 20: 7922. https://doi.org/10.3390/s22207922

APA StyleKaštelan, N., Vujović, I., Krčum, M., & Assani, N. (2022). Switchgear Digitalization—Research Path, Status, and Future Work. Sensors, 22(20), 7922. https://doi.org/10.3390/s22207922