State of Health Estimation Based on the Long Short-Term Memory Network Using Incremental Capacity and Transfer Learning

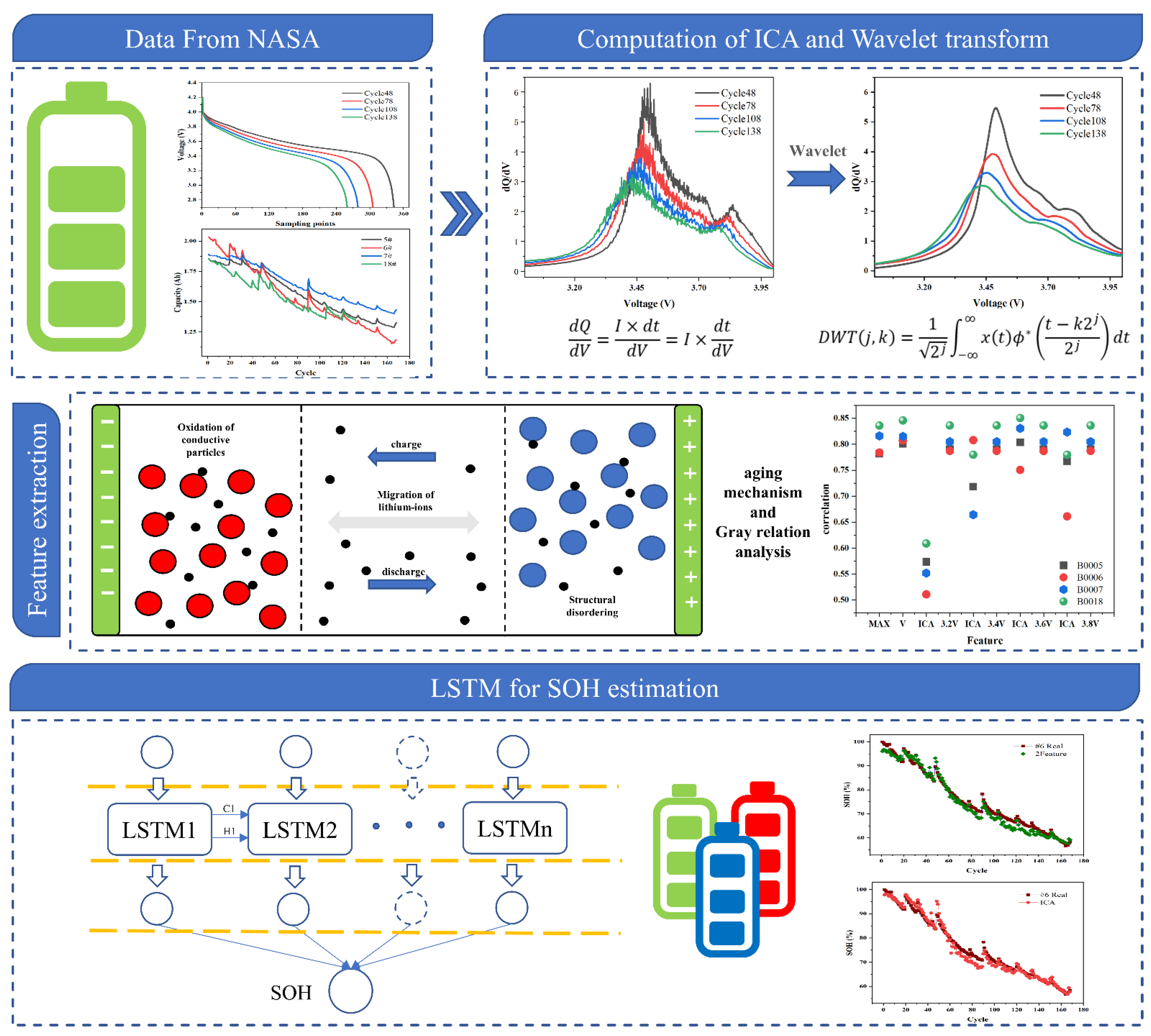

Abstract

1. Introduction

2. Data Preprocessing

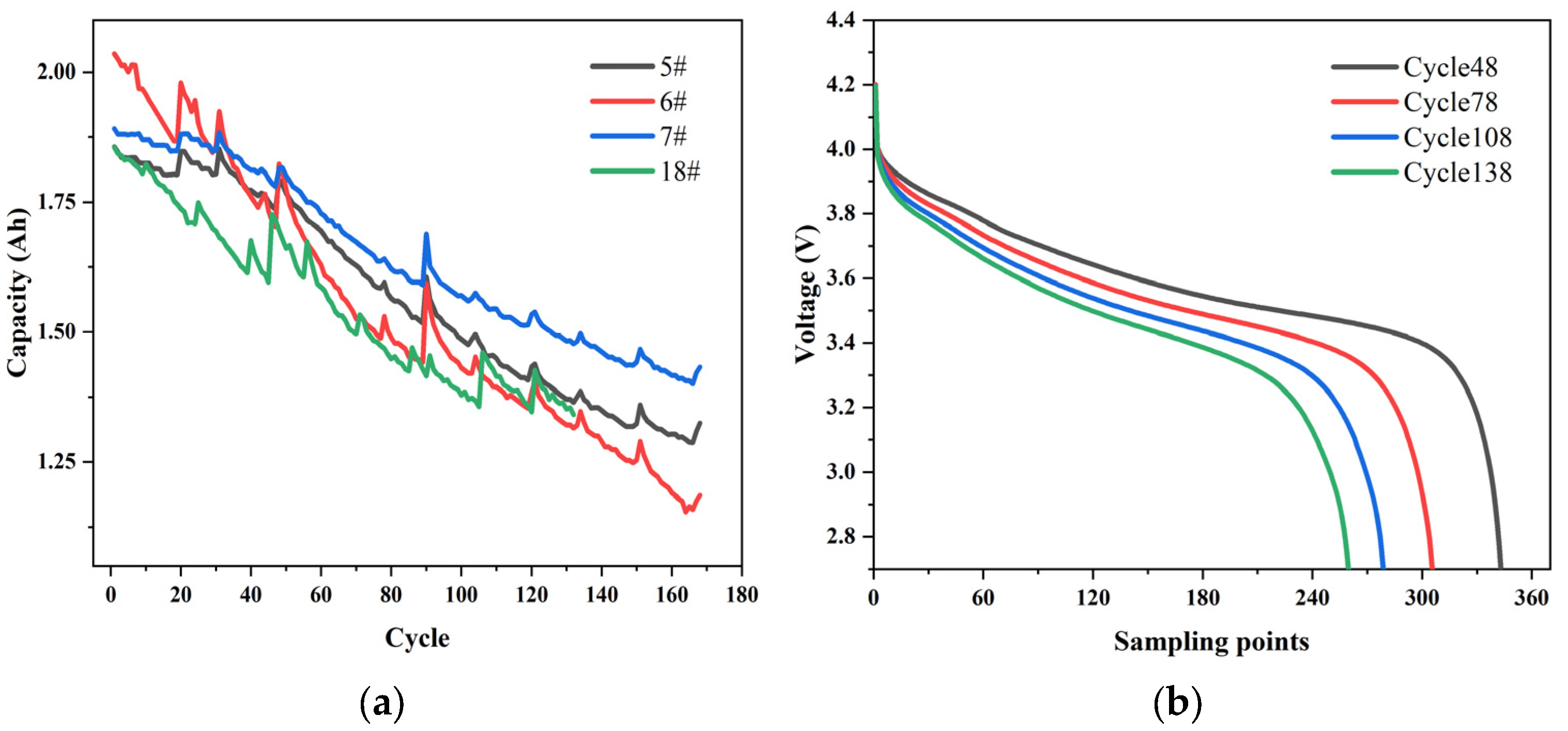

2.1. Data Acquisition

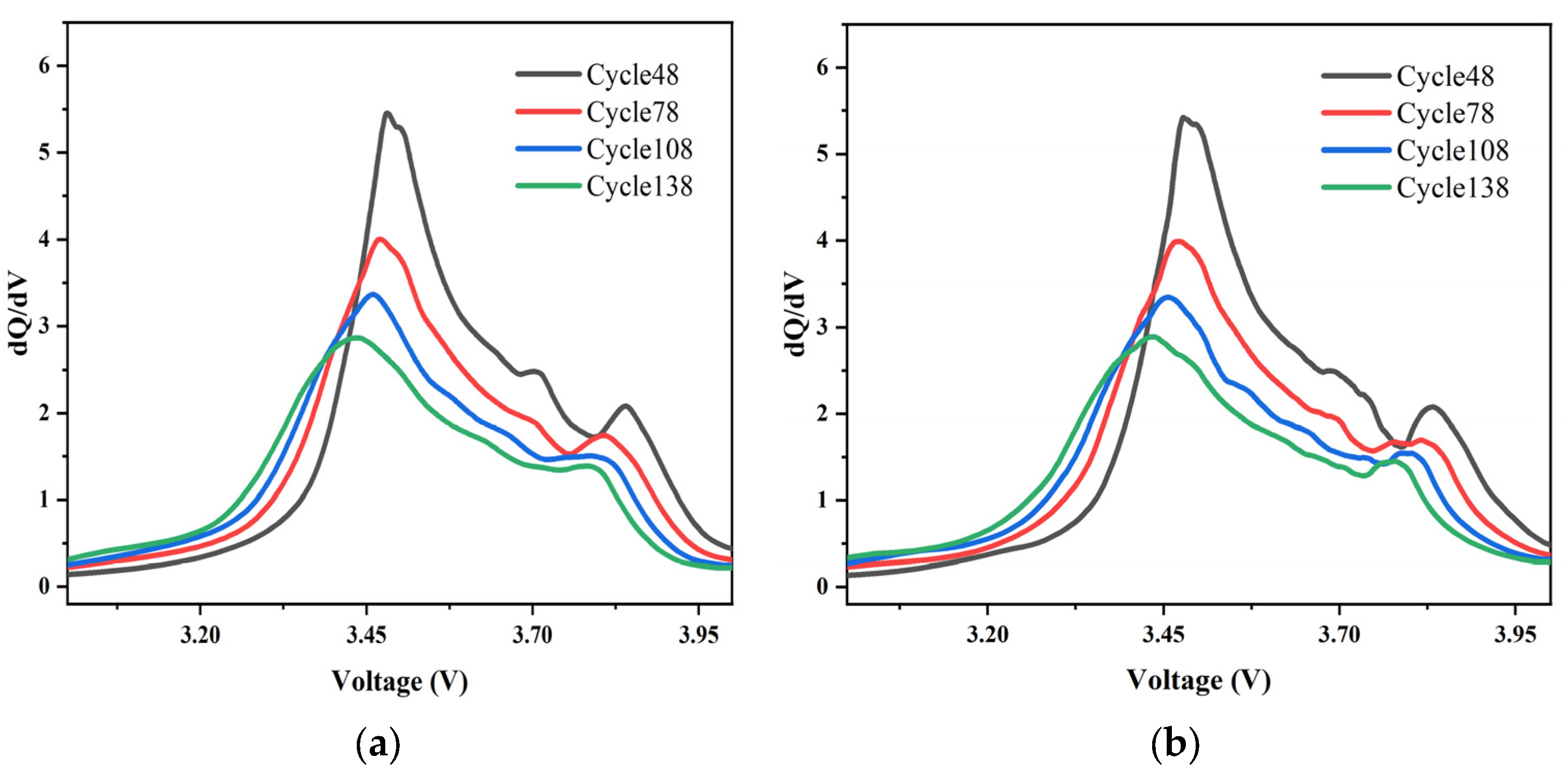

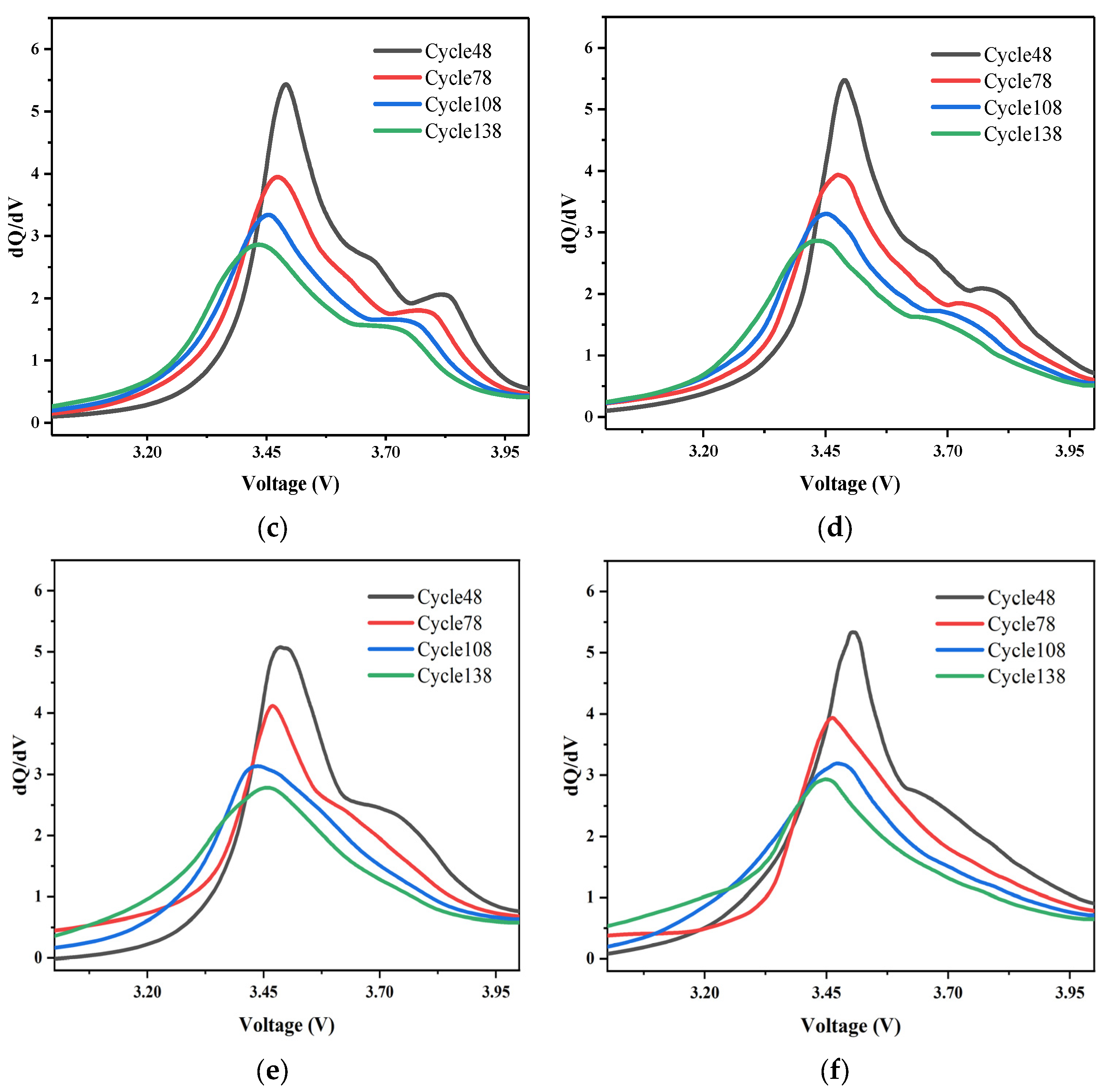

2.2. Increment Capacity Curve Analysis

3. Methodologies

3.1. Grey Relation Analysis

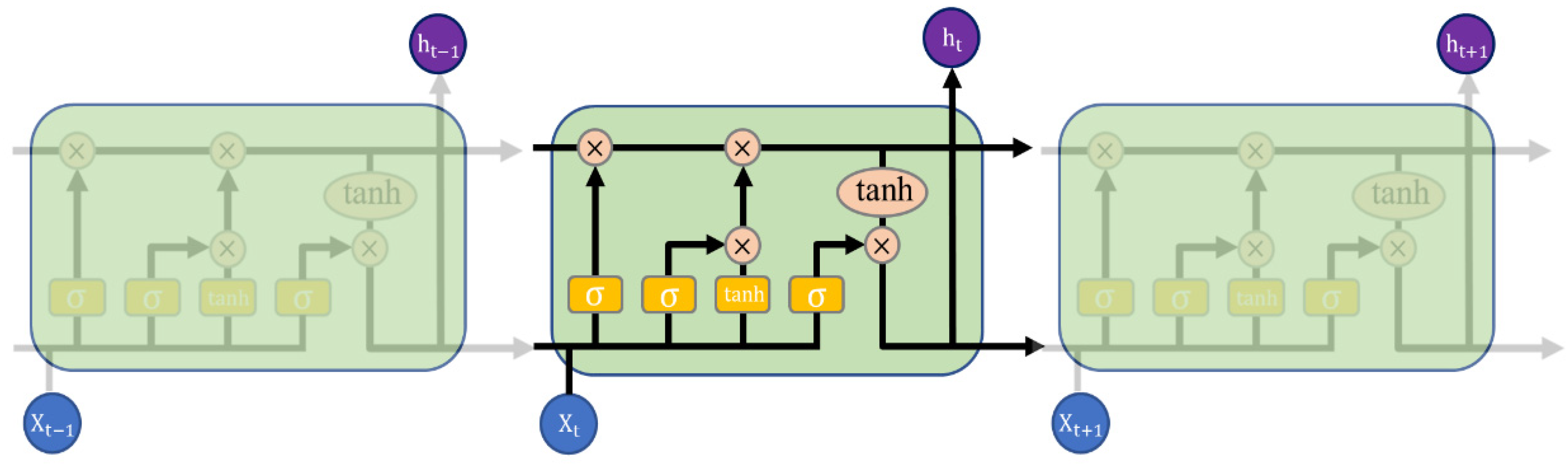

3.2. Long Short-Term Memory Modeling

4. Results and Discussion

4.1. Model Training Structure

4.2. Estimation Results of the Model

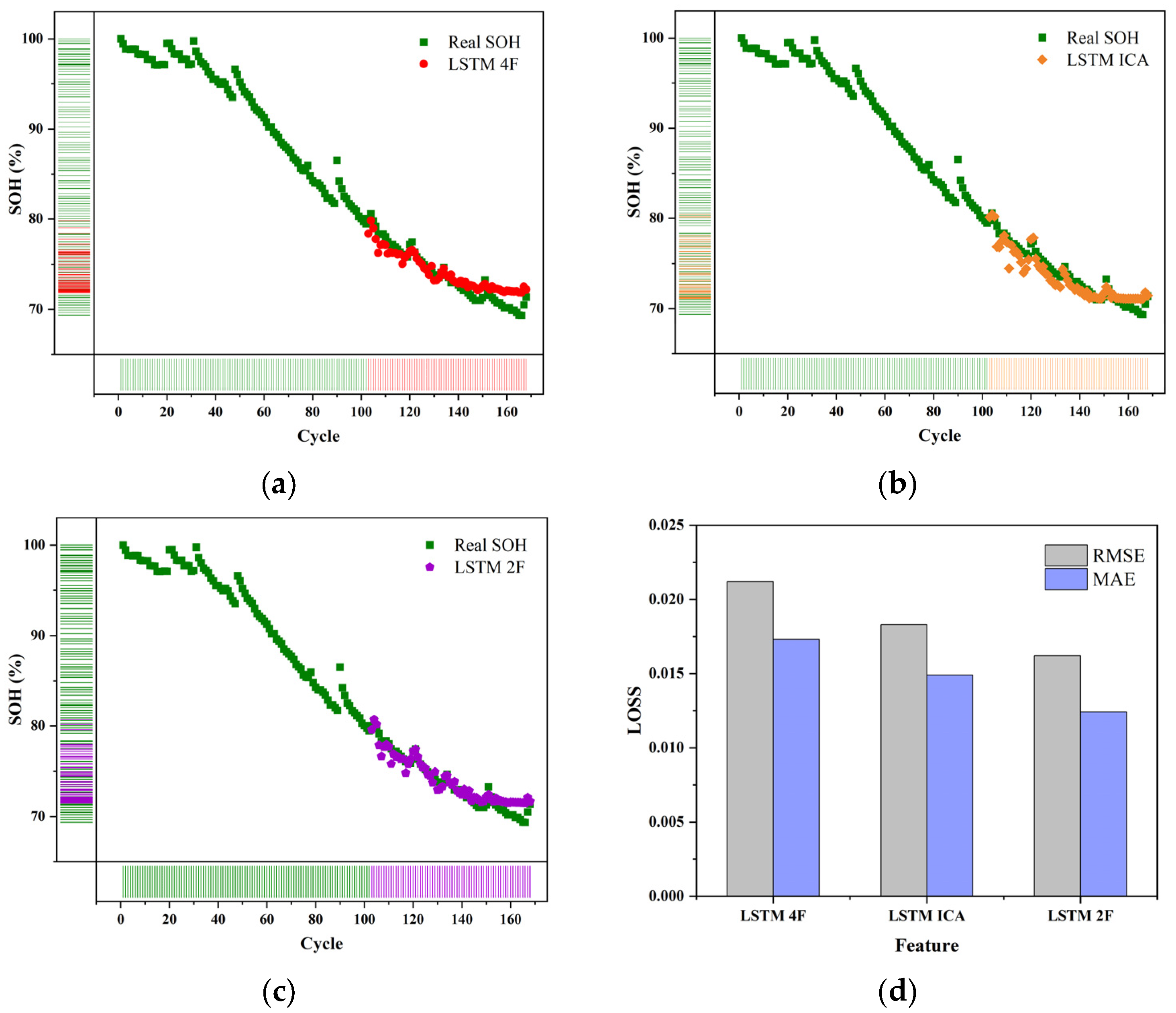

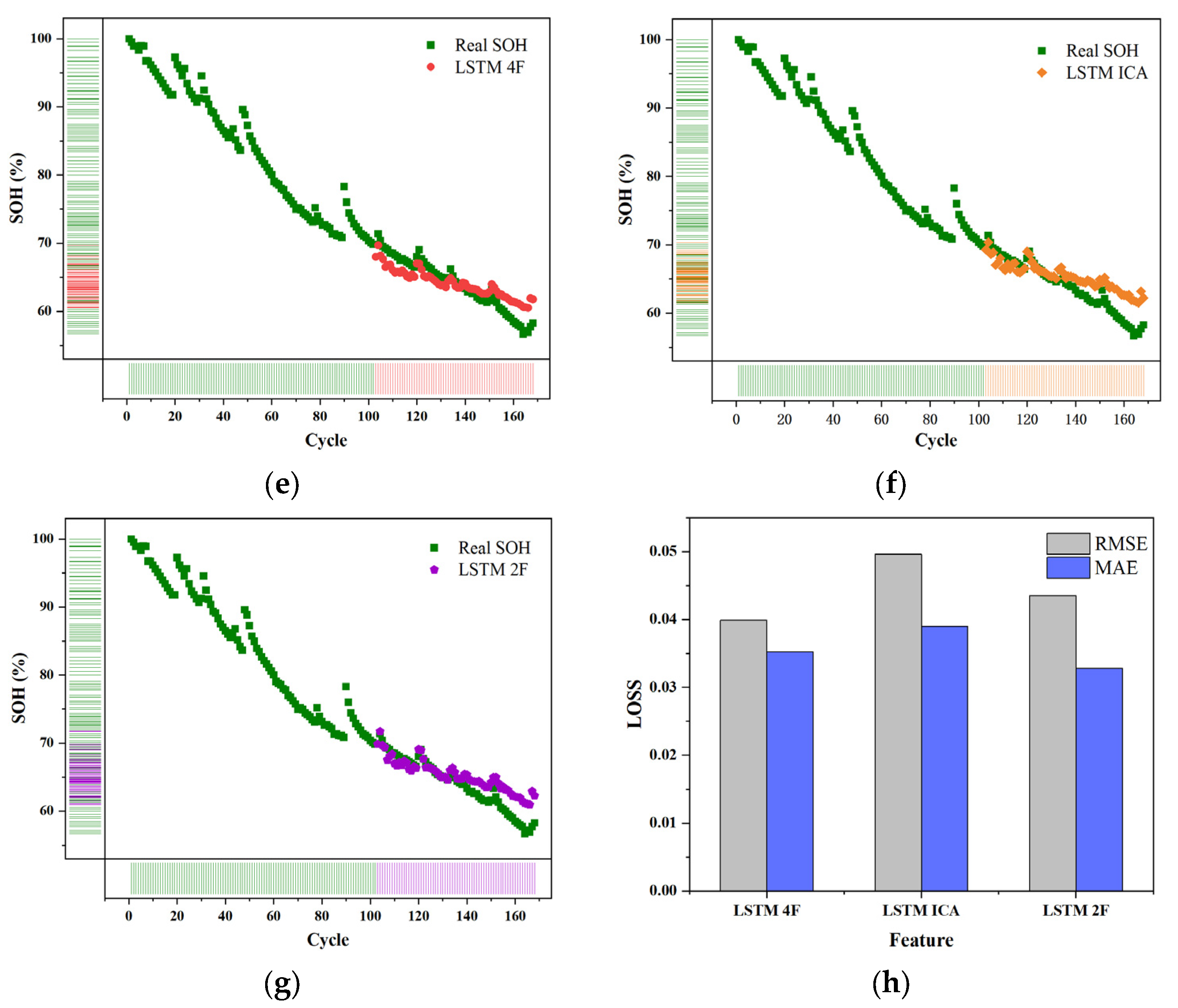

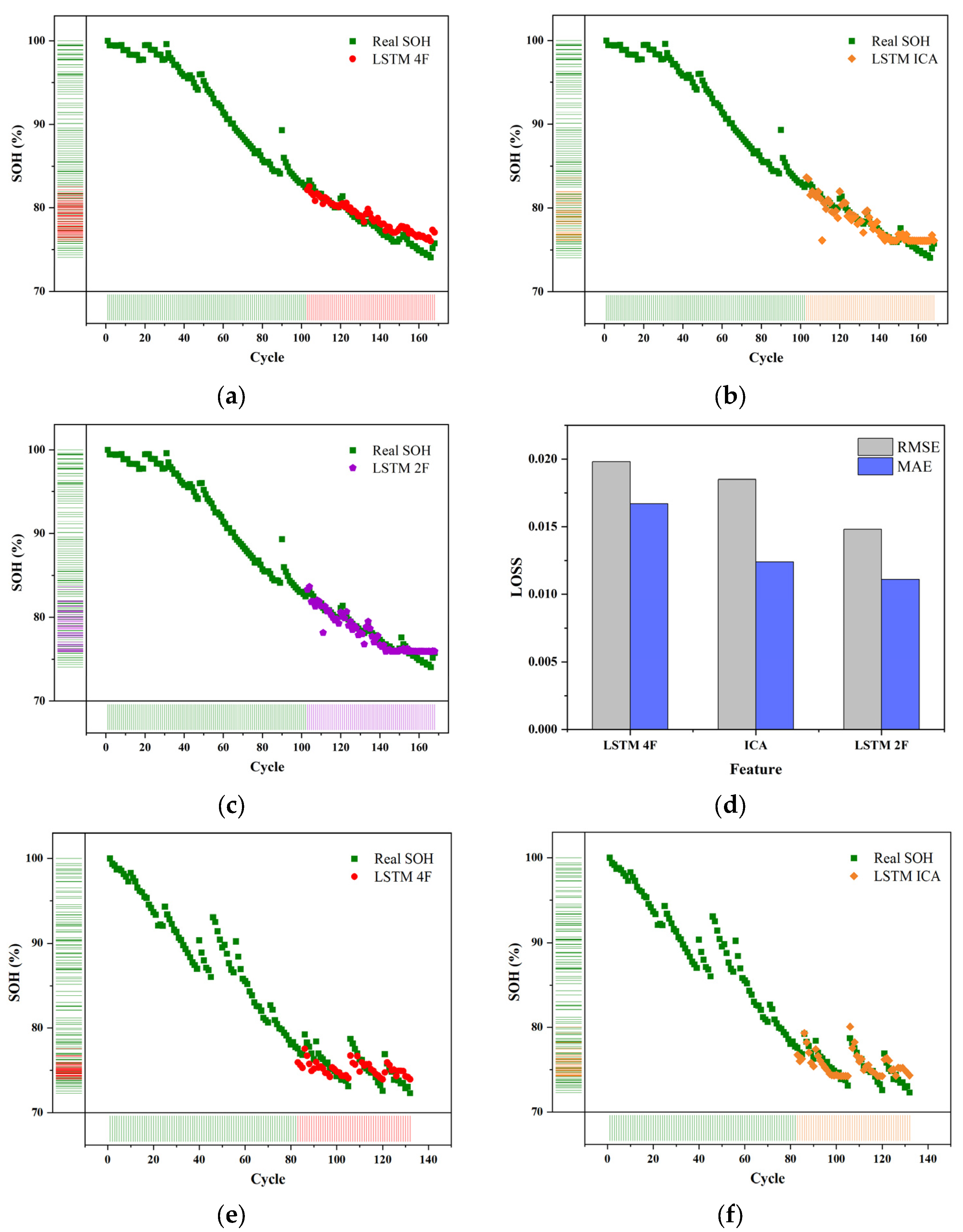

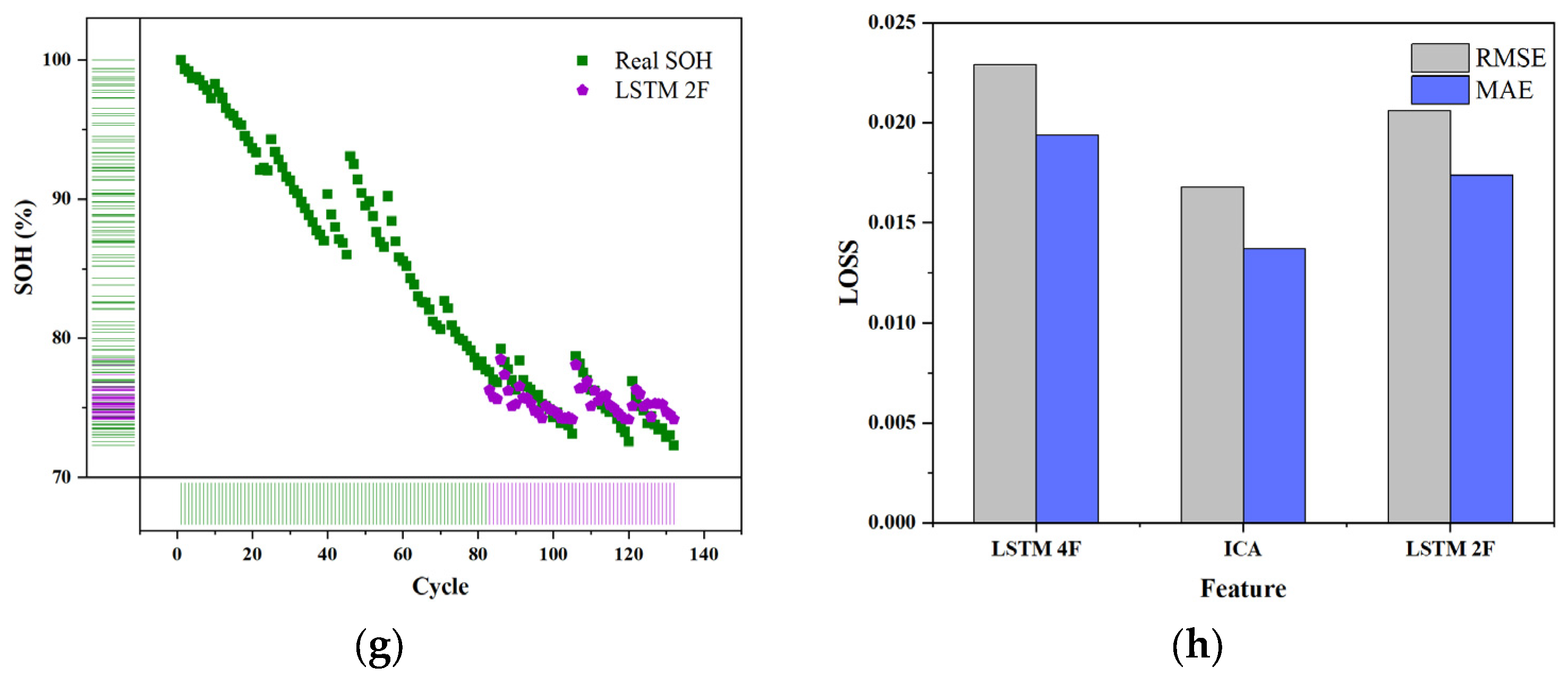

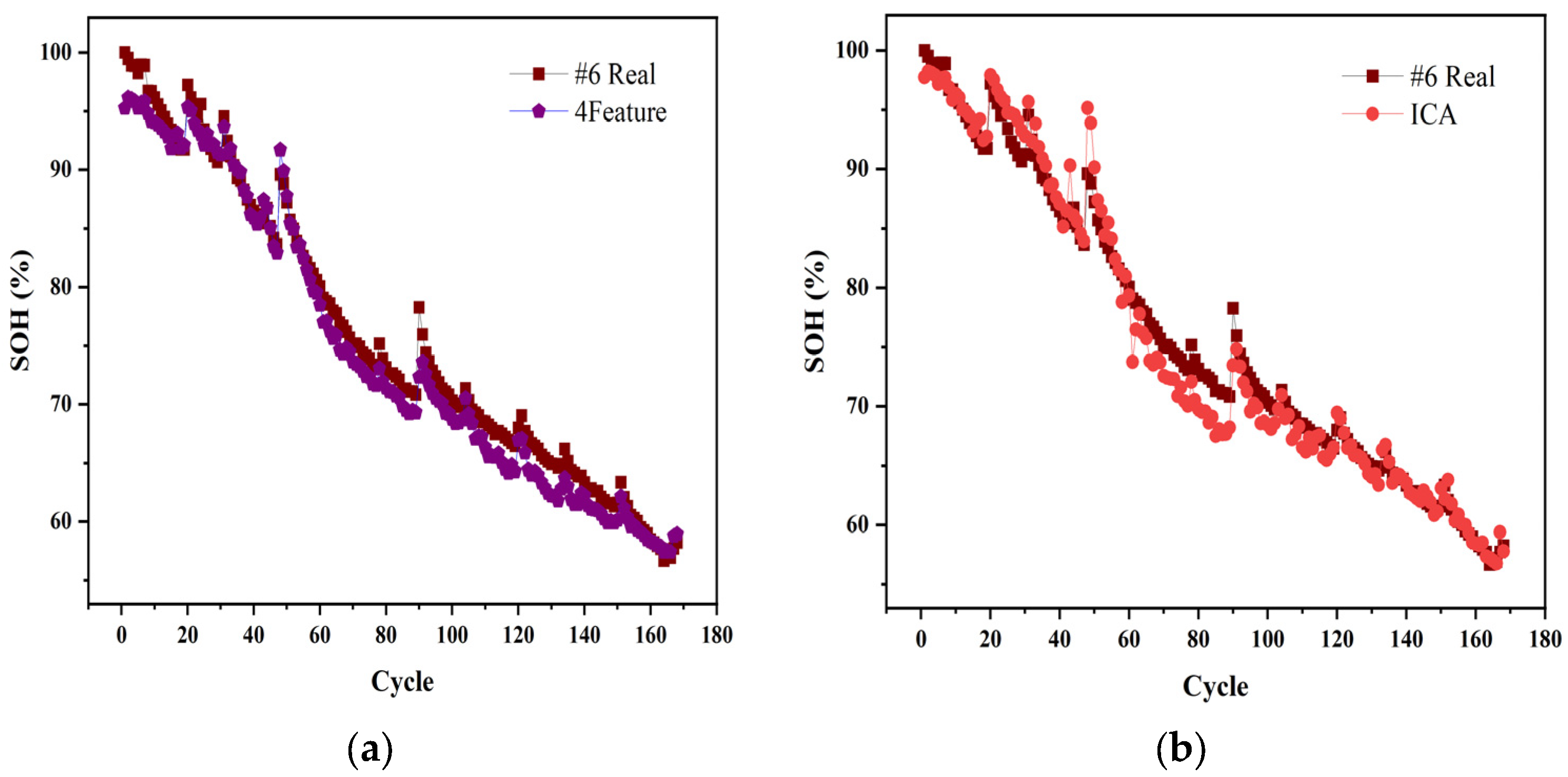

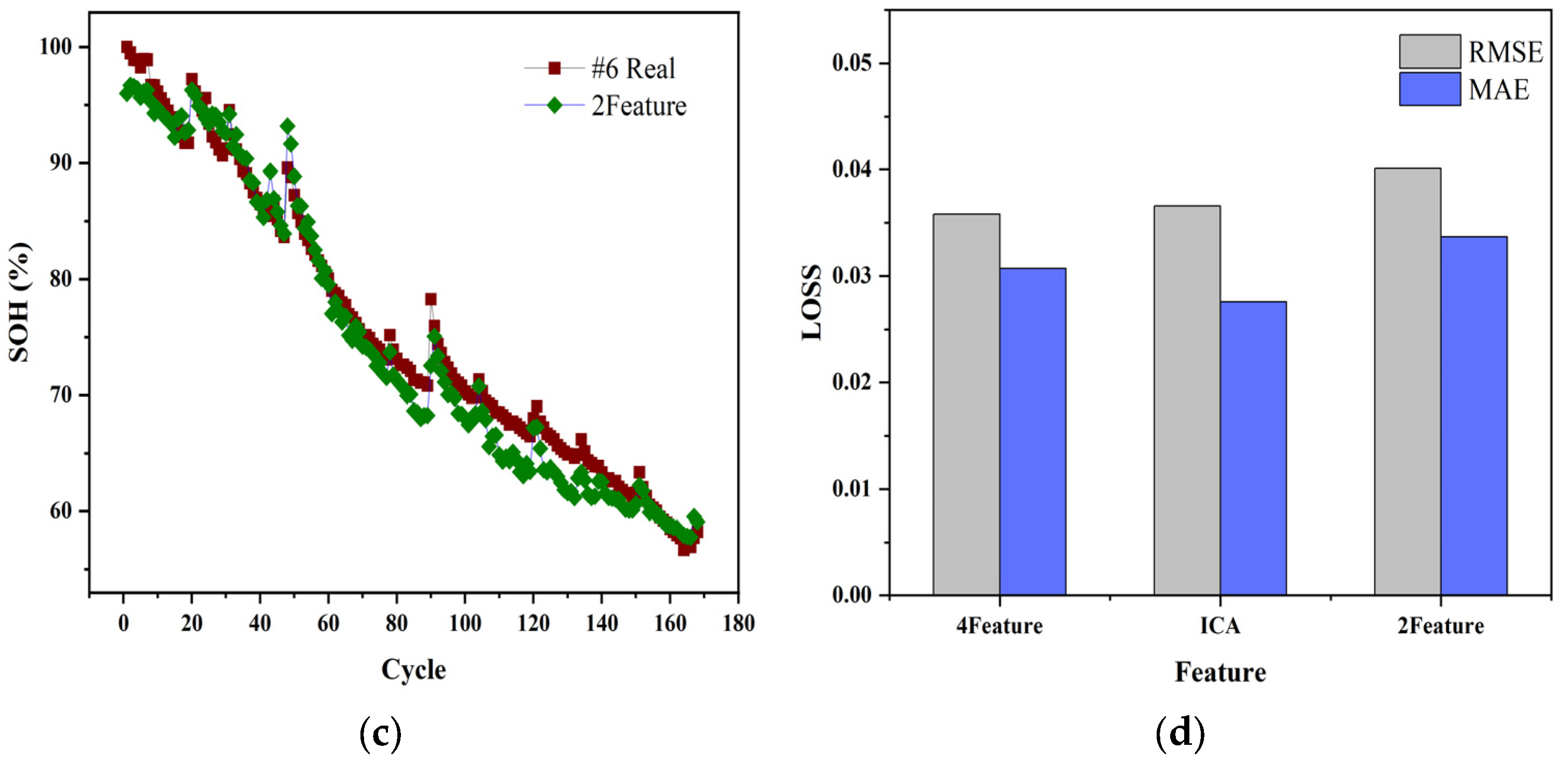

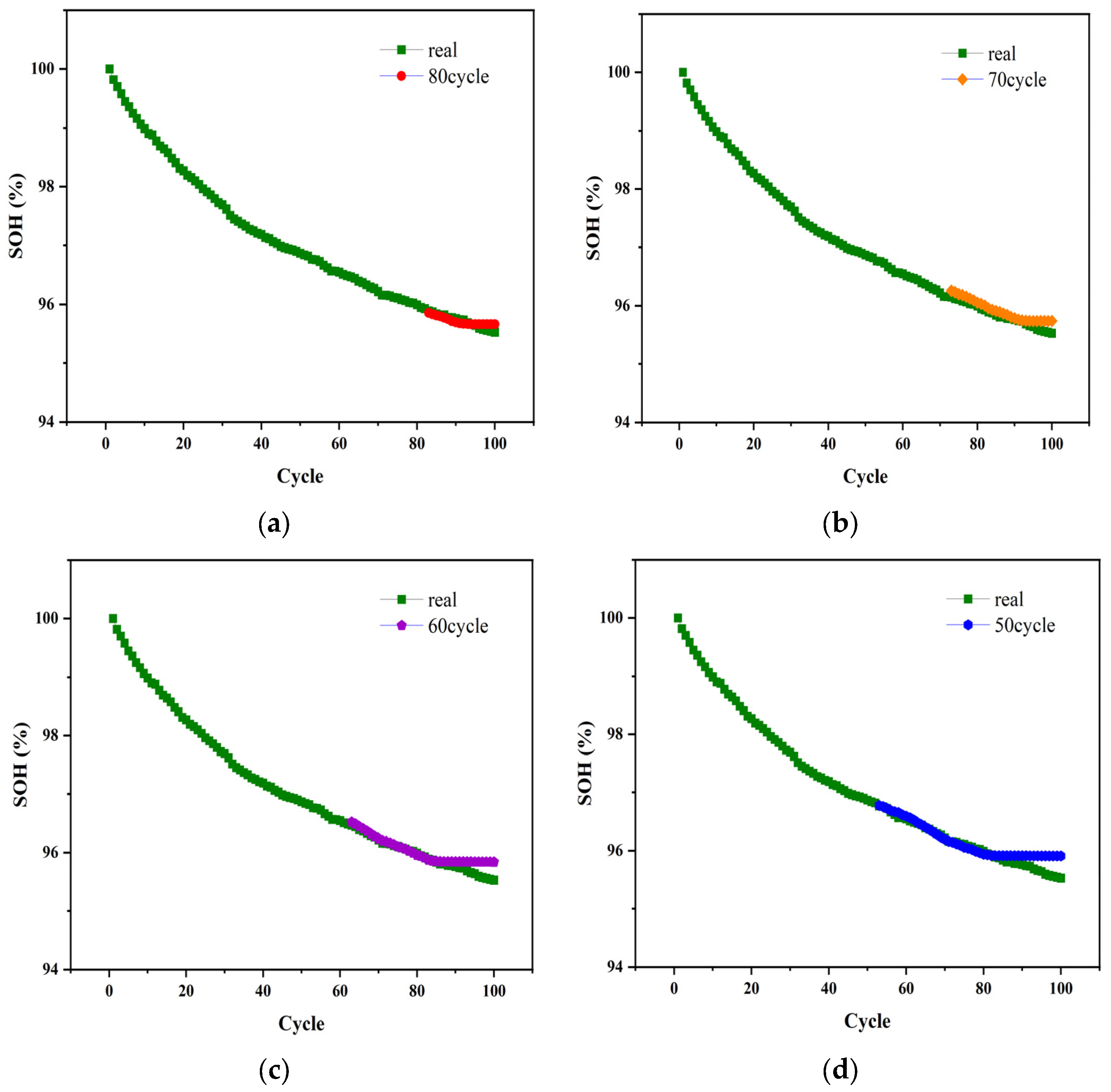

4.3. Estimation Results of the Model

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qin, P.; Sun, J.; Yang, X.; Wang, Q. Battery Thermal Management System Based on the Forced-Air Convection: A Review. eTransportation 2021, 7, 100097. [Google Scholar] [CrossRef]

- Lai, X.; Chen, Q.; Tang, X.; Zhou, Y.; Gao, F.; Guo, Y.; Bhagat, R.; Zheng, Y. Critical Review of Life Cycle Assessment of Lithium-Ion Batteries for Electric Vehicles: A Lifespan Perspective. eTransportation 2022, 12, 100169. [Google Scholar] [CrossRef]

- Shang, Y.; Lu, G.; Kang, Y.; Zhou, Z.; Duan, B.; Zhang, C. A Multi-Fault Diagnosis Method Based on Modified Sample Entropy for Lithium-Ion Battery Strings. J. Power Sources 2020, 446, 227275. [Google Scholar] [CrossRef]

- Cacciato, M.; Nobile, G.; Scarcella, G.; Scelba, G. Real-Time Model-Based Estimation of SOC and SOH for Energy Storage Systems. IEEE Trans. Power Electron. 2017, 32, 794–803. [Google Scholar] [CrossRef]

- Mahmoudzadeh Andwari, A.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A Review of Battery Electric Vehicle Technology and Readiness Levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Song, Z.; Yang, X.-G.; Yang, N.; Delgado, F.P.; Hofmann, H.; Sun, J. A Study of Cell-to-Cell Variation of Capacity in Parallel-Connected Lithium-Ion Battery Cells. eTransportation 2021, 7, 100091. [Google Scholar] [CrossRef]

- Kim, T.; Qiao, W.; Qu, L. Hysteresis Modeling for Model-Based Condition Monitoring of Lithium-Ion Batteries. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; pp. 5068–5073. [Google Scholar]

- Chen, J.-L.; Wang, R.-X. A Modified Model-Based Resistance Estimation of Lithium-Ion Batteries Using Unscented Kalman Filter. In Wireless and Satellite Systems; Jia, M., Guo, Q., Meng, W., Eds.; Lecture Notes of the Institute for Computer Sciences, Social Informatics and Telecommunications Engineering; Springer International Publishing: Cham, Switzerland, 2019; Volume 280, pp. 25–40. ISBN 978-3-030-19152-8. [Google Scholar]

- Lipu, M.S.H.; Hannan, M.A.; Hussain, A.; Hoque, M.M.; Ker, P.J.; Saad, M.H.M.; Ayob, A. A Review of State of Health and Remaining Useful Life Estimation Methods for Lithium-Ion Battery in Electric Vehicles: Challenges and Recommendations. J. Clean. Prod. 2018, 205, 115–133. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, J.; Chen, Z.; Liu, X. Model Based Insulation Fault Diagnosis for Lithium-Ion Battery Pack in Electric Vehicles. Measurement 2019, 131, 443–451. [Google Scholar] [CrossRef]

- Galeotti, M.; Cinà, L.; Giammanco, C.; Cordiner, S.; Di Carlo, A. Performance Analysis and SOH (State of Health) Evaluation of Lithium Polymer Batteries through Electrochemical Impedance Spectroscopy. Energy 2015, 89, 678–686. [Google Scholar] [CrossRef]

- Plett, G. Extended Kalman Filtering for Battery Management Systems of LiPB-Based HEV Battery PacksPart 1. Background. J. Power Sources 2004, 134, 252–261. [Google Scholar] [CrossRef]

- Yang, K.; Chen, Z.; He, Z.; Wang, Y.; Zhou, Z. Online Estimation of State of Health for the Airborne Li-Ion Battery Using Adaptive DEKF-Based Fuzzy Inference System. Soft Comput. 2020, 24, 18661–18670. [Google Scholar] [CrossRef]

- Yao, L.; Xu, S.; Xiao, Y.; Hou, J.; Gong, X.; Fu, Z.; Tang, A. Fault Identification of Lithium-Ion Battery Pack for Electric Vehicle Based on GA Optimized ELM Neural Network. IEEE Access 2022, 10, 15007–15022. [Google Scholar] [CrossRef]

- Pan, H.; Chen, C.; Gu, M. A State of Health Estimation Method for Lithium-Ion Batteries Based on Improved Particle Filter Considering Capacity Regeneration. Energies 2021, 14, 5000. [Google Scholar] [CrossRef]

- Liu, H.W.; Xu, W.J.; Guo, C. Study on State of Health Estimation Algorithm for Lithium Power Battery Used on Pure Electric Vehicle. Adv. Mater. Res. 2012, 608–609, 1577–1581. [Google Scholar] [CrossRef]

- Xiong, W.; Mo, Y.; Yan, C. Online State-of-Health Estimation for Second-Use Lithium-Ion Batteries Based on Weighted Least Squares Support Vector Machine. IEEE Access 2021, 9, 1870–1881. [Google Scholar] [CrossRef]

- Kim, J.; Chun, H.; Kim, M.; Yu, J.; Kim, K.; Kim, T.; Han, S. Data-Driven State of Health Estimation of Li-Ion Batteries with RPT-Reduced Experimental Data. IEEE Access 2019, 7, 106987–106997. [Google Scholar] [CrossRef]

- Gou, B.; Xu, Y.; Feng, X. An Ensemble Learning-Based Data-Driven Method for Online State-of-Health Estimation of Lithium-Ion Batteries. IEEE Trans. Transp. Electrif. 2021, 7, 422–436. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, M.; Shu, X.; Shen, J.; Xiao, R. On-Board State of Health Estimation for Lithium-Ion Batteries Based on Random Forest. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 20–22 February 2018; pp. 1754–1759. [Google Scholar]

- Liu, D.; Pang, J.; Zhou, J.; Peng, Y.; Pecht, M. Prognostics for State of Health Estimation of Lithium-Ion Batteries Based on Combination Gaussian Process Functional Regression. Microelectron. Reliab. 2013, 53, 832–839. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Saad, M.H.; Ayob, A. Neural Network Approach for Estimating State of Charge of Lithium-Ion Battery Using Backtracking Search Algorithm. IEEE Access 2018, 6, 10069–10079. [Google Scholar] [CrossRef]

- Wang, D.; Miao, Q.; Pecht, M. Prognostics of Lithium-Ion Batteries Based on Relevance Vectors and a Conditional Three-Parameter Capacity Degradation Model. J. Power Sources 2013, 239, 253–264. [Google Scholar] [CrossRef]

- Li, R.; Li, W.; Zhang, H.; Zhou, Y.; Tian, W. On-Line Estimation Method of Lithium-Ion Battery Health Status Based on PSO-SVM. Front. Energy Res. 2021, 9, 693249. [Google Scholar] [CrossRef]

- Zhang, S.; Zhai, B.; Guo, X.; Wang, K.; Peng, N.; Zhang, X. Synchronous Estimation of State of Health and Remaining Useful Lifetime for Lithium-Ion Battery Using the Incremental Capacity and Artificial Neural Networks. J. Energy Storage 2019, 26, 100951. [Google Scholar] [CrossRef]

- Bo, C.; Zhifeng, B.; Binggang, C. State of Charge Estimation Based on Evolutionary Neural Network. Energy Convers. Manag. 2008, 49, 2788–2794. [Google Scholar] [CrossRef]

- Kim, J.; Cho, B.H. An Innovative Approach for Characteristic Analysis and State-of-Health Diagnosis for a Li-Ion Cell Based on the Discrete Wavelet Transform. J. Power Sources 2014, 260, 115–130. [Google Scholar] [CrossRef]

- Dong, Y.; Fu, Z.; Peng, Y.; Zheng, Y.; Yan, H.; Li, X. Precision Fertilization Method of Field Crops Based on the Wavelet-BP Neural Network in China. J. Clean. Prod. 2020, 246, 118735. [Google Scholar] [CrossRef]

- Wang, Y.; Pan, R.; Yang, D.; Tang, X.; Chen, Z. Remaining Useful Life Prediction of Lithium-Ion Battery Based on Discrete Wavelet Transform. Energy Procedia 2017, 105, 2053–2058. [Google Scholar] [CrossRef]

- Jianfang, J.; Keke, W.; Xiaoqiong, P.; Yuanhao, S.; Jie, W.; Jianchao, Z. Multi-Scale Prediction of RUL and SOH for Lithium-Ion Batteries Based on WNN-UPF Combined Model. Chin. J. Electron. 2021, 30, 26–35. [Google Scholar] [CrossRef]

- Sui, X.; He, S.; Vilsen, S.B.; Meng, J.; Teodorescu, R.; Stroe, D.-I. A Review of Non-Probabilistic Machine Learning-Based State of Health Estimation Techniques for Lithium-Ion Battery. Appl. Energy 2021, 300, 117346. [Google Scholar] [CrossRef]

- Khumprom, P.; Yodo, N. A Data-Driven Predictive Prognostic Model for Lithium-Ion Batteries Based on a Deep Learning Algorithm. Energies 2019, 12, 660. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.; Li, X. Deep Learning-Based Prognostic Approach for Lithium-Ion Batteries with Adaptive Time-Series Prediction and on-Line Validation. Measurement 2020, 164, 108052. [Google Scholar] [CrossRef]

- Chemali, E.; Kollmeyer, P.J.; Preindl, M.; Fahmy, Y.; Emadi, A. A Convolutional Neural Network Approach for Estimation of Li-Ion Battery State of Health from Charge Profiles. Energies 2022, 15, 1185. [Google Scholar] [CrossRef]

- Jiang, H.; Qin, F.; Cao, J.; Peng, Y.; Shao, Y. Recurrent Neural Network from Adder’s Perspective: Carry-Lookahead RNN. Neural Netw. 2021, 144, 297–306. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Kang, M.; Jeong, H.; Baek, J. State of Health Estimation for Lithium-Ion Batteries Using Long-Term Recurrent Convolutional Network. In Proceedings of the IECON 2020 The 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; pp. 1929–1934. [Google Scholar]

- Su, L.; Wu, M.; Li, Z.; Zhang, J. Cycle Life Prediction of Lithium-Ion Batteries Based on Data-Driven Methods. eTransportation 2021, 10, 100137. [Google Scholar] [CrossRef]

- Fan, Y.; Xiao, F.; Li, C.; Yang, G.; Tang, X. A Novel Deep Learning Framework for State of Health Estimation of Lithium-Ion Battery. J. Energy Storage 2020, 32, 101741. [Google Scholar] [CrossRef]

- Mou, L.; Ghamisi, P.; Zhu, X.X. Deep Recurrent Neural Networks for Hyperspectral Image Classification. IEEE Trans. Geosci. Remote Sens. 2017, 55, 3639–3655. [Google Scholar] [CrossRef]

- Tian, J.; Xiong, R.; Shen, W. A Review on State of Health Estimation for Lithium Ion Batteries in Photovoltaic Systems. eTransportation 2019, 2, 100028. [Google Scholar] [CrossRef]

- Deng, Z.; Lin, X.; Cai, J.; Hu, X. Battery Health Estimation with Degradation Pattern Recognition and Transfer Learning. J. Power Sources 2022, 525, 231027. [Google Scholar] [CrossRef]

| Battery Number | Discharge Current | Voltage Upper | Voltage Lower |

|---|---|---|---|

| B0005 | 2 A | 4.2 V | 2.7 V |

| B0006 | 2 A | 4.2 V | 2.5 V |

| B0007 | 2 A | 4.2 V | 2.2 V |

| B0018 | 2 A | 4.2 V | 2.2 V |

| Battery Number | Grey Relation Coefficient | |||||

|---|---|---|---|---|---|---|

| F1 | F2 | F3 | F4 | F5 | F6 | |

| 5# | 0.7815 | 0.8009 | 0.5735 | 0.7184 | 0.8036 | 0.7674 |

| 6# | 0.7842 | 0.8074 | 0.5109 | 0.8081 | 0.7506 | 0.6611 |

| 7# | 0.8161 | 0.8151 | 0.5519 | 0.6642 | 0.8308 | 0.8235 |

| 18# | 0.8361 | 0.8459 | 0.6090 | 0.7801 | 0.8506 | 0.7799 |

| Parameters | Value |

|---|---|

| Number of units in the LSTM 1 | 75 |

| Number of units in the LSTM 2 | 80 |

| Dense | 25 |

| Dropout | 0.5 |

| Dense | 1 |

| B0005 | B0006 | |||||

|---|---|---|---|---|---|---|

| LSTM 4F | LSTM ICA | LSTM 2F | LSTM 4F | LSTM ICA | LSTM 2F | |

| RMSE | 0.0212 | 0.0183 | 0.0162 | 0.0399 | 0.0496 | 0.0435 |

| MAE | 0.0173 | 0.0149 | 0.0124 | 0.0352 | 0.0390 | 0.0328 |

| B0007 | B00018 | |||||

|---|---|---|---|---|---|---|

| LSTM 4F | LSTM ICA | LSTM 2F | LSTM 4F | LSTM ICA | LSTM 2F | |

| RMSE | 0.0198 | 0.0185 | 0.0148 | 0.0229 | 0.0168 | 0.0206 |

| MAE | 0.0167 | 0.0124 | 0.0111 | 0.0194 | 0.0137 | 0.0174 |

| Train Scale (%) | RMSE | MAE |

|---|---|---|

| 80 | 0.0174 | 0.0146 |

| 70 | 0.0269 | 0.0236 |

| 60 | 0.0319 | 0.0208 |

| 50 | 0.0381 | 0.0248 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, L.; Wen, J.; Xu, S.; Zheng, J.; Hou, J.; Fang, Z.; Xiao, Y. State of Health Estimation Based on the Long Short-Term Memory Network Using Incremental Capacity and Transfer Learning. Sensors 2022, 22, 7835. https://doi.org/10.3390/s22207835

Yao L, Wen J, Xu S, Zheng J, Hou J, Fang Z, Xiao Y. State of Health Estimation Based on the Long Short-Term Memory Network Using Incremental Capacity and Transfer Learning. Sensors. 2022; 22(20):7835. https://doi.org/10.3390/s22207835

Chicago/Turabian StyleYao, Lei, Jishu Wen, Shiming Xu, Jie Zheng, Junjian Hou, Zhanpeng Fang, and Yanqiu Xiao. 2022. "State of Health Estimation Based on the Long Short-Term Memory Network Using Incremental Capacity and Transfer Learning" Sensors 22, no. 20: 7835. https://doi.org/10.3390/s22207835

APA StyleYao, L., Wen, J., Xu, S., Zheng, J., Hou, J., Fang, Z., & Xiao, Y. (2022). State of Health Estimation Based on the Long Short-Term Memory Network Using Incremental Capacity and Transfer Learning. Sensors, 22(20), 7835. https://doi.org/10.3390/s22207835