1. Introduction

Highly flexible and stretchable next-generation wearable devices are anticipated for applications in various fields, such as flexible robotics, displays, smart watches for healthcare, and functional clothing. Accordingly, it is appropriate to conduct in-depth research aimed at developing a high-sensitivity strain sensor that can operate with stability despite deformation, while in contact with human skin, in light of the increasing demand for body-mounted devices.

Studies on strain sensors that can convert mechanical strain, such as body movement, into electrical signals have been actively pursued [

1]. Novel electrodes and substitutes for typical metal or inorganic films have been studied to ensure conductivity and stretchability under strain, including metal nanowires [

2], conductive polymers [

3,

4], the carbon nanotube (CNT) [

5], graphene [

6], and composites of these devices.

In particular, polyaniline (PANI), one of the conductive polymers, has attracted attention as an appropriate substance, due to its environmental stability, cost-effectiveness, and tunable conductivity [

7], which provides scalability in a multi-functional strain sensor capable of sensing various stimuli, such as chemical gases, temperatures, and humidity [

8]. However, strain sensors made by spin-coating or printing PANI dispersed in a solvent are limited because it is difficult to secure high elasticity due to their rigid chain structure.

Cai et al. recently demonstrated stretchability of up to 150% with high sensitivity, and excellent mechanical adaptability via the island-bridge morphology of PANI film using dilute-chemical polymerization, resulting in the expansion of PANI’s versatility as a stretchable electrode [

9].

Studies on stretchable electrodes have been actively conducted. However, studies on packaging, integration, and measurement of strain sensors have not been sufficiently conducted [

10]. Silver paste for wire connections, conductive tapes such as copper tape, and conductive fabric have been directly attached to stretchable electrodes for estimating their performance [

11]. However, such methods have several problems. First, it is difficult to detect minute strain because the deformed region of the stretchable electrode cannot be precisely controlled. Second, contact resistance, based on the unstable attachment and increased instability under external stress, degrades a device’s efficiency. Moreover, the effectiveness of materials that have been used for measurement, including copper and silver, are limited.

There is a restriction in establishing a stable metal semiconductor junction with the various stretchable electrodes. In particular, PANI is a p-type semiconductor whose conductivity results from delocalization by the π-conjugation structure, filling the local electron-deficient part of the cation radical. Thus, its work function is dependent on synthetic methods, such as chemical, electrochemical, and interfacial methods, synthetic conditions, such as the conditions related to dopants, acids, and solvents, and the ambient environment.

The typical work function of PANI is in the range of 4.2–4.7 eV. It should have ohmic contact with metal within this range to achieve high sensitivity [

12,

13,

14]. However, it was not possible to form ohmic contact or to reduce contact resistance by simply employing a metal tape. An additional step, such as using silver paste, has been required [

7,

9]. In addition, most devices do not come with a separate contact area or appropriate connecting methods [

15,

16,

17]. Therefore, adapting a metal contact layer to sensors could assure ohmic contact.

Silicone-based elastomers, such as polydimethylsiloxane (PDMS), Ecoflex, Dragon Skin, and hydrogel, are commonly used as stretchable substrates for body-attached devices. In particular, PDMS is frequently used due to its high elasticity, chemical stability, biological compatibility, transparency, and thermal stability [

18]. Additionally, adjusting the mixing ratio of its components and curing conditions can easily control physical properties [

19,

20]. However, most studies on PDMS have focused on surface treatment, molding, or adhesion improvement. Hence, fabrication methods for a single substrate that is composed of more than two types of PDMS with different physical rigidities, using their advantages, have not been suggested.

Therefore, only a substrate with a single PDMS is provided for stretchable sensors or their applications. Hence, when a metal thin film that is susceptible to deformation is applied to sensors configured with PDMS, polymers such as polyimide and parylene have been required as a protective layer [

21]. Furthermore, although studies on the fabrication of metal patterning on PDMS have advanced, their low surface energy hinders the application of photoresist, due to non-uniformity and low adhesion, preventing precise pattern formation. Additionally, its coefficient of thermal expansion, swelling, and flexibility acts as a hindrance [

22,

23]. Consequently, the patterning on PDMS via conventional photolithography is difficult and restricted.

This paper introduces a study that ultimately aims to improve the operational stability of strain sensors by adapting the metal contact layer (the MCL). We fabricated a strain sensor that included PANI as a sensing material to detect deformation, the MCL to retain ohmic contact with PANI, and a buffer layer to prevent breakage of the MCL by external stress. Additionally, we cut the sensor in the shape of a dumbbell to maximize the protective effect of the MCL and the buffer layer. Furthermore, the possibility of patterning PANI, the MCL, and the buffer layer is suggested, to provide potential for a diverse selection of materials on stretchable electrodes or the MCL (Au and Ag), indicating the versatility of fabrication of stretchable strain sensors.

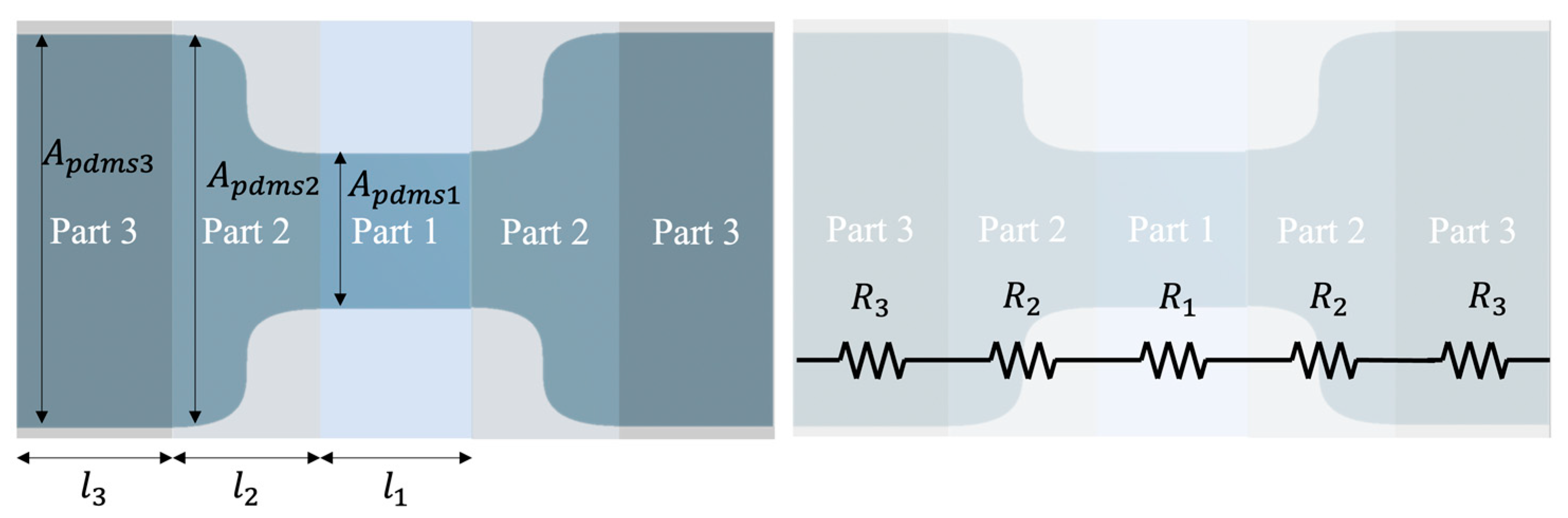

The buffer layer formation was established from the facile controllability of PDMS’s physical stiffness. We fabricated a single substrate composed of two different types of PDMS. As a result, it has high elasticity, but partial regions which have low elasticity can be protected from deformation. These partial regions, the buffer layers, can prevent breakage or peel-off of the MCL during the fabrication or application. The buffer layer is PDMS with a Young’s modulus greater than 3 MPa (more than 6 MPa in this study). It is called hard PDMS (H-PDMS) because it is larger than the general Young’s modulus. The substrate that determines the overall elasticity of the sensor has a Young’s modulus less than 1 MPa (less than 700 kPa in this study); it is called soft PDMS (S-PDMS) because its modulus is smaller than the general Young’s modulus. Furthermore, we carried out the PDMS patterning process to formulate PDMS with different physical properties within a single substrate. We introduced the transfer with a sacrificial layer and an auxiliary substrate to minimize damage during the process.

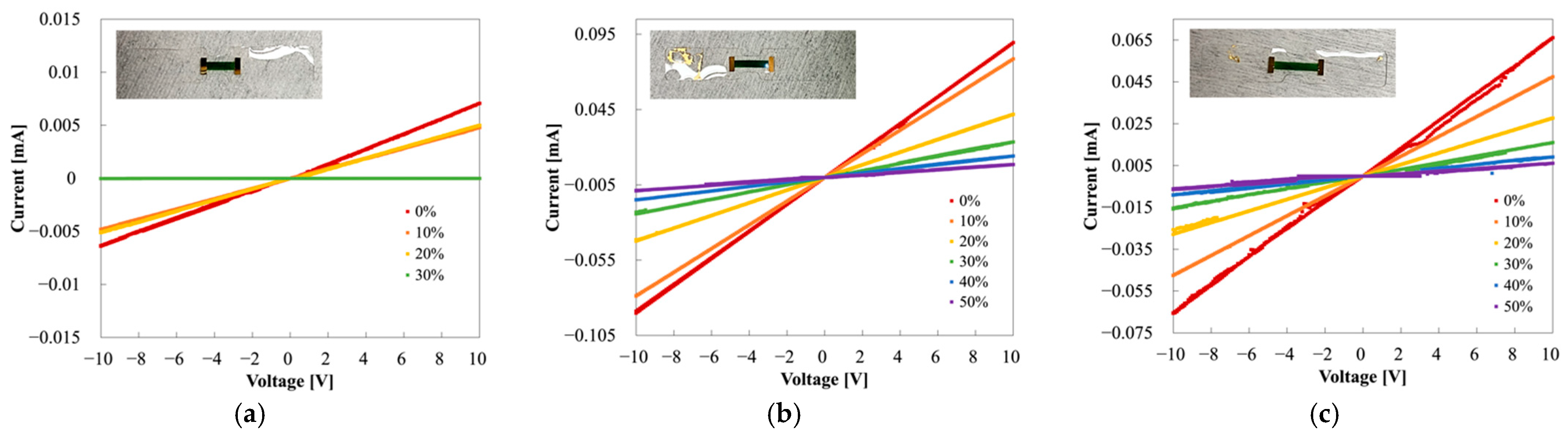

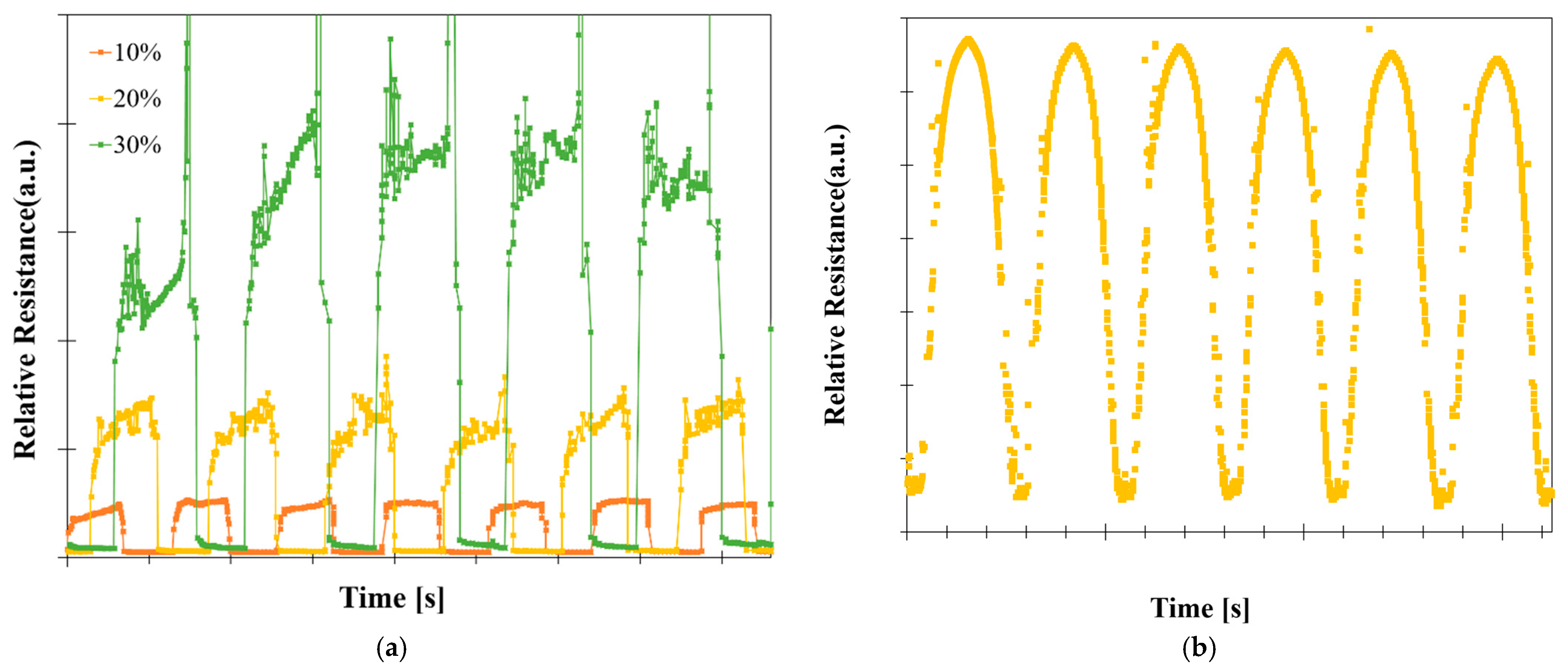

PANI, the MCL, and the H-PDMS can be formed on a single plane with a facile procedure. We demonstrated promising stability, reproducibility, and classification of novel structured sensors based on a comparison of the gauge factors (GFs) of three samples, depending on the MCL and the buffer layer and their transient measurement of relative resistance change under repeated tensile stress. Moreover, current-voltage (I−V) graphs of three types of sensors with different positions of the MCL according to PANI lengths were compared to identify the effect of the dumbbell-shape that was designed in accordance with the standards of the American Society for Testing of Materials (ASTM) [

24,

25,

26].

2. Materials and Methods

2.1. Materials

Aniline (>99.5%, ACS reagent, 62-53-3), sulfuric acid (98%, for analysis EMSURE, 7664-93-9), hydrochloric acid (37%, ACE reagent, 7647-01-0), (3-Aminoprophyl) triethoxysilane (99%, 2554-06-05), and 2,4,6,8-tetramethyl-2,4,6,8-tetravinylcyclotetrasiloxane (2554-06-05) were purchased from Sigma-Aldrich, Seoul, Korea. A graphite rod (GR002H) was purchased from QRINS, Seoul, Korea. ITO-coated glass was purchased from iTASCO, Seoul, Korea. A silicone elastomer base and a curing agent (Sylgard 184 kit) were purchased from Dow Corning, Midland, MI, USA. VDT-731 (67762-94-1), SIT-6831.2 (68478-92-2), and HMS-301 (68037-59-2) were purchased from Gelest, Morrisville, PA, USA. Copper tape was purchased from 3M, Seoul, Korea. All reagents were used as received without further purification.

2.2. Characterization

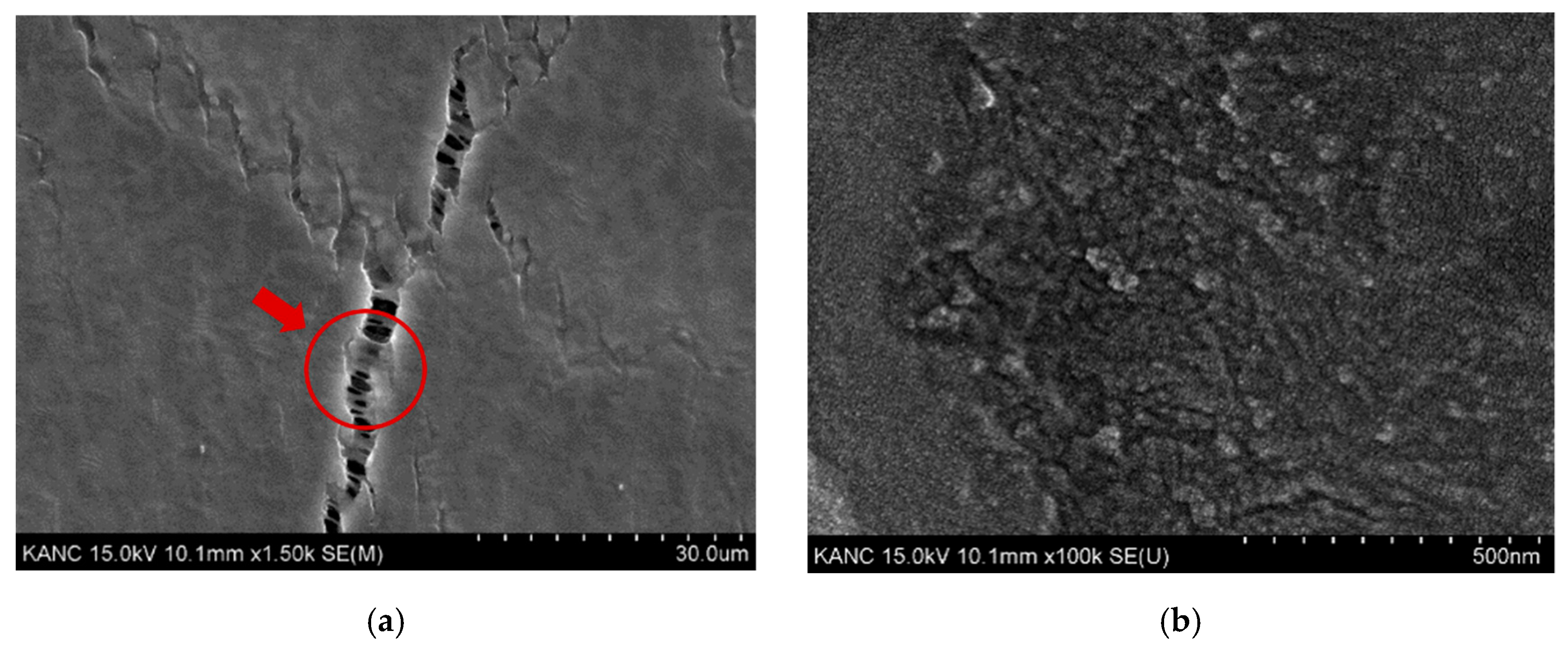

The thickness of PDMS and PANI was analyzed using a surface profiler (Alpha Step 200, KLA/TENCOR). The alignment of PANI, Au thin film (the MCL), and the H-PDMS were observed using a microscope (MX51, Olympus, Tokyo, Japan). The surface morphology of transferred PANI was analyzed via FE-SEM (S-4800, Hitachi, Tokyo, Japan) at the Korea Advanced Nano Fab Center.

2.3. Fabrication of Strain Sensor

2.3.1. PANI/Au/H-PDMS Strain Sensor

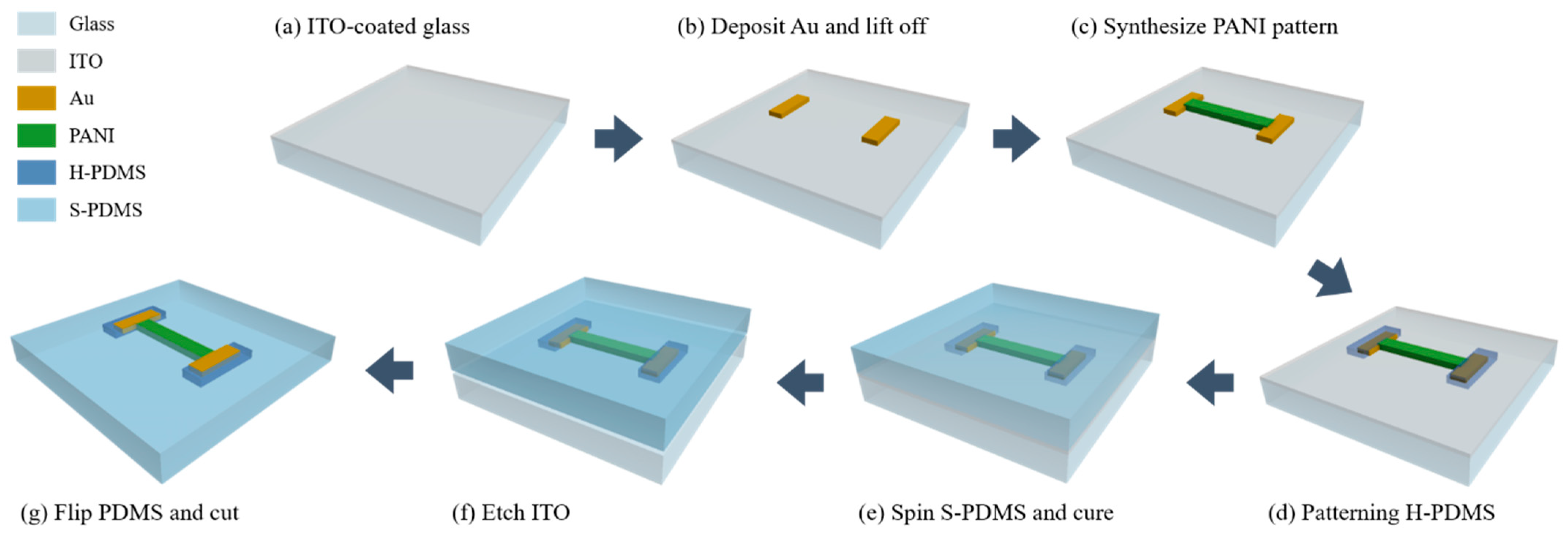

We introduced a strain sensor with the MCL and the buffer layer (PANI/Au/H-PDMS strain sensor). Its fabrication process is shown in

Figure 1. First, we prepared the ITO-coated glass. It was cleaned with acetone, IPA, and deionized water prior to processing. Patterning directly on PDMS may cause alignment difficulties. A transfer process using ITO (185 nm, 10 Ω/cm

2) as a sacrificial layer and glass as an auxiliary substrate was used (

Figure 1a). ITO was chosen as a sacrificial layer because it can act as a working electrode during subsequent PANI synthesis. Typical photolithography was performed to establish the MCL. Photoresist (AZ5214E, AZ Electronics Materials, Charlotte, NC, USA) was spin-coated at 3000 rpm for 30 s. After the exposure, it was immersed in developer (CD-30, AZ Electronics Materials, Charlotte, NC, USA) for 1 min 10 s. Au, which has a significantly larger work function than PANI, was selected as the MCL to form a stable ohmic contact. Thereafter, 150 nm of Au thin film was deposited via an e-beam evaporator (KVE-T5560, Korea Vacuum Tech, Gimpo, Korea), using Au pellets (purity 99.999%) as a source. The deposition conditions were as follows:

Torr, 140 mA, and an 0.8 kÅ/s of deposition rate. It was lifted into a rectangular shape (

) and served as the MCL (

Figure 1b).

Next, photolithography was implemented to define PANI capable of detecting mechanical strain. A PANI mask was aligned to overlap with

of the MCL. A thicker photoresist (KPRO-15, KemLab, Woburn, MA, USA) was used to ensure PANI thickness and spin-coated at 1000 rpm for 45 s. PANI was synthesized electrochemically. Photoresist acted as a deposition mask for patterning (width of

and length of

). The polymerization conditions were as follows: 0.3 M of aniline and 0.7 M aqueous solution of sulfuric acid as an electrolyte, with the ITO-coated glass as a working electrode and the graphite rod as a counter electrode. The electrodeposition was performed for 1 min 10 s at a fixed voltage of 1.1 V at room temperature [

7]. Thereafter, it was baked on the hot plate at 100 °C for 10 min to enhance adhesion to the substrate and dried at room temperature for 24 h to completely remove moisture. It was then soaked in acetone for 10 min to remove the photoresist and the residue was cleaned with IPA and deionized water (

Figure 1c).

Subsequently, the H-PDMS patterning was conducted, as described in detail in

Section 2.4 (

Figure 1d). The S-PDMS determines the stretchability of a strain sensor. It was manufactured by mixing the base and a curing agent (Sylgard 184) with a weight ratio of 15:1. Prior to spin-coating the mixture, the curing agent was spin-coated at 3000 rpm for 30 s to ensure adhesion to the H-PDMS. The mixture was then spin-coated at 500 rpm for 30 s and sufficiently cured at room temperature for 72 h (

Figure 1e). Finally, the ITO film was removed by the etchant, which is a diluent of HCl (37%), and deionized water with a weight ratio of 1:3 (

Figure 1f). In this step, partial PANI that lost conductivity during the process was oxidized to emeraldine salt form and restored in an acidic etchant having low pH. The PDMS film separated from the glass as the ITO was etched, flipped, and washed with deionized water. After that, it was cut into a dumbbell shape based on ASTM D412 (

Figure 1g) [

24,

25,

26]. Additionally, three samples with different PANI lengths (

) were fabricated under the same conditions to optimize the strain sensor according to the position of the MCL and the buffer layer within the same dumbbell structure.

2.3.2. PANI and PANI/Au Strain Sensor

We compared the strain sensor consisting of only PANI (PANI strain sensor) and the PANI/Au/H-PDMS strain sensor to demonstrate the effectiveness of adapting MCL. Additionally, a strain sensor without the buffer layer (PANI/Au strain sensor) and PANI/Au/H-PDMS strain sensor were compared to verify the efficiency of the buffer layer under deformation. The conditions of fabricating PANI, the MCL, and the S-PDMS in these samples were the same as those for the PANI/Au/H-PDMS strain sensors. In the case of the PANI strain sensor, the S-PDMS was applied immediately after defining the PANI on the ITO-coated glass. The sacrificial layer was then etched. PDMS film separated from the glass was cleaned with deionized water and cut into a rectangular shape (). The dumbbell shape was not required because it was composed only of PANI, excluding the MCL and the buffer layer that require structural protection.

The PANI/Au strain sensor was fabricated by coating the S-PDMS on the patterned MCL and PANI. Similarly, the MCL and PANI were aligned with

of the overlapping area. The surface treatment with (3-Aminoprophyl) triethoxysilane (APTES) was processed to enhance the adhesion between the S-PDMS and the MCL just before the S-PDMS coating. An aqueous solution diluted APTES with a weight ratio of 1:100 was used. It was dried with an N

2 gun without a further washing process after immersion of 20 min [

27]. After that, the S-PDMS was coated and cured for a sufficient time. The sacrificial layer was removed using HCl diluent to isolate it from the glass. It was washed by deionized water and cut into the dumbbell shape to protect the MCL structurally.

2.4. Patterning the H-PDMS

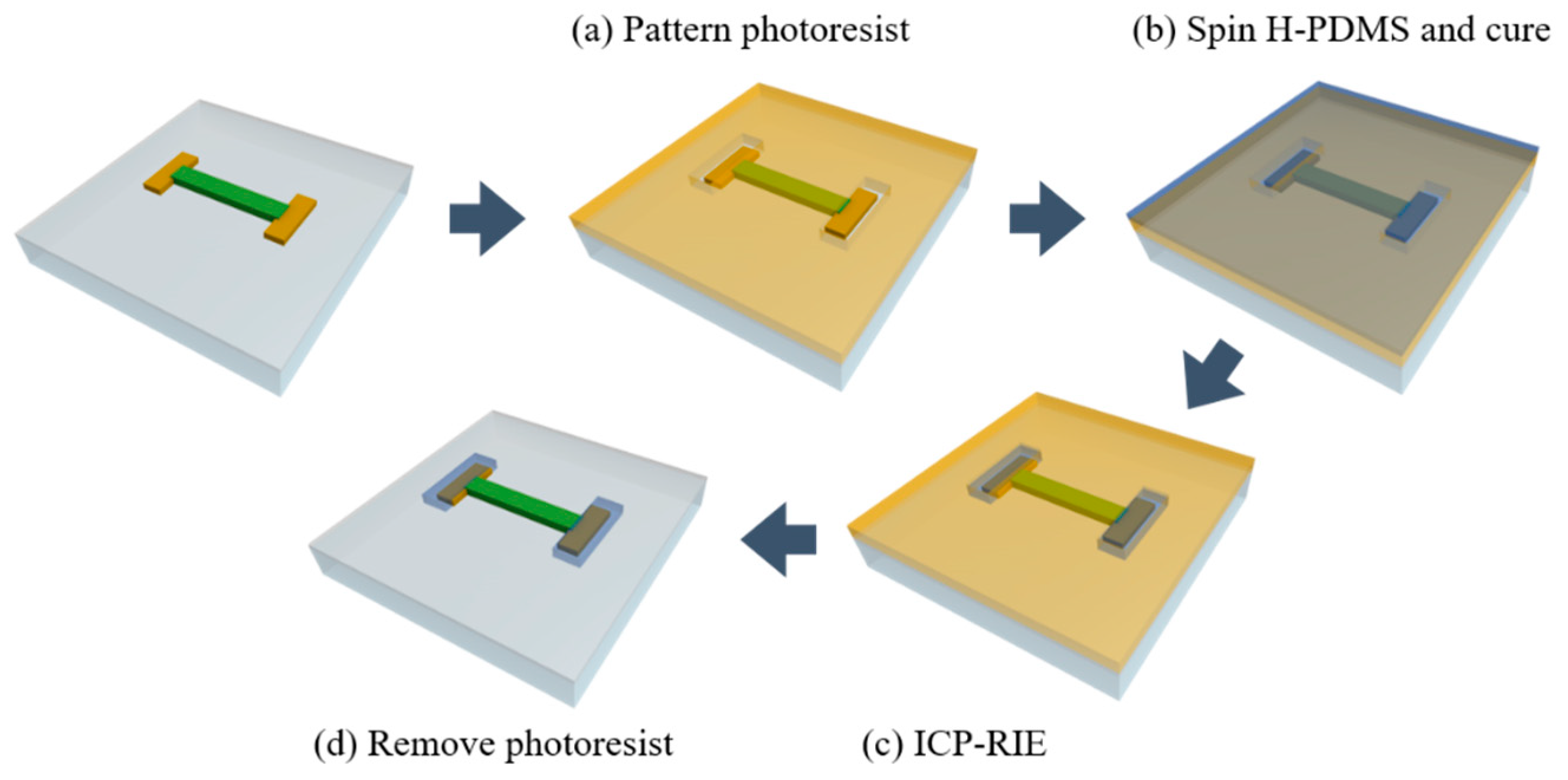

We applied the H-PDMS with a high Young’s modulus as the buffer layer to protect the MCL from deformation. We introduced its patterning process as shown in

Figure 2. First, the thick photoresist was applied to the sample to complete the step shown in

Figure 1c, to ensure sufficient thickness that is fundamental for a durable buffer layer. We spin-coated the photoresist (KPRO-15, KemLab, Woburn, MA, USA) at 1000 rpm for 45 s and soft-baked it to form the first photoresist layer. After cooling, a sufficient thickness of

was obtained by repeating the same process under identical conditions. Thereafter, a pattern with a size of

was aligned with PANI overlapped

and the bulk MCL via conventional photolithography (

Figure 2a). To develop the photoresist to a thickness greater than

, it was immersed in developer (CD-30, AZ Electronics Materials, Charlotte, NC, USA) for 20 min. APTES surface treatment was performed prior to applying the H-PDMS to improve adhesion between the MCL and the H-PDMS. After immersing in APTES aqueous solution diluted at a weight ratio of 1:100 for 20 min, it was taken out and dried with an N

2 gun.

The H-PDMS was established in the following steps. First, 3.7 g of VDT-731 and

of Pt catalyst (SIP-6831.2) were mixed. Then, 0.1 g of modulator (2,4,6,8-tetramethyl-2,4,6,8-tetravinylcyclotetrasiloxane) and 1 g of HMS-301 were added and mixed. The mixture was degassed whenever each substance was added [

28,

29]. The mixture was spin-coated at 1000 rpm for 30 s. Self-leveling for 10 min on a flat place at room temperature was performed immediately after the preceding step. It was then cured in an oven at 60 °C for 4 h (

Figure 2b). ICP-RIE was performed to expose the top surface of the photoresist by etching the H-PDMS. The selectivity of the H-PDMS photoresist was 1.5:1. The following were the ICP-RIE conditions: 500 W of RF power, 200 W of RF bias power, 10 mTorr of pressure with 90 sccm of SF

6 and 6 sccm of O

2, which lasted 32 min (

Figure 2c) [

30]. It was then immersed in an acetone solution to remove the photoresist. Notably, the exposed top surface facilitated its removal. The thickness of the remaining H-PDMS was

. The H-PDMS containing

of PANI and the bulk MCL and an overlapped area with

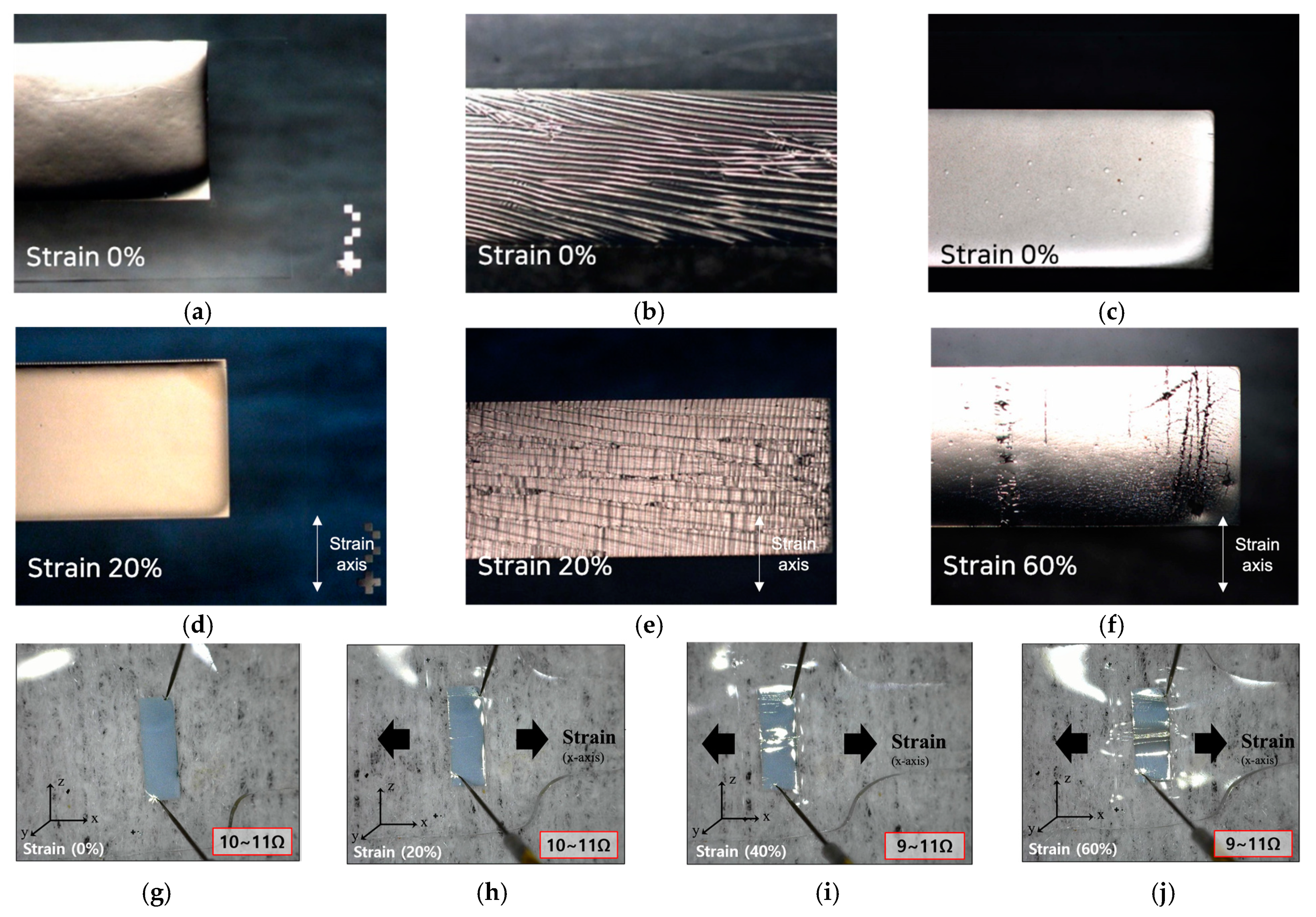

of the MCL and bulk PANI, situated externally to the H-PDMS, guaranteed the interconnection of each part under strain. Additionally, we manufactured Ag/H-PDMS samples and observed the variation of the surface conditions and the resistance based on strain to verify the effectiveness of the H-PDMS. Ag (150 nm) as the MCL and the H-PDMS (

) as the buffer layer were progressed under the same conditions as mentioned above. The S-PDMS was also formed identically using the mixture of a Sylgard 184 kit with a 15:1 weight ratio, and cut into the dumbbell shape.

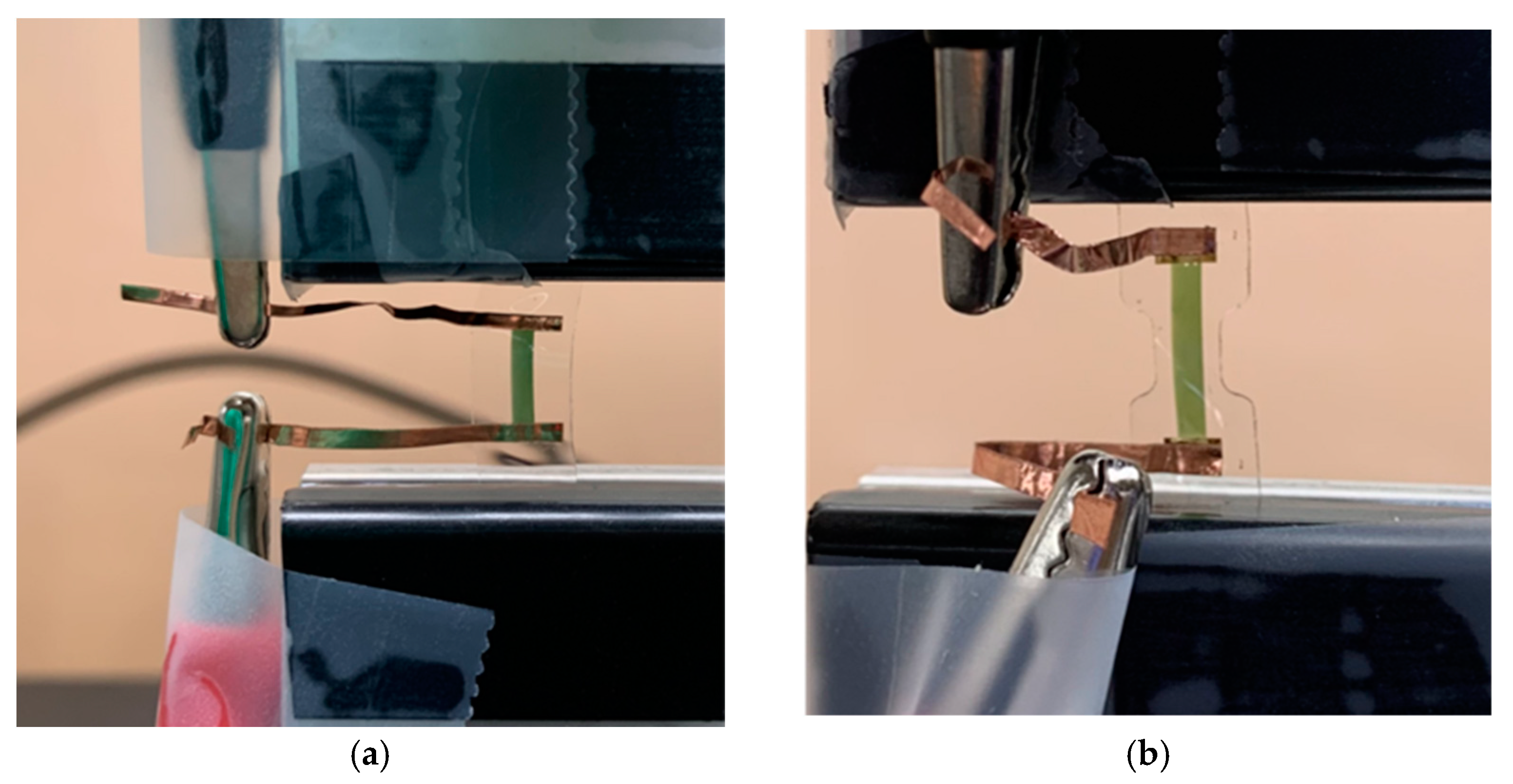

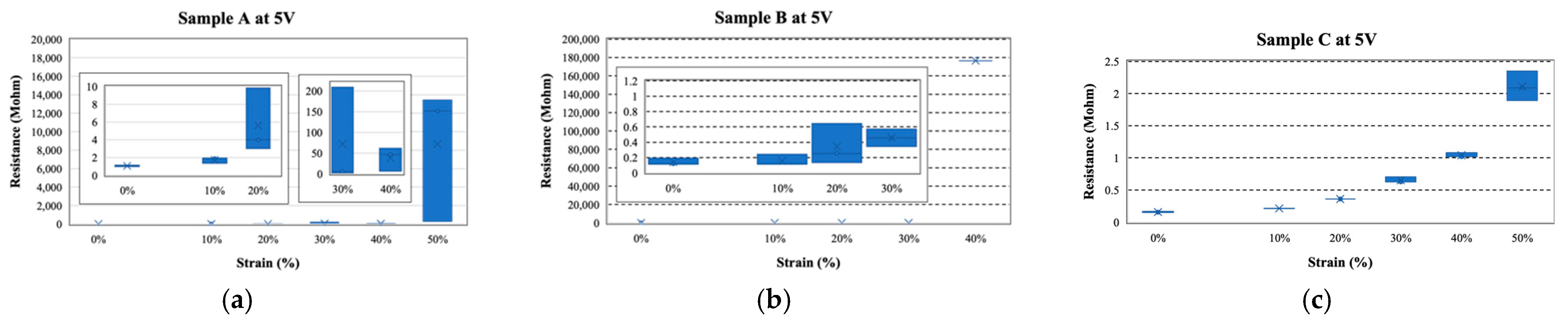

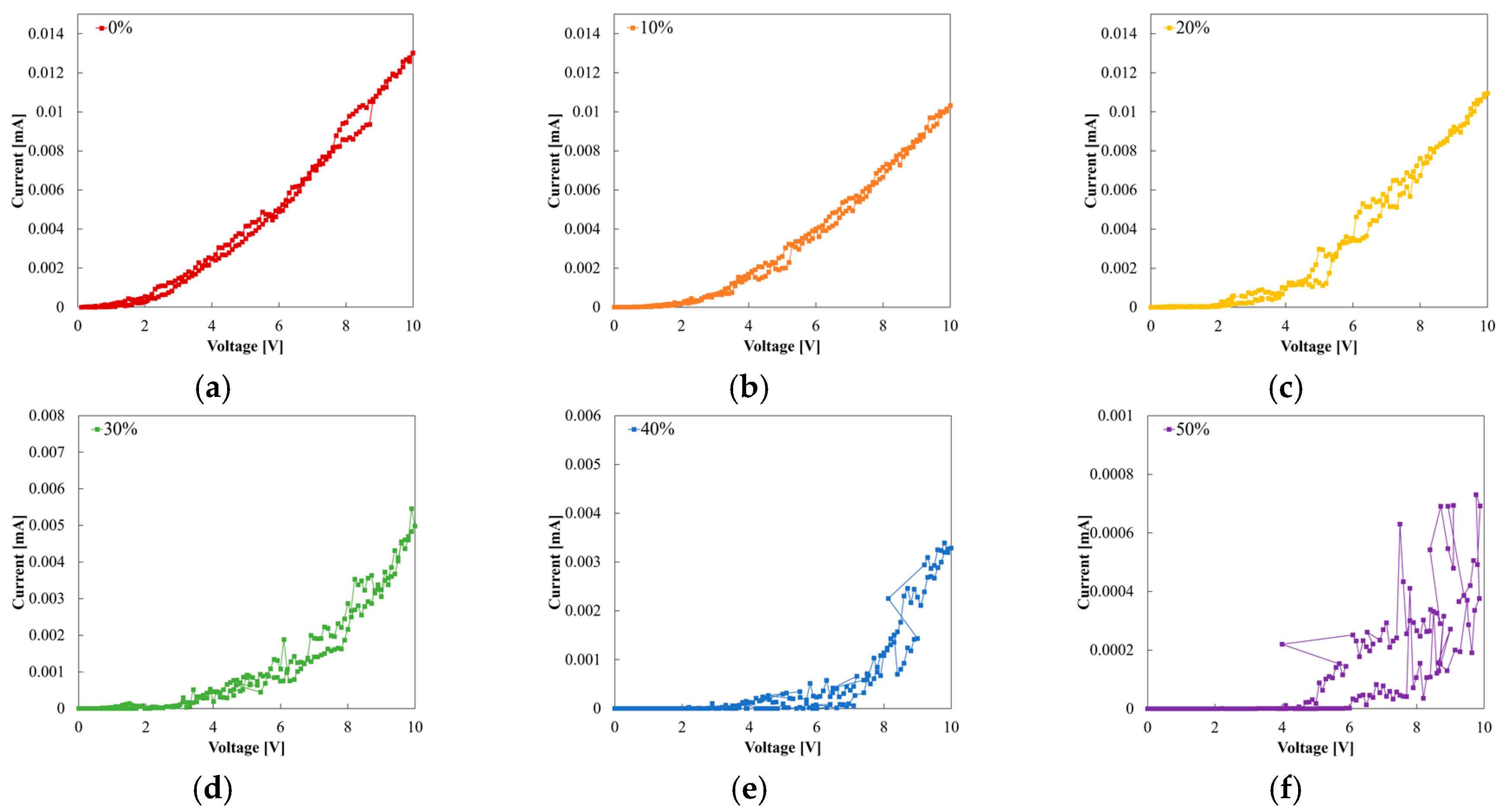

2.5. Measurement Conditions

We prepared three different types of samples with and without the Au thin film as the MCL and the H-PDMS as the buffer layer: Sample A (PANI strain sensor), Sample B (PANI/Au strain sensor), and Sample C (PANI/Au/H-PDMS strain sensor). Sample A was cut into a rectangular shape because it lacked metallic thin film and was vulnerable to external stress. Samples B and C were cut into the shape of the dumbbell based on the ASTM D412 model to maximize the efficiency of the MCL protection. Each sample had a PANI pattern,

of width and

of length, which can detect mechanical deformation. We also prepared three different lengths (

) of PANI in Sample C to explore the effect of the dumbbell structure. The copper tape was prepared in size

and attached directly to PANI or the MCL to measure the electrical properties (

Figure 3). The measurement was repeated consecutively for all samples under the same conditions to obtain I−V characteristics. Measurement conditions were as follows: dual sweep from −10 V to 10 V with 0.1 V step voltage in a fixed state with deformation at 0%, 10%, 20%, 30%, 40%, and 50%. Transient characteristics were measured at speeds of 50 mm/min and 6 mm/min. The former had a waiting time of 10 s, and the latter had a waiting time of 0.1 s. Ag/H-PDMS samples were cut into the ASTM D412 model, and their surface condition was observed using a microscope at 0%, 20%, and 60% strains. Resistance was measured under the 0%, 20%, 40%, and 60% strains using the Au probe.