Design and Implementation of an Ultrasonic Flowmeter Based on the Cross-Correlation Method

Abstract

1. Introduction

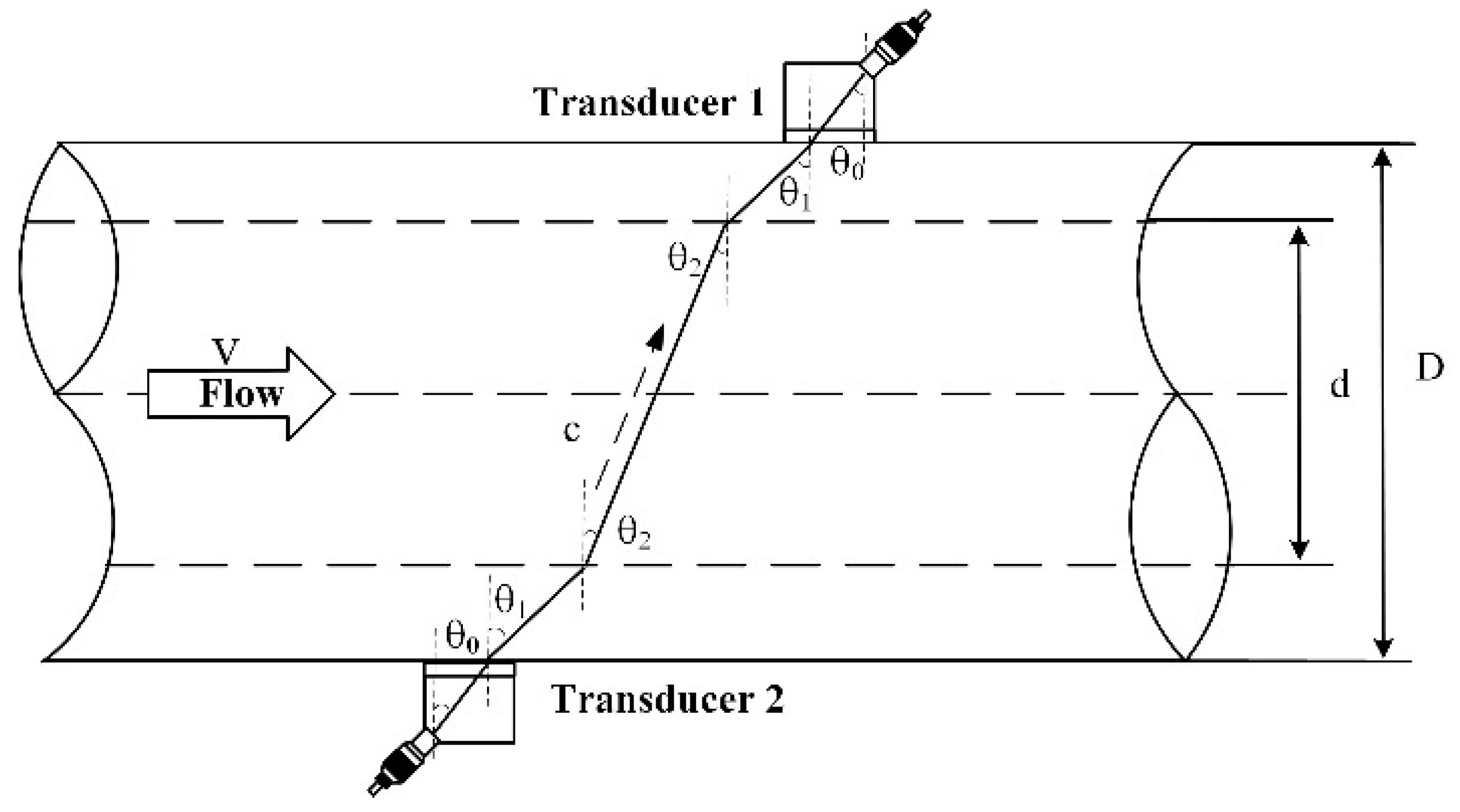

2. Measurement Principle of the Flowmeter

3. Simulation and Analysis of Ultrasonic Flow Measurement

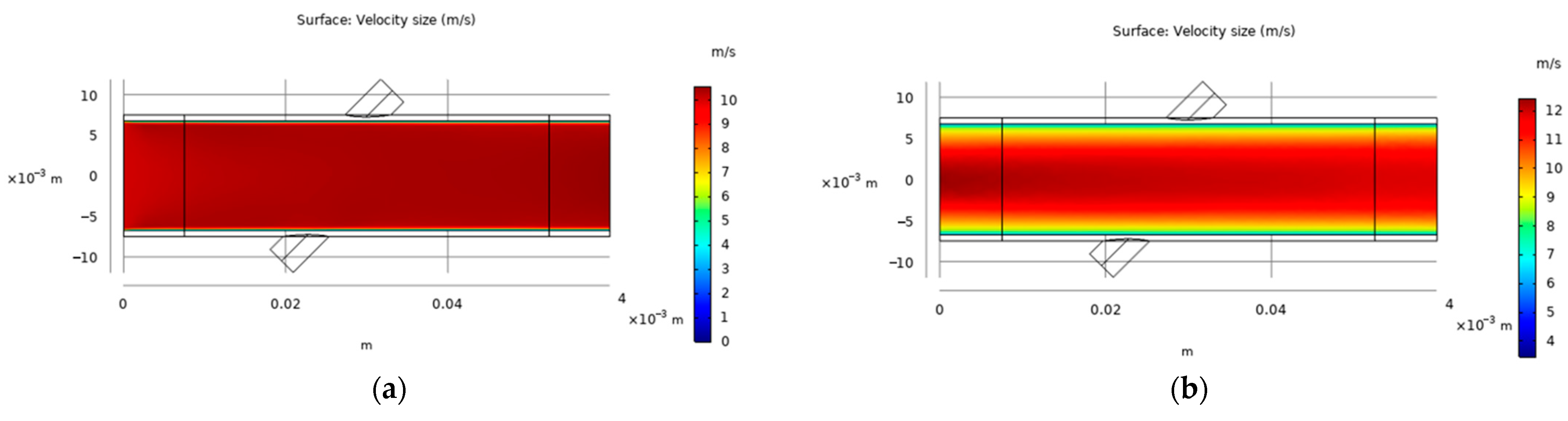

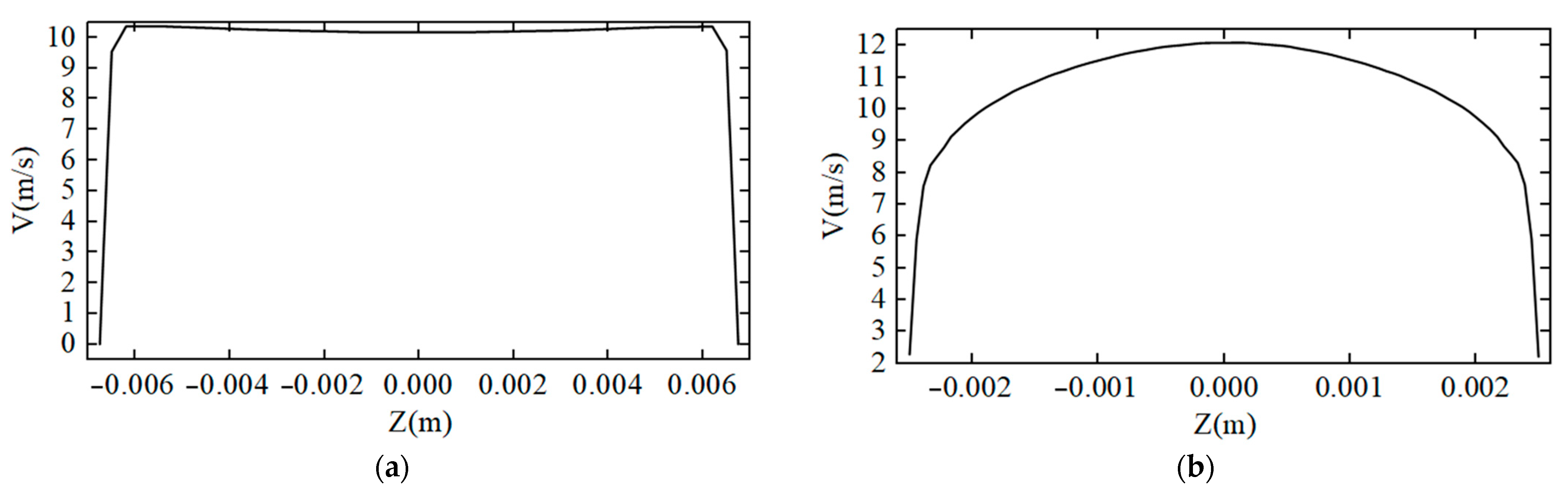

3.1. Background Flow in Different Fluid States

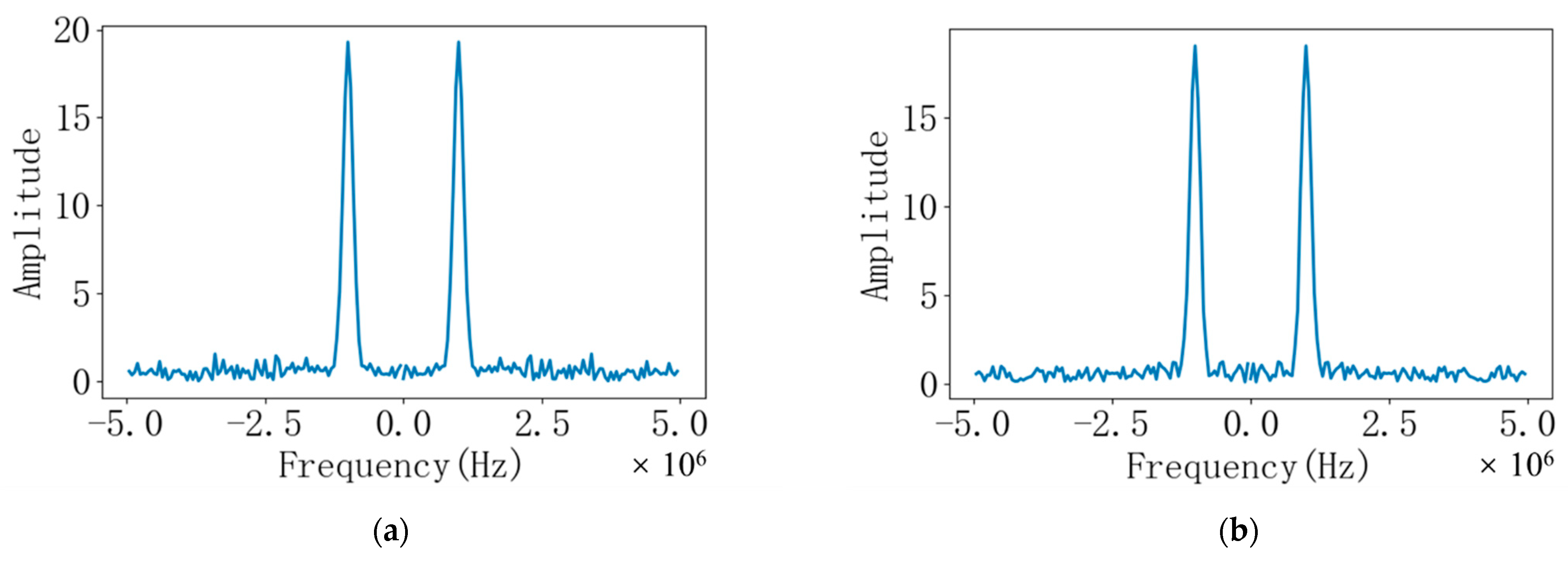

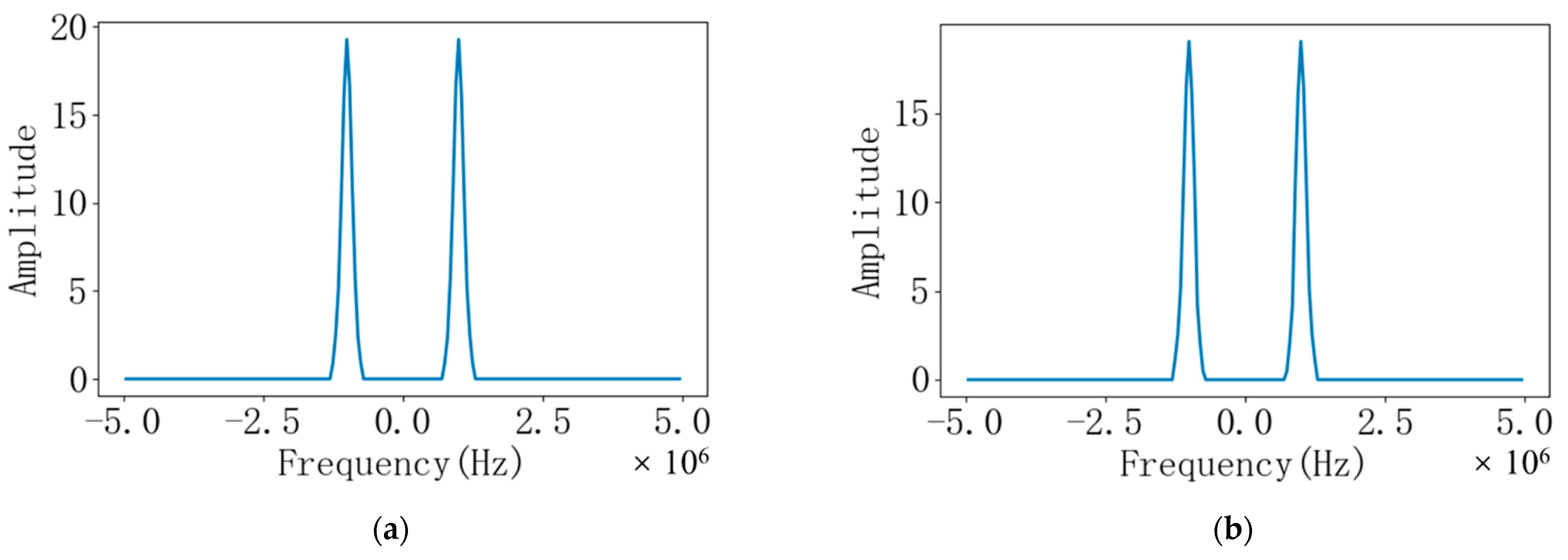

3.2. Influence of Pipe Diameter on Ultrasonic Transmission

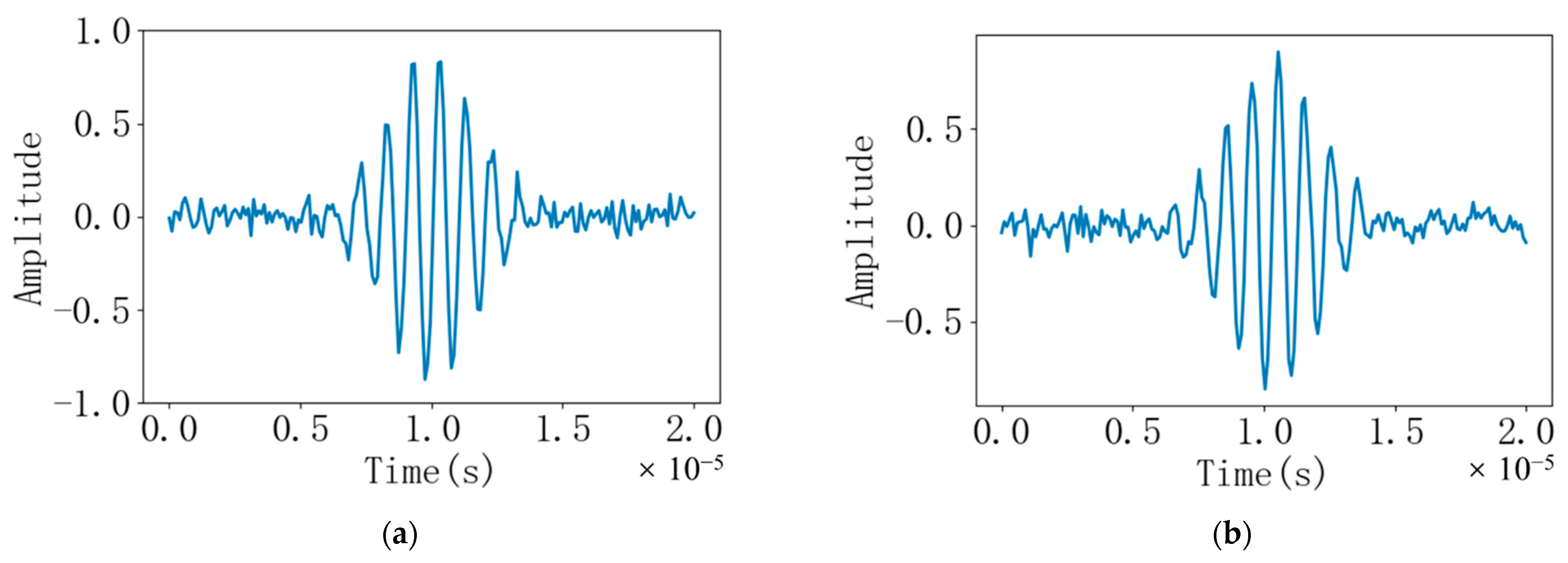

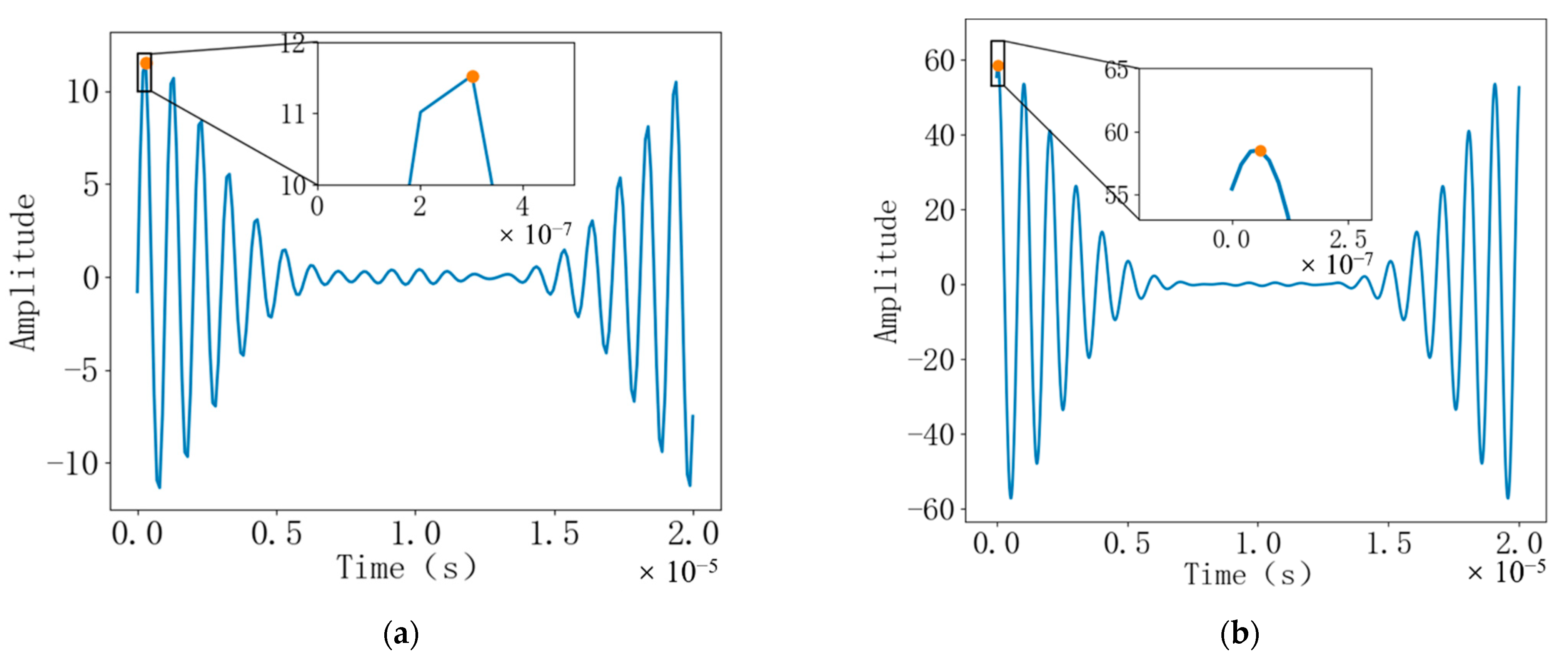

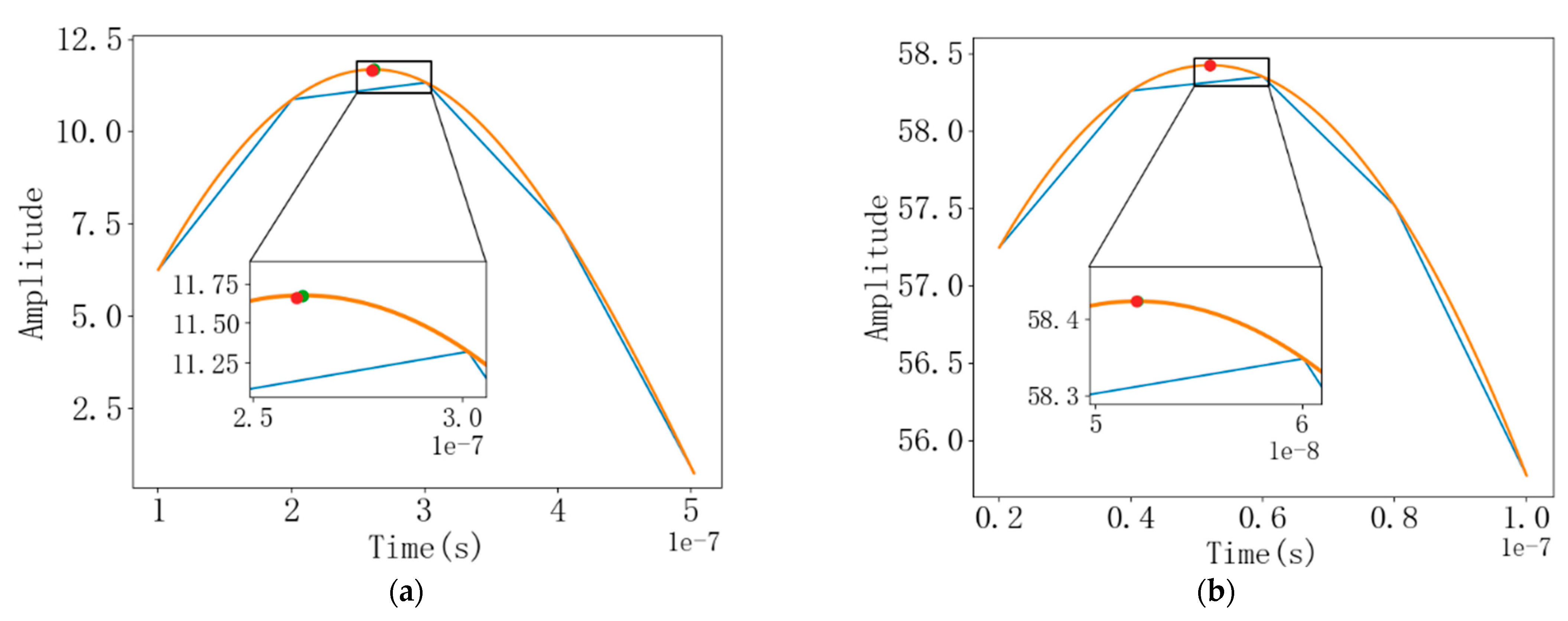

3.3. Simulation Analysis of Ultrasonic Flow Measurement by Cross-Correlation Method

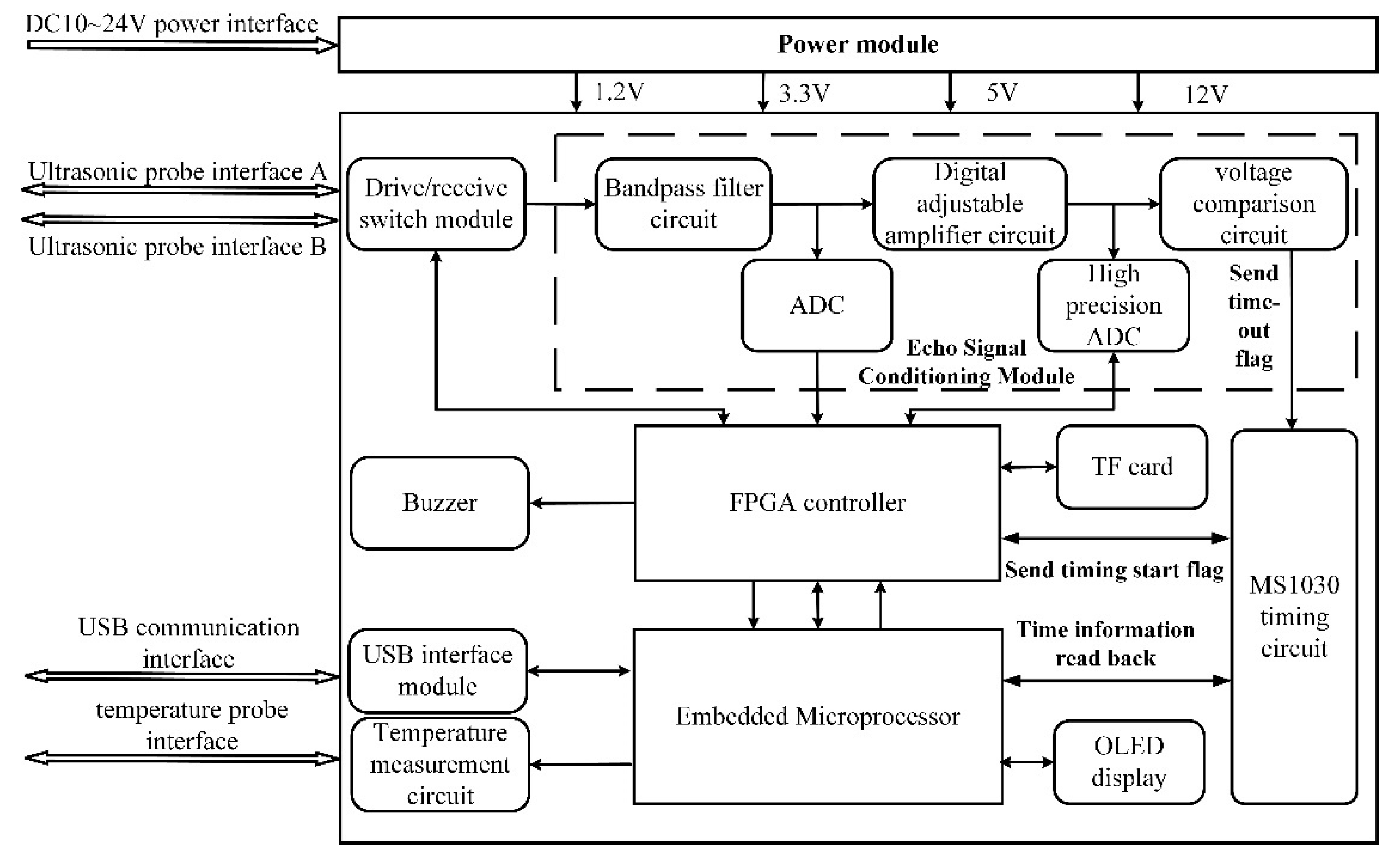

4. Design of Ultrasonic Flowmeter

4.1. Overall Scheme Design

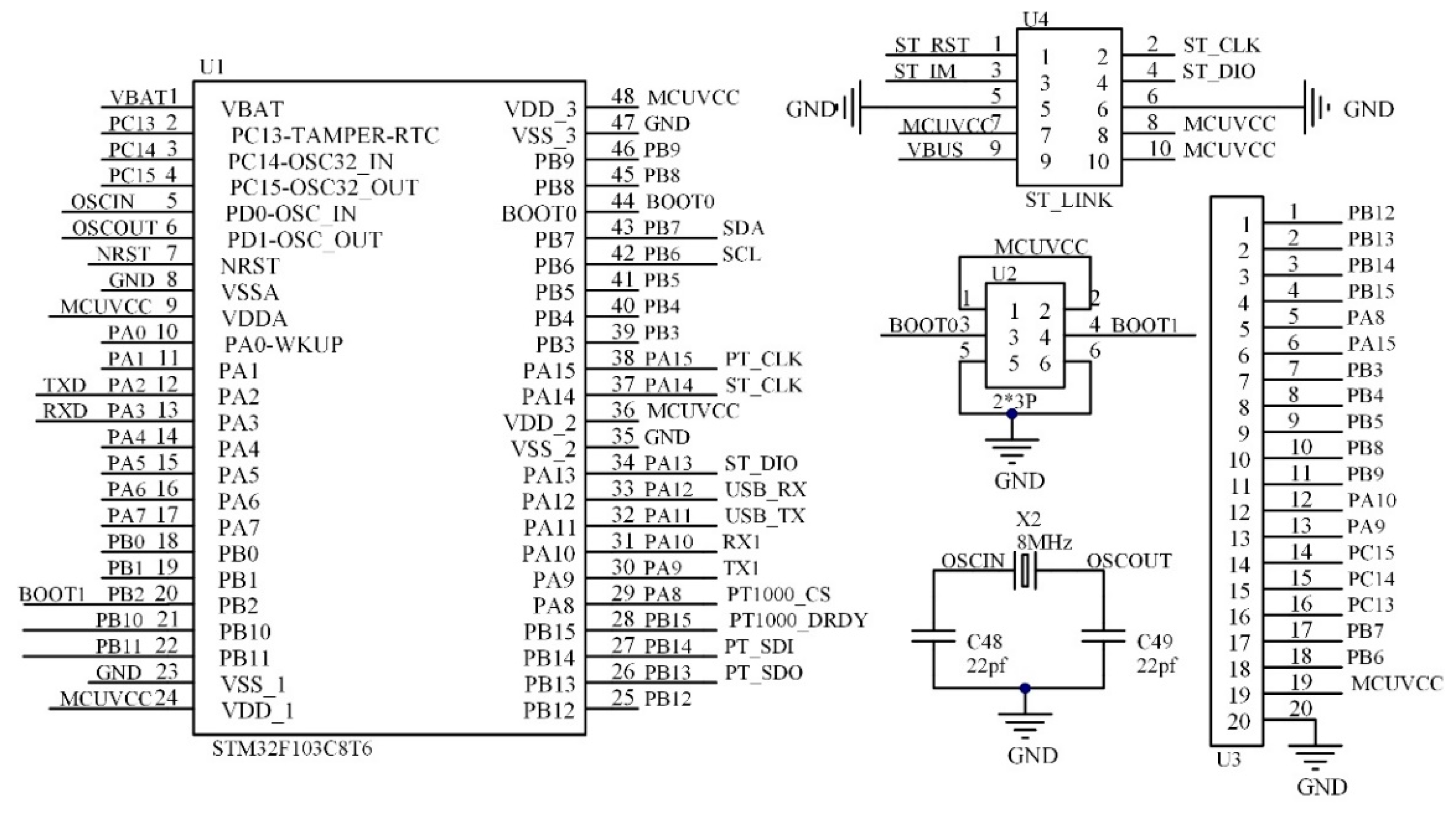

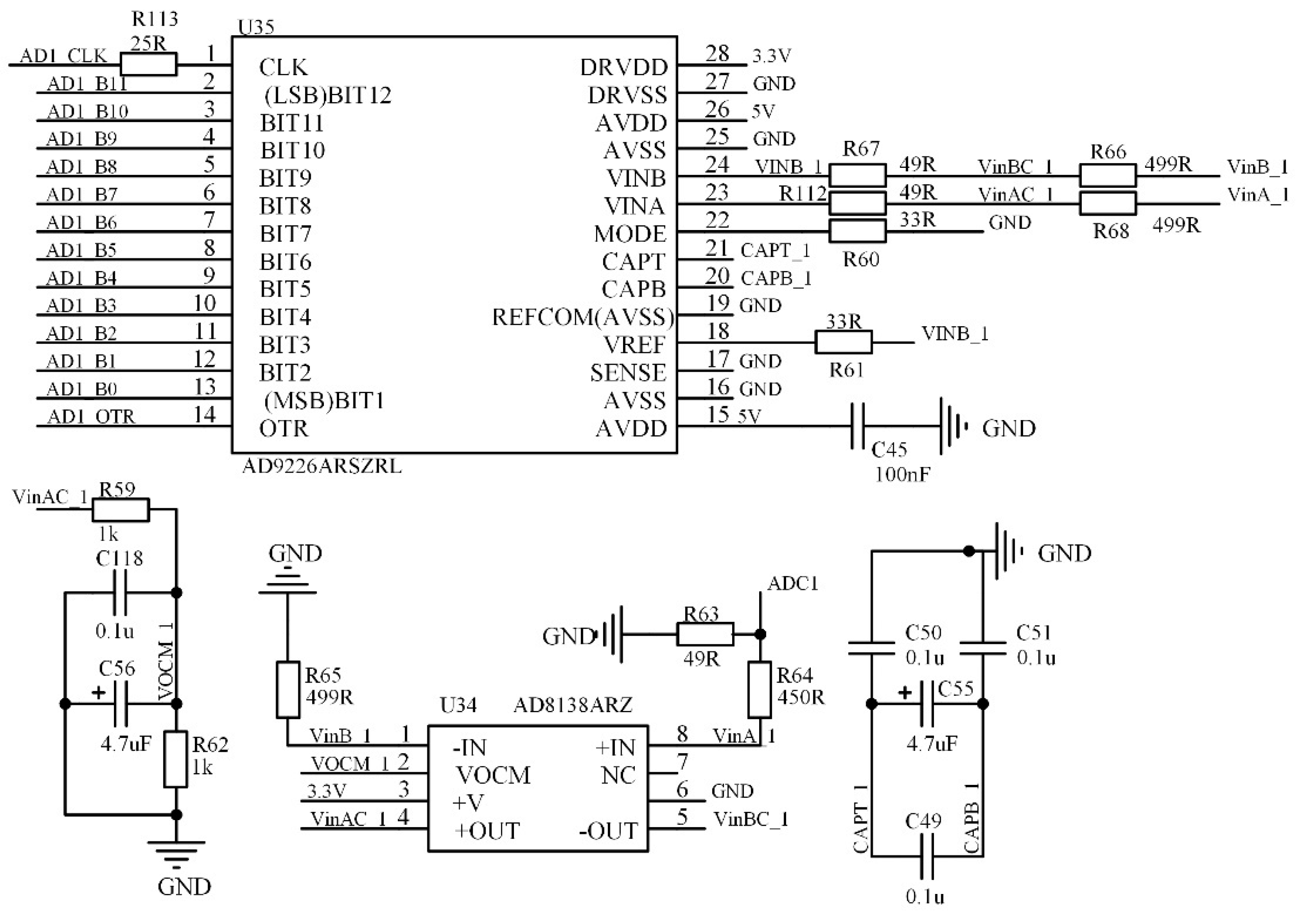

4.2. Hardware Circuit Design

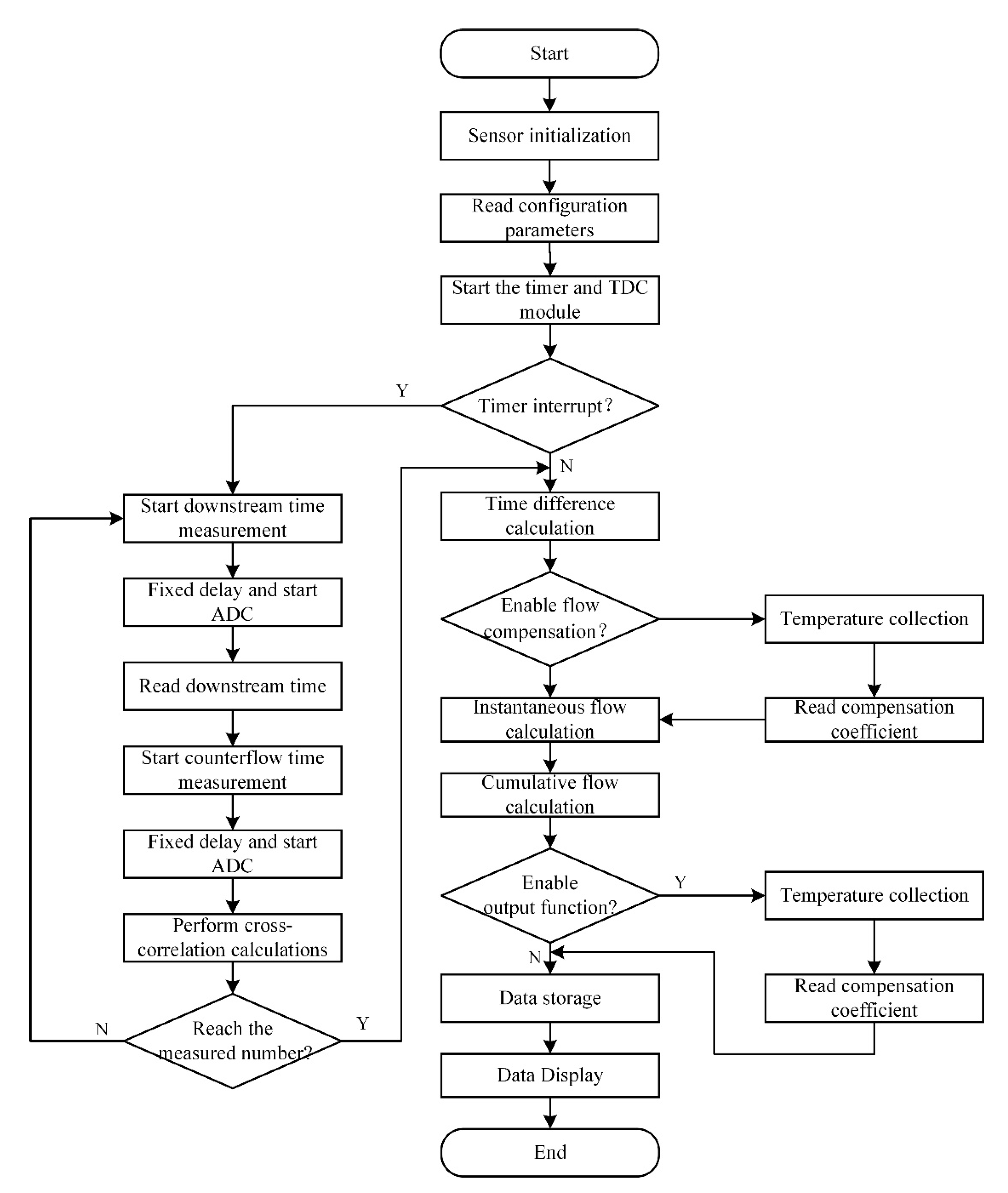

4.3. Software Design

5. System Function Test and Data Analysis

5.1. Still Water Dragging Method

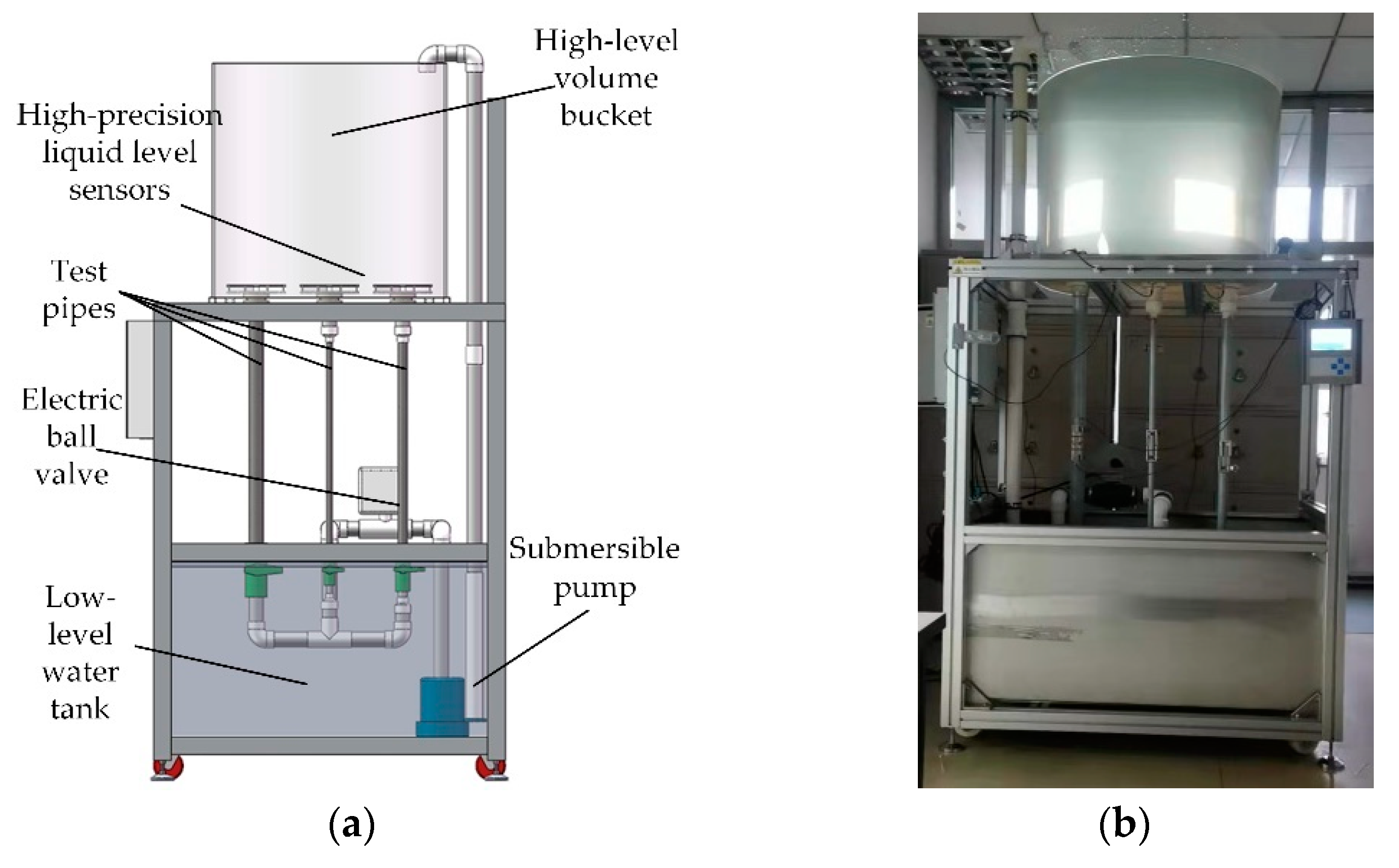

5.2. Dynamic Volume Method

5.3. Field Comparison Method

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, J.; Zhang, K.; Wang, L.; Yang, M. Design of a high precision ultrasonic gas flowmeter. Sensors 2020, 20, 4804. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Chen, J. Volumetric flow measurement using an implantable CMUT array. IEEE Trans. Biomed. Circuits Syst. 2011, 5, 214–222. [Google Scholar] [CrossRef] [PubMed]

- Johnson, A.N.; Harman, E.; Boyd, J.T. Blow-down calibration of a large ultrasonic flow meter. Flow Meas. Instrum. 2021, 77, 101848. [Google Scholar] [CrossRef]

- Lynnworth, L.C.; Liu, Y. Ultrasonic flowmeters: Half-century progress report, 1955–2005. Ultrasonics 2006, 44, e1371–e1378. [Google Scholar] [CrossRef]

- Park, J.; Je, Y.; Lee, H.; Moon, W. Design of an ultrasonic sensor for measuring distance and detecting obstacles. Ultrasonics 2010, 50, 340–346. [Google Scholar] [CrossRef]

- Jiang, Y. Study on weight function distribution of hybrid gas-liquid two-phase flow electromagnetic flowmeter. Sensors 2020, 20, 1431. [Google Scholar] [CrossRef]

- Džemić, Z.; Širok, B.; Bizjan, B. Turbine flowmeter response to transitional flow regimes. Flow Meas. Instrum. 2018, 59, 18–22. [Google Scholar] [CrossRef]

- Thummar, D.; Reddy, Y.J.; Arumuru, V. Machine Learning for Vortex Flowmeter Design. IEEE Trans. Instrum. Meas. 2021, 71, 1–8. [Google Scholar] [CrossRef]

- Joshi, S.G. Ultrasonic flow meter using mode coupling transducers. Ultrasonics 2021, 116, 106497. [Google Scholar] [CrossRef]

- Zheng, D.; Mei, J.; Wang, M. Improvement of gas ultrasonic flowmeter measurement non-linearity based on ray tracing method. IET Sci. Meas. Technol. 2016, 10, 602–606. [Google Scholar] [CrossRef]

- Zhu, K.; Chen, X.; Qu, M.; Yang, D.; Hu, L.; Xu, J.; Xie, J. An ultrasonic flowmeter for liquid flow measurement in small pipes using AlN piezoelectric micromachined ultrasonic transducer arrays. J. Micromech. Microeng. 2020, 30, 125010. [Google Scholar] [CrossRef]

- Yu, W.; Chen, J.; Bao, Z. Multi-mode propagation mode localisation and spread-Doppler clutter suppression method for multiple-input multiple-output over-the-horizon radar. IET Radar Sonar Navig. 2019, 13, 1214–1224. [Google Scholar] [CrossRef]

- Matko, V.; Milanovič, M. Detection principles of temperature compensated oscillators with reactance influence on piezoelectric resonator. Sensors 2020, 20, 802. [Google Scholar] [CrossRef] [PubMed]

- Rupniewski, M.; Mazurek, G.; Rytel-Andrianik, R.; Bohdanowicz, M.; Śliwa, E.; Nałęcz, M.; Piątek, A.; Gumowski, K. Modeling the Response of a Beam Deflection Flowmeter. IEEE Sens. J. 2019, 20, 3016–3023. [Google Scholar] [CrossRef]

- Fang, L.; Ma, X.; Zhao, J.; Faraj, Y.; Wei, Z.; Zhu, Y. Development of a high-precision and wide-range ultrasonic water meter. Flow Meas. Instrum. 2022, 84, 102118. [Google Scholar] [CrossRef]

- Murakawa, H.; Muramatsu, E.; Sugimoto, K.; Takenaka, N.; Furuichi, N. A dealiasing method for use with ultrasonic pulsed Doppler in measuring velocity profiles and flow rates in pipes. Meas. Sci. Technol. 2015, 26, 085301. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, C.; Lin, J. Effects of velocity profiles on measuring accuracy of transit-time ultrasonic flowmeter. Appl. Sci. 2019, 9, 1648. [Google Scholar] [CrossRef]

- Hamouda, A.; Manck, O.; Hafiane, M.L.; Bouguechal, N.E. An enhanced technique for ultrasonic flow metering featuring very low jitter and offset. Sensors 2016, 16, 1008. [Google Scholar] [CrossRef]

- Murakawa, H.; Ichimura, S.; Sugimoto, K.; Asano, H.; Umezawa, S.; Sugita, K. Evaluation method of transit time difference for clamp-on ultrasonic flowmeters in two-phase flows. Exp. Therm. Fluid Sci. 2020, 2020, 109957. [Google Scholar] [CrossRef]

- van Willigen, D.M.; van Neer, P.L.; Massaad, J.; de Jong, N.; Verweij, M.D.; Pertijs, M.A. An Algorithm to Minimize the Zero-Flow Error in Transit-Time Ultrasonic Flowmeters. IEEE Trans. Instrum. Meas. 2020, 70, 1–9. [Google Scholar] [CrossRef]

- Suñol, F.; Ochoa, D.A.; Garcia, J.E. High-precision time-of-flight determination algorithm for ultrasonic flow measurement. IEEE Trans. Instrum. Meas. 2018, 68, 2724–2732. [Google Scholar] [CrossRef]

- Kang, L.; Feeney, A.; Su, R.; Lines, D.; Ramadas, S.N.; Rowlands, G.; Dixon, S. Flow Velocity Measurement Using a Spatial Averaging Method with Two-Dimensional Flexural Ultrasonic Array Technology. Sensors 2019, 19, 4786. [Google Scholar] [CrossRef] [PubMed]

- Maaß, S.; Laukner, M. Ultrasonic Time Delay Difference Estimation with Analytic Signals and a Model System. IEEE Trans. Circuits Syst. II Express Briefs 2020, 67, 2234–2238. [Google Scholar] [CrossRef]

- Munasinghe, N.; Paul, G. Ultrasonic-Based Sensor Fusion Approach to Measure Flow Rate in Partially Filled Pipes. IEEE Sens. J. 2020, 20, 6083–6090. [Google Scholar] [CrossRef]

- Alaeddin, M.A.; Hashemabadi, S.H.; Mousavi, S.F. Numerical study on the effect of circumferential position of ultrasonic transducers on ultrasonic cross-correlation flowmeter performance under asymmetric air flow profile. Ultrasonics 2021, 115, 106479. [Google Scholar] [CrossRef]

- Massaad, J.; Van Neer, P.L.; Van Willigen, D.M.; Sabbadini, A.; De Jong, N.; Pertijs, M.A.; Verweij, M.D. Measurement of Pipe and Fluid Properties with a Matrix Array-based Ultrasonic Clamp-on Flow Meter. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2022, 69, 309–322. [Google Scholar] [CrossRef]

- Han, D.; Kim, S.; Park, S. Two-dimensional ultrasonic anemometer using the directivity angle of an ultrasonic sensor. Microelectron. J. 2008, 39, 1195–1199. [Google Scholar] [CrossRef]

- Chen, Q.; Li, W.; Wu, J. Realization of a multipath ultrasonic gas flowmeter based on transit-time technique. Ultrasonics 2014, 54, 285–290. [Google Scholar] [CrossRef]

- Weston, M.; Mudge, P.; Davis, C.; Peyton, A. Time efficient auto-focussing algorithms for ultrasonic inspection of dual-layered media using full matrix capture. Ndt E Int. 2012, 47, 43–50. [Google Scholar] [CrossRef]

- Iooss, B.; Lhuillier, C.; Jeanneau, H. Numerical simulation of transit-time ultrasonic flowmeters: Uncertainties due to flow profile and fluid turbulence. Ultrasonics 2002, 40, 1009–1015. [Google Scholar] [CrossRef]

- Li, W.; Chen, Q.; Wu, J. Double threshold ultrasonic distance measurement technique and its application. Rev. Sci. Instrum. 2014, 85, 044905. [Google Scholar] [CrossRef] [PubMed]

| Theoretical Time Difference (µs) | Actual Time Difference (µs) | Actual Error (%) | Quadratic Interpolation Error (%) | Cubic Spline Interpolation Error (%) |

|---|---|---|---|---|

| 0.160 | 0.200 | 24.999 | −2.531 | −2.239 |

| 0.170 | 0.200 | 17.647 | 0.820 | 0.974 |

| 0.180 | 0.200 | 11.111 | −0.360 | −0.178 |

| 0.190 | 0.200 | 5.263 | 0.257 | 0.478 |

| 0.200 | 0.200 | 0.000 | 1.118 | 1.269 |

| 0.210 | 0.200 | −4.761 | −1.926 | −1.833 |

| 0.220 | 0.200 | −9.091 | 0.207 | 0.267 |

| 0.230 | 0.200 | −13.040 | −0.467 | −0.430 |

| 0.240 | 0.200 | −16.670 | 0.684 | 0.768 |

| 0.250 | 0.200 | −20.000 | −0.698 | −0.695 |

| Flow Velocity Point (mm/s) | Average Value of the Standard Flow Velocity (mm/s) | Average Value of the Measured Flow Velocity (mm/s) | Standard Deviation (%) | Number of Samples | Average Value of Relative Indication Error (%) | Repeatability (%) |

|---|---|---|---|---|---|---|

| 300 | 299.60 | 299.75 | 0.34 | 74 | 0.05 | 0.11 |

| 400 | 399.46 | 399.33 | 0.29 | 54 | −0.03 | 0.05 |

| 499 | 499.34 | 499.08 | 0.23 | 41 | −0.05 | 0.04 |

| 599 | 599.21 | 599.36 | 0.23 | 33 | 0.03 | 0.09 |

| 700 | 699.81 | 699.64 | 0.21 | 28 | −0.02 | 0.05 |

| 800 | 799.69 | 800.00 | 0.19 | 24 | 0.04 | 0.05 |

| 900 | 899.58 | 899.20 | 0.20 | 20 | −0.04 | 0.03 |

| 1000 | 999.43 | 999.20 | 0.19 | 17 | −0.02 | 0.06 |

| 1099 | 1099.33 | 1099.28 | 0.16 | 15 | −0.01 | 0.07 |

| 1199 | 1199.18 | 1199.03 | 0.20 | 13 | −0.01 | 0.05 |

| 1300 | 1299.77 | 1298.18 | 0.23 | 12 | −0.12 | 0.06 |

| 1400 | 1399.63 | 1397.13 | 0.23 | 10 | −0.18 | 0.06 |

| 1500 | 1499.46 | 1494.76 | 0.24 | 9 | −0.31 | 0.05 |

| Flow Point (m/s) | Average of the Change in Level Height per Second (mm) | Standard Flow (m3/h) | Measured Flow (m3/h) | Relative Indication Error (%) |

|---|---|---|---|---|

| 1.936 | 0.050 | 0.088 | 0.088 | 0.11 |

| 2.155 | 0.056 | 0.098 | 0.097 | −0.10 |

| 2.389 | 0.062 | 0.108 | 0.108 | −0.28 |

| 2.611 | 0.068 | 0.118 | 0.118 | −0.51 |

| 2.822 | 0.074 | 0.128 | 0.127 | −0.31 |

| Ball Valve Opening (%) | Average of the Change in Level Height per Second (mm) | Average Value of the Standard Flow (m3/h) | Average Value of the Measured Flow (m3/h) | Relative Indication Error (%) |

|---|---|---|---|---|

| 30 | 0.187 | 0.323 | 0.325 | 0.464 |

| 40 | 0.487 | 0.847 | 0.846 | −0.071 |

| 50 | 0.739 | 1.286 | 1.283 | −0.191 |

| 60 | 0.909 | 1.585 | 1.579 | −0.379 |

| 70 | 1.006 | 1.747 | 1.747 | −0.017 |

| 80 | 1.060 | 1.830 | 1.842 | 0.676 |

| 90 | 1.075 | 1.871 | 1.867 | −0.186 |

| 100 | 1.079 | 1.883 | 1.875 | −0.427 |

| Ball Valve Opening (%) | Average of the Change in Level Height per Second (mm) | Average Value of the Standard Flow (m3/h) | Average Value of the Measured Flow (m3/h) | Relative Indication Error (%) |

|---|---|---|---|---|

| 30 | 0.296 | 0.516 | 0.514 | −0.314 |

| 40 | 0.543 | 0.937 | 0.943 | 0.589 |

| 50 | 0.933 | 1.625 | 1.620 | −0.343 |

| 60 | 1.325 | 2.308 | 2.301 | −0.294 |

| 70 | 1.665 | 2.876 | 2.893 | 0.597 |

| 80 | 1.868 | 3.256 | 3.244 | −0.370 |

| 90 | 2.002 | 3.460 | 3.478 | 0.524 |

| 100 | 2.060 | 3.568 | 3.579 | 0.299 |

| Ball Valve Opening (%) | Average of the Change in Level Height per Second (mm) | Average Value of the Standard Flow (m3/h) | Average Value of the Measured Flow (m3/h) | Relative Indication Error (%) |

|---|---|---|---|---|

| 30 | 0.552 | 0.956 | 0.958 | 0.195 |

| 40 | 0.740 | 1.280 | 1.285 | 0.365 |

| 50 | 0.998 | 1.737 | 1.733 | −0.287 |

| 60 | 1.744 | 3.044 | 3.029 | −0.493 |

| 70 | 2.507 | 4.341 | 4.354 | 0.294 |

| 80 | 3.727 | 6.443 | 6.473 | 0.462 |

| 90 | 4.540 | 7.936 | 7.886 | −0.638 |

| 100 | 5.370 | 9.291 | 9.328 | 0.398 |

| Standard Flow (m3/h) | Standard Flow Velocity (m/s) | Measured Flow Velocity (m/s) | Average Value of the Measured Flow Velocity (m/s) | Average Value of Relative Indication Error (%) |

|---|---|---|---|---|

| 157.000 | 26.331 | 25.930 | 26.303 | −0.108 |

| 26.675 | ||||

| 131.200 | 22.008 | 21.882 | 21.952 | −0.250 |

| 22.024 |

| Flow Velocity Point (m/s) | Standard Flow (m3/h) | Measured Flow (m3/h) | Relative Indication Error of a Single Point (%) | Average value of Relative Indication Error (%) | Repeat-ability (%) |

|---|---|---|---|---|---|

| 1.51 | 10947.600 | 10875.600 | −0.658 | −0.615 | 0.037 |

| 10929.600 | 10864.800 | −0.593 | |||

| 10886.400 | 10821.600 | −0.595 | |||

| 1.34 | 9694.800 | 9640.800 | −0.557 | −0.643 | 0.150 |

| 9712.800 | 9633.600 | −0.815 | |||

| 9720.000 | 9666.000 | −0.556 | |||

| 1.18 | 8528.400 | 8478.000 | −0.591 | −0.548 | 0.043 |

| 8542.800 | 8499.600 | −0.506 | |||

| 8546.400 | 8499.600 | −0.548 | |||

| 0.98 | 7059.600 | 7012.800 | −0.663 | −0.645 | 0.078 |

| 7074.000 | 7023.600 | −0.712 | |||

| 7066.800 | 7027.200 | −0.560 | |||

| 0.81 | 5868.000 | 5828.400 | −0.675 | −0.695 | 0.094 |

| 5871.600 | 5824.800 | −0.797 | |||

| 5878.800 | 5842.800 | −0.612 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, R.; Wang, H.; Sun, X.; Quan, H. Design and Implementation of an Ultrasonic Flowmeter Based on the Cross-Correlation Method. Sensors 2022, 22, 7470. https://doi.org/10.3390/s22197470

Ren R, Wang H, Sun X, Quan H. Design and Implementation of an Ultrasonic Flowmeter Based on the Cross-Correlation Method. Sensors. 2022; 22(19):7470. https://doi.org/10.3390/s22197470

Chicago/Turabian StyleRen, Rui, Hongliang Wang, Xiaolei Sun, and He Quan. 2022. "Design and Implementation of an Ultrasonic Flowmeter Based on the Cross-Correlation Method" Sensors 22, no. 19: 7470. https://doi.org/10.3390/s22197470

APA StyleRen, R., Wang, H., Sun, X., & Quan, H. (2022). Design and Implementation of an Ultrasonic Flowmeter Based on the Cross-Correlation Method. Sensors, 22(19), 7470. https://doi.org/10.3390/s22197470