Typical Fragment Kinetic Energy Assessment Based on Acoustic Emission Technology

Abstract

:1. Introduction

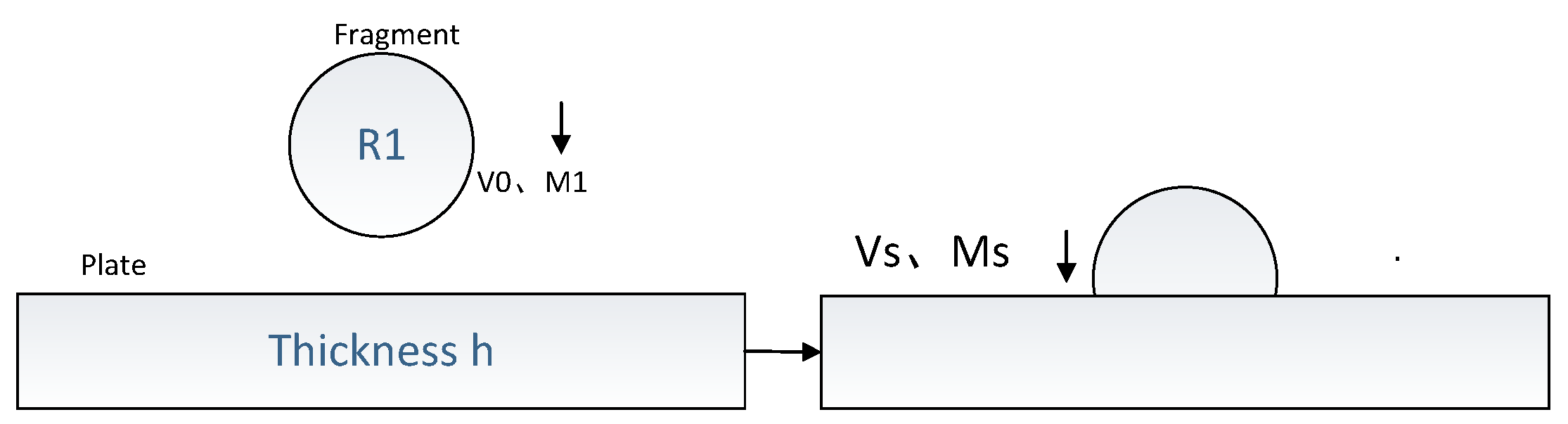

2. High-Speed Impact Dynamic Response of Thin Targeting

3. Typical Evasion Hit Sound Emission Signal Numerical Simulation

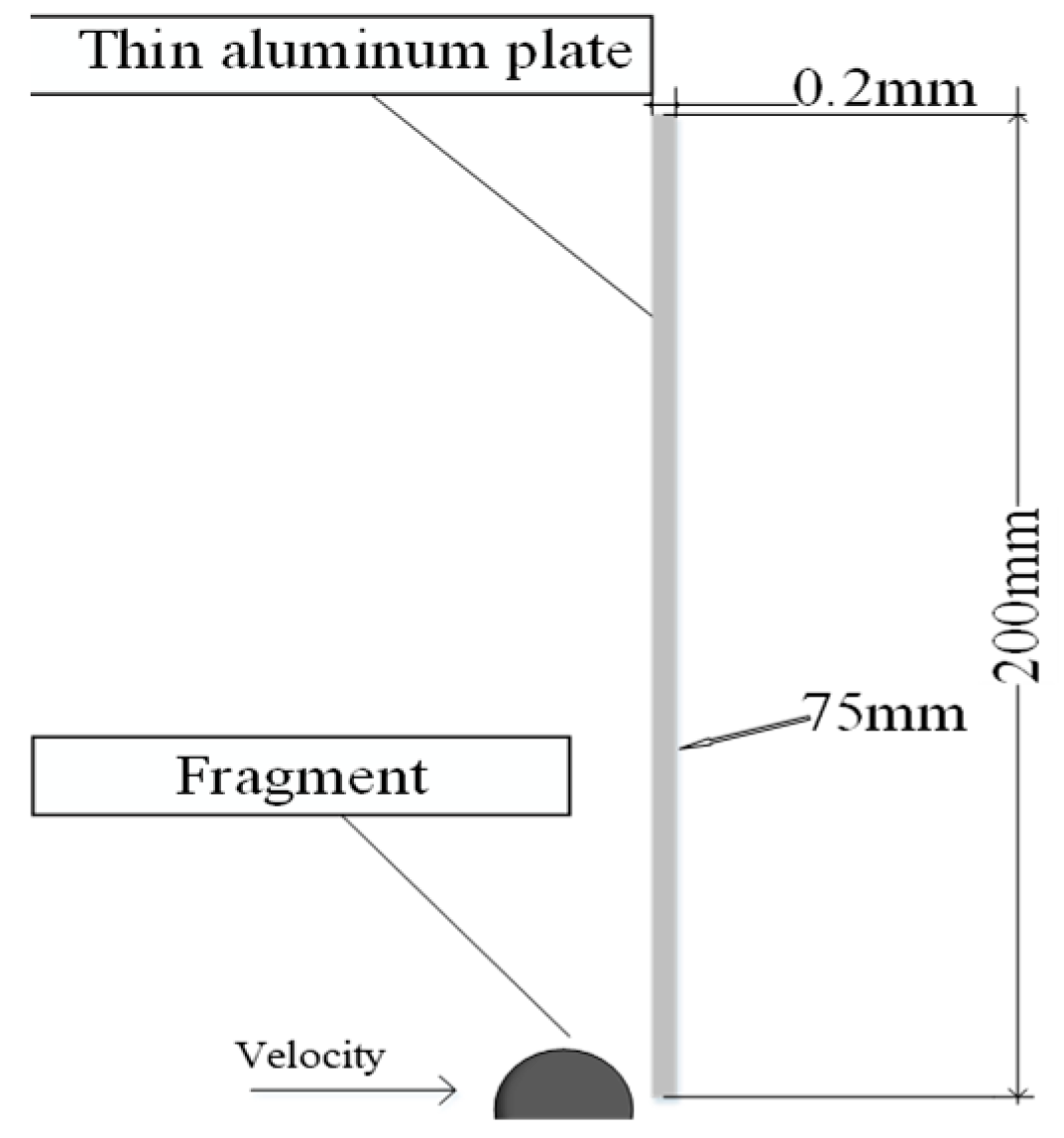

3.1. Finite Element Model

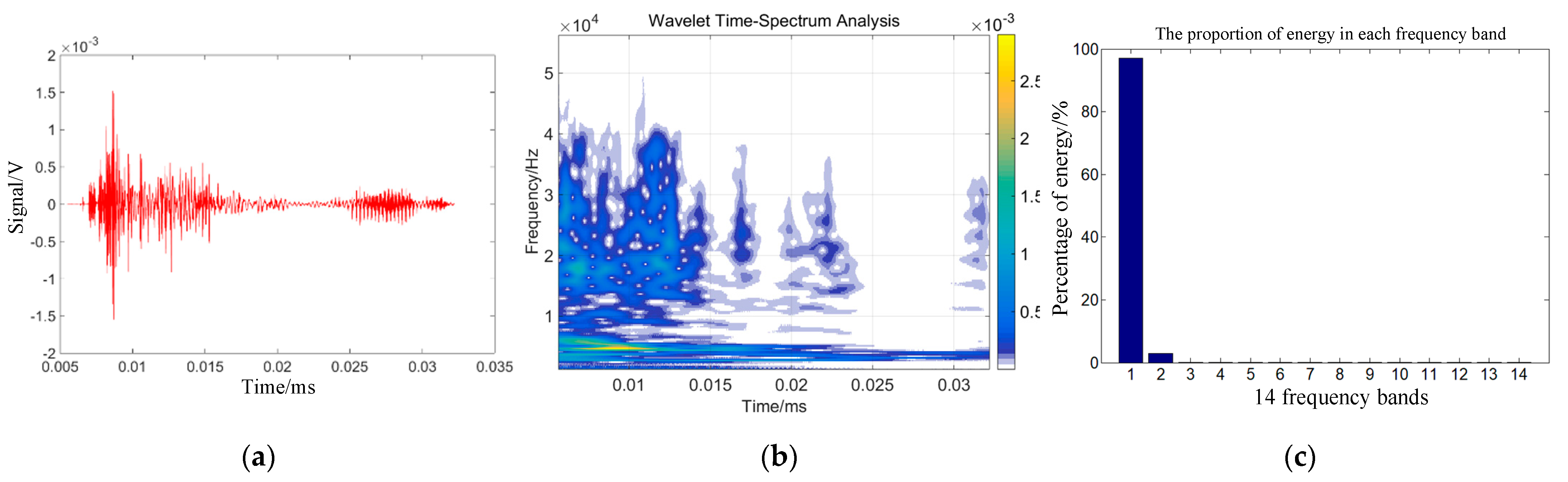

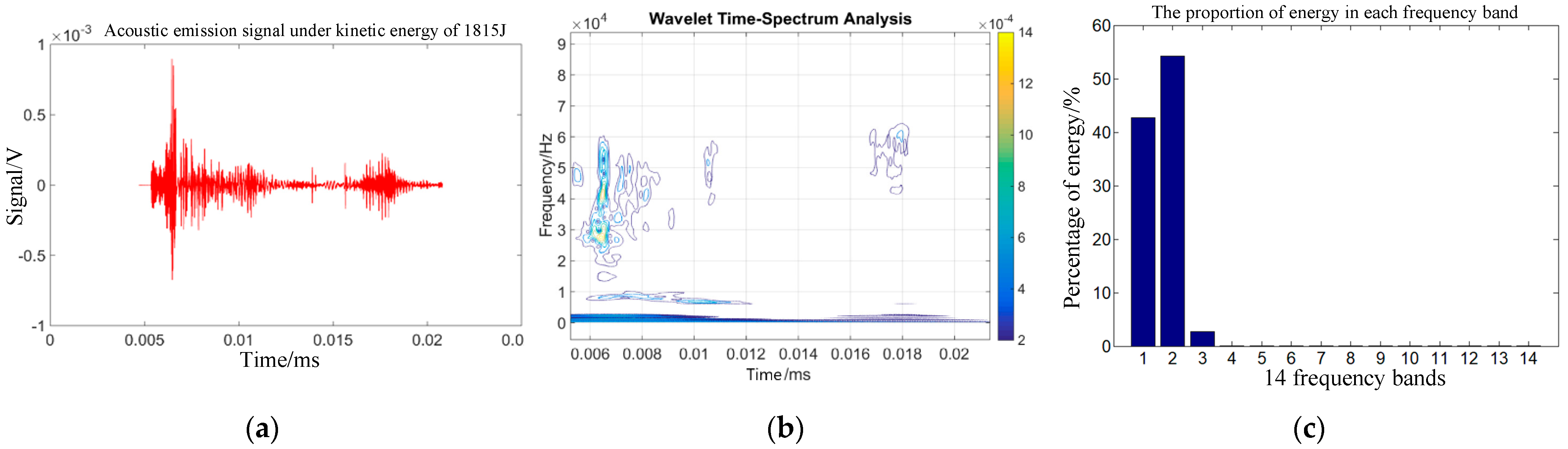

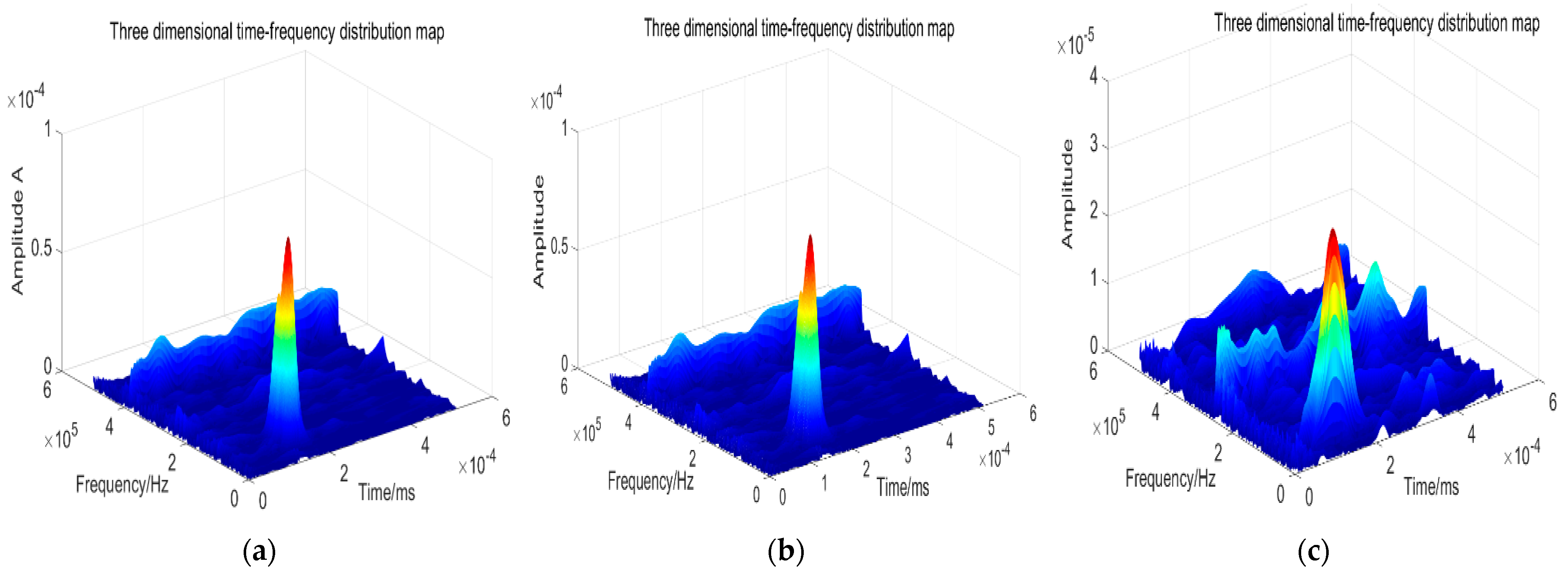

3.2. Sound Transmission Signal Time-Frequency Analysis

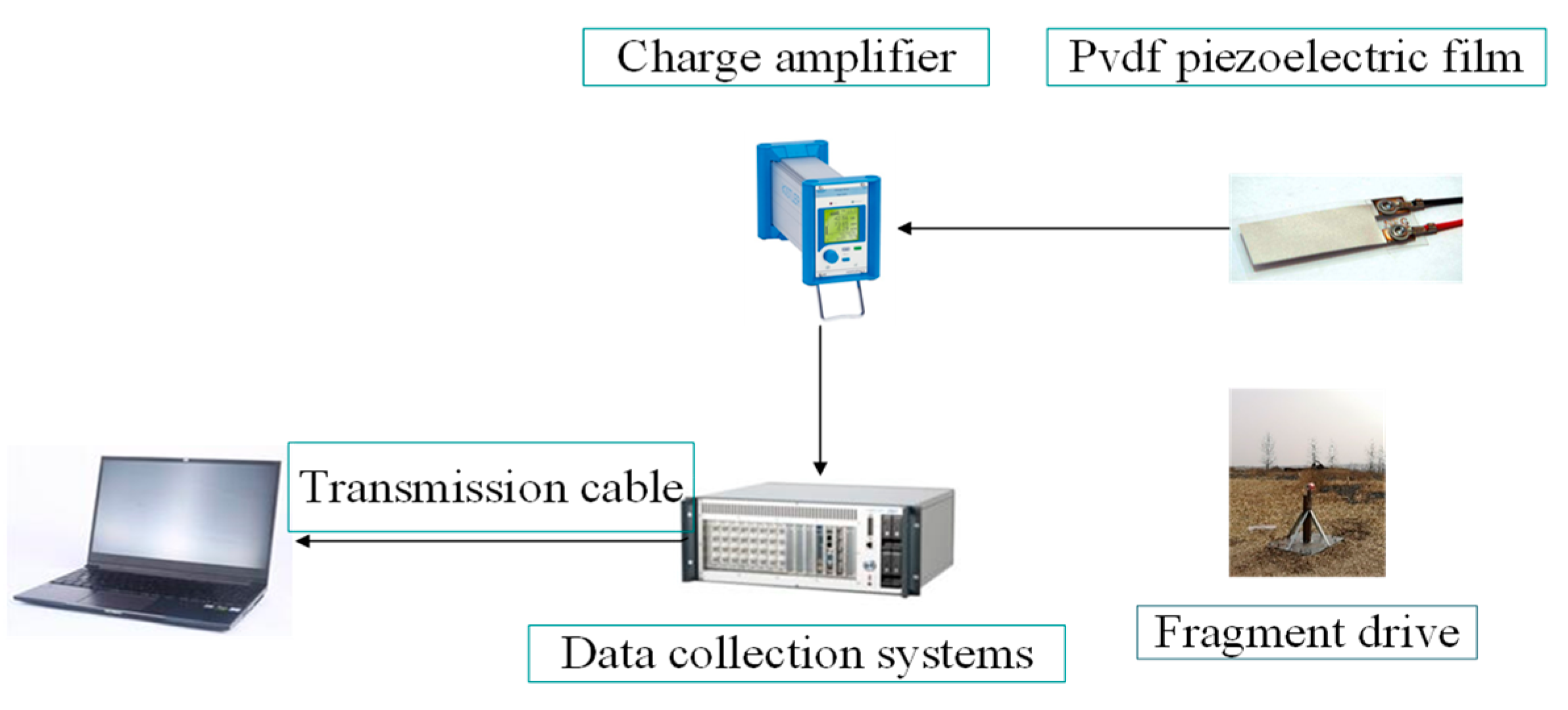

4. Typical Evasion Hit Target Board Test Verification

4.1. Evasion Test Target

4.2. Comparative Analysis and Numerical Calculation Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.; Qian, J.P.; Niu, G.J. Simulation and Damage Analysis about Performed Fragments of Axial Forward Projection Fragment Warhead. Comput. Simul. 2011, 28, 13–17. [Google Scholar]

- Hutchinson, M.D. The escape of blast from fragmenting munitions casings. Int. J. Impact Eng. 2009, 36, 185–192. [Google Scholar] [CrossRef]

- Gong, C.A.; Chen, Z.G.; Yin, L.K. Analysis of movement laws of fragment and shock wave from a blast fragmentation warhead. J. Meas. Sci. Instrum. 2015, 6, 218–222. [Google Scholar]

- Xu, J.; Fu, Z.; Han, Q.; Lacidogna, G.; Carpinteri, A. Micro-cracking monitoring and fracture evaluation for crumb rubber concrete based on acoustic emission techniques. Struct Health Monit. Int. J. 2017, 17, 946–958. [Google Scholar] [CrossRef]

- Watson, E.; Kunert, N.; Putzar, R. Four-view split-image fragment tracking in hypervelocity impact experiments. Int. J. Impact Eng. 2020, 135, 103405. [Google Scholar] [CrossRef]

- Watsona, E.; Gulde, M.; Kortmann, L. Optical fragment tracking in hypervelocity impact experiments. Acta Astronaut. 2019, 155, 111–117. [Google Scholar] [CrossRef]

- Wang, Z.M.; Gao, J.C.; Lei, Z.Y. The Target Calculate Principle of Linear CCI DIntersection Measurement. Shanxi Electron. Technol. 2006, 5, 38–40. [Google Scholar]

- Holroyd, T.J. Practical Applications of Acoustic Emission Technology. Br. J. NDT 1986, 28, 224–227. [Google Scholar]

- Bhuiyan, M.Y.; Lin, B.; Giurgiutiu, V. Acoustic emission sensor effect and waveform evolution during fatigue crack growth in thin metallic plate. J. Intell. Mater. Syst. Struct. 2018, 29, 1275–1284. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Xu, W.; Yang, Q. Diagnosis of damage evolution process for asphalt mixtures using pattern recognition with acoustic emission signals. Const Ruction Build. Mater. 2021, 280, 122536. [Google Scholar]

- ASTM. Standard Guide for Determining the Reproducibility of Acoustic Emission Sensor Response; American Society for Testing and Materials: Philadelphia, PA, USA, 2010. [Google Scholar]

- Carrasco1, Á.; Mendez, F. Short Review of the Use of Acoustic Emissions for Detection and Monitoring of Cracks. Acoust. Aust. 2021, 49, 273–280. [Google Scholar] [CrossRef]

- Wolfinger, C.; Arendts, F.J.; Friedrich, K.; Drechsler, K. Health-Monitoring System Based on Piezoelectric Transducers. Aerosp. Sci. Technol. 1998, 2, 391–400. [Google Scholar] [CrossRef]

- Greszczuk, L.B.; Chao, H. Impact Damage in Graphite-Fiber Reinforced Composites. Compos. Mater. Test. Des. 1977, 617, 389–408. [Google Scholar]

- Hu, K.; Yang, G.; Zhang, Z.; Shi, H. Energy Identification of Engine Blade Produced by Impact Based on Acoustic Emission. In Proceedings of the 2018 Ninth International Conference on Intelligent Control and Information Processing (ICICIP), Wanzhou, China, 9–11 November 2018; pp. 111–116. [Google Scholar]

- Hesser, D.F.; Mostafavi, S. Identification of acoustic emission sources for structural health monitoring applications based on convolutional neural networks and deep transfer learning. Neurocomputing 2021, 453, 1–12. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Vimalathithan, P.K. Damage characterization in composite materials using acoustic emission signal-based and parameter-based data. Compos. Part B 2019, 178, 107469. [Google Scholar] [CrossRef]

- Prosser, W.H.; Gorman, M.R.; Humes, D.H. Acoustic emission signals in thin plates produced by impact damage. J. Acoust. Emiss. 1999, 17, 29–36. [Google Scholar]

- Tang, X. Characteristics of Acoustics Emission Signals Produced by Hypervelocity Impact. J. Astronaut. 2008, 29, 1462–1465. [Google Scholar]

- Liu, W.G. Damage Identification of Single Aluminum Plate Produced by Hypervelocity Impact Based Acoustic Emission. J. Astronaut. 2011, 32, 671–675. [Google Scholar]

- Wang, L.; Shang, F.; Kong, D. Numerical simulation analysis of static and dynamic explosive shock waves. Chin. J. Weapon. Equip. Eng. 2020, 41, 208–213. [Google Scholar]

- Sun, X.; Bai, C.; Wang, H.; Xue, K. Research on safe distance test and numerical simulation of prefabricated fragmentation warhead. Chin. J. Weapon. Equip. Eng. 2021, 42, 27–33. [Google Scholar]

- Zhao, F.; Wang, Z.; Yin, J.; Wang, X.; Wang, S.; Jia, Z. Numerical Simulation of Prefabricated Fragment/MEFP Combination Warhead. Chin. J. Weapon. Equip. Eng. 2017, 38, 52–56. [Google Scholar]

- Wang, L.; Wang, Z.; Ma, W.; Jia, Z. Research on anti-fragment penetration of steel/ceramic/PE/steel structures. Weapon Mater. Sci. Eng. 2022, 45, 103–108. [Google Scholar] [CrossRef]

- Lv, Z.; Du, J.; Du, L. Numerical simulation of armor-piercing of spherical and hexahedral prefabricated fragments. Sichuan Mil. J. 2011, 32, 10–13. [Google Scholar]

- Wang, Q.; Hong, J. Numerical simulation research on the process of high-speed fragment penetration through the target. Collect. Abstr. Acad. Conf. Chin. Soc. Mech. 2005, 2005, 315. [Google Scholar]

| Material | /(g/cm3) | E/GPa | u | |

|---|---|---|---|---|

| Aluminum 7039 | 2.77 | 79 | 0.33 | |

| A/MPa | B/MPa | C | n | m |

| 337 | 343 | 0.01 | 0.41 | 1 |

| Material | /(g/cm3) | E/GPa | u |

|---|---|---|---|

| Tungsten | 1.76 | 350 | 0.284 |

| Test | Target Sheet Material | Fragment Material | Wavelet Energy | Fragment Kinetic Energy (J) | Target Status |

|---|---|---|---|---|---|

| Test 1 | Aluminum 7039 | Tungsten Alloy | 3.114 | 2598 | Perforation |

| Test 2 | Aluminum 7039 | Tungsten Alloy | 3.117 | 2597 | Perforation |

| Test 3 | Aluminum 7039 | Tungsten Alloy | 1.917 | 3112.2 | Perforation |

| Test 4 | Aluminum 7039 | Tungsten Alloy | 1.893 | 3143.5 | Perforation |

| Test 5 | Aluminum 7039 | Tungsten Alloy | 1.693 | 3289.5 | Perforation |

| Test 6 | Aluminum 7039 | Tungsten Alloy | 1.034 | 3778.4 | Perforation |

| Test | Light Curtain Target Spacing (m) | Target Plate Interval (ms) | Velocity at Target (m/s) | Fragment Quality (g) | Fragment Kinetic Energy (J) |

|---|---|---|---|---|---|

| Test 1 | 1 | 0.748 | 1336.3 | 3 | 2678.6 |

| Test 2 | 1 | 0.774 | 1292.4 | 3 | 2505.4 |

| Test 3 | 1 | 0.685 | 1460.6 | 3 | 3200 |

| Test 4 | 1 | 0.665 | 1503.8 | 3 | 3240.3 |

| Test 5 | 1 | 0.486 | 2057.6 | 3 | 3308.1 |

| Test 6 | 1 | 0.412 | 2427.18 | 3 | 3879 |

| Kinetic Energy/J | |||

|---|---|---|---|

| Test | Light Curtain Target Experiment | Wavelet Energy Calculation | Error/% |

| Test 1 | 2598 | 2678.6 | 3 |

| Test 2 | 2597 | 2505.4 | 3.7 |

| Test 3 | 3112.2 | 3200 | 2.7 |

| Test 4 | 3143.5 | 3240.3 | 2.99 |

| Test 5 | 3289.5 | 3308.1 | 0.5 |

| Test 6 | 3778.4 | 3879 | 2.59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, F.; Wang, L. Typical Fragment Kinetic Energy Assessment Based on Acoustic Emission Technology. Sensors 2022, 22, 5914. https://doi.org/10.3390/s22155914

Shang F, Wang L. Typical Fragment Kinetic Energy Assessment Based on Acoustic Emission Technology. Sensors. 2022; 22(15):5914. https://doi.org/10.3390/s22155914

Chicago/Turabian StyleShang, Fei, and Liangquan Wang. 2022. "Typical Fragment Kinetic Energy Assessment Based on Acoustic Emission Technology" Sensors 22, no. 15: 5914. https://doi.org/10.3390/s22155914

APA StyleShang, F., & Wang, L. (2022). Typical Fragment Kinetic Energy Assessment Based on Acoustic Emission Technology. Sensors, 22(15), 5914. https://doi.org/10.3390/s22155914