Review of Neural Network Modeling of Shape Memory Alloys

Abstract

1. Introduction

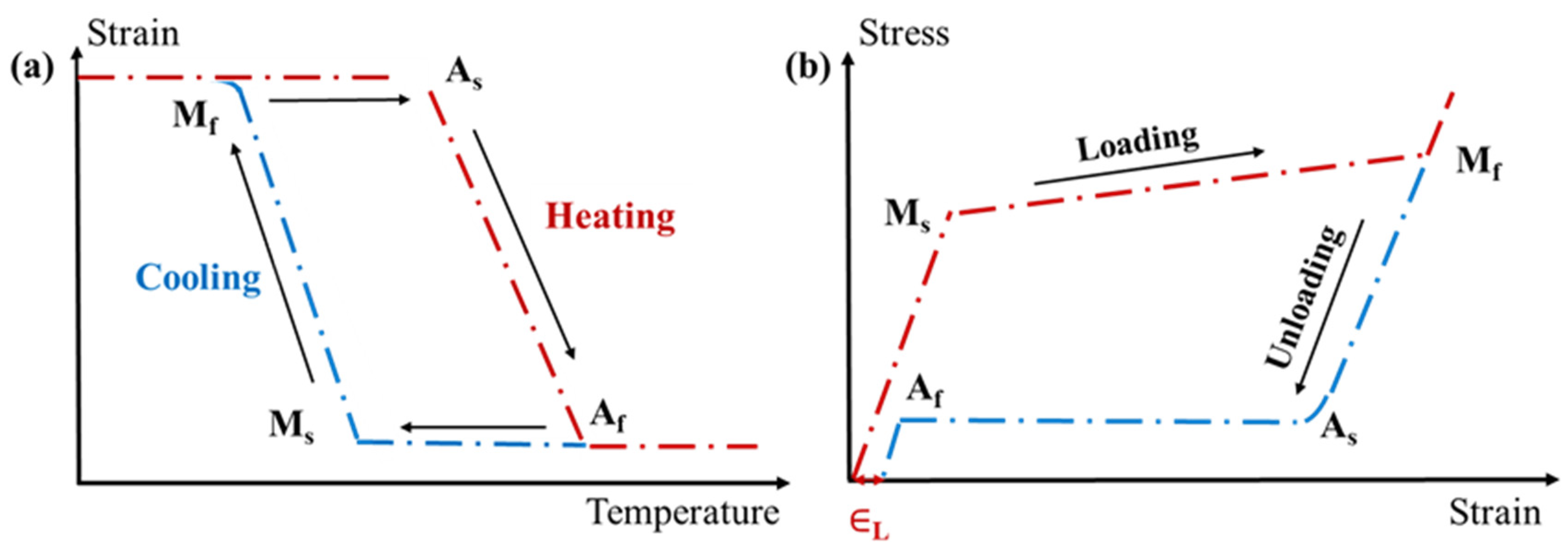

2. Description of the SMAs

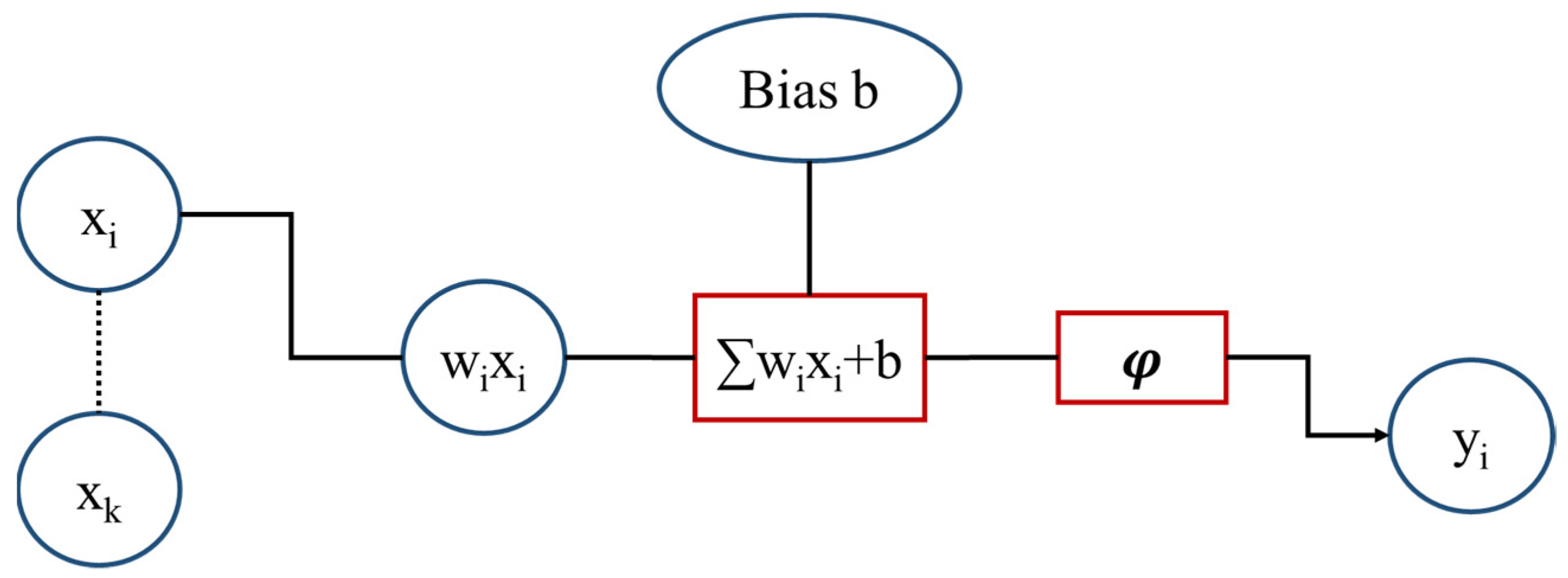

3. Description of Artificial Neural Networks

4. SMA Forms and ANN Applications

4.1. Systems with a Wire for Linear Actuation

4.2. Systems with One Wire and One Spring for Linear Actuation

4.3. Magnetic SMA System

4.4. SMA Wire Systems for Rotatory Actuation

4.5. A Reinforced SMA Concrete Beam

4.6. Porous SMAs

4.7. SMA Bars and Rings as Self-Centering and Damping Device

4.8. SMA Self-Sensing Systems

5. Discussion

| NN | Definition | Domain |

|---|---|---|

| Full feedforward NN | It treats the information only in one direction “forward” from the input nodes, through the hidden nodes (if any) to the output nodes without cycles or loops in the network [114] | Clustering Regression |

| Long short term memory NN | It has feedback connectors. Its unit consists of a cell, an input gate, an output gate and a forget gate. The gate is a threshold help NN distinguishing between using the identity connections over the stacked layers. | Prediction Classifying |

| Multilayer ormal feed NN | It is a full feedforward NN, but with multicomputational layers (multihidden layer). | Clustering Regression |

| Nonlinear autoregressive exogenous NN (NARX) | It is a recurrent NN that has loop connections between the nodes. | Time Series |

| NN estimator | It is NN that is based on an estimator, which is a technique or method that calculates an accurate result that depends on actual observations. | Prediction Classification |

| General regression (GRNN) | It has a radial-basis function layer and a linear layer [115] | Regression Approximation Classification |

| Proportional- integral-differential NN (PIDNN) | It is a dynamic feedforward network, a combination of neural networks with the PID control concept. | Controlling |

| Takagi–Sugeno fuzzy neural network (TSFNN) | It is a fuzzy system model that needs fewer inputs without the capability of handling online data [116] | Clustering |

| Functional link artificial intelligent NN (FLANN) | It is a single-layer higher-order class of an ANN [117] | Pattern Recognition Classification |

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Aïssa, B.; Memon, N.K.; Ali, A.; Khraisheh, M.K. Recent Progress in the Growth and Applications of Graphene as a Smart Material: A Review. Front. Mater. 2015, 2, 58. [Google Scholar] [CrossRef]

- Cao, W.; Cudney, H.H.; Waser, R. Smart materials and structures. Proc. Natl. Acad. Sci. USA 1999, 96, 8330–8331. [Google Scholar] [CrossRef] [PubMed]

- Chaudhari, R.; Vora, J.J.; Patel, V.; López de Lacalle, L.N.; Parikh, D.M. Surface Analysis of Wire-Electrical-Discharge-Machining-Processed Shape-Memory Alloys. Materials 2020, 13, 530. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Y.; Li, Y.; Chen, M.Z.Q.; Wei, Y. Bioinspired Robotic Fingers Based on Pneumatic Actuator and 3D Printing of Smart Material. Soft Robot. 2017, 4, 147–162. [Google Scholar] [CrossRef]

- Prokoshkin, S.; Brailovski, V.; Dubinskiy, S.; Zhukova, Y.; Sheremetyev, V.; Konopatsky, A.; Inaekyan, K. Manufacturing, Structure Control, and Functional Testing of Ti–Nb-Based SMA for Medical Application. Shape Mem. Superelast. 2016, 2, 130–144. [Google Scholar] [CrossRef]

- Isalgue, A.; Torra, V.; Lovey, F.; Terriault, P.; Carreras, G.; Soul, H.; Dieng, L. Experimental study of damping in civil engineering structures using smart materials (NiTi-SMA). Application to stayed cables for bridges. Int. Rev. Mech. Eng. 2010, 4, 601–611. [Google Scholar]

- Tzou, H.; Lee, H.-J.; Arnold, S.M. Smart Materials, Precision Sensors/Actuators, Smart Structures, and Structronic Systems. Mech. Adv. Mater. Struct. 2004, 11, 367–393. [Google Scholar] [CrossRef]

- Ma, N.; Song, G.; Lee, H.-J. Position control of shape memory alloy actuators with internal electrical resistance feedback using neural networks. Smart Mater. Struct. 2004, 13, 777–783. [Google Scholar] [CrossRef]

- Zhang, J.-J.; Yin, Y.-H.; Zhu, J.-Y. Electrical Resistivity-Based Study of Self-Sensing Properties for Shape Memory Alloy-Actuated Artificial Muscle. Sensors 2013, 13, 12958–12974. [Google Scholar] [CrossRef]

- Gómez-Espinosa, A.; Castro Sundin, R.; Loidi Eguren, I.; Cuan-Urquizo, E.; Treviño-Quintanilla, C.D. Neural Network Direct Control with Online Learning for Shape Memory Alloy Manipulators. Sensors 2019, 19, 2576. [Google Scholar] [CrossRef]

- Ölander, A. An Electrochemical Investigation of Solid Caduim-Gold Alloys. J. Am. Chem. Soc. 1932, 54, 3819–3833. [Google Scholar] [CrossRef]

- Zhang, X.P.; Liu, H.Y.; Yuan, B.; Zhang, Y.P. Superelasticity decay of porous NiTi shape memory alloys under cyclic strain-controlled fatigue conditions. Mater. Sci. Eng. A 2008, 481–482, 170–173. [Google Scholar] [CrossRef]

- Qader, İ.N.; Kök, M.; Dagdelen, F.; Aydoğdu, Y. A review of smart materials: Researches and applications. El-Cezeri J. Sci. Eng. 2019, 6, 755–788. [Google Scholar] [CrossRef]

- Alsoruji, G.; Muthuramalingam, T.; Moustafa, E.B.; Elsheikh, A. Investigation and TGRA based optimization of laser beam drilling process during machining of Nickel Inconel 718 alloy. J. Mater. Res. Technol. 2022, 18, 720–730. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Carrera, G.V.S.M.; Branco, L.C.; Aires-de-Sousa, J.; Afonso, C.A.M. Exploration of quantitative structure–property relationships (QSPR) for the design of new guanidinium ionic liquids. Tetrahedron 2008, 64, 2216–2224. [Google Scholar] [CrossRef]

- Xu, S.X.; Koko, T.S. Finite element analysis and design of actively controlled piezoelectric smart structures. Finite Elem. Anal. Des. 2004, 40, 241–262. [Google Scholar] [CrossRef]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S. Review on non-conventional machining of shape memory alloys. Trans. Nonferrous Met. Soc. China 2014, 24, 12–21. [Google Scholar] [CrossRef]

- Kaya, E.; Kaya, İ. A review on machining of NiTi shape memory alloys: The process and post process perspective. Int. J. Adv. Manuf. Technol. 2019, 100, 2045–2087. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Mani Prabu, S.S.; Palani, I.A.; Patel, V.K.; Parikh, D.M.; de Lacalle, L.N.L. Multi-Response Optimization of WEDM Process Parameters for Machining of Superelastic Nitinol Shape-Memory Alloy Using a Heat-Transfer Search Algorithm. Mater. Basel Switz. 2019, 12, 1277. [Google Scholar] [CrossRef]

- Dick, S. Artificial Intelligence. Harv. Data Sci. Rev. 2019. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, T.; Ju, W.; Shi, S. Materials discovery and design using machine learning. J. Mater. 2017, 3, 159–177. [Google Scholar] [CrossRef]

- Mendizabal, A.; Márquez-Neila, P.; Cotin, S. Simulation of hyperelastic materials in real-time using deep learning. Med. Image Anal. 2020, 59, 101569. [Google Scholar] [CrossRef]

- Bogue, R. Smart materials: A review of capabilities and applications. Assem. Autom. 2014, 34, 16–22. [Google Scholar] [CrossRef]

- Bogue, R. Smart materials: A review of recent developments. Assem. Autom. 2012, 32, 3–7. [Google Scholar] [CrossRef]

- Guo, F.; Guo, Z. Inspired smart materials with external stimuli responsive wettability: A review. RSC Adv. 2016, 6, 36623–36641. [Google Scholar] [CrossRef]

- Owusu-Danquah, J.S.; Bseiso, A.; Allena, S. Artificial neural network models to predict the response of 55NiTi shape memory alloy under stress and thermal cycles. Neural Comput. Appl. 2022, 34, 3829–3842. [Google Scholar] [CrossRef]

- Goldberg, Y. Neural Network Methods for Natural Language Processing. Synth. Lect. Hum. Lang. Technol. 2017, 10, 1–309. [Google Scholar] [CrossRef]

- Das, S.; Pegu, H.; Sahu, K.K.; Nayak, A.K.; Ramakrishna, S.; Datta, D.; Swayamjyoti, S. Machine learning in materials modeling—Fundamentals and the opportunities in 2D materials. In Synthesis, Modeling, and Characterization of 2D Materials, and Their Heterostructures; Elsevier: Amsterdam, The Netherland, 2020; pp. 445–468. [Google Scholar] [CrossRef]

- Butler, K.T.; Davies, D.W.; Cartwright, H.; Isayev, O.; Walsh, A. Machine learning for molecular and materials science. Nature 2018, 559, 547–555. Available online: https://www.nature.com/articles/s41586-018-0337-2 (accessed on 6 April 2021). [CrossRef]

- Phillips, C.L.; Voth, G.A. Discovering crystals using shape matching and machine learning. Soft Matter 2013, 9, 8552–8568. [Google Scholar] [CrossRef]

- Majid, A.; Khan, A.; Choi, T.-S. Predicting lattice constant of complex cubic perovskites using computational intelligence. Comput. Mater. Sci. 2011, 50, 1879–1888. [Google Scholar] [CrossRef]

- Lorente, D.; Martínez-Martínez, F.; Rupérez, M.J.; Lago, M.A.; Martínez-Sober, M.; Escandell-Montero, P.; Martínez-Martínez, J.M.; Martínez-Sanchis, S.; Serrano-López, A.J.; Monserrat, C.; et al. A framework for modelling the biomechanical behaviour of the human liver during breathing in real time using machine learning. Expert Syst. Appl. 2017, 71, 342–357. [Google Scholar] [CrossRef]

- Zakerzadeh, M.R.; Salehi, H. Comparative Analysis of Some one-Dimensional SMA Constitutive Models for a Ni-Ti Wire for Shape Control Applications with Experimental Data. In Proceeding of the 20th International Conference on Adaptive Structures and Technologies, Hong Kong, China, 20–22 October 2009; pp. 1101–1113. [Google Scholar]

- Prajna, M.R.; Antony, P.J.; Jnanesh, N.A. Machine learning approach for flexural characterization of smart material. J. Phys. Conf. Ser. 2018, 1142, 012007. [Google Scholar] [CrossRef]

- Farber, E.; Zhu, J.-N.; Popovich, A.; Popovich, V. A review of NiTi shape memory alloy as a smart material produced by additive manufacturing. Mater. Today Proc. 2020, 30, 761–767. [Google Scholar] [CrossRef]

- Morgan, N.B. Medical shape memory alloy applications—The market and its products. Mater. Sci. Eng. A 2004, 378, 16–23. [Google Scholar] [CrossRef]

- Sreekumar, M.; Nagarajan, T.; Singaperumal, M.; Zoppi, M.; Molfino, R. Critical review of current trends in shape memory alloy actuators for intelligent robots. Ind. Robot Int. J. 2007, 34, 285–294. [Google Scholar] [CrossRef]

- Rodrigue, H.; Wang, W.; Han, M.-W.; Kim, T.J.Y.; Ahn, S.-H. An Overview of Shape Memory Alloy-Coupled Actuators and Robots. Soft Robot. 2017, 4, 3–15. [Google Scholar] [CrossRef]

- Song, G.; Ma, N.; Li, H.-N. Applications of shape memory alloys in civil structures. Eng. Struct. 2006, 28, 1266–1274. [Google Scholar] [CrossRef]

- Cladera, A.; Weber, B.; Leinenbach, C.; Czaderski, C.; Shahverdi, M.; Motavalli, M. Iron-based shape memory alloys for civil engineering structures: An overview. Constr. Build. Mater. 2014, 63, 281–293. [Google Scholar] [CrossRef]

- Hartl, D.J.; Lagoudas, D.C. Aerospace applications of shape memory alloys. J. Sagepub 2007, 221, 535–552. [Google Scholar] [CrossRef]

- Exarchos, D.A.; Dalla, P.T.; Tragazikis, I.K.; Dassios, K.G.; Zafeiropoulos, N.E.; Karabela, M.M.; De Crescenzo, C.; Karatza, D.; Musmarra, D.; Chianese, S.; et al. Development and Characterization of High Performance Shape Memory Alloy Coatings for Structural Aerospace Applications. Materials 2018, 11, 832. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A. Shape Memory Alloys in Automotive Applications. Appl. Mech. Mater. 2014, 663, 248–253. [Google Scholar] [CrossRef]

- Bellini, A.; Colli, M.; Dragoni, E. Mechatronic Design of a Shape Memory Alloy Actuator for Automotive Tumble Flaps: A Case Study. IEEE Trans. Ind. Electron. 2009, 56, 2644–2656. [Google Scholar] [CrossRef]

- Fang, C.; Zheng, Y.; Chen, J.; Yam, M.C.H.; Wang, W. Superelastic NiTi SMA cables: Thermal-mechanical behavior, hysteretic modelling and seismic application. Eng. Struct. 2019, 183, 533–549. [Google Scholar] [CrossRef]

- Chemisky, Y.; Duval, A.; Patoor, E.; Ben Zineb, T. Constitutive model for shape memory alloys including phase transformation, martensitic reorientation and twins accommodation. Mech. Mater. 2011, 43, 361–376. [Google Scholar] [CrossRef]

- Lovey, F.C.; Torra, V. Shape memory in Cu-based alloys: Phenomenological behavior at the mesoscale level and interaction of martensitic transformation with structural defects in Cu-Zn-Al. Prog. Mater. Sci. 1999, 44, 189–289. [Google Scholar] [CrossRef]

- Taillard, K.; Chirani, S.A.; Calloch, S.; Lexcellent, C. Equivalent transformation strain and its relation with martensite volume fraction for isotropic and anisotropic shape memory alloys. Mech. Mater. 2008, 40, 151–170. [Google Scholar] [CrossRef]

- Shape Memory Effect—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/chemistry/shape-memory-effect (accessed on 8 April 2021).

- Lexcellent, C.; Leclercq, S.; Gabry, B.; Bourbon, G. The two way shape memory effect of shape memory alloys: An experimental study and a phenomenological model. Int. J. Plast. 2000, 16, 1155–1168. [Google Scholar] [CrossRef]

- Barnes, C. Innovations: Shape Memory and Superelastic Alloys. 1999. Available online: https://www.copper.org/publications/newsletters/innovations/1999/07/shape.html (accessed on 21 April 2021).

- Wang, X.; Hu, G. Stress transfer for a SMA fiber pulled out from an elastic matrix and related bridging effect. Compos. Part Appl. Sci. Manuf. 2005, 36, 1142–1151. [Google Scholar] [CrossRef]

- Divringi, K.; Ozcan, C. Advanced Shape Memory Alloy Material Models for ANSYS. Ozen Eng. Inc. 2016, 94085, 408. [Google Scholar]

- Kirkpatrick, K.; Valasek, J. Reinforcement Learning for Characterizing Hysteresis Behavior of Shape Memory Alloys. J. Aerosp. Comput. Inf. Commun. 2009, 6, 227–238. [Google Scholar] [CrossRef][Green Version]

- Rustighi, E.; Brennan, M.J.; Mace, B.R. Real-time control of a shape memory alloy adaptive tuned vibration absorber. Smart Mater. Struct. 2005, 14, 1184–1195. [Google Scholar] [CrossRef]

- Wang, S.-C. Artificial Neural Network. In Interdisciplinary Computing in Java Programming; Wang, S.-C., Ed.; The Springer International Series in Engineering and Computer Science: Boston, MA, USA, 2003; pp. 81–100. ISBN 978-1-4615-0377-4. [Google Scholar]

- Abraham, A. Artificial Neural Networks. In Handbook of Measuring System Design; American Cancer Society: Atlanta, GA, USA, 2005; ISBN 978-0-471-49739-4. [Google Scholar]

- Kohli, S.; Miglani, S.; Rapariya, R. Basics of artificial neural network. Int. J. Comput. Sci. Mob. Comput. 2014, 3, 745–751. [Google Scholar]

- Abdi, H. A neural network primer. J. Biol. Syst. 1994, 02, 247–281. [Google Scholar] [CrossRef]

- Hansen, L.K.; Salamon, P. Neural network ensembles. IEEE Trans. Pattern Anal. Mach. Intell. 1990, 12, 993–1001. [Google Scholar] [CrossRef]

- Du, K.-L. Clustering: A neural network approach. Neural Netw. 2010, 23, 89–107. [Google Scholar] [CrossRef]

- Ghahari, S.; Queiroz, C.; Labi, S.; McNeil, S. Cluster Forecasting of Corruption Using Nonlinear Autoregressive Models with Exogenous Variables (NARX)—An Artificial Neural Network Analysis. Sustainability 2021, 13, 11366. [Google Scholar] [CrossRef]

- Dorffner, G. Neural Networks for Time Series Processing. Neural Netw. World 1996, 6, 447–468. [Google Scholar]

- Minasny, B.; McBratney, A.B. The Neuro-m Method for Fitting Neural Network Parametric Pedotransfer Functions-Minasny. Soil Sci. Soc. Am. J. 2002, 66, 352–361. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks and Learning Machines, 3rd ed.; Pearson: London, UK, 2008. [Google Scholar]

- Albawi, S.; Mohammed, T.A.; Al-Zawi, S. Understanding of a convolutional neural network. In Proceedings of the 2017 International Conference on Engineering and Technology (ICET), Antalya, Turkey, 21–23 August 2017; pp. 1–6. [Google Scholar]

- Psaltis, D.; Sideris, A.; Yamamura, A.A. A multilayered neural network controller. IEEE Control Syst. Mag. 1988, 8, 17–21. [Google Scholar] [CrossRef]

- Xu, L.; Ren, J.S.; Liu, C.; Jia, J. Deep Convolutional Neural Network for Image Deconvolution. Adv. Neural Inf. Process. Syst. 2014, 1, 1790–1798. [Google Scholar]

- Yang, S.X.; Meng, M. Real-time Collision-free Path Planning of Robot Manipulators using Neural Network Approaches. Auton. Robot. 2000, 9, 27–39. [Google Scholar] [CrossRef]

- Cont, A.; Henry, C. Real-Time Gesture Mapping in pd Environment Using Neural Networks. In NIME; Hamamatsu: Shizuoka, Japan, 2004; pp. 39–42. Available online: https://www.researchgate.net/profile/Arshia_Cont/publication/228795048_Real-time_gesture_mapping_in_pd_environment_using_neural_networks/links/5406c5140cf2bba34c1e582b.pdf (accessed on 17 November 2020).

- Li, Z.; Xia, Y.; Su, C.; Deng, J.; Fu, J.; He, W. Missile Guidance Law Based on Robust Model Predictive Control Using Neural-Network Optimization. IEEE Trans. Neural Netw. Learn. Syst. 2015, 26, 1803–1809. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Wang, N.; Meng, X. Real-time forest fire detection with wireless sensor networks. In Proceedings of the 2005 International Conference on Wireless Communications, Networking and Mobile Computing, Wuhan, China, 23–26 September 2005; pp. 1214–1217. [Google Scholar]

- Mekaouche, A.; Chapelle, F.; Balandraud, X. A compliant mechanism with variable stiffness achieved by rotary actuators and shape-memory alloy. Meccanica 2018, 53, 2555–2571. [Google Scholar] [CrossRef]

- Yuan, H.; Chapelle, F.; Fauroux, J.-C.; Balandraud, X. Concept for a 3D-printed soft rotary actuator driven by a shape-memory alloy. Smart Mater. Struct. 2018, 27, 055005. [Google Scholar] [CrossRef]

- Yuan, H.; Fauroux, J.; Chapelle, F.; Balandraud, X. A review of rotary actuators based on shape memory alloys. J. Intell. Mater. Syst. Struct. 2017, 28, 1863–1885. [Google Scholar] [CrossRef]

- Geaorges, T.; Brailovski, V.; Terriault, P. Characterization and design of antagonistic shape memory alloy actuators-IOPscience. Smart Mater. Struct. 2012, 21, 035010. [Google Scholar] [CrossRef]

- Mohd Jani, J.; Leary, M.; Subic, A. Designing shape memory alloy linear actuators: A review-Jaronie Mohd Jani, Martin Leary, Aleksandar Subic, 2017. J. Intell. Mater. Syst. Struct. 2016, 28, 1699–1718. [Google Scholar] [CrossRef]

- Boufayed, R.; Chapelle, F.; Destrebecq, J.F.; Balandraud, X. Finite element analysis of a prestressed mechanism with multi-antagonistic and hysteretic SMA actuation. Meccanica 2020, 55, 1007–1024. [Google Scholar] [CrossRef]

- Asua, E.; Etxebarria, V.; García-Arribas, A. Neural network-based micropositioning control of smart shape memory alloy actuators. Eng. Appl. Artif. Intell. 2008, 21, 796–804. [Google Scholar] [CrossRef]

- MATLAB Tutorial, Levenberg-Marquardt (Trainlm): Backpropagation (Deep Learning Toolbox). Available online: https://fr.mathworks.com/help/deeplearning/ref/trainlm.html (accessed on 16 November 2020).

- Senthilkumar, P.; Umapathy, M. Use of load generated by a shape memory alloy for its position control with a neural network estimator. J. Vib. Control 2014, 20, 1707–1717. [Google Scholar] [CrossRef]

- Majumder, H.; Maity, K. Application of GRNN and multivariate hybrid approach to predict and optimize WEDM responses for Ni-Ti shape memory alloy. Appl. Soft Comput. 2018, 70, 665–679. [Google Scholar] [CrossRef]

- Hmede, R.; Chapelle, F.; Lapusta, Y. Modeling the butterfly behavior of SMA actuators using neural networks. Comptes Rendus Mécanique 2022, 350, 143–157. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, J.J. Evaluation of the characteristics of a shape memory alloy spring actuator. Smart Mater. Struct. 2000, 9, 817–823. [Google Scholar] [CrossRef]

- Wang, H.; Song, G. Innovative NARX recurrent neural network model for ultra-thin shape memory alloy wire. Neurocomputing 2014, 134, 289–295. [Google Scholar] [CrossRef]

- Song, G.; Chaudhry, V.; Batur, C. A Neural Network Inverse Model for a Shape Memory Alloy Wire Actuator. J. Intell. Mater. Syst. Struct. 2003, 14, 371–377. [Google Scholar] [CrossRef]

- Song, G.; Chaudhry, V.; Batur, C. Precision tracking control of shape memory alloy actuators using neural networks and a sliding-mode based robust controller. Smart Mater. Struct. 2003, 12, 223–231. [Google Scholar] [CrossRef]

- Tai, N.T.; Ahn, K.K. A hysteresis functional link artificial neural network for identification and model predictive control of SMA actuator. J. Process Control 2012, 22, 766–777. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, Y.; Wang, Y.; Zhou, M. Takagi–Sugeno Fuzzy Neural Network Hysteresis Modeling for Magnetic Shape Memory Alloy Actuator Based on Modified Bacteria Foraging Algorithm. Int. J. Fuzzy Syst. 2020, 22, 1314–1329. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, Q. Hysteresis Model of Magnetically Controlled Shape Memory Alloy Based on a PID Neural Network. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Nikdel, N.; Nikdel, P.; Badamchizadeh, M.A.; Hassanzadeh, I. Using Neural Network Model Predictive Control for Controlling Shape Memory Alloy-Based Manipulator. IEEE Trans. Ind. Electron. 2014, 61, 1394–1401. [Google Scholar] [CrossRef]

- Cao, Y.; Fan, Q.; Mahmoudi Azar, S.; Alyousef, R.; Yousif, S.T.; Wakil, K.; Jermsittiparsert, K.; Si Ho, L.; Alabduljabbar, H.; Alaskar, A. Computational parameter identification of strongest influence on the shear resistance of reinforced concrete beams by fiber reinforcement polymer. Structures 2020, 27, 118–127. [Google Scholar] [CrossRef]

- Hannen, J.C.; Crews, J.H.; Buckner, G.D. Indirect intelligent sliding mode control of a shape memory alloy actuated flexible beam using hysteretic recurrent neural networks. Smart Mater. Struct. 2012, 21, 085015. [Google Scholar] [CrossRef]

- Elbahy, Y.I.E.; Nehdi, M.N.; Youssef, M.A.Y. Artificial neural network model for deflection analysis of superelastic shape memory alloy reinforced concrete beams. Can. J. Civ. Eng. 2010, 37, 842–854. [Google Scholar] [CrossRef]

- Wisutmethangoon, S.; Denmud, N.; Sikong, L. Characteristics and compressive properties of porous NiTi alloy synthesized by SHS technique. Mater. Sci. Eng. A 2009, 515, 93–97. [Google Scholar] [CrossRef]

- Ratner, B.D.; Hoffman, A.S.; Schoen, F.J.; Lemons, J.E. Biomaterials Science: An Introduction to Materials in Medicine. San Diego Calif. 2004, 31, 58–60. [Google Scholar]

- Velmurugan, C.; Senthilkumar, V.; Dinesh, S.; Arul kirubakaran, D. Artificial neural network prediction of wire electrical discharge machining properties on sintered porous NiTi shape memory alloy. Mater. Today Proc. 2018, 5, 8382–8390. [Google Scholar] [CrossRef]

- Li, Q.; Yu, J.-Y.; Mu, B.-C.; Sun, X.-D. BP neural network prediction of the mechanical properties of porous NiTi shape memory alloy prepared by thermal explosion reaction. Mater. Sci. Eng. A 2006, 419, 214–217. [Google Scholar] [CrossRef]

- Choi, E.; Nguyen, H.D.; Jeon, J.-S.; Kang, J.-W. Self-centering and damping devices using SMA dual rings. Smart Mater. Struct. 2019, 28, 085005. [Google Scholar] [CrossRef]

- Qiu, C.; Fang, C.; Liang, D.; Du, X.; Yam, M.C. Behavior and application of self-centering dampers equipped with buckling-restrained SMA bars. Smart Mater. Struct. 2020, 29, 035009. [Google Scholar] [CrossRef]

- Torra, V. Damping in Civil Engineering Using SMA. The Fatigue Behavior and Stability of CuAlBe and NiTi Alloys. J. Mater. Eng. Perform. 2009, 18, 738–745. [Google Scholar] [CrossRef]

- Torra, V.; Isalgue, A.; Auguet, C.; Carreras, G.; Lovey, F.C.; Terriault, P.; Dieng, L. SMA in Mitigation of Extreme Loads in Civil Engineering: Damping Actions in Stayed Cables. Appl. Mech. Mater. 2011, 82, 539–544. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Liu, J. Large size superelastic SMA bars: Heat treatment strategy, mechanical property and seismic application. Smart Mater. Struct. 2016, 25, 075001. [Google Scholar] [CrossRef]

- Ozbulut, O.E.; Hurlebaus, S. Evaluation of the performance of a sliding-type base isolation system with a NiTi shape memory alloy device considering temperature effects. Eng. Struct. 2010, 32, 238–249. [Google Scholar] [CrossRef]

- Lu, Y.; Jiang, J.; Zhang, J.; Zhang, R.; Zhang, Q.; Zhou, Y.; Wang, L.; Yue, H. A dynamic stiffness improvement method for thin plate structures with laminated/embedded shape memory alloy actuators. Thin-Walled Struct. 2022, 175, 109286. [Google Scholar] [CrossRef]

- Furst, S.J.; Crews, J.H.; Seelecke, S. Stress, strain, and resistance behavior of two opposing shape memory alloy actuator wires for resistance-based self-sensing applications. J. Intell. Mater. Syst. Struct. 2013, 24, 1951–1968. [Google Scholar] [CrossRef]

- Narayanan, P.; Elahinia, M. Control of a shape memory alloy–actuated rotary manipulator using an artificial neural network–based self-sensing technique. J. Intell. Mater. Syst. Struct. 2016, 27, 1885–1894. [Google Scholar] [CrossRef]

- Formentini, M.; Lenci, S. An innovative building envelope (kinetic façade) with Shape Memory Alloys used as actuators and sensors. Autom. Constr. 2018, 85, 220–231. [Google Scholar] [CrossRef]

- Tung, A.T.; Park, B.-H.; Liang, D.H.; Niemeyer, G. Laser-machined shape memory alloy sensors for position feedback in active catheters. Sens. Actuators Phys. 2008, 147, 83–92. [Google Scholar] [CrossRef]

- Gurung, H.; Banerjee, A. Self-sensing SMA Actuator Using Extended Kalman Filter and Artificial Neural Network. Procedia Eng. 2016, 144, 629–634. [Google Scholar] [CrossRef]

- Bhargaw, H.N.; Singh, S.; Botre, B.A.; Akbar, S.A.; Hashmi, S.A.R.; Sinha, P. Deep Neural Network-Based Physics-Inspired Model of Self-Sensing Displacement Estimation for Antagonistic Shape Memory Alloy Actuator. IEEE Sens. J. 2022, 22, 3254–3262. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Abd Elaziz, M.; Vendan, A. Modeling ultrasonic welding of polymers using an optimized artificial intelligence model using a gradient-based optimizer. Weld. World 2022, 66, 27–44. [Google Scholar] [CrossRef]

- Feedforward Neural Networks 1. What Is a Feedforward Neural Network? Available online: https://www.fon.hum.uva.nl/praat/manual/Feedforward_neural_networks_1__What_is_a_feedforward_ne.html (accessed on 11 May 2021).

- Generalized Regression Neural Networks-MATLAB & Simulink. Available online: https://www.mathworks.com/help/deeplearning/ug/generalized-regression-neural-networks.html (accessed on 11 May 2021).

- Wang, D.; Quek, C.; Ng, G.S. MS-TSKfnn: Novel Takagi-Sugeno-Kang fuzzy neural network using ART like clustering. In Proceedings of the 2004 IEEE International Joint Conference on Neural Networks (IEEE Cat. No.04CH37541), Budapest, Hungary, 25–29 July 2004; pp. 2361–2366. [Google Scholar]

- Naik, B.; Nayak, J.; Behera, H.S.; Abraham, A. A self adaptive harmony search based functional link higher order ANN for non-linear data classification. Neurocomputing 2015, 179, 69–87. [Google Scholar] [CrossRef]

| Activation Function | Equation |

|---|---|

| Step function | , otherwise 1 |

| Linear function | |

| Rectified linear (ReLU) | |

| Hyperbolic tangent | |

| Radial basis function |

| Type of Property | Description |

|---|---|

| Mechanical property | Roughness [98] Maximum peak to valley height [83] Square roughness [83] Microhardness [83] Load measurements [103] Position [10] Moment of inertia [95] Reduction factor betta [95] Green density (D) [99] Compressive yield stress [99] Density [99] Elastic modulus [99] Speed [99] Time response in the hysteresis behavior [86] Shape recovery force [85] Seismic response [104] Frequency [106] Strain response [84] |

| Thermal property | Austenite-finish temperature [8] Temperature [96] Heating rate (V) [99] |

| Chemical Property | Reactant particle size [99] |

| Electrical property | Servo voltage [98] Pulse on time [98] Pulse off time [98] Current [98] Electrical resistance (ER) [8] |

| Dimensional Property | Length of the wire [99] Cross-sectional area [99] |

| Magnetic Property | [90] |

| SMA Form | Application Type | NN Type | Training Method |

|---|---|---|---|

| Wire | Position Actuator | NN multilayer | Levenberg–Marquardt (LM) algorithm [80] |

| NN Estimator | Parameter epochs: 3000 [80] | ||

| Magnetic Actuator | Takagi–Sugeno fuzzy | MBFA and GDA algorithms [90] | |

| Rotatory-Manipulator: actuator | NN direct control with online learning | BP algorithm [10] | |

| Rotatory Manipulator: self-sensor | Shallow NN | LM algorithm [108] | |

| Linear Actuator with a spring bias | Nonlinear-Autoregressive Exogenous NARX NN | Jordan–Elman and Jordan–Plus–Elman algorithm [86] | |

| Proportional–Integral–Differential GRPID NN | Backpropagation algorithm [91] | ||

| Functional Link Artificial Intelligent Neural Network | Particle-swarm optimization [89] | ||

| Self-sensing with a spring bias | Shallow ANN | Extended Kalman Filter [111] | |

| Antagonistic System: Actuator | LSTM | [84] | |

| Self-sensor | DNN | DNN has two LSTM layers [88] | |

| Conventional Machining | General Regression | ||

| Forwarded | |||

| Conventional Machining | Multilayer normal feed | VIKOR FUZZY [83] | |

| Porous | Medical | Multilayer normal feed Full feedforward | Batch Backpropagation [99] |

| Earthquake Civil Damping Self-centering | Feedforward Backpropagation FFBP | Incremental Backpropagation [98] | |

| Vibrational control | Quick Prop algorithm QP [98] Genetic algorithms GA [98] | ||

| Reinforced Concrete Beam | Aircrafts | BPNN | Backpropagation algorithm [95] |

| Ring and Bars | Civil Damping Self-centering | Neuro_Fuzzy Model | [105] |

| Plates | Aircrafts | BPNN | Genetic algorithm [106] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hmede, R.; Chapelle, F.; Lapusta, Y. Review of Neural Network Modeling of Shape Memory Alloys. Sensors 2022, 22, 5610. https://doi.org/10.3390/s22155610

Hmede R, Chapelle F, Lapusta Y. Review of Neural Network Modeling of Shape Memory Alloys. Sensors. 2022; 22(15):5610. https://doi.org/10.3390/s22155610

Chicago/Turabian StyleHmede, Rodayna, Frédéric Chapelle, and Yuri Lapusta. 2022. "Review of Neural Network Modeling of Shape Memory Alloys" Sensors 22, no. 15: 5610. https://doi.org/10.3390/s22155610

APA StyleHmede, R., Chapelle, F., & Lapusta, Y. (2022). Review of Neural Network Modeling of Shape Memory Alloys. Sensors, 22(15), 5610. https://doi.org/10.3390/s22155610